MY EXPERIENCE-

• To equip us with advance woven constructions and enable us to use this creativily in designing and developing woven fabrics.

• To explore the inter-relationship between structures, material, form and function and develop an appreciation and understanding of how to use this knowledge to design innovative fabrics.

As seen the work of seniors, i was waiting for this course so that i would get the knowledge of different structures other than basic tabby, sateen, mock leno, weft faced pile etc. It was really a good experience in terms of knowledge i got by planning the whole warp and then trying out different variations possible in that structure without manipulating its structure. Learning structures like imitation inlay, terry, leno, backed fabric, special warp and weft was a good experience as the whole process of the course was planned and coordinatedvery well. If we would have tried all the structures without taking any reference then the understanding about the structures would not have been very clear as it is now. Since we individually planned all our warps according to our own reference rather than putting a common warp, our understanding is more clear. I feel that the reference which i choose was a bit diverse in terms of photographs i took, so couldn’t go in depth to it. If i would have chosen a single picture and have looked into its structure, different angles and zoomed in versions of it, then the result could have been much better. This time i just looked into the visual look of it and each picture was very different from other so i couldn’t relate to each other like rust and tiles. But overall the course was really helpful in understanding the structures.

ADVANCE STRUCTURES

• BACKED FABRIC

• IMITATION INLAY

• SECIAL WARP AND SPECIAL WEFT

• WARP TERRY

• LENO

• DOUBLE CLOTH

BACKED FABRIC

Purpose-

For increasing the warmth retaining qualities of a cloth and in order to secure greater weight on the surface.

The idea is to employ them in forming a back to a face fabric, and one of the advantages of the backed construction is that the extra weight can be obtained in an economical manner, since material which is inferior to the face yarns may be used on the underside.

Principle-

Backed cloths are constructed in both the backed weft and the backed warp principle, a cloth consisting in the former case of two series of weft threads and one series of warp threads and in the latter case, of two series of warp threads, and one series of weft threads.

• Warp back- 2 series warp, 1 weft

• Weft back- 2 series of weft, 1 warp

• Two different colour on both sides.

The standard orders of arranging the picks in weft backed cloths are:1) 1 face to 1 back, 2) 2 face to 1 back,3) 3 face to 1 back, 4) 2 face to 2 back, 5) 4 face to 2 back.

The last two arrangements are used in place of the first two when a different kind of backing weft from face weft has to be inserted in looms with changing boxes at one side only. The first and the second systems are most commonly used, the former being employed for fine clothes in which the face and back wefts are similar in thickness. Generally the backing yarn is thicker and may be of a lower and cheaper quality.

Weft backed designs, in which the same weft face weave is formed on both sides are reversible weft backed weaves.

5

WAFT BACKED FABRICS

Requires one warp beam and drop box

Costlier to produce due to more picks/cm

Impossible to produce a solid appearance

Lower strength warp way

Inferior from structural point of view

Low quality of backing yarn can be used in weft due to less strain on yarn

Drawing in is cheaper due to less number of ends

Drafts are simpler

The standard orders of arranging the picks are-

1 Face to 1 back, 2 face to 1 back, 3 face to 1 back, 2 face to 2 back, 4 face to 2 back

WARP BACKED FABRICS

Requires two warp beams and no drop box

Cheaper to produce owing to less picks/cm

A more solid appearance can be given to the cloth by the formation of stripe patterns on the underside.

Greater strength warp way

Superior from structural point of view

Low quality of yarn cannot be used in warp due to greater strain in weaving

Drawing in is a costlier operation since there are more number of ends

Drafts are usually more complicated, and a greater number of healds are required in producing similar effects

The standard order of arranging the ends in warp backed cloths are- 1 face to one back, 2 face to 1 back and 3 face to 1 back.

6

The construction of backed fabrics involves the following stages,

• The face and back threads are marked out on design paper. They are marked out according to the order of insertion.

• The face weave is inserted on the face threads only using normal convention for warp backing and reverse convention for weft backed.

• The back weave is inserted on back threads only using the normal and reversed convention. A mark is placed on the back weave between two long floats of the face weave. This hides the binding marks of the back weave by covering float on the face.

End uses-

Backed fabric find uses in shawls, heavier dress materials, overcoats etc.

7

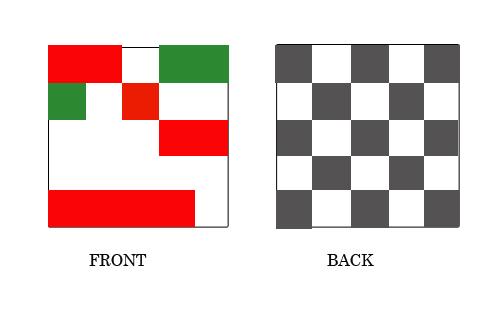

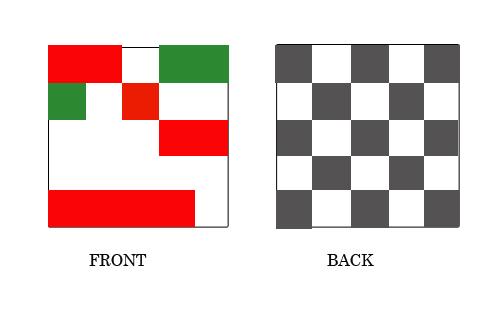

FRONT BACK

EXAMPLE OF WEFT BACKED FABRIC.

IMITATION INLAY- (Imitation of inlay technique)

Purpose-

This technique is used to imitate the hand done inlay technique, where two coloured wefts are used in a single pick.

Even backed fabric can provide heavy weight, but this structure can provide even more weight because there are more than two layers possible in it.Two or more wefts can be used in the same pick giving the posibilty of more patterning. The two sides can be completely different as per the design as the weft which is not being used either on top or back could be sandwithched in between.

Principle-

Two series of warp are used:

Binding warp- which shows on face and back and is thiner as compared to skeleton as it would show on the face.

Skeleton warp- which is the backbone of the structure and holds the sandwitched wefts which is not being used on front or back. So it needs to be thicker and stronger as it holds two or more wefts simultaneously.

Binding warp’s tension is loose while skeleton warp is tight to make the sandwitching not show on top. Binding warp consumpsion is more as it goes from top to botton and many wefts are sandwitched in between. Length of binding warp is usually 2 times the warp of skeleton as it is loose and is occupied more.

It creates the possibility of having different patterns on different faces. Weft from one end goes to the other and gets sandwitched where not to be shown.

If you want a colour on front then don’t lift that shaft, or if you want to show it at the back then lift both the shafts, and if you want to sandwitch then lift one of the two shafts.

Uses- as the fabric weight would range from medium to heavy weight and thus could be used in upholstry.

FRONT AND BACK COULD HAVE TOTALLY DIFFERENT PATTERN

8

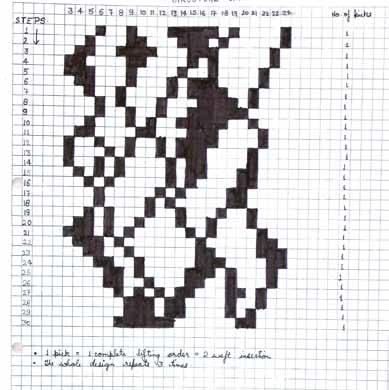

Example how peg plan is determined for face and back.

FRONT AND BACK COULD HAVE TOTALLY DIFFERENT PATTERN

9

Purpose-

Its a special type of structure where both warp and weft are prominent at the same time. The combination of warp and weft leads to the patterning of the fabric. Lot of patterning is thus possible in this structure as even two ends could be treated as one block which requires just two shaft each. So in a 24 shaft dobby 22 blocks could have different patterning. So lot of scope of patterning is possible which is difficult in other structures. Even if patterning is possible in extra weft techniques, the floats are very long. This structure allows to do patterning without any floats as a thin binding is present to bind them.

Principle-

In the structure the pattern warp is binded by thin binding weft, while pattern weft is binded by thin binding warp. Thus pattern is made showing both warp and weft without any float. Pattern warp is thick while binding warp is thin, so that it is not dominant as is shown on the top.

Pattern weft is thick while binding weft is thin as the design is made visible by the pattern weft while binding weft is just to reduce the floats thus needs to be very thin. Thickness of pattern warp and weft should be same so as to make the design very clear and prominent.

There is a particular way lifting is done so that binding warp binds the binding weft and pattern weft binds the pattern warp and not the vice versa happens.

1 Binding pick- all binding shaft up

2 Pattern- 1 shaft of binding

3 Binding- all pattern shafts

4 Pattern 2 shafts of binding warps.

10

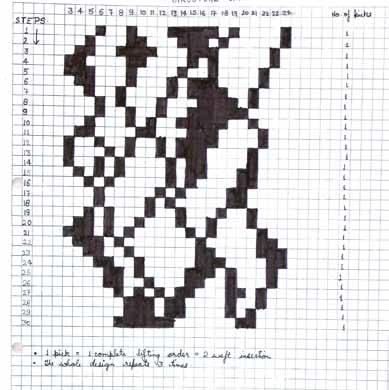

Graph where patterning is done and lifting order is taken and the same design then come s on the fabric.

Likewise 22 steps are possible in a 24 shaft dobby where 2 shafts are taken by binding threads and 22 steps could be created with minimum 2 ends.

Uses-

Bedcovers and other upholstery fabrics have lot of patterning. Even shirting fabrics have this type of structures.

11

Purpose-

Terry pile is also known as turkish towelling is a class of warp pile structure in which certain warp ends are made to form loops on the surface of cloth. Only one series of weft threads is used but the warp consists of two series of threads, the ground and the pile. The loops may be formed on one side only or on the both sides of the cloth thus producing single sided and double sided structures respectively. The formation of terry pile depends on the creation of a gap between the fell of the cloth and two succeeding picks of weft.

Formation of pile-

The formation of terry pile depends on the creation of a gap between the fell of the cloth and two succeeding picks of weft. The gap, the length of which depends on the height of pile requires, results in the formation of uninterlaced warp floats.

To form the gap two succeeding picks are beaten up short of the true cloth fell and produce a temporary false fell. On the third pick of the group full beat up takes place the three picks being pushed forward together to the true fell position. During this action the three picks are capable of sliding between the ground ends, which are kept vary taut. However they cannot slide similarly between the pile ends firstly because they are structurally locked with them and secondly because the pile warp at that moment is slack.

The gap, the length of which depends on the height of pile required, results in the formation of uninterlaced warp floats.

12

Uses-

The looped structure is suitable for towelling puposes as long as the long, free floats of yarn, if made from absorbent materials, are capable of wicking-up readily large amount of moisture. The material best suited for this purpose is cotton.

13

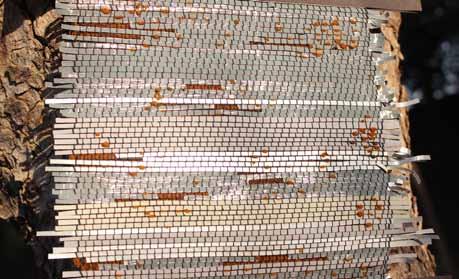

Example of terry fabric

Purpose-

Cross weaving is a useful principle of fabric structure which is adapted extensively in the production of silk, cotton, worsted and linen textures. When it is applied to fabrics of an extremely light, open and flimsy texture and especially if produced from silk, they are usually described as gauze fabrics. But if applied decoratively to heavier textures of cotton and linen they are usually termed “leno” fabrics of which there are two distinct classes namely net leno and leno brocade.

The great merit lies in a very considerable stability of the interlacing combined with its open nature. The size remains stable and uniform even under a degree of pressure.

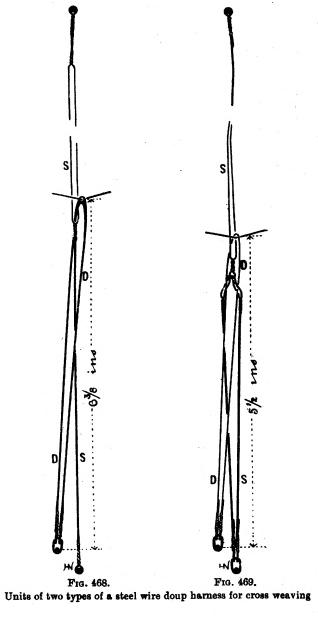

Principle-

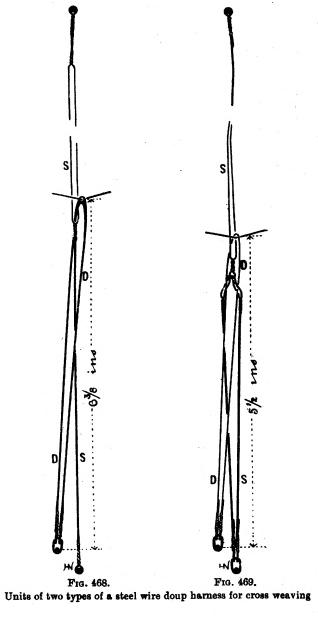

The thread manipulation required to produce the simplest structure is depicted in the diagram .

The simplest way of cross weaving is that in which one or two warp threads cross each other on successive picks or pairs of picks in regular succession so as to produce an open net like structure of uniform texture as represented graphically. The diagram indicates the method of drafting warp threads through the heels and reed at a and order of shedding at b to produce the gauze structure represented at c.

14

Uses-

The fabrics produced by this method are employed for curtains, shirtings, and for blouse and dress materials as well as various industrial uses such as filter cloth, screens and sieves.

15

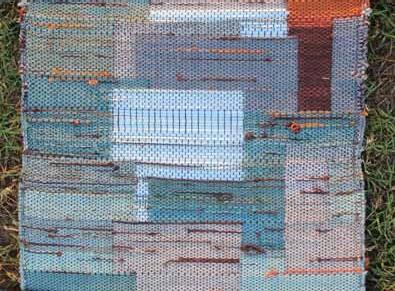

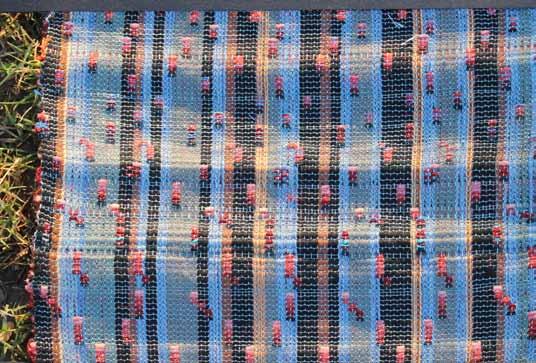

EXAMPLE OF LENO FABRIC