Maximizing lentiviral vector yield while minimizing impurities with a robust and scalable purification platform utilizing an innovative nanofiber adsorbent

S. Yang, C. Daye, J. Fletcher, B. Sant Mora, M. Hummersone and I. Scanlon Astrea Bioseparations, Horizon Park, Barton Road, Comberton, Cambridge, CB23 7AJ, UK

Overview

Process intensification is required to meet the increased interest in lentiviral vectors as modalities for cell and gene therapies. Lentiviral vectors (LVVs) are very sensitive to high salt and shear forces, which can contribute to the large losses observed in downstream processing. To address these challenges, we developed a next generation chromatography matrix that allows LVV purification under the mild conditions of low salt elution and low shear stress environment, coupled with a high binding capacity, that can be operated at speed.

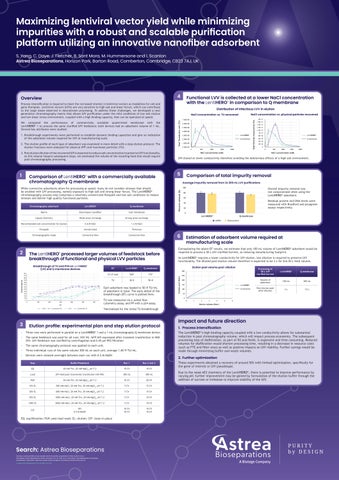

We compared the performance of commercially available quaternized membrane with the LentiHERO® 1 to process the same clarified LVV feedstock; both devices had an adsorbent volume of 1 mL. Several key attributes were studied:

1. Breakthrough experiments were performed to establish dynamic binding capacities and give an indication of the adsorbent volume required for LVV at manufacturing scale.

2. The elution profile of each type of adsorbent was examined in more detail with a step elution protocol. The elution fractions were analyzed for physical (PP) and functional particles (TU).

3. Post elution dilution of the recovered LVV is essential to reduce salt concentration to preserve LVV functionality. As this volume impacts subsequent steps, we estimated the volume of the resulting feed that would require post-chromatography processing.

Comparison of LentiHERO® with a commercially available chromatography Q membrane

While convective adsorbents allow for processing at speed, many do not consider stresses that should be avoided with LVV processing, namely exposure to high salt and strong shear forces. The LentiHERO® chromatography process step comprises a relatively unrestricted flowpath and low salt conditions to reduce stresses and deliver high quality functional particles.

The LentiHERO® processed larger volumes of feedstock before breakthrough of functional and physical LVV particles

Elution profile: experimental plan and step elution protocol

Three runs were performed in parallel on a LentiHERO® 1 and a 1 mL chromatography Q membrane device.

• The same feedstock was used for all runs: VSV VG –GFP LVV expressed after transient transfection in

293. LVV feedstock was clarified by centrifugation and 0.45 µm PES filtration •

• Devices were cleaned overnight between each run with

Impact and future direction

1. Process intensification

The LentiHERO®’s high binding capacity coupled with a low conductivity allows for substantial reduction in post chromatography volume, which will impact process economics. The subsequent processing step of diafiltration, as part of fill and finish, is expensive and time consuming. Reduced volumes for diafiltration would shorten processing time, resulting in a decrease in resource costs (such as FTE and filter area) as well as

2. Further optimization

These experiments obtained a recovery of around 50% with limited optimization, specifically for the gene of interest or LVV pseudotype.

Due to the weak AEX chemistry of the LentiHERO®, there is potential to improve performance by varying pH; further improvement may be gained by formulation of the elution buffer through the addition of sucrose or trehalose to improve stability of the LVV.