WORLD OF ASPHALT/ AGG1 SHOW PREVIEW

BIG NEW KOMATSU GRADER DESIGNED FOR HAUL ROAD WORK

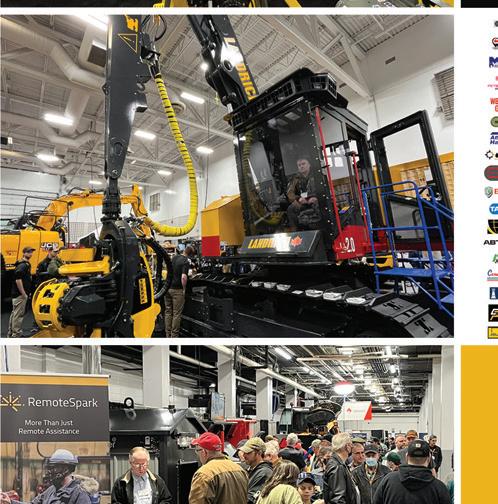

HIGHLIGHTS FROM THE ARA SHOW

heavyequipmentguide.ca

WORLD OF ASPHALT/ AGG1 SHOW PREVIEW

BIG NEW KOMATSU GRADER DESIGNED FOR HAUL ROAD WORK

HIGHLIGHTS FROM THE ARA SHOW

heavyequipmentguide.ca

AS THE GLOBAL LEADER IN ROAD CONSTRUCTION TECHNOLOGY, the world is our proving ground, in every climate, condition, and terrain. From mining and milling, to paving, compaction and rehabilitation—our machines are smart, safe, and sustainable, consistently delivering the highest quality and lowest total cost of ownership.

Renew the passion between you and your excavator with MC-Max from Topcon. Machine control makes you better. And it ne tunes your Excavator’s production. MC-Max o ers you and your Excavator increased precision, speed, accuracy, and scalability, all while keeping you connected… so you can take care of business. We get it, relationships can be complicated. Let Topcon take you and your Excavator to a whole new level. Now, go ahead and make the earth move...

Falling back in love with your Ex(cavator) is easier than ever. Scan the QR code to get in touch. We’ll take care of the rest.

22

WORLD OF ASPHALT/AGG1 SHOW PREVIEW

36

CONSTRUCTION MOVES TOWARD A GREENER FUTURE

52

DATA SOLUTIONS IMPROVE TRUCK FLEET MANAGEMENT

44

HIGHLIGHTS FROM THE ARA SHOW

Turn to page 22 .

Do you have a job site story, innovation, or industry concern that our readers should know about? We’d like to hear from you.

Contact: Editor in Chief Kaitlyn Till at ktill@baumpub.com or 604-291-9900 ext. 330

EDITOR IN CHIEF

Kaitlyn Till ktill@baumpub.com 604-291-9900 ext. 330

EDITOR

Lee Toop ltoop@baumpub.com 604-291-9900 ext. 315

ASSOCIATE PUBLISHER

Sam Esmaili sam@baumpub.com 604-291-9900 ext. 110

ADVERTISING PRODUCTION MANAGER

Tina Anderson tanderson@baumpub.com 604-291-9900 ext. 222

DESIGN & PRODUCTION

Morena Zanotto morena@baumpub.com

604-291-9900 ext. 325

PRESIDENT/PUBLISHER

Ken Singer ksinger@baumpub.com 604-291-9900 ext. 226

VICE PRESIDENT/CONTROLLER

Melvin Date Chong mdatechong@baumpub.com

FOUNDER

Engelbert J. Baum

Published by: Baum Publications Ltd. 124 - 2323 Boundary Road

Vancouver, BC, Canada V5M 4V8

Tel: 604-291-9900

Toll-free: 1-888-286-3630

Fax: 604-291-1906

www.baumpub.com

www.heavyequipmentguide.ca @HeavyEquipGuide

FOR ALL CIRCULATION INQUIRIES

Toll-free: 1-866-764-0227

email: heg@mysubscription.ca

Subscription: To subscribe, renew your subscription, or change your address or other information, go to: http://mysubscription.ca/heg/ Heavy Equipment Guide serves the Canadian engineered construction industry including: roadbuilding and maintenance; highways, bridges, tunnels; grading and excavating; earthmoving; crushing; trucking and hauling; underground utilities; trenching; concrete paving; asphalt paving; demolition; aggregates production; fleet maintenance; and asset security and management. The magazine is distributed to key industry personnel involved in these sectors.

Subscription Price: In Canada, CDN $91.00; Outside Canada, US$149. Heavy Equipment Guide is published eight times a year in January/ February, March, April, May/June, July/August, September, October, and November/December.

Heavy Equipment Guide accepts no responsibility or liability for reported claims made by manufacturers and/or distributors for products or services; the views and opinions expressed are those of the authors and not necessarily those of Baum Publications Ltd.

Copyright 2024, Baum Publications Ltd. No portion of this publication may be reproduced without permission of the publishers.

We acknowledge the financial support of the Government of Canada.

Printed on paper made of FSC®-certified and other controlled material. ISSN 1715-7013.

PUBLICATIONS MAIL AGREEMENT NO. 40069270

Return undeliverable Canadian addresses to:

Circulation Dept., 124-2323 Boundary Road, Vancouver, BC V5M 4V8

email: heg@mysubscription.ca

Toll-free: 1-866-764-0227

I’ll be in Nashville attending World of Asphalt/AGG1 later this month and as OEMs and show organizers start sharing details of what to expect, it has become clear that the 2024 edition is shaping up to address concerns faced by the roadbuilding and aggregates industries in recent years.

Sustainability was a hot topic at World of Asphalt/AGG1 in 2022, and it has only become more vital for the paving and aggregates industries.

In the past two years, several roadbuilding equipment manufacturers have introduced electric machines and prototypes for the paving industry, including asphalt rollers and pavers. These developments are necessary for reducing greenhouse gas emissions in paving, and several of them will be on display at World of Asphalt 2024. However, also vital to sustainability in the roadbuilding industry are connectivity solutions that make paving with conventional diesel machines more efficient. Accurate monitoring solutions reduce overwork and rework and the associated greenhouse gas emissions – and that time savings has a positive effect on a contractor’s bottom line.

Environmental stewardship is also a focus for the aggregates industry this year, with education sessions covering regulation compliance and how to adopt sustainable practices that benefit the environment and help businesses thrive.

Innovation in safety systems will feature heavily, and show organizers have hinted that AI, virtual reality, and augmented reality will all play a part in safer job site solutions demonstrated at World of Asphalt/AGG1. Education sessions will also focus on helping contractors create the safest work zones possible, particularly for road paving crews.

Which brings us to the most imminent concern in both industries – workforce development. Training, recruitment, and retention have never been more important, and every stakeholder in the industry is focused on these topics. OEMs are designing their equipment to be easier to learn and operate, and industry professionals will be focused on education sessions

Sustainability was a hot topic at World of Asphalt/AGG1 in 2022, and it has only become more vital for the paving and aggregates industries.

focused on management of the human element of the business. Theme days, such as Women in Asphalt, will further focus on workforce development.

Turn to page 22 for our World of Asphalt/AGG1 Show Preview. We connected with show organizers to discuss challenges facing both industries and how attending in Nashville can benefit contractors, aggregates producers, and their crews.

Get a taste of the new equipment and technology that will be on display at the show, and check in at heavyequipmentguide.ca throughout March for more advance World of Asphalt/AGG1 coverage.

Kaitlyn Till Editor In Chief

Kaitlyn Till Editor In Chief

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites.

Sturdy and resistant, reliable and safe, able to combine comfort and high performance.

BKT is with you, even when work gets tough.

www.heavyequipmentguide.ca

An agreement signed at CES 2024 will see a joint research centre established in the United States that will leverage the knowledge of several well-known construction brands to develop new technologies.

CNH, the parent company of CASE and New Holland, and HD Hyundai XiteSolution (HDX), the parent company of DEVELON and Hyundai, signed a memorandum of understanding to establish a joint research centre in the U.S.

Both companies possess an extensive background in construction with unique areas of expertise and strengths. The strategic collaboration aims to expand on their existing capabilities to accelerate the development and investment in innovative technologies for customers in the construction industry.

The CE Innovation Lab will explore innovation opportunities in the construction sector. A team of CNH and HDX construction specialists will study emerging technology trends, map new and evolving customer needs, and identify prospects for portfolio enhancements and further growth. Their work will advance the development and adoption of technologies such as automation and artificial intelligence.

In addition, the parties will mutually benefit from each other’s distinctive technological capabilities. HDX will supply CNH with the patented AAVM+ (Advanced Around View Monitoring Plus) 360-degree camera and radar system that develops enhanced safety. CNH will supply HDX with Global Navigation Satellite System technologies through its Hemisphere brand.

Moving forward, CNH and HDX anticipate expanding their collaboration within the research centre to encompass the co-development of new technologies and co-investment in innovative startups via their CNH Ventures and HD Hyundai investment arms.

“We are excited to expand our collaboration with HDX. This joint effort will strengthen our commitment to growing CNH’s construction business and position both our companies as tech authorities in the industry,” says Stefano Pampalone, president of construction at CNH.

“It is highly encouraging that our partnership has extended beyond our product collaboration to include future technologies, a crucial factor to remain at the forefront of the construction equipment market. We look forward to working together even more closely to lead the way in the market,” says Young-Cheul Cho, president and CEO of HDX and Hyundai Infracore Co., Ltd.

United Rentals has outlined ways companies can implement sustainable business practices that reduce equipment greenhouse gas (GHG) emissions while maintaining job site productivity and safety. United Rentals released a white paper, Roadmap to Low-Emission and Zero-Emission Jobsites, which shares four practical steps to reduce emissions and the tools and equipment to make sustainability strategies a reality on the job site.

“For companies with budgets large or small, reducing job site emissions is possible now,” says Grant Zoldowski, director of environmental management at United Rentals. “A smart job site sustainability strategy starts with data. Targeting the predominant sources of emissions on projects and job sites allows companies to focus their efforts and dollars on changes that will yield the biggest results. This approach provides the foundation for more sustainable power generation, battery storage, and electric equipment options.”

Here are four initiatives companies can take today to make their job sites more sustainable:

Identify the biggest improvement opportunities Companies can use data to guide decisions around fleet sustainability efforts and identify changes that yield the biggest return on investment.

Embrace power generation alternatives New power generation options open the door to greener operations that provide the power needed for productivity and safety. Cleanerburning generators that use propane, natural gas, renewable diesel, or hydrogen are available now. Power options include combining solar panels with a battery to provide a quiet, zero-emission renewable energy generator.

Leverage battery energy storage New energy storage solutions enable companies to reduce the use of emission-generating portable power equipment. Bigger and better standalone batteries have the power to replace some diesel generators. Hybrid power systems that use a battery to store excess power can slash generator run time along with fuel use and emissions.

Incorporate electric or hybrid equipment Electric equipment offers performance on par with diesel-fuelled equipment while eliminating direct emissions. Lower operating costs and significantly reduced maintenance needs partially offset the higher upfront expense. Lithium-ion batteries and electric engines are essentially maintenance-free.

FLO Components has reached an agreement to represent AFEX vehicle fire suppression systems in the Americas, Ontario, and Manitoba. AFEX systems are purpose-built to withstand the everyday abuse experienced by heavy-duty mobile equipment.

Construction equipment running hotter and operating around the clock raises the risk of fires. If one piece of mobile equipment catches fire at a work site, the impact can be devastating. There is potential for operator injury, along with halted production while replacement machines are sourced. Resources can be lost, and insurance costs may rise.

“At a show we did in January, one of our customers was telling us that just over a year ago they had a live-bottom truck catch fire inside the service area. They lost not only the truck, but the entire service bay and the office connected to it,” says FLO Vice President Mike Deckert. “You don’t think about the dangers until it happens, and then the results are catastrophic. Vehicle fire suppression systems effectively detect threats ranging from engine to debris fires and protect your people and assets.”

AFEX has been in business for more than 50 years, producing systems specific for heavy equipment. Deckert said FLO was recommended to AFEX as an industry leader and provider of lubrication systems and solutions for heavy machinery.

Boom lifts, telehandlers, scissors & more.

Turn to page 44.

The Canadian Apprenticeship Forum (CAF-FCA) has launched the National Mentor Development Program for Women in the Skilled Trades to offer online programming to develop and enhance mentorship skills for women and gender-diverse individuals in the trades. Tradeswomen identified the need for a program of this type. They recommended establishing and maintaining mentoring programs for women in the trades where experienced tradeswomen mentor and

guide those just starting their careers.

This virtual, four-month program is facilitated by subject matter experts in collaboration with tradeswomen coaches from the manufacturing and construction sectors. The program will be offered free to participants in Canada.

Caterpillar has signed an electrification strategic agreement with CRH to accelerate the deployment of Caterpillar’s 70- to -100-ton-class battery electric off-highway trucks and charging solutions at a CRH site in North America.

Through the agreement, CRH will participate in Caterpillar’s Early Learner program for battery electric off-highway trucks, testing and validating the units in real-world applications. CRH will also provide feedback to address safety, performance, operational, and compliance requirements.

“We are pleased to work with CRH, as our first aggregates industry customer, to expand our electrification solutions beyond mining. When it comes to sustainability, the quarry and aggregates industry requires diverse solutions. Our collaboration with CRH is an exciting opportunity to learn together and gain valuable insights into how our products can best support CRH’s long-term objectives to decarbonize its operations,” says Resource Industries Group President Denise Johnson.

The first TL100VS compact track loaders from Yanmar Compact Equipment for the North American market have rolled off the production line. The TL100VS is one of four sizes of compact track loaders to come from Yanmar along with the TL65RS, TL75VS, and TL80VS.

Yanmar says it leveraged more than 100 years of industry expertise and reliability in the development and manufacturing of the new CTLs. The new machines flesh out the Yanmar compact equipment lineup, which also includes mini excavators, compact wheel loaders, and tracked carriers.

The other three new CTLs will begin production later in 2024.

ELVAAN Equipment Solutions will offer DEVELON’s full line of heavy and compact construction equipment at new locations in Edmonton, Alberta, and Orillia, Ontario.

Suman Mukherjee, president and CEO of ELVAAN Equipment Solutions, says that three core factors led ELVAAN Equipment Solutions to add the DEVELON product line to its Alberta and Central Ontario dealerships.

“There’s a long history of providing exceptional customer service to road machinery, compact, and heavy equipment customers in these two markets,” Mukherjee says. “Another factor is we have a team of highly experienced professionals serving all functions at the Alberta and Central Ontario dealerships, including sales, rental, service, parts, and training. Lastly, ELVAAN Equipment Solutions has been an established DEVELON dealer in the Greater Toronto area for over a year now. Our company’s success with DEVELON has given us the confidence to expand into new territories.”

www.heavyequipmentguide.ca

Kubota

Compact excavator

Equipped with a 66.6-hp Kubota engine, the KX080-5 compact excavator has a working range that includes a digging depth of 15 feet 1.1 inches, a maximum dumping height of 17 feet 2.7 inches, and a bucket breakout force of 14,660 pounds. The 2-pump load-sensing system improves the overall smoothness of operation when using attachments, letting operators effortlessly perform simultaneous tasks. Additionally, the auto-shift system enables automatic travel shift from high to low depending on traction effort and terrain, providing simultaneous operations when dozing and turning. A new programmable Engine Auto Stop feature turns off the engine when idling up to 30 minutes, and an Auto Idling System reduces engine RPM instinctively when high engine speed isn’t needed and the control levers are in neutral for more than 4 seconds.

The cab features an air suspension seat equipped with a slide that can be double adjusted to find the right level of comfort. Joystick consoles on the left and right sides can be adjusted independent of the seat to match individual operator requirements. A new full-colour 7-inch LCD monitor with jog dial provides operators with vital information and easy access to functions like auxiliary flow adjustment and automatic activation of third line hydraulic return.

A rear-view camera displays a fish-eye view on the 7-inch LCD monitor while reversing. LED work lights with turn off delay allow the lights to remain on for up to two minutes after the engine is turned off. The quiet cabin helps to protect the operator from loud engine noise and features an expanded glass area that provides more visibility for loading, unloading, and digging work.

Six all-new models of Manitou skid steers and compact track loaders deliver greater breakout forces, improved operator comfort and control, and numerous exclusive designs such as a new sloped roof and contoured lift arms - plus Manitou exclusives such as the IdealAccess fold-up door and the IdealTrax automatic track tensioning system. Learn more at Manitou.com

See our full range of solutions for your business at Manitou.com.

Yanmar’s all-new 47.6-hp V7 compact wheel loader is a 9,370-pound machine designed to maximize performance and efficiency for operators in landscaping, rental, municipalities, snow removal, and other applications. It has a 0.92-cubic-yard bucket capacity. An optional light material bucket brings capacity to more than a full cubic yard. The compact wheel loader is powered by a Tier 4 Final Yanmar engine allowing for a lifting capacity of 7,981 pound-force.

The V7 features ±40 degrees of articulation and ±10 degrees of oscillation. A newly designed articulation oscillation joint maximizes ground contact with all four wheels for optimal tractive force. Yanmar offers the V7 in canopy and enclosed cab with heat and A/C configurations.

Hydraulic quick couplers deliver fast attachment change-outs, and operators can lift loads with precision without the need for constant readjustment of the load angle thanks to the V7’s parallel kinematics, which is ideal for use with pallet forks.

The new generation BOMAG BMP 8500 multi-purpose compactor has an improved radio remote control design that allows the controller to be used on every BMP 8500 in the fleet. The remote control’s unique “teach” function quickly pairs the unit to the machine. With the BMP 8500, there is a secure, 100 percent connection between the remote-control unit and machine. Multiple trench rollers can be operated simultaneously at the job site without the need to coordinate or adjust individual radio frequencies. Now, two batteries are standard for the remote control, delivering a continuous combined work time of up to 40 hours. The two-battery solution allows one battery to charge while the other powers the controller.

The new generation BOMAG BMP 8500 trench roller offers a variable working width that can be quickly adjusted from 24 inches (600 mm) to 33.5 inches (850 mm) in a few simple steps. It is powered by the 19.4-hp (14,5-kW) Kubota D 1005 diesel engine.

Compact wheel loader

Compactor

Compact wheel loader

Compactor

Superior Industries’ new heavy-duty scalping screen, part of its Guardian Horizontal Screens line, handles a maximum feed size of 18 inches (457 mm). This surpasses its medium-duty predecessor, which maxes out at 14 inches (355 mm). The HD screen is equipped with a perforated top deck, or punch plate, made of heavy-duty 3/4-inch AR steel. A slight slope facilitates the movement of feed material for efficient screening. Guardian horizontal screens are available in two-, three-, or four-deck configurations and footprints from 5 x 16 to 8 x 20.

This new self-propelled pneumatic single gang barrier wall drill can drill a single hole faster and more precisely than multiple gang options, according to Minnich. The company says the new drill eliminates time taken to make manual adjustments and align multiple drill hole measurements. There’s no need to line up drill holes – instead, users align the drill steel through a pre-molded opening in the barrier wall, penetrate the sub-base, drop in the steel pin anchor, and move to the next securing point.

The unit’s 8.5-foot by 6.5-foot frame sits on a 9-foot flatbed trailer for easy transportation. A backhoe or compact excavator can lift the 1,630-pound drill onto a concrete barrier wall.

It reaches a maximum drill depth of 18 to 36 inches, with a drill steel shank of 1 inch by 4.25 inches and a drill bit diameter of 1 to 2.5 inches. It requires 140 scfm and 120 psi of pneumatic power. A tethered handheld remote gives the operator control at a safe distance. An optional dust collection system is available.

Scalping screen Barrier wall drill

Roadbuilding and aggregates professionals will meet in Nashville, TN, March 25–27 for World of Asphalt/AGG1 2024. We spoke with organizers ahead of the event to learn what the show has in store and checked in with exhibitors to preview new products and technology that you can see in Nashville. As always, WOA/AGG1 offers a robust program of educational opportunities for attendees to boost their skills and their business – turn the page to learn more.

World of Asphalt/AGG1 is coming off a record-breaking year in 2022, and attendance is expected to be strong again this year. Asphalt and aggregates professionals from across North America will be in Nashville, TN, to share experiences, learn from their peers, and see the latest equipment and technology for the roadbuilding and aggregates industries. World of Asphalt Show Director Brittany Schmidtke and Jennifer Dugas, vice president of membership and events with the National Stone, Sand & Gravel Association (NSSGA), organizers of AGG1, expect topics like workforce development and retention, sustainability, and new technologies to drive the discussion among attendees and more than 400 exhibitors.

What are the key challenges in the paving and aggregates sectors to start 2024, and how can attendees use the show to set their businesses up for success?

Brittany

SchmidtkeRight now the industry is really strong; it has a lot of funding from the recent [U.S.] infrastructure bill. A hot topic has been sustainability – how are contractors, the equipment manufacturers, the industry as a whole addressing such a large topic? Another common item is workforce development. We know that it continues to require unique solutions for everyone in many industries to find some new routes and avenues.

World of Asphalt provides a place for people to start communicating and finding solutions to some of these problems that can feel really large. When they come together, there’s that energy and ideation that starts happening, especially as they start looking at equipment and software and other services that can sometimes help bridge that gap.

We try to provide time for attend-

Jennifer Dugasees to be able to connect. We hold the Rock and Road Reception where exhibitors can participate as sponsors as well. New this year, we’re having a pre-show attendee event on the night before the show, Sunday, March 24, that really has come about from an attendee group wanting to provide even more networking.

The last day of the show on March 27, the Women of Asphalt are partnering with World of Asphalt for their first ever national meetup, the Women of Asphalt Day. It really ties back into workforce development, and that idea that there’s this budding experience of women in the industry that needs more highlighting and more connection. We’re really excited to support their efforts in that area.

The safety and health of our workers in the aggregates industry is a core value at NSSGA. At the AGG1 Academy sessions, we will be focusing on a lot of safety and health issues, like promoting a zero-injury safety culture, talking about total worker health, and learning more about navigating the rules and regulations of MSHA (Mine Safety & Health Administration).

Something we’ve also been talking about for the past few years is the challenges of the workforce – how to promote bench strength and training programs along with growing a great culture. Another aspect that’s been coming up more and more is recruiting the next generation, so I know that we’re going to be talking about that a lot at the AGG1 Academy sessions. I know upcoming generations are looking for a strong workforce culture inside of their workplace.

Another topic that comes up in every conversation is the community relations piece of what our quarries do – how to be good stewards in the community, and how community support is critical to the success of all the quarries that we represent. In addition, new and emerging technologies and the backbone of quarry operations will be discussed, whether it’s conveying, washing, classifying, screening, or crushing.

The last time we got to meet at the AGG1 Academy and Expo was in 2022. There’s a lot for our members to come together and talk about. AGG1 provides a touchpoint for folks to reconnect and learn about new and emerging technologies that they haven’t been able to see since 2022.

World of Asphalt/AGG1 provides an opportunity to see the latest technology – what highlights and themes can we expect?

Schmidtke A number of exhibitors are keeping a tight lip on some of the new and exciting stuff coming out, but we do know that there are some things coming down the pipeline around artificial intelligence, virtual reality, and augmented reality . . . equipment that is really equipped with the next generation of technology. A lot of that is focused on creating the safest work spaces and building equipment that provides innovation in safety.

A lot of equipment manufacturers are focused on providing sessions, and content in general, on how to utilize equipment in a safe fashion, and how to have a consistently safe workspace. On the exhibit floor and with exhibitors in their booths we are focused on reducing distracted driving, reducing any exposure for workers in a work zone.

Dugas You can expect that exhibitors will be showcasing and talking about how the latest mining machinery design trends are changing aggregates equipment, how electric (vehicle) technologies are addressing concerns that are coming up, and how artificial intelligence can be used to predict failures or improve maintenance. Many innovators are utilizing various aspects of AI. These types of tools will be brought into the heavy equipment industry and revolutionize how our members maintain their products or train their people.

And, obviously, that goes back to safety as well. I know a lot of our members are focusing on utilizing AI for safety issues. This will also come up in some of the education sessions as well.

How will World of Asphalt/AGG1 benefit and support Canadian attendees and other international visitors?

Schmidtke Our partner manager has been working closely with a number of groups in Canada and Mexico. When we look at

Dugasall of North America, we talk about World of Asphalt and the show from a greater scope, and from an international presence, the exhibitors are prepared for a scope that’s larger than just the U.S. buyer. We have delegations coming all the way from Africa, Mexico, and Canada to the show as well. And really, their equipment and their service and sales are ready and able to meet the needs of customers from across the globe.

We work closely with Canada, and all professionals in the aggregates industry, including those in Canada, are encouraged to register to come and learn about the new things that are happening. Some of our manufacturers and service members are located in Canada, and have a big presence here at AGG1. I also encourage Canadian members to set up meetings, whether it’s with prospective clients, if they are participating on the show floor as an exhibitor, or with the media that will be in Nashville. There are lots of different ways to engage and participate at the show.

It’s always exciting to see what’s on the trade show floor at World of Asphalt/AGG1, but the event has far more to share than just new and innovative products. For many asphalt and aggregates professionals, it is also about gaining new knowledge and skills that help build their businesses.

World of Asphalt and AGG1 offer an education program calendar that includes 120 sessions covering everything from paving techniques to tips that help in the office, and all topics in between.

For asphalt pros, the People, Plants and Paving Conference hosted by the National Asphalt Pavement Association provides a variety of sessions. It is divided into five education tracks: People, Plants, Paving, Pavement Preservation, and Environment, Health, Safety & Sustainability. Each track provides a focus on a key area of business for paving contractors. For example, sessions in the People track provide insights into hiring, training, communications, and more, while the Paving track shares techniques and best practices for a broad range of asphalt jobs and situations.

“The People track is increasing in attendance as people try to upskill and learn how to manage a new workforce generation. Or it may be newer crew members or plant operators coming to build up their skills and continue their education,” says World of Asphalt Show Director Brittany Schmidtke. “I love to see programming providing actionable steps that contractors can walk away with and start talking to their team about implementing right away.”

The AGG1 Academy has its own four tracks of sessions: Operations & Production, Safety & Health, Business & People Management, and Environment & Stewardship. Topics for aggregates professionals run from 101-style sessions that cover the basics of the business, all the way to advanced technology and diversifying the aggregates industry.

March 27, the final day of the show, is Women in Asphalt Day, which will feature focused keynotes and education sessions specifically designed for women to learn more, develop leadership skills, and advance professional opportunities in the industry.

1. SAKAI AMERICA

SAKAI America will show the new SW884ND 79-inch asphalt roller featuring its new Guardman safety technology. Guardman is integrated into roller hydraulics on the production line and uses detection tools to identify when personnel or objects are in front of or behind the roller. It provides alerts to the operator, but also slows and brakes the machine to avoid collisions without operator intervention. The system can work through dust and steam, next to walls, or at night. The roller shown at World of Asphalt is the first from SAKAI with both front and rear detection and braking, while other Guardman models are rear-only.

Also on display will be a preview of the battery-electric HV620E walk-behind double-drum roller, a prototype developed in conjunction with Honda. Its Mobile Power Pak lithium-ion battery system was developed to be removable and swappable on the job site, making for more convenient

1

charging, and enabling contractors to power up their batteries without moving the whole machine.

2. BOMAG

BOMAG has modernized the CR 1030 T paver and incorporated an independent auger/conveyor system with outboard driven augers, a new HMI interface, and a brand-new front mount screed. The paver is fitted with a 225-hp Cummins engine and a 14-ton hopper for large jobs. Its independent auger/conveyor system improves material flow and control.

A reorganized operator console includes sections with related functions grouped together. Combined with a new seven-inch touchscreen, this design allows operators to quickly locate relevant information and functions.

BOMAG has paired the CR 1030 T with the new VERSA 20 front-mount screed. This new screed allows for variable paving widths from 10 to 19 feet, and a maximum of 23 feet with bolt-on

2 28 heavyequipmentguide.ca | MARCH 2024

extensions. Reliability has been improved thanks to new hose routing designs. New screed controls include integrated MOBA automation displays. There is an updated control panel on the main screed and remotes on the extensions.

3. WIRTGEN GROUP

Wirtgen Group will introduce the W 150 Fi compact milling machine for the first time. The new machine is powered by an environmentally friendly engine from John Deere and can mill up to six feet in width, making it a good fit for work in restricted spaces. It also includes digital assistance and levelling systems that improve milling performance and reduce fuel consumption.

Wirtgen will also show the recently introduced Hamm HD+ 120i VIO-2 HF articulated tandem roller, which features two VIO drums that work with either vibration or oscillation and do not require maintenance. Hamm’s HD 12e VV electric tandem roller, which will be

available in North America this summer, will also be on display. Pavers from Vögele, including the SUPER 17033i wheeled paver and the SUPER 2000-3i tracked paver, are going to be at the show.

The Wirtgen Group will feature materials processing equipment including the Kleemann MOBIREX MR 110i EVO2 impact crusher, which will be displayed along with a John Deere 744 P-Tier wheel loader.

Wirtgen will emphasize the importance of digitalization and connected systems by showing the John Deere Operations Center for construction machines, a central platform for all present and future digital solutions developed for optimization of processes, machines, and services.

4. AMMANN

3

4

920

Tigercat Industries designed the TCi 920 dozer to excel in demanding forestry applications where other machines struggle.

For heavy duty applications and tough pushing jobs, like stump removal and land clearing, look to the TCi 920, a machine that is built for more.

www.tigercat.com

right side, allowing compaction work on tight job sites. Drum working widths

This all-new compactor is the first in a new line of light tandem rollers fitted with gas engines that meet U.S. EPA Phase III and EU Stage V emissions standards. It is powered by a Honda GX630 (15.5 kW / 21 hp) engine, which is more compact than its diesel counterpart. The smaller size enables positioning that allows cooling from all sides for better operation in hot temperatures. Gas engines generally cost less to run than diesel engines due to the lower price of fuel and reduced maintenance. There is also no need for a diesel particulate filter. Ammann says that gas is also generally more convenient for contractors and rental customers to access.

The Cat CB10 asphalt compactor has been updated for 2024. These updates include split drum options as well as improvements to the cab, edge management, and touchscreen mapping display. Features that make operation simpler and add versatility, along with good fuel economy, include rotary dials, oscillatory vibration, and 360-degere seating. It is ideal for streets, highways, and other intermediate-type applications.

A rubber-track paver, the AP1055, features the Mobil-trac undercarriage which improves speed, traction, and flotation for improved ROI. Easy-touse technology options include Pave Start Assistant, which saves profiles for faster and repeatable

set-up on job sites. Users can keep track of material height and delivery temperatures through an optional hopper level sensor with temperature indication. The paver can be used with SE60 V and SE60 V XW screeds. Cat SDX screed plates can also be used, providing a kneading action that helps reduce air voids as the mix passes under the screed. A modular fastening system enables quick screed plate changes.

2. CDE

Technology will be a major theme for CDE during AGG1, with the company focusing on digital offerings and solutions as well as showing off its projects around the world for visitors.

The SmartTech app is a central part of CDE

technology solutions. The plant management app enables operators to understand their plant’s performance, schedule maintenance, and easily order parts from anywhere, at any time. The app can be used 24/7, and gives operators, managers, and owners the ability to make informed decisions that increase productivity, improve operational efficiency, and maximize uptime.

Attendees will also be able to access the CDE Window to the World, a virtual presentation of CDE products and solutions. Using CDExplore, 360 virtual site tours of various projects across the United States and beyond will be available to experience, along with render animations that get up close with CDE technology.

Haul roads at mines and quarries need to be maintained well for efficient use by large trucks. Keeping those roads in good repair requires a big machine that can handle rugged terrain and ensure surfaces are graded smoothly.

Komatsu focused on those needs in developing its new large motor grader. The GD955-7 is big and heavy to ensure efficient grading, while also fast and maneuverable for increased pro ductivity.

Komatsu previously offered the GD825A-2 motor grader for haul road maintenance, but it has been out of the market in North America for some time, according to Product Manager Sebastian Witkowski.

“We’ve filled that larger motor grader gap with the GD955. While we also offer the GD655, we wanted to scale up and fill those quarry and mining motor grader requirements,” he says.

Komatsu designed the GD955-7 to meet the demands of haul road maintenance. The frame has been developed spe cifically for mine and quarry environments by using larger gauge, higher-tensile steel, which offers more strength. The operating weight of 104,323 pounds is up 50 percent from the previous model.

Power is provided by a Tier 4 Final–compliant Komatsu engine generating 426 hp, an increase of 48 percent. Operators can use the power mode selection system to pick their engine settings based on working conditions: P mode for full engine output and high productivity, E mode for lighter work handled more economically, and middle-speed mode for operators who want fine travel speed control while working at full throttle.

foot standard moldboard, which can be swapped for an optional 20-foot moldboard, covers more ground on each pass.

“This machine is specifically designed for applications that are more demanding, some of the harsher conditions, while the blade and moldboard size increases fill a need for larger quarries and mine sites,” Witkowski says.

Despite its size, the GD955-7 is maneuverable and capable of making U-turns within the standard width of a 100-ton haul road without the need to fully articulate or cut the wheel.

In rugged environments like mines and quarries, maintenance can be a challenge, so Komatsu designed the new grader to reduce maintenance needs as much as possible. Central to that is the use of a bearing-type circle, which cuts maintenance downtime significantly.

“When you have to stop the machine and manually grease every 50 hours, replace wear plates or make circle play adjustments every 500 hours, that adds up pretty quickly,” Witkowski says. “With the adoption of this bearing-type circle, we eliminate the need for those wear plate replacements and circle play adjustments.”

The change has led to a 21 percent reduction in maintenance time, he adds.

A Graco auto-lube system is standard on the GD955-7, meaning operators don’t lose time greasing individual points before the day’s work. A maintenance service point includes fill and evac ports for all vital fluids, providing a central location for daily service.

The GD955-7 cab includes air suspension, heated and ventilated seats, and a control layout that gives operators all

“These operators spend a lot of time in the cab, so we want them to be as comfortable as they can be – a comfortable operator can be more efficient,” Witkowski says. “We’re seeing up to a 92 percent reduction of hand and arm movements related to the ergonomic position of the fingertip work controls when compared to the traditional antler rack style configuration.”

An auto-articulation return to centre feature straightens the machine to a neutral articulation position with the press of a button. When engaged, auto differential lock provides additional traction while managing turning performance, switching the feature off and on when steering input is detected to prevent tire drag.

KomVision, a five-camera vision monitoring system, gives operators bird’s-eye visibility to the immediate working area on a dedicated monitor inside the cab and can be paired with an optional rear-view camera on its own monitor for even better views of the work site. A standard LED lighting system includes 14 lamps, along with an LED access lamp and service light, to promote visibility around the machine.

The GD955-7 is equipped with Komtrax telematics, which continually monitors machine health and maintenance and allows fleet managers to review grader conditions remotely, reducing unplanned downtime while providing valuable data to improve operations.

All in all, the GD955-7 is a big, heavy, and powerful motor grader that remains surprisingly maneuverable.

“This ultimately translates into a more productive job site – if haul roads aren’t clean and level, those impacts can affect the entire haulage operation,” Witkowski says. “Potholes, ruts, and obstructions can impact truck productivity as well, increasing the risk of unplanned maintenance downtime. This grader helps mitigate those challenges while promoting a smooth haulage operation.” HEG

When the first electric cars came to market, they were pocket-sized and not practical for most uses. Then brands like Tesla entered the scene – cars that were luxurious and environmentally friendly but didn’t compromise on performance (for those who could afford them). Today, the development of battery-operated SUVs and pickups are helping more people see that going electric does not mean compromising the efficiency and power of your machine. The construction industry has followed a similar trickle-down effect. At first, we saw small tools and the odd mini excavator, but there was limited use of an electric machine for the average contractor. Today, battery tech is evolving quickly and it’s leading to more diverse electric equipment.

While many contractors have yet to try electric equipment, there’s no denying the winds of change are here. Some are waiting for others to “work out the kinks” before they kick any tires; others aren’t going to make a change until it’s mandated. Concerns including battery charge times, equipment effectiveness, and cost are real hurdles. But, one step at a time, the shift is underway. We can be confident that the short- to medium-term future is electric. From excavators to battery-powered tools and solar generators that last all day, the industry is seeing an influx of equipment that not only performs as well as its diesel counterpart, but is reducing carbon emissions, lowering fuel costs, and creating lasting sustainability in the construction industry.

There’s still some concern with the practicalities of electric equipment – like initial cost, run times, and charging. Equipment manufacturers know that everyone benefits if they can address those concerns, so year after year we’re seeing them bringing better power and performance to the market.

Let’s take the excavator – ubiquitous to nearly every construc-

The path Multiplex has chosen is really inspiring – they’re willing to try something new and they want to measure the impact of the changes they’re making. We’re looking forward to helping them strike that balance between productivity and environmental goals.Scott MacKinnon Director of Sales, Cooper Equipment Rentals

tion site and one of the first compact machines to go electric. The 2-tonne electric excavator from JCB is still one of Cooper Equipment Rentals’ most rented pieces of electric equipment to this day. But now customers are looking for more and, as a result, the whole industry is starting to scale up. Machines like the new 3-tonne excavator from Bobcat are helping fill that gap. Their advanced lithium-ion battery technology means they are performing as well – or better – than their diesel-powered equivalents with batteries providing significantly more hours of continuous runtime than earlier models.

Electric mini track loaders offer reduced noise, minimal maintenance, and zero emissions, making them easier to use in applications like hospitals, schools, and municipalities that

have strict regulations. The battery-powered loader from Cratos runs on lithium-ion batteries with 100 percent fume-free power. Its compact size can fit through standard sized doors. We’re also seeing growing popularity of battery-powered backpack concrete vibrators offered by brands like Wacker Neuson, which give workers flexibility during concrete consolidation. Remote areas can be accessed without having to route a power supply and the batteries’ high-performance delivers enough energy for a whole workday. To top it off, the operator is not exposed to any heat, fumes, engine noise, or emissions.

Electric equipment comes with a bigger upfront cost, there’s no denying it, but in the long run the investment pays off. If you’re unsure about committing to an electric machine, the benefits of renting are twofold: You get to try the equipment before you buy, and you don’t have to worry about maintenance costs. At the same time, your fuel savings could be significant.

Switching to electric not only has environmental benefits by reducing emissions, but also reduces noise pollution as electric machines generate a fraction of the noise of their diesel-powered equivalents. Many municipalities now have bylaws that prohibit noise at certain times of the day. With electric, contractors are able to operate outside of those hours, increasing productivity and getting jobs done faster. For most contractors, once they experience these benefits for themselves they are able to make better informed decisions about the type or size of electric machine that is best suited for the application they are working in. We see many customers want to make the switch to stay competitive with a growing number of public and private companies mandating more sustainable business practices.

As equipment evolves, fuel is evolving too. Diesel still remains the go-to fuel source for traditionally powered equipment, but we are starting to see contractors look to sources like biodiesel, which is comparable in cost. But don’t go switching out your fuels without doing your homework – check with your manufacturer first. In many cases, biodiesel can be used without having to flush out existing fuel. Right now, biodiesel’s big limitation is its sensitivity to cold temperatures; it has a six-month window in most of Canada, from roughly April to October.

In the future we may see more hydrogen-fuelled engines, but we are still a long way off from hydrogen as a reliable and cost-efficient alternative to diesel.

There’s also a growing market around hybrid power solutions for contractors to run their office trailers. The latest models are battery-diesel powered and help solve the problem we see so often – trailers running off generators that are too big. These solutions are bridging the gap between customers who are hesitant to try a battery-only solution and those who want to avoid a diesel generator running an inefficient load.

While you can charge many small machines with a common household outlet, larger equipment needs more – and the more power you can put into your electric machine, the faster it will charge. Training your workers to operate and charge electric equipment is important for the success of the machine. Any time there is a pause in the day the batteries should be charging. It’s also best practice to charge batteries from mid-level to full, as opposed to draining the battery completely before recharging.

ities. While industrial generators are great for powering large operations, they’re inconvenient to transport and undermine emission-cutting efforts. Portable battery banks or power stations will help fill the gap for temporary energy sources for compact equipment. Building an electric infrastructure involves a lot of moving parts. Support from your rental partner that includes the right-sized equipment, generators, job site data, and charging stations is one way to stay ahead of the game.

For global construction company Multiplex, finding an equipment partner that aligns with its innovative sustainability goals is key to success. Multiplex set ambitious regional and global targets to lead the construction industry. This is the first construction company in North America to set a science-based target aligned with the Paris Agreement and one of its key action areas is to have zero on-site emissions by 2030. This includes 50 percent of on-site equipment powered by renewables including electrification, green hydrogen, or biofuels from waste. In 2017, Cooper Equipment Rentals started working with Multiplex, and we now provide both electric and traditional diesel-powered equipment for job sites across the GTA.

When Multiplex started working on the OmniaBio B site in Hamilton, Ontario, the company saw an opportunity to pilot the use of an alternative fuel and renewable energy sources like biodiesel. This ultra-fast-tracked project is the first component of the master plan for the McMaster Innovation Park in Hamilton and is designed with a focus on sustainability and the environment at its core.

“We reached out directly to Cooper to try and understand what type of opportunities were available for biodiesel. We knew they would be the perfect partner for this, and they jumped at the opportunity to get involved. They provided us with the right guidance and advice to make the transition a smooth one,” comments Anya Barkan, Multiplex sustainability manager. Biodiesel was provided by 4 Refuel. Biodiesel is a renewable energy source produced from organic matter or biomass such as corn, sugar, vegetable oils, or waste feedstocks.

From excavators to battery-powered tools and solar generators that last all day, the industry is seeing an influx of equipment that not only performs as well as its diesel counterpart, but is reducing carbon emissions, lowering fuel costs, and creating lasting sustainability in the construction industry.

Biodiesel also offers a CO2 emissions reduction of 15 percent when compared to traditional diesel, which can help companies like Multiplex in reducing GHG emissions.

Our team also helps Multiplex track monthly fuel usage, a key part of Scope 1 emissions that fall under its Science Based Target Decarbonisation Roadmap. As a company on a journey to provide more sustainable solutions to customers, we’re thrilled to partner with Multiplex – we’re collaborating to make construction sites greener without compromising work quality.

“The path Multiplex has chosen is really inspiring – they’re willing to try something new and they want to measure the impact of the changes they’re making. We’re looking forward to helping them strike that balance between productivity and environmental goals,” says Scott MacKinnon, director of sales for Cooper Equipment Rentals.

Innovation is rarely a direct and singular path. Electric equipment will continue to evolve, and we’ll see biodiesel and other alternative fuel adoption continue to grow – especially when it’s an easy substitution for fossil fuels.

ROD LENTINO has over 15 years in the equipment rental industry and is currently the director of rental at Cooper Equipment Rentals, one of the fastest growing rental businesses in Canada.

The L95 is the largest, most powerful model in Bobcat’s compact wheel loader lineup, providing material handling capabilities with large bucket capacity, high lift height, swift travel speeds, and maneuverability.

The L95 is Bobcat’s third compact wheel loader, joining the L65 and L85. At 74 hp and an operating weight of 11,993 pounds, the L95 is more than 800 pounds heavier than the 68-hp L85. It has a rated operating capacity of 3,981 pounds.

A compact size, tight turning radius, and the Power Bob-Tach interface all provide versatility for landscaping, construction, rental, and other applications.

The L95 is powered by a Tier 4 Final turbocharged engine that starts reliably in cold weather and delivers hightorque performance and efficiency while also achieving emissions compliance without a diesel particulate filter (DPF) or selective catalyst reduction (SCR).

A standard bucket capacity of 1.2 cubic yards and 10.5 feet of lift height make the L95 a strong material handling machine. Its electronic hydrostatic transmission (E-HST) allows for easy direction changes, efficient acceleration, and easy speed control. The E-HST transmission and horsepower management automatically adjust the loader’s drive system to maximize pushing and loading power.

Standard features include flex drive, automatic ride

control, high-flow auxiliary hydraulics, advanced attachment control mode, and travel speeds reaching 24 mph.

Low noise levels, an oscillating frame, smooth turning, and automatic ride control combine for improved ride quality and operator comfort. A spacious, pressurized cab is available. A seat-mounted joystick with adjustable armrest adds comfort and controllability. A 5-inch display panel gives operators full-featured machine interaction and monitoring capabilities. An optional rear-view camera integrates with the touch display.

The Power Bob-Tach System comes standard on the L95, which allows operators to pick up and drop nonhydraulic attachments without leaving the seat, and speeds up hydraulic attachment connections.

4 3

1Kohler gasoline engine, the Wacker Neuson SM60 utility track loader fits smaller job sites with 7.1-inch-wide tracks and an overall machine width of 35.5 inches. It has a travel speed of 3.9 miles per hour, hinge pin height of 75.6 inches, and a rated operating capacity (35 percent of tipping load) of 600 pounds. It weighs in at 2,760 pounds. The larger SM120 has a 24.7-hp Yanmar diesel engine, a rated operating capacity (35 percent) of 1,226 pounds, a hinge pin height of 85.6 inches, and a travel speed of 5.2 mph. It has 11-inch-wide tracks for ultra-low ground pressure and is 41 inches wide. The SM120 also features ride control, providing hydraulic cushioning to the lift arms, reducing material spillage and providing a smoother ride.

2

SK1750 mini stand-on loader has a new track system with a tension check window that allows operators to visually check the track tension without threading a separate gauge tool, making maintenance checks easier. The improved track design makes the machine maneuverable with a smooth and stable ride, even when transporting heavy loads across rough terrain. It also causes less ground disturbance, allowing operators to work more efficiently without the need to spend time repairing damaged turf. An improved roller design means rollers last significantly longer, further increasing reliability and productivity.

3 1000 TURBO has a turbo-powered diesel engine with more torque to deliver power more quickly, especially when using trencher and auger attachments. A larger hydraulic filter extends maintenance intervals for less downtime. The TURBO is available in narrow- and wide-track models (weighing 2,826 and 2,911 pounds). The Dingo TX 1000 TURBO has a rated operating capacity of 1,000 pounds and a pin height of 81 inches with its vertical lift loader arms at full reach. A 24.7-hp Yanmar diesel engine powers the loader, which can travel up to 4.1 mph in both forward and reverse. An auxiliary foot control on the suspended platform allows the operator to focus on ground speed and attachment positioning.

4

The CASE TL100 mini track loader, powered by a 25-hp Kubota diesel engine, has a rated operating capacity of 1,000 pounds (35 percent of tipping load) and a standard auxiliary hydraulic setup (13 GPM, 2,700 psi) providing the versatility to run a variety of tools. Attachments connect through a Common Industry Interface (CII) compatible with most major manufacturers of MTL attachments. The TL100 equipped with narrow tracks weighs 3,536 pounds and is 35 inches wide; with wide tracks, it weighs 3,783 pounds and is 40.4 inches wide. Optional equipment includes a 14-pin front electric connector that includes a hydraulic case drain circuit, additional counterweights, environmentally friendly hydraulic oil, and multiple bucket options.

BOOM LIFTS, TELEHANDLERS, SCISSORS & MORE

Skyjack’s new SJ3213 and SJ3219 micro scissors feature fully proportional drive and lift controls and the company says they offer superior drive with more efficiency, controllability, and improved torque, while variable speed brushless AC electric front wheel drive provides excellent duty cycles.

The newest micros have been designed to fit most elevators and work in environments where space is at a premium while still providing a substantial work area.

Key features include 13-foot and 19-foot platform heights, 500-pound platform capacity, AC electric drive performance, fits through a standard door (rails up), 20-inch rollout extension to increase work area and provide up and over capability, low GVW, and low floor loading.

Skyjack’s E-Drive scissors ECO benefits include 16 percent operational carbon saving compared to previous model, up to 20 percent improvement in duty cycle over equivalent hydraulic drive machine, zero emissions, 90 percent recyclable (by weight), optional ECOtray leak containment, approved for use with biodegradable hydraulic oil, and telematics allowing for remote diagnostics to reduce site visits and operational footprint.

The MEC DualReach 85-J boom combines telescopic and articulated capability in one machine. By turning a switch while the machine is stowed, operators can choose between telescopic mode for maximum outreach and articulated mode for up-and-over tasks. According to MEC, the flexibility to adapt to different needs without two different machines means enhanced productivity for projects with different work-at-height needs where, traditionally, both a telescopic boom and an articulated boom may have to be sent to a job site.

The 85-J has a working height of 91 feet. In telescopic mode, it has a maximum outreach of 70 feet. When in articulated mode, the 85-J offers a maximum up-and-over height of 21 feet.

The boom’s articulated jib is capable of up to 135 degrees of movement and has 600 pounds unrestricted and 900 pounds restricted platform capacity at maximum outreach in both telescopic and articulated modes.

“There has long been this challenge of carrying both telescopic and articulated booms to meet all customer needs. With the MEC DualReach 85-J boom design we were able to offer the ability to switch between the two and enable one machine to work around the construction structures that change as the project progresses. One machine that covers the reach envelope of both types ensures you always have the right tool for the job,” says Gary Crook, vice president of engineering, MEC.

A self-levelling platform and optional automatic frame levelling of up to seven degrees on slopes assure stability. Steering options include standard two-wheel, four-wheel, and crab.

New attachments and carriage options for Genie’s latest generation of GTH telehandlers add to their versatility.

Developed for use with the high-pressure, variable speed GTH-5519, the auger attachment offers bits from 8- to 48-inches in diameter that can be used with extensions as long as 8 feet for general purpose and rock drilling and can produce a hole depth of 5 feet to 15 feet.

Two drive motor options deliver either 2,800 ft.-lb. of torque or 5,300 ft.-lb. of torque. It comes with a HALO LED Alignment System, an LED light ring that provides a visual aid to operators and eliminates the need for a spotter. Lights help the operator make sure the hole is being drilled at the correct angle. The auger motors are compatible with skid steers and compact excavators, and Genie offers a full range of extensions, drill bits, and auger tooling.

For the larger GTH-636, GTH-844, GTH1056, and GTH-1256, new attachments and carriage options are available.

The 10-foot truss boom has a lifting capacity of 4,000 pounds, can be rigged from three different points, and has variable reach up to 13 feet. Two heavy-duty buckets enable 6K through 12K GTH telehandlers to scoop and place loose, unpalletized materials. A 72-inch, 1-cubic-yard bucket and 96-inch, 1.5-cubic-yard bucket are new multi-purpose material handling tools.

A new 48-inch side-shift carriage enables the operator to shift the load up to 8.25 inches without exiting the cab. This reduces the need to reposition the telehandler when picking or placing the load. The most common pallet size is 40 x 48 inches, but not all loads are the same shape and size. Genie’s new fork positioner carriage allows an operator to adjust the width of the forks from inside the cab.

Manitou’s new MTA 519 compact telehandler is 5 feet 11 inches wide and 6 feet 4 inches tall with a tight turning radius of 10 feet 10 inches. It can fit through garage doors and down ramps into the lower levels of structures. It has a maximum load capacity of 5,500 pounds, a 19-foot 1-inch maximum working height, and outreach of up to 11 feet 2

inches. Five different tire options are available and ground clearance is 13 inches.

The skid-steer quick attach system allows the machine to operate standard flow skid-steer and CTL attachments and the MTA 519 is built to use a variety of ground-engaging attachments, from snow pushes to brooms, through its ground-engaging boom. The outer shell of the boom is designed with steel of equal thickness on all sides for optimal strength and the extension and retraction of the boom is entirely hydraulically driven. The boom sits lower within the framework of the machine to optimize visibility to the right side of the machine from the cab.

The new telehandler is powered by a 74-hp engine that is also placed low within the framework along with all critical power and drivetrain components. This allows for a low, sloping hood for even greater visibility, as well as easy access to all critical daily and preventive maintenance service points.

The compact telehandler has a two-speed hydrostatic Dana transmission, along with Dana axles with limited slip in the front and open axles in the back.

The compact telehandler features a full-sized cab; it is 31 inches wide, and the entryway is 74 inches tall.

On the jobsite you need a truck that’s tough, safe, and smart. So, we built the new Volvo VHD to be the best-looking, most rugged vocational vehicle in the industry, packed with innovative ideas like Volvo Active Driver Assist and the revolutionary Volvo Dynamic Steering. Your toughest jobs just got easier. Learn more at volvotrucks.ca/en-ca/trucks/vhd/

VOLVO CONNECT IS A ONE-STOP PORTAL FOR MONITORING THE HEALTH AND EFFICIENCY OF VOCATIONAL TRUCKS

BY LEE TOOP, EDITORData collection and analysis is a growing part of managing fleets – it’s important for you to understand how your trucks are being used, driven, and serviced to ensure efficiency and lower costs. Volvo Trucks has combined key data solutions into a one-stop package for owners and managers of its vehicles, including vocational trucks.

Volvo Connect is the latest innovation in fleet management from Volvo Trucks. Launched in late 2023, almost 40 percent of eligible Volvo trucks are already connected, and that growth is expected to continue.

Volvo Trucks has previously offered factory-equipped telematics hardware on its vocational and highway trucks, as well as Remote Diagnostics with remote programming capabilities.

The ability to view all the data collected through telematics through a single portal is a valuable time-saving opportunity for owners and managers, and that is the motivation behind Volvo Connect.

“Volvo Connect is an all-in-one portal for our customers to access connectivity data. It is where they can find all the Volvo trucks in their fleet, access reports for fuel economy and safety, locate every truck’s near-real-time position, provide status on traffic information and route history, see fault codes for any truck in their fleet, and visualize software updates and parameter settings,” says Chayene De Souza, product marketing manager for safety and services, Volvo Trucks North America.

Connect plays into Volvo Trucks’ priorities of safety and sustainability by providing a snapshot of truck operations, including everything from fuel consumption and idle time through vehicle speed and seat belt use, while also managing overall

Volvo Connect is an all-in-one portal for our customers to access connectivity data.

Chayene De Souza

Product Marketing Manager for Safety and Services, Volvo Trucks North America

efficiency and ensuring the fleet is operating at its full potential.

De Souza also notes that the variety of tools within Volvo Connect provide highway or vocational truck fleet managers with a single access point for information about their vehicles. They don’t need to log in to multiple portals as required by many third-party offerings.

Connect is available on all Volvo trucks with 4G Telematics Gateway (TGW), which includes most trucks from 2018 and newer, De Souza says, and gives users access to a broad range of solutions.

Maps available through Volvo Connect allow near-real-time vehicle monitoring and route information, including truck speed and location, fuel level, odometer, and engine hours. Managers can also review basic information about each truck, including specs and the status of any subscriptions that may be active.

Reports generated through Volvo Connect allow for analy-

CONNECT IS AVAILABLE ON VOLVO TRUCKS EQUIPPED WITH 4G TELEMATICS GATEWAY, INCLUDING VHD VOCATIONAL MODELS.

VOLVO CONNECT IS A ONE-STOP PORTAL FOR FLEET MANAGERS TO REVIEW THE STATUS OF THEIR VOLVO VOCATIONAL AND HIGHWAY TRUCKS.

sis of the fuel and safety performance of the fleet. “As you analyze trends, you can reveal your key performance metrics to improve the efficiency of trucks and drivers,” De Souza describes.

Sustainability metrics like fuel economy and time in idle are easier to track through the Connect portal, as are safety measures such as the status of driver seat belts.

Remote diagnostic services are

expanded in Volvo Connect as a basis for improving maintenance programs. Pairing with the ASIST service tracking solution, constant monitoring through Remote Diagnostics ensures that fault code notices are colour-coded by importance. Key components and systems are monitored for problems, so that if a fault is detected the maintenance or repairs needed can be undertaken quickly and maximize vehicle uptime. Each truck’s

service and ASIST history is retained in Connect for easy reference.

Using Volvo Connect, fleet managers can now decide on the best time to push over-the-air remote updates to their trucks without taking them out of service.

Connect is targeted toward fleet managers and owners who need insights on fleet status and health. Drivers are able to connect with their trucks via the My Truck app.

“We are the first OEM in the North American industry to launch an app for the driver,” De Souza says. “With the My Truck app, drivers have the ability at their fingertips to see important status areas of their truck. The app shows fuel range, coolant, and DEF levels, and supports the driver with notifications on potential issues such as light malfunctions and low washer fluids.”

As you analyze trends, you can reveal your key performance metrics to improve the efficiency of trucks and drivers.

Chayene De Souza

Drivers can use the app to remotely start the climate system and schedule days and times for it to start automatically.

Both Volvo Connect and the My Truck app have been well received. Thirty-eight percent of eligible trucks took up Volvo Connect within four months of its launch, and De Souza expects that number to grow. Volvo Trucks is using customer response and input to guide the future development of Connect.

“We will continue to develop this platform to support our customers’ needs,” De Souza says. “We are already getting good feedback from our customers, which helps to direct our next developments to continue to grow this very powerful tool.” HEG

HYDRAULIC EQUIPMENT FOR MOBILE MACHINERY GENERATORS

VARIABLE GENERATORS

WELDING GENERATORS

MAGNET

POWER WASHERS

STREET

PIPE CLEANING

DUST SUPPRESSION

DRILLING

FIRE

HIGH PRESSURE DUST SUPPRESSION SYSTEM

• THE MOST EFFECTIVE DUST CONTROL

• TARGETED WATER MIST

• DOESN’T WET THE WORKSITE

• OPTIMAL WATER CONSUMPTION

• EASY TO USE FROM THE JOYSTICK

• EASY INSTALLATION

• WASHING GUN WITH HOSE REEL

• DOUBLE DUST BOOSTING SYSTEM AVAILABLE

AIR COMPRESSORS

BIN WASHING SYSTEM

POWER BOOSTERS

POWER TAKE-OFF

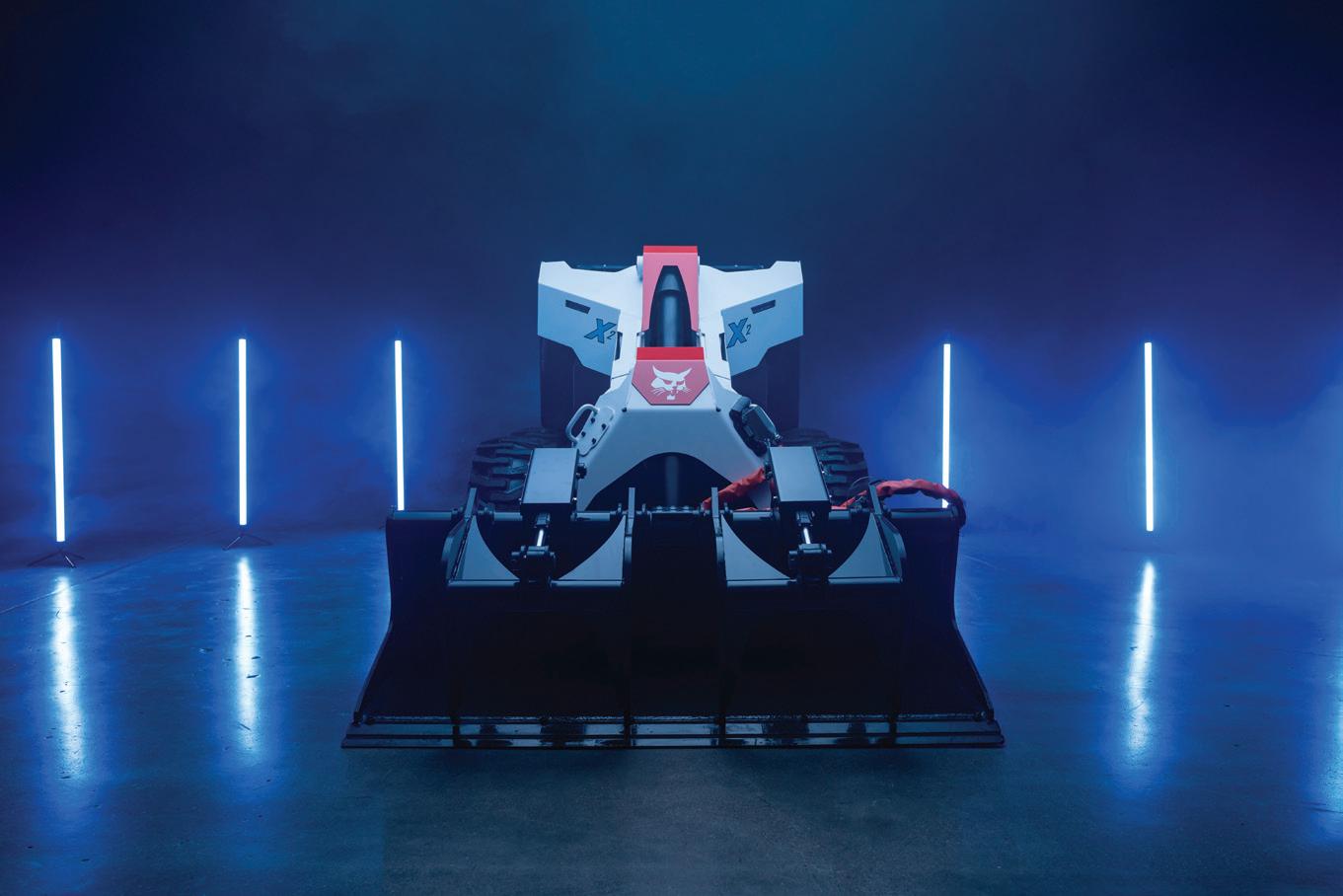

The all-electric, autonomous RogueX concept loader from Doosan Bobcat, which first turned heads at CONEXPO 2023, has evolved. The new iteration, the RogueX2, was revealed at CES 2024. The cab-less RogueX and RogueX2 loaders produce zero emissions and feature a lithium-ion battery, electric drive system, and electrically actuated lift and tilt kinematics with no hydraulics.

Taking the cab off a traditional loader allows for lift geometry experimentation that wouldn’t be possible on a machine with a cab. On the

RogueX machines, that meant combining vertical-path, radial-path, and variable-path lift capabilities in one machine.

Joel Honeyman, Doosan Bobcat vice president of global innovation, calls the RogueX platform a proving ground for Doosan Bobcat to look at designs and potential technology that could be applied to future work vehicles.

“Vehicles like the RougeX2 allow us the opportunity to showcase a number of new technologies and ideas on one concept vehicle,” says Honeyman. “Then in our research and customer evaluation we

The RogueX platform is a proving ground for Doosan Bobcat to look at designs and potential technology that could be applied to future work vehicles.

review each of those innovations individually as well. This where we may determine that one or more of these has value perhaps on a current platform. That means that we are constantly identifying ways to elevate and enhance our products and services, whether they are in a concept phase like the RogueX2,

or they are a tried-and-true product that has been part of our lineup for years.”

The most obvious difference between the RogueX and the RogueX2 is the undercar-

riage. Bobcat has designed this follow-up machine with wheels. Honeyman says changing from a tracked to a wheeled design dramatically increases the time that the electric RogueX2 can run on a charge – up to 8 hours, compared to the 4.5 to 5 hours runtime of the RogueX.

Bobcat says that axial flux motors give the RogueX2 incredible tractive effort, and the new machine delivers greater power output for demanding applications like grading, digging, or powering attachments for heavy-duty

work. The RogueX2 can be operated either autonomously or via remote control.

Bobcat’s legacy as the originator of the skid-steer loader also makes the RogueX2 a particularly suitable project for the company.

“Our roots are in the skid steer,” says Honeyman. “We invented the skid steer, so if we’re going to do a really cool future vehicle, let’s make it a skid steer.”

The RogueX and RogueX2 remain in the research and development phase and are not commercially available. HEG

THE ROGUEX2 ON THE SHOW FLOOR AT CES 2024.

THE ROGUEX2 ON THE SHOW FLOOR AT CES 2024.

Apartnership between SafeAI, a provider of autonomous heavy equipment, and Obayashi Corporation, a global contractor, has developed a retrofitted zero-emission autonomous haul truck. The Caterpillar 725 is the first haul truck retrofitted with autonomous and electrification technology, a breakthrough that allows companies to reuse their existing assets while improving operations and achieving sustainability goals.

“Just as our autonomous solution is designed to be open and interoperable to be applied to any make or model vehicle, we want our solution also to be powered by any energy source. This project is a step in that direction as it showcases how our autonomous ground vehicle stack is EV-compatible,” said Bibhrajit Halder, founder and CEO of SafeAI. “I am proud of our latest endeavour of retrofitting a Caterpillar 725, marking the world’s first haul truck retrofitted with autonomous and electrification technology. This pioneering project is a testament to our commitment to an energy-agnostic, autonomous future where efficiency and sustainability go hand in hand.”

SafeAI retrofitted the vehicle with its OEM-agnostic autonomous technology. AVIA Engineering, a system integrator known for its expertise in the electrification and mechatronics of trucks, retrofitted the vehicle with a fully electric drive system.

“We are proud to be a part of this project at the cutting edge of innovation,” says David Sánchez, owner and CEO of AVIA Engineering. “By retrofitting these vehicles using a 100 percent electric drivetrain, it allows companies to recycle their existing assets and use them in a better, more sustainable way. Our

team, in collaboration with SafeAI and Obayashi, is proud to have successfully integrated a fully electric powertrain and is looking forward to seeing where this first step can take us.”

According to SafeAI, automation and electrification together provide a range of advantages that are more difficult to achieve as independent technologies. For example, the combined uses are safer and allow for a more advanced charging infrastructure while removing employees from dangerous work environments.

Autonomy allows for 24/7 operations combined with lower operating costs, improving overall productivity and cost-effectiveness. Carbon-neutral goals can be met faster with the combination of technologies – autonomy improves environmental performance on work sites by up to 13 percent, and swapping diesel for electricity cuts net life cycle emissions by more than 60 percent. Retrofitting vehicles with autonomous and electric technology reduces the upfront costs and allows for more affordable fleet upgrades.

“When we started working with SafeAI, our partnership focused on safety and productivity. Now, we’re setting our collective sights on our next goal: to usher in a sustainable future for construction,” says Sugiura Shinya, business innovation division general manager of Obayashi. “In addition to demonstrating the synergy between autonomous and electric technologies, we’re also excited about the retrofit aspect of this project. The difference between the OEM approach and this initiative is that it puts the contractor in control. A retrofit approach allows contractors to proactively upgrade their vehicles to advance carbon neutral strategies.”

The fully electric New Agri Concept is designed for flexibility and to support a wide range of tasks. The vehicle’s six independent drive motors and a standard three-point hitch allow it to use many existing implements for common operations including mowing and tilling. Fast charging from 10 to 80 percent in less than six minutes enables flexibility by not constraining customers with long charge times, reduces vehicle downtime, and allows the vehicle to quickly get back to work when in operation. Electric drives enable quiet operation making the New Agri Concept easy to operate in residential settings or at night.

A– an example of the company’s development of future work vehicles that integrate artificial intelligence, automation, and electrification.

“Kubota is transforming from a trusted equipment provider into a solutions provider,” says Todd Stucke, Kubota executive officer and newly appointed president of Kubota Tractor Corporation. “We are well known in the compact equipment market for our versatility, durability, and reliability, and our machines have always been easy to own and easy to operate. Today, they’re evolving to be even more intuitive, putting data and AI directly in the hands of residential equipment owners to enhance their lives and make things easier, more productive, and more efficient.”