Operating Manual and Installation Guide

Evolve® 350 mm Process Column

Operating Manual and Installation Guide

Evolve® 350 mm Process Column

Evolve ® Process Column s are designed specifically for use in b iopharmaceutical a pplications. The column s can be used in pilot or production scale c hromatographic processes.

A pressure rating of 2.5 bar, operating temperature range of 2-30 °C and adjustable bed height makes this column suitable for a wide range of chromatography media types and chromatographic techniques.

Design features

The entire flow path is non-metallic, which has the following advantages:

• Eliminates the risk of corrosion and process contamination

• Allows the use of high concentration sodium chloride solutions and Guanidine hydrochloride

• Prevents product inactivation through metal contact

The Evolve® 350 mm Process Column is fitted with hydrophilic polyethylene bed supports. These are manufactured from high density polyethylene and modified so that the internal and external surfaces are permanently hydrophilic, which has the following advantages:

• The bed supports allow the passage of air and fluid without the need for wetting out procedures; traditional polyethylene bed supports are hydrophobic, and may require the use of high concentrations of organic solvents

• The material is permanently self-wetting for extended storage periods of 5 years or more

• A lower water intrusion pressure helps reduce the pressure drop through the bed supports; values do not limit typical chromatography applications

• A uniform surface facilitates consistent flow across the diameter of the column, enabling an efficient separation process

• Manufactured from high density polyethylene, the bed supports are robust allowing bed support thickness and column design to be optimised

• The material has good chemical compatibility and enables a non-metallic flow path to be maintained through the column

• Easy installation of bed supports allows for rapid turnaround when change is needed

Sealing of the adjuster flow cell to the tube wall is achieved by a moulded Santoprene seal, and central activation ensures even compression. The mechanism to energise and de-energise the seal is simple and easy to operate.

Positioning of the adjuster assembly within the tube is straightforward; location pins and labelling to assist with orientation.

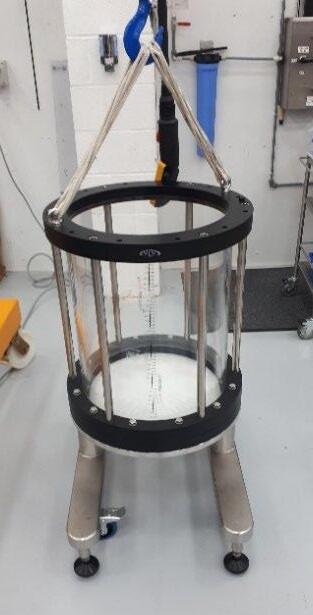

Evolve® 350 mm Process Columns are composed of three main sub-assemblies:

• Adjuster assembly - consisting of the adjuster flow cell assembly, backing plate, adjuster seal components, adjuster flange and a central height adjust threaded rod. Height can be adjusted over the range 50-480 mm

• Tube unit – consisting of the column tube, top/bottom flanges and scale label

• Fixed assembly – flow cell assembly and flow tube, column base with lockable casters and levelling column feet

* Based of liquid with SG of 1.05

** Minimum height needed to remove adjuster out of column unit

The pipework and column contribute to the pressure drop of the chromatographic system. Measuring the pressure drop from the column inlet to the column outlet shows the contribution made by the column hardware. The tests were performed at ambient temperature (15-20 °C) using DI water.

All materials in contact with the process stream have been selected for their suitability for use in equipment utilised in Biopharmaceutical applications and so either conform to relevant sections of FDA code of Federal Regulations vol. 21 170-199 and/or passed USP class VI test for in vivo toxicity.

Materials of construction – process-wetted parts

Column Component Material

Column tube

Adjuster flow tube & adaptor

Cell Flow tube adaptors (adjuster and fixed)

Acrylic

Polypropylene

Polypropylene

Sanitary clamp adapters 20% Glass filled polypropylene

Bed supports High Density Polyethylene

Fixed Bed Support seal EPDM

Column tube seals EPDM

Adjuster seal Santoprene® elastomer

Flow tube seal adjuster Santoprene® elastomer

Flow tube flange gasket seal EPDM

Fixed flow cell

Adjuster flow cell

Bottom Column Flange

Bed support retaining ring

Polypropylene (black)

Polypropylene (black)

Polypropylene (black)

Polypropylene (black)

Bed support retaining bolt 20% Glass-filled polypropylene

Sanitary clamp seals

Pipe spool

EPDM - ethylene propylene diene monomer

Santoprene® elastomer

Polypropylene/20% Glass-filled polypropylene

Materials of construction – non-process-wetted parts

The following table lists further materials used in the construction of the column. These components are not in contact with the process feed stream. These components are manufactured from high quality materials and selected for their suitability in bioprocess environments.

Top Tube flange

Adjuster top and back plate

Threaded central adjust rod, seal adjust tube

Seal adjust boss, seal adjust nut, seal adjust spacer

Acetal Black

Stainless Steel

Stainless Steel

Acetal Black

Thrust bearing washer PTFE

Pipework clamp

Seal adjust handles

Lifting eye bolts

Column Base

Foot 450

Acetal blue

Stainless Steel/ Acetal Blue

Stainless Steel 316

Stainless Steel 316

Stainless Steel with rubber pad

Casters Stainless Steel, acetal and nylon

Bolts, screws, washers, inserts

Stainless teel type 316

Acrylic columns are ideally suited for aqueous-based applications. See the table below for detailed compatibility information.

Resistance Resistant; suitable for continuous use

Not resistant; not recommended

Limited resistance

No information available

Notes General All solvents are at 100% concentration unless noted otherwise

Concentrations: % refer to w/w

All data is referenced to room temperature (15–25 ºC)

Chemical

1,2-dichloroethane

Acetic acid 25%

Acetone 5%

Acetonitrile

Ammonia aqueous <25%

Ammonium Sulphate 10-40%

Benzyl alcohol 1%

Benzyl alcohol 2%

Butanol

Calcium chloride 2

Calcium hydroxide 30%

Calcium hypochlorite

Chloroacetic acid 50%

Chloroform

Chromic acid 10%

Citric acid

Copper sulphate

Dichloromethane

Dimethyl formamide

Dimethyl sulfoxide 10%

Disodium phosphate

Ethanol 20%

Ethanol 70%

Ethylene glycol (1,2-ethanediol)

Formaldehyde 50%

Glycerol (Glycerine)

Chemical Compatibility cont.

Chemical

Guanidine hydrochloride 6 M

Hydrochloric acid 10%

Hydrofluoric acid

Hydrogen peroxide

Industrial methylated spirit (IMS)

Methanol 20%

Methanol 50%

Methyl chloride (Chloromethane)

Methyl ethyl ketone (MEK)

Methylene chloride

Nitric acid 10%

Nitric acid 70%

Peracetic acid 300 ppm

Phosphoric acid

Potassium hydroxide 2 M

Iso-propanol 20%

Iso-propanol 40%

n-propanol 20%

Sodium acetate

Sodium bicarbonate 20%

Sodium carbonate

Sodium chlorate

Sodium chloride 2 M

Sodium chloride 6 M

Sodium hydroxide 0.5 M

Sodium hydroxide 2 M

Sodium hypochlorite 200 ppm

Sodium nitrate

Sodium sulphate

Trichloroethene (Trichloroethylene)

Triton® X-100 surfactant

Urea 6 M

Zinc chloride

The following safety guidelines are presented.

European Pressure Directive 2014/68/EU relates to regulations that are mandatory and govern a wide range of pressure containing vessels. The design and manufacture of chromatography columns, including Evolve® Process Columns, are affected by these regulations.

The regulations are divided into categories, and Evolve® Process Columns have been assessed and found to fall within the Sound Engineering Practice (SEP) category. The foundation of the assessment is based on the following:

• The range of Evolve® Process Columns are liquid chromatography columns and when used in accordance with their o perating i nstructions there should be no gas (e.g., air) present in the columns

• The substances that will be used in the column will remain in liquid form during the entire operation at the maximum stated operating temperature.

In addition:

• The maximum operating pressure is greater than 0.5 bar and less than 10 bar

• The product pressure x volume is equal to or less than 200 bar litres

Users of these chromatography columns must ensure that the maximum operating pressure is not exceeded. It is recommended that an over-pressurization protection device such as a Pressure Relief Valve or equivalent is utilised.

Care should be taken when handling the columns. This large column and its subassemblies are particularly heavy.

All column maintenance and handling procedures should be regarded as two-person operations.

Mechanical handling equipment or manual handling aids should be utilised to safely lift or move or position the column or its subassemblies. This will avoid potential damage to the equipment and injury to personnel.

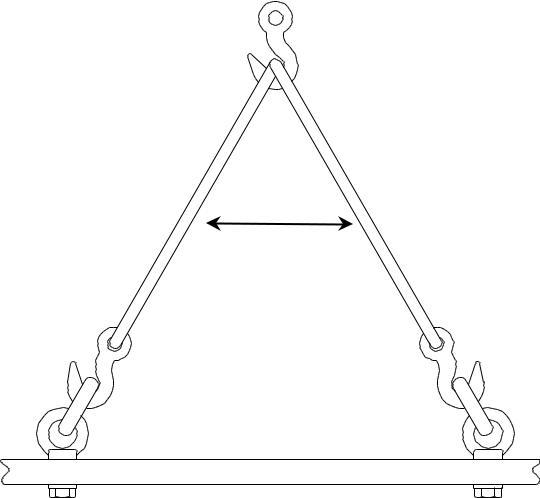

Provision is made for the use of a hoist as eye bolts are fitted to the top of the adjuster and can be fitted to the top of the tube unit.

It is essential that good practice is adopted regarding the use of appropriate slings and associated equipment, and to ensure the safety of personnel and prevent damage to equipment.

It is assumed that the user has available a hoist with hook and slings.

1. Ensure the rated capacity of the lifting equipment is sufficient to lift the column (200 kg)

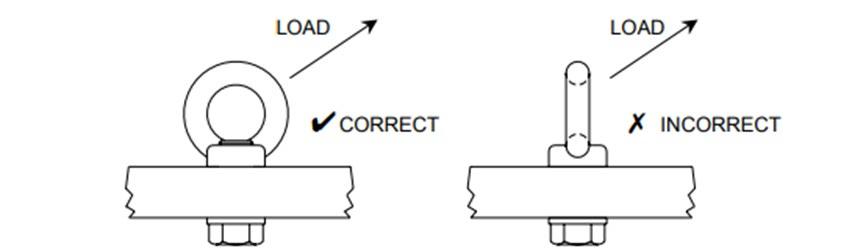

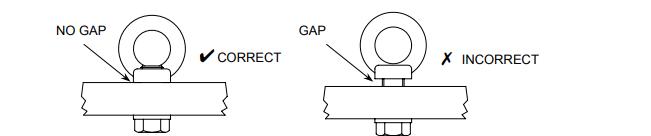

2. Ensure the lifting eyes are orientated in line with the slings. If they are not, there is a possibility of bending the eyes.

3: Orientation of lifting eye and lifting sling.

3. Ensure the shoulder of each lifting eye is in contact with the surface of the load (top plate) and the eye is securely fastened.

4: Correct location of eye nut on top plate of packing rig

4. Use only one sling leg to each lifting eye.

5. Do not fit the sling hook directly to the lifting eye – use a shackle.

6. Ensure the slings are sufficiently long. The included angle should not be more than 60º. Slings which are too short suffer excessive tensile load, which may lead to damage to the lifting eye or the sling. As a rule, ensure the slings are longer than the horizontal distance between the lifting eyes.

These instructions are intended to supplement users’ existing lifting practices rather than replace them and should not take precedence over Company or national standards.

A potential pinch point exists between the adjuster assembly and tube flange.

Labelling highlights this issue, and operators should take care to ensure that when lowering the adjuster flange, operators are clear of this area. Further advice is given in the operation and maintenance section of the manual.

This manual lists those substances for which the columns are compatible. If substances not listed are to be used, the user must consider their effect as the integrity and safety of the column could be compromised.

The column is shipped preassembled. On receipt, it is recommended to check for damage or loosening of components during transit.

Complete instructions for disassembly and reassembly can be found in the maintenance section of the operating manual.

The column is heavy and correct manual handling equipment must be used to remove the item from the packing crate.

On receipt, the packing crate will be marked with instructions on which bolts and panels to remove first. These panels should be removed.

A Certificate of Quality and serial number label are attached to the box. Remove and retain the Certificate of Quality.

Within the crate there is a separate box that contains the manual and operation guide, tool kit, connection kit and spares kit. This should be located and removed from the crate and retained.

The column is transported with its feet lowered. When the column is removed from the crate the column feet should be raised to allow the column to be moved into its location using the fitted castors.

Levelling the Evolve® 350 mm Process Columns

Before use, it is essential that the column is levelled. This ensures even flow and effective air removal. To facilitate this, columns are fitted with height adjustable feet and a spirit level is provided. Adjustment of the feet also increases ground clearance.

Before attempting to adjust the height of the support foot, identify the flat portion of the thread on each column foot.

1. Position the spirit level on the top of the column. Ensure the bubble is located within the central portion.

2. Turn the spirit level 90 degrees and check the level again.

3. To level the column, use the correct spanner/wrench adjust the height of the foot until the bubble is aligned.

4. This needs to be done in two directions.

This section provides general guidance on operating the Evolve® Process range of columns. It includes a hydrostatic leak test to establish that the column is installed correctly and advice for the preparation of the chromatography media.

Further advice specific to each media can be obtained from the media manufacturers; this section only provides general guidance.

The purpose of this test is to check that there are no leaks from the column and the column is ready to use.

Due to the materials of fabrication, when the column is initially exposed to pressure the column components will flex. It is important that the hydrostatic leak test is performed as outlined below following a multiple step operation.

Ensure all fixing on adjuster and fixed end are correctly located and tightened using the correct spanners.

1. Fill the column with WFI (water for injection) or high-quality water and position the adjuster at the operating bed height.

2. Ensure the adjuster seal is wetted with buffer or other suitable liquid prior to assembly. This helps ‘lubricate’ the seal to ensure correct seating.

3. Activate the adjuster seal.

4. Ensure all air is removed from the column and any connections.

5. Attach a calibrated pressure gauge to the top inlet of the column.

6. Open the valve and increase the pressure to 2 bar (29 psi) and close bottom inlet valve. Wait 15 minutes for the pressure to stabilize.

7. Release the pressure in the column.

8. Check and if necessary, re-apply the torque to the fixings.

9. Open the valve and increase the pressure to 4 bar (36.25 psi) and close bottom inlet valve. Wait 15 minutes for the pressure to stabilize.

10. Check and observe the column for any leakage or decrease in pressure.

11. To pass this test the column should hold pressure.

Due the nature of materials it is likely there will be a small pressure drop, however, this should not exceed 0.2 bar.

Below provides a general method for preparing and packing the Evolve® Process Columns. However, it is advisable to follow the media manufacturer’s recommendation for preparation of the media.

1. The media should be prepared as a 50 – 75% slurry in equilibration buffer, packing buffer or other suitable solvent.

2. Media that contains a high level of fines will benefit from a de-fining step prior to packing. Suspend the media in a suitable solvent and allow settling to occur. Gently decant the supernatant containing the fines and discard.

1. To identify the column components, see the schematics in this subsection.

2. Attach a valve to the fixed end pipe spool.

3. Remove the adjuster assembly.

4. Fill the fixed cell with buffer until approximately 20 mm depth of buffer is seen in the column tube. Either pump buffer into the cell via the pipe spool, or pour buffer carefully into the column, ensuring the liquid runs down the side of the tube to avoid creation of air bubbles. If buffer is poured into the column, ensure the flow cell is filled by opening the bottom process pipework and allowing fluid to exit the column. This also ensures all air has been expelled from the process pipework.

5. Ensure the valve at the fixed end is closed.

6. Ensure the slurry is thoroughly mixed.

7. Carefully pour the slurry into the column. Avoid trapping air bubbles in the slurry as it is poured.

8. Do not exceed the maximum fill limit. This is approximately 40 mm from the top of the tube. If you have slurry remaining open the bottom process port to expel some liquid from the slurry to allow further filling of the column.

9. Rinse the top inside surface of the column tube to prevent media from becoming trapped between the adjuster seal and the tube.

10. Set the position of the adjuster so that when it is placed into the column the adjuster cell locates above the liquid level.

11. Using a hoist and correct lifting slings lift adjuster unit into the tube unit. Alignment pins and arrow labels are located in the top flange to assist orientation.

12. Replace the adjuster assembly back into the column tube and secure to the tube flange using the flange fixing bolts. Ensure the adjuster cell assembly is approximately 30 mm from the slurry mixture.

13. Attach a flexible tube to the adjuster flow tube; this tube will be used to drain excess buffer during packing.

14. Continue to lower the adjuster flow cell toward the slurry by turning the height adjust handles, but do not enter the slurry mixture.

15. The slurry will start to settle when a liquid interface is seen gently lower the adjuster in.

16. Set the adjuster seal using the seal actuation nut. To successfully energize the seal, turn the handles on the seal actuation nut. Initially it may be necessary to hold the threaded height adjuster screw to prevent the flow cell from rotating; as the seal actuates the flow cell will stop rotating.

There are two methods to check if the seal has been made. It may be possible to see a witness line or contact line between the seal and the column tube, or that if the stainless steel central threaded adjust tube no longer rotates.

17. At this stage, the seal only needs to be energized enough so that further lowering results in buffer being forced out of the flexible tube attached to the flow tube. The adjuster unit will now be in clear buffer and packing of the media can start.

18. To fully energize the seal, turn the seal adjust nut a maximum of one revolution or until the seal adjust nut will not turn any further.

19. Ensuring that no air is introduced into the line, connect a pump and source of packing buffer to the flexible tube.

20. Consult the media manufacturer for packing recommendations. Ensure that the maximum operating pressure of the column is not exceeded; back pressure will increase as the bed packs.

21. Pump buffer into the column at an appropriate flow rate to pack the bed. Ensure the valve at the fixed end is open. The packing flowrate should be a minimum of 20% higher than the highest flow rate to be used during the process. Some media may pack more efficiently at flow rates considerably higher than the final running flow rate; refer to manufacturer instructions for guidance.

22. When no further packing of the bed is observed and the bed height has stabilized, mark the bed height and stop the pump.

23. Disconnect the top process flexible tube and direct to drain/waste.

24. To lower the adjuster, turn the height adjust handles clockwise; buffer will eject from the flexible tube. If no movement is observed then gently release some of the seal compression.

25. Continue downwards movement until the bed support touches the top of the packed bed.

26. If the media is compressible, the packed bed may expand while the adjuster is being lowered, and it may prove necessary to repeat steps 19 to 23 above.

27. When the final bed height has been reached, turn the seal actuation nut to apply maximum seal compression.

28. After the final compression step, flow in the upwards direction to remove any residual air at the top of the column.

CAUTION: When the column is under pressure do not tighten the seal adjust nut

The column may be unpacked by removing the adjuster, and media can be dug out or reslurried and pumped out of the column tube.

Cleaning

NOTE: Do not use abrasive cleaning materials or pads, as these may score plastic components

The extensive solvent and chemical resistance of the column components allows the use of a wide range of clean in place (CIP) solutions, including:

• Sodium hydroxide (0.5 M - 1.0 M)

• Sodium hydroxide (0.1 M) + ethanol (20%)

• Peracetic acid (300 ppm)

For thorough cleaning after use, the column should be dismantled into its component parts, thoroughly washed with detergent, and rinsed thoroughly with deionized water. The column should then be dried prior to storage.

Storage

For in-process storage, the packed column may be stored in any compatible solvent (refer to the Chemical Compatibility table). Choice of a particular solvent will usually be dictated by the chromatographic media; refer to media manufacturers data. Common storage solutions include 0.1 – 0.5 M sodium hydroxide or 0.1 M sodium hydroxide + 20% ethanol, both of which are suitable for long term (several months) storage with Evolve® Process Columns.

Unpacked columns should be kept in a cool, dry, dust -free location and protected from light. Exposure of acrylic column tubes to direct sunlight for prolonged periods or sterilization with ultra-violet lights may reduce the mechanical strength of the tube

To disassemble and assemble the columns, follow the instructions below. After reassembling the column ensure that the column does not leak by performing a hydrostatic leak test. When assembling/dissembling attention should be paid to:

1. Always use the correct size tools.

2. Ideally components should be at room temperature (approximately 20 °C). If not, take particular care as thermal expansion or contraction may make components fit more tightly and thus more difficult to disassemble.

3. Dismantled assemblies should be rested on a clean, dry surface.

4. Pay particular care not to damage the edge of the flow cells.

5. When unpacking columns be careful not to scratch the inside of the column tubes

6. Be careful not to damage stainless steel surfaces by bumping, knocking or scratching.

7. Do not over-tighten components and use correct torque settings as given in this guide.

8. Good engineering practices should be followed at all times and operations carried out in an approved and safe manner.

Tool

Allen Key Set Various locations

Allen Key 14 mm adaptor & Torque Wrench 3/8" Drive & adaptor

Spanner 17 mm/13 mm AF

Spanner 19 mm/24 mm

Spirit Level

S/Driver with Wide Blade

Eye Bolts

Flow tube adaptor, Adjuster Flow tube, Column Feet

Flanges bolts Adjuster and Fixed

Used to level the column

Removal of bed support retaining ring

Additional eye bolts to fit to tube unit during maintenance procedures

Disassembly instructions are provided to enable routine maintenance of the Evolve® 350 mm Process Column. These procedures enable changing of the bed support or other components in the wetted flow path. Spares and connection components are provided with the column. Other components are available; a complete listing of spares, accessories and kits that are available with the column can be seen towards the end of this manual.

Disassembly of a column of this size should always be a two-person operation.

This procedure does not describe the complete disassembly of the column into its component parts, only procedures for routine maintenance and cleaning.

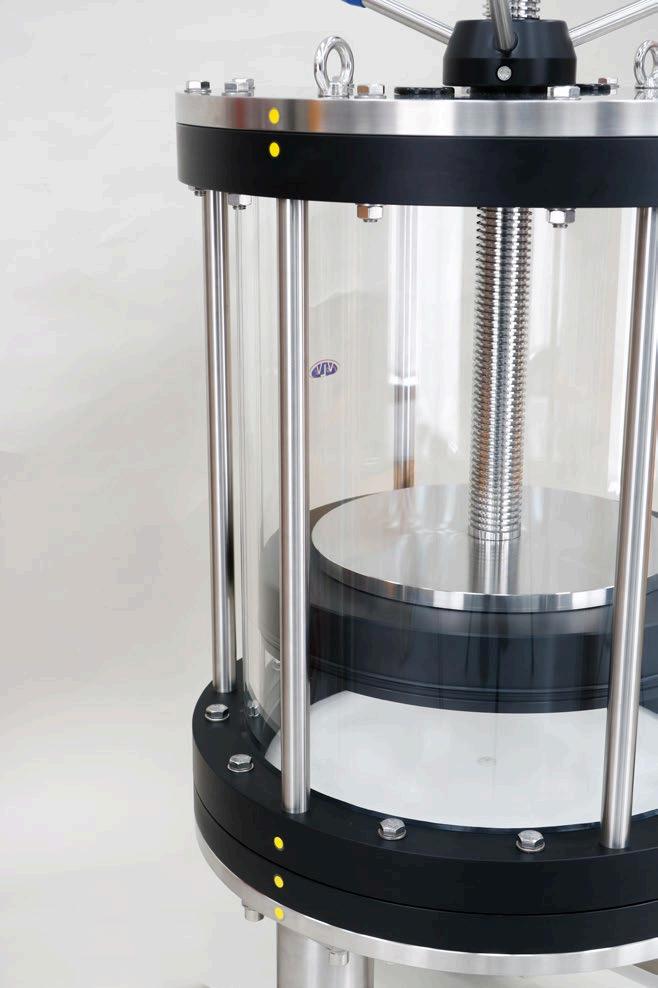

Identify the components as shown in schematic below.

1. Remove flange fixing bolts from the top column tube flange. Retain bolts, nuts and washers.

2. Check that adjuster seal is released by turning the seal adjust nut counterclockwise.

3. Using a hoist lift adjuster unit out of tube unit

ADJUSTER UNITS ARE VERY HEAVY. LIFTING SHOULD ONLY BE DONE USING APPROPRIATE LIFTING AIDS.

4. Move the adjuster away from the remaining column unit so access to the lifted adjuster unit is possible.

5. Place the adjuster assembly so that the flow cell face is on the floor with the hoist still attached.

6. Remove sanitary clamp adaptor using the 17 mm spanner and retain flow tube seal.

7. Remove the seal adjust nut and spacer.

8. Use the hoist to lift the adjuster unit. The adjuster unit will slide over the flow tube and seal adjust tube.

9. Undo the flow cell locking nut and move it downwards towards the back of the flow cell.

10. Using the correct spanner, locate the flats on the stainless-steel tube, and undo to enable the stainless-steel tube to slide off the flow tube.

11. Locate the flats on the flow tube, and using the correct sized (17 mm) spanner, remove the flow tube to expose the flow tube seal.

12. The adjuster bed support can be removed from the adjuster cell by carefully prizing the bed support retaining ring from its location groove in the side of the adjuster cell. A small extraction tool is provided. Care must be taken not to damage the retaining ring, flow cell or bed support. The central retaining bolt can be removed using the correct sized Allen key; retain this item.

13. To exchange the cell flow tube gasket seal, locate the bolts on the rear of the flow cell. Using the correct tool remove theses bolts and retain. Lift flow adaptor and remove and replace the seal.

14. To remove the main column seal, slide the O-ring towards the edge of the flow cell and disengage from the flow cell.

The unit should only be disassembled as a part of an emergency repair procedure; specific details of the method will be provided with replacement parts.

To access the fixed assembly it is necessary to remove the tube assembly unit from the bottom flow cell. This unit is heavy, and a hoist should be used.

1. Attach the eye bolts to the top tube flange.

2. Remove and retain the flange bolts, nuts and washers.

3. Using the hoist and appropriate lifting slings, lift the tube unit off the bottom flow cell and place down on the floor.

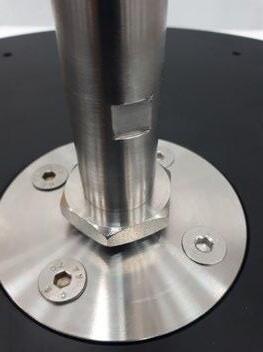

1. Identify the components in the schematic shown in Figure 9.

9: Fixed Assembly Evolve® 350 mm Process Column

2. Disconnect the pipework elbow from the bottom of the column. The pipe spool can be removed completely by undoing the two bolts located in the blue pipe spool clamp.

3. Remove the fixed end bed support, fixed flange seal and bed support seal.

4. Using the correct Allen key locate the four bolts that secure the fixed flow cell to the column base unit. Remove these bolts and retain.

5. Remove the flow cell and place it on a clean work surface.

6. Invert the flow cell and remove the flow tube adaptor bolts and remove the adaptor. This allows access to the flow tube adapter gasket.

Reassembly of the column is the reverse of the disassembly procedures and starts from the base of the column upwards.

Alignment indicators

Alignment indicators are attached to the top flange, tube flanges, bottom flow cell and column base plate to assist with reassembly and ensure that the column components are correctly orientated.

1. Place the fixed flow cell face downwards and ensure the flow cell adaptor gasket is located and fit the adaptor by locating and tightening the bolts using the correct tool.

2. Invert the flow cell to its correct orientation and located on the column base. Alignment indicators are provided to ensure the bolts are correctly located and that the pipework aligns with the front of the column.

3. Fit all the process pipework and ensure all connections are secure but do not overtighten.

4. Replace fixed flange seal; this should be located into the groove in the flow cell.

5. Replace the bed support seal.

6. The bed support should be fitted with the smooth side facing into the column. All handling of bed supports should be performed by a user wearing gloves.

7. Locate and gently tighten the bed support retaining bolt using the correct Allen key and with the tool perpendicular to the bed support (see Figure 11).

Attachment of Column Tube Unit

1. Using a lifting device, carefully lift the column tube unit onto the column base. Use the alignment indicators to correctly align the tube unit and base.

2. Lower the tube unit onto the column base.

3. Locate the fixing bolts and initially hand tighten the bolts, working diametrically opposite to ensure equal loading on the seal.

4. Using the correct spanners tighten the bolts, working diametrically opposite around the column circumference.

Adjuster Assembly

The adjuster assembly consists of the adjuster flange, seal actuation handles, threaded central seal height adjust tube, and seal setting ring.

The adjuster assembly should be lifted using correct equipment and hoist slings.

Replacement adjuster flow cells are provided with the flow cell adaptor fitted.

1. Carefully invert the adjuster flow cell.

All handling of bed supports should be performed by a user wearing gloves.

2. Locate the bed support into the bed support retaining ring. The smooth, glossy side of the bed support should be uppermost with the coarser, dull side in contact with the flow cell. The bed support retaining ring is shown in Figure 12 as blue to highlight assembly – actual component is black.

Smooth Side Coarse Side

12: Orientation of adjuster bed support into bed support retaining ring

3. Fit the bed support retaining ring and bed support to the adjuster flow cell. Working around the retaining ring, click it into position by locating the outer edge into the groove on the outside of the flow cell.

Retaining Ring Adjuster Flow cell Bed Support

13: Location of bed support retaining ring onto the adjuster flow cell

4. Locate the central bed support retaining bolt and secure, initially hand tight.

5. Carefully tighten the central bed support retaining bolt using the correct tool and keeping the tool perpendicular to the bed support. Incorrect use of the tool can cause damage to the bolt and ineffective tightening.

Figure 14: Tightening of the bed support retaining bolt - correct positioning of tool

6. Turn over the adjuster flow cell.

7. Locate the adjuster seal onto the angled circumference of the flow cell.

8. Fit the flow tube seal into the adjuster flow cell and replace the flow tube onto the rear of the flow cell. (See Figure 15a below). Use the correctly sized spanner to tighten.

Figure 15 (a-d): Assembly stages of the Adjuster Assembly – Connection to back of Adjuster Flow cell

9. Ensure that the flow cell locking nut is initially located against the flow cell adaptor (Figure 15b). Slide the stainless-steel central seal setting tube over the flow tube and locate onto the flow cell adaptor (Figure 15c). Tighten the tube hand tight.

10. Move the flow cell locking nut upwards against the seal setting tube and tighten the seal setting tube using the flats and correct spanner (Figure 15d)

11. Using appropriate lifting equipment, lower the remainder of the adjuster assembly such that the seal setting tube and flow tube unit locate inside the threaded adjuster height tube.

12. Replace the spacer and central seal adjust nut and engage the thread.

13. Refit the flow tube seal and ladish adaptor.

14. Using a hoist and correct lifting slings lift adjuster unit into the tube unit. Alignment pins are located in the top flange to assist orientation and alignment indicators are located on the external of the tube unit and column top plate.

CAUTION Adjuster units are heavy.

15. Locate the flange fixing bolts and initially hand tighten, working diametrically opposite to ensure equal loading on the seal.

16. Using the correct spanners, tighten the bolts, working diametrically opposite around the column circumference.

Refer to the maintenance section before undertaking any procedure advised below.

Excessive column back pressure

When troubleshooting sudden pressure increases or decreases, ensure that pressure readings are always taken at the same location so that accurate comparison can be made.

There are numerous factors that can cause excessive back pressure in chromatography, such as problems with the chromatography system (e.g., partial valve failure), issues with the media packed bed (e.g., over compression, consolidation, or bed fouling), the process fluid, or problems with the column.

Sudden decreases can result from bed collapse or cracking, flow instability or pumping issues.

This troubleshooting guide focuses solely on issues related to the column.

Possible Cause

Bed support blockages

Restrictions to inlet/outlet pipework

Incorrect seal size used to connect pipework.

Suggested Actions

Unpack and empty the column, run a pressure drop test over a range of flow rates and compare with pressure/flow curves in manual. If blockage due to viscous feed streams or media containing fines, replace bed supports

Ensure correct connections and diameter of pipework used

Ensure correct pipework seals used

Post column valve blockages Ensure valves fitted to column are correct functioning

Loss of pressure

Possible Cause

Column leakage/ seal failure

Suggested Actions

Identify cause and use advice above on leakage issues and replace parts if required

Bed support integrity lost Replace bed supports

Bed support retaining ring displaced or damaged

Bed support retaining bolts displaced or damaged

Reassembly or replace as required

Reassembly or replace as required

Media or high concentration of media fines not suitable for pore size of bed support.

Incorrect bottom flow cell positioning and/or tightening.

Damage to bottom or top bed support and any bed support seals

Failure of adjuster seal

Bed support retaining ring displaced or damaged

Bed support retaining bolt displaced or damaged

Check particle size distribution of media and ensure a defining process has been performed before use.

Unpack column and check installation of bottom flow cell and seals. Reassembly correctly using guidance in operating manual or refresh kit guide

Replace bed supports or seals as required

Check seal for damage or misalignment. Reassemble or replace as required.

Reassembly or replace as required

Reassembly or replace as required

Care should be taken not to introduce air into the column by ensuring bubble traps are used upstream of the column, media is not vigorously stirred, all connection are primed before made and all buffers are degassed

Air inclusion occurs during flow packing but before adjuster lowered

Air inclusion after packed bed formed

Release adjuster seal slowly and allow air to pass adjuster seal Lower adjuster with top process port open with no restriction

Flow in reverse direction until air is removed or any dry patches become wetted. Always requalify the packed bed after this procedure

Leakage from adjuster seal

Possible Cause

Damaged adjuster seal

Foreign material or media trapped between seal and sealing faces on column tube, flow cell or seal setting ring

Seal not energized sufficiently

Seal not correctly attached to seal adjust ring

Seal not actuating

Suggested Actions

Remove seal and inspect Replace seal if damaged

Clean and inspect seal and reseat seal

Try relaxing and re-energizing the seal

Do not adjust seal actuation handle when column is under pressure

Ensure seal fitted to the seal seating ring on outside and inside surface

When turning seal adjust handles it is necessary to hold central threaded rod to prevent flow cell spinning. Wet adjuster seal with buffer or suitable liquid prior to assembly. Check seal is correctly assembled and not trapped inside seal adjust ring.

Leakage from inlet/outlet of the column Possible

Incorrect installation of flow tubes and flow tube seals.

damage or over-compression of flow tube seals or flow tube adaptor seals

Damage to flow tube adaptor or pipe spool from using incorrect clamp or excessive clamp force

Replace any damaged components

Replace any damaged components. Ensure plastic clamps are used as metal plastic can be over tightened and can cause damage

Leakage from bottom of the column

Incorrect assembly during column refresh operation:

• Bed support seal not fitted.

• Column flange seal not fitted.

• Column tube seal not fitted.

• Flange bolts not tightened.

• Flow cell inlet or gasket not fitted correctly Use operating manual or refresh kit manual to assemble correctly.

Leakage around seal adjust tube/flow tube for column

Possible Cause

Adjuster seal not made

Damage, misalignment or missing flow cell gasket

Suggested Actions

Ensure seal is fully energized using the seal adjust handles.

Ensure correct installation of flow cell inlet gasket seals.

The following kits are supplied with the column:

• Tool kit, including additional eye bolt to assist in column disassembly/assembly.

• Connection Kit

• Spares Kit

It is possible to re-order these kits using the product codes listed in the table below.

Tool kit

This kit contains frequently used connectors and is also supplied with the column.

Several kits are available to order using the product number as shown below.

This includes the Column Refresh Kit, which provides all wetted components and instructions how to exchange these components.

To view our Evolve® Process Column User guides please visit: https://www.astreabioseparations.com/resources/hardware- user-guides For further enquires please contact: sales@astrea-bio.com

To determine chromatographic efficiency of a packing chromatography column it is usual practice to inject a small analytical sample onto the column and monitor the response at the outlet.

Typical solutions used include a low % solution of acetone in water, or a 1 – 2 M NaCl solution. If acetone solution is used, the UV absorbance is measured and plotted. If a NaCl solution is used, conductivity is measured and plotted. The plot obtained is then analysed to calculate chromatographic efficiency.

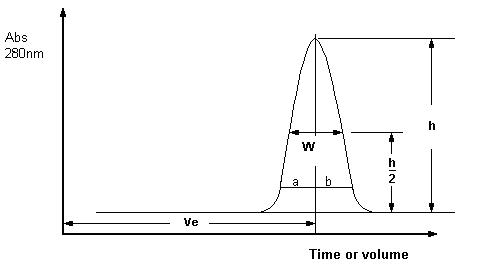

Figure A1: Description of Column Efficiency Calculations

Asymmetry is measured at 10% of the peak height and is calculated according to the equation shown below, where a and b relate to the width of the peak as shown in Figure 1.

Asymmetry =

Chromatographic efficiency is also expressed as HETP (height equivalent to theoretical plate) and N. This is calculated directly from the response plot as shown in the diagram below.

Calculation of HETP: HETP =

Where L is the column height in mm

Where N is the number of theoretical plates

Calculation of theoretical plates (N):

Two further calculations can be performed to describe column efficiency:

Reduced plate height considers the particle size of the media and enables comparison between different media types. A low value of RPH denotes good column efficiency; a RPH of less than 6 is expected.

RPH =

Where Pd is the mean particle diameter.

Dilution factor includes the initial sample volume in the calculation. This allows comparison between different peak shapes. The dilution factor is given by the following equation.

volume sample Initial ba factor Dilution + =

Where the initial sample volume and the values of a and b are all expressed in the same volume units.

Comparison of results should be undertaken with caution.

Different media manufacturers often express performance in terms of the definitions above. Caution must be taken when interpreting performance results. It is advised to check not only the media type used but also the flow rate, column diameter and bed height. Often results are given for tests performed in laboratory scale columns.

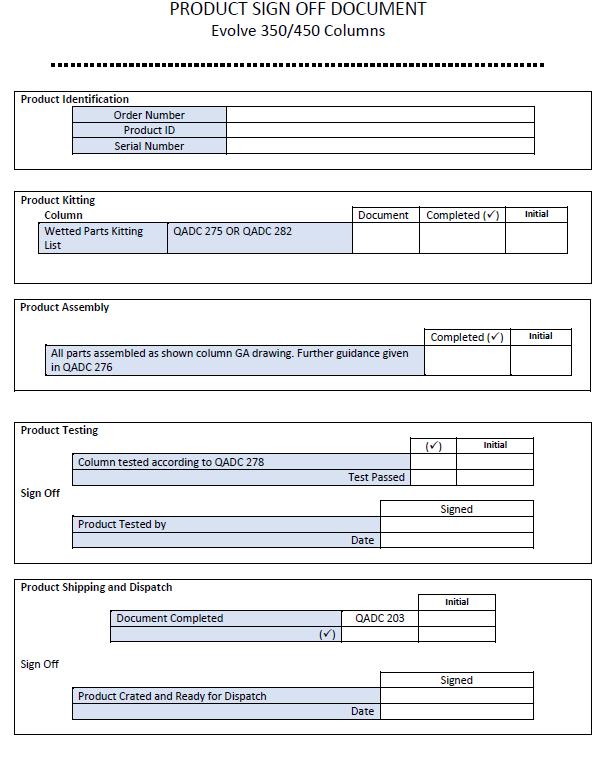

This manual contains a blank example of the documentation that will be provided with the column as delivered.

This form captures date, order information serial number, assembly and testing information at the time of manufacture.

A Initial release Jan 2021

B Updated Trademark registration July 2021

C Update Safety instructions and Guidelines Feb 2022

D Update tool kit components Aug 2022

E Additional maintenance and Trouble shooting advice provided. May 2023

F Rebranding Apr 2024