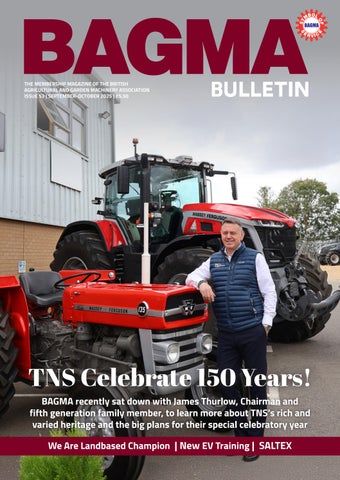

Celebrate 150 Years!

BAGMA recently sat down with James Thurlow, Chairman and fifth generation family member, to learn more about TNS’s rich and varied heritage and the big plans for their special celebratory year

Celebrate 150 Years!

BAGMA recently sat down with James Thurlow, Chairman and fifth generation family member, to learn more about TNS’s rich and varied heritage and the big plans for their special celebratory year

W e are drawing towards the end of summer 2025. Weather wise it has been fantastic, although the economic climate continues to spiral in the wrong direction. Despite this, the buzz at recent county and trade events has remained even if a few familiar names have, sadly, dropped off the map.

The BAGMA team attended The Great Yorkshire show, The Royal Welsh and, most recently, GroundsFest as they strive to support the industry and meet current and prospective members. We have also been visiting local schools alongside We Are Land-based Engineering. I attended an event at Chipping Campden School and another at Hartpury College.

One a teenager and the other was an agricultural engineer/contractor – and past BAGMA member – who was in his early fifties.

by Peter Heming

BAGMA President

There are still more events to come including the BAGMA Golf Day which has proven a massive success over the last two years. We also have our final Connect meet of 2025 at New Holland in early October and will be exhibiting at SALTEX when it returns to The NEC this November.

On another note, I was saddened to learn recently of two deaths on machinery very close to where I live.

These notifications are reminders that our industry is full of dangerous equipment and leads me to emphasise the importance of thorough training. BAGMA’s Handover & Installation training should be a cornerstone for members – ensuring that machines are installed professionally. Not only that, but this training will make sure that the operators are proficient and pay attention to what must be done to keep the equipment maintained and safe. Make sure you do everything to protect yourself and those around you and don’t forget to make use of the services you are entitled to. As a BAGMA member, a 20% discount is available on all BAGMA training courses – including our new EV training, launched this month. More details on page 8.

We must get strength from one another to weather the current situation and look positively to the future.

Very best wishes to all.

Hannah Desborough BAGMA Administrator 07842 431468

For all advertising and media enquiries please email: admin@bagma.com

Peter Heming

BAGMA President peter@heming-engineering.co.uk 07831 585476

Nick Darking

BAGMA General Manager 07512 327109

Richard Jenkins

BAGMA Business Development Manager 07432 290605

Kari Hearn BAGMA Training and Administration Manager 07874 876999

BAGMA Samuelson House 62 Forder Way Hampton Peterborough PE7 8JB 01295 713344

& Production Pan Publicity Ltd 01493 440047

2

BAGMA News

Two new members join BAGMA, BAGMA and Cramer talk landbased tech.

6 EV Training

8

WAL Awards

We Are Land-based Engineering announce Technician of the Year results.

BAGMA launch new Off Highway Electric Vehicle & Power Equipment Training Course.

10

Expert’s View

Employment Law Bill roadmap and the Vanishing Power Tools plague.

12

Member Profile

BAGMA learns about the success of the Thurlow Nunn Group from their chairman James Thurlow.

16

18 Out & About SALTEX 2025. AGRITECHNICA 2025. BAGMA Connect. The Midlands Machinery Show.

Industry News

Grasshopper Network Grows. Hartbury Digital Innovation Farm Recognised. Fendt launch 800 Vario. Deere & Company announce changes. Kubota Terrako.

20

Connecting With Craig Hoare, Sales and Marketing Manager for Toro UK.

After completing close to 100 years of service in the agricultural industry, Colin Harding and Medwyn Evans from RVW Pugh Ltd were recently presented with the prestigous Royal Welsh Agricultural Society’s (RWAS) long service medal - congratulations to them!

You’ll be able to read more about RVW Pugh Ltd in the Jan/Feb 2026 edition of the BAGMA Bulletin.

models of KUHN Farm Machinery’s popular

6m model already in production.

The 7.2m, 722 R, and the 8m, 802 R, mounted drills include many of the same features as the existing 602 R model but feature wider working widths to increase pass-to-pass output.

Month: 402 Units -18.8% change (compared with August 2024)

We want to hear from you!

The BAGMA team are working hard to ensure that our members receive the most valuable and relevant offers and discounts - to bring real benefit to their business.

To help us better tailor our Service Provider offerings, we’re asking our members to spare a few minutes to answer a few questions in our ‘Members Benefit’s Survey’.

As we continue to enhance our offering, please look out for further surveys issued later in the year!

Complete the survey here:

BAGMA are pleased to welcome two new members in the form of Boss Plant Sales Ltd and Toro U.K Limited – the latter becoming the newest addition to an ever-growing list of Industry Partners and providing further strength and support for those working across the agricultural, groundcare and garden machinery sectors.

As the UK subsidiary of The Toro Company, Toro U.K. Limited supply a comprehensive range of professional turfcare and landscape maintenance equipment under their trusted brands –Toro and Hayter.

The Toro range includes commercial mowing equipment, irrigation systems, cultivation tools and utility vehicles designed for contractors, local authorities, sports venues and groundcare professionals. Hayter – a Royal Warrant holder – is known for its premium rearroller mowers, built for professionals and discerning homeowners alike.

AUGUST 2025

Year to Date: 6,151 Units -16.0% change (compared with January-August 2024)

Boss Plant Sales Ltd is a premier supplier of market-leading construction equipment covering London and the home counties. Specialising in renowned brands such as Kubota, Manitou, Thwaites, Bomag and Atlas Copco, they offer high-quality excavators, telehandlers, dumpers, compaction equipment and power solutions to meet the demands of the industry.

With years of experience in the construction sector, Boss Plant Sales Ltd take pride in offering tailored solutions to contractors, plant hire companies and construction professionals. Their commitment to excellence ensures that customers receive durable, reliable and efficient machinery backed by expert advice and exceptional service.

Toro’s collaboration with BAGMA is rooted in shared values: promoting best practice, strengthening dealer capability and driving industry resilience. Through training, events and aftersales support, Toro aim to equip BAGMA members with the tools they need to grow.

Craig Hoare, Sales & Marketing Manager at Toro U.K. Limited added, “BAGMA plays a vital role in supporting and representing the dealer network. At Toro U.K., we value our partnership with BAGMA and its members to ensure we all continue to grow – together – in a changing market.”

BAGMA’s Nick Darking recently teamed up with Jordan Watson, Area Sales Manager at Cramer to introduce students at Rodborough School to some of the exciting opportunities available in the land-based sector.

The talk formed part of a wider careers event and was of extra personal interest for Nick as a former pupil of the Surrey school. The pair set out to quash the stereotype of land-based engineering being a ‘dirty’ industry, highlighting the many opportunities and different career paths available, and the possibilities presented to take a passion for the profession around the world.

Students were then given an insight into some of the new technologies and autonomous solutions from Cramer, and

even had the chance to get ‘hands on’digitally plotting an area to mow.

‘It was great pleasure to speak in front of the students and to show them the vast array of opportunities within the land-based engineering sector” comments Jordan. “Having been in the position of not knowing what career path to take during my teenage years it was really rewarding to help the next generation. It was also great to

ONE BATTERY 160+ PRODUCTS

showcase some of Cramer’s 82V battery equipment, which helped engage the students into what new technologies are being used and how forward thinking we are as a manufacturer.”

On the back of the visit, BAGMA has made connection with 44 career hubs that work closely with schools around the country and is currently in talks with a number of them to coordinate similar visits over the coming months.

by Nick Darking BAGMA General Manager

It’s an extremely difficult period in our industry. There’s no way to sugarcoat that the economy, the climate and other trading factors have resulted in more mergers, acquisitions and closures than I can personally remember in over 35 years in the outdoor power sector. The loss of any dealership is felt deeply by staff, customers, peers and the local community not to mention apprentices taking their first steps into the industry.

When news filters through of another dealer closure, I think it’s difficult not to take stock of your own situation. I know I’ve definitely been reflecting on how BAGMA has fared in 2025. While we, sadly, don’t have a magic wand, we’ve been working incredibly hard this year to introduce new features and benefits for our membership – the Members Forum to facilitate problem sharing and peer-topeer support, the Jobs Hub to promote apprenticeships and career progression and, most recently, the launch of a brand new training course for off-highway electric vehicles and electric power tools.

You can read more about this on page 8.

With such a fantastic network of Industry Partners, Service Providers and expert Trainers, BAGMA are more consolidated than we have been in a long time – we’re alive and kicking! Please ensure you make the most of the resources you have access to.

Following the AEA’s parliamentary reception earlier this year, we’re also pleased to report that a number of MP’s have engaged with BAGMA and BAGMA members within their own constituencies after learning about the challenges in the land-based industry.

It is vital that policymakers hear directly from businesses like yours to understand what’s working, what isn’t and what support is needed. That only happens if we show them. BAGMA are happy to arrange the meeting, provide a briefing beforehand, support with any follow-up afterwards, and even join you on the day if diaries allow.

If you are interested in finding out more, please drop me a line.

In this new series of articles, BAGMA are sitting down with some of our members to celebrate their special industry milestones. 2025 marks 40 years since the formation of GKB Machines and 10 years of GKB here in the UK. We spoke to UK Operations Manager Tom Shinkins to find out more.

What was the founding vision for GKB Machines? What were the early challenges, milestones and successes?

GKB Machines is part of the GKB Group which was established in 1946 by Jan and Pieter-Arie Kraaijeveld. The GKB Group is a renowned civil engineering and contracting firm in The Netherlands who rely on quality, innovative equipment to complete jobs. Finding that this equipment wasn’t always available, the Kraaijeveld’s founded GKB Machines to design and develop machines for their own use.

One of the early milestones was the development of the GKB DrainMaster which remains core to GKB’s range today and is widely used by contractors across the world.

How has GKB Machines adapted to changes in the industry over the last 40 years?

A major factor has been expanding our production facilities to cope with demand. We have three sites in Barendrecht, including Grondbank, which provides GKB with our own reserves of soil, sands and recycled materials. It also provides space for green waste recycling for GKB’s own contracting division and others operating in the area.

We’ve also had to keep pace with changes in surface type and technologies which has seen the launch of a line of synthetic maintenance equipment in 2013 and developments to other machines in our range to suit hybrid and desso constructions.

What values have remained consistent over that time?

GKB has always been about the people, both in terms of employee morale and welfare and putting the customer first when it comes to developing equipment

to meet the needs of the end users. By keeping manufacture in-house in The Netherlands, we’ve been able to retain complete control of materials and build quality, as well as ensuring we keep good stock for timely delivery to market. 2025 also marks 10 years of GKB in the UK. You’ve been personally at the helm for that time. What are you most proud of?

Creating a brand that is recognisable and building a reputation for robust and reliable equipment. GKB’s contracting heritage means we’ve become the port of call for many contractors here in the UK, as well as seeing our machines in a number of high-profile venues around the country.

Since your formation, GKB globally have pursued a dealer route to market – why is this?

A dealer network boosts the sales effort and brings localised knowledge and experience to their respective geographic areas. Some of our dealers around the world also have their own sub-dealers which gives extra breadth and strength to our coverage. From a customer point of view, it provides unbeatable support and peace of mind that help and advice is available on a local level.

Sustainability has been another key part of GKB’s strategy. What is your environmental approach and if/how will this change in the future?

Sustainability is big part of GKB’s operation, particularly our production. Our factory is equipped with solar panels, water recycling, green walls and

We also recently added electric diggers and vehicles to our fleet for transport and work in urban environments. The Netherlands are leading the way in green energy technology so we’re trying to keep pace with making improvements to our infrastructure.

What current industry trends excite or concern you?

The weather is certainly becoming a concern - the lack of rainfall is making the ground too hard and causing more wear and tear on equipment. Labour shortages is another concern as is the increasing amount of trade shows. We should all be singing from the same hymn sheet and supporting events that bring benefit to the wider industry.

How do you build on the legacy of the last 40 years. What’s next?!

Continuing a lot of the good work we’ve already done! We’ll also be looking to expand our dealer network and work closely to support them with the training and information they need to thrive.

www.gkbmachines.com

We Are Land-based Engineering, which is run by the Land-based Engineering – Training and Education Committee (LE-TEC Ltd), is thrilled to announce the winners of the Land-based Engineering Technician of the Year Award 2025.

This prestigious award recognises the next generation of engineering talent driving innovation and excellence across the land-based sector in the UK. With record-breaking entries received, technicians across the country were nominated by their peers, colleagues, employers and lecturers to this year’s awards, answering questions set by the We Are Land-based Engineering panel.

Charlie Nicklin, CEO of Institution of Agricultural Engineers (IAgrE) comments on this year’s competition, “As judges it was a challenge to get to our three winners from the fantastic array of entries we had this year. The three technicians chosen are a credit to their employers and have individually shone through for a variety of reasons, including technical ability, commitment and passion in their roles. They are all great ambassadors for our industry and will hopefully inspire others going forward”.

After multiple rounds of sifting through the entries, the following three technicians were picked and Gareth Ford of the Agricultural Engineers Association (AEA) shared, “These three outstanding technicians showcase the skills, talent and dedication that our industry has to offer. Their achievements reflect the strength of our training providers, employers, and the wider land-based engineering community.”

We’re pleased to announce the top three for 2025 are:

1st place -

2nd place -

3rd place -

Alfie Holstead from Grimme UK winning a Kubota Tool Box

Joe Sweetmore from B&B Tractors winning a Makita UK Job Site Radio

Anna Welland from Rea Valley Tractors winning a Makita UK Tool Kit

The Land-based Engineering Technician of the Year Award continues to shine a spotlight on the vital contributions of young professionals in agriculture, horticulture, and groundcare machinery.

Backed by LE-TEC Ltd, the award is a testament to the sector’s commitment to nurturing future leaders and innovators, whilst showcasing the high quality careers that are available.

“The We Are Land-based Engineering initiative is extremely important to the sector, building awareness of the career opportunities on offer by reaching out to younger generations and potential career changers alike. The calibre of the entrants we saw in this year’s LandBased Engineering Technician of the Year was outstanding, filling myself and my fellow competition judges with pride and optimism for the new talent emerging across the board.” - Nick Darking, General Manager of BAGMA.

For more information about the awards, next year’s competition details, and the work of We Are Land-based Engineering, visit www.wearelandbased. engineering today.

Or scan here!

BAGMA spoke to the three winners, to find out more about their career journeys in land-based engineering.

1 What made you want to be a land-based engineer?

AH Farming has always been an area of interest for me and with an engineering background, pursuing a career in this industry felt like a natural step.

JS I have always had a strong interest in tractors and agricultural machinery, which inspired me to complete my work experience with B&B Tractors where I am working now.

AW Growing up in agriculture, on a beef farm, and in the rural community, I always wanted to do something linked to this industry but never knew what that was. One day I asked for a job at the dealership down the road in the stores, but quickly realised parts wasn’t the role for me. After helping out on a service I fell in love with spannering and since that day pushed forward in being the best technician I can be.

2 What’s the best thing about the land-based engineering industry?

AH The best thing about the industry is everybody is interested and passionate. Someone is always willing to give a helping hand when it’s needed!

JS The best part about the land based industry has to be the variety of work that comes into the depot, it means that every day is very different.

AW Every day is different, you never know where you will be or what you will be doing. This variety keeps me interested in the job and keen to learn, as everyday you’ll be working on something slightly different, which teaches you new skills and knowledge.

The unbeatable ISEKI SXG range of mowers enable cutting and collecting in the wet without clogging up, ideal for the homeowner requiring the next step up in garden maintenance machinery. For the homeowners who require a subcompact tractor the TXGS24 is the most versatile and powerful tractor on the market.

ISEKI compact tractors and mowers are designed and manufactured in Japan with over 100 years experience for quality that lasts.

Contact us and apply to be an ISEKI dealer today, visit www.iseki.co.uk or call 01473 599266.

3 What’s your favourite achievement or part of your career journey so far?

AH My favourite achievement has been becoming a field-based engineer and being trusted with my own work van. I know I am at the early stages of my career so I am sure there will be many more achievements throughout my journey.

JS My greatest achievement so far would be passing my college course with a distinction. It has given me a real sense of pride in my abilities.

AW I think my biggest achievement on paper must be getting distinctions in all parts of my apprenticeship. I’m also very proud to have earned the respect and knowledge look after tractors and other equipment all round the county.

4 Why do you think others should consider a career in land-based engineering?

AH I believe others should consider a land-based career, as it offers the chance to work on a wide range of specialised and diverse machinery while developing valuable skills for the future.

JS There are many reasons! But I feel that one of the main reasons is the many opportunities and skills you gain through learning how to repair a vast range of tractors and machinery. You also get to meet a variety of different people and become part of a great community.

AW It’s not all sunshine and rainbows, the job can be very hard and demanding! It can also be incredibly rewarding helping farmers when they break down and caring for machinery from the day it leaves the depot. This gives me an incredible feeling of pride.

From cars to garden tools, the electrification revolution is reshaping the world around us. Now, it is reaching deeper into the industries supported by BAGMA members.

Over the past decade, the transition from the internal combustion engine to electric vehicles and battery-powered equipment has accelerated and it is showing no signs of slowing down.

This shift offers clear advantages: lower emissions, reduced noise, fewer moving parts, and increasingly, lower running costs. But for many working in sales, service and support of traditional machinery, electrification also brings a degree of uncertainty. Recent technologies mean new challenges and for those unfamiliar with high-voltage systems, the stakes can be high.

Whether it is a battery powered mower or an electric utility vehicle, modern equipment comes with a new set of hazards. These are not simply mechanical machines, they involve complex electrical systems, lithium-ion batteries and stringent safety protocols. Even transporting an electric unit from the dealership to the customer

now involves special considerations. Mishandling batteries during transit, storage, or servicing can have dire consequences.

Recognising this growing need, BAGMA has collaborated with industry partners to develop a new one-day practical training course focused on Off Highway Electric Vehicles (OHEV) and Electric Outdoor Power Equipment (EOPE)

The course is designed to help technicians, sales staff, engineers, delivery drivers and workshop personnel gain a working knowledge of:

• The hazards of high-voltage electric systems

• Best practices for handling and storing battery packs.

• Relevant legislation and compliance requirements

Importantly, the course retains a hands on, practical element.

By the end of the day, attendees will have increased confidence in working with electric machinery, a stronger grasp of their legal responsibilities and a better understanding of safety protocols. The course concludes with a short assessment and participants receive a certificate of completion - an increasingly valuable asset as electrification continues to expand.

As more electric products hit the market, manufacturers and dealers alike will need staff who understand the technology; not just how to sell it, but how to manage it safely and legally.

Whether you are just starting to work with electric systems or you are already involved and want to deepen your knowledge, this course is a vital step in future proofing your skills and your business.

For more information, contact Kari Hearn on info@bagma.com

As the year begins to draw to a close, it is not too late to secure your space on one of our remaining Handover & Installation training days.

This one-day course, delivered by one of BAGMA’s expert trainers, provides dealer staff with practical guidance in the relevant legislation, areas of responsibility, recording and reports for installation of products and services.

At the time of going to press, the three dates hosted at Kubota (UK) are sold out, but limited spaces are available at either GGM Group’s Knottingley and Colne depots - ideal for individuals or small groups where a dedicated training session would not be feasible.

Secure your place today by expressing an interest to Kari Hearn via email on info@bagma.com

Thurs 2nd October - SOLD OUT!

Kubota (UK) Ltd, Dormer Rd, Thame OX9 3UN

Thurs 16th October

GGM Group Ltd, Unit C5, Weeland Park, Knottingley WF11 8FE

Thurs 23rd October

GGM Group Ltd, Regent St, Colne, Lancs, BB8 8LJ

Wed 19th November - SOLD OUT!

Kubota (UK) Ltd, Dormer Rd, Thame OX9 3UN

Wed 3rd December - SOLD OUT!

Kubota (UK) Ltd, Dormer Rd, Thame OX9 3UN

Your guide to what’s coming when

by Angela Carter WorkNest

The Employment Law Bill promises the biggest shake-up of UK employment law in decades. Having recently cleared the Committee Stage, one of the questions we’re hearing most from employers is: “When will these changes actually come into effect?”

The good news is that the government has now published its Implementation Roadmap, which sets out an initial phased plan for rolling out the changes –giving employers a much clearer picture of what’s coming when.

Despite all the buzz surrounding the Employment Rights Bill, 2025 is now shaping up to be a relatively quiet year for employment law, giving employers some welcome breathing space.

be alert to the fact that the protective award for failing to carry out collective consultation will double in April 2026, significantly increasing the risk of sidestepping these duties. However, the proposed change to the collective consultation trigger – adding a new test alongside the current ‘20 redundancies in 90 days’ rule – isn’t expected until 2027, providing some short-term flexibility.

See the full implementation roadmap here

While there will be little actual change, 2025 will be a busy year for consultations. As mentioned, key details still need to be clarified – like what the “light-touch” dismissal process will actually involve, and how many hours must be guaranteed to avoid falling under the new regime.

These consultations will be vital in shaping the final legislation, so employers and HR teams should keep a close eye on developments and be ready to adapt accordingly.

The pace of change will ramp up in 2026, as a range of important reforms kick in, from SSP updates and day one paternity leave to the long-awaited ban on fire and rehire and tougher rules around workplace harassment.

Of note, employers planning restructuring or redundancies should

Additionally, late 2026 will see the government’s ban on controversial fire and rehire practices come into effect, removing a commonly used mechanism for implementing contractual changes. This gives employers just over a year to review and, if necessary, update employee terms and conditions under the current rules – before the new restrictions make such changes significantly harder to carry out.

Thankfully, employers won’t have to contend with some of the more complex and controversial reforms – including day one unfair dismissal rights – until 2027.

This phased rollout offers a valuable opportunity to plan ahead, engage in the consultation process, and prepare for these changes in a structured and informed way.

BAGMA members looking for support can speak to us on 01244 667249 or email bagmahr@worknest.com for Employment Law and HR advice.

22 seconds. That’s how long it took one thief to open a builder’s van. In under five minutes, they’d stolen £15k in power tools. It’s not quite magic, but it’s close...

Up and down the country, it’s a similar story, with the theft of power tools from vans likened to a plague. Here are our top tips for making sure you’re not the next victim.

Don’t treat your van as a storage cupboard

We recommend storing only the tools you need for the day in your van, then moving them to a secure location when you’re finished. Tools shouldn’t be stored in the van overnight (most policies will exclude cover for tools stolen from a van overnight) nor should they be visible to pedestrians.

Beware of the single article limit

Your insurance will most likely have a single article limit. Tell your insurer if you’ve bought any new, pricey tools to ensure they’re covered.

Covered for travelling

Some policies might only cover you in certain areas. That’s why it’s important to make sure your van is covered throughout the UK, so you’re protected wherever you go.

Keep your receipts

If your tools are stolen from your van, and you need to make a claim, you’ll need to provide your insurer with proof of purchase, otherwise your claim may not be accepted.

Prepare for the worst

Sometimes, even when we take precautions, bad things happen – but, with the right protection, it doesn’t have to be the end of the world. Contact Richard Davies at Towergate on 01604 657348 to find out more.

by Richard Davies

With over 600 staff and 17 locations across East Anglia, Thurlow Nunn Group have weathered the highs and lows of the agriculture and motor trades for 150 years. BAGMA met with Chairman James Thurlow to discuss the success of Thurlow Nunn Standen (TNS) and the wider group, how they are marking their special milestone and what’s next for the family-run firm.

Thank you for having us. Firstly, give the readers a potted history of TNS and the wider Thurlow Nunn Group and explain how you, personally, became involved.

The business was founded in 1875 in the mid-Suffolk town of Stowmarket by my great-great-grandfather, George Thurlow, following his move from Leiston in East Suffolk. It is believed that George worked for the renowned steam engineering company, Richard Garrett & Sons, before establishing his own enterprise. In the early years, the business sold more than 350 steam engines, both new and used, and we are fortunate that many of our records from this era are securely preserved in the Suffolk Archives in Ipswich, known as The Hold.

The business passed through two generations before a significant turning point came, following the death of my grandfather in 1968. In 1970, George Thurlow & Sons merged with Frank J Nunn, a fellow Massey Ferguson dealer based in Elmswell, Suffolk. This

merger doubled the size of the business and expanded our operations to four sites across East Anglia. At that time, Thurlow Nunn was solely focused on the agricultural industry and my father was clearly focused on growth.

The late 1970’s marked the beginning of diversification, with the introduction of Kubota – a new compact tractor brand that had recently entered the UK market - which added fresh momentum to the business. However, the early 1980’s brought a more significant shift in direction. While maintaining agriculture at our core, we invested in an Opel (later Vauxhall) motor retail business in Stowmarket, followed a few years later by a petrol station and a used car retail centre, also in Stowmarket. This marked the start of a new era, continuing to strengthen our core business, while embracing growth through new revenue streams.

I joined the business during another pivotal moment in its history. In 1994, nine years after the acquisition of F.A.

Standen in Cambridgeshire, the company expanded further by acquiring two sites previously operated by Cowies Eastern Tractor in East Suffolk. At that time, I had just returned from a six-month placement with Massey Ferguson in Beauvais, France, which marked the beginning of my career in the agricultural sector.

Since 1994 the business has continued to expand, with the amalgamation of Randell NFM in to TNS in 2012, and further significant investment in our motor division.

You’re proudly the fifth generation to take the helm. How important has the family-run ethos been to TNS’ success and is it a model that’s set to stay in the future?

We are and remain a family owned and operated business. This was something my father was incredibly proud of and something he felt defined us. As the business has grown, we have tried to maintain the family feel although,

unlike in my father’s day, I can’t know every employee’s partners or children’s names which is something he would certainly have done! As the business has grown, we’ve introduced stronger corporate governance and processes to differentiate ourselves from a traditional family-run operation, though at our core, we remain very much a family business. We are now transitioning to the sixth generation of leadership with my nephew, Will Tew, taking on the day-today running of the company as Managing Director. Alongside Will’s appointment, we are fortunate to have a young and dynamic board of directors, supported by experienced business leaders who serve as non-executive advisors.

I see a bright future ahead for our family business as we navigate the ever-changing landscape. We must stay true to our heritage while embracing the opportunities of tomorrow.

The company has continuously grown and evolved over the last 150 years. What is the current business split between sectors?

Thurlow Nunn Standen represents 33% of our Group’s turnover and operates within the agricultural sector. It includes our farm machinery retail business, as well as its sister company, SID, which specialises in turnkey farm and crop storage solutions. The remaining turnover comes from our motor retail division, Thurlow Nunn, and its associated parts distribution business.

What are the major challenges or threats of running such a diverse operation?

Growth and scale inevitably bring challenges, but we have found success

by implementing consistent processes across the Group. We take a unified approach to monitoring performance in each business, which has proven highly effective. One ongoing challenge, however, remains universal across the organisation: attracting and retaining talent.

To address this, we are now placing a strong emphasis on retention and development, investing in strategic programmes designed to nurture, grow and retain our own people. You also employ over 600 staff, operating from 17 separate locations. How do you manage this to ensure consistency across the brand?

Our growth and diversification has been key to our success – it’s only when you operate as a certain scale that you attract the attention of some of industry’s major players. However, keeping track of the daily happening’s at this scale becomes challenging. We try to ensure all areas of the group operate in a similar vein and rely on data to achieve this. We’re a very data-driven organisation with every site keeping data on ROI, efficiencies and performance benchmarking to help us analyse the good, the bad and everything in between.

Looking specifically at TNS, are there any franchises which you’d say have been particularly important to your success?

Massey Ferguson has been a constant in our business for over 100 years.

Historical records show entries detailing our sales and distribution of Massey Harris products as far back as 1907 through a subsidiary called Woods & Co, based in Stowmarket. The triple triangle

has remained a cornerstone of our operations, alongside other long-standing brands such as Kubota, Kverneland and Vauxhall, each of which has been part of our portfolio for over 40 years.

These enduring relationships have stood the test of time and we continue to nurture and strengthen them today. Looking ahead, we hope that in 50 years’ time we will still be trading with these suppliers, while also celebrating the success of our newer partnerships.

As a large outfit, is it difficult to remain responsive to changing consumer demands? What are the major trends and requirements you’re witnessing from TNS customers?

Finding the right balance between customer satisfaction and financial performance is increasingly challenging. While we remain committed to operating efficiently and maintaining strong cost controls - because failing to do so would lead to unsustainable pressures - we also place a strong emphasis on delivering excellent customer experiences. Aftersales remains a critical element to the customer experience. How do you ensure your back-up support keeps pace with other areas of the business? We operate a silo approach to management within the individual operating companies. Parts, service and sales all have their leads within each business and site whilst a uniform strategy is created and delivered from the Group board into these silo’s. This gives us a broad overview of what is working in one business and whether that could work in another. We have found that some of the processes work across all sectors and some don’t. We pride

“The generosity shown has been unimaginable, it has truly exceeded all our expectations.”

ourselves that we can react quickly to market changes, unlike some large multinationals and this is what gives the family business its USP.

There’s been a lot of talk about trepidation in the market and concerns more generally about the wider economy. Have you seen any evidence of this?

We have been very deliberate in focusing our investments where we see strong and viable returns. In 2024, we invested in our first Hyundai site, which has proven successful and I expect us to have added more motor sites by the end of the financial year. This does not signal an exit from our agricultural interests; rather, it reflects the current market reality, where returns in certain sectors are stronger.

We’ve all witnessed a decline in farming activity, and having a diverse portfolio allows us to explore alternative revenue streams when market conditions shift. A great example of this adaptability was the opening of our Morrison Local retail store in 2023. We had a vacant building perfectly suited for a convenience store, and we seized the opportunity. Agility is key, we must remain nimble and ready to act when the right opportunities arise. You’ve been busy marking the exciting ‘150 Year’ milestone, all while raising funds for charity. What are some of the things you’ve been up to?!

As we celebrate our 150th year since our foundation in 1875, this milestone is both a moment of pride and one of

reflection. While we are thrilled to mark such an achievement, there is a profound sense of sadness that our mother and father, who played such a pivotal role in the growth of the business, are not here to share it with us. They passed away just 10 days apart in 2024, leaving an enormous gap in our lives.

My father was diagnosed with vascular dementia in 2019 and lived with the condition until his death. The final year was devastating; the disease slowly stripped everything away, especially his dignity. In his memory, we decided to make this anniversary year about more than just celebration. We set ourselves an ambitious goal: to raise £150,000 for Dementia UK in 2025. To get there, we’ve thrown ourselves into a wide range of fundraising efforts fun runs, skydives, river rowing, auctions, BBQ’s, cake sales, raffles—you name it, we’ve done it!

The generosity shown has been unimaginable, it has truly exceeded all our expectations.

As we near our goal, we have more events scheduled for the remainder of the year. We are holding a charity golf day in September closely followed by the auctioning of my father’s MF135 in October at the Cheffins vintage sale, with all the proceeds from the sale given to the charity. Our year of celebration will end with a charity ball in December where our close friends and family will come together to celebrate our 150 years whilst raising vital funds for the charity. We hope to be well over our target by the end of the year.

Thank you for being BAGMA members. What’s the importance of this for you?

BAGMA provides invaluable insight into industry trends on a national scale. However, for us, the real strength lies in its training platform, particularly in areas such as Handover and Installation training. By setting an agricultural industry standard, BAGMA gives us

Growth remains a key priority for us, and we have set ambitious targets for the next five years, supported by strategic investment in new channels. Currently, we are working on an AI-driven project to enhance our service operations across Thurlow Nunn and TNS. In addition, we are exploring the expansion of Morrison

transitions into the hands of the sixth generation of our family, there are some truly exciting projects on the horizon. tnsgroup.co.uk or tngroup.co.uk

The MF 135 shown left, owned by James’ father, is due to go under auction on 18th October at the Cheffins vintage sale, to raise allimportant funds towards their £150,000 target.

If you’d like to donate to the Thurlow Nunn Group fundraiser for Dementia UK you can find their page on Just Giving by searching: Thurlow Nunn Group 150 or scan here:

For almost 80 years, SALTEX has been the trusted stage where machinery meets the professionals who rely on it.

Taking place at Birmingham NEC on 12-13 November 2025, the show remains Europe’s cutting-edge event for the grounds management industry, and a vital platform for manufacturers to showcase the latest innovations in turf care.

What sets SALTEX apart is its purpose. Unlike commercial exhibitions, every surplus generated is reinvested into

the sector by the Grounds Management Association (GMA). That means profits don’t just fill the show floor. They help to fund subsidised GMA memberships and upskill thousands of groundspeople across the UK every single year. In fact, income from the 2024 show helped subsidise more than 2,000 training courses and qualifications, ensuring both volunteers and professionals can access the skills they need to deliver the best possible playing surfaces.

For exhibitors, reinvestment builds loyalty. Long-standing brands such as Dennis Mowers, Husqvarna, Cramer, Kubota and ISEKI UK & Ireland return year after year because SALTEX consistently delivers what matters: direct access to thousands of decision-makers and the opportunity to build lasting relationships. 2025 will also shine a spotlight on fresh ideas through first time exhibitors like Fendt, who will show off their brand new e100 Vario electric tractor to the UK market. In fact, visitors to SALTEX will be amongst the first to see it, and how machinery innovation is reshaping the industry.

With live demos and the launch of the brand-new ‘Workshop’ led by industry expert Tom Stidder, SALTEX 2025 is the hands-on, future-focused event designed to help you get the very best from your kit, and see the latest machinery in action!

And with even more exciting features still to be announced, SALTEX 2025 promises fresh ideas around every corner. Best of all, it’s completely free to attend.

SALTEX takes place on 12-13 November 2025 at Birmingham NEC. Register for free at www.saltex.org.uk.

BAGMA will be hosting a very special BAGMA Connect at SALTEX 2025. Join fellow members, Industry Partners and a selection of our Service Providers for a drink in The Clubhouse from 3pm on Wednesday 12th November.

AGRITECHNICA 2025 is set to welcome around 2,700 exhibitors from over 50 countries, with 65% coming from abroad, filling all 23 halls in Hanover from 9-15 November.

The world’s leading trade fair for agricultural machinery expects 430,000 visitors and will feature a new “7 Days, 7 Topics” format, including highlights like Agribusiness Days (with limited access and premium ticketing for large-scale farmers, dealers, and contractors), International Farmers Day, Digital Farm Day and Young Farmers Day.

The show will present innovations across the entire farming process — from tractors to autonomous systems and digital technologies. A new Digital Farm Center and the parallel Systems & Components exhibition will further enrich the experience.

Special focus will be placed on agricultural machinery dealers, with

exclusive access during Agribusiness Days and a dedicated International Dealer Center in Hall 2.

The UK remains a strong presence, with around 60 exhibitors and 6,000 professionals expected. Since AGRITECHNICA was promoted in the UK this summer, it has become clear that — despite current challenges — the British appetite for innovation is stronger than ever. A solid contingent of UK visitors is

once again expected at the show.

UK travel partner Field Farm Tours offers tailored packages to simplify attendance, currently with two pricing options to align with the themed day program.

The message is clear: AGRITECHNICA is the place to be for innovation, networking, and the Future of Farming.

For more information, or to book tickets, visit www.agritechnica.com/en/

The final BAGMA Connect meeting of 2025 will be taking place on Thursday 9th October 2025 at the New Holland headquarters in Essex.

Members, guests and non-members are welcome to join us between 09:00 and 15:15 at New Holland, Essex College, Cranes Farm Rd, Basildon SS14 3AD . The event is free to attend.

BAGMA Connect is just one part of BAGMA’s wider objective to keep the industry connected.

On the day attendees can expect to listen to expert speakers, providing advice and best practice on some of the industry’s most pressing issues as well as network with fellow professionals from dealerships and manufacturers from around the country.

For more information or to register for your free ticket visit bagma.com/events

The Midlands Machinery Show returns to Newark Showground on Wednesday 19 November 2025, with a new one-day format designed to deliver maximum value for both exhibitors and visitors. This show provides a vital platform to champion British farming, showcase innovation, and connect with key decision makers.

With 72% of attendees having purchasing influence, Midlands Machinery Show provides the opportunity to build relationships, reinforce existing partnerships, and generate new business.

More than just a sales opportunity, exhibiting at Midlands Machinery Show is about standing alongside the businesses shaping the future of UK farming, showcase your expertise and maintain visibility among the people who matter most - your customers. www.midlandsmachineryshow.com

Chandlers Farm Equipment LTD, a leading name in agricultural and groundscare machinery, is proud to announce the expansion of its Grasshopper® Mower dealer network across the United Kingdom.

This strategic growth initiative brings Grasshopper’s renowned zero-turn mowers to even more customers nationwide, delivering high-performance mowing solutions backed by Chandlers’ trusted service and support.

Grasshopper, engineered and built in the USA for over 55 years, is recognised globally for its precision, durability and operator-focused innovation.

Chandlers’ expanded network ensures that commercial landscapers, grounds maintenance teams and estate managers across the UK have better access than ever to the full Grasshopper line-up, including front-mounted and mid-mounted zeroturn mowers.

“We’ve seen a steady increase in demand from professionals who want reliable equipment that stands the test of time,” said Justin Thompson, Groundscare Specialist at Chandlers. “Grasshopper’s commitment to quality, combined with our expanding reach, means we can now support more customers across the UK with expert advice, fast delivery and local service.”

One of those recently appointed to the

Grasshopper Mowers UK dealer network is Readman Mowers, in York. With new dealer locations across England, Wales, and Scotland, Chandlers Farm Equipment Ltd continues to raise the bar for professional turf care solutions.

If you are interested in joining our growing network of dealers, please contact Grasshopper Dealer Principle Justin Thompson on 07387 017279 or email justin.thompson@chandlersfe.co.uk

CAMPEY HALF PAGE AD

For almost four decades we have provided customers with honest, practical turf care advice, introducing industry-defining machinery that has changed the way natural and hybrid pitches are maintained. We’re always seeking ways to innovate turf maintenance, and finding solutions to common issues faced by every turf care professional is a vital part of the Campey operation. Whether you’re tackling localised compaction or carrying out a full pitch renovation, Campey strives to provide industry-leading machinery to meet the needs of groundsmen at every level of sports turf care. Call us on +44 (0)1260 224568 or visit at www.campeyturfcare.com

Hartpury University and Hartpury College’s Digital Innovation Farm has been featured in the UK Government’s Modern Industrial Strategy: Advanced Manufacturing Sector Plan as a key institution driving innovation in the agri-tech sector.

Recognising Hartpury University and Hartpury College’s contributions to agricultural productivity and sustainability, the Digital Innovation Farm is named as a leading institution in the South West region, alongside another prominent agri-tech hub at the Royal Agricultural University.

The strategy supports the institution’s

role in working with businesses and academics, advancing precision technologies, including robotics, automation, advanced sensors, AI and data systems, which are critical to transforming agriculture and ensuring food security. By fostering innovation and supporting the adoption of cutting-edge technologies, Hartpury’s Digital Innovation Farm is helping to address challenges such as climate resilience, emissions reduction and sustainable food production.

Claire Whitworth, College Deputy Principal and Strategic Lead for University and College Agriculture Facilities added: “At Hartpury, we’re committed to ensuring our students are not only gaining qualifications but developing the skills, knowledge and experience they need to thrive in the future world of work. This is also reflected in our £8m investment in our agriculture facilities since 2018. The recognition of agri-tech within the Industrial Strategy reinforces the importance of preparing our graduates to lead in a rapidly evolving industry— equipped to innovate, adapt and contribute to sustainable agricultural solutions from day one.”

Deere & Company has announced key leadership changes as it continues to advance its Smart Industrial Strategy to deliver intelligent, connected machines and solutions that enhance customer economic value.

“We’re focused on building an experienced, purpose-driven leadership team dedicated to improving our customers’ success,” said John May, Chairman and CEO of Deere & Company.

“Each of these leaders brings extensive expertise, a shared vision for innovation, and a deep commitment to delivering value to our customers worldwide.”

Effective November 3, Deanna Kovar has been appointed President, Worldwide Agriculture & Turf Division: Production and Precision Ag, as well as the Americas and Australia markets. In this role, she will have responsibility for major equipment and technology solutions for productionscale agriculture, including large tractors, as well as harvesting and crop

care equipment. Kovar was previously president of the company’s Small Ag & Turf business.

Justin Rose will assume the role of President, Worldwide Agriculture & Turf Division: Small Agriculture and Turf, including responsibility for the Europe, Africa, and Asia markets. Rose will be responsible for equipment and technology solutions tailored to support small agricultural and turf customers worldwide, including small tractors, compact utility tractors, hay and forage equipment, and turf care equipment. He recently served as president of Lifecycle Solutions, Supply Management, and Customer Success for Deere.

In addition, Cory Reed has been named President, Lifecycle Solutions, Supply Management, and Customer Success. Reed will manage Deere’s global aftermarket, customer support, supply chain, precision upgrade, and business transformation initiatives, focusing on delivering exceptional value and support for customers worldwide. Previously, he was president of the company’s Production and Precision Ag business.

Kubota (UK) Ltd has introduced a digital marketplace for customers to streamline ordering of genuine parts using mobile or desktop devices. It is called Terrako, and enables Kubota parts to be ordered through an online portal (http://uk.terrako.com) that also provides instant access to dealer stock levels.

In addition to highlighting the location of their closest Kubota dealer, current stock levels and recommended retail pricing, Terrako also provides access to schematic drawings and parts numbers - simplifying parts identification and ensuring customers order the correct parts for their equipment.

Fendt has launched the new 800 Vario Gen5 series with three models in the range offering 260 to 343 horsepower. The new models feature VarioDrive, the low-speed Fendt iD concept, and a self-cleaning engine air filter for the first time.

The fifth generation 800 Vario includes three models: the 826, 829 and 832 with Power+, Profi and Profi+ specifications available. The range features Fendt’s DynamicPerformance (DP) added power concept which offers a boost of 23 horsepower (17 kW).

Fendt’s latest VarioDrive has been paired with an efficient 8.0 litre, 6-cylinder CORE80 engine to maximise power and reduce fuel consumption.

Like most Fendts the 800 has a low operating weight of 9.9 tonnes and offers a top speed of 60km/h. Fendt’s self-centring Reaction Steering, Stability Control (FSC) and Trailer Brake Assistant (TBA) are all designed to improve operator safety.

The 800 Vario series also offers a variety of options for track width and tyres along with the option of Fendt’s on-board air VarioGrip system.

The Fendt 800 Vario Gen5 can be ordered from autumn 2025.

Shares his experience of working at both dealer and manufacturer level, and how he foresees that dealerships will need to adapt to the advancements in technology.

Firstly, please introduce yourself.

I am Craig Hoare, the Sales and Marketing Manager for Toro in the UK & Ireland. I started here in 2019 and look after our sales team - both field and office based - as well as overseeing the marketing for both the Toro and Hayter brands within the UK.

I have been in the sector since 2000, making 2025 a quarter of century in the garden machinery and groundcare industry.

How did you get into your current role? What’s your background?

When I was just looking for a steady job at the tender age of 21, I started off working in a dealership (Garden Machines Northampton) with no previous experience or connection to lawnmowers. I worked my way through the business over the next 17 years experiencing the various aspects of the dealership before finishing as General Manager.

Working in a dealership gave me great foundations and knowledge which I still utilise today. I pride myself on having a strong understanding of how the various areas of a dealership function including sales, service and parts, as well as working to build the ecommerce side of that dealership starting in the mid-2000’s, so saw the changes as the market moved to embrace the internet.

I then moved to EP Barrus where I was Divisional Manager for the Lawn and Garden division, where I was responsible for the sales team, as well as the product range, visiting suppliers and factories in Europe and China, before moving to my current role at Toro.

Having worked in both a dealership and manufacturer environment, what are the major similarities and differences between the two?

The big difference I noticed when moving from a dealership to a manufacturer is that your view of the industry changes. You are more aware of national and global factors affecting the industry than you are as a dealer.

This was most apparent in recent years, post COVID-19, as we saw interruptions to global shipping and massive cost increases in raw material costs. As a dealer you are much more removed from these challenges, but will see the impact longer-term in product

availability and cost increases. What are the major changes you’ve witnessed in the industry over the years, and how are Toro UK adapting their offering to suit changing and future demands?

The biggest change I have seen in my time is the advancement of technology. This is driven by customer demand, stemming from the benefits that these technologies offer.

The workshop will not be as central to the dealership as it has been at the height of combustion engines, and dealers will need to ensure that they are adapting their dealerships to ensure that they are knowledgeable and trained to support these new technologies.

We at Toro are investing heavily to ensure that we can offer the features and labour saving solutions that our customers demand, especially as more and more businesses including ourselves focus on sustainability.

Toro UK pursue a dealer route to market –why? What are the main benefits of this?

We have been dealing with the UK dealer channel for 80 years, and dealers are best placed to support our machinery and customer’s needs, especially in the

commercial sector.

Commercial users have high demands and downtime is costly, so a knowledgeable and skilled dealer who is able to react quickly is essential. With all of the new technologies coming into our product portfolio, our dealers are best placed to help educate our customers and are our best brand champions in the market.

Lastly, what’s the significance of associations such as BAGMA in supporting you and others in the sector?

Small business owners must master so many different disciplines to run a successful business, ranging from HR to marketing, something I have experienced first-hand. Being a member of an organisation like BAGMA, means you have access to expert advice and knowledge as well as someone who can help facilitate the sharing of knowledge with industry peers.

For manufacturers, we have organisations like the AEA to support us in lobbying government on behalf of our industry and to help promote the virtues and opportunities of our industry to the next generation through campaigns such as “We Are Land-based Engineering”.

Ibcos is excited to present Gold Cloud, a modern, cloud-based solution designed for agricultural, ground care, and construction machinery dealerships. Gold Cloud offers a secure, scalable alternative to traditional, on-premise IT systems, helping you reduce costs and streamline operations.

Simplify Your Infrastructure: With Gold Cloud, there’s no need for on-site servers or costly hardware upgrades. Your dealership benefits from automatic system updates, daily backups, and reliable performance – all managed by our expert support team.

Operate More Efficiently: Free your team from the burden of IT maintenance. Gold Cloud gives you flexible, scalable resources that grow with your business – no significant upfront investments are required – letting you focus more on sales, service, and customer relationships.

Flexible, Predictable

Gold Cloud is available through a subscription-based model, allowing you to spread costs over three years. This makes budgeting easier and avoids surprise expenses, while keeping your systems modern and secure.

For more information on Gold Cloud contact the lbcos team via:

sales@ibcos.co.uk +44 (0) 1202 714200

www.ibcos.co.uk

BAGMA Bank (Birmingham Bank) 03330 048048

Debt Collection (Corbital Trace & Collect) 01905 935003

Card Processing (Global Payments) 0345 7023344

BAGMA Training 01295 713344

Insurance (Towergate) 0333 207 6681

Personal & vehicle finance (Novuna) 07802 871488

Culverdocs (Paperless Solutions) 01793 200664

Health & Safety (SafetyAide) 07903 655506

Marketing (SiteWizard) 01622 200045

Telecoms & Utilities (Utility Options) 0800 195 0123

Waste Management (Valpak) 01789 208778

Recruitment (GBR Recruitment Ltd) 07425 896410

Security (Fog Bandit) 0333 188 9966

Legal Helpline (Maples Solicitors LLP Commercial Law advice) 01775 722261

Legal Helpline (WorkNest HR advice) 01244 667249

Find out more details at: bagma.com/benefits