Specialising in stainless steel and its applications

Photo credit: Greater Western Water.

TPM delivers STAINLESS STRENGTH AT GISBORNE

Delivering resilient water treatment with stainless steel

Stainless steel is fast becoming the material of choice across new and upgraded water infrastructure projects in Australia, valued for its durability, corrosion resistance, and long-term sustainability. This shift was on full display in the Gisborne Recycled Water Plant Upgrade in Victoria, where ASSDA Member and Accredited Fabricator, Total Piping & Mechanical (TPM), delivered expertise that strengthened best practice for stainless steel use in recycled water treatment facilities.

Installed in September 2024, the stainless steel pipework forms a key component of Greater Western Water’s wider upgrade of the Gisborne Recycled Water Plant. The overall project will increase treatment capacity and improve operational efficiency to support the growing Gisborne and New Gisborne communities. The upgrade featured new inlet works with advanced screening and grit removal, a biological nutrient removal (BNR) bioreactor, and the integration of a stateof-the-art four-membrane-tank system (MBR) to meet stringent environmental standards.

At the heart of this delivery was stainless steel. TPM fabricated and installed 12,500m (31.5 tonnes) of 316L stainless steel pipe alongside significant plate fabrication for various components. All pipe was supplied in schedule 10 mill finish and fully passivated by way of passivation bath upon completion, ensuring maximum corrosion resistance and performance in the demanding wastewater treatment environment.

stainless steel contributes to sustainability, being fully recyclable, energy-efficient and low maintenance

Stainless steel was the material of choice which was supplied by ASSDA Member Midway Metals for the Gisborne upgrade due to its exceptional corrosion resistance, durability, and hygiene properties. In wastewater environments, 316L stainless steel resists pitting corrosion, while its smooth surface limits biofilm formation, supporting stringent water quality standards. Its strength and versatility enabled TPM to fabricate complex piping systems, high-pressure components, and precision elements. Beyond technical performance, stainless steel contributes to sustainability, being fully recyclable, energy-efficient and low maintenance – ensuring the upgraded plant delivers long-term operational reliability and reduced lifecycle costs.

The use of stainless steel was not just about meeting today’s demands – it was about safeguarding the plant’s future

TPM’s scope included aeration pipework with fine bubble diffusers, installation of seven new blowers for membrane scouring, sludge handling equipment, advanced chemical dosing systems, a UV treatment system, and odour control units. Each element demanded precision fabrication, integration, and rigorous quality assurance to guarantee the reliability of the upgraded facility.

The project also highlighted TPM’s strength in project management. Its flange management methodology and stringent Quality Management System ensured the integrity of every connection and compliance with Australian standards and has led to TPM achieving ISO 9001 Accreditation. A staged installation approach allowed work to progress without disrupting live plant operations, a critical achievement in maintaining compliance with discharge license requirements.

The use of stainless steel was not just about meeting today’s demands – it was about safeguarding the plant’s future. From energy-efficient aeration systems using stainless steel diffusers to robust mechanical components designed for decades of service, TPM’s fabrication expertise has provided Greater Western

Water and the community with infrastructure that is both sustainable and resilient. These upgrades have also improved energy efficiency across the plant, reducing operational costs and supporting long-term environmental sustainability, while maintaining high water quality standards.

For its outstanding contribution, TPM was recognised for this project with the 2024 Australian Industry Stainless Steel Fabricator Award in the Process Industries category, affirming its leadership in stainless steel fabrication for critical infrastructure.

The Gisborne Recycled Water Plant Upgrade demonstrates how stainless steel is shaping the future of Australia’s water sector. With projects like this, stainless steel continues to prove its worth as the backbone of sustainable and resilient infrastructure – delivering durability, environmental performance, and long-term value for communities nationwide.

STAINLESS STEEL AT THE CORE OF AUSTRALIA’S FIRST

large-scale mRNA facility

Australia is now home to the Southern Hemisphere’s only large-scale mRNA vaccine manufacturing facility, a landmark achievement in global health security and sovereign capability. Located within the Monash Technology Precinct in Clayton South, Melbourne, Moderna’s new facility will produce vaccines annually for respiratory diseases. It will also provide Australia with the rapid-response capacity to deliver pandemic vaccines if needed.

Stainless steel plays a critical role in the facility, providing the purity, durability, and cleanability required for pharmaceutical production. It ensures system integrity for high-purity services such as water for injection, clean steam, compressed gases, and process waste, where contamination is not an option. Its corrosion resistance, ability to withstand rigorous sterilisation, and compatibility with stringent Good Manufacturing Practice (GMP) requirements make it an ideal material for this high-stakes application.

Pure Piping’s role in delivering excellence

ASSDA Member Pure Piping was engaged to deliver the process scope, covering mechanical pipework, electrical design, procurement, installation, pressure testing, passivation, quality assurance, and commissioning. Their scope included over 4,750 metres of stainless steel tube, 2,650 fittings, 980 valves, 150 instruments, and multiple equipment items – all fabricated and installed to the highest pharmaceutical standards.

The facility included 316L stainless steel tube and fittings in both SF1 (mechanically polished, with a maximum Ra of 0.51 µm) and SF4 finishes (mechanically polished and then electropolished, with a maximum Ra of 0.38 µm), in accordance with the surface finish designations of the ASME BPE standard. Pure Piping also designed and fabricated custom stainless steel

infrastructure including a 13,000 litre aqueous waste tank and stainless waste collection systems, in addition to installing 28 bespoke stainless steel ceiling service panels within clean rooms, designed to deliver gases, data, and power to laboratory workspaces.

Pure Piping’s use of orbital welding technology, Trimble digital set-out tools, borescope inspections, purge monitors, and passivation skids underscored its commitment to precision, safety, and efficiency. Welding was performed to rigorous inspection regimes, including golden weld procedures (referring to welds that cannot be visually inspected internally), to ensure the highest levels of craftmanship and compliance with both Australian and international standards.

Precision in stainless steel

Pure Piping’s delivery on this project was defined by technical excellence and quality control:

• Welding quality and traceability

– Over 3,000 welds completed

– Full weld traceability and mapping, with unique welder IDs and extensive inspection records

– Orbital and hand welding procedures developed to AS 3992 Pressure equipment – Welding and brazing qualification and ASME BPE standards

– Internal Argon purge gas monitoring and borescope inspections for high-purity welds, with additional testing on golden welds

– Employment of an in-house certified welding inspector to maintain stringent quality standards

• Mechanical design services

– Development and management of piping and instrumentation diagrams (P&ID) libraries and edits

– 3D model conversion, clash coordination, and updates

– Detailed isometric and fabrication drawings

– Equipment, valve, and instrument registers for procurement accuracy

• Electrical design services

– Full review process of P&IDs for electrical integration

– 3D source model for process electrical, with clash coordination

– Automation architecture, HMI coordination, panel design, and E&I scope

• Stainless steel process services installed

– Water for injection (WFI), purified water, reverse osmosis water

– Compressed/process air, clean steam, CIP supply/return

– Nitrogen and carbon dioxide systems with automated controls

– Process waste, glycol supply/return, temperature control units

– Process vent/exhaust systems, environmental management system, and control panels

ASSDA Members Atlas Steels, Midway Metals, Prochem Pipeline Products, and Stirlings Performance Steels supplied a range of stainless steel materials for the project, while MME Surface Finishing provided electropolishing services.

The technical foundation underpinned the facility’s compliance with the Therapeutic Goods Administration (TGA) requirements and global GMP standards, ensuring quality, safety, and long-term reliability.

Award-winning stainless steel fabrication

The stainless steel expertise demonstrated on this project was recognised nationally, with Pure Piping named the 2024 winner of ASSDA’s Australian Industry Stainless Steel Fabricator Award in the Food, Beverage and Pharmaceutical category for its work on Moderna’s facility. This award highlights its leadership in stainless steel fabrication and installation for highly regulated industries where quality and reliability are paramount.

Pure Piping’s extensive experience in pharmaceutical manufacturing positioned them as the right partner for this pioneering project. Its ability to align Australian and American standards, while innovating improvements such as switching compressed air systems from copper to stainless steel for enhanced cleanliness, exemplifies the value of stainless steel in advancing health technology.

The opening of Moderna’s facility in 2024 marks a milestone not only in Australia’s biomedical capability but also in showcasing the indispensable role of stainless steel in safeguarding public health. Stainless steel fabrication continues to deliver the highest standards of purity, quality, and innovation required for life-saving pharmaceutical production.

ASSDA MEMBER CONTACTS

Pure Piping \ Andrew Owen, Director \ andrew@purepiping.com.au \ 0438 090 838 \ www.purepiping.com.au

Atlas Steels \ William Soonalole, Account Manager – Melbourne SC \ william.soonalole@atlassteels.com.au \ 0418 368 871 \ www.atlassteels.com.au

Midway Metals \ Mark Armitage, Business Development Manager \ marka@midwaymetals.com.au \ 0429 210 658 \ Nick Scanlon, Branch Manager – Melbourne \ nicks@midwaymetals.com.au \ 0403 059 628 \ www.midwaymetals.com.au

MME Surface Finishing \ Gerard Mulcahy, Managing Director \ gerardmulcahy@mme.com.au \ 0458 999 938 \ www.mme.com.au

Prochem Pipeline Products \ Aruna Walgama, State Manager VIC/TAS \ awalgama@prochem.com.au \ 0416 810 799 \ www.prochem.com.au

Stirlings Performance Steels \ Mark Hammill, Territory Manager – Victoria \ markh@stirlings.com.au \ 03 8783 8888 \ www.stirlings.com.au

FROM 30 TONNES OF CARBON STEEL TO 3 TONNES OF STAINLESS CABLE:

Redefining sustainable infrastructure

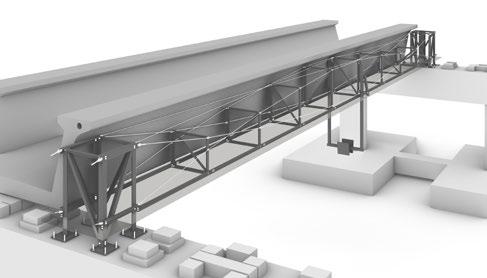

On 28 March 2024, the newly constructed Narre Warren Station officially opened on Melbourne’s Pakenham Line, removing a notorious and congested rail-road crossing and delivering a safer, modern public transport hub. Beyond the construction achievement, the project marks a milestone in material efficiency and sustainable design through the innovative use of stainless steel.

A materials breakthrough

The original ceiling design called for 30 tonnes of 800mm carbon steel deep beams – considerable welded elements that would have been heavy and disruptive to install. The beams were intended to support the ceiling spanning between the tracks above the concourse. Instead, Built Environs turned to ASSDA Member Ronstan Tensile Architecture to investigate whether a lighter, more efficient solution was possible. The result was a structural first for metro infrastructure –a pair of stainless steel cable bow string trusses in each of three bays, spanning 25 metres between bridge crossheads to support the ceiling system. With just 3 tonnes of precision-engineered Ronstan ACS2 8mm and 14mm diameter stainless steel cables, fittings, and bespoke galvanised elements, the design replaced the need for 30 tonnes of conventional structural steel.

Why stainless steel?

Central to the solution was grade 316 stainless steel, used for the bright drawn strand wire rope cables and machined fittings. The material was chosen for its high strength-to-weight ratio, longevity, corrosion resistance, and minimal maintenance requirements, critical attributes for a fully enclosed structure that is nearly impossible to access within a busy rail environment.

By reducing steel usage by 90%, the project dramatically lowered resource dependency and cut the carbon footprint associated with steel production, transport, and installation.

Stainless steel’s durability ensures the cable system will deliver decades of performance without costly or disruptive maintenance, further extending its sustainability benefits.

Efficiency through design

The lightweight nature of the stainless steel cable system delivered significant construction efficiencies. Unlike the original beam design, the modular truss system could be installed incrementally, without shutting down rail services. Its low self-weight also reduced handling complexity and avoided the need for oversized lifting equipment.

Ronstan’s philosophy of “applying the science up-front” played a principal role. The company invested heavily in design development, including load analysis, cable geometry modelling, proof and destructive testing, and a rigorous QA/QC process under ISO 9001 certification. This front-loaded engineering approach ensured that the on-site works were efficient, safe, and risk-minimised.

A sustainable model for the future

The Narre Warren project underscores a broader industry shift towards lightweight, resource-efficient structural systems. Cable-supported designs not only use fewer raw materials but also offer flexibility for future modification or deconstruction, aligning with circular economy principles.

As the first of its kind in this application, the stainless steel cable truss system has set a precedent for future stations in Melbourne and beyond. It demonstrates how intelligent material substitution – replacing conventional carbon steel with stainless steel –can achieve structural efficiency, lower embodied carbon, and extend asset life

Ronstan and the project’s success was recognised with the 2024 ASSDA Fabricator Project of the Year Award in the Architecture, Building, and Construction category. The station stands as proof that when design excellence meets stainless steel, the result is infrastructure built for generations.

Built in Stainless

Collaboration and the ASSDA Young Professionals Network drive a premium outcome

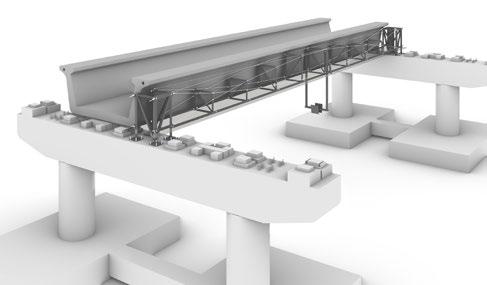

Sydney’s Alfred Street Pedestrian Bridge is a striking landmark for Parramatta, providing residents with a safe, all-abilities active transport link between the northern suburbs and the Parramatta CBD. The $19 million project, co-funded by the City of Parramatta and the NSW Government, forms a key element of the Parramatta River revitalisation program.

Bridges are the lifeblood of communities, designed to connect people, reduce transport costs and emissions, and encourage a healthier lifestyle. For the Alfred Street Bridge, design principles focused on accessibility, safety, elegance, and longevity.

The final result is ‘Alfie’ – Australia’s first diagonal arch pedestrian bridge – an architecturally elegant, technically complex structure that is both practical and sustainable.

From mild steel to stainless steel

When ASSDA Member and Accredited Fabricator Arcus Wire Group (AWG) was engaged by Abergeldie Complex Infrastructure to deliver Full Locked Coil (FLC) structural steel cables for the suspended walkway, the original design called for a mix of mild steel and stainless components. Grade 350 stanchions and grade 350 CHS frames were specified alongside grade 316 stainless steel handrails and mesh in-fill panels.

Following the initial pricing tender, AWG was invited to propose an alternative, more premium solution. Working with fellow ASSDA Member Bespoke Wire & Rope, and drawing on industry expertise, AWG saw an opportunity: convert the balustrade into an entirely stainless steel solution.

The shift addressed concerns around durability, maintenance, and life-cycle costs. Costs and the reflective appearance of stainless steel was questioned, but AWG’s proposal clearly demonstrated the long-term benefits of using grade 316 stainless steel: superior corrosion resistance in a marine environment, reduced maintenance, improved safety, and a consistent premium appearance. Importantly, a fully stainless assembly also avoided dissimilar metal contamination issues, allowing faster installation and greater structural integrity.

Collaboration across the stainless steel industry

AWG’s proposal drew on the knowledge and expertise of multiple ASSDA Members. Early in the design phase, Austral Wright Metals offered valuable input on stainless availability and fabrication options for the stanchions, helping set the foundation for the final solution.

From there, a strong collaboration across the stainless supply chain brought the vision to life. Stirlings

Performance Steels supplied the stainless materials for the stanchions, which were precision cut by Unique Metals Laser and fabricated and installed by First Line Engineering. Bespoke Wire & Rope not only provided specialist design input but also installed the Flexi-Mesh architectural mesh and wire rope framing cables, while AWG supplied the Flexi-Mesh panels and hamma ® X wire rope.

The final specification delivered:

• 262 grade 316 stainless steel stanchions with a 600 grit finish

• 468m of DN40 handrail and 445m of DN50 bike rail with a 400 grit finish

• Over 430m2 of Flexi-Mesh panels, more than 1km of hamma ® X wire rope, and 700 bespoke fittings

In total, more than 14 tonnes of stainless steel was used in the balustrade system alone.

The role of the ASSDA Young Professionals Network

The standout aspect of this project was the involvement of ASSDA’s Young Professionals Network. AWG worked closely with emerging stainless specialists across the ASSDA membership to develop a conforming design proposal, giving them valuable exposure to a highprofile government-funded project. Their contributions demonstrated technical expertise and commercial acumen, helping shift material choice from mild steel to stainless steel.

This experience not only showcased the talent pipeline within the industry but also highlighted the value of ASSDA’s network in facilitating collaboration and innovation. By engaging Young Professionals alongside experienced Members, the project became a platform for knowledge transfer, professional development, and industry visibility.

A showcase of Australian capability

A premium, sustainable outcome

The Alfred Street Bridge required complex engineering: an 80m main span supported by an 82-tonne diagonal arch rising 30m above the river, installed using a 750-tonne crane. Yet alongside its technical achievements, the use of stainless steel ensures the bridge is also a model of sustainability and durability.

Grade 316 stainless steel was chosen for Parramatta’s riverine environment for its superior corrosion resistance, ensuring the long-term safety of bridge users. Its durability and low maintenance needs can extend the bridge’s service life, reduce resource consumption, and minimise environmental impact. Using stainless steel also limits disruptions from maintenance or replacement – an important factor for heavily used infrastructure. At the end of its lifespan, the material is fully recyclable, with current recycling efficiency reaching 95%.

AWG’s conversion of the design from mild steel to stainless was central to achieving an outcome that balances aesthetics, constructability, maintenance, lifecycle costs, sustainability and resilience – values integral to Parramatta Council’s design objectives.

The Alfred Street Pedestrian Bridge is an excellent showcase of the world-class capability within Australia’s stainless steel industry, delivered through collaboration across ASSDA’s membership. It also demonstrates the power of the ASSDA Young Professionals Network in influencing the design, delivering solutions, and shaping the future of stainless steel in Australia.

From concept to completion, the project reflects innovation, technical expertise, and a shared commitment to sustainable urban infrastructure – qualities that will ensure stainless steel continues to play a defining role in Australia’s built environment.

PacRim Stainless 2025

Australia’s only dedicated stainless steel conference event

CONFERERENCE HIGHLIGHTS

INNOVATE. LEAD. SUSTAIN.

PacRim Stainless 2025 delivered two dynamic days of learning, networking, and celebration – a showcase of the Australian stainless steel industry’s strength, innovation, and collaboration.

Held on 15-16 October 2025 at The Island Gold Coast, ASSDA’s 30th National Conference brought together industry professionals from across Australia and abroad to exchange ideas, spark connections, and help shape our future.

Day 1 Conference Highlights

Chaired by Josh Sheedy (Arcus Wire Group), Day 1 set the tone for an engaging and thought-provoking program that explored the people, markets, and forces shaping our industry’s future.

Discussions focused on:

• Succession planning as a strategic imperative in the face of generational change, and the difference between management and leadership.

• The economic and financial market landscape, providing valuable insights into the current and future business environment.

• Global stainless steel markets, with analyses on production, demand, and how geopolitics are reshaping the industry worldwide.

Thank you to our Day 1 speakers for sharing their expertise and perspectives: Bernard Desmidt (Executive and Leadership Coach), Peter Munckton (BOQ), and Dr Gerhard Pariser (SMR – Steel & Metals Market Research).

The ASSDA Young Professionals Network Panel also took the stage, exploring leadership development and generational change in the workplace, featuring Bernard Desmidt, Cameron Clough (Midway Metals), Amanda Greer (Stainless Steel Wire & Mesh), and Jackson Treverrow (Atlas Steels).

Day 2 Conference Highlights

Chaired by Richard Matheson (ASSDA), Day 2 turned the spotlight to technology, sustainability, and the evolving business environment.

Key themes included:

• Robotic welding and automation, and how robotics and AI can help address the projected shortage of 70,000 welders by 2030 – improving efficiency, safety, and productivity.

• Artificial Intelligence (AI) in the workplace, exploring how AI can optimise organisational capability and performance. The session also unveiled a prototype ASSDA Chatbot, demonstrating how the Association is leveraging its knowledge base to deliver, credible, technical stainless steel information to Members and the wider industry.

• Advanced material solutions for a sustainable future, highlighting the role of stainless steel in reducing carbon footprints through life-cycle analysis and innovative applications.

• Climate reporting and regulatory readiness, unpacking Australia’s evolving disclosure requirements and the implications and opportunities for the entire supply chain.

A big thank you to our Day 2 speakers: Nathan Larkin (Verbotics), Warren Beard (Pantheon IQ), Glenn Darley (Alleima), and Joanna Mosur (KPMG Australia) for delivering their insightful presentations.

Celebrating Excellence

At the Gala Dinner, we recognised outstanding achievements in stainless steel fabrication with the 2025 Australian Industry Stainless Steel Fabricator Awards. With 190 guests in attendance, it was a night of celebration and pride for the industry.

Congratulations to Aflex, Pipe-Weld, Total Piping & Mechanical, and Arcus Wire Group for their award-winning projects.

Networking and Tradition

Beyond the conference sessions, delegates connected through social events and traditions that make PacRim Stainless a standout on the industry calendar.

The annual 2-ball Golf Ambrose at Parkwood Golf Course saw David Anderson (Atlas Steels) and Peter Ford (Austral Wright Metals) take home the Barry Durrant Memorial Trophy. Delegates also enjoyed a private YOT Blue charter, cruising through the Gold Coast Broadwater offering a perfect mix of networking and leisure.

The conference concluded in style with a Pool Deck cocktail event at The Island, where delegates relaxed, reflected, and celebrated another successful year for the stainless steel community.

A Conference to Remember

From thought leadership and innovation to collaboration and camaraderie, PacRim Stainless 2025 reinforced why this annual event remains the premier gathering of Australia’s stainless steel industry.

ASSDA extends its sincere thanks to all speakers, sponsors, and delegates for making this year’s conference an incredible success.

We look forward to welcoming everyone back in 2026 for another unforgettable PacRim Stainless experience.

2025 Winners ASSDA Fabricator Project of the Year Awards

Celebrating Australian innovation and excellence in stainless steel fabrication across all sectors.

The Australian Stainless Steel Development Association (ASSDA) is proud to announce the winners of the 2025 Fabricator Project of the Year Awards. The awards were presented at the PacRim Stainless 2025 Gala Dinner on Wednesday 15 October at The Island Gold Coast, recognising outstanding stainless steel projects that demonstrate innovation, technical excellence, and craftsmanship. “These awards highlight the exceptional talent and innovation within Australia’s stainless steel industry,” said ASSDA General Manager, Lissel Pilcher. “From local projects to international installations, our Members continue to set the benchmark for quality, reliability, and creativity.”

CATEGORY: Small Project, Big Impact

AFLEX

PROJECT: Stainless Steel Bellows for Hyperscale Data Centre, Melbourne

ASSDA Member and Accredited Fabricator Aflex supplied and fabricated 10 tonnes of 316 stainless steel bellows and expansion joints for a major hyperscale data centre, engineered for ultra-pure cooling water and AIintensive workloads. Fully annealed and TIG-brush electropolished under Aflex’s ISO 9001 quality system, the compact design absorbs thermal expansion, reduces pumping energy, and saves space, with ongoing cycle testing aiming for EJMA compliance.

www.aflex.com.au

CATEGORY: Food , Beverage and Pharmaceutical

PIPE-WELD

PROJECT: Snackbrands Project Horizon, Sydney

ASSDA Member and Accredited Fabricator Pipe-Weld delivered the full stainless steel mechanical works for a 22,225m2 high-efficiency food manufacturing hub at Orchard Hills, including 26km of 316 stainless steel tube, 4,500m2 of platforms, and 8km of sealed conduits. Fabricated with advanced techniques and strict QA/QC, the project ensures hygienic cleanability, corrosion resistance and long-term performance, supporting local supply chains and operational excellence.

CATEGORY: Process Industries

TOTAL PIPING & MECHANICAL

PROJECT: Viva Energy Hydrogen Generation and Refuelling Station, Geelong

ASSDA Member and Accredited Fabricator Total Piping & Mechanical fabricated and installed 316L stainless steel high-pressure pipework for Australia’s first hydrogen refuelling station, rated above 1,000 bar. Advanced orbital TIG welding and pre-fabricated modular spools ensured a zero-defect installation. The project integrates international hydrogen fabrication standards into the Australian context, setting a new benchmark for safety and performance.

www.totalpiping.com.au

CATEGORY: Architecture, Building and Construction

ARCUS WIRE GROUP

PROJECT: Pathway of Progress, Georgia Tech (USA)

ASSDA Member and Accredited Fabricator Arcus Wire Group delivered an Australian-fabricated stainless steel installation of over 3,500 tiles with mirror, gold, and textured finishes for Georgia Tech in the USA. Thousands of custom fittings, cables, and rods were engineered with precision to create a landmark artwork honouring generations of women, showcasing innovation, technical excellence, and meticulous craftsmanship.

www.pipeweld.com.au

www.arcuswire.com

The Australian Industry Stainless Steel Fabricator Awards continue to celebrate the skill, creativity, and ingenuity of Australia’s stainless steel industry, highlighting projects that push the boundaries of design, engineering, and sustainability.

Celebrating Peter Caswell –2025 Peter Matheson

Industry Service Award Recipient

At the PacRim Stainless 2025 Gala Dinner, Peter Caswell was honoured with the Peter Matheson Industry Service Award for over 45 years of service to the Australian stainless steel industry.

Peter enjoyed a long-standing career at Stoddart, holding leadership roles across general management, finance, and procurement. Beyond his career, he made a lasting impact on the industry through his service with ASSDA, joining the Board in 2006 and serving as President from 2010-2013. During this time, Peter helped restructure the Association post-GFC, putting ASSDA on a stronger financial footing, and developed programs in education, fabricator accreditation, technical assistance, communications, and advocacy that continue to underpin our work today.

Under his leadership, ASSDA achieved advocacy successes, including wire balustrades and engagement with the ABCB, and maintained strong relationships with major sponsors, navigating challenges including ownership changes, income reductions, a sluggish economy, and a high Australian dollar. Peter concluded his presidency in 2013 but continued as a Board Member until 2015 and remained a mentor to the ASSDA team beyond his tenure.

Peter’s dedication, leadership, and vision have left an inedible mark on ASSDA and the stainless steel industry. We are thrilled to honour him and wish him all the best in his retirement.

Congratulations Peter, a well-deserved recognition for a remarkable career!

Special thanks to Prochem Pipeline Products for sponsoring the event and Southern Stainless for sponsoring the award trophies.

Young Professionals Build Connections and Leadership Skills YOUNG PROFESSIONALS NETWORK

As part of PacRim Stainless 2025, the ASSDA Young Professionals Network (YPN) hosted a Leadership Workshop at The Island Gold Coast on 14 October. Participants gained valuable insights from Keith Abraham’s session, “How to build an unstoppable profitable business with velocity,” before networking with the ASSDA Board over refreshments. The day concluded with a Team Challenge at Padlock’d Escape Rooms and evening canapés and drinks. The ASSDA YPN continues to connect and empower emerging professionals, fostering leadership, learning, and collaboration for the future of Australia’s stainless steel industry.

Scan

SILVER MEMBERS: PLATINUM MEMBERS:

Daming International Import & Export Co., Ltd.

Prochem Pipeline Products

Stanch Stainless Steel Co., Ltd.

Stoddart

Venues

YC

AUSTRALIAN STAINLESS MAGAZINE

Steels \ HH Stainless Pte Ltd \ Metal Centre Australia \ Outokumpu \ Sanwa \ Stainless Bar & Wire Company \ Stainless Steel Wire & Mesh \ Stirlings Performance Steels \ Yue-Seng Industrial Co., Ltd.

MORE INFO: Enquiries or further information on any material presented in this publication should be directed to ASSDA:

Level 6, 200 Adelaide St, Brisbane Qld 4000 \ +61 7 3220 0722 \ assda@assda.asn.au \ www.assda.asn.au

EDITORIAL: Contributions of story ideas specialising in stainless steel and its applications are welcome from Members of ASSDA.

ADVERTISING: Advertise in the only publication that reaches a targeted group of 5000+ in the Australian stainless steel industry. Rates available at www.assda.asn.au

CONTACT: Lissel Pilcher, Editor: lissel@assda.asn.au DISCLAIMER: ASSDA