THE ASCET INFORMER

60 Years of providing opportunities for technicians and technologists to Magnify their status as vital members of the engineering team.

• Fire Pump Churn Test -What is the Frequency for a Churn or No-Flow Test for Fire Pumps?

• InspectIon & testIng of Water-Based systems neW exams comIng - nIcet • SOME THINGS TO THINK ABOUT PLUS NFPA 13 UPDATES

Every Drop Counts

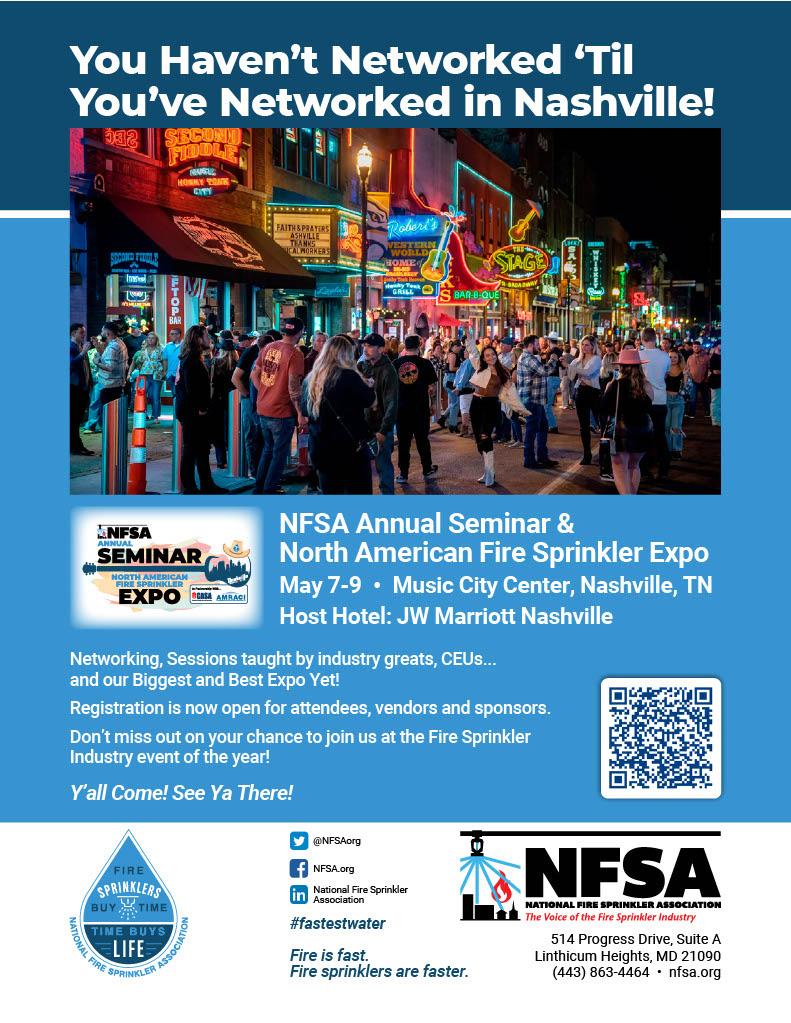

Celebrating a 150 Year Legacy of Water Safety Innovation Join

Water. It’s in our name and close to our hearts. Since 1874, has delivered innovative technologies that make the world’s most precious resource safe and accessible. Every effort, like every drop, has a ripple effect. Together, we can create a more sustainable world today and tomorrow.

Aloha All,

I am writing to provide updates to the activities of ASCET currently for 2025. It is almost April, the time flies. As we embark into this season the board has had monthly meetings to go over the plans for the ACE 2025 in Raleigh, NC this coming November. We have been reaching out to presenters with a call for entries, now we have had 15 responses, and I am sure there are more on the way. Noah and I are heading this committee up. We are looking to have presentations on Design, implementation of codes in the design work, code-oriented programs, and new code information, as well as some presentations for NICET support programs such as:

‣ CMT-Asphalt

‣ CMT-Concrete

‣ CMT-Soils

‣ CMT-Performance Examinations (Optional)

‣ Highway Construction Inspection

‣ Electrical Power Testing

‣ Video Security Systems Testing Discontinued December 31, 2023

‣ Technologist Certification Program

‣ New! Systems Software Integrator

‣ Systems Software Integrator (SSI)

‣ Fire Alarm Systems

‣ Inspection and Testing of Fire Alarm Systems

‣ Water-Based Systems Layout

‣ Inspection and Testing of Water-Based Systems

‣ Special Hazards Systems

‣ In-Building Public Safety Communications

We have contacted an extensive list of past presenters and some new presenters. If you know someone involved with any of the areas listed above, please have them get in touch with us. We really appreciate the input and direction from you, our members. After all, this event is for you, our members. We are narrowing down the location in Raleigh. Marty and his committee have been working diligently to get the venue rapped up so we can get the word out. We are excited and really looking forward to seeing everyone there for the event.

Kyle and his committee have been working on the sponsors and vendors for the event. He did a great job lining up the vendors in Baltimore last year and there are commitments from many who were there already. It is shaping up to be a very good group of vendors to show off all that their companies have to offer.

To move in another direction, I will briefly touch on the IRS issue. We are still working on it sadly. It is good it is still moving but at a snail’s pace. The IRS is illusive and when contacting them we must have correct answers to get to someone to discuss the topic. We have made several attempts. I will say with some of the departures from the

organization that knew more history, our general manager, Lisa, is really putting in the time in an attempt to put this to bed. We have been through multiple accountants and finally we have to have an attorney involved. The accountants that we have used all get to a certain point and go silent. The current one has done the same. We have several EIN numbers, the one used to file taxes was incorrect. Another issue we have found is in moving our fiscal year ending date from June 30 to the calendar fiscal year ending in December was done without properly notifying the IRS. This led to several years of rejections without explanation. We also lost our not-for-profit status with the IRS. We found in the filing of the taxes the wrong forms have been used creating more confusion and concern with the IRS. Once the proper paperwork is filed and we essentially will be re-establishing the organization we will be able to file our taxes and back taxes. This will assist in getting our not-for profit status of the 501 3C back. We are still working on this. The last thing that I will share. We have been told that as a local chapter we never needed to file the taxes to the IRS, there was protection under the umbrella of national, but the year-end paperwork for the local chapter needs to be submitted to national. It is called the “Chapter Annual Report”. Now this is still needed. We have found that all this time, going back to when ASCET started, the local chapters should have been filing taxes separately. From the conversations we have had with the IRS and a lawyer it is nothing more than a postcard. This form number will be provided once more information is obtained. As I mentioned, this is still an evolving topic, we are hopeful of having a final resolution soon. We need to have the conversation with the IRS, this is still being worked on by our general manager. I would like to thank you for being patient. We know how frustrating it has been. We are all affected by this. It does not appear that any penalties will come from this. We are trying to fix things that were wrong for a long time.

As the year progresses, we will be reaching out to you all to keep you updated and more transparent. Frankly we have been transparent the IRS issue ignorance was due to not having the knowledge we currently obtain. It certainly has changed things. We have gone through and stripped the budget down to bare bones. There is concern that we are not managing the budget, I can say that the group we have now is very active and watchful of our budget. We have had unforeseen expenditures in the past and we were being wary of the impact that a penalty of the IRS would have on ASCET. I feel we are moving past this, and we have good direction.

Moving into the health of the association we have slowly gotten smaller with some long-standing chapters closing down. We are pushing to gain membership and always looking for opportunities to open more chapters. If interested or know of anyone looking to get involved, please direct them to the board and we can assist in getting things up and running.

We do have election for two regional vice president positions this year. We have the Southeast Region and the Central Region positions that will be open for election this coming July. If interested please forward your bio information to me by June 1, 2025. This election will be in July and the announcement of the new officers will be announced in September and an introduction to the membership at the ACE in November. We did have a resignation of the Northeast Regional Vice President, Noah Koski has decided to resign. This position now has been filled with a former holder of the position, Joe Krieger from the Delaware Chapter of ASCET. We are grateful for Joe to accept the position and will serve the full term, which is 2 years. Thank you Noah Koski for your short tenure and the energy that was brought to us.

Jamie, our Marketing Manager, is constantly looking for articles to put in our very good-looking magazine. I am asking all members, including sponsors and advertisers, to please submit articles. We need them from all areas as I listed previously. This all matters and keeps our members active and informed! From doing this for a year, I know firsthand how hard this is. Jamie is not a certified tech and has no experience in any

of the technologies we are all involved in. She has few contacts in the industries. Jamie needs our assistance to have the magazine continue. As I have asked previously, if you know someone willing to write articles have them contact her and submit.

In closing, I am looking to have a good year. We are only a quarter of the way through and there is so much happening. With everyone’s help, input and participation we can continue and make ASCET better for us all.

Aloha and Mahalo,

James V. Lynch, III, SET

ASCET Chairman of the Board National

Call For Candidates

The 2025 ASCET is now seeking candidates for National offices as follows

Southeast Regional VP, Central Regional VP and Western Regional VP

At some time during his or her technical career, every member of ASCET should consider volunteering as a candidate for office at the local or national level. Assuming responsibility as an officer requires much personal time and effort and often some unanticipated personal expenses are encountered in fulfilling a commitment. However, as an officer you may have opportunities that would not normally occur in your daily work. You will make many new personal contacts and develop professional skills that can increase your efficiency on the job. You will also become more knowledgeable about all aspects of your Society and its continuing efforts to promote the recognition of the Certified Engineering Technician. The Nominating Committee has prepared a packet of information and resume forms for candidates. If you are interested in becoming a national representative of ASCET, please contact office@ascet.org.

Fire Pump Churn Test

What is the Frequency for a Churn or No-Flow Test for Fire Pumps?

by Rob Stewart

An easy way to identify frequency for Inspections and Tests for Fire Pumps is to go to Table 8.1.1.2 in NFPA 25 2023 - See Below

We see for Diesel Pumps it is a weekly Churn or No Flow Test and we look at 8.3.1.1 for more details. For Electric Pumps the Frequency is weekly or monthly. Why?

Because there is an exception for Electric PumpsLook at 8.3.1.2.1 - Except as permitted in 8.3.1.2.2 and 8.3.1.2.3, a weekly test frequency shall be required for the following electric fire pumps:

1)Fire pumps that serve fire protection systems in buildings that are beyond the pumping capacity of the fire department

(2)Fire pumps with limited service controllers

(3)Vertical turbine fire pumps

(4)Fire pumps taking suction from ground level tanks or a water source that does not provide sufficient pressure to be of material value without the pump.

Take note of the exceptions that require a weekly run for an Electric Pump. How do we start the pump? Note what the Standards says at 8.3.2.2 - "The test shall be conducted by starting the pump automatically."

What is meant by an automatic start? The NFPA 25 Handbook says this"Paragraph 8.3.2.2 requires that pumps be started automatically, rather than by the use of the “start” button on the front panel of the fire pump controller. The pump must be started by drawing water from the sensing line to simulate a pressure drop in the system. As the pressure drops, the pressure switch will sense this drop in pressure and should start the pump automatically. Using the start button on the fire pump controller does not constitute an automatic start."

Yes - we want to start the pump by draining water from the sensing lines. This is good information to cover with our customers who we do pump testing for. Educating ourselves and our customers strengthens our industry!

Are you looking for training for your team on inspecting and testing fire pumps? Fire Tech Productions, Inc has upcoming "Hands-On" workshops coming up that will provide real ROI to your company and customers. Check out the link to upcoming workshops –Hands-On Workshops Calendar Please reach out directly with anything related to training in our industry to rob@firetech.com

Inspection & Testing of Water-Based Systems (ITWBS)

New Exams Coming June 2, 2025

NICET, along with industry volunteers, began updating ITWBS nearly 18 months ago. The main purpose was to update exam content to reference newer codes and standards for all levels. Dozens of knowledgeable volunteers participated to update the job task analysis, write test questions, review test questions, and verify reference material. The updated ITWBS exams will be based on the 2023 edition of NFPA 25 and other sources. Levels I and II will be available in the typical format.

The Level III exams will be administered as a pilot test initially. The job task analysis group and validation survey confirmed adding the following new domains to the exam:

3.6 Interpret Flow Test Results (Questions related to these tasks make up 12-22% of the exam.)

3.6.1 Analyze five-year flow tests of standpipe systems and their components.

3.6.2 Analyze five-year flow tests of private fire service mains.

3.6.3 Analyze forward flow of backflow preventers.

3.6.4 Analyze pump test results.

3.7 Automated Inspection and Testing (Questions related to these tasks make up 1-9% of the exam.)

3.7.1 Analyze automated inspection and testing results.

3.7.2 Verify automated testing equipment for listed use and purpose.

3.7.3 Identify frequencies for automated inspection and testing

The pilot test is designed to collect data on exam performance to assist with determining the final exam items and passing score.

Level IIs with at least five years of ITWBS experience are encouraged to participate in NICET’s pilot. The first 110 applicants will receive a 50% discount on exam fees (for exams scheduled and taken during the pilot period).

Apply Now:

Contact tech@nicet.org if you are interested in participating.

The pilot will run from June 2, 2025 to August 31, 2025. Test takers will NOT receive a score immediately at the end of the exam. Test results will be issued no later than early Nov 2025. For data analysis purposes, participants are only permitted to test once during the pilot period. If the work experience documentation is submitted before the testing window ends on August 31, 2025, NICET will prioritize the review of experience documentation for the pilot test takers. Once the results are announced and if you have passed, you will receive your Level III certification immediately.

Testing Discount:

Level III exam $180 (regularly $365) – limited to first 100 people

Exam Window:

June 2, 2025 to August 31, 2025

Tomaselli Fire Protection Engineering

Independently owned and operated

Fire Protection Engineering Consulting firm.

With our previous experience as the Engineering Manager for the Plan Review Division of one of the largest Counties in Maryland. We know what it takes to attain code compliance. Even in the grayest of areas.

We currently hold Professional Engineering licenses in Maryland, Virginia, DC, California, and Colorado with the ability to obtain licensure on demand.

We offer services that range from feasibility studies.

• System adequacy reports

• Hydraulic analyses

• Warehouse analyses

• Third party plan review

• All the way to working as the fire protection engineer of record for a variety of projects.

• Fire Protection Engineering services for anything you can think of.

Life safety and building code analyses sprinkler.

Fire alarm

Foam, Wet chemical and Dry chemical

Grease hood & duct, and other special hazard systems.

If you would like more information about Tomaselli Fire Protection Engineering or to discuss your project’s needs you can contact us at tomasellifpe@gmail.com.

A NEW CHAPTER IN TRAINING

We are proud to announce the foundation of Instructional Design Group, LLC, or "IDG."

Instructional Design Group, LLC launched IDG University in January of 2025.

The online courses will cover subjects associated with Fire Alarm, Fire Protection, Fire Suppression, Civil, CCTV, Security, Electrical and Essentials Skills. Instructional Design Group, LLC is a NICET Recognized Training Provider. We don't teach the test; we teach the codes. IDG University offers single-topic "Quick Courses" covering material from NFPA and ICC codes and standards. Quick Courses can be used to review before industry certification exams, or increase your knowledge of a topic. Courses are 3 contact-hours in duration, and award a Certificate of Completion. All courses include a 20-question quiz with answers directly from codes and standards. The certificate can be used to earn 3 NICET CPD's, or 3 NFPA points. Our courses will satisfy credit to any organization who awards points for training with contact hours.

CLICK LINK BELOW

https://designmycourse.net/

Instructional Design Group, LLC has established a 15% discount for ASCET members. Use coupon code “ASCET15” at checkout for any course.

Instructional Design Group, LLC, “IDG,” is dedicated to providing training and development programs designed to a higher, industry-recognized standard. Our courses will focus on building knowledge of the codes and standards that are adopted and specified across trades and industries.

“We Don't Teach the Test; We Teach the Codes” ™

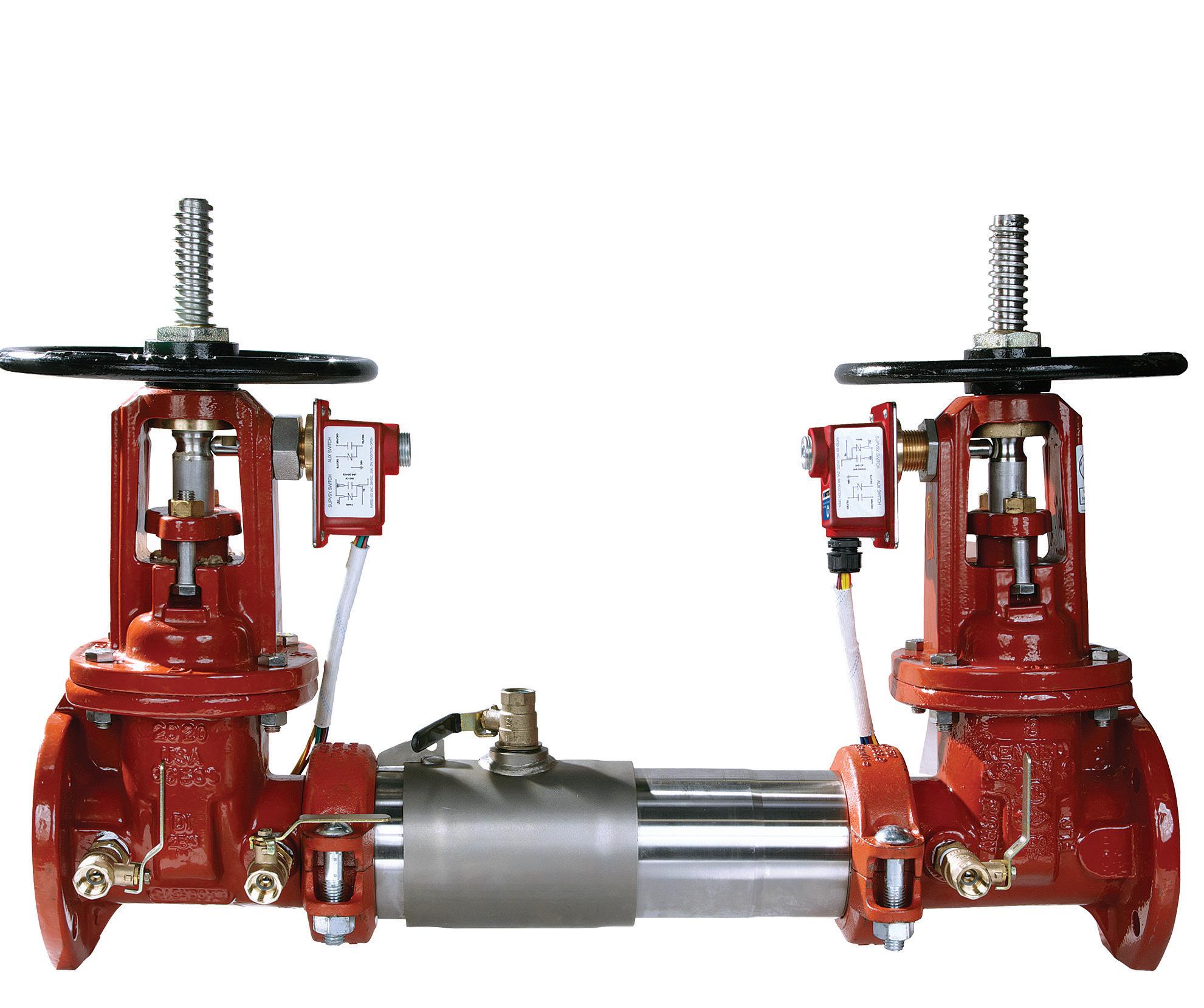

900XL3 Series

Zurn

Wilkins Backflow Preventers

The Contractor Favorite Just Got More Compact

Smaller

Valve. Better Value. The Zurn Wilkins 900XL3 Series Small Backflow Preventer delivers convenient size and substance to cut down on labor. We engineered the new and improved model to be even shorter and more compact than before, while integrating the time-tested features from our contractor favorites. Our repair kits allow for faster, cost-effective repairs, saving owners up to 20% over the life of the product. Upgrade to the greatest value with the most compact backflow preventer in its class for your next project.

Easy Install

• Shortest bronze small backflow preventer in its class to fit any application

• Vertical installation approved for the double check model to save more space

• Short lay length makes installation faster and easier

Quick Repairs

• Test ports located on valve’s centerline make install and testing easy

• Easy to remove check cover and relief valve cover makes valve servicing easier

• EZSwap® modular check with top access speeds up repairs and replacements

• Interlocking connected checks provide ¼ turn to access and disassemble

Super-durable

• All bronze body ensures durability against the elements

• Noryl™ check body and stainless steel fasteners resist corrosion over time

• Low-cost repair kits extend the lifespan at a significantly lower cost

• Check design minimizes moving parts to reduce wear and extend lifespan

Certification Updates and Maintenance

Highway Construction Inspection (HCI)

The last update of this program occurred in 2016 and was originally scheduled for maintenance in 2021, but due to complications caused by COVID, NICET was not able to begin until now. HCI is NICET’s premier certification for civil engineering technology. We are excited and encouraged by the volunteer participation and can’t wait to see what we accomplish together over the next several months.

NICET hosted the Job Task Review November 11-13, 2024, at the NSPE headquarters in Alexandria. A pilot validation survey was released to the JTA panel in December. 2024. The complete Validation Survey was distributed February 5-25, 2025. We expect to finalize the content outline/exam blueprint in April.

The Item writing/review for Level I has already begun and Item writing/review for Level II will begin at the end of March-early April. It is anticipated that the updated HCI exams will be available early to mid-2026.

Electrical Power Testing (EPT)

NICET began the update through collaboration with industry stakeholders to recruit SMEs for an Advisory Panel. The panel met virtually in January 2025 to discover significant industry changes and expand stakeholder input.

A Job Task Analysis (JTA) workshop is scheduled for April 7-9, 2025, at the NSPE Headquarters in Alexandria, VA. It is anticipated that the Validation Survey will be distributed in June 2025. Once the JTA is finalized the Item Writing/Review phase will begin. New exams are expected in late 2026.

UL 162 Listed FM 5130 Approved

More sprinkler listings than any other fluorine-free foam!

SOLBERG® RE-HEALING™ RF3 3% Foam Concentrate rapidly extinguishes Class B hydrocarbon fuel fires. Versatile SOLBERG® RE-HEALING™ 3x3 SP-100 Foam is the first UL-listed fluorine-free foam for both hydrocarbon and polar solvent fuel fires.

Custom Equipment Solutions

From bladder tanks and other proportioning systems to discharge devices and mobile products, we design hardware tailored to your needs.

Explore our full range of solutions at www.perimeter-solutions.com. SOLBERG® RE-HEALING™ foams are the gold standard in fluorine-free firefighting solutions.

perimeter-solutions.com

AGF Manufacturing Launches PURGENVENT™

Model

7940BLE:

A BABAA-Compliant Automatic Air Vent Assembly for Wet Fire Sprinkler Systems

Malvern, PA – [Date] — AGF Manufacturing proudly announces the release of the PURGENVENT™ Model 7940BLE, a Build America, Buy America Act (BABAA) compliant automatic air venting valve assembly designed to increase the longevity and reliability of wet pipe fire sprinkler systems. With integrated features for streamlined installation, system protection, and NFPA 13 compliance, the 7940BLE sets a new standard for air management in fire protection.

“The 7940BLE is a comprehensive solution to help contractors meet NFPA 13 code requirements while simplifying installation and improving long-term system performance,” said Jim McHugh, President of AGF Manufacturing. “It’s everything you need for compliant venting in one factory-assembled, American-made package.”

NFPA 13 now mandates air venting on all wet pipe fire sprinkler systems using metallic pipe. The 7940BLE is engineered to meet this requirement with a UL Listed and FM Approved 7900V automatic air vent that efficiently expels trapped air during normal operation, helping reduce internal corrosion and the risk of system damage.

The 7940BLE features the FM Approved and UL Listed 7900V automatic air vent, which utilizes a conical, recessed design and a single-float mechanism for precise, protected venting. An integrated isolation valve and strainer allow for safe maintenance while preventing debris from entering the system. The assembly also includes a purge valve with union and hose connection that speeds up air removal during system filling, simplifies strainer cleaning, and acts as a vacuum breaker to assist with complete system drainage. To support federally funded projects, the 7940BLE is constructed with Build America, Buy America Act (BABAA)-compliant materials, including domestic pipe, couplings, and end caps. Its durable branch line extension (BLE) is fabricated from Schedule 10 or 40 domestic pipe, finished with a tough red powder coating and clearly marked with “AIR VENT” signage for easy identification during inspections and servicing.

AGF recommends installing the 7940BLE near the high end of system branch lines—where air naturally accumulates—for optimal performance. The unit’s high-visibility signage and built-in service features ensure quick location and easier maintenance access, especially in overhead or hard-to-reach locations.

About AGF Manufacturing

AGF Manufacturing has been developing innovative, American-made fire protection products for over 35 years. From the original TESTANDRAIN® valve to industry-leading air vents, auxiliary drains, and risers, AGF continues to deliver solutions that improve fire sprinkler system longevity and simplify code compliance.

For more information about the 7940BLE or to find a distributor in your area, visit www.agfmfg.com or contact AGF at (610) 240-4900.

PREVENT FALSE ALARMS AND IMPROVE SAFETY WITH REGULAR SMOKE DETECTOR CLEANING

Smoke detectors are critical safety devices that require regular upkeep to ensure they function effectively Cleaning them is a simple yet essential task to keep them performing properly when needed most.

How Often Should You Clean a Smoke Detector?

The frequency with which you clean your smoke detector depends on several factors, but as a general guideline, you should clean your detectors at least twice a year. A good way to remember this is to clean your smoke detectors when you change your clocks for daylight saving time this ensures you never forget

Over time, smoke detectors naturally accumulate dust and debris from the air. This is evident in areas with poor ventilation, construction dust, or high levels of indoor pollutants. Moisture in the air can cause dust and other particles to stick to the detector, which can interfere with its function In these environments, it is recommended to clean your detectors every three to four months

How Do You Clean a Smoke Detector?

Cleaning a smoke detector is straightforward, but it must be done correctly to avoid damaging the unit If your smoke detector is mounted high on the ceiling or hard to reach, you’ll want to safely remove it using a Solo 200 Detector Removal Tool. This tool is specifically designed to help you detach smoke detectors from their mounting brackets without risk of damage

Now, grab an air duster like Blowout, which quickly removes contaminants and prevents buildup that could affect performance.

Blowout is gentle yet powerful, ensuring sensitive components inside your detector are cleaned without damage This helps maintain the sensor’s sensitivity and functionality

Next, wipe down the exterior of the detector with a soft cloth or microfiber towel to remove any remaining dust and grime Once cleaned, reinstall and your detector is ready to go

What Are the Risks of a Dirty Smoke Detector?

Neglecting to clean your smoke detector can have serious consequences, both in terms of performance and safety A dirty smoke detector is much more likely to fail when you need it the most Here’s why:

Reduced Sensitivity: Dust, dirt, and debris can block the sensor and interfere with its ability to detect smoke This reduces the effectiveness of the alarm, which could delay your response time in the event of a fire

False Alarms: A buildup of particles in the detector can also lead to false alarms. Dust or residues might trigger the detector when there’s no real threat, leading to frustration and, in some cases, complacency causing people to ignore or even disable their detectors

Premature Failure: A dirty smoke detector works harder to detect smoke, which can cause internal components to wear out faster A buildup of grime can reduce the lifespan of the detector, meaning you may have to replace it sooner than necessary

Fire Safety Risk: Ultimately, the biggest risk of a dirty smoke detector is that it may fail to alert you in the event of a fire. The peace of mind that comes with knowing your smoke detectors are working properly is invaluable

Cleaning your smoke detectors regularly is an easy, cost-effective way to ensure your safety equipment continues to work as it should With the right tools like Blowout for cleaning and the Solo 200 Detector Removal Tool for safe removal you can keep your detectors functioning at their best.

ANY DETECTOR ANY TIME

Testifire is the ultimate all-in-one test tool designed for fire maintenance professionals who prioritize efficiency. This tool simplifies on-site testing of smoke, heat, and CO detectors, offering fast and accurate results. With features that eliminate re-alarms, ensure easy storage and transport, and provide ondemand smoke testing, Testifire enhances productivity and helps maintain the reliability of fire detection systems

All-in-one

One tool for testing smoke, heat and CO allows testing of any detector regardless of type.

Quicker testing

Saves time and inconvenience with no need to switch between test tools. No re-alarms

Built-in ‘clearing’ mode prevents re-alarms minimizing disruption and saving time.

Easy Storage & Transportation

Non-hazardous, non-pressurized capsules, allows for easier storage and transportation. On-demand smoke

Less wasted smoke and no risk of detector contamination.

Universal

Tests multiple stimulus in sequence, simultaneously or sequentially.

HERE IS YOUR SIGN

\\

NFPA 13, 13D, 13R, 14 AND 20 REQUIREMENTS

JOHN A. DENHARDT, P.E., FSFPE | American Fire Sprinkler Association

The comedian Bill Engvall made the saying “Here is your sign” well-known. When he said it, it was directed at someone who just said something that was obvious or just plain stupid. One story I remember Engvall telling at a comedy show was about a gentleman who was using a coat hanger trying to unlock his car. Another person walking past looked at the gentleman and asked, “You locked your keys in the car?” The gentleman responded, “No sir, I’m just trying to hang my car up to dry.” Here is your sign.

So, what does this have to do with sprinkler systems? Failure to include the required signage is an obvious mistake that can be costly. Numerous signs are required by NFPA 13, Standard for the Installation of Sprinkler Systems , and other standards; however, many sprinkler designers, installers, and inspectors are not familiar with the signs they are required to provide. We all know about the requirement for control valve and main drain signs, but what about the rest? This article will discuss required signs and explain why they are critical to the safe operation of a fire protection system.

NFPA 13 REQUIREMENTS

Let’s start by looking at NFPA 13, 2025 edition. Table A.16.17 is a summary of the signs that must be provided and was developed to make it easier to identify what signs are required by the body of the standard.

Section 16.9.11 requires all control, drain, venting, and test connection valves be provided with permanently marked weatherproof metal or rigid plastic identification signs. The identification signs must be secured with corrosion-resistant

wire or chain or other approved means. The control valve signs need to identify the portion of the building served. Figure 1 shows the front and back of a typical control valve sign that meets these requirements. Systems that have more than one control valve that must be closed to work on a system or space are required to have a sign referring to the existence and location of the other control valve. Not providing this sign cost one building owner over $500,000 in property damage. In an emergency situation at this facility, all the control valves could not be turned off in a timely manner as no onsite personnel knew the location of the second control valve.

Section 8.6.1.4 requires that for all antifreeze systems that are remote from the system riser, a placard must be mounted on the system riser that indicates the number and location of all remote antifreeze systems supplied by that riser. Section 8.6.1.5 requires a placard at the antifreeze system control valve that indicates the manufacturer type and brand, volume, and minimum use temperature of the antifreeze solution used in the system.

Section 16.10.5.3.7 has a requirement that most are not aware of. Even though this requirement has been in NFPA 13 since the 2007 edition, I seldom see this sign provided. All auxiliary (low-point) drains on dry pipe systems or preaction systems require a sign at the dry pipe or preaction valve indicating the number of low-point drains and the location of each individual drain. Failure to provide this signage has caused numerous installing contractors to lose legal claims that were brought against them when systems experienced freeze damage. In one case, a maintenance crew drained all the low points they saw, but the system still experienced pipe damage

due to freezing. There were seven low points, but two of them were not obvious. The low points were shown on the “as-built” drawings, but because the required signage was not provided, the installing contractor was still found liable for damage that occurred long after the system was completed. Luckily this claim was small, but it could easily have been much different. I have found that providing an 11-in. x 17-in. outline of the system indicating the number and location of the low-point drains and the inspector’s test connection has satisfied this requirement. I usually install the outline in a picture frame and mount it near the dry or preaction valve. I also include this outline in our Operation and Maintenance manuals. This sign ensures that important information about the system is posted for future use and reference.

Section 16.12.5.8 covers the requirements for signage at the fire department connections (FDCs). Each FDC must include a sign having raised or engraved letters at least 1-in. high on a plate or fitting reading the type of systems served. If any system served requires 150 psi or more, a sign must be provided indicating the system demand pressure. Where an FDC serves only a portion of a building, a sign should be provided indicating the portion(s) of the building served.

Section 29.4 requires a Hydraulic Design Information Sign, sometimes referred to as a Hydraulic Data Nameplate. Like the valve identification signs required by Section 16.9.11, we all should be familiar with this sign since it has been around for years. However, over the years, a few modifications and new requirements have been added to this sign. Every hydraulically calculated system is required to have this sign. This means that if a multistory building has multiple systems, each system that has a water supply source, control valve, waterflow alarm, and drain requires its own signage. The sign must be placed at every alarm valve, dry pipe valve, preaction valve, or deluge valve supplying the corresponding hydraulically designed area unless the Authority Having Jurisdiction (AHJ) approves an alternate location. In addition, NFPA 13 requires signage at every system riser and floor control assembly. The Hydraulic Design Information Sign must include the location of the design area or areas, size (area) of or number of sprinklers in the design area, the discharge densities over the design area(s), the required flow and residual pressure demand at the base of the riser or fire pump (if applicable), the occupancy classification or commodity classification and maximum permitted storage height and configuration, the hose stream allowance included in addition to the sprinkler demand, and the name of the installing contractor.

Where a system has been designed using the pipe schedule method, Section 29.5 requires a Pipe Schedule Design Information Sign or nameplate located on the corresponding system riser.

Section 29.6 requires a General Information Sign. Even though this requirement has been in NFPA 13 since the 2007 edition, it is often missed. The installing contractor must provide a General Information Sign that can be used to

determine system design basis and information relevant to the inspection, testing, and maintenance requirements of NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems . The General Information Sign must be placed at each system control riser, antifreeze loop, and auxiliary system control valve. It needs to include the following information: name and location of the facility protected, edition of NFPA 13 the system was designed in accordance with, occupancy classification, commodity classification, presence of high-piled and/or rack storage, maximum height of storage planned, aisle width planned, encapsulation of pallet loads, presence of solid shelving, flow test data, presence of flammable/combustible liquids, presence of hazardous materials, and presence of other special storage. In addition, the sign must include the location of venting valve(s), location of auxiliary drains and low-point drains on dry pipe and preaction systems (note that this is also required by Section 16.10.5.3.7), original results of the main drain flow test, original results of the dry pipe or double interlock preaction valve test, and name of the installing contractor or designer. The sign must also indicate the presence and location of antifreeze or other auxiliary systems. Where injection systems are installed to treat corrosion (including microbiologically influenced corrosion or MIC), the type, concentration, and disposal requirements of the chemical must be shown. Finally, the sign must indicate the presence of nitrogen when used to allow for an increased C-factor in dry or preaction systems.

For marine systems, Section 31.2.7.5 requires an 18-in. x 18-in. sign displaying the applicable symbol for an FDC as shown in Table 5.2 of NFPA 170, Standard for Fire Safety and Emergency Symbols, 2024 edition. The symbol must be placed at the connection so that it is in plain sight from the shore access point.

Section A.16.11.2 suggests installing a sign near the local alarm device required by Section 16.11.2. (Remember, the annex contains material that explains or clarifies the body of the standard but is not legally enforceable.) The sign should

Figure 1. Sample front (at top) and back (at bottom) of a control valve sign.

be located near the device in a conspicuous position and include wording such as: SPRINKLER FIRE ALARM— WHEN BELL RINGS CALL FIRE DEPARTMENT OR POLICE.

While not necessarily classified as a sign, Section 16.2.7.7 requires a list of the sprinklers installed in the property to be posted in the spare sprinkler cabinet. This requirement was added during the 2007 revision to NFPA 13. This list needs to include the following information:

1. Sprinkler Identification Number (SIN), if equipped; or the manufacturer, model K-Factor, deflector type, thermal sensitivity, pressure rating, and temperature rating;

2. Manufacturer’s sprinkler wrench model number for each sprinkler type;

3. General desription;

4. Quantity of each type of sprinkler installed in the property;

5. Quantity of each type to be contained in the cabinet;

6. Issue or revision date of the lis..

NFPA 13D, 13R, 14, AND 20 REQUIREMENTS

In this section, we will cover the signage requirements in NFPA 13D, Standard for the Installation of Sprinkler Systems in One- and Two-Family Dwellings and Manufactured Homes, 2025 edition; NFPA 13R, Standard for the Installation of Sprinkler Systems in Low-Rise Residential Occupancies, 2025 edition; NFPA 14, Standard for the Installation of Standpipe and Hose Systems, 2024 edition; and NFPA 20, Standard for the Installation of Stationary Pumps for Fire Protection, 2025 edition.

NFPA 13D – This standard has only one requirement for a sign, and that is for a multipurpose piping system, which is defined by Section 3.3.13.3 as: “A piping system intended to serve both domestic needs in excess of a single fixture and fire protection needs from one common piping system throughout the dwelling unit(s).” This is not the typical independent sprinkler system most sprinkler contractors are installing. This is a combined domestic water/sprinkler system for the dwelling unit(s). In accordance with Section 6.3.4, when a multipurpose piping system is installed, a warning sign with minimum 1/ 4-in. letters is required to be affixed to the main shutoff valve and states the following:

WARNING: THE WATER SYSTEM FOR THIS HOME SUPPLIES FIRE SPRINKLERS THAT REQUIRE CERTAIN FLOWS AND PRESSURES TO FIGHT A FIRE. DEVICES THAT RESTRICT THE FLOW OR DECREASE THE PRESSURE OR AUTOMATICALLY SHUT OFF THE WATER TO THE FIRE SPRINKLER SYSTEM, SUCH AS WATER SOFTENERS, FILTRATION SYSTEMS, AND AUTOMATIC SHUTOFF VALVES, SHALL NOT BE ADDED TO THIS SYSTEM WITHOUT A REVIEW OF THE FIRE SPRINKLER SYSTEM BY A FIRE PROTECTION SPECIALIST. DO NOT REMOVE THIS SIGN.

The intent of this sign is to warn the unknowing homeowner or residential contractor about the need to consider the

sprinkler system before adding any device to the combined water system.

NFPA 13R – Section 5.2.14.4 requires all control, drain, and test connections be provided with permanently marked weatherproof metal or rigid plastic identification signs. The identification signs must be secured with corrosion-resistant wire, chain, or other approved means. The control valve signs need to identify the portion of the building served. Systems that have more than one control valve that must be closed to work on a system or space are required to have a sign referring to the existence and location of the other valves.

Section 6.11.3 requires signage for FDCs. Each FDC to a sprinkler system must be indicated by a sign having raised or engraved letters at least 1 in. in height on a plate or fitting indicating the type of system(s) served (e.g., AUTOSPKR., OPEN SPKR., or STANDPIPE).

While not necessarily classified as a sign, Section 11.1.7 requires a list of the sprinklers installed in the property to be posted in the spare sprinkler cabinet. This requirement is similar to the NFPA 13 requirement. The list must include the following information:

1. Sprinkler Identification Number (SIN), if equipped; or the manufacturer, model, orifice, deflector type, thermal sensitivity, pressure rating, and temperature rating;

2. Manufacturer’s sprinkler wrench model number for each sprinkler type;

3. General desription;

4. Quantity of each type of sprinkler installed in the property;

5. Quantity of each type to be contained in the cabinet;

6. Issue or revision date of the list.

NFPA 14 – Section 7.10 requires that all required signs be permanently marked and constructed of weather-resistant metal or rigid plastic materials.

Section 8.7.1 has numerous requirements for signs. It requires that all main and sectional system control valves, including water supply control valves, be equipped with a sign indicating the portion of the system controlled by the valve. In addition, all control, drain, and test connection valves must be provided with signs indicating their purpose. Where sprinkler system piping supplied by a combined system is supplied by more than one standpipe (“loop” or “dual-feed” design), a sign must be located at each dual or multiple feed connection to the combination system standpipe to indicate that to isolate the sprinkler system served by the control valve, an additional control valve or valves at other standpipes must be shut off. The sign must also identify the location of the additional control valves. Where a main or sectional system control valve is in a closed room or concealed space, the location of the valve must be indicated by a sign in an approved location on the outside of the door or near the opening to the concealed space. Where hose connections are not located in exit stairways, signs must be provided in accordance with NFPA 170 to identify the location of the hose connection in an approved manner.

Valve cabinets, where provided, must be marked to indicate the contents. Lettering must be red with a white background and 2 1 / 2 in. in height. Annex section A.8.7.1.5 suggests that it might be necessary to mount hose connection signs parallel, perpendicular, or at an angle to the plane of the mounting surface on which the sign is located. The point is that the sign must be readable in an emergency by responding personnel. Dry systems with low-point drains must have a sign at an approved location indicating the number of low-point drains and each individual drain.

Where a fire pump is provided to supply an automatic standpipe system, Section 8.7.2 requires a sign at the pump indicating the minimum pressure and flow required at the pump discharge flange to meet the system demand.

Section 8.7.3 requires a Hydraulic Design Information Sign to identify the basis of the system design. The sign must be located at the water supply control valve for automatic or semiautomatic standpipe systems and at an approved location for manual systems. The sign must indicate the location of the two hydraulically most remote hose connections, the design flow rate for the connections, the design residual inlet and outlet pressures for the connections, the design static pressure, the design system demand (i.e., flow and residual pressure) at the system control valve or at the pump discharge flange where a pump is installed, and at each FDC.

Section 8.7.4 requires that all pressure-regulating devices be equipped with a sign that indicates the static and residual inlet and outlet pressures and flows. Section A.8.7.4 states that the sign can be mounted on the valve or in the vicinity of the valve as long as it is visible during periodic tests and inspections.

Section 9.9 has requirements for FDC signage. Each FDC must be supplied with a sign labeled STANDPIPE with letters at least 1-in. high that allows the sign to be read from the street. For manual systems, the sign must also indicate that the system is manual and that it is either wet or dry. If automatic sprinklers are also supplied by the FDC, the sign or combination of signs must indicate both designated services (e.g., STANDPIPE AND AUTOSPKR or AUTOSPKR AND STANDPIPE). A sign must also show the pressure required at the inlets to deliver the standpipe system demand if over 150 psi. Where an FDC serves multiple buildings, structures, or locations, a sign must be provided indicating the buildings, structures, or locations served.

Section 12.11 requires the installation of signs required by this standard to be verified at system acceptance.

NFPA 20 – For positive displacement pumps, Section 8.4.10 requires a permanently marked weatherproof metal or rigid plastic sign affixed to the system that indicates the required time to achieve the system design pressure. The sign is required for acceptance testing and future periodic testing.

Section 10.1.2.5.2 has a requirement for electrical fire pump systems when multiple pumps serve different areas or portions of the facility. In these applications, an appropriate

sign must be conspicuously attached to each controller indicating the area, zone, or portion of the system served by that pump or pump controller. Section 12.1.3.3.2 has the same requirement for engine-driven controllers.

Section 11.4.2.4 requires a method to avoid overfilling diesel fuel tanks. One method that is allowed is the installation of a permanent sign at the fill point with the tank calibration chart and instructions for the filling procedure, which includes having the person performing the fill operation determine how full the tank is prior to filling and calculate the quantity of fuel that it will take to get the tank to 90 percent of its capacity. Where climatic conditions are such that the sign could be obscured by ice or snow, weathered beyond readability, or otherwise rendered unreadable, the fill procedure and chart can be stored in an office window, lock box, or other location accessible to the person filling the tank.

THE BOTTOM LINE

In summary, the installation of signs is often ignored or thought of as unimportant. However, the need for signs is clear. Failure to provide the required signage can cost valuable time in an emergency and leave the installing contractor liable for damages. Additionally, NFPA 25 requires that many of the required signs be checked during required inspections, and if missing, they must be replaced. Specifically, the Hydraulic Design Information Sign must be replaced if missing. This could result in the installing contractor receiving a telephone call from the property owner asking, “Where’s my sign?” Having another contractor develop a Hydraulic Design Information Sign without the benefit of the as-built drawings can be expensive. No matter what type of system you are installing, make sure you follow all the requirements for proper signage. Don’t make this obvious (and often expensive) mistake. You need to be able to say, “Here is your sign!” n

ABOUT THE AUTHOR: John August Denhardt, P.E., ET, FSFPE, is AFSA’s vice president of engineering and technical services. He is a member of the NFPA 13 Sprinkler Discharge Committee and is a Fellow of SFPE. Denhardt is an NFPA Research Foundation trustee, sits on the University of Maryland (UMD) Department of Fire Protection Engineering’s board of visitors, and is a member of the SFPE board of directors. Denhardt holds a Bachelor of Science degree in fire protection engineering from UMD in College Park.

EDITOR’S NOTE: This article was first published in the January/February 2017 and March/April 2017 issues of Sprinkler Age . In 2023, the article was updated and published in the September/October 2023 issue. As one of the most-read Sprinkler Age articles to date, it was revised in 2025 to reflect the latest editions of the applicable standards.

IMPORTANT NOTICE: The article and its content do not represent a Formal Interpretation issued pursuant to NFPA Regulations. Any opinion expressed is the personal opinion of the author and presenter and does not necessarily represent the official position of the NFPA and its Technical Committee.

APPRENTICE

FIRE

CUSTOMIZED

Why Tamper with Your Time?

Ames Integrated Tamper Switch Eliminates Install Delays

Now Available Pre-Installed on Backflow Assemblies

Select Ames backflow preventers now come with factory integrated, UL/FM certified, fire tamper detection. This will eliminate the hand-assembly, manual field installations, and opportunity for error associated with installing aftermarket tamper (supervisory) switches on existing backflow preventers.

How to Buy

SOME THINGS TO THINK ABOUT PLUS NFPA 13 UPDATES

By Dr. Paul D. Flannigan

One of the things that always is a concern for me, especially when doing retrofits or tenant fit-outs, is the use of flexible hose assemblies, or as we tend to group them, flex-drops. Depending on the length, a flex-drop could have a serious increase in equivalent length when using them to relocate a sprinkler head. A 60” flex-drop could have an added equivalent length of 25’ or even more depending on manufacturer. However, a couple of sprinkler manufacturers (not that many left) such as Viking and Victaulic, have a flex-drop with a sprinkler head fully attached listed with an equivalent length of zero feet. This goes beyond anything that I think hydraulics and friction loss should be, but the entire assembly has been calibrated as a 5.6 k-factor assembly. No need to add any equivalent feet. Definitely eases calculation issues with retro-fits and fit-outs.

NFPA is getting a bit in the weeds when it comes to qualified, experienced, knowledgeable, trained, or certified labels when identifying individuals who design, install, services, or otherwise work on fire protection systems. For example, NFPA 13 (2025) now states that systems shall require design and installation by knowledgeable and trained personnel. My understanding, as I have been told by a committee member, is that NFPA is not intending to set the parameters of what certification means. That is up to legislatures and authorities to determine exactly who is qualified to work on fire protection systems and what certifications they should have. So, you will probably see wording changes in other standards as well.

In NFPA 13 (2025), in a retirement home for example, a common area lounge/kitchen/laundry, could also meet the definition of a “dwelling” unit and be designed according to dwelling unit criteria. These common areas typically were considered light hazard. Maybe this is a stretch, but it might give a designer some ways of saving a bit on costs.

In NFPA 13 (2025) instead of having extra sprinklers for obstructions, they are called supplemental sprinklers, a sprinkler that is installed below an obstruction. What is new about this is when the piping does not follow overhead sizing patterns, four sprinklers maximum must be calculated at the obstruction footprint with no balancing.

A word of caution, the new NFPA 13 (2025) has a ton of changes for sloped ceilings, obstructions, sprinkler restrictions for certain ceiling heights, discharge adjustments, and miscellaneous storage. DO NOT rely on your usual design protocols using the 2019 or 2022 editions. Read and re-read the 2025 edition to make sure you are designing properly.

Something that blew my mind and is a bit contrary to what I have been told for decades is a change in the system area limitations for system coverage. We have always been used to a maximum area of coverage of a system (off of one control valve) to be 52,000 sq. ft. for light and ordinary hazards. That has changed. Check this out. A light hazard system, which is wet, and that has electrical supervision, can now be up to 78,000 sq. ft. This is the rub as I see it and I have not been given a suitable explanation for the change. The system area limitations have historically (and more related to pipe schedule size), limited in size to avoid having too much of a system out of service or a fire under the control of one valve. The other practical issue as I see it is when sprinkler technicians need to work on a system, now they have potentially 78,000 sq. ft. of system to drain and re-fill and re-pressurize if on a fire pump. How many hours of labor have been added to services calls and other. I am not a fan of this change and believe it was not aligned with the practical aspects of servicing a system. But that is just my opinion. Another perplexing problem with the increase in the size of the protection area is the arbitrary, again,

my opinion, increase to 78,000 sq. ft. Coincidently that is 50% more than 52,000. Was there research and testing that supported this? And here is another rub. Possible, but not sure how likely, because of the increased distance of the most hydraulically remote area, there could be increases in pipe sizing, especially with weak water supplies. That means increased material costs and labor costs for installation. Again, not buying the logic behind this change or the explanations I have been provided. Your thoughts?

Just when or if you thought you had all of the elevator requirements straight in your head, you often had an elevator inspector have his own ideas on how things should be done. I upgraded sprinklers for two elevators and two elevator machine rooms in the same building, phased in at different times. The first was done and approved by the elevator inspector. The second was done exactly the same and not approved by a different elevator inspector. I say this because NFPA 13 (2025) now has new requirements for elevators and elevator machine rooms. Sprinklers can be omitted from elevator machine rooms, machinery spaces, control rooms, control spaces, elevator pits, and hoistways if the elevator is non-combustible rated (they all should be now) and there are no flammable hydraulic fluids. Check out those requirements in detail.

You are probably aware of the change in density curves in the 2022 edition of NFPA 13. That remains in the 2025 edition. Something I do like is how the 2025 edition addresses sprinklers in alcoves where filing cabinets or storage lockers might be located. For an alcove, light hazard occupancy, maximum 10’ ceiling, 50 sq. ft., an 18” clearance does not have to be maintained from the files or storage. Only a 1” clearance. This is similar to small closets housing mechanical equipment no larger than 400 cubic feet where it can be impossible to locate a head. In that situation, a single sprinkler can be installed without regard to obstructions or minimum distances to walls. Both make sense.

Just in case you didn’t know, check out Annex G in NFPA 25 (2023). The Annex stipulates tag colors for inspections and what they mean. Green tag - no deficiencies, Yellow tag – noncritical deficiencies found, Orange tag – critical deficiencies found, Red tag – impairments found, and a White tag –correction/repair tag. Several states follow this standard for inspection tags, and many do not. I would suspect, and hope, that with the adoption of NFPA 25, authorities would require this standard in all jurisdictions. Just makes sense.

About the author: Dr. Paul D. Flannigan has been involved in fire protection for over 50 years, has served in leadership roles with many fire protection companies, with the American Society of Certified Technicians, and is currently the Vice Chair of the NICET Board of Governors. Dr. Flannigan continues to work as a private fire protection consultant, enjoys providing training, teaches at seminars and conferences when he can, and also works with several fire protection companies around the US, remaining active in the industry on a daily basis. Dr. Flannigan also does research on leadership and earned his Doctoral degree in Leadership from the American College of Education.

SuStaining Corporate SponSorShip opportunitieS

Who is ASCET?

We are the only professional organization specifically for, and operated by, engineering technicians and technology’s. We value and encourage certification, training and education by our members and believe strongly in the ‘Engineering Team’ concept.

Why become a Sustaining Corporate Sponsor?

We have a codependent relationship. You provide us with financial support, in return, we provide you with positive Public relations, training opportunities, and a boost in business. As a Sustaining Corporate Sponsor, we offer to you:

Brand Visibility

Your company Logo and information will be displayed on our organizations website and in our monthly membership Informational magazine, THE ASCET INFORMER (Sent by via email up 6 times per year).

Recognition

Throughout the year your company will be recognized In THE ASCET INFORMER as a sponsor, with the opportunity to have featured articles and advertisements that promoting your organization. THE ASCET INFORMER is distributed to our members. Providing valuable exposure will help enhance your company’s visibility, presence and awareness of your company within our community.

Annual Conference & Expo Discounts

You will receive first opportunity to be an exhibitor, at our, Annual Conference and Expo (ACE). At the conference, you will receive recognition as a Sustaining Corporate Sponsor In the conference Digital program. The cost of becoming a Sustaining Corporate Sponsor will pay for itself just by participating in the Annual conference and Expo by:

• Getting in front of your target audience

• Lead Generation and New Contacts

• Getting your Brand Noticed

• Giving the attendees a ‘taste’ of your business

SuStaining Corporate SponSorShip opportunitieS

BRONZE - $500.00

1 Year ASCET National Membership & Corporate Sponsorship, & logo on ASCET’s Website (www. ascet.org) with Hyperlink.

SILVER- $1,000.00 (Plus Bronze Level)

Promotion on all Social Media Platforms, Logo & Feature articles In THE ASCET INFORMER The digital magazine, & $15O.OO of vour sponsorship donated to ASCET’s Scholarship Fund.

GOLD - $1,500.00 (Plus Silver Level)

25% off 8’ Vendor Booth at the ACE (The year you sponsor) for two people, Logo in Pre-Event Promotional Emails & in our Annual Conference and Expo (ACE), Digital magazines, & $200.00 of your sponsorship is donated to the ASCET’s Scholarship Fund.

PLATINUM - $2,000.00 (Plus Gold Level)

FREE 8’ Vendor Booth WITH POWER at the ACE {The year you sponsor) for two people, PAID Parking, & $250.00 of your sponsorship is donated to the ASCET’s Scholarship Fund.

There will be a special distinction between each tier on the website, scrolling banner and sponsorship pages

PLEASE NOTE: Contributions to section 501 (c(6)) disorganization are not deducible as charitable contributions on donor’s federal income tax return. They may be deductible as trade or business expenses if ordinary and necessary in the conduct of the taxpayer’s business.

Ready to Become a Sustaining Corporate Sponsor?

Our Sponsorship program is the least expensive, but greatest value, that you will find In the industry. Please visit www.ascet.org and select “’Join Now,”’ then choose “Sustaining Corporate Sponsor,” and follow the prompts. If you have any questions. Please contact Kyle Watterworth, Sponsorship Chairman at sponsorship@ascet.org

Board of Gover nors

NICET's Board of Governors (BoG) meets twice each year to set strategic goals and establish operating policies for NICET. Board members serve in a volunteer capacity. Seven are knowledgeable in the fields of engineering and engineering technology, while the eighth represents the general public

Board members are selected by a nominating committee and confirmed by the Board. It is a multifaceted process that includes vacancy announcements issued by NICET, the Interest Groups of the National Society of Professional Engineers (NSPE) and other engineering societies including the American Society of Certified Engineering Technicians Self-nominations by NICET certificants and NSPE members are also accepted A term on the Board lasts three years, and Board members may serve up to two consecutive terms. , , , Chair Elect Austin, TX

https://www.nicet.org/about-us/board-of-governors/

Please contact the marketing director if you have articles or advertisements you would like to see published in an upcoming issue of The ASCET Informer magazine. The publication is scheduled to be released every other month. If you have any content to submit or would like to update Information, in The ASCET Informer magazine, please send it to marketing@ascet.org

I am eager to hear from all of you and am excited about the possibility of featuring your contributions in our magazine.

Thank You

Jamie Redden marketing@ascet.org

You can also Find us on: www.ASCET.org Facebook -@ASCETNational LinkedIN -ASCET Social Media

THE ASCET STUDENT OF ENGINEERING TECHNICIAN / TECHNOLOGY CASH GRANT

This grant - formerly known as the ASCET Student of Engineering Technician /Technology Cash Grant small cash grant - is designated for current or incoming post-secondary students attending an ABET accredited college, university, junior college or vocational technology school who are, or will be, majoring in a field within engineering technology. The grant was originally suggested by students and faculty advisors who recommended that a grant be awarded to deserving students and that this award carry as few restrictions as possible. The award shall be in the amount of $1,200.00 to be used to offset the cost of educational expenses as desired.

QUALIFICATIONS

• Be either a student, certified, regular or registered member of ASCET OR,

• Be a High School senior in the last five months of the academic year who will be enrolled in an Engineering Technology curriculum no later than six (6) months following selection of the award.

• By achieving passing grades in their present curriculum.

SELECTION AND AWARD

All applications are reviewed by the Financial Aid Committee which also selects the recipients. Recipients will be notified in July and checks will be mailed to the recipients in September. Award checks will be issued directly to the students upon notification and verification that they are enrolled in an Engineering Technology curriculum in an institute of higher learning.

INSTRUCTIONS FOR APPLICATION

• Complete the APPLICATION FORM which applies to you (ASCET Member or High School Student).

• Attach at least one (1) LETTER OF RECOMMENDATION from a personal acquaintance, faculty member or employer outlining motivation, progress, outstanding achievements, and an evaluation of your potential in the field of Engineering Technology.

• Attach a copy of your TRANSCRIPT.

• Be sure all documents are mailed in sufficient time for receipt by the ASCET Office by January 30 of each..

• NOTE: Failure to complete or include any items in the application package may be grounds for rejection unless the committee, at its discretion, is able to notify you of the incomplete or omitted items, and such items are submitted within the evaluation period time schedule.

• This package should contain:

1. (A)Application Form ASCET Member or (B)Application Form High School Senior

2. Recommendation Letter

NOTE: Only Engineering Technology students qualify for this grant, not those seeking an engineering degree. For ENGINEERING scholarship information we suggest you contact the National Society of Professional Engineers for their scholarship requirements. Please contact: NSPE Scholarship Division, Educational Foundation; NSPE; 1420 King Street, Alexandria, VA 22314-2715; (703/684-2858)

THE ASCET STUDENT OF ENGINEERING TECHNICIAN/TECHNOLOGY CASH GRANT

A. ASCET Member APPLICANT

Name___________________________________________________Telephone ( )_________________________

Mailing Address____________________________________________________________________

street ________________________________ city ________________state _________zip_______________

What is your membership category? ______________________________________________________________

If a student member, list student chapter______________________________________

Faculty Advisor____________________________________________________________________________

What institution do you attend?_________________________________________________________

Address_________________________________________________________________________________

street ________________________________ city ________________state _________zip_______________

Are you a full time or part time student?

Are you receiving other financial aid? yes or no If yes,in what amount? $_____________

Why are you applying for this grant?__________________________________________________________________

__________

ATTACH A COPY OF YOUR TRANSCRIPT TO THIS APPLICATION. I here by certify that the answers given in this application are true and accurate.

Date______________Your signature__________________________________

I attest to the applicant's passing grades.

Date______________Signature______________________________________ FacultyAdvisor/Instructor

THE ASCET STUDENT OF ENGINEERING TECHNICIAN/TECHNOLOGY CASH GRANT

B. GRANT APPLICANT

Name___________________________________________________Telephone( )_________________________

Mailing Address____________________________________________________________________

street ________________________________ city ________________state _________zip_______________

What is your membership category? ______________________________________________________________

If a student member, list student chapter______________________________________

Faculty Advisor____________________________________________________________________________

What institution do you attend?_________________________________________________________

Address_________________________________________________________________________________

street ________________________________ city ________________state _________zip_______________

Are you a full time or part time student?

Are you receiving other financial aid? yes or no If yes,in what amount? $_____________

Why are you applying for this grant?__________________________________________________________________

__________

ATTACH A COPY OF YOUR TRANSCRIPT TO THIS APPLICATION. I here by certify that the answers given in this application are true and accurate.

Date______________Your signature__________________________________

I attest to the applicant's passing grades.

Date______________Signature______________________________________ FacultyAdvisor/Instructor

THE ASCET STUDENT OF ENGINEERING TECHNICIAN/TECHNOLOGY CASH GRANT

(Recommendation by personal acquaintance, faculty member, or employer to include an outline of motivation, progress, outstanding achievements, and your opinion of applicant's potential in the field of Engineering Technology) I recommend ___________________________ as a recipient of THE ASCET STUDENT OF ENGINEERING Applicant’s name.

TECHNICIAN / TECHNOLOGY CASH GRANT:

Name (please print)__________________________________________________

Address _________________________________________________________________________________________

Date__________________________

Do not write below this line For committee use only. Date received ________________

Application form Recommendation Transcript

Pressure-Tru® Field Adjustable ZW5000/5004 Series Pressure Reducing Valve

Less Force, More Flow

ZW5000

Pressure-Tru

Field Adjustable

Pressure Reducing Hose Valve

Our Pressure-Tru ZW5000/5004 Series Pressure Reducing Valve fits in tight spaces, takes only 9 ft lb of torque to field adjust, and delivers optimal flow performance – making it ideal for any application, retrofit or new.

For the Contractor: The Size of It

• Compact design fits in tighter spaces

• Angle or inline globe body comes with grooved or threaded connections

• Tamper-proof shield (standard) drops out for easy start-up adjustments in the field for new construction

• Lightweight aluminum adjusting rod aids field adjustments

ZW5000 vs. Competitor Angle Body, 250 GPM

The ZW5000 provides up to 30 psi in higher residual outlet pressure than competitor models.

For the Fire Ground Force: The Ease of It

• Low torque takes only 9 ft lb of force to field adjust under flow or no-flow conditions

• Tamper proof shield (standard) breaks away for on-the-fly adjustments in cases of emergency

• Larger handwheel ensures easy operation.

PATENT PENDING

ZW5004

Pressure-Tru

Field Adjustable

Pressure Reducing

Floor Control Valve

For Everyone: More Flow Performance

• Widest range of flow performance satisfies virtually any application or replacement of any competitor’s valve

• Valve regulates pressure under both flow and no-flow conditions

• Tamper resistant integral supervisory switch comes standard on all floor control valves

• UL® and C-UL® Listed meets standards

Announcement below for our upcoming training classes. Fire Alarm Systems Training classes at Cape Fear Community College will start MAY 5 2025 and registration link is below. Our courses are self-paced and offered online to anyone with an Internet connection. The registration fee for the four-month course is $185 (USD) and awards 14.4 CEU’s. NICET awards 1 CPD point for 0.1 CEU (10 points per CEU). Those who are using the course to obtain NICET Continuing Personal Development (CPD) points will max out the category “Additional Education” and earn 72 points. Click Here https://cfcc-register.fundfive.com/filtered/course/FAST to sign up for the class and select "Alarms 101" or "Alarms 102."

Alarms 101

This course is designed for those individuals who are in the fire alarm industry and will focus on fundamentals. Students will learn basic electrical theory and understand resistance, voltage and current. Individuals currently in the fire alarm industry would benefit from the concepts and theories, which will be built upon in the Alarms 102 course. Students will also acquire a basic understanding of the physics involved in the chemical reaction and the by-products of fire. Students will learn basic electrical workmanship and installation methods of fire alarm equipment and devices. The student will gain an understanding of the requirements of codes and standards that govern fire alarm systems and installations. (14.4 CEU/45 CPD awarded) Students will become familiar with NFPA 72, National Fire Alarm and Signaling Code, and NFPA 70, the National Electric Code (NEC). These references are consistent with NICET’s allowable references for Level I and II Fire Alarm Systems exam(s).

Alarms 102

This course is designed for individuals who are fire alarm technicians or have intermediate experience in the fire alarm industry and will focus on application and design. The subject matter will build upon concepts addressing the behavior and generation of smoke, the combustion process and the requirements of codes and standards that govern fire alarm systems and installations. (14.4 CEU/45 CPD awarded)

Students will become familiar with NFPA 72, National Fire Alarm and Signaling Code, NFPA 70, the National Electric Code (NEC), NFPA 101, the Life Safety Code, and the International Building (IBC). These references are consistent with NICET’s allowable references for Level III and IV Fire Alarm Systems exam(s).

Please contact me for more information or Click Here https://cfcc.edu/job-training/construction-careers/fire-alarm-systems-training/ to visit our web page for complete course information. We have scholarships available. Please see the next 4 pages of The ASCET Informer for application.

The Cape Fear Community College Foundation has established a scholarship for our Alarms 101 and Alarms 102 courses and NICET exam reimbursement. The John E. Lucas Memorial Scholarship Fund will enhance the quality of life in our community by cultivating Life Safety (Fire Alarm) Engineering Technicians and promoting industry certification by the National Institute for Certification in Engineering Technologies (NICET). Cape Fear Community College scholarships come from the reimbursement for continuing education courses. CFCC does not award scholarship funds before enrollment or tuition payment for a course.

John E. Lucas Memorial Scholarship Application

Continuing Education Courses – Alarms 101, Alarms 102, &

NICET Exam Reimbursement

Please read this important information before completing your scholarship application:

The John E. Lucas Memorial Scholarship Fund will enhance the quality of life in our community by cultivating Life Safety (Fire Alarm) Engineering Technicians and promoting industry certification by the National Institute for Certification in Engineering Technologies (NICET).

Important Note: At Cape Fear Community College, scholarships come in the form of a reimbursement of expenses for continuing education courses. CFCC does not award scholarship funds prior to enrollment or payment of tuition for a course. If selected, you will receive the scholarship funds upon meeting the eligibility requirements and providing this application along with proof of participation in the exam.

Students who receive scholarship funds will be asked to submit a thank‐you letter to their scholarship donor(s) prior to receiving scholarship funds.

Depending on the scholarship awarded, students may also be asked to attend a scholarship recognition event.

Students will be notified of the committee’s decision regarding scholarships through their campus e‐mail accounts and/or program director.

Eligibility Requirements:

o Applicant shall be considered without regard to race, religion, creed, national origin, age, or handicap.

o Applicant must not be in a suspension or revocation status by NICET

o Applicant must fill out this application and sign NICET Code of Ethics (below)

Scholarship Overview – awarded on a first come, first serve basis once eligibility has been confirmed:

Alarms 101 – 3 seats per semester (9 total per year) at $185 Each

Alarms 102 – 3 seats per year (3 total) at $185 Each

NICET Exam – 2 per semester (6 total) at $125 Each 2 options:

Fire Alarm Systems [FAS] Level 1

Inspection & Testing of Fire Alarm Systems [I&TFAS] Level 1

Student’s Full Name:

CFCC Student ID #

Street or Mailing Address:

City, State, Zip:

County of Residence:

Phone: ______(Cell) _______(W) ________(Home)

Personal Email Address:

CFCC Email Address:

Date of Birth: ______/______/________ Gender: Male Female

Program of Study:

Please list the program of study or individual class(es) within CFCC Continuing Education for which you are requesting reimbursement through scholarship funds: Alarms 101 Alarms 102 NICET Exam

Other: (Please write in)

Anticipated date of completion for class(es):

Educational/Work History

High School Attended:___________________________________ Graduation year:

College or University Attended: Graduation year:

Highest Degree Attained:

History

Please check all that apply to you:

I am currently unemployed. (Beginning date of unemployment: _____________)

I am a military veteran

I am a member of the NC National Guard

Continuing Education Scholarships are distributed as a reimbursement for educational expenses after completion of your class or program of study. Please indicate the total amount you have spent on your current program of study at CFCC:

NICET Exam Fee: $ (Must provide NICET Examination Test Report generated by Pearson Vue to prove they participated in the exam. Passing the exam is not required, only participation.)

By signing this scholarship pledge form, I agree to sit for the Fire Alarm Systems (FAS) or Inspection & Testing of Fire Alarm Systems (I&TFAS) exam and become certified by NICET upon completion of the training course. I also pledge to abide by the terms and guidelines of the NICET Code of Ethics1 below.

NICET Code of Ethics

NICET‐certified engineering technicians and technologists recognize that the services they render have a significant impact on the quality of life for everyone. As they perform their duties and responsibilities on behalf of the public, employers, and clients, they shall demonstrate personal integrity and competence.

Accordingly, certificants shall:

1. Have due regard for the physical environment and for public safety, health, and well being. If their judgment is overruled under circumstances where the safety, health, property, or welfare of the public may be endangered, they shall notify their employer, client, and such other authority as may be appropriate. An employee shall initially express those concerns to the employer.

2. Undertake only those assignments for which they are competent by way of their education, training, and experience.

3. Perform their duties in an efficient and competent manner with fidelity and honesty.

4. Admit and accept their own errors when proven wrong and never distort nor alter the facts in an attempt to justify their decisions.

5. Avoid conflicts of interest whenever possible. When unavoidable, they shall disclose to their employer or client, in writing, any action that might create the appearance of a conflict of interest.

6. Avoid receiving and granting bribery in all its forms.

7. Strive to maintain their proficiency by updating their technical knowledge and skills in engineering technology.