Curing labour pains

A look at labour-saving technology in development for vegetable row crops | 12

Picturing peaches

A robotic solution to crop monitoring | 9

The evolution of PYO How today’s farms are coping with the changing consumer | 26

Curing labour pains

A look at labour-saving technology in development for vegetable row crops | 12

Picturing peaches

A robotic solution to crop monitoring | 9

The evolution of PYO How today’s farms are coping with the changing consumer | 26

CANADA’S PREMIER HORTICULTURAL EVENT

FEBRUARY 20–21, 2019

Scotiabank Convention Centre, Niagara Falls, Ontario

B.C.-based organization is helping vegetable farmers create more domestic seed availability.

Picturing peaches

Georgia researchers work to develop a robotic solution for monitoring highdensity peach orchards.

BY BIPUL BISWAS

Curing labour pains with robotics

A look at laboursaving techonolgy in development for use in vegetable fields.

BY JENNIFER PAIGE

The evolution of PYO and how today’s farms are coping with the ever-changing consumer. BY

CATHY BARTOLIC

Being born and raised in what is referred to as the “Wheat City”, it is safe to say my love affair with agriculture began early. Brandon, Manitoba is a prairie town with much of its accomplishment coming on the backs of farmers. I later became further entrenched in the industry as an agriculture journalist, covering everything from the cattle grazing systems to the development of Direct Farm Manitoba, a member owned cooperative that works to support the small-scale farm sector.

After a few years of covering the agriculture industry in Manitoba I hopped the fence to Ontario and began a, shall we say, more ‘fruitful’ endeavour. Now, after a year in the position of associate editor with Fruit and Vegetable magazine, I am excited to be taking on the role of editor.

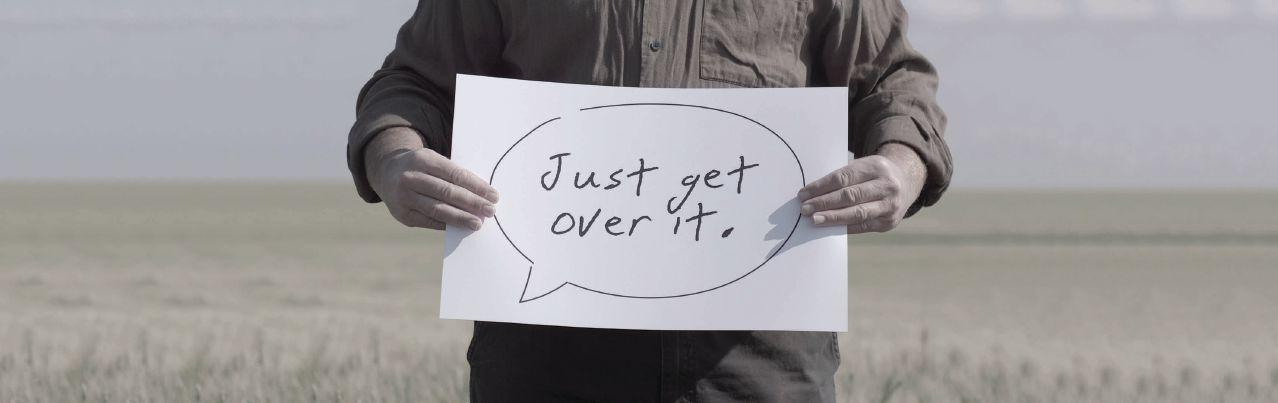

Much of my first week as editor was spent enthralled in an evergrowing pile of emails trying to educate myself on the industry’s most pressing issues. Headline

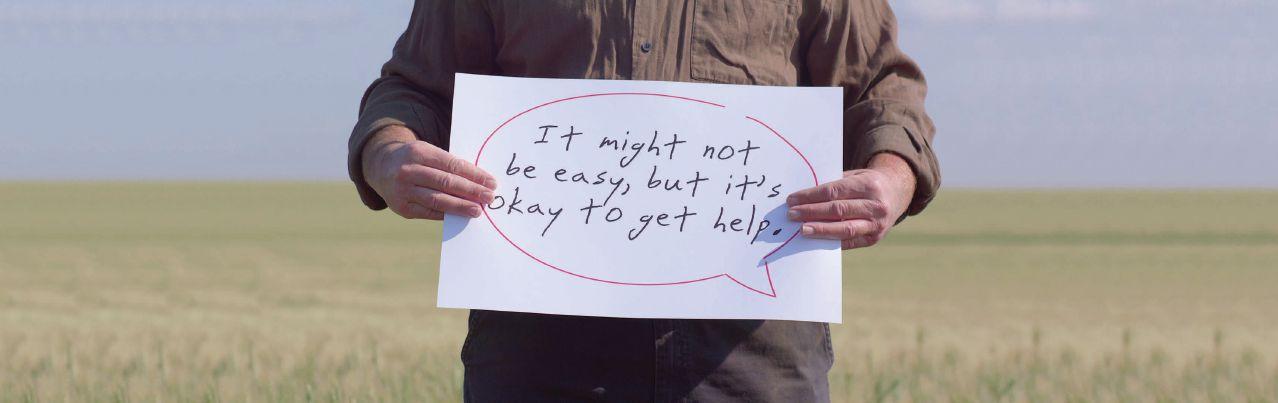

many across the province, it is a prime example of the consistently changing policy being delivered by various controlling bodies to farmers across the country. In my opinion, this is one of the greatest challenges when it comes to fueling farms with skilled workers. It also leads me to wonder, how are growers coping with these everchanging policies and regulations? And, how can F&V magazine assist in navigating these stormy-HR waters?

In this issue, we explore the labour issue from the angle of technology and automation. On page 12 you will find a profile of Nexus Robotics, a Canadian-born startup whose latest advancements aim to help vegetable farmers fill the tedious role of weeding vegetable beds.

As I move forward in my new role as editor I hope to continue the conversation of farm labour and seek out ways F&V magazine can fill its pages with relevant and engaging articles that offer growers

How are growers coping with these ever-changing policies?

after headline discussing labour shortages, rights, regulations and commentary continued to pour across my desk.

In early October, the government of Ontario outlined its plans to repeal amendments to Bill 148, which was introduced in 2017 and touches on minimum wage and various employment standards (take a look at page 6 for the details). And while this announcement comes as a relief to

useful industry insights and practical takeaways.

Another new addition I would also like to introduce another new face here at F&V , Amanda McCracken. Amanda is the new account manager for the magazine and joins the publication after eight years of running her own small-scale vegetable farm in Norfolk county, Ont. Check out Amanda’s details on page 25.•

JENNIFER PAIGE jpaige@annexbusinessmedia.com 416-305-4840

Advertising Manager AMANDA MCCRACKEN amccracken@annexbusinessmedia. com 226-931-5095 • 888-599-2228 ext. 266

Account Coordinator MARY BURNIE mburnie@annexbusinessmedia.com 519-429-5175 • 888-599-2228 ext. 234

Media Designer CURTIS MARTIN

Circulation Manager AASHISH SHARMA asharma@annexbusinessmedia.com 416-442-5600 ext 5206

VP Production/Group Publisher DIANE KLEER dkleer@annexbusinessmedia.com

President/CEO MIKE FREDERICKS

Publication Mail Agreement #40065710

Printed in Canada ISSN 1488-7959

Fruit & Vegetable Magazine is published five times a year (January/

Roshni Thava rthava@annexbusinessmedia.com

Tel: (416) 442-5600 ext. 3555 Fax: (416) 510-6875 or (416) 442-2191

Mail: 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1 Occasionally, Fruit & Vegetable Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2018 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

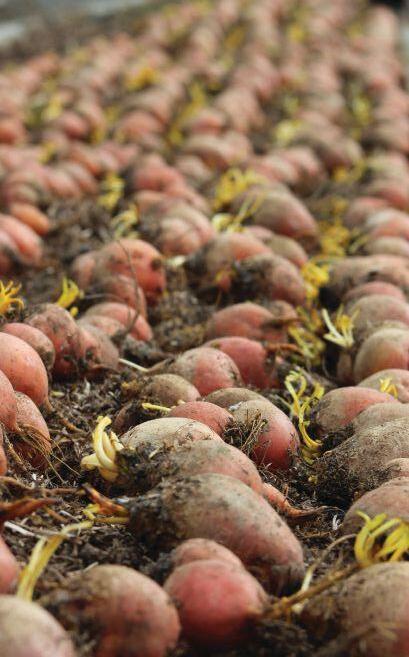

We’ll let our product do the talking. Titan® Emesto® is the number one potato seed-piece treatment used by Canadian potato growers. The unique red formulation is easy to apply and see. It protects against the broadest spectrum of insects plus all major seed-borne diseases, including rhizoctonia and silver scurf. It also provides two modes of action against fusarium, even current resistant strains. It takes a lot of confidence to grow a healthy potato crop season after season and we’re proud Canadian potato growers keep choosing Titan Emesto to do it.

Learn more at TitanEmesto.ca

The Canadian Grapevine Certification Network (CGCN) recently received an $8.4 million investment from Agriculture and Agri-Food Canada. The CGCN is a national not-for-profit corporation that was founded by the B.C. Wine Grape Council, Grape Growers of Ontario, the Quebec Wine Council and the Grape Growers Association of Nova Scotia in 2017.

“This is the first time the four grape growing provinces have joined forces to form the Canadian Grape and

Wine Science Cluster. Research plays an important role in the continuous enhancement of the quality of grapes and wine and the reduction of the environmental footprint of the entire production cycle,” said Hans Buchler, chair of the CGCN. This research investment, which includes up to an additional $3.7 million from industry contributions, will help growers better protect their crops, test new vine varieties and analyze growing practices that are better for the environment.

In late October the government of Ontario proposed the Making Ontario Open for Business Act, which would repeal amendments made by the Fair Workplaces, Better Jobs Act, 2017 (Bill 148)

If the legislation passes, the amendments would include alterations to the Employment Standards Act, 2000 (ESA), including keeping the minimum wage at $14 on Jan. 1, 2019, not rolling back

any previous minimum wage increase, and establishing a 33-month pause in minimum wage increases with annual increases to the minimum wage, tied to inflation, to restart in 2020.

The Ontario Fruit and Vegetable Growers’ Association (OFVGA) welcomes the announcement. Since its introduction in 2017, Bill 148 has been a significant concern for Ontario’s farmers.

Labour represent a substantial portion of the cost required to produce quality fresh fruits and vegetables for Ontario consumers and export markets. The increase from $11.60/ hour to $14/hour on Jan. 1, 2018 was a significant blow to the competitiveness of the sector, which competes with low cost imported produce.

“The impact of Bill 148 is not yet fully known, but we have

seen some farmers exit the business, and there will likely be more in the future,” said Ken Forth, chair of the OFVGA Labour Section and the Labour Issues Co-ordinating Committee. “Pausing minimum wage at $14 until 2020 will at least allow farmers to adapt their businesses to current labour costs and prepare for future increases, meaning more farmers can afford to remain in business.”

1,100 jobs were vacant in 2014, which cost the industry

$240 MILLION

people were employed by the field fruit and vegetable industry in 2014

33% 36%

44%

of field fruit and vegetable producers are experiencing a worker shortage reported lost sales due to lack of workers delayed or cancelled expansion plans due to lack of workers

60% 11% OVER THE NEXT DECADE…

2,400

Source: Canadian Agri-Food Human Resources Council of the industry’s workforce is located in Ontario

21,000 of the industry’s workforce are foreign workers additional jobs will be required The number of domestic workers will decrease by

1,100

ABOVE

Hortau’s irrigation management scheduling ensures there is enough water available to meet the crop water demands, even during a heat spell.

Quebec-based firm Hortau has developed a smart farming platform for agriculture that allows growers to detect crop stress, optimize growth, and reduce water and energy use.

The technology combines real-time soil tension sensor data with a simple-to-use mobile platform, allowing growers to anticipate the water needs of the crop and manage irrigation accordingly.

Most vegetable crops require a uniform supply of moisture throughout the growing season. The average rainfall in Ontario is 70 mm/month during the growing season. This provides only 65 per cent of the water needed for optimum yield.

This platform’s irrigation management scheduling ensures there is enough water available to meet the crop water demands, even during a heat spell. This technology is already being used in places like California, where the conservation of water is critical for growers.

“The reality is, our farmers are facing tougher challenges than ever before as they work to feed a growing population with fewer resources,” said Jocelyn Boudreau, chief executive officer and co-founder of Hortau. “We know our products make a difference, reducing water use by 25 per cent while increasing yields.”

In June, Export Development Canada (EDC) backed the cleantech company with an investment of $7 million.

“We see a lot of potential in Hortau and know there is a demand for their technology around the world as the need to better manage water resources becomes increasingly important,” says Carl Burlock, senior vice president, financing and international growth capital at EDC. Sustainable Development Technology Canada (SDTC) also provided Hortau with funding in the amount of $5.9 million this year for new technology development.

This summer, Manitou introduced an expanded offering of industrial forklifts for the North American market.

A number of diesel machines with eight internal combustion diesel models, as well as four new electric models are now available. With the addition of these 12 new machines, Manitou’s industrial forklift line for North America now includes 12 models in the MI Industrial Forklift Range and 14 models in the ME Industrial Forklift Range.

Eight new diesel-powered industrial forklift models, with lift capacities ranging from 8,000 to 22,026 pounds, offer new medium and high capacity options.

These machines are designed for heavy-duty applications indoors or out. The tires, engine power and robust components sustain intense use in storage, production and distribution industries. The MI 40D, MI 45D, MI 50D, MI 50LD, MI 60D and MI 70D come equipped with a 74-horsepower engine, while the MI 80D and MI 100D have a 114-horsepower engine. All new diesel models have a maximum lift height up to 19-feet, eight-inches. Manitou has also introduced four new electric models to the ME Industrial Forklift Range. The ME 440, ME 445 and ME 450 add greater lift capacities to the line, providing options that can handle 8,047 to 11,000 pounds. All three models feature four wheels, an 80-volt battery, 34-horsepower lifting motor, and maximum lift height of 19-feet, eight-inches. The Manitou ME 315C also joins the ME Range and provides a smaller three-wheeled option. This compact machine can easily maneuver through aisles as narrow as 10-feet, three-inches. It is powered with a 24-volt battery and 11.5-horsepower lifting motor.

For more information, visit: manitou-group.com

BY BIPUL BISWAS, COLLEGE OF AGRICULTURE, FORT VALLEY STATE UNIVERSITY

Researchers at the Fort Valley State University have been working to develop a robotic solution for monitoring high-density peach orchards.

Researchers at the Fort Valley State University have been working to develop a robotic solution for monitoring and spraying peach orchards.

“Plants cannot walk to their doctors or plant researchers to convey that they are sick. So, how can we solve this problem? A monitoring system is the likely solution,” says Bipul Biswas, research professor with the college of agriculture at Fort Valley State University.

Researchers originally thought using UAV (unmanned aerial vehicle) to capture images of the peach trees may be the answer. However, in order to be effective, close-up photos of individual trees are required, not the canopy of the total orchard. Unfortunately, when the UAV was run it was unable to get close enough to the

trees to collect the proper images.

“We thought maybe I can buy a golf cart and drive through the orchard with a video camera. But that wasn’t possible either because this was a high-density peach orchard with intercropping. There wasn’t enough room,” Biswas says. “I then talked to the NASA scientist who developed a UAV that can count the number of apples on a tree. However, that wouldn’t work because you need to take the pictures from the same location every time so you can compare with the next picture. You can’t take them from different directions on different days,” Biswas says.

Researchers concluded they would need to develop a robot specific to their needs. The robot would be outfitted with cameras that can follow GPS coordinates.

The AgBot is 25-inches in height, 25-inches wide and 45-inches in length. It has six wheels with four-inch clearance from the ground. With four Logitech C922x Pro Stream Webcams, the robot is capable of capturing high-resolution pictures from exactly the same position every time.

With a 12-volt battery, the robot operates six-to-eight hours when fully charged and will return automatically to a charger, when required.

Four pictures are captured of each tree, the upper and lower for each side. The sequentially arranged photos can be used to monitor the health condition of each tree for biotic or abiotic stresses.

The robot is programmed to follow a red line throughout the orchard, pausing to take photos every time it hits a blue spot, as placed by the operator.

The AgBot can also be used to spray in the orchard for controlling weeds and pests as required. When the camera detects or ‘sees’ a tree it is triggered to spray.

“There’s a minimum of four sprays you need: Before flowering, after flowering but before the fruit comes, when the fruit comes and after harvesting. This robot can help to do that,” Biswas says.

The Agbot is capable of carrying a few hundred pounds, can be driven automatically or manually. •

A number of B.C.-based organizations are working together to develop shared resources for both new entrants, small seed businesses and exisiting ventures.

BY RONDA PAYNE

Canada currently imports millions of dollars’ worth of seed every year, despite mild winters in the southwest of B.C. that position the province as a viable climate for seed production.

“Seed is mainly imported in B.C.,” explains Shauna MacKinnon, program co-ordinator with FarmFolk CityFolk, a not-for-profit organization that is leading a provincial project that is aimed at increasing seed production capacity and customer base for seed farmers. “We’re quite dependent on imported seed for farmers. We’ve been working with the B.C. Seed Initiative [the Bauta Family Initiative on Canadian Seed Security (BFICSS)] for over 10 years. It’s our third year of B.C. seed trials with the University of British Columbia (UBC) Farm. And, we also work with about 25 other farms across B.C. We have an opportunity here.”

There are currently 15 operating seed companies within the province of B.C., including co-operatives. There are also a number to community seed initiatives, including 20 seed libraries, and a number of post-secondary institutions that are active in seed trails and processing.

Together, the BFICSS, FarmFolk CityFolk, the B.C. Eco Seed Co-op, and UBC Farm are working with 75 different seed strains of 15 different vegetables, including spinach, beets and kale.

Government support

efficiently and affordably process seed.

“The mobile seed unit is a unique shared infrastructure project which arose from the seed-grower feedback that without proper equipment, it was hard to scale up production,” said Chris Thoreau, B.C. seed security program co-ordinator with FarmFolk CityFolk in a news release. “The mobile unit will provide seed growers with several seed-cleaning tools to help them scale up production and processing capacity. If proven effective, the unit can act as a model for permanent seed-cleaning facilities at strategic sites across B.C. Further, the unit will be an effective outreach tool at agricultural events and conferences around B.C.”

Mel Sylvestre, UBC farm seed hub co-ordinator and B.C. Eco Seed Co-op member, adds that as a small-scale seed producer, who also grows fresh market crops, having access to a mobile seedprocessing unit will help increase production capacity.

In October, both the provincial and federal governments demonstrated their support for the growth of a B.C. seed industry with $100,000 in funding for FarmFolk CityFolk through the Canadian Ag Partnership.

With the help of the government funding, FarmFolk CityFolk will continue to develop shared resources for both new entrants and small seed business as well as aiding existing seed ventures to expand their seed production skills through training opportunities.

The funding will also allow for the development of a mobile seed-processing unit to help small- and mid-scale seed farmers

ABOVE

“Many of the pieces of equipment needed to clean seeds efficiently are too expensive or hard to secure at our scale. The mobile seed-processing unit will allow us to grow larger quantities of seed crops without having to upgrade our current processing setup,” Sylvestre says. “Seed production is an emerging sector in B.C. and we still have so much to learn in order to develop the right techniques and processes adapted to our regions and scales. For that reason, I am looking forward to the educational opportunity offered through this program.”

For many contemplating producing seed, one of the first questions isn’t how to do it, but how to sell seed and who to sell it to.

“We are doing market research on the market for seed in B.C. today,” MacKinnon notes. “Seedy Saturday and Sunday events are one source for sales, with many events listed online. This year, there are about 50 of these events across B.C.”

The second route to market is to join and sell seed through the

Shauna MacKinnon is a program co-ordinator with FarmFolk CityFolk.

Golden beets laid out at Local Harvest Market in Chilliwack, B.C., to select the best roots for a seed crop.

B.C. Eco Seed Co-op, which can be accessed online.

The B.C. Seed Gathering is a biannual event, organized by FarmFolk CityFolk, that brings together seed producers and experts from across the country.

“The third market is growing seed for other seed companies,” MacKinnon says. “If you’re just starting out, there are a lot of smaller seed companies looking for people to grow seeds for them. It’s a great opportunity for certified organic growers to grow seed for some of these companies.”

Together with UBC Farm, FarmFolk CityFolk has created a seed production enterprise budget template. This is presented to potential growers through workshops. These course offerings also include sample contracts, cases studies and export procedures for those who want to take their business into other countries. Additionally, when it comes to production and getting help, MacKinnon notes that the Organic Seed Alliance is a great resource for production guides.

There are other aspects to having a successful, thriving seed production business beyond who to sell to and understanding production estimates.

“If you’re getting into growing seed, quality assurance and best practices are essential,” MacKinnon notes. “You might be able to do these germination tests at home or you may have to send them to a lab.”

The testing that needs to be done for selling seed includes: Isolation distances and population sizes, germination testing and purity, vigor and disease testing.

She adds that while there isn’t a lot of information publicly available on quality assurance and best practices right now, the website (bcseeds.org) does offer some.

“We’ve been interviewing seed companies to get that information,” she says.

She suggests contacting those in the seed growing market and ask what some of the gaps are within the market that could be taken advantage of.

“A lot of Canadian seed markets just can’t grow the seeds they need,” she notes of the B.C. climate advantage. “Approach companies in your region and grow with them. Maybe start with one seed crop initially, then see what else that company may need.

MacKinnon has been instrumental in helping to host the B.C. Seed Gathering, which was held over two days in November 2017 in Richmond. The event is heavy on interaction and networking, but also provides information and the opportunity for producers to provide input on the current state and issues in the sector. The event is suitable for both existing and potential producers and focuses on bringing together seed producers and experts from across the country, on a biannual basis.

According to MacKinnon, there is still plenty of work to be done in the domestic seed industry. Efficacy of seed must be proven in order to attract consistent, long-term buyers and producers must find markets for their seeds to stay viable. But, by working together, taking advantage of available information and focusing on the seeds needed by the market, there are a lot of positives on the horizon for seed growers across Canada. • FOR ADDITIONAL INFORMATION AND RESOURCES ON B.C.’S EMERGING SEED INDUSTRY, VISIT:

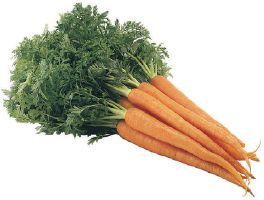

A Canadian-born startup, Nexus Robotics, is working diligently to create an autonomous vehicle capable of weeding vegetable crops.

As producers across Canada continue to struggle with finding and keeping skilled labour, three innovative Canadians have partnered up to explore a highly sought-after solution – Robotics.

While running a vegetable farm in Lunenburg County, N.S., Teric Greenan was unsettled by the number of labour-heavy, monotonous tasks that were necessary to sustain productivity and farm profits.

Following his in-field brainstorming, he contacted his friend and computer engineer, Jad Tawil, and the pair proceeded to reach out to Dalhousie University professor of computer science, Dr. Thomas Trappenberg, with the proposal to build an agricultural robot.

BY JENNIFER PAIGE

“I thought that vegetable farming would be a great place to have robotics step in and handle some of the burden and repetitive work,” Greenan says.

ABOVE

“It was really great timing. My background is machine learning and there have been a lot of breakthroughs in recent years surrounding robotics for agriculture,” Trappenberg says.

The three-person start-up entitled themselves Nexus Robotics and began researching. Over the course of their research, it was determined that

In the spring of 2019, Nexus Robotics will begin testing the robotic weeder infield in Ontario with the help of an experienced team.

weeding vegetable crops would be the producer-pain point they would target, specifically looking at onions and carrots.

Creating R2-Weed2

Nexus first developed an autonomous vehicle capable of maneuvering the field.

“It is a cube, five-feet by five-feet and four feet high, so it can go over several roads of the width of a tractor and a robot arm on the interior,” Trappenberg explains.

The machine then operates using a deep neuron network, or what is often referred to as Artificial Intelligence (AI). Once a network is designed, developers feed the machine a number of examples of plant species, both of crop and weed.

“We had to collect a lot of data as you need a lot of examples. Then you show these examples to the learning machine and if you have enough it will train the network,” Trappenberg continues.

Once the program has collected enough data, it processes the necessary features to distinguish between classes. Trappenberg explains that every pixel in the image is labelled with a certain probability that it is a certain kind of plant. Once a species has been labeled a weed, the robotic arm is directed for removal.

he explains. “Offering a service locally will be our entry way into the market, and then once we establish ourselves, we will look at selling the units outright.”

In early 2018, Nexus Robotics set their sights on the 2018 Weed and Feed competition held in Rockville, Ind., in May, which challenged innovators to build autonomous vehicles capable of performing agriculture tasks.

“Technology is increasing way faster than it ever has before and I am optimistic about our ability to improve the design and algorithms to a point that this robot will be very functional.”

Nicknamed R2-Weed2, in a controlled environment the robotic prototype was capable of operating at 99 per cent accuracy when working over a distinguished row.

In the spring of 2019, Nexus Robotics will begin testing the robotic weeder infield in Ontario with the help of an experienced team.

“We have been invited by the University of Guelph and Ontario Ministry of Agriculture, Food and Rural Affairs to do a field trial in Ontario. We will be working with farmers in the Holland Marsh area. I think it will be really valuable for us to have a team of people that are so experienced in the field actually getting involved in the improvement process for this robot,” Greenan says.

With boots on the ground, the group plans to begin testing on onions and hopes to achieve 90 per cent in-field accuracy, while ensuring there is no negative impact to the crop.

“We want to ensure that the way the algorithm works is that, if it is unsure at all whether it is a crop or a weed it won’t cut it. In testing with this high level of caution, it will likely take some time to reach the desired level of accuracy.”

In terms of feedback from farmers, Greenan says so far, most producer concerns are related to the speed of the robot.

“In the immediate future it will be difficult for us to keep up with a human workforce in terms of speed, but I think as we improve the technology it is just going to get better and better,” Greenan says. “Technology is increasing way faster than it ever has before and I am very optimistic about our ability to improve the design and algorithms to a point that this robot will be very functional and exceed expectation.”

Once Nexus is satisfied with the on-field performance, Greenan says they will look to offer the robotic weeder as a service to Nova Scotia farmers.

“The idea would be that we show up to the farm and charge a per-acre fee. That way, while we are in the development phase, we can ensure that the robot is still working as well as we planned,”

“The competition was a good way to gauge how it was working and what needs to be improved,” Trappenberg says.

After showcasing their robot at the agBOT Challenge, Nexus Robotics earned first place in the international challenge, which included a cash reward of $30,000.

Nexus Robotics has also been recognized by Innovacorp, a Nova Scotia-based early stage venture capital organization. The startup was awarded $32,000 in Innovacorp’s Spark Innovation Challenge last fall and also earned a spot in an acceleration program created for clean technology start-ups.

“Throughout this process I have been really surprised at not only how supportive the government has been but also everyone in the agriculture community, just hearing about this and getting excited. I did not expect such unanimous support,” Greenan says.•

For your orchard, only the best protection will do!

For your orchard, only the best protection will do!

Bartlett Superior “70” Oil is formulated with Petro-Canada’s ultra-pure oil base fluids. This combination delivers 99% unsulphonated residue and less phytotoxicity – which means it’s better for your orchards. Bartlett Superior “70” Oil is also better to use because it has reduced toxicity and is environmentally biodegradable. Outstanding fruit protection from an alliance you can trust – N. M. Bartlett and Petro-Canada. Now that’s revolutionary!

A & L CANADA LABORATORIES INC.

2136 Jetstream Rd.

London, ON N5V 3P5 Canada

Tel: 519-457-2575 Fax: 519-457-2664

Toll Free: 1-855-837-8347

www.alcanada.com

One of Ontario’s largest Agricultural and Environmental Laboratories specializing in soil, plant tissue, fertilizer, disease diagnostics, pesticide and water testing. A&L is a Health Canada, SCC registered Medical Cannabis testing laboratory.

A.M.A. HORTICULTURE INC.

2011 Spinks Dr.

Kingsville, ON N9Y 2E5 Canada

Tel: 519-322-1397 Fax: 519-322-1358

Toll Free: 1-800-338-1136

www.amahort.com

AEF GLOBAL

925 Rue des Calfas

Levis, QC G6Y 9E8 Canada

Tel: 418-838-4441 Fax: 418-838-9909

Toll Free: 1-866-622-3222

www.aefglobal.com

AGRICULTURE AND AGRI-FOOD CANADA

1341 Baseline Rd.

Ottawa, ON K1A 0C5 Canada

Tel: 855-773-0241 Fax: 613-773-1081

Toll Free: 1-855-773-0241

www.agr.gc.ca

AGROHAITAI LTD.

2764 Hwy. 99

Lynden, ON L0R 1T0 Canada

Tel: 519-647-2280 Fax: 519-647-3188 www.agrohaitai.com

ALPINE NURSERY (NIAGARA) LTD.

RR #4 845 Four Mile Creek Rd.

Niagara-on-the-Lake, ON L0S 1J0 Canada

Tel: 905-262-4971

ARYSTA LIFESCIENCE

138 Dovercliffe Rd. Guelph, ON N1G 3A6 Canada

Toll Free: 1-866-761-9397 www.arysta-na.com

ASB GREENWORLD

332911 Plank Line Rd.

Mount Elgin, ON N0J 1N0 Canada

Tel: 519-688-3413 Fax: 519-842-8091

Toll Free: 1-800-265-8846

www.asbgreenworld.com

BARR REFRIGERATION

1423 Planeview Dr. Oshkosh, WI 54904 USA

Tel: 920-231-1711 Fax: 920-231-1701

Toll Free: 1-888-661-0871 www.barrinc.com

BARTLETT N.M. INC.

4509 Bartlett Rd.

Beamsville, ON L0R 1B1 Canada

Tel: 905-563-8261 Fax: 905-563-7882

Toll Free: 1-800-263-1287 www.bartlett.ca

BASF CANADA INC.

100 Milverton Dr. Mississauga, ON L5R 4H1 Canada

Toll Free: 1-877-371-2273 www.AgSolutions.ca/horticulture

BAYER CROPSCIENCE INC.

679 Southgate Dr., 2nd Floor Guelph, ON N1G 4S2 Canada Tel: 1-888-283-6847 cropscience.bayer.ca

BELCHIM CROP PROTECTION CANADA

104 Cooper Dr. Guelph, ON N1C 0A4 Canada

Tel: 519-826-7878 Fax: 519-826-7675

Toll Free: 1-866-613-3336 www.belchimcanada.com

BELLWYCK (HORTICULTURAL DIVISION)ALSO KNOW AS HORTICOLOR 1025 8th St. E. Owen Sound, ON N4K 1M5 Canada Tel: 519-376-7909 Fax: 519-376-8726

Toll Free: 1-866-258-2992 www.horticolor.net

BEN BERG FARM & INDUSTRIAL EQUIPMENT LTD.

42134 Hwy. 3

Wainfleet, ON L0S 1V0 Canada

Tel: 905-899-3405 Fax: 905-899-3507

Toll Free: 1-800-387-4713 benberg.com

BERRY GROWERS OF ONTARIO

72 Julia Dr. Welland, ON L3C 0E7 Canada Tel: 905-735-5379 Fax: 905-734-4411 www.ontarioberries.com

BIOWORKS, INC.

100 Rawson Rd., Ste. 205 Victor, NY 14564 USA Tel: 905-932-0300 Fax: 585-924-4412

Toll Free: 1-800-877-9443 www.bioworksinc.com

C. FRENSCH 4774 Hinan Dr. Beamsville, ON L0R 1B1 Canada Tel: 905-563-4774 Fax: 905-563-5053

CANADIAN CORRUGATED AND CONTAINERBOARD ASSOCIATION

3 - 1995 Clark Blvd. Brampton, ON L6T 4W1 Canada Tel: 905-458-1247 Fax: 905-458-2052 www.cccabox.org

CHERRY LANE

4230 Victoria Ave. Vineland, ON L0R 2E0 Canada

Tel: 905-562-4337 ext 210 Fax: 905-562-5577

Toll Free: 1-877-CHERRY-6 www.cherrylane.net

CODERRE PACKAGING

Canada

COOPER MILL LTD. RR 3

CUSTOM LABEL PRINTINGHAMPSHIRE LABEL

CUSTOM LABELS - CUT SHEET LABELS

Tel: 519-288-5787

GINTEC

DOMINION & GRIMM INC.

DON ARTHUR ORCHARD EQUIPMENT

Tel: 519-599-3058

ECKERT MACHINES INC.

ECO+ INC.

2457, 4E Rang Sud

Canada

Tel: 519 803-4878

FARM CREDIT CANADA

Regina, SK S4P 4L3 Canada

FRESH VEGETABLE GROWERS OF ONTARIO

FRONTLINE GROWING PRODUCTS 81 Adel Dr.

Tel: 289-668-6131

GORMAN

GRIMO NUT NURSERY LTD.

979 Lakeshore Rd., RR3

Niagara-on-the-Lake, ON L0S 1J0 Canada

Tel: 905-934-6887

www.grimonut.com

GRINDSTONE CREEK NURSERY

148 Concession 6 Rd. East Millgrove, ON L8B 1M4 Canada

Tel: 905-689-5466 Fax: 905-689-8584 www.gcntrees.com

GROWERS MINERAL SOLUTIONS

PO Box 1750

Milan, OH 44846 USA

Tel: 419-499-2508 Fax: 419-499-2178

Toll Free: 1-800-437-4769 www.growersmineral.com

H&W EQUIPMENT

827 Line 4

Niagara-on-the-Lake, ON L0S 1J0 Canada

Tel: 905-468-5015 www.vineyardmachines.com

HARCO AG EQUIPMENT

5808 Hwy 9, RR 4

Harriston, ON N0G 1Z0 Canada

Tel: 519-338-2923 Fax: 519-338-2756

Toll Free: 1-800-461-0847 www.harcoag.ca

HGI AND COMPANY INSURANCE & FINANCIAL ADVISORS

1913 Dundas St. East Whitby, ON L1N 2L5 Canada

Tel: 905-728-6956 Fax: 905-728-7194 Toll Free: 1-800-376-3187 www.HGIandCompany.com

HORTICULTURE NOVA SCOTIA

32 Main St., Blair House, Kentville Agricultural Centre Kentville, NS B4N 1J5 Canada

Tel: 902-678-9335 Fax: 902-678-1280 www.horticulturens.ca

I2I AUTOMATION INC.

6796 - 178 St. Surrey, BC V3S 9E1 Canada

Tel: 778-574-1889 i2iautomation.com

INDUSTRIAL WIRE CLOTH - WIRE CLOTH MANUFACTURERS INC.

110 Iron Mountain Rd.

Mine Hill, NJ 07803 USA

Tel: 973-328-1000 Fax: 973-328-0919 wireclothman.com/industrial_wire_cloth.html

JOHNNY’S SELECTED SEEDS

955 Benton Ave.

Winslow, ME 04901 USA

Tel: 877-564-6697 Fax: 207-238-5375 Toll Free: 1-877-564-6697 www.johnnyseeds.com

KAM’S GROWERS SUPPLY (HEAD OFFICE - GUELPH)

Unit 2- 32 Airpark Place Guelph, ON N1L 1B2 Canada Toll Free: 1-877-821-1684 Fax: 519-821-5714 www.kams.ca

KAM’S GROWERS SUPPLY (KINGSVILLE OFFICE)

39 South Talbot Rd. Cottam (Kingsville), ON N0R 1B0 Canada Tel: 519-839-4778 Fax: 519-839-5931

KARCHER PROFESSIONAL WASH SYSTEMS, DIV. OF D&S DOWNHAM EQUIPMENT LTD.

3982 Perth Line 26

Stratford, ON N5A 6S3 Canada

Tel: 519-273-1740 Fax: 519-273-0222

Toll Free: 1-800-865-6025 www.karcherpro.ca

KERIAN MACHINES INC.

PO Box 311, 1709 Hwy 81 South Grafton, ND 58237 USA

Tel: 701-352-0480 Fax: 701-352-3776 www.kerian.com

KOOLJET REFRIGERATION

150 Adams Blvd.

Brantford, ON N3S 7V2 Canada

Tel: 519-688-6803 Fax: 519-688-5962

Toll Free: 1-866-748-7786 www.kooljet.com

KOPPERT CANADA LIMITED

3 - 40 Ironside Cr.

Scarborough, ON M1X 1G4 Canada

Tel: 416-291-0040 Fax: 416-291-0902

Toll Free: 1-800-567-4195 www.koppert.ca

L & R SHELTERS

461 Hwy. 5

Dundas, ON L9H 5E2 Canada

Tel: 905-627-1101 Fax: 905-627-1109

Toll Free: 1-866-216-4113 www.lrshelters.ca

LAKEVIEW VINEYARD EQUIPMENT INC.

40 Lakeshore Rd., RR 5

Niagara-on-the-Lake, ON L0S 1J0 Canada

Tel: 905-646-8085 Fax: 905-646-3289

Toll Free: 1-866-677-4717 www.lakeviewvineyardequipment.com

LAMBERT PEAT MOSS INC.

106 Lambert Rd.

Riviere-Ouelle, QC G0L 2C0 Canada

Toll Free: 1-800-463-1313 Fax: 418-852-3352 www.lambertpeatmoss.com

MAXWELL PRUNING

PO Box 553

Thornbury, ON N0H 2P0 Canada Tel: 519-599-6194

MGI LTD. 5 Iroquois Rd.

Leamington, ON N8H 3V7 Canada

Tel: 519-326-8200 Fax: 888-567-1297 Toll Free: 1-888-770-8454 www.madleyglobal.com

MIKE AND MIKES ORGANICS 1 Royal Gate Blvd., Unit F Woodbridge, ON L4L 8Z7 Canada Tel: 416-987-2772

MOHAWK EQUIPMENT LTD. PO Box 103 Brantford, ON N3T 5M3 Canada Tel: 519-753-3164 Fax: 519-753-3166 www.mohawkequipment.ca

MONTE PACKAGE COMPANY 3752 Riverside Rd. Riverside, MI 49084 USA Tel: 269-849-1722 www.montepkg.com

MUCK VEGETABLE GROWERS CONFERENCE

125 Simcoe Rd. Bradford, ON L3Z 2A8 Canada Tel: 905-775-3317

NATURAL INSECT CONTROL (NIC) 3737 Netherby Rd. Stevensville, ON L0S 1S0 Canada Tel: 905-382-2904 Fax: 905-382-4418 www.naturalinsectcontrol.com

NEW WAY IRRIGATION #20, 91008 Range Rd. 210 Lethbridge County, AB T1J 5P2 Canada Tel: 403-328-3777 Fax: 403-327-0405 www.newwayirr.com

NNZ

2076, 192 St., Unit 107 Surrey, BC V3S 3M3 Canada Tel: 778-819-1139 Fax: 778-785-1128 nnz.ca

NNZ INC.

136 Main St. W., Unit 3 Norwich, ON N0J 1P0 Canada Tel: 519-863-5782 Fax: 519-863-5784

NORFOLK FRUIT GROWERS’ ASSOCIATION

99 Queensway E., PO Box 279 Simcoe, ON N3Y 4L1 Canada Tel: 519-426-0640 www.nfga.ca

MACHINERY & ACCESSORIESCULTIVATION EQUIPMENT

Harco Ag Equipment

ProduceTech

Red Trac International

Willsie Equipment Sales Inc.

DIGGERS & SUPPLIES

Harco Ag Equipment

ProduceTech

Willsie Equipment Sales Inc.

DITCHERS

Mohawk Equipment Ltd.

Red Trac International

Timm Enterprises Ltd.

DRILLS

H&W Equipment

Red Trac International

FORK LIFTS & LIFT TRUCKS

ProduceTech

Red Trac International

FRONT END LOADERS

Ben Berg Farm & Industrial Equipment Ltd.

Red Trac International

FRONT HITCHES

Red Trac International

GPS/GIS

Red Trac International

HARVEST EQUIPMENT

Garlic-EEZ

i2i Automation Inc.

Johnny’s Selected Seeds

Oxbo International, Corp.

ProduceTech

Provide Agro

Timm Enterprises Ltd.

Willsie Equipment Sales Inc.

LOG SPLITTERS

Ben Berg Farm & Industrial Equipment Ltd.

Harco Ag Equipment

Red Trac International

PLOWS

H&W Equipment

Red Trac International

SPADING EQUIPMENT

Red Trac International

Timm Enterprises Ltd.

STONE PICKERS

Harco Ag Equipment

ProduceTech

Red Trac International

Willsie Equipment Sales Inc.

TILLERS

Ben Berg Farm & Industrial Equipment Ltd.

H&W Equipment

Harco Ag Equipment

Johnny’s Selected Seeds

Mohawk Equipment Ltd.

ProduceTech

Red Trac International

Timm Enterprises Ltd.

Willsie Equipment Sales Inc.

TRACTOR CABS

Ben Berg Farm & Industrial Equipment Ltd.

Red Trac International

VEGETABLE TRANSPLANTERS

Johnny’s Selected Seeds

Oxbo International, Corp.

ProduceTech

Vanden Bussche Irrigation

Willsie Equipment Sales Inc.

MAINTENANCE & REPAIR

Ben Berg Farm & Industrial Equipment Ltd.

Karcher Professional Wash Systems, Div. of D&S Downham Equipment

Lakeview Vineyard Equipment Inc.

MGI Ltd.

ProduceTech

MARKETING & ADVERTISING

Bellwyck (Horticultural Division)

Willsie Equipment Sales Inc.

MARKETS - ON FARM MARKETS

Fresh Vegetable Growers of Ontario

Grape Growers of Ontario

Grindstone Creek Nursery

MULCHERS

Ben Berg Farm & Industrial Equipment Ltd.

Don Arthur Orchard Equipment

H&W Equipment

ProduceTech

SICKLE BAR

Ben Berg Farm & Industrial Equipment Ltd.

H&W Equipment

Harco Ag Equipment

ProduceTech

Red Trac International

MULCH EQUIPMENT & SUPPLIES

Ben Berg Farm & Industrial Equipment Ltd.

Gintec Shade Technologies, Inc.

Lakeview Vineyard Equipment Inc.

ProduceTech

Vanden Bussche Irrigation

PEAT MOSS

A.M.A. Horticulture Inc.

ASB Greenworld

Ben Berg Farm & Industrial Equipment Ltd.

Frontline Growing Products

Lambert Peat Moss Inc.

Terralink Horticulture Inc.

NURSERY & PLANT STOCK

Alpine Nursery (Niagara) Ltd.

G.W. Allen Nursery Ltd.

Grimo Nut Nursery Ltd.

Grindstone Creek Nursery

Norseco

Nourse Farms, Inc.

Phytocultures Ltd.

Strawberry Tyme Farms Inc.

Upper Canada Growers Ltd.

V. Kraus Nurseries Ltd.

Warwick Orchards & Nursery Ltd.

PEST CONTROL - BIRD SCARING EQUIPMENT

Gintec Shade Technologies, Inc.

Grape Growers of Ontario

Industrial Wire Cloth - Wire Cloth Manufacturers Inc.

Johnny’s Selected Seeds

Red Trac International

FUNGICIDES

Bartlett N.M. Inc.

BASF Canada Inc.

Belchim Crop Protection Canada

BioWorks, Inc.

Johnny’s Selected Seeds

Kam’s Growers Supply

Terralink Horticulture Inc.

UAP Canada Inc.

Upper Canada Organic Products Inc.

Vineland Growers Co-operative Ltd.

HERBICIDES

Bartlett N.M. Inc.

BASF Canada Inc.

Bayer CropScience Inc.

Belchim Crop Protection Canada

Johnny’s Selected Seeds

Kam’s Growers Supply

ProduceTech

Terralink Horticulture Inc.

UAP Canada Inc.

Vineland Growers Co-operative Ltd.

INTEGRATED PEST CONTROL

Bartlett N.M. Inc.

Bayer CropScience Inc.

BioWorks, Inc.

Grape Growers of Ontario

Kam’s Growers Supply

Koppert Canada Limited

Natural Insect Control (NIC)

Spectrum Technologies, Inc.

Terralink Horticulture Inc.

Upper Canada Organic Products Inc.

PESTICIDES

Arysta LifeScience

Bartlett N.M. Inc.

BASF Canada Inc.

Bayer CropScience Inc.

Belchim Crop Protection Canada

BioWorks, Inc.

Kam’s Growers Supply

Terralink Horticulture Inc.

UAP Canada Inc.

UPI

Upper Canada Organic Products Inc.

Vineland Growers Co-operative Ltd.

PHEROMONE INSECT TRAPS

AEF Global

Bartlett N.M. Inc.

Cooper Mill Ltd.

Grape Growers of Ontario

Natural Insect Control (NIC)

Terralink Horticulture Inc.

Upper Canada Organic Products Inc.

Vineland Growers Co-operative Ltd.

PLANT GROWTH REGULATORS / MONITORING

Bartlett N.M. Inc.

BASF Canada Inc.

Belchim Crop Protection Canada

Frontline Growing Products

Kam’s Growers Supply

Terralink Horticulture Inc.

UAP Canada Inc.

POLLINATION

Kam’s Growers Supply

Koppert Canada Limited

Natural Insect Control (NIC)

Ontario Beekeepers’ Association

Parker-Bee Apiaries Ltd.

PONDS & STORAGE TANKS

Harco Ag Equipment

Red Trac International

Rittenhouse Since 1914

POST HARVEST CHEMICALS

Bartlett N.M. Inc.

Terralink Horticulture Inc.

POTATO EQUIPMENT

Coderre Packaging

Eckert Machines Inc.

Kerian Machines Inc.

Red Trac International

Willsie Equipment Sales Inc.

PRODUCE PROCESSING AND PACKAGING BAGS

A.M.A. Horticulture Inc.

Coderre Packaging

NNZ Inc.

ProduceTech

Terralink Horticulture Inc.

BASKETS

A.M.A. Horticulture Inc.

Monte Package Company

NNZ Inc.

Pacific Injection Molding Ltd.

ProduceTech

Terralink Horticulture Inc.

Vineland Growers Co-operative Ltd.

CLAM SHELL FILLERS

Eckert Machines Inc.

i2i Automation Inc.

ProduceTech

CONVEYORS

Eckert Machines Inc.

ProduceTech

Provide Agro

Willsie Equipment Sales Inc.

COUNTING DEVICES

Coderre Packaging

i2i Automation Inc.

MGI Ltd.

ProduceTech

FIELD PACKING EQUIPMENT

Monte Package Company

ProduceTech

Wellmaster Carts

Willsie Equipment Sales Inc.

FLATS & TRAYS

A.M.A. Horticulture Inc.

Johnny’s Selected Seeds

Monte Package Company

Pacific Injection Molding Ltd.

ProduceTech

Terralink Horticulture Inc.

Vineland Growers Co-operative Ltd.

GRADERS & SIZERS

Climatrol Solutions Ltd.

Coderre Packaging

Eckert Machines Inc.

i2i Automation Inc.

ProduceTech

Provide Agro

Willsie Equipment Sales Inc.

LABELLING EQUIPMENT

C. Frensch

Coderre Packaging

Custom Label Printing - Hampshire

Label

Custom Labels - Cut Sheet Labels

i2i Automation Inc.

Johnny’s Selected Seeds

MGI Ltd.

ProduceTech

Provide Agro

PALLETS

ProduceTech