52 | JULY-AUGUST 2025

52 | JULY-AUGUST 2025

BAGMA recently had the pleasure of visiting family-run garden machinery dealers Stuart J Daws & Co Ltd, to discuss the challenges of a single depot operation and the successes to be had by focusing on the face-to-face customer experience.

Members Forum | Thorough Examination Training | Out & About THE MEMBERSHIP MAGAZINE OF THE BRITISH AGRICULTURAL AND GARDEN MACHINERY ASSOCIATION

Dear Industry Members,

It’s been a busy couple of months for the BAGMA team, with county shows and other events coming thick and fast.

The Royal Highland Show was, once again, very well attended and it was great to see so many of our members in attendance. It was also a pleasure to be supported by a number of our Service Providers on the stand which helps to showcase just a small selection of the services BAGMA can provide.

Alongside shows, you’ll also be able to read more about our recent visits to some of the country’s leading agricultural colleges on page 5. I am incredibly passionate about reaching out to the future generations through our schools and colleges and pledge to continue forging strong relations with the educational organisations for the remaining two years in my role as BAGMA President.

at Hartpury College in Gloucestershire. With some fantastic speakers, the day was very well received and it was great to explore some of the wonderful facilities available to the students. If you missed out, the next Connect meeting will be hosted at the New Holland facility in Basildon on Thursday 9th October.

For BAGMA and the wider industry to thrive, we must all be looking to the future. Time moves quickly and we must move with it and prepare our members as best we can to cope with the challenges ahead.

by Peter Heming BAGMA President

I’m pleased to say we already have more dates in the diary but if you have an idea of somewhere that would welcome a visit, please let us know.

On the theme of colleges, we also recently hosted the latest BAGMA Connect meeting

Agricultural & Garden Machinery Association

Peter Heming BAGMA President peter@heming-engineering.co.uk 07831 585476

Nick Darking BAGMA General Manager 07512 327109

Richard Jenkins

BAGMA Business Development Manager 07432 290605

Kari Hearn BAGMA Training and Administration Manager 07874 876999

This was discussed at length in a very positive joint meeting we had with our parent company, The AEA. With the two associations working together to represent manufacturers and dealers, we can present a united front.

As I enter my third year as President, I would like to reach out to all members, build more links and offer events in more far-reaching locations. BAGMA are your listening ear and voice, please get in touch if we can support you.

I look forward to seeing lots of you at events across the summer. Good luck and best wishes to all.

Hannah Desborough BAGMA Administrator 07842 431468

For all advertising and media enquiries please email: admin@bagma.com

BAGMA Samuelson House 62 Forder Way Hampton Peterborough PE7 8JB 01295 713344

Editorial & Production Pan Publicity Ltd 01493 440047

bagma@panpublicity.co.uk www.panpublicity.co.uk

2

5

BAGMA News

Two new members join BAGMA. BAGMA launches new Members Forum. AEA Milestone marked.

BAGMA Goes Back to School!

President Peter Heming and General Manager Nick Darking have recently toured a number of the UK’s leading landbased colleges.

6

Geoff Wall outlines the importance of Thorough Examination Training.

8

Expert’s View

Guide to Fair and Unfair Dismissals from WorkNest and Culverdocs explains the Importance of Effective Stock Management.

Member Profile

BAGMA learns the value of face to face service with Lincoln Daws of Stuart J Daws & Co. Ltd.

14

Out & About

Lawn Mower Racing Roars into GroundsFest 2025. BAGMA’s Richard Jenkins reports on Royal Highland Show 2025. BAGMA Golf Day & Dinner 2025.

16

Protecting Machinery with SelectaDNA. Manufacturers announce a number of dealer network updates. Student Greenkeeper of the Year finalists announced.

20

Connecting With Martin Hamer, Director & Sales for the Fendt business in North West Europe.

Hamilton Ross Group are pleased to announce the appointment of Paul Johnstone as Groundcare Area Sales Manager for Perth and Fife –based at their Perth and Cupar depots. He can be contacted on 07977 499283 or via email on paulj@hamiltonbros.co.uk

BAGMA is delighted that its membership continues to grow – with Farm Tech Supplies Ltd and Reesink UK the latest in a long list of companies to sign up and add further depth and strength to our combined industry voice.

Farm Tech Supplies Ltd was founded in 2011 when the founder identified a gap in the market for smallholding maintenance equipment without the premium agricultural price tag. Having

Echoing these sentiments are fellow new members Reesink UK. With a portfolio of leading brands and products, including the sole Toro distribution in the UK for golf and sports fields equipment and irrigation products, Reesink UK operates on the core principles of innovation, quality, value and range. Through four divisions, they deliver a comprehensive selection of products, together with practical solutions and extensive expertise to professionals in turfcare, groundscare and fleet management across the UK and Ireland.

“There are many benefits to being a member of the British Agricultural and Garden Machinery Association, but the main reason we choose to support it is because of how closely our values align when it comes to supporting dealers” comments Alastair Rowell, Managing Director of Reesink UK.

UK AGRICULTURAL TRACTOR REGISTRATIONS - JUNE 2025

Month: 852 Units -2.0% change (compared with June 2024)

Year to Date: 4,869 Units -17.2% change (compared with January-June 2024)

BAGMA were pleased to attend the inaugural conference on Integrated Weed Management for the Amenity Sector hosted by Kersten (UK) Ltd on Thursday 5th June at Birmingham’s Highbury Hall. Following the publishing of the National Biodiversity Strategy & Action Plan in February and the new Pesticides National Action Plan, the event focussed on integrated and alternative methods of weed control to reduce reliance on conventional chemical pesticides. The day included talks from DEFRA, Cambridge City Council and Parks for London, together with working demonstrations of a number of current tools and techniques in the amenity weed control arena.

found its niche, the company established the Winton brand in 2016, starting with top-selling mowers and extending the range over time.

More recently, the company has expanded, becoming William Hackett’s main paddock harrow stockist in 2022, and the exclusive UK importer of the Serbian brand FPM Agromehanika in 2023. The latter has allowed the company to provide customers with an extensive range of attachments for larger tractors.

On joining BAGMA, a spokesperson said, “Joining BAGMA reinforces our commitment to quality, professionalism and outstanding customer service. As part of this respected trade association, we gain access to valuable industry insights, training and compliance resources - allowing us to better support our customers and grow alongside other trusted names in UK agricultural machinery.

“Our dealers are instrumental to our business and in all the work BAGMA does, it has the dealer front and foremost. As an association BAGMA has always been dedicated to improving and providing support in areas such as staff and workplace training which is where our work together will lie. We very much look forward to pooling our resources for the betterment of the industry.

We’re always looking for ways to support the development of the turfcare industry in all areas and work with many associations as a result. BAGMA is a welcome addition to that, shining a light

This is another step forward in our mission to deliver reliable equipment backed by expert advice and aftercare.”

on all those working across the UK in the agricultural, garden and groundscare sectors. For years our branch teams have been providing our customers in these sectors with the machinery they need, and now BAGMA’s specific industry training for Reesink staff will ensure specialised service as well.”

In response to industry feedback, BAGMA are pleased to announce the launch of the Members Forum. Available within the dedicated members area of the BAGMA website, the forum is designed to offer a platform dedicated to open, respectful and constructive discussion with your fellow members.

Alongside a space for ‘General Discussion’, a number of topics have already been created to make the forum a user-friendly place to contribute and search for posts of relevance to your business. These include specialist

discussions on Health & Safety matters, Battery & Technology questions, Financials and any queries regarding BAGMA Benefits and Training.

To access the Members Forum, you will need to register for your access to the members area of the BAGMA website if you haven’t already done so. You will only need to register your details and be approved once. After this, you’ll be able to log in wherever and whenever you like and take full advantage of the exclusive content within from BAGMA and many of our Service Providers.

“We know that communication is key and introducing a Members Forum is another way to enhance knowledge sharing and support within the BAGMA community” comments General Manager Nick Darking. “The forum will of course come with guidelines of use and all contributions should align with the forums purpose - sharing knowledge, asking questions and supporting each other.”

To view or contribute to the new BAGMA Members Forum visit www.bagma.com

BAGMA’s Nick Darking along with other members of the BAGMA Council were delighted to attend a Parliamentary Reception at the Palace of Westminster back in May, as part of ongoing celebrations to mark the 150th anniversary of the Agricultural Engineers Association (AEA).

The event was hosted by Sam Carling the Labour MP for North West Cambridgeshire, and included thoughtprovoking talks from speakers including George Freeman MP and UK Trade and Investment Envoy, David Withers of ISEKI UK and Ruth Bailey, CEO of the AEA.

The BAGMA Council were delighted to engage with a number of industryleaders and parliamentarians at the event, honouring the AEA’s legacy and discussing the future of the landbased engineering sector. As a result, BAGMA have welcomed subsequent opportunities and invitations to meet with constituency members – some of

whom are already BAGMA members. The ongoing meeting and dialogue signifies the important role of BAGMA in supporting dealerships across the agricultural, groundcare and garden machinery sectors.

by Nick Darking

BAGMA General Manager

Having spent months ‘on pause’ while we waited for the weather to play ball, both the agricultural and groundcare sectors seem to have finally gathered some pace as the crops and grass grow once again.

As I sat down to watch the latest series of Clarksons Farm, I was reminded that the spring of 2025 compared to the spring of 2024 could not have been more different! Extremes of wet and dry are just one of the many challenges facing the farming community that Jeremy highlights with both humour and, at times, heart.

Love him or loathe him, the mass appeal of the series certainly does put a spotlight on the ever-increasing trials and tribulations of working in the agricultural sector, and the sheer resilience and grit required to operate a farm business.

It’ll come as no surprise that many of the issues documented in Clarksons Farm were discussed at length when The

AEA and BAGMA recently came together for a joint meeting. Representatives from the BAGMA Council were joined by members of The AEA Board to talk through industry matters and found a huge amount of overlap in the difficulties faced at both dealership and manufacturer level.

BAGMA came away with renewed vigour and the overwhelming support of manufacturers, many of whom rely on the depth and strength of a dealer network.

It therefore feels like the right time to remind members of the breadth of training and services available via BAGMA and our approved Service Providers. If your business needs support with finance, HR, legals, utilities, marketing and more then get in touch – preferential rates and exclusive offers are available to you. Our team are always available, so if there’s anything you need help with, please do get in touch.

Engaging the next generation of landbased engineers is widely recognised as critical to securing the future of the agricultural and groundcare sectors. In an attempt to address this, BAGMA President Peter Heming and General Manager Nick Darking have recently toured a number of the UK’s leading landbased colleges - introducing students to BAGMA and showcasing the vast and varied opportunities and career paths the industry has to offer.

Over recent weeks, the pair have visited Moreton Morrell in Warwickshire, East Durham College and Hartpury College in Gloucester with one key objective – to engage, educate and inspire.

Nick delivered an introduction to BAGMA, explaining the support the association provides to the employers of many of the students and reaffirmed that, as a sector, young, enthusiastic and skilled students are incredibly important. After collectively exploring routes through the industry, students were encouraged to share their individual experiences and aspirations –generating interesting discussion and feedback.

“BAGMA was largely an unknown entity to the students, but they quickly recognised the significance of associations like ourselves in providing pivotal support and services to our members –their employers – through the good times and bad” Nick explains. “It was great to see good numbers of students enrolled and each talk provided a good opportunity to highlight help and initiatives such as We Are Landbased Engineering – there to support them through the next steps in their careers.”

discussion. Apprentices gained a deeper understanding of the agricultural machinery industry landscape, the importance of professional development and the long-term career advantages that association with an organisation like BAGMA can provide.”

He added, “The session sparked significant interest and provided our apprentices with a fresh perspective on their career paths within the industry.”

Together with further landbased colleges, BAGMA are also looking for opportunities to engage with children at a younger age – coordinating a number of visits into schools, starting with Rodborough School where notable alumni include BAGMA’s own Nick Darking!

“Nick and Peter delivered a highly engaging presentation to the AGCO apprentices at Moreton Morrell College that went beyond a typical overview of BAGMA’s offerings” commented Lecturer Andy Southerton. “While they did touch upon the valuable training and courses available through BAGMA, along with the numerous member benefits, the true impact came from their broader

“We need to be highlighting how diverse the industry is now – with robotics, data and technologies adding ever-increasing appeal and prospects for the next generation” Nick adds.

If you think your local school or college would welcome BAGMA in for a career’s session, please get in touch via admin@bagma.com

by Geoff Wall Owner & Director of Powering Hub

It is of vital importance that operators and businesses understand their responsibilities when it comes to Thorough Examination. HSE make it very clear that machinery being used in a workplace needs to be safe for use and has to be inspected regularly.

HSE definition of the legal requirement

“Thorough Examination of workplace machinery is required under health and safety law: LOLER 1998, which covers lifting equipment, and PUWER 1998, which deals with all other safety-related items, such as brakes, steering and tyres. Your regular inspections as part of a preventive maintenance scheme or scheduled service are not a Thorough Examination.”

I suppose the first question we should ask is what is a Thorough Examination?

A full Thorough Examination consists of meeting the requirements of both LOLER 1998 and PUWER 1998. They outline what is required for the testing of workplace machinery. LOLER and PUWER are both constantly being updated with the requirements; below is an extract from Regulation 6 of PUWER and Regulation 9 of LOLER.

Regulation 6 Inspection – PUWER 1998

“This new regulation covers the extent and nature of inspection. It formalises the practice of systematic in-house checks on work equipment that already exists in many organisations. The regulation focuses on:

n The different situations where inspection of work equipment is required.

n The purpose of the inspection in each case.

n Who carries out the inspections.

n Keeping records of inspection.

n Work equipment not covered by regulation 6.”

Regulation 9 Thorough Examination and inspection – LOLER 1998

“Regulation 9 concerns the Thorough Examination of lifting equipment: the detailed and specialised examination by a competent person. The examination required by this regulation is similar to Thorough Examinations required by previous sector specific legislation such as the Factories Act 1961. The regulation is in seven parts. Parts 1–4 contain the main provisions for the Thorough Examination of lifting equipment:

n Before it is put into service for the first time.

n After installation or reassembly.

n During its exposure to conditions which cause deterioration.

n And of the requirement for evidence of the last such examination when the equipment is used outside the undertaking.

Parts 5–7 deal with exclusions and matters relating to previous regulations.”

LOLER in agriculture

In agriculture, the term covers a wide range of equipment including:

Tractor foreloaders, fork-lift trucks and telescopic handlers (telehandlers); Workshop hoists and rope hoists; Cranes on machines (e.g. on lorries or fertiliser spreaders); Lifting attachments and accessories.

Equipment for lifting people

People should only be raised on work equipment which is specifically designed for that purpose but can, in exceptional circumstances, be lifted by other machines provided that they have a purpose-made carrier, suitably constructed and attached – see HSE guidance PM28 - Non integrated platforms on lift trucks. Nobody should ever be lifted in a telehandler bucket, in a potato box, on the forks of a fork lift truck or similar attachment, to carry out work or used as a means of access e.g. to get onto the roof of a building or bale stack.

Thorough Examination

Thorough Examination of lifting equipment is to protect both operators and people in the vicinity of lifting operations who may be at risk if the equipment suddenly failed. Lifting equipment used to lift loads will require a Thorough Examination by a competent person. This includes but is not limited to telehandlers, fork-lift trucks, MEWPs and fore-loaders.

Competent persons

Where lifting equipment requires a Thorough Examination, you will need to arrange for this to be carried out by a competent person. This will normally be an independent person, such as an engineer, who has the necessary knowledge, experience and training of the lifting equipment concerned to enable them to detect any defects. Who is responsible for work equipment? It is the responsibility of the employer to make sure workplace machinery is safe and that all rules are being abided by including those of your employees.

Some important points to consider as an employer are:

n Those hiring out equipment for use at work are considered as suppliers under section 6 of the Health and Safety at Work Act and so have broad responsibilities for the safety of the products they hire out. This includes (so far as reasonably practicable) prehire testing and inspection to ensure continued safety, and the provision of information.

n Those hiring out work equipment also have responsibilities under PUWER and if lifting equipment LOLER,

in so far as they exercise control over that equipment (for example, ensuring the Thorough Examination of lifting equipment and other routine inspections have taken place at the required intervals).

n It may be appropriate for the user to organise the periodic Thorough Examinations (which should be by written agreement, particularly for long-term hire). However, unless part of the hire agreement, those hiring out work equipment can’t normally be responsible for the day-to-day and other pre-use safety checks which

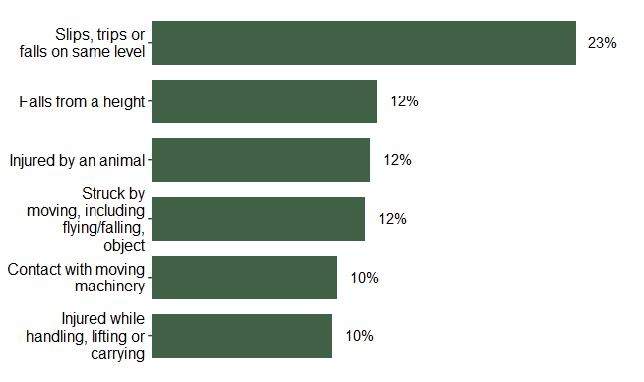

Fatal injuries

Non-fatal injuries

should be undertaken by the user.

n The implications of not following LOLER and PUWER regulations could result in HSE audits, large fines, prosecution, accidents or even fatal injuries.

Below are some HSE statistics, which you could say could have been reduced or stopped if the rules were being followed and all involved had been safe.

To book BAGMA’s Thorough Examination Training please get in touch with Kari Hearn via info@bagma.com or 07874 876999

by Gerard O’Hare Legal and Partnerships Director, WorkNest

Adding to this complexity, the landscape of employment law is changing. In October 2024, the Labour Government published the Employment Rights Bill, which will see significant changes to many areas of employment law, including in relation to fair dismissal. The most significant change is that protection from unfair dismissal will become a ‘day one’ right – in other words, employees will no longer require two years’ service to bring a claim. However, it seems highly likely that there will be some caveats to this, including where an employee is in their probationary period.

While the details of these changes are still being finalised, they’re expected to come into force by 2026. For employers, this will mean more employees having the right to claim unfair dismissal, increasing the importance of fair, welldocumented processes across all aspects of employee management.

If you need to part ways with an employee due to conduct issues, capability concerns (including medical capability), redundancy, or ‘something else’ that doesn’t quite fit into these categories, it’s essential to understand what a fair dismissal process looks like, what might constitute unfair dismissal, and what dismissals are considered automatically unfair.

Download

When it comes to dismissing an employee who has more than two years’ service, the stakes are high. A single misstep could be the difference between successfully defending your actions and losing an Employment Tribunal claim. With the average award for unfair dismissal now sitting at £13,749, it’s a risk no employer can afford to take.

What is a fair dismissal?

The key points to a fair dismissal are:

1. Having a valid reason to dismiss

2. Acting reasonably in the circumstances

In relation to the first criteria, the Employment Rights Act 1996 lists five potentially fair reasons for dismissal. These are conduct, capability, redundancy, statutory restriction, or some other substantial reason. From a legal standpoint, however, it’s not enough that the employer has a valid reason to dismiss; you must also be able to demonstrate that you acted reasonably in the circumstances.

While there is no legal definition of ‘reasonableness’, in determining whether a dismissal was fair, an Employment Tribunal will consider a number of factors. It’s important to note that even if the employer follows a fair dismissal procedure, the employee may have certain protected characteristics that still render the dismissal unfair. Employers should be fully aware of their duty to make reasonable adjustments where applicable. A failure to properly manage a case involving an employee with a relevant protected characteristic may not only result in an unfair dismissal claim, but could also give rise to other claims such as discrimination.

A dismissal will be considered unfair if:

n The reason for dismissal does not fall under the scope of one of the five potentially fair reasons for dismissal outlined previously;

n The employer did not follow a fair dismissal process;

n The employer failed to treat its staff in a consistent way; and/or

n The decision to dismiss was outside the range of reasonable responses open to the employer.

In some cases, dismissal will be automatically unfair. More information on what classifies as automatically unfair can be found in our free Guide to Fair and Unfair Dismissals, which can be downloaded using the QR code. Employment law is complex and can be difficult to manage, so this is just a reminder that WorkNest is here to help BAGMA members with any employmentrelated issues.

Whether you have a specific query or need ongoing support, we’re just a phone call or email away. Call 01244 667249 or email bagmahr@worknest.com for Employment Law and HR advice and bagmahs@worknest.com for Health & Safety support.

Effective stock management is essential for dealerships supplying machinery, parts and equipment. Many businesses rely on a Dealership Management System (DMS) to track stock, but without clear processes in place, inventory can quickly become inaccurate. Ensuring updates are made immediately when purchases, hire/loan equipment movements or sales occur is key to maintaining an efficient system.

Without a structured approach, stock can become difficult to track across multiple depots, leading to administrative burdens and operational delays. Unfulfilled or misplaced stock allocations can disrupt cash flow, while employees waste valuable time searching for stock that recently moved but was not properly recorded. These inefficiencies impact customer service, delay repairs and can result in lost sales and/or also impact financial and insurance audits where discrepancies occur.

To maximise efficiency and accuracy, dealerships should ensure their DMS and employees are continuously updated when

stock movements occur. Best practices include:

n Ensuring stock movements are recorded in real-time

n Having spreadsheets or shared logs for smaller parts

n Utilising QR code tracking for improved accuracy

n Conducting regular stock audits

n Having defined processes for stock transfers e.g between depots

Your DMS is a powerful tool, but its usefulness depends on the information entered. That is why it is critical to ensure employees understand the importance of timely and accurate updates. A good starting point to ensure this happens is to make the DMS as user-friendly as possible. Culverdocs can enhance your stock management by providing mobile access to business data, ensuring real-time updates from the field, allowing teams to:

n Look up stock, order status and allocations.

n Submit update requests directly from the field.

by

Jeremy Janisch Director, Culverdocs

n Capture real-time machine status with the location, photos, damage and run hours.

n Set reminders for back-office staff to maintain system accuracy.

If you’re looking to improve stock management, get in touch on info@bagma.com to find out how Culverdocs can streamline your business administration and help your dealership enhance visibility, reduce errors and maintain better stock control.

Established in 1971, Stuart J Daws & Co. Ltd supply a range of forest and garden machinery from their facility in Canterbury, Kent. BAGMA recently stopped by for a chat with Lincoln Daws - the second generation of the founding family to take the helm. He discusses how the product range and customer requirements have developed over the last 50 years, but how the desire for face-to-face customer service has never changed.

Thank you for having us. Firstly, give us a brief history of the company and explain how you, personally, became involved.

Our company was started by my father Stuart J Daws in 1971, operating from a small Nissen hut. Not the most luxurious accommodation I admit but it was cheap! We didn’t sell ride-on’s and garden equipment at that time so, although the hut was small, it was ample for selling chainsaws which were the ‘new thing’ on the market.

By 1977, the company had outgrown ‘the hut’ and began work on a custommade premises near some woodland in Challock which we moved into in 1978. We continued to grow steadily until the

storm of 1987 when most of the trees in our area were felled overnight! Although our sales of chainsaws went through the roof that year, it was soon clear that demand for that type of equipment wouldn’t return for a while so we shifted our emphasis towards garden machinery.

We moved premises a number of times over the following years as we sought to find somewhere with more space to accommodate a showroom, workshop and stores. We’ve been in this current purpose-built showroom since 2005.

I, myself, have not always worked for the firm. It was my parents wish that my brother and I should have experience of work outside of the company, so I chose to work for a bank. It did me good and

during this time I learned a great deal about computers which I have been able to put to good use when I returned to the company years later.

With you, the second generation, at the helm the company remains proudly family-run. Is this a business model you hope will continue into the future?

We currently employ 11 members of staff, many of which are family members. There are many advantages to employing family members and we are pleased to now be seeing a third generation family member working with us.

Growing the business is something that we believe there is opportunity to do in the future, be that with family members or not. We will continue to change and

adapt to the needs and events of the future.

As a single depot operation, what changes have you had to make to your location or processes to accommodate business growth?

Many! When we moved in in 1978, we thought we had space to spare for some time but the following year we had to add a wooden building to increase our storage space. This not only gave us extra space but also allowed us to section a part off for training local authority personnel in the use and maintenance of chainsaws.

Shortly afterwards in 1980 we added a further wooden building which was later joined to the old building when we began to move into housing garden machinery.

We then looked again for more suitable premises and, after a long search, found an old restaurant that had some land and good roadside frontage. After modifying the buildings as best we could we opened this showroom in 1993. We then saved hard over the next five years to build a new workshop and store area. This allowed us to move entirely from our old site in Challock in January 2000.

Five years later we began work on replacing the old showrooms. We couldn’t afford to shut the operation down while it was being built so decided to build around the old showrooms and then take them down afterwards. We’ve been here since 2005 and have purchased additional land that came up to erect two further buildings. Seemingly, we are always adding to or updating our premises!

How has your product range changed over the years? Which brands would you say have been key to your success?

We deal primarily with domestic customers from all walks of life so have cheap, mid and premium versions of most products. I don’t like to offer more than three choices of any product as customers tend to find the choice too overwhelming! Makes are grouped together in the showroom, as well as colours. I find that it encourages customers to walk around to see what each manufacturer has to offer.

In terms of brands, we started with Husqvarna, Solo, Sachs Dolmar and McCulloch chainsaws. Over the years we went on to add garden machinery from Husqvarna, Spear & Jackson, Dennis, Wolf, Al-Ko, Stihl and many more. I’d like to think we have adapted to the various trends in terms of popular manufacturers to ensure we offer our customers the best machinery in the industry.

Are you seeing a shift towards more sustainable solutions to forest and garden machinery, if so, how do you cater for this?

Everyone has a different definition of what constitutes as sustainable. In my view, it is difficult to consider battery powered equipment as sustainable if you

are throwing away serviceable equipment, or having to dispose of batteries every few years!

In our experience, customers have to return battery powered items for repair much more frequently compared to petrol powered equipment, contributing to more down time and extra journeys. Batteries do not last well in this industry and trying to dispose of the spent batteries is difficult. The warranty and backup from manufacturers is also poor.

You choose not to trade online, instead focusing on face-to-face business. Why is that and how is this received by your customers?

We did initially start to sell online in the very early days but quickly decided that the costs involved outweighed the amount of profit that we were happy making. There are still a lot of loyal customers out there that don’t want to buy products in a box, get them delivered and hope they work.

Our customers can be assured that

“I don’t like to offer more than three choices of any product as customers tend to find the choice too overwhelming!”

“Many customers genuinely enjoy the experience of talking with someone who has experience and can offer advice on getting the best tools for their requirements.”

they will get something assembled and working when they get it from us. Many customers genuinely enjoy the experience of talking with someone who has experience and can offer advice on getting the best tools for their requirements. How did this approach help or hinder your business through the COVID period? And what did you learn about the company in this time?

We adapted in a matter of days to operate a pre-purchase and collection system by phone or email and our sales during COVID were very good. At times we struggled with obtaining stock like a lot of dealerships but overall, it worked well for us and our customers.

I think the big thing we took away from the experience was that with a bit of thinking on your feet and by making a few changes you can make good out of a bad situation.

You pride yourselves on a strong aftersales and parts business. How do you ensure this keeps pace with changing customer requirements and trends?

We just try to keep improving and looking for ways to be more efficient in the way we do things. To ensure we can cater to customers quickly and effectively, we keep a good stock of popular items which help to make the workshop element of the business more profitable.

The company has a long history in robotics. What opportunities and demand do you see with this?

Our history with robotics dates back to 1995, starting with the Husqvarna Solar mower. In fact, we had the very first machine supplied to a dealer in the UK! Over the subsequent 30 years we’ve

installed quite a few robots as you might imagine.

We currently sell several makes of robot, the newest ones featuring wireless GPS which seems to be satisfying customer demand for both technology and efficiency.

What other opportunities or challenges do you see on the horizon for Stuart J Daws & Co?

We don’t focus on anything specific but like to think that we can adapt to any new challenges or opportunities that come our way. Only time will tell what that might be!

Thank you for being loyal BAGMA members. Why do you consider this to be important and are there any benefits of your BAGMA membership you have found particularly useful?

We like being BAGMA members as it’s a good way for us to keep up to date with what’s going on.

There are many services that BAGMA offer that are useful to us, particularly Safety Aide who we have used to help us with Health and Safety assessments over the last few years. They have always been very helpful, pointing us in the right direction of what we need to do.

www.stuartjdaws.com

GroundsFest 2025 is revving things up with one of its boldest and most exhilarating attractions yet — Lawn mower racing and the inaugural GroundsFest Cup.

Taking place across both days of the event, this professionally run spectacle promises edge-of-your-seat action, heart-pounding excitement and a whole lot of fun.

This is no gentle ride around the garden. These are specially modified racing mowers, stripped of their blades but supercharged with adrenaline, skill and competitive spirit. Expect high speeds, roaring engines, tight turns and a field of elite riders battling it out on a custom-

built track in front of a live crowd.

Organised by the West Midlands Lawn Mower Racing Association, some of the UK’s most experienced lawn mower racers will be competing for glory and the honour of becoming the first ever winner of The GroundsFest Cup. It’s fast. It’s furious. It’s fiercely competitive – but above all, it’s seriously good fun!

And there’s more to it than just the thrill of the race. GroundsFest visitors will get to see a range of lawn mower brands in action, used and pushed to their limits by the pros. It’s a unique chance to witness these machines in a whole new light — not just as tools of the trade, but as vehicles of pure entertainment.

Lawn mower racing is guaranteed to turn heads and create excitement at GroundsFest 2025. It’s just one more way GroundsFest continues to break the mould and deliver something truly different to any other trade event.

Think you’ve seen everything a grounds management event has to offer? Think again. This is lawn mower racing. This is GroundsFest.

Who will take the chequered flag? Join us on 9 and 10 September at Stoneleigh Park, Warwickshire, to find out.

Register for your FREE tickets at www.groundsfest.com

You can also follow GroundsFest on X, Facebook and Instagram @GroundsFest for much more news, reviews and insightful views.

The countdown is on for Scotland’s largest two-day agricultural event –which is set to take place on Sunday 3 to Monday 4 August 2025. Each year, Turriff attracts those from near and far to experience and exhibit the very best of northeast farming and its quality produce.

Balmaud Distillery, a new family-run business based in Turriff and launching in summer 2025, is the lead sponsor of the 2025 show, which brings together over 24,000 visitors looking to explore the very best of Scottish agriculture - from livestock classes and trade stands to sampling Scotland’s iconic food and drink. Crowds gather around the impressive main ring to enjoy a packed schedule of entertainment throughout the two-day event.

Turriff Show is well-regarded for showcasing some of the nation’s best livestock, equestrian, small animal, and

dog classes, awarding one of the largest monetary awards in the UK. In total 340 trophies are presented and over £88,000 is paid in prize money across more than 1,500 exhibitor classes. Animal classes include prime cattle, sheep, horses & ponies, rabbits, cavies, dogs and pigeons. Industrial and craft classes are for skills including baking, vegetable growing and flower arranging.

Exclusively in the main ring this year will be ‘The March of Time’, a captivating procession of agricultural machinery from across the ages - taking you on a fascinating journey in time as farm machinery of all vintages parade past the crowds.

The main entertainment line-up also promises a

thrilling experience. From the exhilarating Flyin’ Ryan stunt show to the return of the ever popular and hilariously entertaining Sheep Show, there’s something for everyone over the two days.

For more information, or to buy tickets, visit www.turriffshow.org

This year’s show, sold out on Saturday, welcomed over 212,000 visitors from across the UK and beyond. The BAGMA team enjoyed fantastic weather for most of the fourday event, with bustling bars and a lively atmosphere—until heavy showers cooled everyone off on Sunday.

It was a pleasure to connect with both long-standing and new members, including Mumby Machinery Ltd who signed up during the show – thank you Gary and Sue! We would also like to extend a special thank you to everyone who joined BAGMA on the opening day

for drinks and networking with fellow members and Service Providers including Ibcos, SafetyAide and Worknest who were present on the stand throughout the show.

We were particularly saddened by the absence of Pollock Farm Machinery, a valued BAGMA member, following their unexpected closure earlier this year. They had exhibited at the Royal Highland Show for over 50 years and were greatly missed.

Still the UK’s leading agricultural show, the Royal Highland Show is a memorable day out for all, with over 750 exhibitors including ourselves there is something for everyone in both farming and rural

The highly competitive BAGMA Golf Day & Dinner is set to return to Nailcote Hall on Wednesday 24th September 2025 with just a handful of spaces still available!

Now into its third year, the BAGMA Golf Day has become a firm fixture in the calendars of members and non-members alike, putting their putts to the test on two rounds of the deceptively-tricky 9-hole Nailcote course.

If you think you’ve got the skills to topple last years top-placing team from GKB Machines, grab your clubs and get involved! Tickets for the golf element of the event, together with the separate networking drinks and dinner in the evening are available by contacting admin@bagma.com

Thank you to our headline sponsors Iseki UK, along with the sponsors of the other holes; Airter UK, Campey Turfcare, GKB Machines, Global Payments, Heming Engineering, Ibcos, Kubota (UK), Novuna Business Finance, SafetyAide and Toro UK.

life. We’re already looking forward to next year’s event!

Early bird tickets for the 2026 Royal Highland Show (Thursday 18th June –Sunday 21st June) are already available via www.royalhighlandshow.org

In the face of rising rural crime and a significant increase in agricultural equipment theft, SelectaDNA is proud to offer an effective and proven solution for farmers and rural businesses. The advanced forensic marking technology enables owners to uniquely tag their machinery and tools, making them less appealing to thieves and easier to recover if stolen.

SelectaDNA works by applying a uniquely coded, synthetic DNA solution to any valuable items such as tractors, trailers and power tools. The solution is near-invisible to the naked eye but glows blue under UV light - thus allowing police to identify recovered items and link them to their rightful owners. The scheme is already being used successfully across the UK, but North Yorkshire and York are seeing particularly positive results.

Statistics

n SelectaDNA has marked & protected over 15 million items since 2005

n Their forensic marking solutions are trusted in over 37 countries around the world

n SelectaDNA brings over 30 years of expertise in crime reduction and prevention

SelectaDNA in Action

In a major initiative led by North Yorkshire Police, SelectaDNA marking kits are being distributed free of charge to local farmers as part of a broader strategy to combat rural crime. This comes in response to a 65% rise in trailer thefts in the region between 2022 and 2024.

Sgt David Lund of the Rural Task Force has praised the effectiveness of the scheme saying “property marking is an excellent way to deter criminals as it makes stolen goods easily identifiable and can help secure prosecutions. By tagging property with SelectaDNA, we can ensure that stolen items are tracked and returned to their owners, while also making it much harder for thieves to profit from their crimes.”

The unbeatable ISEKI SXG range of mowers enable cutting and collecting in the wet without clogging up, ideal for the homeowner requiring the next step up in garden maintenance machinery. For the homeowners who require a subcompact tractor the TXGS24 is the most versatile and powerful tractor on the market.

ISEKI compact tractors and mowers are designed and manufactured in Japan with over 100 years experience for quality that lasts.

Contact us and apply to be an ISEKI dealer today, visit www.iseki.co.uk or call 01473 599266.

The scheme is supported by the Safer Streets Fund, with kits delivered through local drop-in sessions and the Rural Watch network. These engagements provide an opportunity to distribute kits and register farm equipment, offer crime prevention advice and receive SelectaDNA warning signage, which is another powerful deterrent to potential thieves.

New figures released by North Yorkshire Police show that the cost of rural crime in North Yorkshire and York has dropped to £1,476,000 in 2024 - a significant fall from £1,910,000 in 2023.

SelectaDNA is committed to supporting the agricultural sector and encourage BAGMA members to consider incorporating SelectaDNA into your farm security strategy. It can mean the difference between recovery and loss.

Learn more about protecting your assets

Toro U.K. Limited is set to unveil a brand-new Dealer Hub at GroundsFest 2025, taking place 9th – 10th September at Stoneleigh Park.

Purpose-built for its dealer network, the hub will serve as a central meeting point for strategic updates, early product previews and meaningful conversations about the season ahead.

Positioned within Toro U.K.’s significantly expanded stand, featuring the full breadth of the Toro® and Hayter® ranges, the Dealer Hub underscores the company’s commitment to supporting its nationwide dealer base.

“GroundsFest is the ideal opportunity to reconnect with our dealers in person,” said Craig Hoare, Sales and Marketing Manager, Toro U.K. Limited. “This year, we’re putting our dealers front and centre. Offering

early access to new-season materials and a dedicated space to talk opportunities, challenges and everything in between. The Dealer Hub is our way of saying: we’re here, and we’re listening.”

Dealers visiting the hub will benefit from:

n Early-release product information and campaign previews.

n Exclusive co-branded sales materials and POS tools.

n Direct access to Toro and Hayter’s commercial and marketing teams.

n Light refreshments in a relaxed, business-friendly setting.

In addition to the Dealer Hub, visitors can explore Toro and Hayter’s latest innovations across the residential, landscape contractor and grounds care sectors, including walkbehind and zero-turn mowers, the latest Harrier® Pro and 60V Hayter models and Toro Revolution™ battery-powered tools.

GroundsFest is free to attend and combines live demonstrations with an industry-led exhibition, educational sessions and entertainment. Toro U.K.

Limited invites all dealer partners and professional users to visit the stand, discover the latest product developments, and see how Toro continues to support the turf care industry, every step of the way.

To register for GroundsFest, visit: www.groundsfest.com or to explore the full Toro and Hayter range, visit: www.toro.com/en-gb or www.hayter.co.uk

Merlo UK are pleased to confirm that longstanding partner RVW Pugh Ltd has been appointed to take over the South Lancashire territory with a new depot at Lathom.

An authorised Merlo dealer since 1997, RVW Pugh has developed a strong reputation for customer service, product expertise and a loyal following for Merlo telehandlers. Their knowledge of the range and commitment to aftersales support

makes them ideally placed to ensure continuity for existing Merlo customers in the area.

Operating from their head office in Churchstoke, Powys, and with depots at Holmes Chapel in Cheshire and Newport in Shropshire (TR Machinery), RVW Pugh will now expand their footprint by operating from the former Malpas Tractors site at Spa Lane, Lathom.

In addition, Carr’s Billington have also expanded their Merlo coverage and support to additional depots in Stranraer and Penrith. Building on a successful start and several high-profile sales, the expansion marks the next step in delivering premium telehandler solutions to more customers across the region.

Trilo have announced an expansion of territory for Lister Wilder and the appointment of George Browns Ltd. As two of the UK’s most experienced and respected groundcare machinery dealerships, this move brings greater strength and support to the central, east and southeast regions.

Lister Wilder has long been recognised for their experience in supplying a range of leading machinery franchises to golf courses, local authorities, contractors and more. In recognition of their performance with the Trilo brand to date, the partnership and dealership area has been extended to include Kent, Sussex, Berkshire and south London boroughs.

“It’s great to now be working with Trilo across all of our branches” commented Lister Wilder Sales & Hire Director Phill Hughes. “We have held a strong relationship with this leading manufacturer for many years and are delighted to be asked to support their growth throughout the South of England. The vacuums are really well received by our

customers and compliment the other highquality machinery franchises within Lister Wilder so we are excited to see what the future holds across the new areas.”

Bringing outstanding customer service and decades of industry knowledge to Buckinghamshire, Hertfordshire, Northamptonshire, Leicestershire, Oxfordshire, Essex and the east is George Browns Ltd. With immediate effect, the George Browns team are the port of call for the full range of Trilo debris loaders and vacuum trailers.

Tim Mason, Group Groundcare Sales Manager for George Browns Ltd added, “Having had previous experience selling Trilo - knowing how well they are built and how well they perform in the field - I am excited to add the Trilo range to our line-up of market leading brands.”

KUHN Farm Machinery has strengthened its dealer network in the north of England with the appointment of Clapham Agricultural Engineering Limited as a full product line dealership.

Clapham Agricultural is run by Ed and Debbie Clapham and the move reinforces KUHN’s presence in a key grassland and livestock region. From the dealership’s base at Ripponden, near Halifax, West Yorkshire, Ed said he’s excited to grow the KUHN brand across his area.

“KUHN machinery is well-respected and popular, and I think there’s great potential to get more machines onto farms. KUHN’s bedding and feeding lines, alongside its extensive grassland kit, should be of interest to users.”

Speaking of the appointment, Karl Ridsdale, KUHN’s Area Sales Manager for Northern England, said: “I’ve known Ed for several years and his dedication to providing a first-class service, with particular focus on aftersales, fits well with KUHN’s vision for its dealer network. The area Clapham Agricultural will cover is predominately livestock, so our product range will dovetail nicely with what farmers are requiring.”

Alongside Clapham Agricultural, Ed and Debbie run Harry Travis, a dairy engineering and supplies business from the same Ripponden site. Ed believes that many dairy producers will already be familiar with the service they receive from this business.

“Customers using our dairy business will know the service and proactive attitude we have. We take this ethos into our agricultural work and I’m confident that farmers will want to see how KUHN machines, sold and supported through our dealership, can help them. This partnership means we can now provide support from grass through to milk.”

The British & International Golf Greenkeepers Association (BIGGA) and co-founders and sponsors Toro and Reesink UK have revealed the line-up for the 2025 Toro Student Greenkeeper of the Year Awards.

Held at Rudding Park in Harrogate on 9-11 September, the finalists will compete in a series of challenges that are designed to test their technical knowledge and passion for the greenkeeping profession. Winners will then be crowned in the categories of Toro Student Greenkeeper of the Year and Toro Young Student Greenkeeper of the Year.

BIGGA Learning and Development Manager Deb Burnett said: “Our finalists are all excellent and they demonstrate the extraordinary talent that is present in today’s greenkeeping industry. The degree of knowledge they possess is testament to the quality of training they receive, both at work and with their training providers.”

David Timms, National Accounts Manager for Reesink Turfcare and Young Award judge, comments: “The overall knowledge

and professionalism of these young student greenkeepers is very high and deserves to be recognised and celebrated. It was clear to see in the interview process which candidates had conducted research into the competition and the sponsors of the

The Toro Student Greenkeeper of the Year finalists are:

Jamie Beattie, assistant greenkeeper at Royal Liverpool/student at Myerscough College

Ruth Etches, assistant greenkeeper at Trentham Golf Club/student at Myerscough College

Oliver Pate, deputy head greenkeeper at Worksop Golf Club/student at Askham Bryan College

Chris Szoradi, first assistant greenkeeper at Manchester Golf Club/student at Askham Bryan College

Brad Taylor, assistant greenkeeper at Beau Desert Golf Club/student at Myerscough College

awards, with the finalists all standing out in their respective categories. The whole process was great fun to be part of and we thank the guest judges for their support again.”

The Toro Young Student Greenkeeper of the Year finalists are:

Oliver Badger, apprentice greenkeeper at Parkstone Golf Club/student at Myerscough College

Andrew Semple, apprentice greenkeeper at Machrihanish Dunes Golf Club/student at SRUC Elmwood

Matthew Strutt Donnelly, apprentice greenkeeper at Stoneham Golf Club/ student at Berkshire College of Agriculture (Windsor Forest Campus)

400+

AGCO’s Martin Hamer discusses how humble beginnings on the family farm has shaped 30 years of experience with one of the world’s leading agricultural manufacturers.

Firstly, please introduce yourself.

I’m Martin and I am Director & Sales for the Fendt business in North West Europe. I’ve held this position since 2014 and have been with AGCO since 1996 so am now into my 30th year!

I manage a team of 4 National Sales Managers, 7 Area Sales Managers, 7 Product Experts, 1 Marketing Manager and 1 Advertising and Sales Promotion Manager.

During my AGCO career I’ve worked with different brands, in different departments and in different countries which makes my experience vast and varied.

Where did it all start for you? How have you seen the agricultural industry evolve over that time?

I am the son of a Dairy Farmer, but at a young age decided I did not want to milk cows for a career. I applied myself in school, particularly in Engineering – with my school offering a City and Guilds foundation in Engineering which I

loved. I continued then into Agricultural Engineering at Technical College.

My first job was as an apprentice engineer at the Banbury depot of Burgess. I then moved to a John Deere dealer –Bruce Hopkins Ltd and progressed further as an engineer/technician. My commute to Bruce Hopkins was around 7 miles and, on that journey in the late ‘80s, I would pass 14 different farms and most with John Deere tractors. The same journey would tell a very different story today.

In 1996 I started working for AGCO as a Massey Ferguson technical trainer before progressing into Engineering and then Sales. When I joined the sales department in the late ‘90s, the UK tractor industry was registering 24,000 machines annually – today it’s less than half and falling. However, the total horsepower sold is around the same.

In addition, when I worked for MF in Banner Lane, I was one of 3,500 employees producing 40,000 tractors a year. Now, it’s a housing estate…

Seeing such a decline in the numbers of people connected with the land and manufacturing is incredibly sad and a huge loss of value in exports for the country. Both types of work can be physical and challenging, but is more than offset by the satisfaction of seeing the results of your labour.

Over the years, I managed to ‘borrow’ the latest kit for ‘product familiarisation’ on the farm and still like to keep my hand in with the assistance of the occasional Fendt demonstrator. These days I have to seek extra help from our Product Experts to get the best of all the systems – the productivity and ease of operation are light years away from where we were in the ‘90’s!

Do you find that being ‘hands-on’ on the family farm helps or influences your role within AGCO?

Yes very much so. I often entertain groups of employees at the farmdemonstrating how our equipment is used, the challenges of being a farmer and how what they do at AGCO directly impacts farming businesses.

I’m also chairman of our local National Farmers Union branch. Networking with the farming community helps me identify trends and where we at AGCO might need

to tailor our products or offering to meet the requirements of the farming sector.

How are AGCO responding to these new and changing customer requirements?

AGCO have a ‘Farmer First’ strategy which may seem obvious, but everything we do is focussed on giving farmers – our customers – a great experience; be that the products we sell, the support we provide or the finance/parts/technology packages we can offer.

To achieve that, we work closely with our dealers and forge strong, sustainable partnerships to enable them to help our customers at every stage of the purchase process.

We are increasingly focused on our environmental footprint and have carbon accounting activities throughout our business to ensure we operate sustainably in both the financial and environmental sense. This is something our farmers also request to demonstrate to their customers.

Being first to market with an electric tractor is also something Fendt are very proud of. It’s quite a different concept and we’re really excited at the potential it has in the marketplace.

You’re also on the AEA Board of Directors. What is the importance of The AEA and associations like BAGMA in supporting the industry?

Even though AGCO is a global corporation, it’s hard for us to effectively lobby governments on legislation. Being part of the AEA provides all members with a voice that demands to be listened to in government. The AEA is proudly nonpolitical and has a highly credible technical team who are able to have non-biased, informed discussions with all government departments on how best to go forward in our industry. If changes are proposed, our members get time to understand the impact for their businesses before implementation.

BAGMA are very important too given that most manufacturers don’t sell directly and rely on a network of professional dealers to promote and support their products. The suite of services that BAGMA offers allows even the smallest dealers access to resources such as HR support that are important for them to run their business efficiently.

WorkNest work closely with organisations nationwide to provide high-quality, pragmatic, and professional advice and support. In fact, over 40,000 UK employers across 45 vertical sectors now seek WorkNests help on some of their most sensitive issues.

Through the BAGMA Legal free advisory service, you can speak to qualified experts about matters relating to:

l Employment Law & HR

l Health & Safety

l Tax, VAT and HMRC

Worknest are holding multiple regional events across the country on the topic of: Employment Rights

Bill Understanding employers legal obligations.

Scan below for more information on the regional events and WorkNest’s upcoming webinars

BAGMA Bank (Birmingham Bank) 03330 048048

Debt Collection (Corbital Trace & Collect) 01905 935003

Card Processing (Global Payments) 0345 7023344

BAGMA Training 01295 713344

Finance (Swiss Finance Corp.) 020 7412 0500

Insurance (Towergate) 0333 207 6681

Personal & vehicle finance (Novuna) 07802 871488

Culverdocs (Paperless Solutions) 01793 200664

Health & Safety (SafetyAide) 07903 655506

Marketing (SiteWizard) 01622 200045

Telecoms & Utilities (Utility Options) 0800 195 0123

Waste Management (Valpak) 01789 208778

Recruitment (GBR Recruitment Ltd) 07425 896410

Security (Fog Bandit) 0333 188 9966

Legal Helpline (Maples Solicitors LLP Commercial Law advice) 01775 722261

Legal Helpline (WorkNest HR advice) 01244 667249

Find out more at: bagma.com/benefits