PureSpray™ GREEN Spray Oil 13E. Protection at its purest –CAS# 8042-47-5

Introducing PureSpray GREEN Spray Oil 13E, from the largest producer of white oils. It’s proof that not all spray oils are created equal. It is an innovative isoparaf n oil that offers the highest purity levels on the market with CAS# 8042-47-5. This means it’s formulated with 99.9% pure isoparaf n base oils and is guaranteed to be free of aromatics, which harm the food chain. And since it’s suitable for organic production, both organic and traditional growers can bene t from its many strengths.

PureSpray GREEN Spray Oil 13E effectively protects your high value grape crop by quickly controlling pests and disease, and providing extended protection within your IPM program. All without any

resistance, phytotoxicity or burning issues, when used as directed. So use it early to avoid the need for traditional toxic chemicals later.

As many pesticides are being delisted, your choices are limited and becoming more so every day. So when you have a choice to make, be sure to choose the purest – PureSpray GREEN Spray Oil 13E.

It’s an effective choice with unlimited possibilities. For more product information visit www.purespraygreen.com/grapes.

It’s an effective choice with unlimited possibilities. For more

Editor

November/December 2013

Volume 69, No. 6

Margaret Land mland@annexweb.com

519-429-5190 • 888-599-2228 ext. 269

Advertising Manager

Sharon Kauk skauk@annexweb.com

519-429-5189 • 888-599-2228 ext. 242

Sales Assistant

Mary Burnie mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext. 234

Media Designer

Chris Springle

Group Publisher

Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

PuBLiCatioN MaiL agreeMeNt #40065710 returN uNDeLiVeraBLe CaNaDiaN aDDreSSeS to CirCuLatioN DePt., P.o. Box 530, SiMCoe, oN N3Y 4N5

e-mail: subscribe@fruitandveggie.com

Fruit & Vegetable Magazine is published six times a year (January/ February, March, april, May, october, November/ December) by annex Publishing & Printing inc., P.o. Box 530, 105 Donly Dr. S., Simcoe, oN N3Y 4N5

Printed in Canada ISSN 1488-7959

Circulation e-mail: subscribe@fruitandveggie.com tel: 1-866-790-6070 ext. 202 Fax: 1-877-624-1940

Mail: P.o. Box 530, Simcoe, oN N3Y 4N5

Subscription Rates

Canada – 1 Year $ 21.00 (includes gSt – #867172652rt0001) $22.60 (includes QSt/HSt)

u.S.a. – 1 Year $35.00 uS

Foreign – 1 Year $ 55.00 uS

Occasionally, Fruit & Vegetable Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2013 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

The U.S. fresh fruit and vegetable industry was rocked recently by the guilty pleas of two Colorado cantaloupe growers to federal misdemeanour charges stemming from a 2011 listeria outbreak that killed 33 people.

Brothers Eric and Ryan Jensen were formally charged by the Food and Drug Administration (FDA) in September 2013 and will be sentenced in January. Both men were originally facing criminal charges but entered a plea deal in October 2013, pleading guilty to six counts of introducing and delivering adulterated food into interstate commerce. They could be sentenced to up to six years in jail and pay up to $1.5 million each in fines.

As a result of this case, many produce producers across the U.S. are re-examining their food safety protocols, including the relationship they have with auditing firms.

Jensen Farms has filed a lawsuit against Primus Labs, the company the brothers hired to perform food safety audits on their farm. The audits were subcontracted to a Texas company, Bio Food Safety, which visited the Colorado operation in the summer of 2011, just weeks before the listeria outbreak.

According to the Jensen brothers, their operation received a 96 per cent score and a rating of superior by the auditing firm just six days before the outbreak, allowing produce from the farm to be Primus-certified. In the aftermath of the outbreak, the FDA inspected the farm and discovered serious issues with a new washer/dryer system and a conveyor system.

The Jensens are alleging negligence, breach of contract, negligent hire, negligent

misrepresentation, and unfair and deceptive trade practices. They are seeking compensation for all damages incurred, including those from civil lawsuits, criminal charges and the loss of the business.

Repercussions from the food safety breach are still being felt. Other cantaloupe growers from the same area as Jensen Farms have formed a growers as sociation and undergo U.S. Department of Agriculture (USDA) audits plus third-party audits, both announced and unannounced. Some have even taken the expensive step of hiring an on-site food safety manager.

Colorado State University has increased food safety training and programs for fruit and vegetable growers. A new study by researchers at the university shows that consumers have concerns about the safety of conventionally grown produce and government regulatory processes in place to protect the public. The study is being published in the January 2014 issue of the scientific journal Food Quality and Preference.

Meanwhile, in Alberta, the province’s department of Agriculture and Rural Development is using federal funds from Growing Forward 2 to provide information to producers on the benefits of sound food safety practices.

“Food safety is becoming a priority for consumers,” says Karen Goad, a direct farm marketing specialist with Alberta Agriculture. “Consumers are looking for documented assurance that the food they’re eating is produced safely. To remain

January 13-14 – Ontario Fruit & Vegetable Growers Association Annual Meeting, Niagara Falls, Ont. www.ofvga.org

January 27-28 – Scotia Horticultural Conference 2014, Wolfville, N.S. www.hortns.com

January 28-29 – Ontario Processing Vegetable Industry Conference, London, Ont. www.opvg.org

January 28-30 – Manitoba Potato Production Days, Brandon, Man. www.mbpotatodays.ca

January 28-30 – NS Fruit Growers Association Annual Convention 2014, Wolfville, N.S. www.nsapples.com

January 30-February 1 – Pacific Agriculture Show, Abbotsford, B.C. www.agricultureshow.net

competitive, farm direct producers and small-scale processors must adapt to the changing environment.”

A workshop was held in Alberta in November to help producers learn about the regulations impacting the production, processing and marketing of food, including how the top 10 food safety practices apply to their farm. They also heard presentations from four different farm operations about how food safety affects their business.

“It’s easy and inexpensive to start incorporating a safe food philosophy in your farm direct business,” says Monika Frank-Ruediger, a safe food systems specialist with Alberta Agriculture. “It starts with the right mindset and a good dose of common sense.

“The first step can be as simple as establishing proper hand washing practices or regularly recording the temperature of your refrigeration equipment and then building to a solid foundation of prerequisite programs,” she says. “It’s important to start small and incorporate first those steps that make the most sense for your business. As your business grows, you may choose to invest the time and money to implement one of the established food safety systems such as On Farm Food Safety (OFFS) or Hazard Analysis Critical Control Point (HACCP).”

Fruit & Vegetable Magazine plans to address food safety issues in upcoming issues of the magazine. Keep your eyes open for more information in 2014. ❦

@FruitVeggieMag

January 30-February 2 – 33rd Annual Guelph Organic Conference, Guelph, Ont. www.guelphorganicconf.ca

February 18 – Ontario Berry Growers Association Annual Meeting, Niagara Falls, Ont. ontarioberries.com

By Kendra Sauerteig and Dr. John A. Cline

The Ontario peach industry produces an annual farm gate value of $27 million (Statistics Canada, 2012), but crop load management remains critical for profitability, due to over-cropping. Hand thinning of peaches is common 40 to 50 days after full bloom in order to increase fruit size, but this process is labour intensive and expensive. A two-year study was conducted beginning in 2010 to evaluate mechanical blossom thinning (MBT) of peaches using a string-thinning device, and to determine the effect on crop load, yield, and fruit quality.

This experiment was conducted in 2010 and 2011 using seven-year-old Allstar/ Bailey peach trees in a commercial orchard (1,121 trees·ha -1) in Virgil, Ont., which were 3.7 m tall and 1.7 m wide. The six treatments were applied at 80 to 90 per cent full bloom and consisted of: 1) MBT at a rate of 180 rpm; 2) MBT at a rate of 210 rpm; 3) MBT at a rate of 240 rpm; 4) HBT simulating the 180 rpm treatment (HBT low); 5) HBT simu -

Table 1

Mechanical string thinner used to remove flowers from peach trees.

lating the 210 rpm treatment (HBT medium); 6) HBT simulating the 240 rpm treatment (HBT high); and in 2011, 7) a hand-thinned control treatment, was added. Hand blossom thinning treatments simulated MBT, to assess mechanical damage caused by the rotating

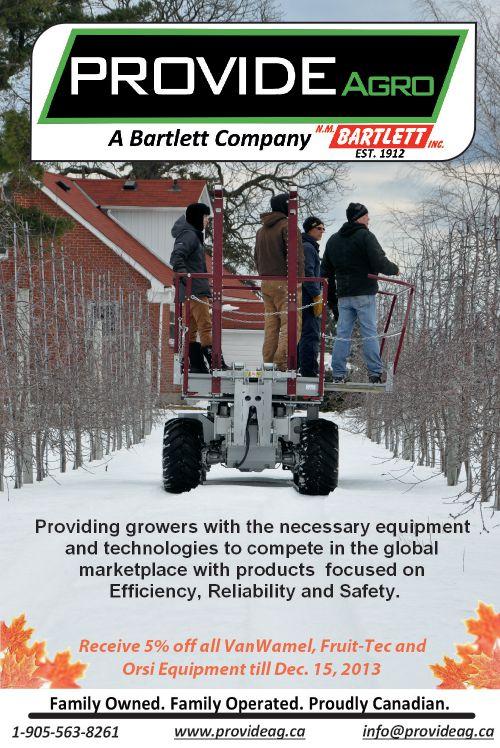

strings. The mechanical string thinner (Darwin 300, Fruit-Tec, Deggenhausertal, Germany, available through N.M. Bartlett, Beamsville, Ont.) was mounted to the front of a tractor and consisted of a 3.0 m-tall rotating spindle

After June drop, trees were hand

Effect of mechanical and hand blossom thinning on flower removal (%) and fruit set (%) of ‘Allstar’ peach trees.

a Mechanical blossom thinning (MBT) and hand blossom thinning (HBT).

b Means with the same letter are not significantly different according to Tukey’s Studentized range test at P = 0.05.

thinned and time required to thin was recorded. This was then extrapolated to hours per hectare (h·ha-1) based on orchard tree density. At harvest, the total number and weight of fruit harvested per tree was recorded, as well as the number and weight of naturally dropped fruit. Fruit firmness and soluble solids concentration were measured on a subsample of unblemished fruit. Fruit were also graded, and due to a price incentive for growers, are presented as the percentage of fruit >70 mm.

In both years the two methods of thinning were similarly efficacious in removing blossoms (Table 1). In 2010, fruit set decreased linearly with increasing MBT and HBT, while in 2011, fruit set for the hand-thinned control treatment was higher than all other treatments. In 2010, only the HBT high treatment required significantly less time to hand thin at “June drop” compared to all other treatments (Table 2). In 2011 the control and HBT low treatments required the greatest amount of time for hand thinning, while the HBT high treatment again required less hand thinning.

Total yield was affected by treatments in both years, and there was a general trend of decreasing yield with increasing thinning rate (Table 3). In 2010, marketable yield decreased linearly with increasing rates of thinning, while in 2011 marketable yield did not differ across treatments. In both years, there was a linear reduction in the number of fruit harvested per tree with increasing rates of thinning. In 2010 mean fruit weight was unaffected by treatment, whereas in 2011 mean fruit weight increased with increasing magnitude of thinning. In 2010, there was no effect of treatment on percentage of fruit in an incentive size category (> 70 mm), but in 2011 the MBT 210 rpm and 240 rpm treatments yielded significantly more fruit in the incentive category. In both years, fruit firmness and soluble solids concentration were unaffected by treatments (data not shown).

Approximately 50 per cent of peach blossoms need to be removed to achieve a commercial crop (Marini and Reighard, 2008). Flower removal rates in this study were comparable with other work

Effect of blossom thinning on number (fruit·tree-1) and weight of fruit

(Baugher et al. 2010b; Schupp et al. (2008), but in some cases were higher than other reports (Baugher et al., 2010a), perhaps due to the suitability of the orchard for mechanical blossom thinning. Growers should consider their orchard management before using a mechanical thinning device, as other research has found that results can be variable if the canopy is poorly suited for thinning with the device described here (Miller et al., 2011; Schupp et al., 2008).

Early in the growing season, developing fruitlets are competing for limited carbohydrate reserves, therefore thinning early will help allocate more reserves to fewer fruit, thereby improving fruit size (Marini and Reighard, 2008). In 2011 MBT and HBT reduced the amount of follow-up hand thinning after “June drop” by 33-57 h·ha -1 and 24-70 h·ha -1, respectively (Table 2). Other studies have reported time savings as well (Baugher et al., 2010a; Baugher et al., 2010b), where others have proved more variable (Miller et al., 2011; Baugher et al., 2009).

In this experiment, there was no significant treatment effect on marketable yield, indicating a compensatory effect

per tree (kg·tree-1), mean fruit weight (g), and time spent thinning during follow-up hand thinning at ‘June drop’ (h·ha-1) of ‘Allstar’ peach trees in 2010 and 2011. 2011 data for number of fruit removed per tree were log-transformed. The means and data presented below are untransformed.

a Mechanical blossom thinning (MBT) and hand blossom thinning (HBT).

b Means with the same letter are not significantly different according to Tukey’s Studentized range test at P = 0.05.

of reduced fruit number by increased fruit weight among thinned trees. Other studies have observed improvements in marketable yield (Baugher et al., 2009), while others have proved variable (Miller et al., 2011). With thinning it is important to improve fruit size, but not forfeit economic yield (Marini and Reighard, 2008). In this study there also were no significant treatment effects on fruit firmness or soluble solids concentration (data not shown), which may have been due to the fact that peaches were harvested based on maturity.

Prior to the widespread adoption of mechanical blossom thinning there are several issues that must be addressed. Most importantly, trees must be managed properly to provide adequate access of strings to the tree canopy (Marini and Reighard, 2008). In less suitable orchards compared to the one used in this study, follow-up thinning may be necessary to mitigate inconsistent thinning (Baugher et al., 1991). Another important concern for grow -

Table 3

ers is the risk of frost (Baugher et al., 1991), which could further decrease crop load. One final area of interest that warrants more investigation in Ontario is the timing of mechanical blossom thinning (Costa and Vizzotto, 2000; Schupp et al., 2008).

Overall, mechanical blossom thinning might be approached as a twopart strategy to reduce the amount of hand thinning needed after June drop. Since concern exists of over-thinning due to the higher probability of frost at or shortly following bloom, partial removal of the crop load could be achieved by mechanical blossom thinning with the intention of follow-up hand thinning to reach the targeted final crop load after set has been determined (Myers et al., 2002).

Peach trees can overset, and to solve this problem growers will adjust crop load by hand, the universal thinning strategy (Myers et al., 2002) and by

chemical means (Coneva and Cline, 2006; Greene et al., 2001; Osborne et al., 2006), although results have been inconsistent (Marini and Reighard, 2008). In this article we propose mechanical blossom thinning as an alternative, but more research is needed in order to fully understand its effects in Ontario orchards and in order to adequately advise growers (Marini and Reighard, 2008).

We gratefully acknowledge George Lepp for the use of his orchard, as well as the technical assistance of Debbie Norton, University of Guelph. ❦

Kendra Sauerteig and Dr. John A. Cline are with the University of Guelph.

Effect of blossom thinning on total yield (kg·tree-1), marketable yield (kg·tree

a Mechanical blossom thinning (MBT) and hand blossom thinning (HBT).

b Means with the same letter are not significantly different according to Tukey’s Studentized range test at P = 0.05. For

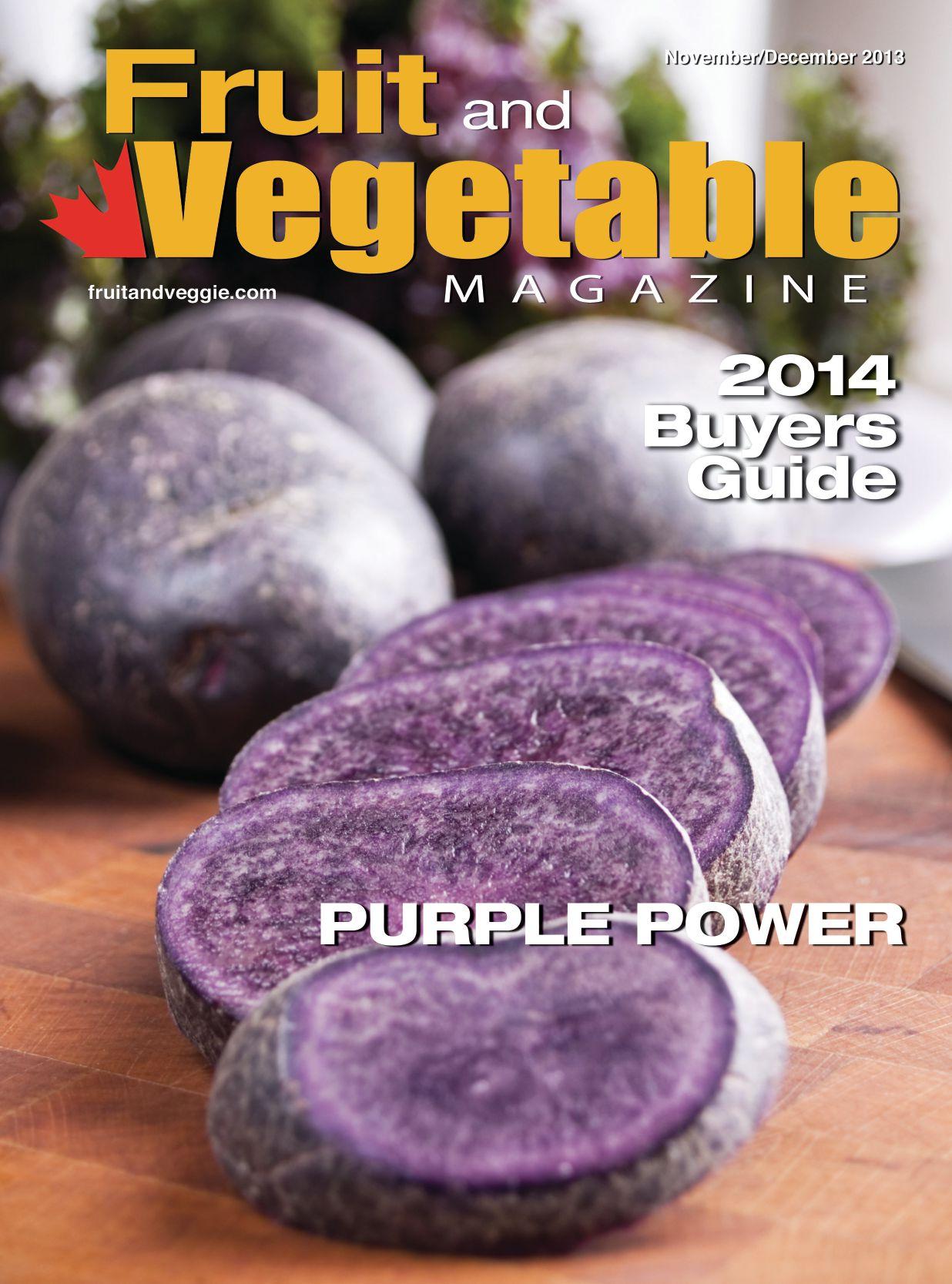

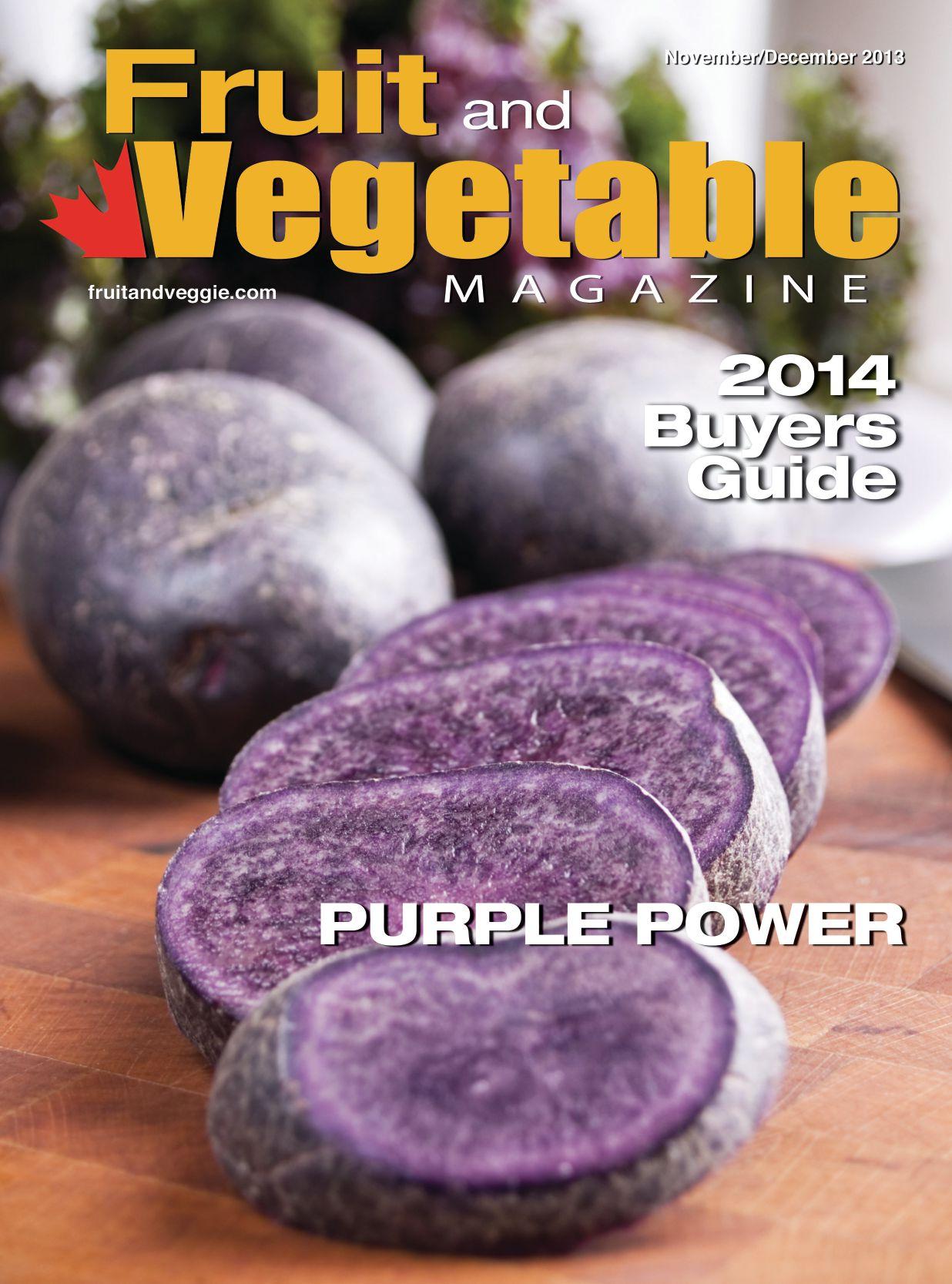

Do the antioxidant properties of purple carrots and potatoes make them the biggest thing since blueberries?

By Rosalie I. Tennison

Can vegetables get healthier?

There is no question that eating vegetables is a good way to minimize the risk of some cancers, maintain a healthy body weight, increase the intake of vitamins and minerals, and, generally, contribute to overall health. But, as food scientists study how the many components in vegetables can improve human life in multiple ways, they are learning that the colour also can be beneficial for human health.

Natively grown in South American countries, purple potatoes were seldom a favourite of North American consumers. The same is true of purple carrots. However, what can almost be termed “heritage varieties” remained interesting to home gardeners, who kept these vegetables from disappearing completely. Now, research is being conducted on the antioxidant properties of purple potatoes and carrots and how these vegetables can improve our health beyond the health benefits of white potatoes and orange carrots.

“Most vegetables have some antioxidant properties, but purple carrots and potatoes have more,” explains Dr. Mary Ruth McDonald, a researcher in the Department of Plant Agriculture at the University of Guelph in Ontario. “Purple carrots have more antioxidants than orange carrots and even the purple skin on the potatoes is high in antioxidants. It’s due to pigments called anthocyanins that produce the intense colour.”

Dr. McDonald and a team of other researchers, including Dr. Rong Cao of Agriculture and Agri-Food Canada and Drs. Kelly Meckling and Al Sullivan of the University of Guelph, are currently conducting research into the health benefits of purple carrots and potatoes. She believes the antioxidants in these vegetables, when consumed regularly, will reduce high blood pressure and improve the quality of life for people with Type 2 diabetes. Her study is investigating how strong an effect, if any, eating

Purple potatoes such as these have seldom been a favourite of North American consumers, but research is underway examining the antioxidant pro-perties of purple potatoes and carrots and how these vegetables can improve health beyond the benefits of white potatoes and orange carrots.

purple potatoes or carrots in comparison with eating white potatoes and orange carrots will have on subjects suffering from Type 2 diabetes, high blood pressure and other lifestyle-related health problems. Research has been completed using rats, which showed encouraging results of significant reductions in blood glucose levels when the animals ate the purple vegetables.

The research is now progressing towards working with human subjects. In the study, subjects will have to eat either purple carrots or purple potatoes every day, while the control group will eat either orange carrots or white potatoes every day.

“It’s important to see what eating these compounds does for human health,” Dr. McDonald explains. “We need to understand how the compounds are absorbed into the body.”

She expects to have some prelimi -

nary results from the study in 2014.

If Dr. McDonald proves the health benefits of the purple vegetables, there will be increased opportunities for commercial vegetable growers. At present, purple vegetables are largely the niche cornered by market gardens, the purveyors of heritage varieties, organic produce and scale farming operations. There is some commercial production of purple carrots in the Holland Marsh area of Ontario, but the yields are poor in comparison to their orange cousins. However, Dr. McDonald believes, if the health benefits are proven, an increase in breeding programs and production research will be likely.

“The purple carrots are requiring more management because the varieties we have are not well adapted to our growing conditions,” Dr. McDonald says. “There has not been a breeding focus for our production system.”

That is starting to change as breeding programs are including purple carrots and potatoes in order to have varieties available to Canadian growers once the market is developed.

If the health benefits are proven, the mainstream media will likely get on board to excite the public interest and opportunities will increase for growers. Once good varieties are available, the production system should work similarly to the present system for white potatoes or orange carrots. However, steps may need to be taken to maintain the colour of these vegetables because in some potato-growing areas sustaining the colour of red-skinned potatoes is a challenge.

Then, there is the cooking issue. Consumers will have to be educated on the best way to prepare the vegetables in order to maintain the antioxidant benefits. If the potatoes are cut, the colour leaches out into the cooking water and the antioxidants are reduced, so the best way to prepare purple potatoes is to bake them to preserve all the benefits in one tasty package. The purple pigment in the carrots and potatoes is water soluble, so baking or preparing the vegetables whole will keep their health benefits intact. Dr. McDonald also believes there is an opportunity to get children eating healthier because they may think eating purple vegetables is “cool.”

What’s next?

“We need the demand for these vegetables and then we need adapted varieties for our growing areas,” Dr. McDonald admits. “We need varieties that yield as well as a white potato or an orange carrot to make it worthwhile for growers to add them to their production plans.”

When blueberries became the fruit of choice because of their proven antioxidant properties, production soared and the fruit began to appear everywhere from the fresh counter to the juice aisle. Dr. McDonald says purple carrots are being used as a juice ingredient, but it is a specialized market, and the products are not readily available in all stores. Nevertheless, the system is in place to make the most of the antioxidant properties of purple potatoes and carrots. The results of Dr. McDonald’s research may be the spark to get varieties developed and larger-scale production underway. ❦

The Nova Scotia Fruit Growers Association’s 150th anniversary celebration evoked an end-ofan-era feeling. The event was held at Blair House on the Atlantic Food and Horticulture Research Centre campus in Kentville, N.S., this past summer.

The NSFGA used its sesquicentennial celebration to pay special tribute to three people who have many years of service to the NSFGA and the tree fruit industry.

After 50 years as a provincial tree fruit specialist and a tree fruit scientist, Charles Embree retired from Agriculture and Agri-Food Canada last November.

Bill Craig, a provincial tree fruit specialist for 35 years, will retire early in 2014 from Nova Scotia’s agricultural extension and consulting agency, Perrenia.

Dela Erith also resigned after 15 years as NSFGA’s executive-director.

These three departures represent a collective loss of 100 years of institutional memory, technical expertise and administrative experience to the Nova Scotia tree fruit industry.

In presenting Embree with an NSFGA thank-you gift and certificate of appreciation, the NSFGA’s Doug Nichols – a former research associate of Embree –noted that during Embree’s 50 years in the tree fruit industry, he wrote 60 peerreviewed scientific research papers and 125 technical bulletins.

Embree began his career in 1963 with the Nova Scotia Department of Agriculture as a tree fruit specialist, becoming NSDA’s horticulture and biology branch director in 1978, then joining AAFC as a tree fruit research scientist in 1982.

In the 30 years since, Embree served as a reference co-ordinator for the

By Dan Woolley

United States regional research committee in North Central Regional Research, and as a member of the U.S. Germplasm Committee and the North East Plant Growth Regulator Working Group, said Nichols.

Embree also has mentored graduate and undergraduate students as an adjunct professor at the Nova Scotia Agricultural College since 1988 and as a guest speaker at the annual meetings of apple grower groups in Maine, New Brunswick, Nova Scotia and Prince Edward Island, he said.

Embree, observed Nichols, is a pastpresident and director of the Nova Scotia Institute of Agrologists as well as a former director of the Agricultural Institute of Canada, the Canadian Society of Horticultural Science and the NSFGA.

Nichols also cited the numerous

awards and distinctions Embree has earned over the years: the International Society for Horticultural Science’s medal of recognition for organizing its first symposium on organic apples and pears, the NSIA’s Distinguished Life Member’s award, the NSFGA’s Honorary Life Membership, and, more recently, an honorary Doctor of Laws degree from Dalhousie University in 2010 and the NSAC Alumni Association’s Distinguished Alumnus Award.

“He has been a huge asset to our association,” said NSFGA vice-president Stephen Van Meekeren as he presented Bill Craig with a commemorative gift and certificate. “I am amazed at his memory of all aspects of our industry from rootstock to pests. We were really blessed as

an association to have him with us for the past 35 years.”

In reply, Craig commented to the growers that he started working with their fathers and he is now working with their grandchildren.

A lot has changed in the past 35 years, he added, but he has found growers to be open-minded.

“Now, that I am about to retire, thank you very much and all the best in the next 150 years,” he said.

Dela Erith

Craig presented Dela Erith with her farewell gift of appreciation and certificate.

“It takes a big machine to move an industry like this forward,” said Erith. “I want to thank all the many people who have contributed to the success of the industry.”

As part of its sesquicentennial celebration, the NSFGA prepared for distribution certificates of appreciation to 62 individuals who were either longserving NSFGA members or significant contributors to the health of the tree fruit industry.

The NSFGA 150th anniversary tea also heard from several dignitaries full of praise for the grower organization.

Dr. Christine DeLauriers praised the NSFGA for “a tremendous job representing the industry’s interests in various negotiations.”

The NSFGA also has been very important, she stated, in providing direction on what cultivars to plant and what research should be done. While there are fewer growers today, they have higher productivity because of technology and information sharing among

NSFGA members who have been early adapters of new technology.

“The Nova Scotia Fruit Growers Association has a heritage of 150 years of development and growth that is truly amazing,” said Linda MacDonald, the Nova Scotia Department of Agriculture’s director of corporate services and policy.

Dennis Boudreau, Nova Scotia Federation of Agriculture president, praised the NSFA for 150 years of leadership in Nova Scotia Agriculture in developing new varieties, new technology and the

expansion of export markets.

Scott Brison, the MP for Annapolis Valley-Hants, reflected on the 150 years of change in Valley fruit growing and stressed the importance of localized and regional research in light of the fact the Annapolis Valley has different demands and needs than other growing regions. ❦

Monday, January 27 and Tuesday, January 28, 2014

Old Orchard Inn, Wolfville, N.S.

• Meet our keynote speaker Dr. David Gray, Dean, Dalhousie Faculty of Agriculture

• Participate in “farmer to farmer” forums and discussions.

• Network with professionals from many areas of agriculture.

• Experience sessions like “Keeping up with the times” and “Making a living off the beaten track.”

• Learn what’s new in berry and vegetable research.

• Discover what is happening in industry-related technology and innovation.

• Enjoy great food and company at our banquet while listening to the motivating words of Jamie Reaume, Executive Director, Holland Marsh Growers’ Association.

Anew study indicates that Reusable Plastic Containers (RPCs) used to ship fruit and vegetables in Canada pose a risk for contamination.

The report, developed by a University of Guelph researcher, calls the possibility for contamination a significant concern.

“The main outcome of the study is that the RPCs meant to be delivered in a sanitary condition were not effectively cleaned,” said Keith Warriner, food safety and quality assurance program director at the University of Guelph and author of the study. “From a food safety perspective, this could mean that pathogens such as salmonella, norovirus and cyclospora could be transferred to produce.

“In addition to human pathogens, it is also possible that plant pathogens such as Erwinia, Pseudomonas, Xanthomonas and Ascomycetes could be transferred, thereby resulting in premature spoilage of produce,” he added.

In Canada, some retailers demand farmers ship fruit and vegetables from the farm to the store using RPCs. The containers are rented by farmers to ship their produce and then returned to the United States for cleaning. In Ontario, for example, RPCs are shipped to Chicago for sanitization.

For Warriner’s study, farm locations in Ontario and Quebec were visited and at each location, 10 randomly selected RPCs were sampled.

A combination of ATP (adenosine triphosphate) swabs and microbiological analysis were the methods chosen to determine the sanitary status of the RPCs. ATP readings taken at farms provided an estimate of viable cells present on the surface of RPCs.

The standards set were those expected of a cleaned surface of a food contact surface within the food industry with a 20 per cent failure rate being deemed the upper limit of acceptability. Trays were sampled as delivered thereby ruling out contamina-

A new study indicates that Reusable Plastic Containers (RPCs) used to ship fruit and vegetables in Canada pose a risk for contamination.

tion at the packing facility.

Containers at the Ontario and Quebec farms were tested for overall sanitary status (visual inspection and ATP testing), in addition to bacterial counts (total aerobic counts) that included potential fecal indicators (enterobacteriaceae and coliforms). Collectively, 64 per cent of all RPCs failed in terms of sanitary standards and 56 per cent of trays had a higher aerobic count than expected on a cleaned surface. Trays were sampled as delivered thereby ruling out contamination at the farm.

“The results provided evidence to make a case of potential hazards,” said Warriner. “RPCs used to ship food are a recipe for disaster. We recommend that the decontamination method for RPCs be reviewed to prevent carriage and transfer of human pathogens.”

The results also show a significant variation in the sanitary status of RPCs,

and that many RPCs were damaged and visibly dirty. Visual inspection of RPCs revealed a proportion that were damaged or had labels affixed from previous use. While the root of this problem is unknown, inefficient cleaning systems and travel to and from wash stations in the U.S. may explain the sanitary issues.

The study was commissioned following food safety concerns expressed by the growers who are told to ship fruit and vegetables using RPCs, rather than the traditional choice, corrugated boxes.

“We have heard anecdotal reports from growers that the RPCs delivered to their farms sometimes arrive dirty,” said André Plante, general manager of the Quebec Produce Growers’ Association. “For the safety of Canadians, we need to ensure all food in Canada is shipped using clean packaging, regardless of whether it is paper or plastic.” ❦

Tomatoes are a $2 billion crop in the United States, but a common complaint is that the varieties in supermarkets often lack the flavour of locally grown varieties. To improve flavour, breeders need to know more about the types of tomatoes that hold the greatest potential for enhancing taste.

U.S. Department of Agriculture (USDA) molecular biologist Joanne Labate and plant geneticist Larry Robertson at Geneva, N.Y., worked with Dilip Panthee of North Carolina State University to explore tomato’s diversity in a study designed to help breeders develop tastier tomatoes.

Labate and Robertson work at the Agricultural Research Service (ARS) Plant Genetic Resources Unit at Geneva. ARS is USDA’s principal intramural scientific research agency, and this research supports the USDA priority of promoting international food security.

The team raised 173 varieties on test

plots in North Carolina, trained 10 volunteers in sensory analysis, and asked them to rate the varieties on a scale of one to five in four sensory areas: odor, taste, flavour, and texture. The varieties were selected from the approximately 6,000 accessions in the ARS Tomato Germplasm Collection in Geneva because they represent a cross-section of the world’s tomato diversity.

The results, published in Plant Genetic Resources: Characterization and Utilization (2013), represent one of the most comprehensive efforts to date for identifying sources for boosting flavour among commercial varieties and lines used for breeding. They also are a treasure trove for breeders, offering a comprehensive set of rankings on flavour qualities, sweetness, vitamin C content, sugar and acid content, and other characteristics.

The findings show that although thousands of compounds go into determining flavour and other characteristics, two compo-

One of numerous varieties of tomatoes grown and analyzed for compounds that play a role in determining flavour.

nents play a key role: the amounts of sugar and acid. There also was a positive correlation between sweetness and flavour.

The findings are good news for breeders because they show a lot of variation and a broad range of possibilities for adjusting sugar levels and developing more flavourful tomatoes. ❦

Ateam of researchers based at Ludwig-Maximilians-Universitaet (LMU) in Munich, Germany, and the Technical University of Munich (TUM) has shown how temporal control of a single gene solves two problems during fruit ripening in strawberries.

Not only human consumers find the rich, red colour of ripe strawberries attractive. In wild strawberries, it also serves to lure the animals the plant then exploits to spread its seeds. When birds and small mammals feed on the fruit, they subsequently excrete the indigestible seeds elsewhere, thus ensuring the dispersal of the species. However, as long as the fruit is in the growth phase and not yet mature, drawing attention to itself would be counterproductive. Moreover, the developing fruit also has to contend with the attentions of pathogens and pests.

Dr. Thilo Fischer, Privatdozent at the Chair of Plant Biochemistry and Physiology at LMU, and Dr. Wilfried Schwab of the Center for Life and Food Sciences Weihenstephan at the Technische Universität München (TUM), took a closer look at how the shift between repulsion and attraction is accomplished. Their findings, which are reported in the journal New Phytologist, elucidate the role played by the enzyme anthocyanidin reductase (ANR) in the switching process.

Botanically speaking, strawberries are neither berries nor fruits. The fleshy part of the fruit is actually a modification of the shoot tip from which the flowers develop. The yellow achenes embedded in its surface are the true fruits, each consisting of a single seed and a hard outer coat. During the growth phase of the fruit, the enzyme anthocyanidin reductase contributes to the synthesis of metabolites called proanthocyanidins in the green fruits. These compounds help to protect the developing fruit against predators, pathogens and abiotic stresses. When the seeds are ripe, the ANR gene is turned off. This makes precursors of proanthocyanidins available for use in the production of anthocyanins, the red pigments that give the mature fruit its alluring colour.

tivated the ANR function in growing fruits. This intervention led to the appearance of red stigmas in the flowers, and the production of anthocyanins in immature fruits.

“This finding indicates that the ANR function and the synthesis of protective compounds are also important in the stigmas of the flower,” says Dr. Fischer.

“With the aid of this model, it will be

possible to carry out more detailed analyses of the functions of proanthocyanidins,” says Dr. Schwab.

This is also of interest to strawberry breeders, because the timing of the switch between warding off pests and the initiation of pigmentation not only controls the quality of the fruit but also determines the level of pesticide use. ❦

All season weed control. One application. Protect your vine and orchard fruits with one easy-to-use granular herbicide. Casoron ® G-4 provides residual season-long control of more than 30 different weeds and grasses. It is easy to measure and apply, and requires no in-season re-application, so you will have more time for all your other important tasks.

www.chemturaagrosolutions.com

In their study, Dr. Fischer and Dr. Schwab, in co-operation with the Julius Kühn Institute in Pillnitz near Dresden, specifically inac-

The Vineland Research and Innovation Centre recently announced that its board of directors has appointed three new members.

Rory Francis, executive director of BioAlliance; Dr. Warren Jestin, senior vicepresident and chief economist with Scotiabank; and Phil Tregunno, president of Tregunno Fruit Farms Inc., will join Vineland’s board, effective immediately. The appointments increase the number of Vineland directors from 10 to 13.

“Rory, Warren and Phil bring remarkable talent to the board and I’m grateful for their support, as well as the ongoing support from all of the directors,” said Dr. Jim Brandle, chief executive officer of the Vineland Research and Innovation Centre.

Rory Francis has 30 years’ experience in professional, management and leadership roles in the public and private sectors. Francis has led transformative change in several public sector organizations encompassing economic and social policy, programs and services.

Since 2004, he has been executive director of BioAlliance, a not-for-profit network of bioscience business, academic and research organizations and government agencies based on Prince Edward Island.

He is a member of the Canadian Bio Accord and serves as a board member with the Canadian Agri-Food Policy Institute and the PEI AgriFood Alliance Inc. He also is chair of the advisory board for the Culinary Institute of Canada’s Technology Access Centre.

Dr. Warren Jestin is chief economist with Scotiabank and has been with the bank since 1979. Jestin also has worked at the Bank of Canada and taught at several Canadian universities. He is economist-in-residence at the College of Management and Economics of the University of Guelph and has served on advisory boards for the University of Guelph and the Sobey School of Business at Saint Mary’s University.

Jestin has been a member of the C.D. Howe Institute’s Monetary Policy Council and has been involved with policy committees of the Canadian and Ontario Chamber of Commerce and the Toronto Board of Trade. As chair of Scotiabank’s Sponsorship and Donations Committee, he works closely with a wide variety of charitable institutions.

Phil Tregunno is a fourth-generation

farmer operating the 700-acre Tregunno Fruit Farms Inc. along the Niagara River in Ontario. With a focus on new technologies, improved varieties and organics, the operation has grown and prospered, packing quality fruit for the Canadian marketplace.

Tregunno serves as chairman of the Ontario Tender Fruit Producers Marketing Board, as chairman of Vineland Growers Co-operative and as director of the Winery and Growers Alliance of Ontario.

The Ontario Fruit and Vegetable Growers’ Association (OFVGA) is seeking nominations for its Industry Award of Merit, which is presented annually to an individual or organization who has made outstanding contributions to the fruit and vegetable industry.

This can include strategic leadership, technical input, and/or the dedication shown by an individual or organization to Ontario’s fruit and vegetable sector.

“The objective of the award is to recognize grassroots innovators and longtime supporters of our industry, or to acknowledge outstanding contributions to Ontario’s fruit and vegetable industry,” says Art Smith, CEO of the OFVGA. “There are many individuals and organizations that have had tremendous positive impact on our edible horticulture sector and they deserve to be recognized for their work.”

To be eligible, nominees must be a member, a farmer/producer, a group of farmers, a combination of agri-food businesses, or an agri-food related organization within the fruit and vegetable industry. They also also reside in Ontario and be a Canadian citizen or have permanent resident status.

Nomination forms are available at www. ofvga.org or by contacting the OFVGA office. Completed forms are due by 5 p.m. on Nov. 30 to Deanna Hutton at OFVGA and may be submitted via e-mail to dhutton@ ofvga.org, fax to 519-763-6604 or postal mail to 105-355 Elmira Rd. N., Guelph ON N1K 1S5.

The Award of Merit recipient will be announced at the OFVGA’s 155th Annual General Meeting in Niagara Falls on Jan. 13, 2014, and will be the subject of a feature article in the February 2014 issue of The Grower.

Recent award winners have included FARMS (2013), Steve Peters (2012) and Adrian Huisman (2011).

On Saturday, October 5, 2013, the Asparagus Farmers of Ontario celebrated its 75th anniversary at the Hungarian Hall in Delhi, Ont. Diane Finley, MP, Haldimand-Norfolk, was on hand to present the current and past chairs with a plaque honouring the dedication of the organization’s members to the Ontario asparagus industry. From left to right: John Jaques, Jason Ryder, Diane Finley, Ken Wall, Ed DeHooghe, Brenda Lammens, Ernie Killian.

Tomato spotted wilt virus (TSWV) and the thrips that transmit it can cost growers millions of dollars in yield losses, not just for tomatoes but also for peanuts, tobacco, peppers, potatoes, and many other crops.

Dr. Scott Adkins, Research Plant Pathologist at the USDA Agricultural Research Service, addresses this important issue in the latest Focus on Tomato webcast, titled Tomato Spotted Wilt Virus.

This presentation will help consultants, growers, and other practitioners in North America to identify and manage TSWV. The presentation also includes:

Historical and current perspectives on TSWV and related viruses that cause significant economic losses to fresh market and processing tomato.

Information about host range, symptoms and transmission

Key TSWV management techniques. By the end of this presentation, viewers should know more about the tomato spotted wilt virus’ biology and its relation to virus management.

Tomato Spotted Wilt Virus is open access through January 31, 2014.

Users can view other recent webcasts

in the Focus on Tomato resource at http:// www.plantmanagementnetwork.org/fot.

Webcasts on a variety of other crops can be found in Plant Management Network’s (PMN) Education Center.

To take advantage of PMN’s full line of resources, please sign up for the PMN Update online newsletter.

Edible Horticulture participant packages for the 2013 program year are now being mailed to eligible producers. To participate, producers can submit their deposit requests and cheques to Agricorp by Feb. 1, 2014. To withdraw funds this year, deposit and withdrawal requests must be received by Oct. 31, 2013.

The 2012 provincial budget included the continuation of risk management plans with $100 million in available funding each year. To ensure all pro -

ducers have equal access to the funding, government contributions are now made in instalments, and will not equal 100 per cent of producer deposits. The first government contribution is made at the time of the producer’s deposit, and a second contribution will be made in the summer of 2014 after all participating producers have made their deposits.

The self-directed risk management (SDRM) plan for edible horticulture is part of Ontario’s Risk Management Program to help producers manage risks beyond their control. To be eligible, producers must have a minimum of $5,000 in allowable net sales, grow an eligible commodity, participate in AgriStability, and provide a valid premises ID.

MANA Canada recently welcomed Kevin Jacobson to the company’s management team.

Davis Fuels is a family-owned and operated fuel distributor servicing Brantford, Brant County, Woodstock, London, Simcoe, Hagersville and Tillsonburg for over 55 years.

We carry a complete line of high quality petroleum products for the agriculture industry including:

• Clear diesel

• Colour diesel • propane • Lubricants

For reliability and service, call us today to learn how we can help you manage all of your petroleum needs.

Jacobson joins MANA Canada in the new position of Canadian portfolio manager, responsible for managing MANA Canada’s product portfolio, as well as leading the company’s new product development and innovation program.

“Kevin is an ideal fit for MANA Canada,” said Andrew Mann, general manager. “His expertise in agribusiness is proven through 25 years’ experience.”

Jacobson has a strong agricultural background, providing him with an understanding of the challenges and opportunities facing the industry.

Prior to joining MANA Canada, Jacobson spent 25 years working in the agriculture industry for Cargill AgHorizons, Monsanto, Richardson International Limited and most recently at WinField Solutions as its Canadian business development manager.

MANA Canada provides post-patent products for the crop protection market.

Case IH recently announced that the company’s Continuously Variable Transmissions (CVT) technology is now available for the Maxxum® tractor lineup, with Maxxum 110, 120 and 130 CVT options.

First introduced into the North American market with the Puma family in 2008, Case IH CVT simplifies tractor operation while also delivering balance of power and fuel efficiency.

CVT combines the stepless speed variability of a hydrostatic transmission with the mechanical efficiency of a traditional gear transmission.

Case IH offers an active stop feature that will stop the tractor without the driver having to push the clutch. This makes it easier to operate the tractor, and it makes starting and stopping as simple as driving a pickup truck.

All Maxxum tractors are equipped with standard Power Boost, which provides additional engine power of up to 20 horsepower to maintain working speeds in tough crop conditions or on inclines and to provide more power for roading, mobile hydraulics or PTO applications. Maxxum CVT tractors also feature increased hydraulic capacity for more responsive implement and steering control.

Adding to the Maxxum MultiController models is an updated Case IH Multifunction Handle that simplifies operation.

Redesigned buttons are raised and backlit, and sized to differentiate functions, based on feedback from operators. Drivers can tell the buttons apart by touch alone to make operation even simpler.

Other cab enhancements for Maxxum CVT, Maxxum Multicontroller and Puma models include a newly designed headliner control bank, featuring AC controls, relocated into a more natural line of sight when operating the tractor. The headliner also has three additional slots – one for radio and two for additional storage.

www.caseih.com

Recycled plastic vineyard posts provide an ethical benefit in regards to deforestation issues, but they also stand the test of time better than any wood could, according to Close the Loop Company.

“Vineyard poles are highly durable; are not susceptible to rot, termites, carpenter bees or other wood boring insects; never need painting; look good and function well for many, many years,” states inventor and manufacturer, Patrick Kelley, adding that where wood continues to rot and requires constant upkeep (and money), plastic requires very little, if any, follow-up maintenance over the same lifespan.

According to the company, growers should not be concerned about the plastic itself, and whether or not it contains any chemicals that might be leached into the earth. Unlike pressure-treated wood, the plastic contains no hazardous chemicals that could be leached.

Close the Loop was established in October 2000 and products are made in U.S. from recycling of plastic scrap and waste wood fibre are used as a non-wood alternative building material for the fencing and plastic lumber market in such products as recycled plastic fencing, posts, rails, vineyard poles and composite lumber.

For more information, please visit http://www.closetheloop.com, or check the company’s Facebook page

Syngenta Canada Inc. recently announced the launch of a mobile website – m.syngenta.ca – for Canada’s agricultural community.

This website gives growers fingertip access to agriculturerelated information based on their specific preferences.

“Our new mobile site is a step-change in the mobile experience currently available to growers,” stated Trevor Heck, head of marketing for Syngenta Canada Inc. “This app-like experience is an exciting advancement, providing growers with information to make timely, informed production decisions – wherever they are.”

While m.syngenta.ca provides weather, market and product information, growers who register for the site by providing their name, postal code, crop information and e-mail address (for login purposes only) will receive customized content that is updated regularly, including:

• Local weather – specific to their area based on postal code;

• Market information – detailed futures prices for selected crops, key market indicators and the current value of the Canadian dollar;

• Agronomic news – local news and information that is relevant to selected crops, together with national and international agriculture-related information.

Additionally, Syngenta product information (including product updates) is tailored specifically to the grower’s chosen crops, providing direct access to the most current resources, including pests controlled, application timing and rates, tank-mix compatibility and product labels.

All this information fits on the grower’s mobile device screen, meaning the content will automatically adjust to fit the screen of the viewing device.

“We are excited by what the new m.syngenta.ca mobile site offers growers,” added Heck, “and we are confident it will become a site of choice for busy, on-the-go growers.”

TOMRA Sorting Solutions showcased its Halo 500 system at the 2013 Produce Marketing Association’s (PMA) Fresh Summit Expo held recently in New Orleans.

Representing the latest advance in sensor-based optical sorting and grading, the Halo can be used across a wide variety of foods. It views and analyzes attributes – such as colours, shapes, blemishes, foreign materials and difficult-to-see defects in product composition – for an accurate sort.

“Using top and bottom sensor banks to view each object in flight, the Halo uses a combination of light-emitting diodes, in the visible and near infrared (NIR) spectrum,

to perform targeted spectroscopy with 1 mm precision,” said Jim Frost, market unit manager with TOMRA Sorting Solutions. “Offering high capacity, low maintenance, flexibility, gentle handling and consistent, long-life accuracy, the machine provides quality control and feedback via an intuitive touch screen.”

TOMRA says the Halo system’s benefits for customers include labour cost reductions, averaging 80 per cent upwards; yield increases of up to four per cent; low operational costs; up to 25 per cent faster throughput; improved product quality; a faster pack; and speedy return on investment.

Fresh pack Halo applications include all sizes and varieties of potatoes, carrots, parsnips, onions, garlic, tomatoes, and cucumbers. Processor applications include peeled and unpeeled potatoes; carrots; peaches; pears; tomatoes; green beans, onions; and apricots.

For more information please visit www.tomrasorting.com.

The Pest Management Regulatory Agency (PMRA) recently announced the approval

of a minor use label expansion for Scholar 230SC fungicide (fludioxonil) for control of post-harvest white mold (Sclerotinia) on carrots during storage. Scholar fungicide was already labelled for management of several diseases on a range of crops in Canada.

This minor use submission was sponsored by the Agriculture and AgriFood Canada, Pest Management Centre (AAFC-PMC) in 2008 in response to minor use priorities identified by carrot producers in Canada.

This was also the subject of several repeat emergency use submissions and registrations in several provinces over the past few years.

Access to post-harvest white mold management tools is a priority for carrot producers and the label expansion of Scholar fungicide will provide producers with a helpful disease management tool. Users should consult the complete label before using Scholar fungicide.

For copies of the new minor use label, contact Marion Paibomesai, OMAF/ MRA, Guelph, at 519-826-4963 or visit http://www.syngenta.com/country/ca/ en/Pages/home.aspx.

The innovative technology of smartphones, tablets and mobile devices allow farmers, ranchers, property owners, and farm managers to access information quickly and conveniently in the home, office or field.

To fully leverage this technology, John Deere recently announced a new mobile version of jdparts.deere.com. The new service allows customers to access these sites whenever they are online using their mobile devices.

“Accessing the mobile version can be accomplished by simply typing in jdparts.deere.com on any browser on any smartphone,” said Jim Goldschmidt, product line manager for John Deere. “The user will automatically pick up the mobile version, m.jdparts.deere.com of the website.”

The mobile site can also be accessed on tablets by typing in m.jdparts.deere.com. The “m” is essential on tablet devices to pick up the mobile configuration and not the normal computer desktop version.

The mobile version of jdparts.deere.com allows customers to search by parts catalog, model number, part number, or keyword to locate the appropriate parts and attachments.

www.JohnDeere.com

Reward yourself for a job well done by redeeming your Hot Potatoes® reward points today. You can redeem your points for cash and/or the group trip to beautiful Hawaii in February 2014!

Redeem your points by visiting Hot-Potatoes.ca or calling 1 877-661-6665 today. The deadline for redeeming your points is November 30, 2013.

Case Construction Equipment recently introduced the new Case 521F wheel loader.

The machine is available in standard Z-bar, extended reach and tool-carrier models.

The company chose the selective catalytic reduction (SCR) technology for the 521F to meet Tier 4 Interim emissions standards that are based on the machine’s application tasks and power demands. SCR results in lower temperatures in the exhaust system while optimizing combustion.

The benefits of SCR technology are greater efficiency and reduced downtime because there’s no heightened fuel burn or diesel particulate filter (DPF) regeneration. In addition, lower ambient temperatures mean slower degradation of lubricating oil, which extends service intervals.

The new 521F wheel loader offers optional heavy-duty axles. These axles, with auto-locking front and open rear differentials, have the same design as the larger F series wheel loader axles, including metal face seals and sintered bronze brake linings. They offer traction in all conditions and help reduce tire wear when working on hard surfaces.

www.casece.com

A & L CANADA LABORATORIES

2136 Jetstream Rd.

London, ON N5V 3P5

Tel: 519-457-2575 Fax: 519-457-2664

Toll-Free: 1-855-837-8347

e-mail: alcanadalabs@alcanada.com www.alcanada.com

A.M.A. PLASTICS LTD.

1367 Oxford Ave.

Kingsville, ON N9Y 2S8

Tel: 519-322-1397 Fax: 519-322-1358

Toll-Free: 1-800-338-1136

e-mail: ama@amaplas.com www.amaplas.com

AG GLOBAL

155 Gordon Baker Rd. Toronto, ON M2H 3N7

Tel: 905-947-9444 Fax: 905-477-4449

Toll-Free: 1-888-614-7336 www.buyagglobal.com

AG LEADER TECHNOLOGY

2202 South River Side Dr. Ames, IA 50010 USA

Tel: 515-232-5363 Fax: 515-232-3595

e-mail: info@agleader.com www.agleader.com

AGRICORP

1 Stone Rd. W., Box 3660 Stn. Central Guelph, ON N1H 8M4

Tel: 519-837-6362 Fax: 519-826-4118

Toll-Free: 1-888-247-4999

e-mail: contact@agricorp.com www.agricorp.com

AGRICULTURAL CREDIT CORPORATION

660 Speedvale Ave. W., Suite 201

Guelph, ON N1K 1E5

Tel: 519-766-0544 Fax: 519-766-9775

Toll-Free: 1-888-278-8807

e-mail: info@agcreditcorp.ca www.agcreditcorp.ca

AGRICULTURE AND AGRI-FOOD CANADA

- ONTARIO REGION

174 Stone Rd. W. Guelph, ON N1G 4S9

Tel: 226-217-8555 Fax: 226-217-8187

www.agr.gc.ca

AGROHAITAI LTD.

2764 Hwy. 99

Lynden, ON L0R 1T0

Tel: 519-647-2280 Fax: 519-647-3188

e-mail: seed@agrohaitai.com www.agrohaitai.com

AGROSPRAY LIMITED

85 Spruce St.

Tillsonburg, ON N4G 5C4

Tel: 519-842-8408 Fax: 519-688-0456

Toll-Free: 1-800-640-AGRO (2476)

e-mail: admin@agrospray.com www.agrospray.com

ALPINE STEEL BUILDINGS

1-1385 Stevens Rd. West Kelowna, BC V1Z 2S9

Tel: 778-436-2681 Fax: 888-332-9804

Toll-Free: 1-800-565-9800 www.alpinesteelbuildings.com

ARYSTA LIFESCIENCE

138 Dovercliffe Rd. Guelph, ON N1G 3A6

Toll-Free: 1-866-761-9397 Fax: 519-7660415

e-mail: mark.mclear@arystalifescience.com www.arystalifescience.ca

ATAGO U.S.A., INC.

11811 NE First St., Suite 101 Bellevue, WA 98005 USA

Tel: 425-637-2107 Fax: 425-637-2110

e-mail: customerservice@atago-usa.com www.atago.net

AXTER AGROSCIENCE INC.

1180 Post Point Lane, Box 227 Erieau, ON N0P 1N0

Tel: 519-365-7363

e-mail: dean.jones@axter.ca www.axter.ca

BAG SUPPLIES CANADA LTD.

38 North Pointe Estates

Stratford, ON N5A 8C3

Tel: 519-271-5393 Fax: 519-271-5395

e-mail: info@bagsupplies.ca www.bagsupplies.ca

BARTLETT N.M. INC.

4509 Bartlett Rd.

Beamsville, ON L0R 1B1

Tel: 905-563-8261 Fax: 905-563-7882

Toll-Free: 1-800-263-1287

e-mail: info@bartlett.ca www.bartlett.ca

Main Products/Services: Crop protection production products, plant nutrition, picking aids, safety supplies.

BASF - THE CHEMICAL COMPANY

100 Milverton Dr. Mississauga, ON L5R 4H1

Toll-Free: 1-877-371-2273 www.AgSolutions.ca

BAYER CROPSCIENCE

5-160 Research Lane

Guelph, ON N1G 5B2

Toll-Free: 1-888-283-6847

e-mail: askus@bayercropscience.ca www.bayercropscience.ca

BC AGRICULTURE COUNCIL

230 - 32160 South Fraser Way

Abbotsford, BC V2T 1W5

Tel: 604-854-4454 Fax: 604-854-4485

Toll-Free: 1-866-522-3447 www.bcac.bc.ca

BC FRUIT GROWERS’ ASSOCIATION

1473 Water St.

Kelowna, BC V1Y 1J6

Tel: 250-762-5226 Fax: 250-861-9089

e-mail: info@bcfga.com www.bcfga.com

BEJO SEEDS INC.

1088 Healey Rd.

Geneva, NY 14456 USA

Tel: 315-789-4155 Fax: 315-789-1961

e-mail: info@bejoseeds.com

BEN BERG FARM & INDUSTRIAL EQUIPMENT LIMITED

42134 Hwy. 3

Wainfleet, ON L0S 1V0

Tel: 905-899-3405 Fax: 905-899-3507

e-mail: info@benberg.com www.benberg.com

BRAEMAR BUILDING SYSTEMS

3149 Haldimand Rd. 9 York, ON N0A 1R0

Tel: 905-772-3551 Fax: 905-772-3422

Toll-Free: 1-800-215-1996 www.braemarbuildings.com

BRITESPAN BUILDING SYSTEMS

37651 Amberley Rd.

Lucknow, ON N0G 2H0

Tel: 519-528-2922 Fax: 519-528-2890

Toll-Free: 1-800-407-5846

e-mail: info@britespanbuildings.com www.britespanbuildings.com

BUHLER INDUSTRIES INC.

1201 Regent Ave. W. Winnipeg, MB R3C 3B2

Tel: 204-661-8711 Fax: 204-654-2503

e-mail: info@buhler.com www.buhlerindustries.com

CCADMAN POWER EQUIPMENT LTD.

38 Main St. Box 100

Courtland, ON N0J 1E0

Tel: 519-688-2222 Fax: 519-688-2100

Toll-Free: 1-866-422-3626

e-mail: paulsontrop@cadmanpower.com www.cadmanpower.com

CAMPBELL’S LIME SERVICE

RR 8, Brantford, ON N3T 5M1

Tel: 519-647-3448 Fax: 519-647-3535

Toll-Free: 1-800-788-3320

CANADA’S OUTDOOR FARM SHOW

160 Research Lane, Unit 101 Guelph, ON N1G 5B2

Tel: 519-822-2890 Fax: 519-829-1777

Toll-Free: 1-800-563-5441

e-mail: info@outdoorfarmshow.com www.outdoorfarmshow.com

CANADIAN ASSOCIATION OF FARM ADVISORS (CAFA) INC.

Box 578, Blaine Lake, SK S0J 0J0

Tel: 306-466-2294

Toll-Free: 1-877-474-2871

Fax: 306-466-2297

e-mail: info@cafanet.com www.cafanet.com

CANADIAN CLIMATROL SYSTEMS LTD.

307-17665 66A Ave. Surrey, BC V3S 2A7

Tel: 604-576-7677 Fax: 604-576-7688

Toll-Free: 1-877-576-7677

e-mail: ccsbc@ccsbc.com www.ccsc.com

CANADIAN CORRUGATED AND CONTAINERBBOARD ASSOCIATION

3 - 1995 Clark Blvd. Brampton, ON L6T 4W1

Tel: 905-458-1247 Fax: 905-458-2052

e-mail: info@cccabox.org www.cccabox.org

CANADIAN HORTICULTURAL COUNCIL

9 Corvus Court

Ottawa, ON K2E 7Z4

Tel: 613-226-4880 Fax: 613-226-4497 www.hortcouncil.ca

CHERRY LANE

4230 Victoria Ave. Vineland Station, ON L0R 2E0

Tel: 905-562-4337 Fax: 905-562-5577

Toll-Free: 1-877-CHERRY-6 e-mail: sales@cherrylane.net www.cherrylane.net

CHRISTIAN FARMERS FEDERATION OF ONTARIO

7660 Mill Rd., RR 4

Guelph, ON N1H 6J1

Tel: 519-837-1620 Fax: 519-824-1835 www.christianfarmers.org

CLAUSSEN FARMS CUSTOM FARMING INC.

76402 Airport Line

Brucefield, ON N0M 1J0

Tel: 519-233-3198 Fax: 519-233-3199

e-mail: claussen@tcc.on.ca www.claussenfarms.com

CODERRE PACKAGING

413, route 122

St-Germain de Grantham, QC J0C 1K0

Tel: 819-395-4223 Fax: 819-395-2636

e-mail: coderre@embcoderre.com www.embcoderre.com

CROP QUEST INC.

74 Sylvia St., PO Box 357

Mitchell, ON N0K 1N0

Tel: 519-348-1121 Fax: 519-348-0030

Toll-Free: 1-866-630-2767

e-mail: cropquest@quadro.net www.cropquest.ca

CROPLIFE CANADA

612 - 350 Sparks St. Ottawa, ON K1R 7S8

Tel: 613-230-9881 www.croplife.ca

CURTIS WAGNER PLASTICS CORP. PO Box 840885

Houston, TX 77284 USA

Tel: 713-937-3784 Fax: 713-937-3338

Toll-Free: 1-800-332-1663

e-mail: sales@cwplastics.com www.cwplastics.com

DARLING INSURANCE & REALTY LTD.

193 Aylmer St. N. Peterborough, ON K9J 6Z3

Tel: 705-742-4245 Fax: 705-742-8901

Toll-Free: 1-800-387-1627

e-mail: farmfresh@darlinginsurance.net www.darlinginsurance.net

DAVIS FUELS

22 King St. Burford, ON N0E 1A0

Tel: 519-449-2417 Fax: 519-449-5942

Toll-Free: 1-800-369-0480 www.davisfuels.ca

DECADE PRODUCTS

3400 Innovation Court

Grand Rapids, MI 49512 USA

Toll-Free: 1-877-999-6229 Fax: 616-254-4259

e-mail: david.gargett@decadeproducts.com www.decadeproducts.com

DEGROOTE-HILL CHEVROLET-BUICKGMC LTD.

Hwy. 3, Tillsonburg, ON N4G 4H3 Tel: 519-842-9026 Fax: 519-842-9027

Toll-Free: 1-800-668-0857

e-mail: gord@degrootehill.com www.degrootehill.ca

DFK EQUIPMENT SALES INC.

475 James St. S., Box 938

St. Marys, ON N4X 1B6

Toll-Free: 1-800-881-3794

Fax: 519-349-2099

e-mail: sales@dfkequipment.com

DOMINION & GRIMM INC.

18766 Communication Rd.

Blenheim, ON N0P 1A0

Tel: 519-676-1914 Fax: 519-676-0968

Toll-Free: 1-877-676-1914

e-mail: heather@dominiongrimm.ca www.dominiongrimm.ca

DON ARTHUR ORCHARD EQUIPMENT

496426 Grey Rd. 2, RR 2

Clarksburg, ON N0H 1J0

Tel: 519-599-3058 Fax: 519-599-3378

e-mail: donarthur3@gmail.com

DOW AGROSCIENCES CANADA INC.

2100 - 450 1st St. SW Calgary, AB T2P 5H1

Tel: 403-735-8800 Fax: 1-888-296-6188

Toll-Free: 1-800-667-3852

e-mail: solutions@dow.com www.dowagro.com/ca

DUBOIS AGRINOVATION INC.

710 Old Hwy. 24, RR 3 Waterford, ON N0E 1Y0

Tel: 519-443-4834 Fax: 519-443-8257

Toll-Free: 1-800-815-9929

e-mail: info@duboisag.com www.duboisag.com

DUBOIS AGRINOVATION INC.

478, Notre-Dame, PO Box 3550

St-Remi, QC J0L 2C0

Tel: 450-454-4641 Fax: 450-454-6638

Toll-Free: 1-800-667-6279

e-mail: info@duboisag.com www.duboisag.com

DUPONT CANADA

Head Office: PO Box 2300 Streetsville Mississauga, ON L5M 2J4

Toll-Free: 1-800-667-3925

Fax: 905-816-3064

e-mail: ag.hotline@can.dupont.com www.cropprotection.dupont.ca

DURWARD JONES BARKWELL & COMPANY LLP

69 Ontario St.

St. Catharines, ON L2R 6V9

Tel: 905-684-9221 Fax: 905-684-0566

e-mail: rwismer@djb.com www.djb.com

E. R. VOLLANS LTD.

1682 County Rd. 20 W., RR 3

Kingsville, ON N9Y 2E6

Tel: 519-733-5233 Fax: 519-733-2860

EASTERN FARM MACHINERY LTD.

RR 3, PO Box 3613

Guelph, ON N1H 6P1

Tel: 519-763-2400 Fax: 519-763-3930

e-mail: sales@easternfarmmachinery.com www.easternfarmmachinery.com

ECO+ INC.

2457, 4e Rand Sud

Saint-Charles-sur-Richelieu, QC J0H 2G0

Tel: 450-584-1122

e-mail: mrichard@eco-plus.ca www.eco-plus.ca

EGGER TRUCK & MACHINE LTD.

85 Robinson Rd., RR 1

Dunnville, ON N1A 2W1

Tel: 905-774-1060 Fax: 905-774-6815

Toll-Free: 1-800-429-8819

e-mail: roger@eggertruck.com www.eggertruck.com

EMILE SENECHAL ET FILS LTEE

190 Industrial Rd.

Grand-Sault Falls, NB E3Y 3V3

Tel: 506-473-2392 Fax: 506-473-4306

Toll-Free: 1-888-966-2247

e-mail: esfltee@esfltee.com www.esfltee.com

ENGAGE AGRO CORPORATION

1030 Gordon St.

Guelph, ON N1G 4X5

Toll-Free: 1-866-613-3336

Fax: 519-826-7675

e-mail: info@engageagro.com www.engageagro.com

ENVIREM ORGANICS INC.

122 Killarney Rd.

Saint Marys, NB E3G 9E2

Tel: 506-459-3464 Fax: 506-453-1332

Toll-Free: 1-800-524-9411

e-mail: sales@envirem.com www.envirem.com

ENVIROGRO - DIV. OF FILCHEM INC.

1225 Gorham St., 22

Newmarket, ON L3Y 8Y4

Tel: 905-853-1363 Fax: 905-853-2334

Toll-Free: 1-800-263-7427

e-mail: sales@filchem.com www.filchem.com

ERIE REFRIGERATION

1270 County Rd. 28

Langton, ON N0E 1G0

Tel: 226-567-4098

e-mail: ian@erierefrigeration.ca www.erierefrigeration.ca

EVERGREEN LIQUID PLANT FOOD LTD.

RR 6, Breslau, ON N0B 1M0

Tel: 519-742-8377 Fax: 519-570-1257

e-mail: info@evergreenliquidplantfood.com www.evergreenliquidplantfood.com

FARM CREDIT CANADA

100-120 Research Lane

Guelph, ON N1G 0B5

Toll-Free: 1-800-387-3232

Fax: 519-826-2066 www.fcc-fac.ca

FARMERS’ MARKET ONTARIO

54 Bayshore Rd. Brighton, ON K0K 1H0

Tel: 613-475-GROW (4769) Fax: 613-475-2913

Toll-Free: 1-800-387-FARM (3276)

e-mail: fmo@farmersmarketsontario.com www.farmersmarketsontario.com

FBC, CANADA’S FARM & SMALL BUSINESS TAX SPECIALISTS

2109 Oxford St. E. London, ON N5V 2Z9

Tel: 519-453-5040 Fax: 519-453-4506

Toll-Free: 1-800-265-1002

e-mail: fbc@fbc.ca www.fbc.ca

FRASER VALLEY STEEL & WIRE LTD.

3174 Mt. Lehman Rd. Abbotsford, BC V4X 2M9

Tel: 604-856-3391 Fax: 604-856-0603

Toll-Free: 1-877-856-3392

e-mail: fvsteel@shawbiz.ca

FRESH VEGETABLE GROWERS OF ONTARIO

Ag Business Centre, 120 Main St. East Ridgetown, ON N0P 2C0

Tel: 519-674-1500 Fax: 519- 674-1512

e-mail: rcfvgo@uoguelph.ca www.freshvegetablesontario.com

FRONTLINK INC.

1492 Windham Rd. 12, RR 4 Simcoe, ON N3Y 4K3

Tel: 519-428-9812 Fax: 519-428-2640

Toll-Free: 1-877-553-2524

e-mail: sales@frontlinkinc.com www.frontlinkinc.com

G.W. ALLEN NURSERY LTD.

7295 Hwy. 221, RR 2 Centreville, NS B0P 1J0

Tel: 902-678-7519 Fax: 902-678-5924

e-mail: sales@gwallennursery.com www.gwallennursery.com

RUPP SEEDS INC.

17919 County Rd. B

Wauseon, OH 43567 USA

Tel: 419-337-1841 Fax: 419-337-5491

Toll-Free: 1-800-700-1199

e-mail: info@ruppseeds.com www.ruppseeds.com

SAC DRUMMOND INC.

192 Station Rd.

St-Germain, QC J0C 1K0

Tel: 1-877-395-4286 Fax: 1-877-395-4288

e-mail: denisb@sacdrummond.qc.ca

SAKATA SEED AMERICA, INC.

18095 Serene Dr.

Morgan Hill, CA 95037 USA

Tel: 408-778-7758 Fax: 408-778-7768

Toll-Free: 1-800-778-7768

e-mail: info@sakata.com www.sakata.com

SASKATCHEWAN FRUIT GROWERS ASSOCIATION

Box 1107, Yorkton, SK S3N 2X3 Tel: 306-782-0256 Fax: 306-783-8645

Toll-Free: 1-877-97-FRUIT (37848)

e-mail: kp.stewart@yourlink.ca www.saskfruit.com

SCHOLTENS

156 Old Orchard Rd. Burlington, ON L7T 2G1

Tel: 905-632-9637 Fax: 905-632-1696

SEEDWAY LLC

99 Industrial Rd. Elizabethtown, PA 17022 USA

Toll-Free: 1-800-952-7333

Fax: 800-645-2574

e-mail: vegseed@seedway.com www.seedway.com

SHUR FARMS FROST PROTECTION

1890 N. 8th St. Colton, CA 92324 USA

Tel: 909-825-2035 Fax: 909-825-2611

Toll-Free: 1-877-842-9688

e-mail: info@shurfarms.com www.shurfarms.com

SIEGERS SEED COMPANY

13031 Reflections Dr. Holland, MI 49424 USA

Tel: 519-773-3250 Fax: 888-765-8715

Toll-Free: 1-800-962-4999

e-mail: jammie.underhill@siegers.com www.siegers.com

SLIMLINE MANUFACTURING LTD.

559 Okanagan Ave. E. Penticton, BC V2A 3K4

Tel: 250-493-6145 Fax: 250-492-7756

Toll-Free: 1-800-495-6145 www.turbomist.com

SOMMERS MOTOR GENERATOR SALES LTD.

101 Woodstock St. S. Tavistock, ON N0B 2R0

Tel: 519-655-2396 Fax: 519-655-3176

e-mail: laura.mckay@sommersgen.com www.sommersgen.com

SOUCY GROUP

5450 Saint-Roch St. Drummondville, QC J2B 6W3

Tel: 819-474-6666 Fax: 819-474-8262 www.soucy-group.com

SPECTRUM TECHNOLOGIES

3600 Thayer Court Aurora, IL 60504 USA

Tel: 815-436-4440 Fax: 815-436-4460

Toll-Free: 1-800-248-8873

e-mail: info@specmeters.com www.specmeters.com

SPER SCIENTIFIC

7720 E. Evans Rd., Suite 103 Scottsdale, AZ 85260 USA

Tel: 480-348-0278 Fax: 480-348-0279

e-mail: orders@sperdirect.com www.SperDirect.com

ST. CATHARINES NEW HOLLAND LTD.

1410 4th Ave., RR 3 St. Catharines, ON L2R 6P9

Tel: 905-688-5160 Fax: 905-688-9994

STAN PETERSON FRUIT TREE SALES

2574 S. Benedict Rd. Ludington, MI 49431 USA

Tel: 231-499-9292 Fax: 231-843-4113

Toll-Free: 1-888-333-1464

e-mail: stan@fruit-treesales.com

STEVENS IRRIGATION

49 James Ave.

Tillsonburg, ON N4G 1A3

Tel: 519-842-9583 Fax: 519-842-7779

STOKES SEEDS LTD.

296 Collier Rd. S., PO Box 10 Thorold, ON L2V 5E9

Toll-Free: 1-800-396-9238

Fax: 800-272-5560

e-mail: stokes@stokeseeds.com www.stokeseeds.com

STRAWBERRY TYME FARMS INC.

1250 St. John Rd. W., RR 2

Simcoe, ON N3Y 4K1

Tel: 519-426-3099

Fax: 519-426-2573

e-mail: styme@kwic.com www.strawberrytyme.com

SURPLUS REFRIGERATION LTD.AGRICHILL

1469 Taunton Rd. W. Pickering, ON L1V 2P8

Tel: 905-686-3411 Fax: 905-428-1969

Toll-Free: 1-800-563-7684

e-mail: info@agrichill.com www.agrichill.com

SYFILCO LTD.

320 Thames Rd. E. Exeter, ON N0M 1S3

Tel: 519-235-1244 Fax: 519-235-1280

Toll-Free: 1-877-235-1233

e-mail: syfilco@syfilco.on.ca www.syfilco.on.ca

SYNGENTA CROP PROTECTION CANADA INC.

140 Research Lane, Research Park Guelph, ON N1G 4Z3

Toll-Free: 1-888-368-4211 Fax: 519-823-0504 www.SyngentaFarm.ca

TTERRALINK HORTICULTURE INC.

464 Riverside Rd. Abbotsford, BC V2S 7M1

Tel: 604-864-9044 Fax: 604-864-8418

Toll-Free: 1-800-661-4559

e-mail: info@tlhort.com www.tlhort.com

TIMM ENTERPRISES LTD.

5204 Trafalgar Rd. Milton, ON L0P 1E0

Tel: 905-878-4244 Fax: 905-878-7888

Toll-Free: 1-888-769-TIMM (8466) www.timmenterprises.com