SUBSCRIBER ACTION REQUIRED, P.27

SUBSCRIBER ACTION REQUIRED, P.27

So switch on your crops’ natural defenses and protect them from disease with Regalia Maxx.

and

we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2014 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Lukie Pieterse

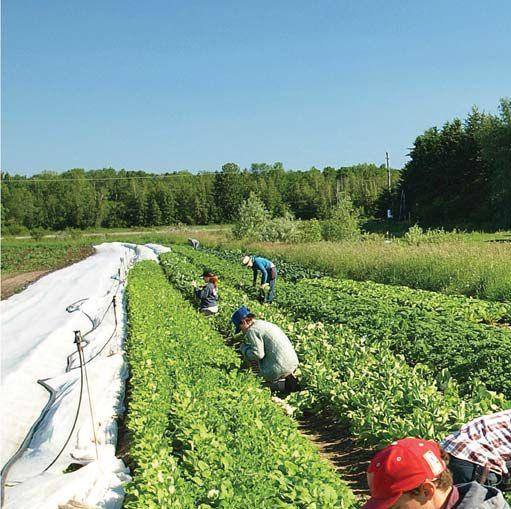

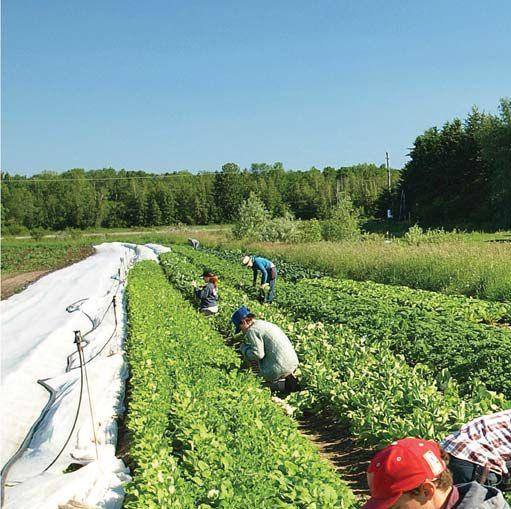

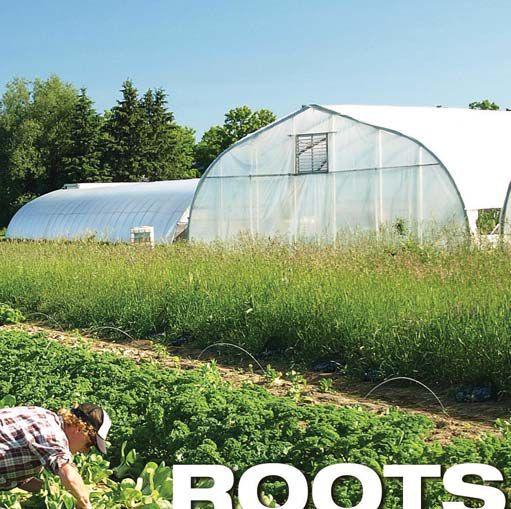

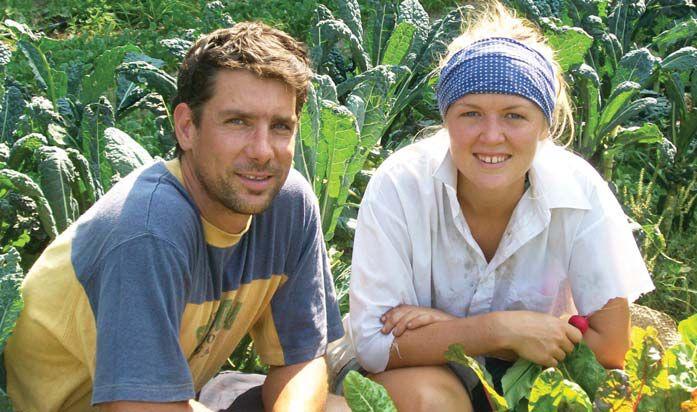

close and personal Being close to a major urban centre one of the keys to Roots and Shoots Farm success

Kryzanowski

Lilian Schaer

Revolutionizing Ontario’s cider industry Geissberger Farmhouse Cider’s packaging – and their portable cider mill – is taking the province by storm

Iwas in Nova Scotia in late January to take part in Horticultural Nova Scotia’s annual conference and the Nova Scotia Fruit Growers’ Association’s 150th annual meeting. It was while I was there that the Ontario government announced the latest increase in minimum wage from $10.25 per hour, set in 2010, to $11 per hour.

The increase probably came as no surprise to most farming organizations in the province, many of which made submissions to the Minimum Wage Advisory Panel last fall. But that doesn’t make the decision any less alarming to growers and other farm producers who rely on employees to help prepare, plant, manage and harvest crops.

According to Ken Forth, president of Foreign Agricultural Resource Management Services (FARMS), who happened to be present for part of Hort Nova Scotia’s conference, fruit and vegetable growers in Ontario were “terrified” by the rise in minimum wage, which hadn’t yet been announced at that time. He added the increase meant Ontario producers would be at a disadvantage in the North American market considering wages in the U.S. and Mexico are lower.

Farmers are price takers, he said, not price setters.

With the announcement on Jan. 30, several farming organizations announced their concerns surrounding the increase.

“[The] OFA has long protested that an increase in the minimum wage will hurt Ontario Farmers – especially fruit and vegetable farmers who rely heavily on seasonal labour,” the Ontario Federation of Agriculture stated in a press release. “Farmers are unable to recoup wage increases by adding the additional cost of production to the price we receive from our farm products.”

The Grape Growers of Ontario (GGO), who also appeared in front of

the province’s advisory panel for minimum wage, advised against a “significant lump-sum increase that we have seen in the past.” Instead, they suggested minimum wage increases be connected to the Consumer Price Index (CPI) “to establish a regular, predictable and sustainable” rate pattern.

It was a view shared by the OFA.

“[The] OFA supports tying minimum wage increases to the [CPI], believing this approach will lead to more predictable adjustments for which all businesses can plan.”

This support was echoed by the Christian Farmers Federation of Ontario (CFFO).

“We believe there needs to be a fair and just way to move forward on this policy,” stated Nathan Stevens, general manager and director of policy development for the CFFO, in the organization’s weekly commentary. “When you run the numbers from 2010, which is the last time the minimum wage increased, using CPI as a means to establish the minimum wage, $11 is not unreasonable.”

The CFFO hopes the loss of value in the Canadian dollar will help cushion the blow for export producers, considering the timing of the increase.

The GGO was also concerned with the timing of the increase, preferring any jump in minimum wage occur “outside of [the] traditional seasonal labour period of April to November to avoid increases during the season.”

Ontario’s 75-cent minimum wage increase is set to begin on June 1, 2014. Under the proposed legislation, any future increases would be announced by April 1 and come into effect on Oct. 1.

In the fall of 2009, just prior to Ontario’s previous increase in the minimum

wage, the George Morris Centre released a 40page report entitled Minimum Wage Increases in Ontario: Understanding the significance in horticulture . Authored by Al Mussell, a senior research assistant, and Claudia Schmidt, a research associate, the report presented an analysis of the apparent cost and risk management impacts of an increase to the minimum wage. According to the reported results, the cost to growers of increasing the minimum wage to $10.25 was estimated at $73 million and was expected to result in decreased profitability for producers.

“In particular, when an enterprise with few alternatives to substitute for labour is examined (peaches), a 28 per cent increase in manual labour expense decreases profitability by almost 50 per cent,” the report stated. “Since little opportunity currently exists to adjust to this labour cost change in industries like peaches, these constitute real cash losses for farmers.”

The report’s Executive Summary ended with a dire prediction.

“The minimum wage increase … artificially piles sharp labour cost increases on an industry that is already struggling. Moreover, it puts public policy at odds with itself, and confuses the public interest that government has articulated for horticulture. This warrants corrective action to restore profitability to Ontario horticulture as it relates to minimum wage increases. The apparent result of inaction will be a catastrophe for much of Ontario horticulture.”

Admittedly, the dire consequences of the 2009 report did not come to fruition. Hopefully this newest minimum wage increase will not be the catalyst for that predicted catastrophe.

By Lukie Pieterse

John Griffin, president and general manager of WP Griffin Inc. – a family owned and operated potato farming and packing business located in Elmsdale, P.E.I. – is keen on fresh.

“I’m very positive about the future of the potato industry here on Prince Edward Island and across North America,” he says. “Although the processing industry has been the main driver of growth in many areas, including Prince Edward Island, I believe that going forward, retail and food service channels will continue to consolidate the fresh potato sector.”

WP Griffin Inc. was founded in 1947 by Wilfred Griffin and, 67 years later, the

company is still on a growth path, cultivating potatoes and other crops on several thousand acres of land and distributing fresh pack potatoes across Canada and the United States.

The company is run by brothers John and Peter Griffin. John takes care of office administration, including strategic business development and marketing, while Peter is in charge of field operations and packing house processes.

As president and GM, John started the process of developing a senior management team 10 years ago. Today, the team oversees all business functions related to the WP Griffin Inc. operation. The senior

management team includes 10 subcommittees, featuring a wide array of company staff members. Committee responsibilities range from personnel matters, quality control issues, crop improvement initiatives, workplace safety matters, food safety regulations, new product developments, to capital budgeting concerns. The senior management team meets monthly to review the company’s performance.

“We have invested in new varieties, new packaging methods and equipment, as well as improved processing systems for over 20 years,” says John. “It sure wasn’t easy to move forward without challenges during the first 10 years, but our hard work and

persistence has certainly paid off during the course of the last few years. We will continue to change and innovate in the future since sensible change and continued innovation has of late become the ‘new normal’ for any business that is serious about future growth and development.”

The farming division of WP Griffin Inc. showcases a range of new table varieties, sustainable farming practices, as well as food safety and quality assurance initiatives.

“We annually produce 3,400 acres of potatoes, grains, soybeans, hay and rye grass,” says John. “Potatoes are our passion though, and we cultivate many different potato varieties and types including Russets, reds, whites as well as yellow fleshed potatoes.”

The packaging and wash plant division of the company has the capacity and expertise to package and distribute a wide variety of traditional fresh pack potato products, as well as a line of value-added specialty products. According to John, this division has undergone a complete makeover over the past five years, integrating state-of-the-art technologies and equipment to accommodate the growing demands of consumers looking for the highest quality products in retail stores.

Branding themselves “Griffin Prince Edward Island Potato Specialists,” the company takes great pride in growing, packaging and shipping a wide variety of potatoes and consumer-convenient fresh potato product choices. WP Griffin Inc. potato products are sold across Canada, primarily to Sobeys Inc. and Foodland stores. Their food service customers include GFS Gordon’s Food Services and The Keg restaurant chain in Eastern Canada, for which brand name products are produced.

WP Griffin Inc. also services the Eastern United States as well as other international markets. In 2012, the company sealed a contract to supply Outback Restaurants in the Eastern U.S. Other signature private labels produced and distributed to retail chains include Griffin, Bud The Spud and Dole.

“Finding new customers is always a challenge,” says John. “But at times there are certain unforeseen rewards that come along during this process as well. When we were selected to supply all of the baker and red potatoes to The Keg restaurant chain, we were of course very excited. Since there aren’t any Keg restaurants on P.E.I., we really enjoy going to a Keg for a steak and a great P.E.I. potato when we travel to Toronto or Moncton,” he added jokingly.

Recent developments and expansions of note at WP Griffin Inc. include an upgrade to its bagging equipment, the installation of a new Volm VP12000 with duel wicket poly bagger and the acquisition of a Matrix vertical fill-form-seal bagger.

“This investment is for the long term,” says John. “I do believe that growers can and will benefit from innovative marketing initiatives in the fresh produce sector. This year we launched the Potato by Usage program at Sobeys in collaboration with Earth Fresh. This program is modelled after a similar initiative in New Zealand. The goal is to make potato selection for a desired meal occasion easier for consumers in retail stores,” he says.

Thus, if consumers are looking for a potato that is best suited for baking, all they need to do is to buy the potatoes packaged in a red bag. Blue is for mashing, yellow for roasting and green is for boiling.

WP Griffin Inc. has entered into a grower-packer contract with Albert Bartlett in the United Kingdom for cultivation of Bartlett’s Red Rooster variety in Prince Edward Island.

“We are very excited about this development,” says John. “Next we plan to launch a full line of Albert Bartlett products at Walmart stores in Eastern Canada and New England.”

What is in store for WP Griffin Inc.’s future? According to John: “the company will focus on execution in the near term. By execution I mean being fully committed to high-quality products and unmatched service on a year-round basis. In the longer term we will continue to look for new ideas to innovate our varieties, packaging and our production and cultivation activities.”

John is unequivocal about continual change and innovation at WP Griffin Inc.

“New customers, new products, and new technologies – we like to keep moving forward at a constant and goal-oriented pace,” he says.

In 2012, WP Griffin Inc. was the Atlantic winner of the Ernst & Young Entrepreneur of the Year award in the business-toconsumer products and services category. Last year, John was named one of the Top 50 CEOs in Atlantic Canada by Atlantic Business Magazine.

Scientists have discovered vital clues as to how the pathogen responsible for the Irish potato famine adapted to spread between different plant species.

Researchers at Oxford University and The Sainsbury Laboratory, Norwich, looked in unprecedented detail at how Phytophthora infestans, a pathogen that continues to blight potatoes and tomatoes today, evolved to target other plants.

The study, published recently in the journal Science, is the first to show how pathogens switch from targeting one species to another through changes at the molecular level. Researchers examined the biochemical differences between Phytophthora infestans and sister species Phytophthora mirabilis , a pathogen that split from P. infestans around 1,300 years ago to target the Mirabilis jalapa plant, commonly known as the four o’clock flower. They found that each pathogen species secretes specialized substances to shut down the defences of their target hosts.

“Plants have these enzymes called proteases that play a key role in their defence systems,” said Dr. Renier van der Hoorn, co-author of the study from Oxford University’s Department of Plant Sciences. “When a plant becomes infected, proteases help plants to attack the invading pathogens and trigger immune responses. P. infestans secretes substances called effectors that disable proteases in potatoes and tomatoes. These are highly specialized to block specific proteases in the host plant, fitting like a key into a lock.”

The effectors secreted by P. infestans are less effective against proteases in other plants such as the four o’clock, as they do not fit well into the locks. The researchers found that P. mirabilis evolved effectors that disable the defences of the four o’clock plant but are no longer effective against potatoes or tomatoes.

Researchers are examining the biochemical differences between Phytophthora infestans and Phytophthora mirabilis , a pathogen that split from P. infestans about 1,300 years ago to target the Mirabilis jalapa

“For the first time, we have found a direct molecular mechanism underpinning the change in host specialization,” said Dr. van der Hoorn. “We looked at specialization in the blight pathogens’ secret weapon, a key family of effectors called EPIC that can pass through plants’ defences undetected to disable the proteases. The EPIC effectors secreted by P. infestans have evolved to fit the structure of potato proteases just as P. mirabilis has evolved effectors that fit four o’clock proteases.

“If we could breed plants with proteases that can detect these stealthy EPIC effectors, we could prevent them from

sneaking in and thus make more resistant plants. Within the next decade, we plan to exploit the specialized nature of these effectors to develop proteases that are resistant to their action or can even trap them and destroy the pathogen. Potato and tomato plants with such proteases would be resistant to the blight pathogens, and combined with other resistant traits, could provide another wall of defence against the pathogens.”

Phostrol® helps maintain the quality of your potatoes while in storage so you can get the most out of your crop. Phostrol® is an extremely systemic and highly unique fungicide that provides effective, convenient & flexible preventative protection of late blight and pink rot when applied during the season and at harvest.

Always read and follow label directions Phostrol is a registered trade-mark of Engage Agro Corporation. For more information on Phostrol please contact Engage Agro 1-866-613-3336 engageagro.com

MAKE TIME FOR WHAT REALLY MATTERS. CORAGEN® CAN HELP.

You’re proud of your potato crop, but let’s face it. No one ever looks back and wishes they’d spent more time with crop damaging, yield robbing insects. We get that. DuPont™ Coragen® insecticide belongs to a unique class of chemistry with a novel mode-of-action that delivers extended residual control of European corn borer, decreasing the number of applications needed in a season. And, if your Colorado potato beetle seed-treatment control breaks, Coragen® can provide the added control you need. Which means you’ll have more time for the important things. It’s also easy on bees, beneficials and the environment. For farmers who want more time and peace of mind, Coragen® is the answer. Questions? Ask your retailer, call 1-800-667-3925 or visit coragen.dupont.ca

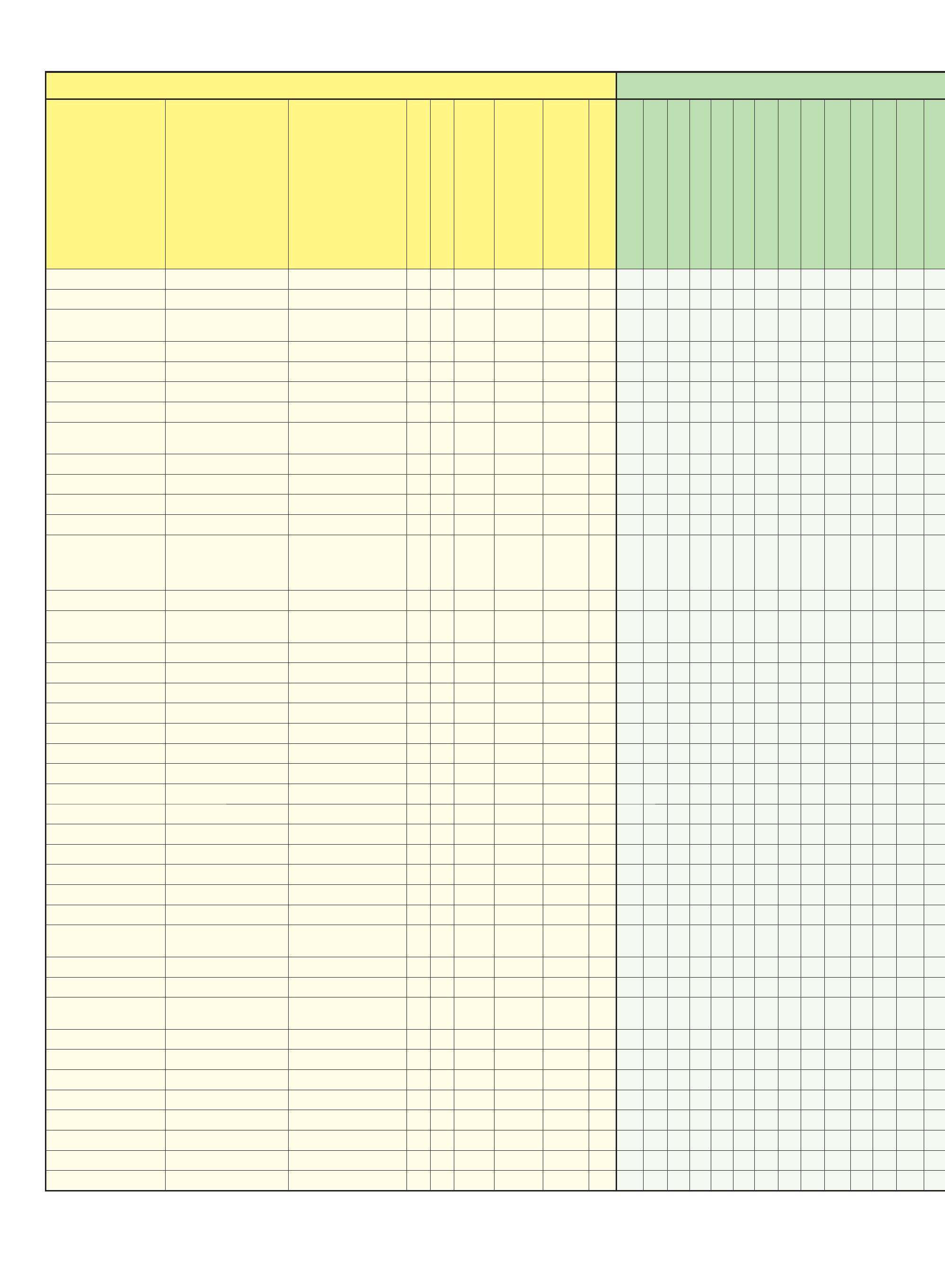

Insect management products Commonname Chemicalgroup (rotategroupsto manageresistance)

Soil/Foliar appliedAerial/GroundPre-harvest interval days Re-entry period (hrs)

Actara25WGthiamethoxamneonicotinoidFG6012102

Admire240Fimidacloprid4-neonicotinoidFG7242

Agri-Mek1.9ECabamectinavermectinFG28-1

Alias240SCimidacloprid4FG72472

AltacorchlorantraniliproleanthranilicdiamideFG51210-14

Ambush500ECpermetherin3AFG7

Apolloclofentezine10FG21121

Assail70WPacetamiprid4FG72-6days124

Beleaf50SGflonicamid9CFG214873

BioprotecCAFkurstaki11FG1004

Calypsothiacloprid4-neonicotinoidFG3012seelabel3

CloserSCsulfoxaflorsulfoxaminesFG71273

Clutch50WDGclothianidin4AFG71210-142

Confirm240Ftebufenozide18FG14124

CYD-XcydiapomonellagranulovirusFG0NA7-14

Decis5ECdeltamethrin3-pyrethroidFG112103

DelegateWGspinetoramspinosynFG712143S

DiPel2XDFbacillusthuringiensis11FG003-14

DiPelWPbacillusthuringiensisBtmicrobial7-10

Entrust80WspinosadspinosynFG7dry73S

Envidor240SCspirodiclofen23-tetronicacidderivativeFG712n/a1

ExirelcyantraniliproleanthranilicdiamideG3127

GF-120NFNaturalytespinosadspinosynFG1dry7

Imidan70WPphosmet1BFG141685

Intrepid240FmethoxyfenozideecdysoneagonistFG14122

Kanemite15SCacequinocyl20BFG1412212

KumulusDFsulphur124

LannatemethomylcarbamateFG824

Malathion85Emalathion1BFG3

Matador120EClambda-cyhalothrinpyrethroidFG72473

Movento240SCspirotetramat23-tetronicacidderivativeFG712143

Nexterpyridaben21FG25242

OpalpotassiumsaltsoffattyacidsinsecticidalsoapFG0NA

Pouncepermethrin3FG7

Rimon10ECnovaluron15FG14124

Ripcord400ECcypermethrin3FG7NA

Silencer120EClambda-cyhalothrin3FG72473

Success480SCspinosadspinosynFG7123

Superior70oilmineraloilFG121

Up-Cyde2.5ECcypermethrin3FG7123

VydateLoxamylcarbamateFGN/A48

Usesufficientwaterforthoroughcoverage.

McDanielSpidermite

Beginapplicationswhentreatmentthresholdshavebeenreached.Adequate coverageisessentialforoptimumcontrol

Readandfollowlabeldirections

Readandfollowlabeldirections

SS=Suppression

RegisteredonBrownMarmoratedStinkBug.Thisproductistoxictobees exposedtodirecttreatmentorresiduesonbloomingcrops.Donotapplyduring bloomorwhenbeesarepresent.Pleasenote:Clutch50WDGisregisteredon ApplesandPears(samepestsandrates)

Readandfollowlabeldirections

Applicationtimingshouldtargetsmalllarvaejustafteregghatch,andpriorto enteringfruit

Noteformulationchangefrom80Wto240SC

Readandfollowlabeldirections

Readandfollowlabeldirections

Readandfollowlabeldirections

AppleBrownBug,appleleafmidge,Fruittreeleafroller,Paleappleleafroller, wintermoth,Tarnishedplantbug

Readandfollowlabeldirections

Donotallowtankmixestositforlongperiods.Mixandsprayassoonas possible.

Readandfollowlabeldirections

Readandfollowlabeldirections

Avoidsprayingwhentemperaturesareabove25C WAL

Readandfollowlabeldirections

Readandfollowlabeldirections

SpanwormMoth/BruceWinter

GrubsWhite

Weevil

WebwormCaterpillar/FallTent

Symphylans

DrosophiliaWingSpotted

Scale Slugs

Mites

Leafrollers

Leafhoppers

AdultsBeetleJapanese

Grubs

MidgeMidge/TipGall

BeetleFlea

FruitwormFruitworm/CranberryCherry

BugStinkMarmoratedBrown

MaggotBlueberry

seasonpertimesMax. Aphids

(hrs)periodRe-entry applicationsbetweenDays

daysintervalPre-harvest

Aerial/Ground

appliedSoil/Foliar

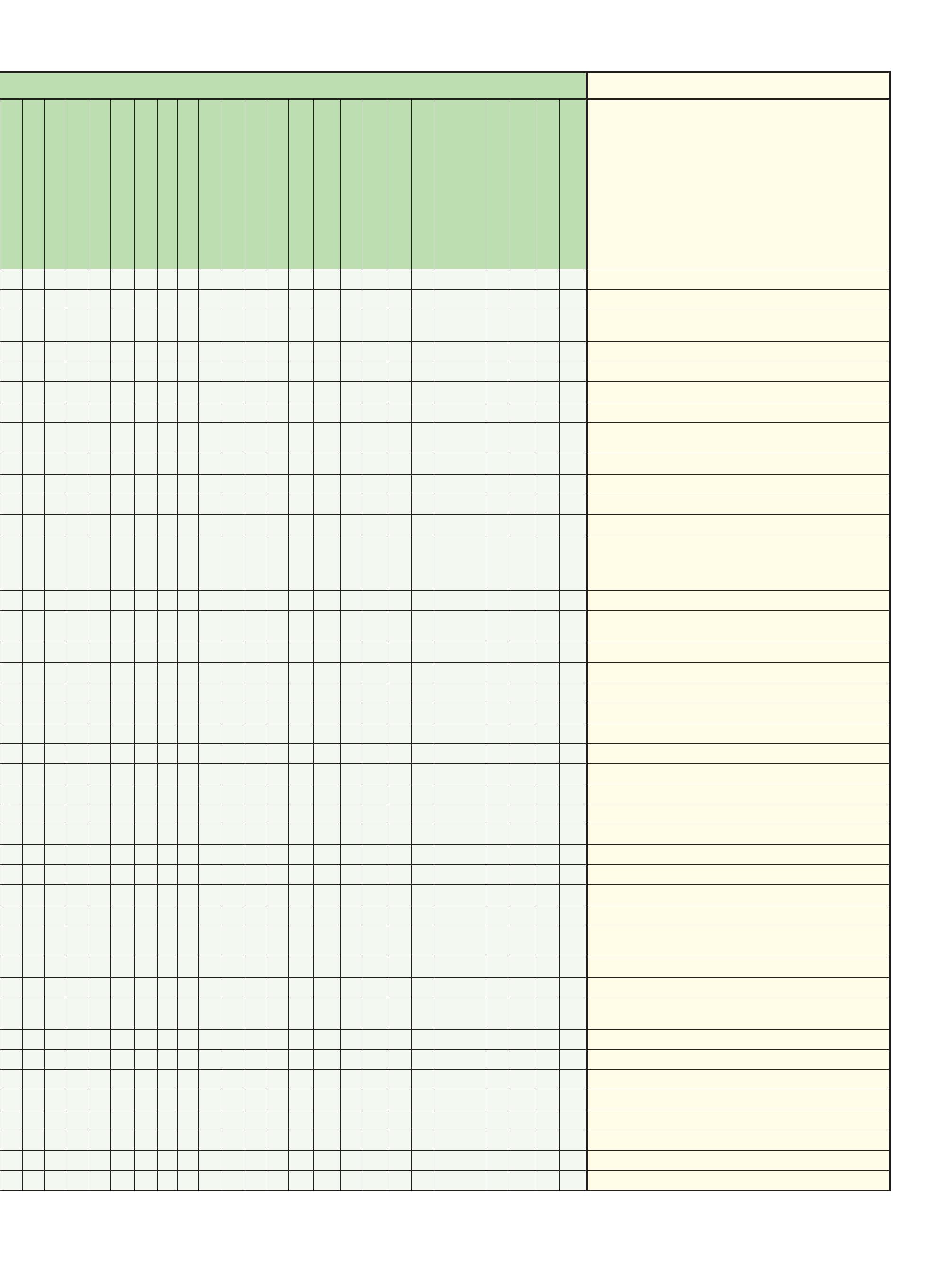

Common name Chemical group (rotate groups to manage resistance)

of European Chafer and Japanese Beetle

Obliquebanded Leafroller,

Begin application when insect populations reach recognized economic threshold levels. Monitor fruiting field by placing sticky traps in the field at the beginning of July. Apply within 7 days of the first blueberry fruit fly capture.

Provides control of Leaf Tier and Bruce Spanworm

S = Suppression

Suppression

Blueberry gall midge, BB maggot (S), Plum curculio, Japanes Beetle, Cranberry fruitworm, Oblique banded leafroller, Threelined leafroller, fruittree leafroller, European leafroller, Eyespotted budmoth, BB aphid

first applicationprebloom, second applicationpost-harvest

MiteSpiderTwo-spotted

LeafrollerStrawberry Thrips

CutwormStrawberry

WeevilClipperStrawberry

DrosophiliaWingSpotted

LeafhopperPotato Slugs

BugsPlant

MiteCyclamen

(hrs)periodRe-entry applicationsbetweenDays seasonpertimesMax.

daysintervalPre-harvest

Aerial/Ground

name Chemical group (rotate groups to manage resistance) appliedSoil/Foliar

black vine weevil and cranberry weevil

Admireimidacloprid4neonicotinoidSG3024n/a1Controls aphids, reduces number of larve of European Chafers

Admireimidacloprid4neonicotinoidFG72452Controls aphids, suppresses leafhoppers

Begin application when insect populations reach recognized economic threshold levels Consult the provincial extension service or professional consultants or other qualified authorities to determine the appropriate threshold levels for treatment in your area. Adequate spray coverage is essential for optimum control.

Read and follow label directions Assail 70 WPacetamiprid4FG172

Registered on Brown Marmorated Stink Bug. This product is toxic to bees exposed to direct treatment or residues on blooming crops. Do not apply during bloom or when bees are present.

Read and follow label directions

Clutchclothianidin 50 %4AFG7121

Clutch 50 WDGclothianidin4A7121

Decis 5ECdeltamethrin3pyrethroidFG14122

Delegate WGspinetoramspinosynFG112 3-43 SS = Suppression Dibromnaled1BFG4482

Fruittree leafroller, European leafroller, Obliquebanded leafroller, Threelined leafroller

Read and follow label directions

DiPel 2X DF bacillus

Lagondimethyloate1BFG7102

Lorsban 4EchlorpyrifosorganophosphateFG20241

Read and follow label directions

Note Lorsban 4E formulation change to Lorsban NT Malathion 25 Wmalathion1BFG3

Read and follow label directions

Also controls whiteflies

Matador 120 ECcyhalothrin-lambdapyrethroidFG72473

Meadow Spittle bug, suppression of black vine weevil adults, Nexterpyridaben21FG10242

Oberonspiromesifen 23tetronic acid derivative FG31273

Opal potassium salts of fatty acids insecticidal soapFG0NA

Avoid spraying when temperatures are above

Do not allow tank mixes to sit for long periods. Mix and spray as soon as possible. Ripcord 400 ECcypermethrin3FG7NA3

25 C Silencer 120 EClambda cyhalothrin3FG72473

Read and follow label directions

Strawberry aphid Sluggo Professionalferric phosphate014 UP-Cyde 2.5ECcypermethrin3FG71273

ThripsFlowerWestern

Two-spotted MiteSpider

AsianMulticoloured BeetleLady Snails&Slugs

(FirstMothBerryGrape generation) MothBerryGrape generation)(Second PhylloxeraGrape Form)(Leaf BeetleJapanese Leafhoppers Leafrollers BugsMealy

MarmoratedBrown BugStink WormBag MiteRedEuropean

(hrs)periodRe-entry betweenDays applications seasonpertimesMax.

Pre-harvest daysinterval

Aerial/Ground

Chemical group (rotate groups to manageresistance) appliedSoil/Foliar

Common name

Admireimidacloprid4neonicotinoidFG024142

12 hours21 days depending on the activity 212 13 days for training, bunch thinning, hand pruning, tying and leaf pulling activities

Admireimidacloprid4neonicotinoidS G3024n/a1 Agri-Mek 1.9

Use sufficient water for thorough coverage.

S = Suppression. Begin applications when treatment thresholds have been reached. Thorough coverage is important to obtain optimum control.

Registered on Brown Marmorated Stink Bug. This product is toxic to bees exposed to direct treatment or residues on blooming crops. Do not apply during bloom or when bees are present. Clutch 50 WDGclothianidin4AF112142

Delegate WGspinetoramspinosynFG71253

Diazinon 50 Wdiazinon1BFG16 DiPel 2X DF bacillus thuringiensis, var. Kurstaki 57% 11FG007-10

2X DFbacillus thuringiensisBt microbial003-144 Entrust 80WspinosadspinosynFG71273SSS S = Suppression, Note Formulation Change Entrust 80W is now Entrust SC Envidor 240 SCspirodiclofen 23tetronic acid derivative FG14 n/a1

Also controls mealbug and suppresses lecanium scale

Imidan 70-WP Instapakphosmet1BFG1414 days3

Intrepid 240 Fmethoxyfenozide ecdysoneagonist FG3024 10-14 3 Kumulus DFsulphurFG21Once residues dry108

Controls Grape erineum mites Malathion 85Emalathion1BFG3961 Movento 240 SCspirotetramat 23tetronic acid derivative FG71230 seelabel

Do not allow tank mixes to sit for long periods. Mix and spray as soon as possible.

Apply when infestation begins. Apply higher rates when population is very high.

potassium salts of fatty acids insecticidal soapFG0NA

Nexterpyridaben21FG25241Opal

Pouncepermethrin3FG212Ripcord

400 ECcypermethrin3FG2 2-3seelabel

Avoid spraying when temperatures are above 25 C Sluggo Professionalferric phosphate014

Success 480 SCspinosadspinosynFG71273SSSS = Suppression UP-Cyde 2.5ECcypermethrin3FG7123

seasonpertimesMax. Armyworm Aphid CutwormBlack MarmoratedBrown BugStink LoopersCabbage EarwormCorn RootwormCorn Cutworms

ap-betweenDays plications

(hrs)periodRe-entry

intervalPre-harvest days

appliedSoil/Foliar Aerial/Ground

timingApplication

Common name Chemical group (rotate groups to manage resistance)

Do not disturb soil for 5 days after application.

BorerCornEuropean ArmywormFall Leafminers Slugs Ambush 500 ECpermetherinpyrethroidFA/G112

and follow label directions

Suppression

Maintain spray pH of 6 or greater, Note Formulation Change Entrust 80W is now Entrust SC Force 3.0 GtelfluthrinpyrethroidplantingInfurrowG12n/aone

Apply in-furrow at planting black cutworm, wireworm, seed corn maggot Intrepid 240 Fmethoxyfenozideecdysone agonist apply at the first signs of feeding damage before the insect enters the fruit FG312 5-10 3 Lannatemethomyl carbamateat thresholdFG3242-5 S Use high rate for corn borer. S = Suppression

Armyworm, Western bean cutworm

Read and follow label directions

Read and follow label directions

Read and follow label directions

Read and follow label directions

Do not disturb soil for 5 days after application.

Read and follow label directions

Use high rates on severe infestations.

Do not apply within 7 days of forage harvest

Read and follow label directions

Read and follow label directions

Lorsban 4Echlorpyrifosorganophosphate2-5 leaf stageFG7024

Matador 120 EClambda-cyhalothrinpyrethroidrefer to labelFA/G1244-7 3 (2 aerial)

Movento 240 SCspirotetramat 23tetronic acid derivative After pollen shed FG 1273

Orthene 75 SPacephate1BFG214

Pounce 384 ECpermethrin3FA/G12 aerial

Pyrinex 480 ECchlorpyrifos1B2-5 leaf stageFG70

Rimon 10ECnovaluron15FG91275

Ripcord 400 ECcypermethrinpyrethroid5 leaf stageFA/G5-21

Silencer 120 EClambda-cyhalothrin3FA/G12442 aerial

Sluggo Professionalferric phosphateinorganicFG0

Success 480 SCspinosadspinosyn small larvae/ low popula-tions FG72

Up-Cyde 2.5ECcypermethrin3FA/G51243

Voliam Xpress lambda-cyhalothrin chlorantraniliprole pyrethroiddiamide refer to labelFA/G12472

Warhawk 480 ECchlorpyrifos1BFG70241

By Treena Hein

To say that the Geissbergers were busy during the fall of 2013 with their mobile cider mill is a bit of an understatement.

“We did a little bit of pressing in the fall of 2012 when we first got the mill and a bit last spring for ourselves, but things really exploded in September 2013,” says Gord, who co-owns Geissberger Farmhouse Cider with his brother Garry in Clarington, Ont. “There’s been a great response, even though it’s new technology.”

The brothers brought their mobile mill and bag-in-box packaging to about 17 different farms last fall, visiting some sites multiple times.

“We’ve met so many great people in so many beautiful places throughout Ontario,” Gord notes. “We’ve been north of Owen Sound, around Guelph, east of Kingston, at

small, medium and large orchards. Everyone’s been so pleased. In some cases, we’ve been back three times.”

For decades, the Geissbergers had used a press custom built by their dad’s cousin from Switzerland, but knew around 2011 that they needed to replace it.

“We did a business plan and contacted a press manufacturer in Austria,” Gord remembers. “We discovered that the company’s Canadian contact was Frank Deiter, who owns Mobile Juice Factory in Vernon, B.C., and he suggested going with bag-in-box packaging and one of his customized portable mills.”

Gord says what really caught their attention was the no-refrigeration nature of the packaging, with no preservatives needed. The cider stays fresh unopened for a full year, and for three months once opened.

“This really changes things for the or-

chard owner,” Geissberger explains. “Refrigeration equipment is expensive, and if that can be removed from the equation, it becomes much more cost-effective to make cider.”

The fact that this packaging keeps unopened cider fresh for a year also means growers can press all their apples at the peak of their flavour, rather than storing some for later processing.

“It all adds up to fewer costs for producers and tastier cider for their customers,” Gord sums up. “This system also allows you to use the apples that you wouldn’t think of, the small and large and so on that are not number 1 grade, so it gives orchard growers another revenue stream for juice apples. If you were to sell your juice apples to a large company, you get .06 cents per pound, and this way, you can get about ten times

that. And because we come to your farm, it means growers for whom buying a press isn’t feasible can carry cider as a product for the first time.”

Before they bought the unit, the Geissbergers did their research, and tried samples themselves to make sure the claims about shelf life were true.

“We got a bag-in-box from Mobile Juice Factory and had some cider, and then left it on the counter for three months and it was still great at the end of that time,” Gord says.

In mid-2012, they took the plunge and purchased one of Deiter’s custom-made mobile cider mills (there are another three being used in B.C. so far).

“You have everything on the trailer –the pasteurizer, the packager, spray washer, shredder and press,” Gord explains. “Frank came out and worked with us for two days, showing us how to do the cleaning and so on, and that was really good because it’s a little intimidating at first.”

Due to shipping problems, the Geissbergers did not receive their new mobile mill until late October of 2012.

“Although we missed a lot of the 2012 season, we really consider it a blessing in disguise because by starting slow it gave us time to learn the system,” Gord explains, “and it gave us time to develop the type of products we want to represent our business.”

Geissberger Farmhouse Cider offers natural sweet ciders and non-alcoholic sparkling and non-sparkling ciders in flavours such as apple strawberry, apple cranberry and apple raspberry kiwi.

To have the Geissbergers visit your orchard, you need a minimum of six bins (120 bushels), which can come from your farm and

from neighbours’ farms as well.

“We hook up to your potable water source, and the apples are loaded into the washer,” Gord explains. “Although the fruit will pass through a high-pressure washing system, we strongly recommend that fruit should be relatively clean and tree-picked without obvious dirt and debris.”

The apples are mashed, put through a hydraulic packing press, filtered and then pasteurized. The system can process about 40 bushels in an hour into about 500 litres of cider.

The almost completely dry mash can be used as fertilizer, compost or animal feed. Gord says the pulp is being sold to hunters for deer season, but that they’re also working on other ideas for it. While the bag can be filled with juice only once, the cardboard box can be reused many times (or recycled).

“We give $1 off to our customers who bring their box back,” Gord says. “The boxes stand up for a long time, and have room for each farm’s custom label.”

Although Gord and Garry were impressed with it, at the same time, they were quite nervous about the bag-in-box packaging because they had not seen it used for apple cider before.

“We weren’t sure if customers would respond well because they can’t see the product,” he says. “But people love the fact that they can put it on the counter and it doesn’t take up space in the fridge. People try the cider, love it and buy more.”

Their packages have even appeared on the CBC television show Dragon’s Den

“Frank asked us if we would mind letting him borrow our mill and use some of our product in April 2013, so we brought it to Toronto to the CBC studio, they took it up 10 floors, and it was our cider that the Dragons tasted,” says Gord. “Frank got a

Garry Geissberger discusses mak ing apple cider with Grade 3 stu dents at Durham Farm Connections in front of the Geissberger Farm house Cider mobile apple cider mill. Photo courtesy of Geissberger Farmhouse Cider

deal. It aired again in November and a lot of people saw it and commented to us at a holiday market event.”

During 2013, the Geissbergers produced between 35 000 to 40 000 litres from their own apples and mobile custom work.

“Our wives, and my and Wanda’s three daughters Samantha, Melody and Melinda help out,” says Gord. “We have friends, Joe and Dale, that help out as well. We love to visit other farms, and it’s like a mini apple festival at each farm when we come, says Gord. We tell people to advertise ahead of time, and put us in a visible location so their customers will be able to see the cider being made and ask questions. We also tell them to put out samples. People buy the cider once they taste it.”

Garry and Gord also enjoy experimentation with different flavours.

“We’ve done a cider with about 20 to 30 per cent carrots,” Gord says. “It’s a smooth finish and a little more orange in colour. At one orchard, we did an apple, carrot, beet mix that tasted really good. It was very red. We’ve done some apple-pear as well.”

Receiving two awards in 2013, the Geissbergers were recognized for their use of bag-in-box packaging through the Ontario Farm Fresh Marketing Association in February and also received an Ontario Leadership in Agricultural Innovation Award for the implementation of the mobile apple cider mill from Premier Kathleen Wynne in October.

“We are greatly honoured with the recognition, and it’s still overwhelming,” says Gord.

However, tradition is still important. The Geissbergers are still on a section of their grandfather Hans’ farm, and still care for a few trees that were planted by their dad in 1960s. In the near future, they have plans to expand the orchard and grow varieties that complement the flavour of their cider.

For more, visit www.farmhousecider.ca.

Being close to a major urban centre one of the keys to Roots and Shoots Farm success

By Treena Hein

The path to organic vegetable farming for Robin Turner was a happy accident. After spending his twenties traveling in Asia and teaching English, he had returned to Canada to study environmental science.

“We had to take some agriculture courses as part of the degree, and it really opened my eyes to the problems with our food system,” he says. “I met some people who were farming organically and once I saw what their lives were like, it sold it for me.”

“I like what an organic farmer does on a day-to-day basis,” Turner explains. “It’s hands-on and mechanical and interacting with living things, but there’s a social element and a business element, all of which provide a diversity of challenges all the time. It’s constant problem solving and I really like that.”

Since finishing university in 2004, Robin worked on and managed organic vegetable farms in Montreal, Boston and Ottawa. His partner (and farm manager) Jess Weatherhead has a degree in history and English lit-

erature, and has been farming her entire life. The path to their present farming operation, started in 2010, was also a case of happy accident. Robin was involved in another farm business in the Ottawa area, and was approached by a landowner looking for someone to farm his land.

“I actually wanted to be even closer to the city, but I went and took and look, and decided to take him up on his offer,” Turner says.

Roots and Shoots certified organic farm was born. It is located just south of the Ottawa airport, a 20-minute drive from downtown.

“Being this close to a major centre is pretty important,” Turner explains. “It’s easy for media outlets to come out and do a story, or call me for my opinion on a topic, and media attention is critical for a new business of any kind. It’s a short drive for people to come and visit our farm store, and not far for us to take

the harvest to farmer’s markets.”

Their CSA business has grown enormously, from 60 shares in 2010 to 250 in 2013. Customers pick up their weekly share at a central drop point. The CSA aspect makes up about 60 per cent of their profits, with farmers market sales contributing about 30 per cent, with remainder from their farm store, grocery stores and a few restaurants.

Turner and Weatherhead rent the land they farm, which is working out well.

“It can be tricky to rent land, especially if the property is also being used by the owners,” Turner says. “In this case, the owners use all the barns for their business, and we use temporary structures for our equipment. They’re very respectful of our use of the land, and that’s really important. You need to have autonomy in what you’re doing.”

In 2011, the house beside the property

just happened to come up for sale, and the couple snatched it up.

“So, while we’re not building equity in the land we farm, we are gaining equity in the house, which is a good thing,” Turner notes.

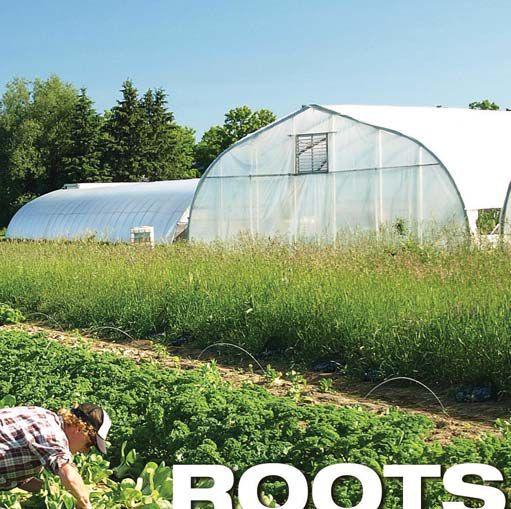

Turner and Weatherhead grow 10 acres (irrigated and tile-drained) of assorted certified organic vegetables, and also use three high tunnels (one Harnois 35 by 100 feet and two Hol-Ser 30 by 100 feet). In spring and summer, the tunnels house trellised tomatoes, cucumbers, peppers, and eggplants. In the fall and winter of 2012 and again last year, the couple grew spinach, kale and lettuce in the high tunnels, after doing a great deal of research about cold temperature cultivation.

“The profit of our farm is of course mainly in the warm months, but the greens are important in that they help us move our root crops through the winter,” Turner explains. “Even if you have a little bit of fresh organic greens to offer, people will also buy carrots, onions, potatoes. It keeps us in touch with our customers and the winter greens business also helps keep our employees working for longer.”

The high tunnel greens are seeded in September to ensure the plants are well established by the time it gets really cold. Then, they are covered and harvested on days when the ambient temperature reaches 3 Celsius.

“Growing them was easier than I thought it was going to be,” Turner says. “You just have to realize it depends a lot on the weather and how much work you want to put into it. For optimum performance, the plants need sunlight but you need to protect them at night by covering them. It’s a bit of a pain to uncover and cover them again on sunny days, and you can also leave the row covers on during the day, as the material does transmit light. But obviously, direct sunlight is better.”

Turner says the winter of 2012-2013 was perfect in terms of timing.

“We were lucky that first year, because the day before each planned delivery was warm and we could harvest,” he explains. “This winter was just too cold, from late November onward, in this area. You’re at the mercy of winter and cloud cover and just have to live with that.”

Watering in the winter is a challenge, and the farm has no frost-free hydrants at

after a landowner approached Robin looking for someone to farm his land.

tunnel at Roots and Shoots Farm houses trellised tomatoes, cucum bers, peppers, and eggplants.

the tunnels.

“Last year, we just watered the latest in the season that we could and then again in the spring,” Turner notes. “You also have to keep the tunnels clear of snow so that the light can come through. We use a snow rake, which is hard on the plastic, but there isn’t much alternative.”

Roots and Shoots continues to grow.

“The amount of machinery we have has increased a lot and we’re always investing profit back into equipment and infrastructure to make things more efficient,” Turner explains. “We have several tractors, a mechanized seeder, mechanical transplanter, mulch layer, potato harvester, and bed-making implements. Some organic farmers are resistant to mechanizing, but there is so much out there that makes things so efficient.”

Turner says the market for organic veggies is extremely strong, and they could have easily sold another acre’s worth of carrots this year.

The farm supported eight employees last summer.

“We have lots of applications every year, but retaining people is a challenge in the way that we have to make good money in order to provide a better wage to keep great employees coming back,” Turner says. “It pushes you to scale up and focus on efficiency and profits, but I enjoy those challenges of looking at mechanization options that will allow us to do that, and the management aspects.”

Turner says he was pleased to be awarded with the Premier’s Award for Innovation. It meant more media attention and the money was appreciated.

“It’s a bit vexing when someone says ‘you must work so hard,’ and yes, farming is a lot of work, but any new business or challenging job is a lot of work,” he says. “It’s very satisfying to see how you can structure things so that you make a good profit, if you do it the right way, in the right markets.”