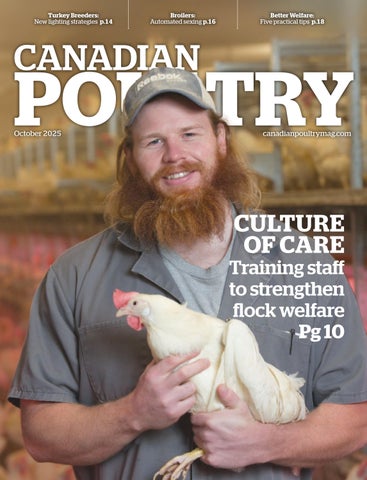

by Brett Ruffell

Animal welfare is one of those subjects that cannot be siloed. It’s not only about science, technology or policy – it’s about people. Our cover story this month (page 10) underscores a truth that often gets overlooked: the most advanced equipment in the world cannot replace the eyes, instincts and care of barn staff.

Every decision team members make – whether adjusting airflow, flagging a concern, or handling birds – carries direct welfare implications.

As Shawn Harman of Star Egg re-

“Welfare is not a one-time lesson. It is a living culture, reinforced daily.”

minds us, a “birds-first” mindset is not just a slogan. It’s culture. From onboarding to toolbox talks to shared KPI dashboards, the operations we profile demonstrate that welfare thrives when the human element is supported, trained and empowered.

The same principle is evident at Burnbrae Farms, where annual multi-module training ensures staff recognize the subtleties of bird behaviour and biosecurity. It is equally clear at McDermott Farms, where conversations, mentoring and shadowing embed respect for birds into everyday

practice. What ties these examples together is that welfare is not a onetime lesson. It is a living culture, reinforced daily.

Complementing our cover story is a practical feature on page 18 with expert-backed tips producers can put to work immediately. From cracking inlets to scheduling darkness, rotating enrichments, supporting gut health and preparing pullets, each recommendation illustrates how small changes – grounded in science –translate into healthier, more resilient flocks. Together, these pieces remind us that welfare is both principle and practice, both big-picture culture and small daily choices.

As we celebrate these stories, it’s also important to recognize leadership more broadly across agriculture. On October 21 at 12:00 p.m. ET, join us for the Influential Women in Agriculture Summit 2025. This free, virtual event (agwomen.ca) brings together our seven honourees and other leaders for lively discussions about balance, communication and the future of farming from a uniquely female perspective.

Animal welfare depends on people – their training, their values, and their vision. So too does the future of agriculture. We hope you’ll be part of both conversations this October.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep.

Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager

Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Julie Montgomery jmontgomery@annexbusinessmedia.com 416-510-5163

Media Designer

Curtis Martin

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager

Anita Madden amadden@annexbusinessmedia.com 416-510-5183

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates

Canada - Single-copy $10.00

Canada – 1 Year $33.15

Canada – 2 years $56.61

Canada – 3 years $78.54

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2025Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

From the initial conversation, to the installation, and for years after your first flock, we strive to deliver next level solutions and support to you and your flock. We are hands-on when it comes to helping your flock excel, and are always available to help you find better ways to maximize your investment in the systems we offer.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

The finalized amendments to the Code of Practice for the Care and Handling of Pullets and Laying Hens are now available. Led by the National Farm Animal Care Council and Egg Farmers of Canada, the updates address round feeders, pullet space allowance in multi-tier systems, and barn tier limits. Developed by a 15-member committee and refined through public consultation, the amendments reflect the latest science and welfare priorities, supporting continuous improvement across Canada’s egg sector.

Canada and Mercosur have formally reopened trade talks following Canadian Trade Minister Maninder Sidhu’s visit to Brazil on August 25. Negotiations, stalled since 2021, are expected to resume this fall with the goal of reaching a deal within a year. For Canada’s poultry sector, the talks raise concerns: Brazil is the world’s largest chicken exporter and already Canada’s second-largest supplier. Any concessions on market access could pressure supply-managed producers already impacted by CPTPP and CUSMA.

The National Farm Animal Care Council (NFACC) is celebrating 20 years of advancing farm animal welfare in Canada. Founded in 2005, NFACC has grown from 20 members to more than 50 organizations, uniting farmers, animal welfare groups, government, and others in a unique collaborative model. Over two decades, it has developed or updated 14 Codes of Practice.

finalized Canada’s Federal-Provincial-Territorial Agreement on egg marketing.

Egg Farmers of Canada (EFC) has recognized Harold Froese, a long-time egg industry leader, with its first-ever Lifetime Achievement Award. Froese is celebrated as a pillar of the sector for his decades of contributions to agricultural policy and the advancement of egg farming in Canada.

In 2021, Froese played a central role in guiding the final discussions of the Federal-Provincial-Territorial Agreement (FPTA) on Guiding Principles for the Marketing of Eggs in Canada.

Under his leadership as chair of the FPTA committee, the agreement was endorsed by all egg boards, 10 provincial governments and the Northwest Territories. The accomplishment modernized Canada’s egg marketing framework and marked a historic outcome for the industry.

“Harold’s impact extends well past the farm gate. He is known for his impressive ability to inspire others to put their differences

aside and work together to address some of our sector’s biggest challenges,” says Roger Pelissero, chair of EFC.

“We deeply appreciate what he has done in his career as a farmer, mentor and advocate. Harold’s legacy will have a lasting impact on generations of farmers and he has helped clear a path forward to a promising future for egg farming in Canada.”

Raised on an egg farm in Manitoba, Froese graduated from the University of Manitoba in 1974 with a Bachelor of Science in Agriculture. After working at Farm Credit Canada, he returned to the family farm in Oak Bluff in 1983.

He went on to serve on the Manitoba Egg Farmers, Egg Farmers of Canada and Canadian Federation of Agriculture boards of directors, dedicating countless hours to discussions that strengthened both the egg sector and Canada’s food system.

British Columbia says it will be providing $2.5 million in funding that will allow about 75 poultry farms in the Fraser Valley to upgrade their barns to reduce the risk of avian flu.

The Agriculture Ministry says in a news release that the flu can enter barns through airflow, water sources and other means and, despite increased measures, there have been about 200 outbreaks in the Fraser Valley and Lower Mainland since 2022.

It says the Novel Tools and Technologies Program will help egg and poultry producers equip their barns with tools such as air filters and ultraviolet light systems.

The ministry says the program will provide as much as $30,000 per farm for future projects or those that began after Jan. 1, 2025. Advertisement It says most projects should be

complete by the fall, which is when the disease is at the highest risk of spreading to poultry on farms or backyard flocks due to migration.

About 9 million birds have been culled in B.C. since 2022 and the ministry says the last reported case of avian flu in a commercial flock happened in January, at the end of the last fall migration.

Agriculture Minister Lana Popham says farmers in the region have been battling against avian influenza since the first outbreak in 2004.

“Despite the personal stress and losses caused by the virus, producers still rise every morning to care for their birds and build our food supply,” she says in the release. “This program will help them do that by adding extra defence measures against the virus to their barns.”

OCTOBER

OCT. 1-3, 2025

PSIW 2025, Banff, Alta. poultryworkshop.com

OCT. 23, 2025

PIC’S AGM, Hybrid Virtual and In-Person, Elora, Ont. poultryindustrycouncil.ca

NOVEMBER

NOV. 4-5, 2025

Poultry Tech Summit Atlanta, Ga.

wattglobalmedia.com/events/ poultrytechsummit

NOV. 12, 2025

PIC’S Producer Update –All Breed, Virtual poultryindustrycouncil.ca

NOV. 20-21, 2025

PIC’S Innovation Conference Niagara Falls, Ont. poultryindustrycouncil.ca

DECEMBER

DEC. 12TH, 2025

Producer Update Elora, Ont. poultryindustrycouncil.ca

JANUARY

JAN. 27-29, 2026

IPPE 2026

Atlanta, Ga. ippexpo.org

FEBRUARY

FEB. 4-5, 2026

National Poultry Show London, Ont. poultryindustrycouncil.ca 9M

The B.C. Supreme Court has upheld a provincial pricing formula for live chickens, dismissing a challenge from the Primary Poultry Processors Association of B.C. Processors argued prices should be tied to lower Ontario costs, but Justice Jan Brongers ruled the decision was not unreasonable and followed fair process. The formula, approved by the B.C. Farm Industry Review Board, is based on grower efficiency and aims to ensure fair returns for farmers while maintaining processor competitiveness.

Hubbard, in partnership with the Gates Foundation, is rolling out a five-year project to boost poultry production in Ghana and Mozambique. Working with WAFAD Group and Maëva Group, the initiative will distribute 10 million dual-purpose chickens to 500,000 small-scale farmers, with a focus on women and youth. The project aims to improve food security and rural incomes through brooder units, hatchery expansion, training, and access to feed and vaccines.

Ontario chicken farmers donate 650 kilograms of locally raised chicken to the Meaford Food Bank, providing more than 5,500 meals for families in need. The contribution is part of the Chicken Farmers of Ontario’s CFO Cares: Farmers to Food Banks program, which has delivered over 10 million meals since 2015. MPP Paul Vickers joins farmers at the recognition event, highlighting more than 40,500 chicken meals donated to Bruce–Grey–Owen Sound food banks since 2022.

Applications are now open for the recently announced Chicken Farmers of Ontario (CFO) growth programs designed to support both emerging and established demand within the province’s chicken industry.

The programs are intended to help processors respond to changing consumer preferences, support market innovation, and stimulate long-term growth across Ontario’s dynamic chicken sector.

“These programs represent a critical investment in the future of Ontario’s chicken industry,” says CFO Chair Murray Opsteen. “By supporting our processors with targeted growth opportunities, we are strengthening the entire value chain – from farm to table – and ensuring that Ontario consumers have continued access to high quality, locally-grown chicken.”

The CFO growth programs now accepting applications are the New Entrant Chicken Processors Policy, intended for new market partici-

pants and existing small processors looking to enter the industry as primary processors; the Ontario Market Opportunity Policy, which allows primary processors to access available supply to meet or address a specific market opportunity and drive chicken consumption; and the Small Whole Bird Supply Policy, which enables processors to address demand for birds in the 1.60–1.84 kg range, including those supplied to Portuguese barbecue and small barbecue bird restaurants.

“These growth programs are the result of meaningful engagement with processors, farmers, and industry partners,” says CFO CEO Denise Hockaday. “At CFO, we believe strongly in the power of collaboration to design solutions that foster long-term success for Ontario’s chicken sector.”

All questions related to the CFO growth programs and the application process must be submitted by the intended applicant to growth@ ontariochicken.ca.

Find the latest poultry-related news, stories, blogs and analysis from across Canada at: canadianpoultrymag.com

When team members prioritize healthy birds, the bottom line benefits.

By Ronda Payne

Agriculture may be undergoing a transformation that puts automation at the forefront, but the human element remains essential. It’s impossible to separate poultry health and wellness from the key roles that farm team members play.

Both on-farm and behind the scenes, daily decisions make a difference to bird health and, correspondingly, the bottom line. Training is an important tool, but top-down culture and communication are foundational elements as well.

Shawn Harman is the director of business development with the Harman Group of Companies, which has multiple flocks throughout Saskatchewan and Manitoba. He is also the CEO of Star Egg Company. He believes that when the culture of the companies is emulated through team members, it creates a foundation for success.

“Healthy hens, healthy business is our guiding principle,” he says. “Everyone knows that bird welfare overrides production targets and we encourage staff to flag issues immediately. No blame. Just solutions.”

But it’s certainly more than a motto or something staff are told. That guiding

principle of hen health ripples through daily activities, onboarding, hiring, audits, communication and more. Plus, these standards are expected from every producer who ships eggs to Star Egg.

“We look for people who demonstrate respect for livestock and have a ‘birds-first’ mindset,” he says. “Previous livestock experience is an asset, but not mandatory. Attitude is.”

The company also looks for people who have good observation skills and attention to detail, are comfortable with automation in hen houses and prove their reliability and willingness to work within the organization’s strict standard operating proced-

ures (SOPs) and audit frameworks.

“Standards are covered during onboarding, reinforced through posted SOPs in each barn, reviewed in weekly toolbox talks and tracked using our digital compliance checklists,” Harman says. “KPI dashboards (mortality, condemnations, feed conversion) are shared with staff so everyone sees the link between welfare and performance.”

Bringing the data to team members gives them insight into how their actions make a difference in the barn on a day-today basis. While some individuals are naturally attuned to animal welfare practices, those who come from different livestock or non-livestock backgrounds

may not always appreciate the subtleties of their actions on poultry health and welfare outcomes.

Team members at Burnbrae Farms are trained annually through a multi-module program that enables poultry technicians to observe and take action as needed. These individuals watch the birds and their environment on a daily basis.

“All our poultry team members are trained annually in animal care practices as part of our standard training procedures,”

Katy Tarrant, associate professor of poultry science at California State University, Fresno, had a realization that animal science programs were falling short when it came to animal welfare.

“Given how central this topic is to poultry production, that gap stood out,” she says. “My goal at the start was pretty focused. I wanted to create applied animal care training for students who might not get that exposure in the classroom.”

But quickly, it was clear that the training would benefit those already in the field, and Tarrant’s experience in education allowed the Center for the Optimization of Poultry (COOP) to expand with online training together with the International Poultry Welfare Alliance (IPWA). Built on the core areas of evidence-based animal care practices, workforce training and applied research, all training uses the key welfare indicators created by IPWF.

“What sets COOP apart is how it’s structured around the KWI framework, which was intentionally developed to be accessible and adaptable across the supply chain,” says Tarrant. “Our asynchronous courses are flexible enough to fit any schedule, whether someone’s learning on a lunch break or

says a Burnbrae spokesperson. “There are several modules included in the training, such as poultry behaviour and health, biosecurity, handling and transportation.”

The hiring process Burnbrae has created looks for individuals with interest, education and experience in caring for animals or other relevant roles that illustrate that commitment to animal welfare.

“Animal welfare is a fundamental commitment for us at Burnbrae Farms,” the spokesperson says. “We are committed to treating all poultry under our care in a safe and humane manner and to continu-

between tasks on the farm.”

The program incorporates extended reality (XR) to simulate real-world situations. This allows for practical learning without risk. It’s also available in English and Spanish and can be practiced through any device with a Wi-Fi connection.

Additionally, COOP can be accessed through self-paced online courses through Fresno State or through the XR learning modules, which reinforce the course content but are optional. Organizations can sign up an entire team or one individual at a time, depending on their needs.

“As of July 2025, learners have completed over 950 COOP training courses since it launched in

ously improving our animal care practices as more scientific research and other evidence becomes available. We have zero tolerance towards the unacceptable treatment of our animals.”

The organization also employs a fulltime animal care specialist who ensures standards of hen care are considered as essential practices for birds in the company’s care across Canada. While animal welfare training is an essential part of team protocols, it would lose its benefits without day-to-day oversight, so managers constantly monitor and enforce standards.

Burnbrae also meets the Egg Farmers of Canada Animal Care Program requirements based on the Code of Practice for the Care and Handling of Pullets and Laying Hens.

At McDermott Farms in Abbotsford, B.C., Erv Wiens and his son Jordan know that bird care is the key element of their operation, where they have turkeys, broilers and layers.

“The comfort of the bird, the health of the bird, I would say it’s number one,” says Erv. “And it might be for selfish reasons. I mean if the bird does well, if you take care of its welfare, it’ll take care of our welfare.”

2024,” she says. “Over 100 participants have engaged with our XR modules so far and the feedback has been really positive.”

Because the course structure is designed to be flexible, people can log in and learn whenever it suits their schedule. Plus, because the classes are built on IPWA’s key welfare indicators, the courses have a significant focus on why the different lessons matter and are standardized for all learners, taking the pressure off producers to create training on their own.

“Our content dives into the science behind the decisions being made, the basis behind why animal-based indicators are essential, and how those connect to outcomes in real production settings,” Tarrant says. “On top of that, the XR component brings a level of engagement that’s hard to match. People can practice scenarios repeatedly, get feedback, and explore complex situations without the biosecurity or scheduling challenges that often come with in-person facility visits.”

This approach is important because she says that people are more likely to adopt and stick with education when they understand why it matters. It moves lessons beyond a command to do something to an appreciation of what something means over time. As Tarrant summarizes, this leads to better outcomes for animals and the workforce.

The Wiens lead by example with daily record keeping, in-person checks of the birds, inspecting inputs like water meters and feed monitors, and having cameras in place to aid with watching at any time.

Regardless of the type of poultry, the focus on the birds remains constant.

Conversations are the starting point to make sure staff and new hires are always aware of what is expected. With a new hire coming on board, Erv was in the middle of sharing the farm’s practices.

“We’re doing it right now, so it’s very relevant for us. I just met with a fellow that’s going to work for us,” he says. “I had an almost two-hour meeting with him … a conversation along the way, the importance of how we treat the birds, how we take care of the birds.”

As the new hire comes on board, the conversation continues with about a month of job shadowing. Doing things

together, like picking up and handling birds, helps bring the talking points to life and into practice. Training also continues beyond that first month.

“It’s not just a one-off,” Erv says. “It involves a training program. It’s a lot that needs to go into this.”

Tech makes the job easier with some of the tools currently available, and this is where Jordan shines.

“There’s always something to look at on the computers or cameras,” he says. “We can see what’s going on and help learn together.”

Because the whole team is in the production process together, monetary incentives apply based on the performance of a flock.

Bird welfare is reliant on the knowledge and practices of team members. When organizational culture focuses on bird welfare, not only do birds fare better, but so does the farm as a whole.

MELLER POULTRY EQUIPMENT INC.

826 Nanticoke Creek Parkway, Jarvis, Ontario, N0A 1J0

Call us on: 519-587-2667 or visit our website: www.mellerpoultry.ca

Authorized dealer VDL Jansen VDL Agrotech

Strong welfare culture benefits both birds and farm success.

Training matters: Burnbrae Farms trains all poultry staff annually on behaviour, health, biosecurity, handling and transport.

Culture counts:

Star Egg reinforces welfare through SOPs, toolbox talks, compliance checklists and KPI dashboards.

Hands-on leadership:

At McDermott Farms, new hires receive job shadowing, mentoring and continuous training.

Technology assists: Cameras, computers and dashboards give staff real-time insight into flock welfare.

Expanding education: COOP training (see sidebar on page 11), developed with IPWA, has logged 950+ completions since 2024, with over 100 XR module users.

Phone: 204-371-1800

oversight. Its narrow width minimizes obstacles, aiding pullet movement. An integrated manure belt enhances house hygiene and increases space for more birds.

OPTIMAL TRAINING

The feed and water lines are placed at different levels during the rearing period. This encourages the pullets to fly and jump and move through the system.

The manure falls through the slats on the integrated manure belt. The ventilation tube dries the manure, thereby reducing the amount of ammonia. This contributes significantly to a healthier environment in the house.

Due to the integrated manure belt, the system is high enough for pullets to roam around under the system. Because this surface can be counted as a living surface, the house surface can be used optimally. THE NIVOMAXX READIES PULLETS FOR AVIARY LIFE AND CONTRIBUTES TO AN OPTIMAL PERFORMANCE OF THE LAYING HENS!

Egg Farmers of Canada is proud to support the next generation of egg sector leaders through our National Young Farmer Program and Women in the Egg Industry Program. These initiatives cultivate knowledge growth and provide networking and leadership opportunities.

INTERESTED? CONTACT YOUR EGG BOARD TO LEARN HOW TO GET INVOLVED.

By Jane Robinson

Clara Ziezold loves working with turkeys and solving puzzles. As a graduate student at the University of Guelph, she’s combining these passions to look at how lighting may be a key component to balance growth performance and reproductive efficiency in turkey breeders.

It was a happy accident that brought Ziezold into turkey research. A guest lecturer in one of her undergraduate courses made such a big impression on the opportunities with lighting in poultry production that she’s now nearing the end of her PhD with him, Grégoy Bédécarrats in the Department of Animal Biosciences.

Her research is focused on how light intensity and spectrum could impact turkey breeder performance and, hopefully, inform on-farm lighting recommendations.

“Turkey breeders are among the most labour-intensive birds to manage, and there isn’t much new research on the impact of lighting for breeder management,” says Ziezold.

All birds take in light through the eye and two areas of the brain – the pineal gland and the deep brain or hypothalamus. The turkey’s visual reception is slightly more sensitive to the colour spectrum than the chicken’s, allowing turkeys to see better in the ultraviolet range.

Red light has been used effectively across poultry species to improve egg production. This response to lay is acti-

vated by receptors in the deep brain – a space that red light is better able to reach.

“Lighting research in turkey breeders hasn’t been looked at for decades and we wanted to update our knowledge,” says Ziezold.

The other part of her research is about light intensity. “Light intensity recommendations are much higher for turkeys than chickens, and we wanted to know whether that made a difference for reproductive performance, or if we could actually be using lower intensities.”

Ziezold’s research began in 2023 at the Arkell Research Station at the University of Guelph. There were 24 pens of turkey hens divided into four rooms – two with white light and two with red spectrum light. During rearing, all birds had low intensity lighting.

At 30 weeks of age, light exposure was increased to trigger photostimulation and some birds were then exposed to high intensity light (100 lux, which is the commercial recommendation), and some

birds were kept on the same low intensity lighting as during rearing.

Throughout the research period, data was collected on individual body weight, daily and cumulative egg production, egg quality, nest usage and floor eggs.

Most of the differences Ziezold found in turkey breeder performance were related to the level of light intensity and not the colour of the light. The only exception was time of lay.

“The data I’m most excited about is the ability of light to better synchronize time of lay for turkey breeders,” says Ziezold. “Under red light and high intensity, we saw more birds laying their eggs during the daily peak and in a more synchronized way. More importantly, we had fewer eggs laid at night under red light compared to white light.”

Low intensity lighting saw additional positive outcomes, regardless of the spectrum. Birds were more uniform in body weight, had higher egg weights and a tendency for stronger shell strength.

Ziezold found no differences in cumulative egg production or floor egg production across all treatments for light intensity and light spectrum.

So, high intensity lighting wasn’t needed to start or maintain egg production, or to discourage floor laying.

“There was no difference in the number of eggs laid on the floor between light intensities, but hens spent more time in the nest boxes under high intensity lighting,” says Ziezold. “Birds might have been using the nests for other purposes under high intensity and that has labour implications, especially when workers need to push hens out of the nests manually on an hourly basis, and many of them have no eggs to collect.”

Ziezold knows the industry is likely most interested in performance measures like cumulative egg production and time of lay. And while it’s too soon to make definitive recommendations, she can say

they found no downside to low intensity lighting. “If we can use lower intensity light and still get good performance, there are energy saving implications for producers,” she says.

“We didn’t measure feed consumption but if birds are less active under low light – with less pecking and overall activity but still productive – that would be important information for future lighting recommendations.”

Her research is adding to the body of knowledge to help update lighting recommendations in turkey breeder management. And based on what she’s found, she has a few tips for producers.

She advises using high quality LED lights to control spectrum and improve energy efficiency. If barns rely on white lighting, she recommends choosing a warm white that delivers a good portion of its output in the red spectrum. She also

stresses the importance of checking light distribution throughout the barn to help prevent floor laying.

Ziezold loves being at the intersection of fundamental science that has practical applications. “We continue to struggle with reproductive efficiency in turkey breeders and that makes environmental management even more important. Given how under-researched this sector is, it’s important we keep working on this puzzle for the turkey industry.”

1. Use high quality LED lights to control spectrum and increase energy efficiency.

2. If using white lighting, choose a warm white with strong red output.

3. Check barn light distribution to help prevent floor laying.

Automated feather sexing could transform broiler production, boosting efficiency and cutting labour costs.

By Melanie Epp

Anew wave of automation is transforming broiler production in Canada – and it’s happening one feather at a time. WingScan, an AI-powered feather-sexing system developed by U.S.-based ag-tech firm TARGAN, has landed in Quebec, marking the company’s first international installation – and a bold step forward for the Canadian poultry industry.

WingScan uses advanced imaging and artificial intelligence to determine the sex of day-old chicks based on feather development – a task once done manually by trained workers. As chicks pass through the system, high-speed cameras capture detailed images of their wing feathers. The AI then analyzes subtle differences in the length and positioning of covert and primary feathers – indicators that distinguish males from females.

Installed first at Trouw Nutrition’s Ramsay Hatchery in Saint-Félix-de-Valois and shortly after at Boire & Frères, the country’s

largest hatchery, the system delivers up to 98 per cent accuracy and processes as many as 160,000 chicks per hour, depending on configuration.

According to Ali Matloub, director of technical sales and business development at TARGAN, the technology addresses one of the most difficult and labour-intensive tasks in the hatchery – and its work ethic is unquestionable.

“WingScan doesn’t go on vacation, doesn’t get COVID, and doesn’t get tired,” he says. “Hatcheries can now reassign staff to other jobs, reduce labour costs, and dramatically speed up processing.”

Quebec was a natural place to start. The province had maintained manual feather sexing for decades, even as hatcheries in Ontario and Western Canada moved away from the practice due to staffing and cost constraints.

“In Quebec, we already had hatcheries that understood the value of sexed birds,”

Matloub says. “What they lacked was the workforce to keep up.”

Boire & Frères, which processes over 120 million chicks per year, was among the first to adopt WingScan.

“Before WingScan, we manually sexed 70,000 chicks per hour. That’s now up by more than 50 per cent to 110,000 chicks per hour,” says Jean-Guy Robillard, general manager at Boire & Frères, in a TARGAN press release. “It’s really a game changer.”

Feather sexing itself is nothing new. According to a training brochure compiled by Aviagen, manual feather sexing relies on visual inspection of wing feathers to distinguish males from females. However, the method is only viable with specific genetic pairings, and requires bright lighting, careful handling and skilled eyes. While faster and gentler than vent sexing, it’s still labour-intensive – and largely impractical for hatcheries outside Quebec, where manual sexing has become unsustainable.

Despite its early success in Quebec, TARGAN acknowledges that rolling out WingScan across the rest of Canada will take time, planning and industry-wide cooperation.

“In Ontario and Western Canada, most hatcheries stopped feather sexing years ago – not because it didn’t offer value, but because the labour required made it unfeasible,” says Bautista. “Now that automation has removed that barrier, it’s time to reassess.”

According to Matloub, introducing WingScan into these regions won’t just be about the hatcheries buying equipment.

Beyond the hatchery

WingScan’s impact is felt far beyond the walls of the hatchery. For producers, automated feather sexing enables uniform flocks of either all males or all females –unlocking new levels of efficiency and control.

“When you raise males and females separately, you can tailor the feed, reduce competition and improve overall flock health,” says Matloub. “Farmers are seeing better feed conversion, lower mortality, and more consistent birds coming into processing.”

That consistency has major implications for the processing plant. With tighter weight ranges and less variation in carcass size, equipment calibration becomes easier, line speed can be maintained and product yield improves.

“Uniformity matters,” says Carlos Bautista, marketing strategy manager at TARGAN.

“It impacts how efficiently birds move through primary and secondary processing. The better the uniformity, the fewer hiccups down the line.”

The logistics are improved, too. At Trouw Nutrition’s Ramsay Hatchery, hatchlings now leave the facility hours earlier than before. “Delivery trucks have been able to arrive around four hours earlier than what we would have expected with manual sexing,” Jimi Godin, continuous improvement manager at Trouw Nutrition, explained in the official announcement. This improves animal welfare by accelerating access to feed and water, and decreases first-week mortality by up to 0.5 per cent – a significant gain.

WingScan also enhances biosecurity. Fewer people handling chicks reduces contamination risk, and automation eliminates the need for teams of 30–40 people working shoulder-to-shoulder – a major concern during outbreaks of disease.

“This isn’t just about doing the same job faster,” says Matloub. “It’s about rethinking how we manage chicks from the moment they hatch. WingScan reduces touchpoints, improves sanitation and helps deliver stronger, healthier birds to the barn.”

160,000

is the chicks-perhour speed at which TARGAN’s WingScan AI can process hatchlings – with up to 98 per cent accuracy.

“This is an industry decision,” he says. “Hatcheries, feed mills, producers, and processors all need to sit at the same table. If one link isn’t aligned, it won’t work.”

The changes required are real. Farmers will need to consider whether they want to raise all-male, all-female or split flocks. Feed mills must be prepared to deliver tailored diets. Processors may need to adjust target weights or reconfigure product mixes. Contracts across the chain may need revision.

But for those willing to make the leap, the benefits are compelling. “If done right, everybody wins,” says Bautista. “Hatcheries save on labour, producers get better-performing flocks, and processors see more efficient throughput. Even the feed mills benefit from improved feed conversion ratios.”

While TARGAN’s primary customers are hatcheries, the company is committed to supporting all stakeholders. “We don’t sidestep relationships, but we’re ready to speak with farmers – through the hatcheries – and help them understand what a sexed system would look like on their farm,” says Bautista. “We’ve already seen the impact in Quebec. Now we’re ready to bring that value to the rest of Canada.”

WingScan’s introduction to Canada isn’t just a product launch – it’s a signal of how automation and data are reshaping animal agriculture. For farmers, processors, and everyone in between, it offers a glimpse of a more precise, efficient and welfare-conscious poultry industry.

The transition is going to take collaboration, dialogue and a willingness to rethink long-standing systems. For now, though, WingScan is setting the standard in Quebec. The question for the rest of Canada isn’t whether the technology works – it’s whether the industry is ready to work together to adopt it.

“This is the future of broiler production,” Matloub says. “The technology is here. Now it’s time for the value chain to come together.”

By Ronda Payne

Every poultry farmer has stood in the barn wondering what an expert would suggest. How to enhance flock health? How to provide more enrichment? How to reduce costs while improving lighting? The questions can feel endless.

Often, the best improvements come from one clear piece of advice – with an understanding of why it matters. That’s why Canadian Poultry reached out to five experts for their top tip, and how it benefits both welfare and the bottom line.

Many producers are afraid of opening the air inlets when they place a flock of chicks. It’s natural to worry about keeping tiny birds warm, but when it comes to airflow, Jerry Emmanuel, part of Cargill’s poultry team for Western Canada, says those fears keep chicks from thriving.

“Open your inlets when you get your chicks into the barn,” Emmanuel says. “Don’t be afraid to get your air moving from day one.”

He’s heard producers say that cracks in the barn let enough air in, and he’s on a mission to end that kind of thinking. He had one producer who was concerned something was wrong with his chicks –after opening the inlets, the birds improved dramatically.

“If you and I were in a facility, lacking in oxygen, we don’t feel too great, we don’t

move much,” he explains. “The CO 2 is building up. The same thing is happening to them.”

The lack of airflow makes chicks more inactive and less likely to seek out food and water, delaying weight gain. Condemnations rise, as do conditions like ascites.

“It’s a simple thing,” Emmanuel says. “You paid enough for those vents – let’s use them because they work when you use them properly. It promotes a good environment in the barn. Birds thrive better. It’s just a fact.”

Proper use comes from staggering open vents and striving for “good” rather than

“perfect.” He uses an airspeed tool but says that’s only necessary for those who want to get deep into the technicalities.

Open vents help push warm air down. While it may mean turning the heat up in winter, airflow and oxygen are essential for chicks. Healthier chicks generate better financial returns, offsetting heating costs. In summer, inlets should be wide open.

“Oxygen, airflow – it’s a win-win,” he says. “Don’t be scared to try it.”

Boredom gets to all animals, and, like teenagers, poultry will tire of the same enrichment devices over time. Marisa Erasmus, associate professor of Animal Sciences at Purdue University, wants producers to choose the right enrichment elements and rotate them to maintain interest.

“The decision about which enrichment to implement depends on the behaviour that we want to target,” she says.

“For example, poultry have a natural drive to forage, scratch and peck. Environmental enrichments that can be manipulated, such as straw bales, stimulate these behaviours and can direct behaviour away from their flock mates.”

Changing or rotating enrichments is far more effective for overall health than keeping the same item perpetually.

“Thinking about enrichment as part of a program and not a one-time change is also important,” Erasmus says.

Choose enrichment by inspecting feathers, footpads, hocks and walking ability. “If feather condition has been deteriorating, this could be due to feather pecking and enrichments that direct pecking behaviour away from other birds would benefit the flock,” she says. “For broiler chickens and turkeys that become less active over time or that have reduced walking ability, enrichments that promote activity and foraging … are beneficial.”

Straw bales are an easy solution for multiple behaviours. While the science on density is still evolving, a minimum of one bale per 1,000 birds is a practical starting point; place bales throughout the barn. Rotate pecking blocks with other pecking elements; provide perches and nest boxes for layers, and ramps plus bales for broilers and turkeys.

“Enrichment is not a one-and-done –it takes time, energy and effort to maintain effective enrichment, and animals get used to it, so effectiveness may decline over time,” she says.

Build a program: source types, decide quantities, set a rotation/replenishment cadence, account for cost and labour, and consider biosecurity implications. The payoff is better affective states, activity levels and health.

3. Healthy guts make healthy poultry

Humans hear a lot about gut health – the same holds true for poultry. Chanelle Taylor, a veterinarian with Cargill Canada, wants gut-health support in feed from day one to processing.

“This will help to keep good guts healthy and [give] guts that have seen early challenges a chance to recover and reseed with good gut bacteria, minimizing potential later-age gut health problems,” she says.

Digestive health drives nutrient absorption, immunity and performance. Whether the goal is eggs or muscle, a healthy system starts with the gut. “When the gut becomes dysregulated and leaky, then the birds have a harder time developing muscle appropriately, feathering adequately and keeping their immune system functioning well,” Taylor says of broilers.

Around three to four weeks – often the starter-to-grower transition and when coccidiosis is fully cycling – humidity, litter moisture and gut health must be on point. If not, “it leads to gut dysregulation, coccidiosis over-cycling, the chance for non-beneficial bacteria to take over (such as Clostridium) and leaky guts,” she says. Because broilers have short lifespans, day-one support matters. “Every time we have something that causes dysregulation in the body, it costs the producer money through reduced performance, and so it’s important to get that gut going the right direction from the start.”

Work with your veterinarian and feed team on tools such as probiotics, prebiotics, essential oils and digestive enzymes. Keep an open mind – flocks differ. “When

the gut is performing well, feed conversion is good, immunity is optimal and the birds grow well with fewer issues,” she says.

4. Hit the hay and turn the lights out Scheduling four to eight hours of darkness helps birds establish rhythms, sleep better, grow faster and stay healthier, says Karen Schwean-Lardner, professor in the College of Agriculture and Bioresources at the University of Saskatchewan.

“That sleep in the dark has such a positive impact on health, on behaviour, on other welfare parameters such as bone quality, bone strength and on productivity,” she says. “And it means that the lights aren’t running, so it has an economic benefit beyond all of these different things.”

Constant light once seemed logical to boost intake and growth, but research shows regular dark periods are better. The Canadian code of practice minimum is four hours; notable health and behaviour benefits appear at six, and older birds may need up to eight. Longer dark periods can reduce sudden death syndrome, ascites and leg problems.

How dark is dark? Birds need a clear day–night cue. As a rule of thumb, if a barn runs 10 lux by day, about 1 lux at night delivers “night” without penetrating the skull. Avoid flicker: LED systems need proper controller/dimmer boxes designed for LED. Birds see flicker we do not.

Better lighting control improves energy use and feed efficiency. “Birds will learn,” she explains. “If lights go off at 11:00 p.m., in a few days they eat about an hour before. With longer dark periods, they eat more beforehand, feed remains longer in the GI tract and digestibility improves.”

Result: healthier birds with better growth.

5. Give the pullet a familiar home

Animals adapt better when young, but familiarity remains key. Tina Widowski, professor at the Ontario Agricultural College, University of Guelph, advises rearing pullets in systems as close as possible to their future laying houses.

“A young hen, while she’s growing up, has to learn how to navigate a complex system,” Widowski says. “The more opportunities she has to jump, climb ramps, alight on perches and engage in perching behaviour, the more easily she will be able to navigate the henhouse.”

Experience builds stronger bones and muscles, reduces fear and improves adjustment. Birds that can find feed, water, nest boxes and perches early are more likely to lay in nest boxes and maintain intake later.

Three-dimensional spaces matter. Provide ramps to higher tiers so pullets learn to use them. “Ramps seem very important for hens,” she notes. “If they don’t have experience with ramps, they don’t use them as well.” Ramps also help reduce keel fractures, supporting healthier ageing.

Expert advice doesn’t only come from conferences – sometimes it’s a tip you can try today. Understanding why it works makes it easier to implement and to see benefits in health, welfare and the bottom line.

Chicken Farmers of Canada’s Young Farmers Program is a professional development program that teaches young leaders aged 18-40 in the chicken sector about governance, succession planning and personal branding, while also networking with key agriculture and government stakeholders. It also helps young farmers better understand the sector and gives them the tools to succeed.

Learn more about the Chicken Farmers of Canada’s Young Farmer Program, and apply today!

chickenfarmers.ca/young-farmers-program-2026-2027-application/

chicken.ca / chickenfarmers.ca

By Lauren Dawson and Nayara Tavares Ferreira

Across Canada and the globe, the egg industry is shifting toward longer laying cycles. This change supports sustainability and improves efficiency, but it also introduces new challenges for bird health and welfare. One critical concern is bone strength.

Egg production is a physically demanding process. Each day, a hen needs to mobilize about two grams of calcium to form an eggshell. While some of that calcium comes from the diet, a significant portion is drawn from the skeleton, acting like a calcium bank to supply the mineral during the night when dietary calcium isn’t available. Over time, this can lead to bone loss, fractures and osteoporosis. These issues don’t just affect the birds’ comfort – they impact productivity, feed efficiency and mortality.

A study conducted at the Trouw Nutrition Poultry Research Centre in Spain examined hens at the end of a long laying cycle (100 weeks old) to better understand how

bone quality relates to egg production and shell strength (Alfonso-Carrillo et al., 2021). In short, hens with high egg production and strong eggshells had weaker bones, as assessed based on lower ash weight and lower amounts of medullary bone. These birds were more efficient at pulling calcium from their skeletons to support shell formation, but that came at the cost of their bones being more fragile. Conversely, hens with lower egg production or poorer shell quality had stronger bones and more medullary bone. They weren’t mobilizing as much calcium, so their skeletal structure remained more intact, and they could retain a larger amount of medullary bone. This suggests that high-performing hens may be more prone to bone problems, especially later in life.

However, the study also found that there wasn’t a clear-cut relationship between bone parameters (e.g., tibia weight, breaking strength) and egg production or eggshell quality. In other words, just because a hen lays a lot of eggs doesn’t automatically mean her bones will suffer – and vice versa. This

means that producers don’t have to choose between strong bones and strong eggs –they can aim to improve both.

Bone fractures are one of the most serious welfare issues in laying hens. They cause pain, reduce egg production, increase feed costs and raise mortality. Fractures often go unnoticed until they affect performance, but by then, the damage may be done. Supporting strong bones by focusing on nutrition allows hens to better cope with the demands of extended laying cycles. By focusing on nutrition for improved bone health, producers can improve both performance and welfare.

Supporting bone health is one of the ways producers can improve hen welfare. Some strategies can include:

1. Focusing on the pullet phase. This stage is crucial for bone and skeleton formation. During this period, the bird’s skeletal system undergoes significant development, establishing the foundation

Save on average 6 grams of feed per bird, per day with the ECO

The ECO Unit is a smart solution for layer farmers to achieve minimum ventilation while optimizing feed consump tion and egg yield through improved indoor conditions. This innovative investment ensures cost savings, improved bird welfare, and increased profitability for your farm’s future.

For more info visit www.vencomaticgroup.com

BLR Solutions

QC - T: +1 450 772 2929 jfbourbeau@blrsolutions.ca

Eric Griffin Agri. Equip. Ltd.

NS - T: +1 902 542 0160 andrew@ericgriffinagriequip.ca

Penner Farm Services

AB - T: +1 403 782 0675

MB - T: +1 204 326 3781 webuildfarms@pennerfarmservice.com

Pols Enterprises Ltd.

ON - T: +1 905 708 5568 sales@polsltd.ca

United Agri

BC - T: +1 604 859 4240 webuildfarms@unitedagri.com

Western Ag Systems

SK - T: +1 306 382 0700 webuildfarms@westernagsystems.com

“Producers don’t have to choose between strong bones and strong eggs – they can aim to improve both.”

for strong bones to support future egg production. Proper nutrition is essential during this phase to ensure optimal bone health. Additionally, providing a well-balanced diet along with suitable housing conditions can help prevent skeletal issues and promote long-term overall well-being.

2. Delaying the age at first lay. Giving hens more time to build their bones before they begin producing eggs can help maintain skeletal strength through the lay cycle. Early onset of lay may limit bone development and increase the risk of bone fractures.

3. Using coarse calcium sources, such as larger particles of calcium carbonate. These are absorbed more slowly and help reduce the need for calcium to be pulled from the bones, which in turn supports bone integrity.

4. Adjusting the calcium levels in the hens’ diet as they age. Older birds absorb calcium less efficiently, so they may need more in their feed to maintain bone and shell quality.

5. Supporting the development of the oviduct. The oviduct is responsible for

forming the eggshell. A healthy, well-developed oviduct is essential for producing strong eggshells, and it relies on balanced nutrition, especially during the pre-lay period.

As the egg industry continues to extend laying cycles, it’s more important than ever to give hens the nutritional support they need to stay strong, inside and out. With the right strategies, producers can help their birds lay longer, stay healthier and live better. Nutrition plays a central role in this effort. As research continues to evolve, so too will the tools and knowledge available to support healthier, more resilient flocks.

PhD,

VALLI has always believed in the “Aviary” project as an alternative system for raising laying hens in a comfortable habitat.

Hens are raised inside single-story or multi-story buildings with access to many “shared spaces” throughout the building—offering them greater freedom to move from one area to another, stretch their wings, fly, and take dust baths.

The VALLI BABY AREA is ideal for rearing of pullets...in freedom!

The VALLI SPACE COLONY is designed to maximize animal welfare and is customizable from three to twelve tiers.

We can meet your layer equipment needs. Call us for more details: Dennis Pine dennis@county-line.ca | 519-292-9635 www.county-line.ca

Happy Thanksgiving

At Thanksgiving, we give thanks to the hardworking Canadian turkey farmers who bring tradition to the table. Every turkey raised on Canadian farms reflects care, expertise, and commitment to Canada’s food system.

By Dr. Gigi Lin

I’ve worked with many producers who are intimidated by welfare audits and have reached out to me for advice. I’ve also been on the other side of the table as an auditor, where just my presence sometimes made people see me as a threat. It is a common reaction: audits can feel like a judgement rather than an opportunity. But what if we put on a different set of lenses? Instead of seeing the audit as something scary, think of it as a set of metrics that can help you identify management gaps early.

In one of my audits, I had the pleasure of working with a broiler producer who turned what could have been a negative report into one of his most valuable management tools. The audit revealed his flock’s footpad health scores were above the acceptable threshold, something he would not have noticed without the close plant-level inspection that comes with an audit.

Rather than dismissing the finding, the producer began tracking footpad scores across multiple flocks over several cycles. This active monitoring allowed him to pinpoint a specific barn that consistently housed flocks with higher rates of footpad lesions.

With this knowledge, he focused his attention on that barn and compared its

conditions to barns with minimal foot pad conditions. He addressed the problem immediately by reducing stock density to buy some time while adjusting other management practices such as fine-tuning ventilation settings, improving litter management, and tightening waterline checks. Although the fine-tuning took time, the modifications eventually paid off, with fewer footpad lesions and better overall performance.

What started as a bad audit turned into a targeted improvement strategy that made his operation stronger. Stories like this show that audits don’t have to be intimidating – they can be powerful management tools. With that in mind, here are some practical tips to help you ace your next welfare audit.

One of the most practical ways to prepare for a welfare audit, especially if you are new to it, is to familiarize yourself with different auditing guidelines. Think of them as the marking criteria before an exam – your study materials.

Depending on the processor, integrator, or market your supply to, producers have different guidelines or audit checklists may be used. One of the most widely adopted in the North American broiler industry is the National Chicken Council (NCC) Broiler Welfare Guidelines and Audit Checklist. This is a comprehensive, science-based framework for promoting consistent, humane care of chickens through all stages of their life from hatchery to processing.

The checklist covers staff training and

OCTOBER 21, 2025 @ 12:00 P.M. ET

REGISTER FOR THE SIXTH ANNUAL INFLUENTIAL WOMEN IN CANADIAN AGRICULTURE SUMMIT.

Join us live online, from anywhere, to hear from today’s most influential leaders and changemakers in Canadian agriculture.

Hear from the 2025 IWCA honourees and other agricultural trailblazers as they share their experiences, triumphs and lessons learned during the virtual IWCA Summit.

Join us for an afternoon of panels, interactive conversation and audience Q&A as our honourees pass down their knowledge, wisdom and advice to other women in agriculture.

corporate commitment, hatchery operations, growout operations, catching and transportation, and processing operations. It is a great tool to start with if you are unfamiliar with what a welfare audit looks like.

While welfare audits are powerful tools for detecting early signs, identifying gaps, and driving improvements, it is important to recognize their limitations and think of ways to work around them.

1. Snapshot in time

An audit reflects what is happening on the day of assessment, not necessarily the week before or after. To overcome this limitation, consider internal mini audits at key flock ages to monitor trends. Producers can also set their own internal targets to compare flocks over time and make continuous improvements. For this purpose, broiler management handbooks from the breeding

stock companies are great references to build an internal checklist.

2. Beyond minimum standards

Passing an audit doesn’t always mean the birds are thriving. Some audits are designed based on the minimum standards. For example, some audit guidelines set a threshold of 25 ppm or less for ammonia at the birds’ level. Passing at 24 ppm still means birds are living in high ammonia levels that could affect health and performance. For many parameters, do not overlook the passing checkboxes. Instead, pay attention to the actual numbers and investigate beyond the checklist.

3. People-driven outcomes and audit fatigue

It is human nature that, over time, checklists can become tedious paperwork rather than performance tools. Even with strong SOPs, success depends on staff buy-in, consistency, and training. An

audit might verity that SOPs exist, but it can’t always measure how well they are being followed when no one is watching. I have seen producers who offer extra bonuses to the entire farm team when the condemn rates are below a certain percentage, or the mortality rate is reduced. Create incentives to make it fun and reward the team can go a long way.

To sum up, welfare audits do not have to be intimidating. When you use them as a guide rather than a verdict, they become a living management tool that keeps birds healthier, production more efficient, and teams more accountable. After an audit, respond to findings quickly and transparently, engage your staff in practical corrective action plans, and track progress across multiple cycles to ensure continuous improvement.

This is the most up to date, complete and practical guide to chicken nutrition that you can buy.

It covers the underlying theory of poultry nutrition making it easier to recognise problems in the field. As the most important aspects of the diet are those that make up the largest proportion of the costs, this book focuses on these areas; e.g Energy, Protein and Key Minerals. $98.00 | Item#1899043422

By Crystal Mackay

Mackay is CEO of LOFT32 and co-founder of UTENSIL.ca, the unique online toolbox of training resources for people in agriculture and food. She created both with the goal to elevate people, businesses and the conversations on food and farming as a keynote speaker and trainer.

Who uses a cute voice when you talk to your dog? Who takes their pets to the vet? Who makes sure chickens and turkeys are well cared for and healthy?

According to Agriculture and Agri-Food Canada, in 2024, pet food retail sales in the Canadian market totalled $6.7 billion, with 10 per cent growth in sales of dog and cat food over the past five years. With just under 40 per cent of households owning a cat or dog or both, we are an animal-loving society.

Many find it uncomfortable to talk about animal welfare with people who are animal lovers –because of the age-old awkward transition between “we care for them, and then we eat them.” I’ve been working on this topic for many years, with consumer and industry audiences, and want to share some insights to help increase your comfort and confidence.

Animal rights is not animal welfare

Animal welfare is rooted in the belief that we have the right to use animals and the responsibility to care for them. Animal rights supporters do not believe in the use of animals for human benefit.

We can hire nurses and put red carpets in our barns or put all the birds outside – it’s not going to make an animal rights supporter happy. It’s confusing (on purpose sometimes) because many animal rights groups use animal welfare examples or push for welfare reforms, but it’s not their end goal.

2. Share your why first

The common approach to answering a question is to jump in with the how and the details about what we do to care for animals. Back it up to be sure to communicate the why first. Why did you choose to farm? Why are you committed to improving animal care in your role? Why does caring for birds matter?

At the heart of it all is a reminder from Theodore Roosevelt: people don’t care how much you know until they know how much you care.

No one is more qualified or committed to caring for birds and talking about it.

3. Animal care is what you do

It’s not a press release or a publicity stunt – you are committed to caring for birds 365 days a year. No one is more qualified or committed to caring for birds and talking about it.

4. Tradeoffs and context

There is no such thing as perfect animal welfare or housing, and no simple solutions. When working with birds, it’s always a balancing act between many things – including health, welfare, sustainability, economics, food safety and quality.

If we focus on one aspect alone,

we can throw another out of balance or have serious unintended consequences.

5. Continuous improvement

I often think back to hand-watering and carrying feed to the chickens and turkeys on our mixed farm when I was a kid, and marvel at the advances we’ve seen in how we care for birds – and what’s to come.

How we care for birds is rooted in science, with the “ask the birds what’s best” through research approach. What humans think is best doesn’t always fit with what the birds can show us through their behaviour. Farmers and industry groups fund research to keep asking and improving, echoing Maya Angelou’s words: do the best you can until you know better. Then when you know better, do better.

your voice

Build bridges and join in the conversations about animal welfare, and share how you care for birds whenever you get a chance. Canadians need and deserve to hear your credible voice.

*Protection against GA08, GA13 and DMV/1639/11 IBV types.

A live monovalent bronchitis vaccine. Every droplet of Cevac IBron™ carries a tidal wave of protection against the DMV isolates of the avian infectious bronchitis virus. This live, monovalent bronchitis vaccine can be administered using coarse spray application or the gel spray route for rapid uptake.

Cevac IBron™ is the latest example of Ceva’s continual commitment to research and innovation, both today and in the future. Contact your Ceva representative today to turn the tide on avian infectious bronchitis, with IBron™.

Tel: 800.510.8864 • service.canada@ceva.com • ceva-canada.ca

Introducing Poulvac® Procerta™ HVT-IBD. Timing is everything in a poultry operation, and Zoetis created its newest vector vaccine to put time back on your side. Backed by the latest science resulting in excellent overall protection, studies found that Poulvac Procerta HVT-IBD protected chickens fast against classic IBD and AL-2.1-3 It’s a quick way to full protection from infectious bursal disease. Contact your Zoetis representative or visit PoulvacProcerta.com.