THE SEED of an idea

Half

a century of nurturing and community support has grown a single acre of strawberries into the operation Alf and Sandee Krause run today.

BY JEFF TRIBE

Fifty years into building an impressively diversified addedvalue agri-business with wife Sandee, Alf Krause still finds inspiration in the natural rhythms of the seasons.

Summer carries production’s craziness, meeting the challenge of hand-harvesting 200 acres of plump, juicy strawberries, raspberries, blueberries and blackberries at their flavourful peak.

Fall represents comparative rest and recovery, winter, fresh ideas germinating toward spring fruition, new growth both in the fields and in the business.

“I think that’s kept us going,” says Krause.

Their Krause Berry Farms and Estate Winery (KBFEW) is a shared journey that began with a single acre of strawberries a teenaged Krause hoped offered decent returns with a three- to four-week harvest window. The Krause poultry layer operation was sold upon his graduation and berries became an anchor crop, progressing along with their marriage and eventual arrival of six children.

He adds, “So the farm and our family expanded and grew.”

Krause’s agricultural passion combined with his ag business post-secondary education dovetailed well with Sandee’s business/guest and baking background. The combination ultimately led in 2000 to seeking returns beyond selling to packing houses. “Control our own destiny,” he explains.

rather than shipping product out. Speaking broadly, Alf looks after all the agriculture, picked and U-pick berries and Sandee looks after all the added value and the farm market. Together they are a true team, overseeing multiple value-added initiatives they developed.

In simplistic terms, it meant bringing guests to their Langley, B.C.-area property (roughly an hour from downtown Vancouver)

“Or, let’s be clear here,” Krause laughs. “She has the ideas.”

Agriculturally, extended-season berry varieties were chosen, the end of May to Thanksgiving for strawberries, and the end of June to Thanksgiving for raspberries. Krause likes the term “whole farm approach,” evolving environmentally responsible practices incorporating energy efficiency, disease-resistant varieties, soil-building rotations, organic and “green” manures; weed, disease and pest control through plastic coverings and biologicals; and, where necessary, judicious application of organic and conventional pesticides. “We want to be ‘sensible sustainable,’” he says.

Over 90 per cent of Krause berries are hand-harvested, options including U-pick, in which Alf sees potential opportunity to bridge the rural-urban divide through guest education. “They connect their mouths with their hands with their heads, hopefully.”

Seventy per cent of the farm’s production supports KBFEW products – vertical integration amounting to their own ’packing house.’ A ‘Coles Notes’ version of the mind-boggling list begins with the harvest production kitchen and includes a market and bakery featuring over 125 products created from fruits

PHOTOS

Alf and Sandee Kraus.

ABOVE

and vegetables grown on their farms (pies being a particular hit), a waffle bar (blueberry compote and chocolate options in regular and gluten-free vegan through Valentine’s week), smoothies and milkshakes from ‘The Porch,’ and a western-themed estate winery featuring award-winning wines.

Sandee has authored “The Krause Berry Farms Cookbook,” celebrating 50 years of farming with sweet and savoury recipes. Available on April 30, Indigo Canada has selected it as one of the most anticipated culinary publications for 2024.

The farm offers indoor and outdoor venue-planning, not to mention providing the backdrop for a lengthy list of Christmas, holiday and other movies, which for the record, neither Sandee or Alf have been featured in.

“I should have said I wanted to be in all of them to some degree,” he laughs.

All joking aside, their purpose is to provide “excellent care” and is anchored in a framework of their core values of safety, quality, wow and efficiency for growing, production, products, staff and guests alike.

“You can start something, but you can’t keep going if it’s not built on something solid,” says Krause. The effort begins quite literally from the ground up, growing the best possible produce, which is required for producing equivalent-quality pies, preserves and wine. “The two go hand-inhand.”

The farm’s growth means Krause misses longer “thinking cap” hours he used to spend in a tractor, but he remains as involved as possible while confident in committed, long-term staff aligned with farm goals and core values. “We’re fortunate to have staff who know and love our purpose of excellent care.”

Some of the farm’s veteran staffers include his two main field supervisors, who have been in place for over 25 years, Sandee’s market manager (since 2006), as well as many ten-year-plus staff members.

“They know what to do,” says Krause, who is also able to find some separation yet be accessible on demand through his phone or the Internet.

In total, KBFEW employs 35 people year-round and 200 seasonally – a mixture including students, some of whom have maintained years-long connections. The farm also welcomes a cadre of long-term temporary foreign workers from Mexico, sponsoring two families from the latter contingent for residency, both of whom have chosen to continue working with the operation.

KBFEW was recognized by the Greater Langley Chamber of Commerce as its 2021 Employer of the Year. The award highlights businesses recognizing employees as a top priority, the importance of diversity, inclusion and respect, and procedures and strategies contributing to positive leadership and organizational and employee growth,

recruitment and retention. “It was a nice honour,” Krause says.

As well as giving back to their community through the farm’s extended economic impact, the Krauses have and continue to contribute to their industry through supporting and hosting research, participating in breeding development programs and serving on various berry and horticultural boards and bodies.

“He’s a very strong advocate for agriculture,” credits Lisa Craig, Raspberry Industry Development Council/BC Strawberry Growers Association manager.

Despite his own farm’s requirements, Krause contributes significantly to the broader fruit and vegetable sector, says Craig, grateful for his guidance and support during her early days as manager. “He always has time.”

When a spokesperson is needed for the media, Krause is willing to stand up and answer the bell in a positive manner, she added. “He is never negative.”

Krause is also a pillar in his community, exemplifying unity and growth within different businesses in the area, even when they may overlap with KFBEW, says Craig. “He is very inclusive with that.”

His agri-business acumen is unquestionable, but she believes Krause remains a farmer at heart.

“It’s both,” says Craig, noting Krause oversees the operation’s business aspects, but also remains involved day-to-day, where possible. “He still loves to do the work, [and] is still passionate about the berries.”

Board and other industry-related participation does require a time commitment in an extremely busy world, but beyond feeling responsibility to contribute, Krause believes the experience is mutually beneficial. “You learn things and are at the forefront of what’s going on.”

Continuing to evolve is important, Krause says, cautiously optimistic about the potential benefits of AI and increased mechanization. The mentality mirrors a solution-based approach to inevitable issues which arise, dealing with rather than dreading them. “That’s kind of the fun part, seeing what the future holds.”

This year’s focus will be on celebrating the business’s fiftieth anniversary. Krause says, “We had a seed of an idea, we nurtured it and it has grown because of 50 years of community support, which we are so grateful for.” •

Krause Berry Farms and Estate Winery in Langley, B.C.

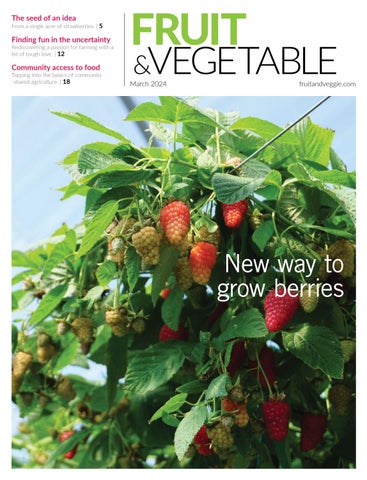

PICKING a new way to produce berries

Ferme Onésime Pouliot balances tradition and innovation to grow a better future for the business.

BY ROSALIE TENNISON

BELOW

Guy Pouliot works hard on and off the farm to improve Canadian agriculture.

On the picturesque and historic Île d’Orléans, near Quebec City, an area known for its artists and agriculture, one family has deep roots in both the culture and the land. For more than 10 generations, the Pouliot family has farmed the island’s soil. The most recent seven generations have stayed on the same piece of property, supporting many family members and using innovation to grow the business.

Known as the “Garden of Quebec,” Île d’Orléans farmers produce most of the strawberries found on the province’s tables. In fact, 80 per cent of Ferme Onésime Pouliot’s production can be found in the province’s supermarkets. The remaining 20 per cent find their way to tables in the northeastern United States and, occasionally, shoppers in Ontario are treated to the farm’s excess production. But the Pouliot family’s main crops are not the farm’s only business. When brothers Guy and Daniel took over Ferme Onésime Pouliot from their father Onésime in 2001, they looked for ways to diversify and improve the operation and grow it for their children.

A berry operation is labourious but not nearly as backbreaking as it was in Onésime’s day thanks to innovations the brothers have introduced. The sight of workers crawling on their knees through sprawling fields of strawberries picking into boxes or baskets is almost a historic view at Ferme Onésime Pouliot. Instead, the farm is in transition from strawberries grown in fields to strawberry

PHOTO COURTESY OF DONNA PARDY.

Brought to you by DOES THE FUTURE OF AGRICULTURE SEEM GREY TO YOU?

Agriculture in the Classroom is cultivating curiosity by providing hands- on, immersive learning experiences to educate and engage students. The next generation of farmers, policy-makers, and innovators is in the classroom today. Together, we can inspire young people to drive our industry forward.

Change the future at aitc- canada.ca

TOP RIGHT

Table-top strawberries help the farm fill the production gap until the field berries are ready.

BELOW

The farm's raspberry production system was an investment, but necessary to compete with other berry-growing countries.

plants grown in substrate on tables. This production model allows the workers to walk beside the tables picking berries at waist-to-shoulder height. About four acres of strawberry plants are grown on the table top, which helps fill the production gap until mid-July when the field berries are ready.

“Workers can pick 1.3 times faster when the strawberries are chest high,” Guy says. “We hope to get better in the future just like we did with raspberries.”

Instead of fields of raspberry canes at Ferme Onésime Pouliot, the plants are grown in pots with two plants per pot. Each year, new plants are started in a greenhouse and then transferred to a plastic-covered structure or “tunnel” shielding them from the rain. The several-acre “umbrella” allows for careful timing of production. The plants are renewed each year and the previous year’s plants are sent to compost along with the substrate-grown strawberry plants.

Initially, 10 acres of raspberry plants are transferred with an expected late-July maturity. Another 10 acres of plants are added a few weeks later, allowing for picking to continue until October. Fertilizer and water are delivered by an irrigation system that can

be adjusted as needed. Plants are transferred earlier or later so production can begin sooner or continue well past the time when field berries are no longer available.

“With this system, we can produce 1.3 kilos of berries per raspberry cane,” Guy explains. “A decade ago, we would get one kilo of berries per cane when we were growing them in a field.” He says the investment for the structure and tables and the technology will take 10 years to recoup but it was necessary in order for the farm to compete with other berry-growing countries, where labour is cheaper and regulations might not be as stringent.

“We are pioneers in this new technique,” says Guy. “Ferme Onésime Pouliot was one of only two or three farms producing raspberries this way when we started in 2008. This system uses less land, but not resources.” Guy is very aware of consumer preferences and says the farm produces raspberries that have a clear red colour because that is what attracts shoppers. He says there are berries with better taste, but they aren’t what catches consumers’ eyes.

The Ferme Onésime Pouliot nursery, which produces the plants for the farm, was spun off into a separate company,

Onésime Pouliot Agriplant, in 2014. It also provides “plugs” to other berry producers.

A research division keeps the farm on the cutting edge of technology and constantly improving how it manages production.

“We usually have about nine projects of our own every year that are managed by our research department, composed of three employees holding masters degrees in plant biology,” Guy explains. In addition, the farm participates in research run through a university program. The university provides the plants and does much of the work developing techniques and plants suitable for the island’s climate.

Another part of the farm’s diversification, “Onésime Pouliot Solutions,” launched in 2019. It’s an agency to facilitate the hiring of temporary foreign workers (TFWs) for Ferme Onésime Pouliot and other Quebec growers. The company fills about 1,000 vacancies – mostly in agriculture but a few are arranged for other sectors as well. Guy is adamant that, without the TFWs, farmers would struggle to produce the bounty Quebec shoppers have grown to expect.

At Ferme Onésime Pouliot, 300 TFWs from Honduras, Mexico and Guatemala sow plants and pick berries throughout the season. In early 2024, as he is preparing for the farm’s next berry crops, Guy is lobbying governments to ensure the TFW system is fair to all.

“These people come here and work really hard for six months,” Guy explains, adding then they go home to their country with the equivalent of three and half years’ salary. They use the money to improve the lives of their families by buying land or houses.

Ferme Onésime Pouliot is also attuned to the requirements of food management. The farm can track a container of strawberries back to the section of the table it came from and who picked it. He says the big chain supermarkets are demanding this type of traceability.

“We have so much paperwork,” sighs Guy. “We have thousands of forms to complete and every year there is something new we have to do. My father Onésime would not recognize what we are doing now compared to what he did when he took over the farm from his father.”

Continuous innovation keeps the operation competitive. Guy says the farm is producing more on less land. The farm harvests up to eight times more raspberries with the canes in pots in the plastic tunnel than it did when the canes were grown in field rows.

“I have more plants per acre and I’ve almost doubled my production per acre with more yield per plant,” Guy explains. “We fertilize the substrate the strawberry plants are in and, for raspberries, we irrigate 20 to 25 times per day.”

Always looking for ways to diversify, Guy and Daniel started selling their second-class raspberries in 2023 to be used for production of an alcoholic beverage. It’s another revenue stream that could keep their less-than-perfect berries out of the compost system and meets the brothers’ commitment to growing the farm for another generation.

Certainly the farming tradition is continuing as one of Guy’s daughters is active in the farm’s operation. Daniel’s children are too young to take an interest in the business side of the enterprise, but two of his three children work on the farm during the season. However many descendants follow in their footsteps, the brothers plan to hand over a business that uses up-to-date technology and is supported by research and hard work.

Guy says, “We want to pass a better farm to the next generation.” •

with welcoming thousands of tourists to the farm each weekend of harvest season – Bourgeois appreciates the lesson his father was trying to teach him.

“He didn’t do it to punish me. He just knew that the potential was there, but I had to wake up. At 18, we’re too smart,” he says.

“I think it’s a good lesson to go somewhere else and see something else. Because we take it for granted some days, when we’re young.”

ADDING VALUE

The clay loam soil where the Belliveau orchards sit has produced apples for over 90 years, and have been in the Bourgeois family since Louis Bourgeois – Samuel’s grandfather – purchased the farm in 1967.

Within 20 years, Robert Bourgeois introduced fresh-pressed sweet cider to the Maritimes, using waste apples – those that fall to the ground or are too misshapen or blemished to sell – that had previously been sent to a buyer in Quebec for “next to nothing.”

“My dad’s motivation behind that was let’s take something that we call waste and transform it into something that’s worth a few dollars,” Bourgeois says.

“That’s where we started our value-add. Sweet cider was new in Atlantic Canada, so it took time to build sales. My dad did a lot of farmers’ markets and all that to promote the product.”

The family built a juice plant in 1987 and started making sparkling juice, hard cider and fruit wine a decade later, hiring a full-time winemaker who remains on staff today.

Turning the fruit farm into a cottage winery prompted other new ventures, including a farm market and café, and a pick-your-

“Honeycrisp brought the industry to where it is today. Really, it probably saved the industry in New Brunswick because there was money to be made. Without Honeycrisp, I’m sure that there would be less acreage than there was 20 years ago. It brought back succession on farms that did not exist before.”

own experience from August to October.

Visitors buy a five, 10 or 20-pound bag, take a tractor ride out to the orchard, and fill their bag with juicy ripe apples before having a glass of wine or cider on the terrace overlooking the farm.

“We don’t charge to get in, and every year it’s been growing,” Bourgeois says, calling the U-pick operation a chance to show visitors – up to 5,000 on a busy weekend – the reality of apple farming up close.

“A lot of people who come in here are city people. So you hope they appreciate the countryside, the fresh air, and obviously the work that goes into growing that crop,” Bourgeois says.

Having farmers tell their own stories directly to consumers helps to avoid the spread of misinformation about agriculture. On the topic of pest management, for example, Bourgeois can explain how and why the farm sprays its trees.

“We only spray when we really need to,” he says. “It’s money gone every time the tractor goes out. It’s because it needs to be done to protect the crop at that time.”

Six years after graduating from Dalhousie Agricultural Campus, Bourgeois received the school’s young alumni achievement award for his agricultural advocacy.

“When you talk to the public, you’ve got to keep it simple,” he says. “So I try to keep it as simple as I can, because then you hope they understand it and they feel better.”

GROWTH STAGE FOR APPLE INDUSTRY

On top of its agrotourism offerings, Belliveau runs a climatecontrolled cold storage facility for the apples harvested from its nearly 100,000 trees, along with fruit picked at other farms.

Bourgeois is also kept busy as the only packer in the province and the board chair of the Apple Growers of New Brunswick (N.B. Apples), an industry association that lobbies governments for programs to aid farmers with growing and storing their crop.

N.B. Apples is not involved in marketing, and some growers opt to send their apples out of province to Nova Scotia, Ontario or Quebec to be packed and sold.

“At the end of the day, there shouldn’t be any borders. As growers, you sell where you feel the most comfortable and where your relationships are the best,” Bourgeois says.

Part of his job as board chair is telling the story of New Brunswick apples to consumers, media and the general public.

“The last five to seven years, we probably doubled in acreage. We’re probably close to double in volume,” he says. “But we were small. We might have gone from 300 to 600 acres, that kind of thing. Still small, but the industry’s growing.”

SWEET AS HONEYCRISP

One concern Bourgeois has is the province’s reliance on Honeycrisp, a commercially prized sweet apple that takes more effort to harvest.

“Honeycrisp brought the industry to where it is today. Really, it probably saved the industry in New Brunswick because there was money to be made,” he says. “Without Honeycrisp, I’m sure that there would be less acreage than there was 20 years ago. It brought back succession on farms that did not exist before.”

After lean years for the industry in the 1980s, some newer farms planted higherpriced Honeycrisp trees on 70 to 90 per cent of their land. While growers appreciate the extra revenue, the challenge for harvest and the labour needs are acute, as each apple’s stem must be snipped and each tree requires several passes because the fruit ripens in waves.

Contrast this to harvesting a hardier apple like Gala or Empire, where the whole tree can be picked clean at the same time and apples can be plucked from the branches by hand.

The labour demands make Honeycrisp 20 to 30 per cent more expensive to pick than other apples, Bourgeois says. And when labour is hard to get – New Brunswick uses local and offshore workers – farmers can start to sweat.

“Some farms are struggling. It’s just the labour that’s become a pain,” Bourgeois says. “Other than that, the industry is benefitting from that growth.”

‘EVERY DAY IS DIFFERENT’

With so many hats to wear, it’s no wonder Bourgeois sees the variety inherent to farming as a major draw.

“Our industry changes basically every day,” he says. “Sounds crazy to say it, but today if it’s sunny, we’ve got to do this, tomorrow if it’s rainy, we’ve got to do that. Every day is different.”

Being comfortable with change helps him weather the literal and economic storms that bring price fluctuations, unpredictable growing conditions, and

changing consumer preferences.

“In the marketplace, nothing is consistent. It’s fun,” Bourgeois says. “Not when [the price] goes down, but it’s fun.”

Hoping for the best but planning for the worst remains a sound strategy, he adds.

“At the end of the day, you’ve got to make sure you can afford the lows,” Bourgeois says.

“If you benchmark yourself against everyone else and you can do it as cheap if not cheaper than the rest, you’ll be in business.” •

At Belliveau Orchards, Honeycrisp accounts for 40 to 50 per cent of the farm’s 100 acres, with 15 to 20 per cent dedicated to higher-quality McIntosh varieties popular in Atlantic Canada, and the balance in Jonagold, Idared, and some heritage varieties like Cox’s Orange Pippin and Russet that end up in the family’s small-batch artisanal hard cider sold under the SCOW Cider brand.

“We balanced our farm to spread the labour out,” Bourgeois says. “Yes, Honeycrisp is amazing, good returns, but we felt it was a bit too risky on our labour side just to focus on one variety.”

For more information, visit Syngenta.ca/Miravis-Prime, contact our Customer Interaction Centre at 1-87-SYNGENTA (1-877-964-3682), or follow us on Social Media @SyngentaCanada

Always read and follow label directions. Miravis®, the Alliance Frame, the Purpose Icon and the Syngenta logo are trademarks of a Syngenta Group Company. Other trademarks are property of their respective owners. © 2024 Syngenta.

aggregation, such as single-grained (very sandy) or massive (high clay content) structures, can affect the movement of water. Because water movement is largely dependent on the number of pores and pore size, management practices which promote compaction can have a sizable impact on infiltration and internal drainage.

There are several ways you can measure soil water in the field, including soil water meters, tensiometers, using hand-feel method, or collecting

samples to be analyzed in the lab. Soil moisture meters can use several different measurements, but most often are represented as a percentage. The ideal soil moisture percentage range for plant-available water measured by a soil moisture meter will depend on the crop, the soil type and the type of meter. Conversely, a tensiometer measures the tension of water between soil particles. The units are typically centibars, and the lower the centibars, the wetter the soil. If the centibar reading is between zero

and 10, that means that soil is typically saturated. However, these methods are not always available to producers, and water measurements are most effective if you can monitor water over time. Care should be taken when using soil water measurements for irrigation or drainage management. Without equipment, producers can get a general sense of water holding capacity by knowing your soil texture, soil structure and management practices.

Soil water management can vary and depends on the soil type, commodity and climate. More extensive practices such as drain tile are common ways to help control the amounts of water on the field. Some less invasive practices, such as building soil organic matter and keeping off fields in wet weather, can go a long way to help manage water in your fields or at least prevent crop damage from water stress. Overall, water management is a bit of a goldilocks situation: you don’t want too much, but you don’t want too little either,and finding that perfect plant-available water content can be difficult. Understanding your soil and how water is made plant-available can give a better sense of how to manage water on your farm. •