PureSpray™ GREEN Spray Oil 13E. Protection at its purest –CAS# 8042-47-5

Introducing PureSpray GREEN Spray Oil 13E, from the largest producer of white oils. It’s proof that not all spray oils are created equal. It is an innovative isoparaf n oil that offers the highest purity levels on the market with CAS# 8042-47-5. This means it’s formulated with 99.9% pure isoparaf n base oils and is guaranteed to be free of aromatics, which harm the food chain. And since it’s suitable for organic production, both organic and traditional growers can bene t from its many strengths.

PureSpray GREEN Spray Oil 13E effectively protects your high value grape crop by quickly controlling pests and disease, and providing extended protection within your IPM program. All without any

resistance, phytotoxicity or burning issues, when used as directed. So use it early to avoid the need for traditional toxic chemicals later.

As many pesticides are being delisted, your choices are limited and becoming more so every day. So when you have a choice to make, be sure to choose the purest – PureSpray GREEN Spray Oil 13E. It’s an effective choice with unlimited possibilities. For more product information visit www.purespraygreen.com/grapes.

becoming more so every day. So when you have a choice to make,

Editor

November/December 2012

Volume 68, No. 6

Margaret Land mland@annexweb.com

519-429-5190 • 888-599-2228 ext. 269

Advertising Manager

Sharon Kauk skauk@annexweb.com 519-429-5189 • 888-599-2228 ext. 242

Sales Assistant

Mary Burnie mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext. 234

Production Artist

Emily Sun

Group Publisher

Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

PUBLICATION MAIL AGREEMENT #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT.,

P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: lmorrison@annexweb.com

Fruit & Vegetable Magazine was published six times in 2012 (January, February, March, April, Mid-April, November/ December) by Annex Publishing & Printing Inc., P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Printed in Canada ISSN 1488-7959

Circulation

e-mail: subscribe@fruitandveggie.com

Tel: 1-866-790-6070 ext. 202 Fax: 1-877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $ 21.00 (includes GST – #867172652RT0001) $22.60 (includes QST/HST) U.S.A. – 1 Year $35.00 US

Foreign – 1 Year $ 55.00 US

Occasionally, Fruit & Vegetable Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2012 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Ilove a good-news story.

Deep down, I think most human beings do: the missing child suddenly found, the dog rescuing the baby from the fire, the miners all being brought up alive, the little girl making it out of the well. We all love to hear that something wonderful has happened when the exact opposite was also a possibility.

Recently, Canada’s apple industry has been experiencing just that – good-news stories. And with the disaster that was the 2012 apple season – at least in eastern parts of the country – a good-news story for apple growers is nothing to scoff at.

This fall, B.C. growers have been basking in their good news – a bumper crop fetching high prices. The weather disaster in eastern Canada and the eastern U.S. this past spring has meant a shortage of apples on the North American market and a prime opportunity for west coast growers. And just in time, too.

“(The) last four years have been devastating,” B.C. Fruit Growers Association president Kirpal Boparai told CBC News. “I’m hoping everybody makes a few cents.”

This is the same association that in early 2010 had members selling their apple crop at 13 cents per pound, almost 10 cents per pound below the break-even point for cost of production.

Of course, this good-news story comes at the cost of Ontario apple producers, some of whom lost most of their crop to a spring frost that followed an early warm spell in late March. This resulted in a loss of about 88 per cent of the province’s apple crop, according to Brian Gilroy, chair of the Ontario Apple Growers. In some cases, growers with on-farm markets were forced to supplement their spotty or non-existent produce with apples shipped in from Quebec.

La belle province also had a good-news story this year with an announcement of $150,000 in funding from the federal government to help in the development of an “experimental commercial process and production chain prototype” to extract the natural sugars from low-grade apples. The project is being tackled by Les Vergers Cataphard & Fils Ltd., the third-largest apple packer in Quebec, which is located in the Laurentide region with production of about 20,000 trees.

“We are thrilled to have received support,” said Martin Cataphard, president of the operation, adding the investment will help

with the development of their value-added products.

This is very similar to the good news that another business, Martin’s Apple Fruit Farm, located near Waterloo, Ont., received back in July when the federal government announced a $1.5-million investment in the operation to create a new processing line for apple crisp snacks and cider.

“Together, we will be creating a new opportunity to contribute to the growth and sustainability of the Ontario apple industry,” said Kevin Martin, president of Martin’s Apple Fruit Farm.

And the good news just kept on coming. In early October, the feds had another good-news announcement for the Canadian apple industry – the naming of a new apple variety. Formerly known as SPA493, the medium-sized, late-harvest pink and yellow apple is now known as Salish – the language and name of a First Nations tribe that lives along the west coast of Canada. It was developed and tested by Agriculture and Agri-Food Canada in partnership with the Okanagan Plant Improvement Corporation (PICO) and originated from a cross of Splendour and Gala cultivars.

“With already 15 orchardists committed to growth Salish, we look forward to having increased production year after year,” said John Kingsmill, general manager and CEO of PICO. “This … apple holds the promise of being one of the best.”

There have been other good-news stories in the apple industry this year, including a visit by the International Fruit Tree Association to apple producers in Quebec, several demonstrations of a fruit-picking machine from Europe that can potentially help cut labour costs by 35 per cent, plus an orchard automation workshop in Nova Scotia that introduced apple producers to the future of fruit production.

It’s awesome to hear about good-news stories, especially for an industry that has struggled in the past. I look forward to hearing and reporting on more promising news from Canada’s fruit and vegetable industry in the new year.

• • •

On a sad note, the Canadian apple industry

lost a great friend and ambassador this past summer. Gary Ireland, a Simcoe, Ont., apple producer for more than 50 years, passed away Aug.16 at Brantford General Hospital. He was 68.

I can remember the first time I met Gary. I was a young, wet-behind-the-ears junior reporter at the local Simcoe newspaper intent on writing a series on the future of farming – and failing at it miserably. I think Gary took pity on me. He spent an afternoon driving around with me in his truck visiting his various orchards and talking about his favourite subjects – apples and farming.

I don’t remember how that series worked out but I do remember Gary’s kindness and patience with a cub reporter who might have understood agriculture but had a lot to learn about apples.

Many years later, as editor of Canadian Fruit Grower and Fruit and Vegetable Magazine, I interacted with Gary numerous times, touring his orchards and marvelling at his many innovative production ideas that he was only too willing to share with all apple producers. I also attended Canadian Horticultural Council Apple Committee meetings when he served as chair.

To list Gary’s accomplishments in the apple industry is daunting. He was a past president and director of the Ontario Apple Commission, a member of the Norfolk Fruit Growers, a past president of the Ontario Fruit and Vegetable Growers’ Association, a past winner of the Golden Apple Award, a past chair of the Ontario Food Terminal’s board, a past member of Horticulture Crops Ontario and part of the group that helped create the annual Ontario Fruit & Vegetable Convention. That organization recently founded an annual scholarship at the University of Guelph in Gary’s name to express appreciation for the work he did to help that show become a success.

Gary is survived by his daughter, Meredith, her husband, Dion Klitzke, and their son, Garret. I extend to them my deepest sympathies. Gary was a wonderful, kind man. ❦

By Dan Woolley

North American strawberry growers spent two days in mid-August visiting some of Nova Scotia’s best berry farmers.

The 65 delegates from 12 U.S. states and six Canadian provinces in the North American Strawberry Growers Association started their tour by visiting Webster Farms of Cambridge, N.S., located in the Annapolis Valley.

Greg Webster told the visitors he and his two brothers moved from perennial raspberry production to biennial growing over the past several year to reduce their labour and management efforts.

They are also doing berry test planting with numbered cultivars from the Atlantic Food and Horticulture Research Centre’s fruit breeding program, Webster adds, although the only raspberry production cultivar they are now growing is Nova. It is a good variety,

he said, but they are looking to replace it.

Webster says they are examining the just-named raspberry cultivar, Eden, which he feels is “head and shoulders above Nova. We don’t want for Nova to peter out before we look at another cultivar.”

According to Webster, all cultivars appear to have a life cycle.

“We tried Encore one year,” he recalls. “It was the berry from hell,” he said, adding that it bled after picking.

Since an adjustable raspberry trellis system did not work for them, the Websters modified a three-wire replacement trellis. Increased problems with two-spotted spider mites prompted the brothers to place beehives around their berry plots.

In 2010, the three brothers planted new raspberry plots from which they are now harvesting about 29,000 pints per acre.

By modifying the operation’s trellis system, adopting biennial production and drip irrigation, Webster estimates they’ve increased their raspberry production from 5,000 pints per acre for all plots to 10,000 to 16,000 pints per acre, exceeding the average Nova Scotia yield.

“It is more like the B.C. crop yield,” he said.

The Websters also grow strawberries; they are currently trialing two new cultivars, including KO412, which Webster likes in a matted-row system. Production averages about 12,000 to 14,000 quarts of strawberries per acre from their matted rows, which they renew every one to three years.

Webster adds that they tried the strawberry variety Myra but it tasted and looked unpleasant.

The brothers have also tried growing the

variety Jewel but removed it after one year due to phytophthora and root rot issues.

Rolf Meiers of Centreville, N.S., manages about 25 acres of day-neutral strawberries, mainly Albion and Dar Select, growing in a plasticulture system, plus an additional 18 acres of June-bearing berries. Experimentation has shown him that many common strawberry varieties grown in the Annapolis Valley do not thrive under plastic.

As a result, Meiers follows a strict crop management program involving two to three sprays for powdery mildew during the growing season while cropping a row for two years. He then lifts the plants, fumigating the row before replanting to control the high incidence of verticillium that has occurred in his fields in the past.

A great believer in compost, Meiers applies municipal compost to the row at a rate of 1.5 to two pounds per row foot before planting the crowns into plastic. Overall, he applies about 1,500 pounds of compost per acre. He has found it has improved his soil quality while also saving him about $300 in dry fertilizer costs.

Every month, he brews a compost tea and applies it to his berry crop through the trickle irrigation system, along with 26 pounds of nitrogen and 42 pounds of potassium.

Meiers uses only trickle irrigation on his strawberry plantings and claims he experienced a 95 per cent survival rate in an 11acre plot of strawberries he planted during last July’s drought.

He also uses Typar row covering, applying it over the rows in early October. He has found it works very well at insulating the crop and the strawberry crowns will continue to grow under the covers until early December.

During the fruiting season, Meiers harvests Albion every second day, picking about 50 flats per acre. He also has a fiveweek Dar Select season, although he has found the variety is temperamental to manage and very susceptible to powdery mildew.

Meiers recently purchased a new German-built, tractor-mounted strawberry runner cutting machine for use on his dayneutral strawberries.

In northern Nova Scotia near Debert, Curtis Millen operates the province’s largest berry farm with extensive trickle irrigation and fertigation for 55 acres of matted-row strawberries, 55 acres of day-neutral berries and 20 acres of short-day (60-day) ber-

ries, with the short-day and day-neutrals both produced using plasticulture.

“He is just experimenting on a big scale, trying to find the right varieties for his needs,” says John Lewis, a berry and grape specialist with Perennia. He adds that Millen is working to extend his berry season earlier into the spring and later into October.

Millen’s objective is to produce berries under row covering for spring and winter protection.

“Our intention is to make sure we don’t have to protect more than 20 acres for frost early in the spring,” Millen says.

He also believes that growing strawberries under poly is a more desirable production method.

“With matted-row we are running into tired plants and ugly fruit,” he says.

Millen’s short-day strawberries are not yet profitable and so he continues to search for the right cultivar while planting them as three- to four-week-old plugs under highdensity poly using a tractor fitted with GPS and auto-steering.

“We are still looking for that silver bullet,” he says, adding every cultivar he now grows is under trial.

Early in the 2012 season, Millen purchased a Fresh QC traceability system, which gives each picker and the boxes they fill a distinctive bar code. This system works as a means of traceability and quality control, and is a productivity monitor. ❦

By Dan Woolley

Growing vine grapes in cold climate areas can be a challenge, particularly when winter temperatures dip below -25 C and late spring frosts strike just as the vines are preparing for warmer temperatures.

A wind machine can be a useful machine for wine growers with vines in frost susceptible areas, according to Joe Pilliteri, owner of Lakeview Vineyard Equipment. And in 2012, some weather made it seem like everybody was in a susceptible area.

“This is one piece of equipment you are going to borrow money for,” said Pilliteri during the 2012 Atlantic Canada Wine Symposium held in Halifax, N.S. “This is a machine it makes no sense not to borrow for.”

Ken Slingerland, who joined Lakeview recently after 36 years with the Ontario Ministry of Agriculture, Food and Rural Affairs as a vineyard specialist, explained winter stress injury can cause vine collapse and aggressive sucker growth. Most winter stress injury occurs about four to six inches above the ground in the vineyard, he said, adding crown gall is endemic in Canada as a result of winter injury.

Maximum vine hardiness in Canadian vinifera usually occurs in January, said Slingerland, adding that vine hardiness is dynamic, changing over time.

“That is why we can get sub-zero temperatures and the grapevine will continue to grow.”

The flip side to that is a late spring frost can result in bud damage and decreased yield. A winter freeze or spring frost can reduce vineyard yield and it can take two to three years for the vineyard to recover with replacement vines, said Slingerland.

To combat the possibility of winter injury, he recommends growers avoid planting vines in frost pockets – low areas where cold air settles.

But even with a well-planned vineyard, growers are still at the mercy of Mother Nature. On one night in 2005 when the temperature plunged to -25 C in the Niagara area of Ontario, more than $25-million

worth of grapes in farm gate value was lost, explained Slingerland.

“After that, a lot of growers decided [that] if they were in the industry for the long haul, to get wind machines.”

As a result, the Ontario vineyard industry has been swift to adopt wind machines.

“Before 2005, we only had about 15 machines,” said Slingerland. “Now, we have over 500 in the Niagara Peninsula alone.”

A wind machine works in areas where air temperature inversion layers occur. An inversion layer of air over a vineyard –which can be as high as 20 metres above the ground – can have temperatures as much as 5 C higher than ground temperature, explained Slingerland. The wind machine acts like “a giant egg beater” mixing the higher warm air of the inversion layer with the colder air at ground level, thus raising the temperature in the vineyard.

With one wind machine, about 15 acres of vineyard can be covered, protecting about $100,000 worth of crop, he said.

When positioning a wind machine on a cement pad in the vineyard, Slingerland advised growers to consider the vineyard’s slope, the drift of the land that directs the

airflow over the vineyard’s surface and the prevailing winds over the site. The blade of the machine should angle down about six degrees from the horizontal plane.

“If the hill is steep we use a tilted head,” he said.

Wind machines can be fuelled using propane, diesel or natural gas. About 70 per cent of the wind machines Lakeview sells use propane, 15 per cent use diesel and the remaining 15 per cent are fuelled with natural gas.

The capital cost for one machine –which has a service life of about 35 years – is about $34,000 with an annual fuel cost of about $840 on average, said Slingerland.

While wind machines are equipped with mufflers and are very quiet, they can also create an oscillating sound as the machine head rotates every five minutes. It’s recommended they be set back at least 400 feet from property lines and away from neighbouring homes if possible.

“Be proactive,” said Slingerland. “Visit your neighbours before you install the machine.”

If wind machines are beyond your price range, Slingerland said, oil-fuelled heaters are another protection method. Smoke will rise, then spread out showing the height and location of the inversion layer. Under freezing conditions, the heaters can be effective but also expensive as many of the burners will be required, he added.

An intense bonfire in the vineyard can also help break up an inversion layer, as will a low-flying helicopter, said Slingerland, adding that it is expensive to rent a helicopter at $1,000 an hour and it must return over the vineyard every six to eight minutes to ensure the air doesn’t stratify again.

A forced-air displacement system will also work by pushing air up into the inversion but it will only work on very small acreages and in very small spots.

“It is a very site-specific system,” Slingerland said.

Spraying water is another age-old frost preventive method but “if you run out of water, it will freeze on the vines,” he said. ❦

“We’re optimistic. We’re producing more and better products and seeing a positive result.

I think the future is going to be great.”

– Sabrina Caron, Quebec

Canadian agriculture is a modern, vibrant and diverse industry, filled with forward-thinking people who love what they do. But for our industry to reach its full potential this needs to be better understood by the general public and, most importantly, by our industry itself.

The story of Canadian agriculture is one of success, promise, challenge and determination. And the greatest storytellers are the 2.2 million Canadians who live it every day.

Be proud. Champion our industry

There is such a problem as too much of a good thing. And Dr. Kevin Ker has seen it with the overuse of fertilizer in vineyards.

“If you don’t need extra nutrients; why pay for them?” he asked those attending the Atlantic Canada Wine Symposium held recently in Halifax, N.S.

The critical elements required for grapevine development are nitrogen, phosphorus, potassium, calcium and sulphur, explained Dr. Ker, an independent vineyard consultant and research associate at the Cool Climate Oenology and Viticulture Institute (CCOVI) at Brock University in St. Catharines, Ont. Other required micronutrients include boron, copper, zinc and chlorine.

Problems in a grape can be aggravated by over-applying nitrogen, said Dr. Ker. Nitrogen stimulates plant growth, which is linked to excess flowering on the vine. As a result, nitrogen applied during the blooming period will result in poor fruit set.

“I never apply all my nitrogen in the spring,” he said, adding that growers really shouldn’t apply any nitrogen within four weeks of bloom.

“You don’t need to apply nitrogen before bud break,” Dr. Ker said.

Once leaves appear on the grapevines, their roots start taking up nutrients from the soil.

Phosphorus is involved in root production and has a role in disease control in vines, he explained.

“Be aware of this so you don’t overapply phosphorus as a nutrient.”

Potassium is involved in the active transportation of nutrients into the grapevine’s cell structure, said Dr. Ker. He warned that “a little is good” but too much potassium can create problems for the winemaker because the sugar levels in the grapes will be unstable.

Calcium makes the grape skins harder and Dr. Ker recommends it be applied as a foliar spray application against the Botrytis spore. Growers should also consider applying calcium during periods of drought or when

By Dan Woolley

calcium levels are low, he added. It costs about $8 to $10 per acre to apply and Dr. Ker suggested it be combined when growers are spraying pesticides or herbicides.

Manganese contributes to fruit quality and too much calcium or potassium can displace manganese, he said.

Sulphur is necessary for protein building and also plays a role in growth regulation and plant hormone production, said Dr. Ker. It is also a key nutrient for seed production.

“No seeds, no berries,” he said.

Sulphur is also a component of chlorophyll and sulphur deficiency makes fruit set difficult and will lead to “fruit shatter,” said Dr. Ker.

Boron has a role in germination, fruit set and shoot development and, if it is deficient, will affect root growth, he said. The micronutrient is typically applied as a foliar application beside the row as a low-cost stimulant for vine roots, Dr. Ker advised.

If zinc is deficient, he urges growers to apply it but understand high application rates will likely not help cold tolerance in the vines.

Dr. Ker recommends growers apply nutrients below the canopy drip line as 95 per cent of nutrient uptake occurs in this narrow zone. He added that the uptake of

nutrients by the vines occurs within the top 18 inches of the soil.

Growers should establish their vineyards’ base level nutrient requirements to help diagnose problem areas, and the nutrient levels should be monitored over time, advised Dr. Ker. Site-specific soil tests can tell growers the nutrient levels in the soil. Samples should be taken beneath the vines on each side of the row about 18 inches out with at least 10 to 15 soil core samples along each row. Each core sample should be between eight and 12 inches in depth.

He recommends removing surface debris before taking a core sample or it’s possible the vegetation will bias the results.

Dr. Ker added that growers should try to take core samples at the same time each year.

“If you do it in September, it is the time when decisions on vineyard management should be made,” he said.

Soil structure is another important component of grapevine health and vineyards should be monitored for soil compaction as it can cause productivity problems, said Dr. Ker, adding that growers may want to consider sub-soiling regularly to maintain good soil structure.

“Organic matter is one of your best friends,” he said.

As a result, growers should try to maintain a soil profile of between two and four per cent organic matter, said Dr. Ker, adding that a light, sandy soil will need more frequent organic matter applications.

“Grapevines really don’t need or want much nutrient,” he said. “They like a little bit of water but they don’t swim.”

Tissue samples can also tell a grower if nutrients are reaching the grapevine’s cellular structure. Dr. Ker said tissue samples can provide information on the nutrient concentrations in the vine’s tissues. The results will be variable with the tissue sample collected and the time of the growing season when collected, he said, adding that the nitrogen content in tissues can also fluctuate over the season, depending on the stresses being experienced by the vines. ❦

Only one of these potato seed-pieces is protected from the broadest spectrum of insects and diseases. Only one is safeguarded with two new fungicides. Only one takes fusarium protection to the max — even against resistant strains. And only one is covered with Titan™ Emesto™, the first and only coloured liquid seed-piece treatment. It’s easy to use and even easier to see the difference it makes. And you’ve never seen anything like this before.

Learn more at

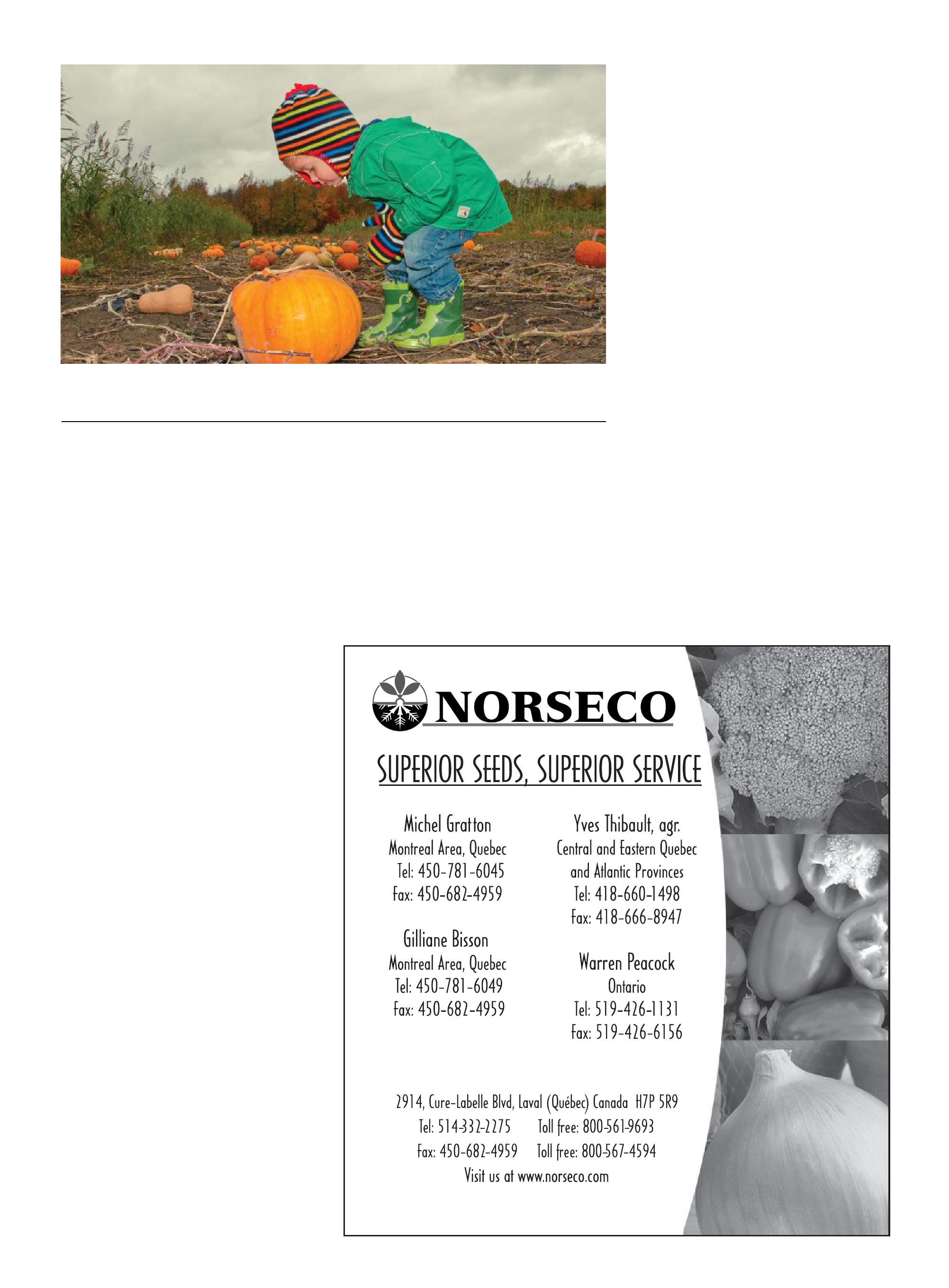

By Treena Hein

The agriculture industry, like all other sectors, requires lots of fresh ideas and novel thinking to keep it profitable and vibrant on an ongoing basis. Indeed, during challenging times such as these – with high input costs, ever-expanding global competition and consumers that demand more – innovation is the only way to flourish.

Vortex Packaging is one of those innovations. Invented by Phil Short, who owns NBF (Niagara’s Best Fruit) Produce of Vineland, Ont., Vortex recently won the Premier’s Award for Agri-Food Innovation Excellence from the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA).

Vortex containers are see-through, lidded, easy-to-handle, stackable – all features that combine to make them a solution to many problems that Short had noticed over his long career in the produce industry.

“My background gave me what was necessary to design something that would satisfy the retailer, consumer and grower,” he says.

Development of the containers took two years and began in 2007. The Vortex basket was marketed by 2009, and has since expanded its reach from coast to coast. Short is an avid cyclist, and chose to name the containers after one of his favourites: the Litespeed Vortex bicycle.

“One big issue with the open cardboard basket is that it allowed consumers to touch the fruit and exchange fruit from one basket to another,” he explains. “These baskets also could not be stacked and required retailers to constantly replenish the display.

“I could see that retailers were trying to reduce store labour and were attracted to consumer-ready packaging that required less maintenance and created attractive displays.”

The Vortex lidded basket provides an untouched product and satisfies all food safety issues.

“It presents well, is easily managed and

Vortex containers are see-through, lidded, stackable – features that combine to solve problems that Phil Short had noticed over his career in the produce industry.

reduces retail shrink by about 20 per cent,” says Short. “It allows you to easily create stepped pyramid displays that are eye-catching with little effort. Consumers like to be able to see through the containers, and we have proven that the Vortex basket increases storage life by seven days through retaining moisture and re-hydration of the fruit.”

Vortex first used virgin PET plastic as it provided the best clarity, but later switched to a plastic containing 50 per cent minimum post-consumer material in order to support recycling of used plastic. By 2009, the company was testing a prototype model in Loblaw stores in Ottawa and made several design and mold changes before arriving at the finalized production model – the first clear plastic basket with a handle used in a major retail market.

“The biggest challenge in the design process was coming up with a shape that would allow stacking at least four layers high and still look attractive,” says Short. “Stackability is very important for retailers to be able to create large volume displays to satisfy sales with minimal labour.”

With respect to manufacturing, the main challenge was applying the side label and end label in a continuous production line. How was this solved? Specialized labelling equipment was designed to apply the labels.

As word got out, a large potato shipper suggested that Vortex include a tinted lid to protect potatoes from the fluorescent lighting at retail stores.

“The tinted lids are still being tested for effectiveness of greening,” says Short.

Vortex has recently introduced a onelitre container specifically for berries.

“We’re targeting the berry industry because we saw an increase in blueberry pro-

duction and consumption,” he explains. “With that demand, we figured consumers would want to buy more blueberries and in larger containers.”

When asked whether he sees any limitations for size or type of fruit or vegetable, Short says, “There are no reasonable limits for our lidded baskets and we are currently designing ones larger than three litres.”

Vortex containers themselves do cost a little more, but Short believes when all aspects are taken into account, they save money.

“The cost difference is really just for the lid, as the cardboard basket has a bottom and handle with no lid,” says Short, “but this extra is completely offset by proven improved sales and reduced retail shrink, for better displays and a fresher product for the consumer.”

Short has no plans to move into international markets at this time but the company has nonetheless attracted international attention. “We are attending the U.S. Produce Marketing Association Fresh Summit in Anaheim, Calif., soon as Vortex is one of the top 25 finalists for their packaging excellence award,” says Short. “We’re excited about it and very delighted with the Regional Premier’s Award as well.”

He says the biggest lesson he has learned during the creation of new packaging is that “retail sales are what it’s all about. They drive everything from the ground up.”

He notes the whole experience has been valuable in a variety of ways.

“I’m very grateful for having the opportunity to supply our packaging to other growing regions outside Niagara,” he says. “I’ve also met many other innovative people and been exposed to new cultural practices in agriculture. It’s a very dynamic field.” ❦

January 14-16, 2013 – Ontario Fruit & Vegetable Growers Association Annual Meeting, The Crowne Plaza Hotel, Niagara Falls, Ont. www.ofvga.org

January 23-24, 2013 – Manitoba Potato Production Days, Keystone Centre, Brandon, Man. www.mbpotatodays.ca

January 24-26, 2013 – Pacific Agriculture Show, Tradex Exhibition Centre, Abbotsford, B.C. www.agricultureshow.net

January 28-29, 2013 – Scotia Horticultural Congress 2013, Old Orchard Inn, Wolfville, N.S. www.hortns.com

January 29-31, 2013 – Nova Scotia Fruit Growers Association Annual Meeting, Old Orchard Inn, Wolfville, N.S. www.nsfgaconvention.com

January 29-30, 2013 – Ontario Processing Vegetable Industry Conference, Hilton Hotel, London, Ont. www.opvg.org

January 31-February 3, 2013 – Annual Guelph Organic Conference & Expo, University Centre, Guelph, Ont. www. guelphorganicconf.ca

February 19, 2013 – Ontario Berry Growers Association Annual Meeting, Embassy Suites, Niagara Falls, Ont. www.ontarioberries.com

February 20-21, 2013 – Ontario Fruit & Vegetable Convention, Scotiabank Convention Centre, Niagara Falls, Ont. www.ofvc.ca

February 23-March 1, 2013 – International Fruit Tree Association Annual Conference, Boston, Mass. www.ifruittree.org

March 12-15, 2013 – Canadian Horticultural Council Annual General Meeting, Westin Hotel, Ottawa, Ont. www. hortcouncil.ca

April 17-19, 2013 – Canadian Produce Marketing Association Convention & Trade Show, Direct Energy Centre, Toronto, Ont. www.cpma.ca

By Dan Woolley

It is a risky business operating a vineyard in a cool climate, according to Matthew Speck, vice-president of viticulture at Henry of Pelham Family Estate Winery in St. Catharines, Ont.

“You need a business plan for a vineyard and winery that works,” he advised those attending the Atlantic Canada Wine Symposium held recently in Halifax, N.S. Matthew and his two brothers, Daniel and Paul, grow grapes on 170 acres. Their family first planted vines in 1984. They now produce about 90,000 cases of Vintners Quality Alliance (VQA) wine annually with about half of their wine grapes supplied by other Niagara Peninsula growers.

“You have no choice but to manage risk,” said Speck. “A business needs stability. The key to long-term success is to optimize your strength while minimizing weaknesses.

“You must understand the business of cool climate to realize your opportunities,” he stressed.

While all Canadian regions could be considered cool climate viticulture regions, the opportunities for viticulture are best in areas that produce aromatic wines with a fresh, fruit-forward taste and a balanced finish, said Speck.

Their greater acidity also allows for a range of wine styles from dry to sweet, he said, noting wines that express their place of origin – terroir – will be sought by consumers who want those characteristics.

Cool climate viticulture has its particular challenges, he conceded, with variable rainfall, variable temperatures, variable crop sizes – all due mainly to variable winter conditions.

In Canada, grape growing’s limiting parameters are related to climate, not soils, said Speck.

“To manage a vineyard effectively, we need to know what the climatic extremes are and how often they occur,” he said. “What are the prevailing winter temperatures and how many frost-free days and how often do they occur?”

Growers must understand these factors at a regional level. Even more importantly, they must understand the nature of the climate in their vineyard over a 10-year minimum period “to plan for those once in 10

by

years climate events,” said Speck.

Regional data is not a substitute for microclimate data as grape varieties will perform differently at different spots in the vineyard, he said.

As an example, in the Henry of Pelham vineyard, Speck has noticed Baco Noir is perfect in a low spot while Merlot performs well in higher areas.

“You need all your vines producing well,” he said. “You need to get production as even as possible between all your vines. Plant the right varieties in the right places, or it won’t pay its way.”

A vineyard “is not a high margin business,” said Speck. “Therefore, the most important piece of equipment in the vineyard is its weather station. You can’t run an efficient vineyard without it.”

To help with cold weather and late frosts, Henry of Pelham uses wind machines.

“Wind machines are very useful on a cold night,” said Speck. “They will warm up the vineyard by a few degrees and that can make all the difference.”

“We try and delay winter pruning as late as possible,” said Speck.

Mechanical pre-pruning helps to speed up the pruning process. Speck recommends both the hardiest vines as well as the weakest should be pruned. Leave twice the required number of buds until the final threat of frost has passed, he said, then cut off the extra canes.

Speck recommends managing rainfall on the vineyard by cultivating every second row while draining heavy soils to push roots in the row deeper into the soil. The goal is to have a full canopy along the row trellis.

Speck likes to have two trunks per vineyard row and he suggested growers leave excessive grapes on the vine, reducing them as the growing season advances. The objective is to convert “grapes to wines to dollars,” he said.

Reducing a vineyard’s crop load will produce better quality grapes and obtain a higher price, post harvest, per bottle, said Speck.

“The character and quality of wines start in the vineyard and they are captured in the winery,” he said. “Your cost structure – what you must charge for wine – is determined in the vineyard.”

The cost of the wine and its quality derives from the vineyard with the wine’s cost, plus the grower’s equity in his vineyard, driving the wine’s retail price, Speck explained.

A vineyard, therefore, must be operated separately from its associated winery, he asserted.

“We operate with two different sets of balance sheets.”

Lightly managed varietal rows earn $2.00 per kilogram of grapes when sold to a winery while more intensively cultivated Estate Tier rows receive $3.50 per kilogram to pay for the extra grapes that were thinned before harvest and the extra management and higher production costs for the Estate Tier row, Speck explained.

Variability of grape supply and wine vintage are a given, he said, noting the winery will respond through inventory management, carrying juice inventory in bulk

tank storage, bottling the wine as close as possible to when it is needed for the market.

Try not to store wine in bottle for more than 12 months, Speck suggested. Instead, match vineyard production to what the market needs by outsourcing production.

Everyone in the secondary bulk market is either a buyer or a seller of wine, Speck observed.

“In Niagara you have Custom Vintners and the Niagara Wine Exchange that help everyone manage their inventory,” he said. “It is the most expensive part of winery management.” ❦

“Celebrating our Farmers” Monday, January 28 and Tuesday, January 29 Old Orchard Inn, Wolfville, NS.

• Many Farmer to Farmer presentations

• We are pleased to have Canadian Horticultural Council and Canadian Produce Marketing Association celebrating with us.

• Focus on good growing and good marketing

• Take a midwinter break to network with friends old & new, check out the trade show and pick up new information

By Robert Spencer

Whether you are an experienced producer or someone who is just exploring the potential opportunities offered by the direct market fruit and/or vegetable industry, visiting an existing farm operation can be very enlightening and beneficial. As the host(s) unfolds the ins and outs of their operation, the whole group starts to share their own insights, experiences and ideas, resulting in a net benefit for everyone.

Over the past several years, many farms have opened their gates and their playbooks to help build the market garden industry in Alberta. In August 2012, a number of existing and prospective producers visited the area around Olds, Alta., for a full-day field day.

To start off, participants visited Olds College. Insect and disease pest identification labs were set up to display a selection

of common pests of fruit and vegetables. Attendees examined fresh, dried, mounted and photographic specimens of plants and pests, using microscopes or the naked eye. Experts were on hand to answer questions and provide information.

Participants also went on a tour of the Prairie Fruit Demonstration Orchard, which features approximately 30 selections (species and cultivars) of prairie fruit crops and is managed for the education of students. During the tour, visitors had an opportunity to look at different fruit crops and learned about basic establishment and management of the different crops and the challenges that come with each.

After lunch, participants headed north to visit the Bowden Sun Maze (a.k.a. Eagle Creek Farms) at Bowden, Alta. Originally a traditional crop and livestock farm, the farm has transitioned to higher-value crops and taken on a different focus within the last decade, particularly after John Mills came back to farm with his father, Stan. The farm now features the only sunflower maze in Canada, as well as you-pick flowers and vegetables, a range of agri-tourism activities, some high tunnels, raised-trough strawberries and a large Community Supported Agriculture (CSA) business.

One of the main draws to the farm is agri-tourism, focused on the eight acre sunflower maze. The farm also has corn, sunflower/corn and bale mazes and is currently growing a willow tree maze. Visitors can spend 1.5 to two hours working to find and solve the puzzles located throughout the maze. Exits are located approximately every 15 to 20 minutes for those who need them. This type of maze is geared to families with children who are six to 15 years of age. John has noticed a big difference between the organic sunflower maze and the herbicide-treated corn maze, with better growth in the sunflowers.

Eagle Creek Farms is moving towards organic certification and is largely pesticide free, which is consistent with their philosophy. To reduce their environmental impact, John uses corn-based biodegradable plastic mulches in combination with mechanical tillage for weed control. Almost all plants are watered using drip irrigation systems to increase efficiency. As is common among producers across the world, labour is a major issue and expense for the farm. John likes to use local labour to keep money in the local economy. It does lead to challenges when students go back to school, but John feels that it is worthwhile and reduces the

farm’s hours of operation starting in the fall. There is one foreign worker on the farm, but maintaining a constant workload can be difficult.

The CSA program started up three years ago, with the farm now running a 300+ full family share operation. They have approximately 20 acres of vegetables in production to supply the boxes that are delivered over approximately 14 weeks to several locations in and around Calgary, including some farmers markets. They use sequential planting and high tunnels, and grow a wide variety of crops to supply a varied selection to their customers. Despite the drive, there is a strong demand for produce in that population base and limited competition from other producers.

Through the CSA, John is able to educate customers on how to grow their produce and how to use different products.

He can help customers see that product that isn’t perfect and pristine can still taste great; he can also use product that would be graded out of the farmers’ market. People get a direct and closer relationship with the farm and the producer gets the money up front, with a sharing of the risk. Customers see the risks that producers carry and become more understanding of losses.

Over the course of the producer tour, participants saw some of the features of the farm and through the information that was shared and the questions that were asked, not only learned about different production practices and marketing options but also had their views and opinions challenged. ❦

Robert Spencer is a commercial horticulture specialist with Alberta Agriculture and Rural Development. He can be reached at robert.spencer@gov.ab.ca.

By Myra Shuster

Over the past year, there’s been a surge in the number of visitors to Quinn Farm (la ferme Quinn), Montrealers’ treasured rural oasis established in 1982 on nearby Ile Perrot, Que.

Quinn Farm has long served as a retreat for city dwellers who want to escape the daily grind and express their inner farmer, while scrunching hay underfoot and inhaling the scent of ripening fruit. Family members young and old can pick their own apples, pumpkins and strawberries. But a more primal impulse drawing people to the farm is the Eat Local movement, according to owner Phil Quinn, and its offshoots have led to a boon in business for the family. The farm broke records on Thanksgiving weekend in 2011 when it received an unprec-

edented 10,026 visitors, and the unusual wave of premature spring weather in midMarch this year resulted in more than 200 people coming out to just wander around the grounds. Quinn says there’s no clear explanation to account for the large crowd in March. His farm is known for its you-pick business, and there was obviously no fruit to be picked in early spring.

“There were some baked goods in the bakery and meat in the freezer for purchase, and the hens were laying eggs like crazy,” he recalls.

But none were the draw that accounted for crowds so early in the season. It seems people just wanted to get down to the farm.

“People want to put a face on their food,” says Quinn, who purchased the farm

from his parents and now operates it with his wife, Stephanie. “They want to make a connection with the people producing it and the farm it’s produced on. You don’t get that connection in grocery stores or at Walmart. There’s a general lack of human contact these days, with people sitting in cubicles at work all day.”

He describes Europe’s longstanding tradition of heading out to the farm to select the meat and produce for the family’s kitchen.

“People will come to a farm to choose the lamb they want for supper and come back the next week to pick it up, ready to cook. There’s a certain comfort in seeing where your food comes from,” says Quinn.

The Eat Local movement squares well with the farm’s history; dealing directly

Quinn

with the consumer has been the backbone of Quinn Farm since its inception. Quinn credits this approach for their success.

“We’re a 75 per cent you-pick operation,” he says. “We don’t do wholesale.”

Quinn’s father Elwood put a premium on developing this direct marketing approach from the start. In the pre-Internet 1980s, he established good relations with the community by making personal contact with the media. One day, he thrilled popular and beloved morning man radio host George Balcan when he brought a 300-pound pumpkin to the local radio station, CJAD. Balcan became a loyal friend of the farm from then on. Elwood Quinn also marketed the youpick feature of the business to daycares and schools, which continue to bring a steady flow of visitors during harvest season.

Quinn has carried on his father’s tradition of reaching out to the community. Like other successful businesses, such as Ben and Jerry’s, whose marketing model includes showing gratitude for and giving back to the community they serve, Quinn Farm donates several pumpkins and Christmas trees, and dozens of cobs of corn to local food banks. In 2011, they launched an appeal on Facebook announcing that anyone coming with a non-perishable food item for food banks would be given free admission to the farm. In addition, visitors were offered the opportunity to fill an extra box with apples for the hungry after picking their own.

Quinn also tries to create a family feeling amongst employees by encouraging a sense of belonging and ownership. Several family passes are given to employees, which they can then distribute to friends, family and visitors they consider deserving, generating a kind of extended Quinn Farm family.

“We try to be genuine and warm, and create a family atmosphere,” says Quinn. “That includes treating the staff well.”

Staffing hasn’t always been without its challenges. In 2011, the Quinns began the strawberry harvest season with 72 employees, and finished with only five. Many of the employees were young students and, although the pay was very good, they had a hard time sticking it out until the end of the

season. This year the Quinns employed two Guatemalan employees under the foreign workers program.

The family continues to innovate in other ways, providing new attractions for families. For this year’s harvest season, they created a straw castle and straw jumping site, and duck races where kids will get to urge ducks to the finish line by pumping water from old kitchen pumps, propelling them along.

Quinn grew up on the farm and learned to drive a tractor at the age of four when his father couldn’t afford to hire outside help. He was initially ill at ease with limiting his own career path to taking over his dad’s enterprise, and decided to strike out on his own. He studied farm management technology at McGill for two semesters but found the farming industry was way ahead of what educators were teaching in the university. He worked in agricultural construction for a while but, as he says with a chuckle, “It turns out I couldn’t leave this place.”

Fortunately for the Quinns, Montrealers appear to feel the same way about the farm – they just can’t leave the place. They keep coming back, and in numbers that are growing all the time. ❦

The federal government recently announced an investment for the Canadian Trucking Alliance (CTA) that will help to strengthen the organization’s food safety program, as members met for their general meeting in Halifax, N.S.

This investment of more than $415,000 will help the CTA update its existing Trucking Food Safety Program to include the latest food safety standards, regulations and practices, including the addition of a new audit and certification process and creating a user-friendly online system that carriers can operate more easily.

It’s hoped these improvements will help to reduce the risk of food contamination beyond the farm gate and give food processors, distributors and retailers more confidence that their products are handled properly during transportation. A strong food safety system also reassures Canadians of the safety of their food, which

in turn helps to boost the bottom lines of farmers.

“Just about every food and beverage consumed by Canadians is carried on a truck at some point,” noted David Bradley, CEO of the CTA. “The alliance is proud of its Trucking Food Safety Program, but we know it can be made even better through improvements such as automation and enhanced audit protocols. This would not be possible without the financing provided by the Growing Forward program and is a good example of government and industry collaborating to enhance food safety transportation in Canada.”

The B.C. government is trying to raise a stink about a little bug that could wreak havoc on fruit and vegetable crops.

The province is asking people to be on the lookout for the brown marmorated stink bug, which can attack tree fruits, berries, grapes, vegetables, corn and ornamental plants.

The bug has been found in California, Oregon and Washington, and while it isn’t present in B.C. yet, the agriculture ministry is anxious to keep it out.

The ministry says the best way to do that is for travellers not to bring fruits or vegetables into B.C. from the U.S., other countries or other provinces. (Canadian Press)

The apple flea weevil, a sporadic insect pest in the early 1900s, has reemerged as a severe pest in organic apple orchards in Michigan, where outbreak population levels have been observed since 2008, and damage has resulted in up to 90 per cent losses for apple growers.

According to the authors of The Reemergence of an Old Pest, Orchestes pallicornis (Coleoptera: Curculionidae) – an open-access article appearing in the most recent issue of the Journal of Integrated Pest Management – the weevil can be managed by broad-spectrum insecticides used in conventional agriculture, but there are currently no proven management options for use in organic production. As broad-spectrum materials are replaced by reduced-risk compounds, it is possible the

apple flea weevil will increasingly become an important pest in apple production.

The apple flea weevil is a small, twoto three-millimetre-long black weevil with enlarged high legs for jumping. Adults feed on buds and leaves, and the larvae are leaf miners.

In the article, the authors discuss the apple flea weevil’s biology and the damage it does to plants, as well as methods growers can use to monitor and manage them.

Nunhems, the vegetable seed business of Bayer CropScience, has expanded its efforts in the Canadian market for cucumber, lettuce and tomato seeds.

As of Oct. 1, 2012, the sales structure of Nunhems has changed.

Nunhems was represented in Canada for many years by Growers Consulting, Inc. This business agreement came to an end on Sept. 30, 2012. Nunhems is now selling cucumber seeds directly to growers in all areas of Canada.

Ali Mohammad, a Nunhems employee who specializes in cucumbers, will be the new sales specialist. He will be the contact for cucumber seed orders and follow-up. Ali and his family live in Windsor, Ont., and he is part of the international cucumber crop team of Nunhems. He can be contacted at ali.mohammad@bayer.com.

Nunhems is also introducing a new cucumber variety, Cyrus (NUN 13077 CUL). Cyrus has already been tested in Canada by several growers for two years. They were very satisfied with the nice fruit quality and the good production.

In addition to cucumber, Nunhems also has a full line of lettuce varieties. Since Growers Consulting was not a lettuce distributor, there are no changes in the distribution. Lettuce is already sold mostly direct to key customers. If you should have any questions regarding lettuce, please contact Nunhems’ specialist Chantal Veilleux, chantal.veilleux@bayer.com.

Nunhems has also started trials of a new tomato program for greenhouse production. Trials include several varieties of tomatoes on the vine (TOV) with an average fruit weight of 150 grams, and also cherry on the vine varieties. The cherry

tomatoes weigh around 12 grams and have a deep red colour. With a Brix level of 10, they score very well on taste. For more information on the Nunhems tomato assortment and variety recommendations, please contact Harm Ammerlaan, harm.ammerlaan@bayer.com.

The Ontario Federation of Agriculture (OFA) has congratulated the Ontario government on its recent introduction of a bill that will provide support and promotion for food grown and processed in Ontario.

The Local Food Act promises to support Ontario’s agriculture and agri-food sector by, among other things, providing a framework for developing goals and targets around the production, processing, distribution, sales and marketing of Ontario food.

“The Local Food Act has been an interest of the Ontario Federation of Agriculture for some time,” says Mark Wales, OFA president. “If passed, this act could provide a framework for a more sustainable agriculture sector for Ontario.”

The OFA worked closely with the Canadian Federation of Agriculture and other organizations to create a National Food Strategy, a blueprint for the future of food in Canada. The document is the culmination of months of feedback from Ontario’s entire agriculture and agri-food value chain. It reflects a vision for the future of food in Canada, from the people who grow it, process it, distribute it and sell it.

“Canada’s agri-food industry has a clear vision for our sector, and the OFA looks forward to working with the Ontario government to incorporate that vision and leadership into the provincial statute,” Wales says.

More information about the National Food Strategy is available at www.nationalfoodstrategy.ca.

Farmers can learn more about international export at a series of workshops being hosted this fall by the Agricultural Management Institute (AMI).

The Agriculture Going Global sessions are designed to help participants make important exporting decisions, avoid common pitfalls and increase their understanding of international trade and foreign markets.

“Canada is a global agricultural exporter and there are international opportunities available to farmers,” says Ryan Koeslag, executive director of AMI. “We hosted a conference on international opportunities for Ontario farmers this past winter and as a result of that, we noticed a real need in the sector for more information on export development.”

The workshops will cover topics like assessing international market opportunities, issues related to marketing agricultural products internationally, managing flow of goods efficiently and key elements of trade finance such as export costing, payment methods and risk insurance.

Sessions will be held at the University of Guelph on Dec. 11 (University Centre, Room 103) and Dec. 18 (Rozanski Hall, Room 105) from 9 a.m. to 4 p.m. Costs range from $70 for one day and $120 for both days. An early bird rate of $100 for both days is available for participants who register before Nov. 15. Space is limited to 40 participants per session on a first come, first served basis. To register, please visit www.takeanewapproach.ca/ events or call AMI at 519-822-6618.

“These workshops are part of AMI’s ongoing commitment to provide Ontario farmers with a range of business management tools to meet the needs of their farm businesses,” adds Koeslag.

British Columbia cranberry producers are benefiting from a $218,500 investment in research to test new cranberry varieties and provide growers the information they need to increase their productivity and profitability.

The investment will help the B.C. Cranberry Marketing Commission (BCCMC) select the most promising new cranberry varieties for B.C. conditions, and determine the best growing mediums and horticultural practices for each new, higher-yielding cranberry variety. Much of this research will be conducted at the newly established Cranberry Research Centre in Delta, B.C.

“Cranberry farmers deeply appreciate this support and the recognition of the importance of our facility,” said Todd May, commissioner of the BCCMC. “This acknowledgment further reinforces the dedication and financial commitment of our farming families toward the future of the cranberry industry in British Columbia.”

The BCCMC has been a part of the province’s cranberry farming since 1965. The commission regulates the transportation, processing, packing, storage and marketing of cranberries grown in B.C. It also supports the industry by providing production research, grower education, and promotional activities for domestic and foreign markets. T:3.375”

yourself on a job well done with the 2012/13 Hot Potatoes® Rewards Program. Every eligible purchase you make earns you Hot Potatoes reward points that can be redeemed for cash or a group trip to Hawaii! Redeem your interim point balance by November 30, 2012 to receive a cash rebate this year, or save them for an even better reward in 2013.

Challenger recently introduced the MT700D Series, available in two models. The tractors are powered by 8.4L diesel engines, built for smooth operation and longer life.

With the powerful engine and Challenger’s Mobil-trac system, the MT700D Series tractors put power to the ground. A new cab and controls make operating a Challenger easier.

The AGCO Power 8.4L diesel in the

MT765D is rated at 285 PTO/350 engine HP, while the MT755D engine is rated at 260 PTO/327 engine HP. Both diesel engines feature a single-piece cast iron block with wet cylinder liners. This enables the engine to handle high-horsepower loads without overheating, and extends its service life. Four valves per cylinder, improved fuel regulation and combustion from a new pump and injectors help maximize engine efficiency.

The power plant achieves Tier 4i emissions standards and maximizes power output while minimizing exhaust treatment costs by varying the diesel exhaust fluid (DEF) rate based on real-time emission measurements.

Challenger’s Mobil-trac five-axle undercarriage system with oscillating midwheels minimizes compaction while maximizing traction and pulling power to work in the most demanding environments.

Standard polyurethane mid-wheels provide long life in abrasive environments and where long transport distances are required. Gauge settings, ranging from 72 to 160 inches, plus a wide selection of track widths, allow Challenger tractors to fit the needs of a wide range of farming operations.

www.Challenger-ag.com

Tivano, a bio-fungicide and bactericide, has recently received regulatory approval.

Registered by AEF Global Inc. of Lévis, Que., and marketed through UAP Canada Inc., Tivano is a liquid product whose active ingredients are citric and lactic acid.

Tivano is registered for suppression of several diseases in a variety of crops including, tomatoes, strawberries, squashes, pumpkins, grapes and roses. It is also the only product registered in Canada for use on angular leaf spot in strawberries. Bacterial canker in tomatoes is also on the Tivano label, as are powdery mildew (strawberries, roses, squashes, pumpkins), downy mildew (grapes) and black spot (roses).

Tivano is designed for and suitable for use as part of both conventional and organic production systems.

Tivano should be applied preventatively when conditions are conducive to disease

development, with application continuing until run-off. The interval between applications ranges from five to 10 days depending on the crop and the disease and there is no (i.e. zero day) pre-harvest interval requirement. Foliar spray volumes range from 200 L/ha to 800 L/ha, again depending on the crop and disease of interest.

Porchak notes that to maximize effectiveness, Tivano should be used prior to or at the early stages of disease development. Tivano should be applied in sufficient volume to ensure full coverage, using a standard or industrial sprayer with flat-fan nozzle tips.

Tivano is packaged in 10 L jugs, marketed through UAP Canada Inc. and sold to ag retailers across the country.

www.uap.ca

Juniper Systems recently announced its partnership with Pennsylvania-based SDG Systems to market the Mesa Rugged Notepad with Android (AOSP) 2.3 operating system, a handheld computer known as the Rampage 6 and distributed exclusively through SDG Systems.

Availability of the Rampage 6 is scheduled for the fall of 2012.

The Android (AOSP) 2.3 operating system on the Rampage 6 offers advantages for data collection, including multitasking, a modern user interface, rich programming environment, multi-platform development, abundant application data storage, open source flexibility and the opportunity for a custom Android interface developed by SDG Systems. Additionally, its optional kiosk mode allows only certain applications to be accessible by the user, successfully creating a single-

purpose device without distractions.

The Rampage 6 features a large 5.7-inch viewing display, IP67 ingress protection rating for water and dust, integrated twoto-five-meter GPS receiver, optional integration of a 1D/2D barcode scanner, and optional Class I, Division 2 certification for use in hazardous locations.

www.sdgsystems.com

The Energy Series of threeand four-wheel AC electric 1.5 to 3.0 ton forklifts from Stärke Material Handling Group are being marketed as delivering material handling solutions.

Stärke Energy electric forklifts provide a quiet, environmentally friendly, noemission option to reduce carbon footprints and keep workers safe from potentially harmful fumes and noise pollution. The Energy Series is available in a choice of traditional cushion tires for durability in indoor/ warehouse operations, or resilient/pneumatic tires for a smooth ride on rough indoor or outdoor terrain.

SME AC controller functions include:

• Anti-roll back with adjustable ramp stop time

• Regenerative braking

• Acceleration/deceleration

• Management of static return to function

• Overheating protection for inverters and motors

• Full short circuit/open circuit protection

All Stärke Energy Series Models are equipped with domesticsized battery compartments and a wide-view mast and are backed by a two-year/4,000-hour warranty.

www.starkecanada.com

www.starkeusa.com

The Original Muck Boot Company offers a durable all-weather boot designed to weather the wear and tear associated with farming and ranching.

The Chore is designed to provide all-day comfort throughout the rugged terrain and extreme conditions that can be associated with farming and ranching. The boot is offered with or without a steel toe, in high- and mid-boot heights. It features a flexible, lightweight rubber outsole with an additional Achilles reinforcement and steel-shank arch support for comfort and support, in addition to a triple-reinforced toe/quadruple-reinforced heel area for protection. It is designed on a wide-cut heel base to maximize stability.

The Chore is constructed of a neoprene flex-foam bootie with four-way stretch nylon lining that is also 100 percent waterproof, with a stretch-fit top-line binding that fits snug to the calf to keep warmth in and cold out. Its rubber overlay provides a lightweight and durable shell that is easy to clean. It is available in black in sizes five to 16 (men’s) and six to 13 (women’s). A CSA-approved version is also available.

The Chore’s 100 percent waterproof foam bootie features a

removable sock liner with breathable lining to wick away humidity and perspiration while providing molded comfort and support. The boots are constructed of a vulcanized rubber, making them as lightweight and flexible as they are durable and easy to clean. www.muckbootcompany.com

Regalia Maxx biofungicide approved in Canada

Marrone Bio Innovations, Inc. (MBI), a provider of natural pest management products for the agricultural and water treatment markets, recently announced that Health Canada’s Pest Management Regulatory Agency has approved Regalia Maxx biofungicide for outdoor and greenhouse use on a variety of fruits and vegetables, as well as on wheat and ornamentals.

In conjunction with the approval, MBI has signed an exclusive distribution agreement with Engage Agro, a Canadian distributor specializing in high-value fruit and vegetable crops.

Regalia Maxx is a product derived from a natural plant extract of Reynoutria sachalinensis, which triggers plants’ natural defense systems to combat several bacterial and fungal diseases. It will be sold in Canada for use in fields and greenhouses to protect tomatoes, grapes, strawberries, cucurbits, ornamental plants and wheat. Used in tank mixes, in program rotations and as a stand-alone product, Regalia Maxx helps control diseases such as powdery mildew, botrytis bunch rot and grey mould, bacterial blight and septoria leaf spot. The product can be applied up to and including the day of harvest (pre-harvest interval of zero days). In addition, its exemption from the requirement of a food tolerance is particularly important for crops that are subject to maximum residue levels.

www.engageagro.com

A. KOOLMEES IRRIGATION

RR 1, Middle Townline 712651

Otterville, ON N0J 1R0

Tel: 519-879-6878 Fax: 519-879-6319

e-mail: springfordenterprises@execulink.com

A.M.A. PLASTICS LTD.

1367 Oxford Ave.

Kingsville, ON N9Y 2S8

Tel: 519-322-1397 Fax: 519-322-1338

Toll-Free: 1-800-338-1136

e-mail: ama@amaplas.com www.amaplas.com

ADAMS COUNTY NURSERY, INC.

26 Nursery Rd., PO Box 108

Aspers, PA 17304 USA

Tel: 717-677-8105 Fax: 717-677-4124

e-mail: acn@acnursery.com www.acnursery.com

AGRICORP

1 Stone Road West, Box 3660 Stn. C Guelph, ON N1H 8M4

Tel: 519-837-6362 Fax: 519-826-4118

e-mail: contact@agricorp.com

AGRICULTURAL CREDIT CORPORATION

660 Speedvale Ave. W., Suite 201 Guelph, ON N1K 1E5

Tel: 519-766-0544 Fax: 519-766-9775

Toll-Free: 1-888-278-8807

e-mail: info@agcreditcorp.ca www.agcreditcorp.ca

AGRICULTURE AND AGRI-FOOD CANADA 1341 Baseline Rd. Ottawa, ON K1A 0C5

Tel: 613-773-1000 Fax: 613-773-2772

e-mail: info@agr.gc.ca www.agr.gc.ca

AGROGREEN CANADA INC.

1938 Hwy 20, RR 1 Fonthill, ON L0S 1E6

Tel: 905-892-8286 Fax: 905-892-0111

Toll-Free: 1-866-650-1136

e-mail: mike@agrogreencanada.com www.agrogreencanada.com

AGROHAITAI LTD.

2764 Hwy 99

Lynden, ON L0R 1T0

Tel: 519-647-2280 Fax: 519-647-3188

e-mail: seed@agrohaitai.com www.agrohaitai.com

ALPINE - THE STARTER FERTILIZER COMPANY

30 Nevilles St

New Hamburg, ON N3A 4G7

Tel: 519-662-2352

Toll-Free: 1-800-265-2268 www.alpinepfl.com

ALPINE STEEL BUILDINGS

1-1385 Stevens Rd. West Kelowna, BC V1Z 2S9

Tel: 778-436-2681 Fax: 1-888-332-9804

Toll-Free: 1-800-565-9800 www.AlpineSteelBuildings.com

ARYSTA LIFESCIENCE

138 Dovercliffe Rd. Guelph, ON N1G 3A6 Fax: 519-766-0415

Toll-Free: 1-866-761-9397

e-mail: mark.mclear@arystalifescience.com www.arystalifescience.ca

ASB GREENWORLD

332911 Plank Line Rd. Mount Elgin, ON N0J 1N0 Tel: 519-688-3413 Fax: 519-842-8091

e-mail: timc@asbgreenworld.com www.asbgreenworld.com

ATAGO U.S.A., INC.

12011 NE First St. Bldg C, Ste 110 Bellevue, WA 98005 USA

Tel: 425-637-2107 Fax: 425-637-2110

e-mail: customerservice@atago-usa.com www.atago.net

BAG SUPPLIES CANADA LTD.

38 North Pointe Estates Stratford, ON N5A 8C3

Tel: 519-271-5393

Toll-Free: 519-271-5395

e-mail: info@bagsupplies.ca www.bagsupplies.com

BASF - THE CHEMICAL COMPANY

100 Milverton Dr. Mississauga, ON L5R 4H1

Toll-Free: 1-877-371-2273 www.AgSolutions.ca

BAYER CROPSCIENCE

5-160 Research Lane Guelph, ON N1G 5B2 Tel: 1 888-283-6847 e-mail: askus@bayercropscience.ca BayerCropScience.ca

BC FRUIT GROWERS’ ASSOCIATION 1473 Water St. Kelowna, BC V1Y 1J6 Tel: 250-762-5226 Fax: 250-861-9089

e-mail: info@bcfga.com www.bcfga.com

BEJO SEEDS INC. 1088 Healey Rd. Geneva, NY 14456 USA Tel: 315-789-4155 Fax: 315-789-1961

e-mail: info@bejoseeds.com www.bejoseeds.com

BEN BERG FARM & INDUSTRIAL EQUIPMENT LIMITED 42134 Hwy. 3

Wainfleet, ON L0S 1V0

Tel: 905-899-3405 Fax: 905-899-3507

e-mail: info@benberg.com benberg.com

BRITESPAN BUILDING SYSTEMS INC.

37651 Amberley Rd. Lucknow, ON N0G 2H0

Tel: 519-528-2922 Fax: 519-528-2890

Toll-Free: 1-800-407-5846 www.britespanbuildings.com

C. FRENSCH LTD.

4774 Hinan Dr.

Beamsville, ON L0R 1B1

Tel: 905-563-4774 Fax: 905-563-5053

CADMAN POWER EQUIPMENT LTD.

38 Main St. Box 100

Courtland, ON N0J 1E0

Fax: 519-688-2100

Toll-Free: 1-866-422-3626

e-mail: paulsontrop@cadmanpower.com www.cadmanpower.com

CANADA’S FRUIT & VEG TECH X-CHANGE PO Box 536

Port Rowan, ON N0E 1M0

Tel: 226-381-0282 Fax: 226-381-0284

e-mail: info@fruitveg.ca www.fruitveg.ca

CANADIAN ASSOCIATION OF FARM ADVISORS (CAFA) INC.

Box 578

Blaine Lake, SK S0J 0J0

Tel: 306-466-2294 Fax: 306-466-2297

Toll-Free: 1-877-474-2871

e-mail: info@cafanet.com www.cafanet.com

CANADIAN CORRUGATED AND CONTAINERBBOARD ASSOCIATION

#3 - 1995 Clark Ave.

Brampton, ON L6T 4W1

Tel: 905-458-1247 Fax: 905-458-2052

e-mail: info@cccabox.org cccabox.org

CANADIAN HORTICULTURAL COUNCIL

9 Corvus Court

Ottawa, ON K2E 7Z4

Tel: 613-226-4880 Fax: 613-226-4497 www.hortcouncil.ca

CHERRY LANE

4230 Victoria Ave.

Vineland Station, ON L0R 2E0

Tel: 905-562-4337 Fax: 905-562-5577

Toll-Free: 1-877-CHERRY-6

e-mail: sales@cherrylane.net www.cherrylane.net

CHESTERMAN FARM EQUIPMENT

14493 Bayham Dr., RR 3 Tillsonburg, ON N4G 4G8

Tel: 519-842-5977 Fax: 519-842-9228 www.chesterman.ca

CLAUSSEN FARMS CUSTOM FARMING INC.

76402 Airport Line

Brucefield, ON N0M 1J0

Tel: 519-233-3198 Fax: 519-233-3199

e-mail: claussen@tcc.on.ca www.claussenfarms.com

CODERRE PACKAGING

413, route 122

St-Germain de Grantham, QC J0C 1K0

Tel: 819-395-4223 Fax: 819-395-2636

e-mail: coderre@embcoderre.com www.embcoderre.com

CORPORATE BENEFIT ANALYSTS, INC.

515 Riverbend Dr., Suite 102

Kitchener, ON N2K 3S3

Tel: 519-579-7749 Fax: 519-579-4422

Toll-Free: 1-800-463-2555

e-mail: MemberServices@corpben.com www.corpben.com/ofa-member-benefit-plan

CURTIS WAGNER PLASTICS CORP.

PO Box 840885 Houston, TX 77284 USA

Tel: 713-937-3784 Fax: 713-937-3338

Toll-Free: 1-800-332-1663

e-mail: sales@cwplastics.com www.cwplastics.com

DDFK EQUIPMENT SALES INC.

475 James St. S., Box 938

St. Marys, ON N4X 1B6 Fax: 519-349-2099

Toll-Free: 1-800-881-3794

e-mail: sales@dfkequipment.com

DIATOMITE CANADA INC.

1938 Hwy 20, RR 1 Fonthill, ON L0S 1E6

Tel: 905-892-8286 Fax: 905-892-0111

Toll-Free: 1-866-650-1136

e-mail: mike@diatomitecanada.com www.diatomitecanada.com

DIRECT SOLUTIONS

260D Campion St. Kelowna, BC V1X 7S8 Fax: 250-765-0258

Toll-Free: 1-866-765-0290

e-mail: DSCanada@AgriumAT.com www.aatdirectsolutions.com

DON ARTHUR ORCHARD EQUIPMENT

496426 Grey Rd. 2, RR 2 Clarksburg, ON N0H 1J0

Tel: 519-599-3058 Fax: 519-599-3378

e-mail: donarthur3@gmail.com

DOW AGROSCIENCES CANADA INC.

2100, 450-1st St. SW Calgary, AB T2P 5H1

Tel: 403-735-8800 Fax: 1-888-296-6188

Toll-Free: 1-800-664-3324

e-mail: solutions@dow.com www.dowagro.ca

DUBOIS AGRINOVATION INC.

710, Old Highway # 24, R.R. # 3

Waterford, ON N0E 1Y0

Tel: 519-443-4834 Fax: 519-443-8257

Toll-Free: 1-800-815-9929

e-mail: info@duboisag.com www.duboisag.com

DUPONT CANADA

Head Office: PO Box 2300 Streetsville Mississauga, ON L5M 2J4

Fax: 905-821-5505

Toll-Free: 1-800-667-3925

e-mail: ag.hotline@can.dupont.com www.cropprotection.dupont.ca

DURWARD JONES BARKWELL & COMPANY LLP

69 Ontario St., PO Box 505

St. Catharines, ON L2R 6V9

Tel: 905-684-9221 Fax: 905-684-0566

e-mail: dmcdonald@djb.com www.djb.com

E. R. VOLLANS LTD. 1682 County Rd. 20 West, RR 3 Kingsville, ON N9Y 2E6 Tel: 519-733-5233 Fax: 519-733-2860

EASTERN FARM MACHINERY LTD. RR 3, PO Box 3613 Guelph, ON N1H 6P1 Tel: 519-763-2400 Fax: 519-763-3930

e-mail: sales@easternfarmmachinery.com www.easternfarmmachinery.com

ECO + 2457, 4e Rang Sud Saint-Charles-sur-Richelieu, QC J0H 2G0 Tel: 450-584-1122 Fax: 450-584-1122 www.eco-plus.ca

ECO-LIGHT

21831 Cooks Rd. Mount Brydges, ON N0L 1W0 Tel: 519-264-2708 Fax: 519-264-2945 www.eco-light.net

ENGAGE AGRO CORPORATION

1030 Gordon St. Guelph, ON N1G 4X5 Toll-Free: 1-866-613-3336

Fax: 519-826-7675

e-mail: info@engageagro.com www.engageagro.com

ERIE REFRIGERATION

1270 Cty Rd 28 Langton, ON N0E 1G0

Tel: 226-567-4098

e-mail: ian@erierefrigeration.ca www.erierefrigeration.ca

FARM CREDIT CANADA

100-120 Research Lane

Guelph, ON N1G 0B5

Fax: 519-826-2066

Toll-Free: 1-800-387-3232

e-mail: richard.gruener@fcc-fac.ca www.fcc-fac.ca

FBC, CANADA’S SMALL BUSINESS TAX SPECIALISTS (TM)

Head Office - #150, 3015-5th Avenue NE Calgary, AB T2A 6T8

Toll-Free: 1-800-265-1002

e-mail: fbc@fbc.ca www.fbc.ca

FOODLAND ONTARIO - OMAFRA

1 Stone Rd. W., 3rd Floor

Guelph, ON N1G 4Y2

Fax: 519-826-3460

Toll-Free: 1-888-466-2372

e-mail: stephanie.chaytor@ontario.ca www.foodlandontario.ca

FRESH VEGETABLE GROWERS OF ONTARIO

Ag Business Centre, 120 Main St. East Ridgetown, ON N0P 2C0

Tel: 519-674-1500 Fax: 519- 674-1512

e-mail: fvgo@ridgetownc.uoguelph.ca www.freshvegetablesontario.com

GILLISON’S VARIETY FABRICATION INC.

3033 Benzie Hwy.

Benzonia, MI 49616-9747 USA

Tel: 231-882-5921 Fax: 231-882-5637

Toll-Free: 1-800-392-6059

www.gillisons.com

GINTEC SHADE TECHNOLOGIES, INC.

1887 East Quarter Line

Windham Centre, ON N0E 2A0

Tel: 519-443-4743 Fax: 519-443-8120

Toll-Free: 877-443-4743

e-mail: gintec@gintec-shade.com www.gintec-shade

GRAPE GROWERS OF ONTARIO

P.O. Box 100

Vineland, ON L0R 2E0

Tel: 905-688-0990 Fax: 905-688-3211

e-mail: info@grapegrowersofontario.com www.grapegrowersofontario.com

GRIMO NUT NURSERY

979 Lakeshore Rd., RR 3

Niagara-on-the-Lake, ON L0S 1J0

Tel: 905-YEH-NUTS (934-6887) Fax: 905-YEL-NUTS (935-6887)

e-mail: nuttrees@grimonut.com www.grimonut.com

HFRUIT AND VEGETABLE MAGAZINE

105 Donly Dr. S., PO Box 530 Simcoe, ON N3Y 4N5

Tel: 519-429-5189 Fax: 519-429-5189

Toll-Free: 1-888-599-2228

e-mail: skauk@annexweb.com www.AgAnnex.com

G.W. ALLEN NURSERY LTD.

7295 Hwy. 221, RR 2

Centreville, NS B0P 1J0

Tel: 902-678-7519 Fax: 902-678-5924

e-mail: gwallennursery@bellaliant.com www.gwallennursery.com

H&W EQUIPMENT

827 Line 4

Niagara-on-the-Lake, ON L0S 1J0 Tel: 905-468-5015 Fax: 905-468-5676

e-mail: info@vineyardmachines.com www.vineyardmachines.com

H.A. STAFF LIMITED

310 Staff Ave., RR 1 St. Catharines, ON L2R 6P7 Tel: 905-562-4719 Fax: 905-562-3334

e-mail: hastaff@vaxxine.com

HARRIS SEEDS

355 Paul Rd., PO Box 24966 Rochester, NY 14624-0966 USA Fax: 877-892-9197

Toll-Free: 1-800-544-7938

e-mail: growers@harrisseeds.com www.harrisseeds.com