It’s a matter of trust

Galvanizing the food and farming sector in a quest to gain back the public’s trust.

TREENA HEIN

TOM WALKER

HEIN

It’s a matter of trust

Galvanizing the food and farming sector in a quest to gain back the public’s trust.

TREENA HEIN

TOM WALKER

HEIN

You have to hand it to government and bureaucracy – they sometimes have a way of making even the most honest and supportive member of society turn into a negative naysayer with the mere swipe of a pen.

Case in point – B.C.’s groundwater licencing and well registration program. According to a recent article in Country Life B.C., the province has extended the deadline for applying for a groundwater licence without a fee from March 1 to Dec. 31, 2017, due to “underwhelming response.” As of the first week of January, the B.C. Ministry of Environment had received only 500 existing groundwater licence applications and 50 new licence forms despite estimating that the licencing and registration requirements applied to about 20,000 wells in the province.

It would appear they have a way to go to bring everything in line with the province’s new Water Sustainability Act, which came into effect more than a year ago on Feb. 29, 2016. Under the legislation, those using groundwater for non-domestic purposes – irrigation, animal agriculture, industrial and

encouraged to register their wells so their water use can be protected.

“If the provincial government staff reviewing a licence application doesn’t know about your well, they won’t be able to consider your water use when making their decision,” said Anna Warwick Sears, executive director of the Okanagan Basin Water Board (OBWB). “If you want to make sure that water continues to be available ... it’s prudent to register your well.”

The OBWB recently developed a guide to help well owners sort out the new regulations since there has been “confusion” about the program.

“There are still a large number who are on their own wells and they should know how groundwater licencing will affect them,” said Sears.

Based on the Country Life B.C. article, the ministry has been busy making presentations across the province. But there’s been little buy in.

The B.C. Agriculture Council has urged its members to follow the law, adding that licencing and registering wells will protect their right to water based on the current First-in-Time-

If you’re a heavy water user, that could mean big savings.

municipal waterworks – require a licence and must pay for the water they use. Existing groundwater users need to apply for a water licence by March 1, 2019.

“We are actively encouraging existing groundwater users to get their licence applications in early so their use is known and can be protected,” said Mary Polak, minister of the environment.

Even though domestic well users –homeowners with a well that provides water for household use, lawn and garden watering plus water for pets –are exempt from obtaining a licence and paying fees, they are still being

First-in-Right (FITFIR) allocation system.

“Under the FITFIR system, licensees with earlier licence dates (senior licensees) have priority over later licence dates (junior licensees) for accessing water,” the council stated in its most recent newsletter. “These rights are important during times of drought or water scarcity.”

It makes sense to take the licencing plunge while the fee is waived, considering one-time application fees can range anywhere from $250 to $10,000, depending on water use and volume. If you’re a heavy water user, that could mean big savings.

MARGARET LAND mland@annexweb.com

519-429-5190 • 888-599-2228 ext. 269

Advertising Manager SHARON KAUK skauk@annexweb.com 519-429-5189 • 888-599-2228 ext. 242

Account Coordinator MARY BURNIE mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext. 234

Media Designer CURTIS MARTIN Circulation Manager BARB ADELT badelt@annexbizmedia.com 416-442-5600 ext 3546 VP Production/Group

CIRCULATION email: blao@annexbizmedia.com Tel: 416-442-5600 ext 3552 Fax: 416-510-5170 Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9 Occasionally, Fruit & Vegetable Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. Annex Privacy Officer privacy@annexbizmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2017 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

At BASF, we’re proud of our long-term commitment to the apple industry. And we’re even prouder to be a part of our customers’ continued success. Visit agsolutions.ca/horticulture to learn more about our innovative solutions designed to help you overcome the pest challenges you face on your farm.

Always read and follow label directions.

Ontario’s Minister of Agriculture, Food and Rural Affairs, Jeff Leal, has appointed Elmer Buchanan, former provincial ag minister, trustee of the Ontario Processing Vegetable Growers’ (OPVG) board.

“I ... was recently informed by growers, processors and the Ontario Farm Products Marketing Commission (OFPMC) that negotiations have reached an impasse, jeopardizing this year’s crop season,” Leal stated. “Risking this year’s tomato crop, and the thousands of jobs that support it, is something I am not prepared to do.”

According to Minister Leal, Buchanan will

temporarily assume the powers of the OPVG board to negotiate 2017 contracts, until elections for a new OPVG board can be held.

In a letter to the OPVG board, OMAFRA Deputy Minister Greg Meredith explained that the Ontario government was forced to take action by making a regulation under the Farm Products Marketing Act.

“This regulation is now in force and has the effect of terminating the terms of office of the members of OPVG holding office ... and terminating the terms of office of the members of each district vegetable growers’ committee holding office.”

Brenda Lammens, former chair of the Ontario Fruit and Vegetable Growers Association (OFVGA) and the Ontario Asparagus Growers, passed away Saturday, Feb. 11, 2017. She was 61.

“Brenda was a strong, influential leader who contributed much to the edible horticulture sector and

Canadians surveyed are unsure whether the Canadian food system is heading in the right direction

believe it’s heading in the right direction believe it’s on the wrong track

the agricultural industry as a whole,” said Jan VanderHout, current OFVGA chair. “She was a positive voice for growers, and had a particular passion for mentoring women in agriculture. She will be fondly remembered.”

In January, Brenda was named the 2017 recipient of the OFVGA’s Industry Award of Merit – an award

given out annually to an individual who has made outstanding contributions to the fruit and vegetable industry. For more than 30 years, she and her husband, Raymond, operated their family farm, Spearit Farms located in Norfolk County. She served on the OFVGA board for seven years and became the second woman to

chair the OFVGA in 2007.

“We offer our deepest condolences to the Lammens family during this difficult time and hope they take some comfort knowing the legacy that she leaves behind as a champion for agriculture may serve as a powerful source of inspiration,” VanderHout said.

Source: 2016 Canadian Public Trust Research from the Canadian Centre for Food Integrity

of Canadians surveyed are concerned about eating food that comes from genetic engineered crops 50% 30% 21% 93% 69% 23% 13% 29% 46% 41%

of Canadians surveyed know a little, very little or nothing about farming practices of Canadians surveyed were concerned about the rising cost of food of Canadians surveyed trust the government food inspection system

of Canadians surveyed believe Canadian food is amongst the most affordable in the world today of Canadians surveyed believe Canadian farmers are good stewards of the environment of Canadians surveyed are concerned about the use of pesticides in crop production

65 years, our

B.C. winery one of Canada’s best-managed companies

Part of the Kelowna business community for more than 25 years, Quails’ Gate Winery was recently named one of Canada’s Best Managed Companies.

“We are absolutely thrilled to be recognized among such renowned businesses across the country,” said Tony Stewart, CEO of Quails’ Gate.

“From the beginning, our family has always strived not only to be good stewards of the land and our community, but also to create exceptional wine and culinary experiences for our guests. We are extremely proud to have such an incredible team that has been able to execute our family’s vision.”

As one of the original estate wineries in the Okanagan, Quails’ Gate and the Stewart family have helped shape the development of the wine industry in Canada by taking a collaborative approach to build and promote the wine industry both nationally and internationally. This approach positioned Quails’ Gate as a respected, knowledgeable and pioneering winery with strong support from the community, and was one of the defining principles that led to its recognition as one of Canada’s Best Managed Companies.

The 2017 Best Managed program recognizes the best-in-class of Canadian-owned and managed companies with revenues over $15 million demonstrating strategy, capability and commitment to achieving sustainable growth.

This year’s winners of the Canada’s Best Managed Companies award were honoured at a gala in Toronto on April 19, 2017.

The Ontario Pesticide Education Program has released a new manual for farm workers.

If you work on a farm where pesticides are used, you need to know how to work safely around pesticides. The information in this manual explains how farm workers can work safely on a farm that uses pesticides. It can be downloaded from their website (5 MB). For those without Internet access or with a need for a print version, you can request the manual from OPEP at 1-800-652-8573 (Ontario only) or 519674-2230.

A Spanish version will be released very soon. Please ensure that all your farm workers are familiar with the information in this manual.

Chateau herbicide, by Valent Canada, Inc. is now registered for use on broccoli and caneberry.

Broccoli and caneberry growers in Canada now have another tool to assist in the control of Group 2-acetolactate synthase (ALS) resistant weeds, such as red root pigweed, green pigweed, eastern black nightshade and common ragweed.

Chateau, containing flumioxazin (51.1 per cent), is a residual preemergent herbicide. A PPO inhibitor, Chateau’s mode of action is different than many other herbicides, so it helps fight resistance, while providing long-lasting control of tough weeds

including Group 2-resistant weeds.

“Chateau has proven to be an effective herbicide on a wide range of crops” says Maria Dombrowsky, horticulture specialist at Nufarm Agriculture Inc. “I am pleased that this tool is now available to broccoli and caneberry growers for incorporation into their IPM program.”

Chateau should be used in rotation with other herbicide modes of action. Chateau is also registered for use on other crops, including pome fruit, blueberries and strawberries. For more information, consult the complete product label at www.nufarm.ca/product/chateau/.

Total organic agricultural land is increasing in Canada.

The Canada Organic Trade Association (COTA)’s latest research has revealed 5,053 certified organic operations in Canada, accounting for 2.43 million acres of land.

“Canada’s organic sector continues to rely on the voluntary disclosure of data by certifiers and provincial organizations,” said Tia Loftsgard, COTA’s executive director. “In 2016 we finally have universal participation, resulting in the most rigorous production data yet. However, year-over-year change and inconsistencies remain a risk until a national mandatory data system has been implemented.”

Key findings:

Organic acreage in Canada increased by more than 70,000 acres to 2.43 million acres, or 1.5 per cent, between 2014 and 2015.

Organic areas now account for approximately 1.5 per cent of total agricultural land in Canada.

While pasture still occupies the largest share of all organic acreage, its proportion has decreased from 65 per cent to 63.8 per cent primarily due to significant increases in vegetable and root crop acreage, as well fruit and nut acreage.

In 2015, Canada imported at least $652 million worth of organic products, representing a 37 per cent increase from 2012.

There are 5,053 certified organic operations in Canada, over half of which are in Quebec, Saskatchewan and Ontario.

Of the certified operations, there are 4,045 primary producers, 618 livestock operations and 1,542 processors, manufacturers and retailers in Canada.

Despite the growth of Canadian organic acreage in recent years, demand for organic is significantly outpacing supply. Organic retail sales in Canada are now worth $4.7 billion annually, a 13.6 per cent growth per year since 2007, while organic production is experiencing much slower growth.

“Our organic agricultural production in Canada cannot keep up with the exponential growth of the demand, this is resulting in an increased reliance on import organics,” Loftsgard said. “Our government must introduce incentives to encourage farm operators to transition to certified organic agriculture.”

Our reputation for innovative solutions is no secret. That’s why growers have trusted BASF herbicides to get their crops off to a clean start for decades. Of course, our fungicides have also gained a reputation for managing the toughest diseases. Go to agsolutions.ca/horticulture to learn how BASF can help you maximize your operation.

Always read and follow label directions.

Galvanizing the food and farming sector in a quest to gain back the public’s trust

BY TREENA HEIN

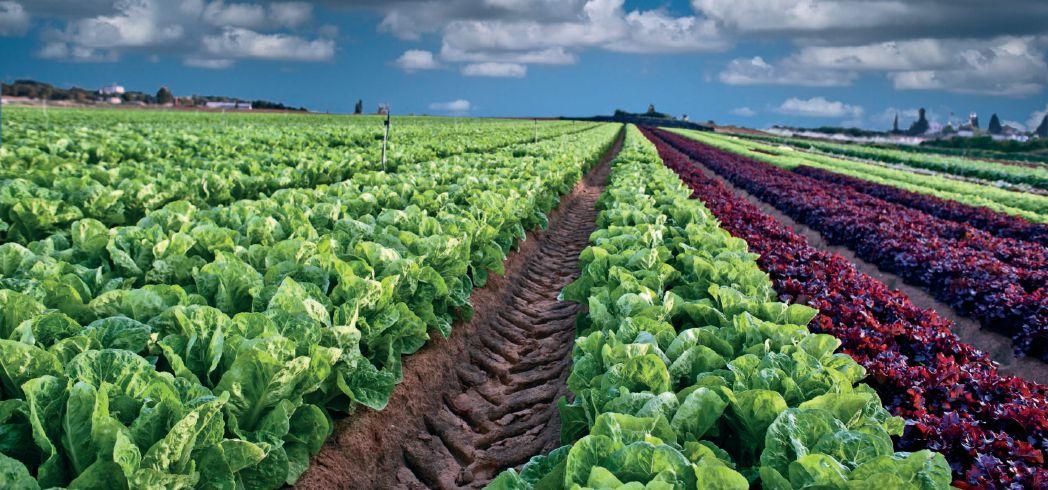

If you ask a group of random Canadians about whether they trust farmers and Canada’s food system on the whole, you’ll likely hear a variety of responses.

Putting livestock farming issues such as animal welfare, hormones and antibiotic-resistant bacteria aside, there’s a large number of thorny public trust issues that relate directly to fruit and vegetable production, from E. coli on lettuce and the use of pesticides, to the bee population drop, labelling issues and so-called Frankenfoods.

Keith Kuhl, president of the Canadian Horticultural Council, believes “farmers want to be transparent and are committed to continue to find ways to allow the public to influence how their food is produced. We need to better

ABOVE

understand what information consumers want.”

One of the big milestones in global public trust relating to fruit and vegetables was perhaps the commercialization of the geneticallymodified Flavr Savr tomato in 1994. It was the first genetically-engineered crop product to be marketed, designed with genes allowing it to stay firmer and fresher for longer. Because not enough consumers had faith in its safety, by 1997 it was no longer for sale. Many see the whole Flavr Savr story as one that illustrates the critical importance.

The Canadian Centre for Food Integrity was launched June 2016 at the first Public Trust in Agriculture Summit, held in Ottawa. Photo courtesy of Farm and Food Care Canada

INSET

Crystal Mackay, CEO of the Canadian Centre for Food Integrity. Photo courtesy of Farm and Food Care Canada

A panel discussion involving five typical urban Canadians illustrated how much mistrust is held towards the Canadian agri-food system and the low level of knowledge about farming within the population. Photo courtesy of Farm and Food Care Canada

of public trust in agricultural success. Only time will tell how differently things will be when later this year, Okanagan Specialty Fruits in Summerland, B.C., markets its GMO nonbrowning Arctic Apple.

Putting genetics and crop production issues aside, the trust of consumers in the food system is also tested on an ongoing basis through a literal onslaught of countless media stories and weighty books about food, which – sometimes published within the same year – contain conflicting claims about the health benefits, non-benefits and even detriments of food items like eggs, whole grains, fats and even certain vegetables and fruits. Google the phrase “vegetable health risks” and you’ll get 8,280,000 results. “Dr. Oz Explains How Some Fruit Could Be Bad for You” is the title of a Youtube video with more than 70 000 views.

To gauge the degree of public trust in the Canadian food system, the Canadian Centre for Food Integrity (CCFI) did a large survey in 2016. The CCFI is a division of Farm & Food Care Canada, a charity with a vision to earn public trust in food and farming, and an affiliate of the well-established U.S.-based Center for Food Integrity. Both organizations are made up of members representing the diversity of the entire food system. In Canada, that includes Dow AgroSciences, Monsanto and John Deere Canada (see full list of founding members in sidebar).

The survey results may shock you. The CCFI’s poll of over 2,500 Canadians found that a whopping 93 per cent says they know little or nothing about farming. Exactly 50 per cent are unsure about whether our food system is going in the right direction, and 21 per cent believe it’s on the wrong track. Yes, that’s less than a third of Canadians who believe our food system is going in the right direction.

The CCFI was launched in June 2016 at the first Public Trust in Agriculture Summit, held in Ottawa. Speakers and participants came from all aspects of food production, from

seed companies, chefs and farmers to academics, farming associations and large companies. The summit was intended to “encourage continuous collaborative discussions amongst farm and food system leaders, while developing concrete actions for earning public trust.”

A panel discussion involving five typical urban Canadians illustrated all too well how much mistrust is held towards the Canadian agri-food system, and the low level of knowledge about farming among the panelists was – for many of the audience members who live and breathe food production on a daily basis – shocking. But to be fair, many attendees also recognized how difficult it is for anyone outside of agriculture, the health care system, forestry or any other complex sector of our economy to make time to learn the basics, let along keep up with the many changes in practices and policy that are standard today.

But what’s more serious – and especially relevant to farmers – is that because trust in the food system has been lost, consumers (as well as retailers and restaurant chains) are now in a position where they are all but dictating what happens in barns and fields. The conversion to cage-free egg production is one example, and the final decision of McDonald’s restaurant chain in late 2014 not to serve GMO potatoes is another.

Once trust has been lost in any arena, it’s hard to build it back up again. But the summit highlighted the fact that for farmers, it’s no longer only a quest to regain public trust in agriculture, but to keep their social licence – their very ability to dictate their own farming practices and have the general public believe them competent to look after animals, crops, the land –a “freedom to operate” if you will. On that note, here is another CCFI survey result to ponder: only 29 per cent of Canadians believe Canadian farmers are good stewards of the environment.

“Control has already been lost,” noted summit presenter Charlie Arnot, CEO of the Center for Food Integrity in the U.S.

He and other presenters suggested that perhaps building public trust in the food system starts with accepting that the social licence of farmers may henceforth always be shared to some extent with the consumer. However, several speakers pointed out this fact is not yet accepted by many in agriculture. On the whole, the summit presented a new “normal” that farmers should strive to get used to as quickly as they can.

A CCFI statement published in a summit booklet summarizes the severity of the situation in business terms: “We see consumer alienation from agriculture and the food system expressed through concerns about nutrition, food safety, affordability, environmental sustainability, animal well-being and other issues. Some argue that maintaining public trust is a worthy goal, but not relevant to success in business.

Canadian Centre for Food Integrity founding members:

• A & W Food Services Canada Inc.

• Alberta Agriculture and Forestry

• Alberta Livestock and Meat Agency Ltd.

• Alberta Pork

• Association of Canadian Faculties of Agricultural and Veterinarian Medicine

• Beef Farmers of Ontario

• Burnbrae Farms

• Dow AgroSciences

• Egg Farmers of Alberta

• Egg Farmers of Ontario

• Farm Credit Canada

• Food and Beverage Ontario

• John Deere Canada

• L.H. Gray & Son Limited

• Maple Leaf Foods

• SeCan

• Shur-Gain, Landmark

• Tim Hortons

Research Partners included Alberta Agriculture and Forestry, Nova Scotia Ministry of Agriculture, Ontario Ministry of Agriculture Food and Rural Affairs

New members:

• Canadian Canola Growers Association

• Government of Saskatchewan

• Manitoba Egg Farmers

Don’t let fungus steal the fruits of your labour.

Strike botrytis and powdery mildew where it hurts with Fracture, the only biological that physically attacks fungal cells with multiple unique modes of action. With exceptional effectiveness and resistance management, and no re-entry interval, you can get back to your crop faster.

STRAWBERRIES | GRAPES | STONEFRUIT TOMATOES | ORNAMENTALS | FMCcrop.ca

Use DuPont™ Exirel™ insecticide, powered by Cyazypyr™, early in the season to give your pome fruit, stone fruit and blueberries the head-start they need during the most critical stages of development. Exirel™ has fast acting, translaminar and xylem systemic movement so you’ll be protecting new growth from di cult chewing and sucking pests, including aphids, plum curculio, apple maggots, codling moth, Oriental fruit moths, leafrollers, weevils and spotted wing drosophila.

Exirel™, powered by Cyazypyr™, an important part of an integrated pest management program.

Questions? Ask your retailer, call 1-800-667-3925 or visit exirel.dupont.ca

It’s time for producers to manage for average production above 40 bins to the acre of apples and grow fruit production potential in B.C., even if it means pulling out old varieties and replanting new

BY TOM WALKER

Planning not to replant is planning to get out of business, according to Hank Markgraf, grower services manager at the B.C. Tree Fruits Cooperative.

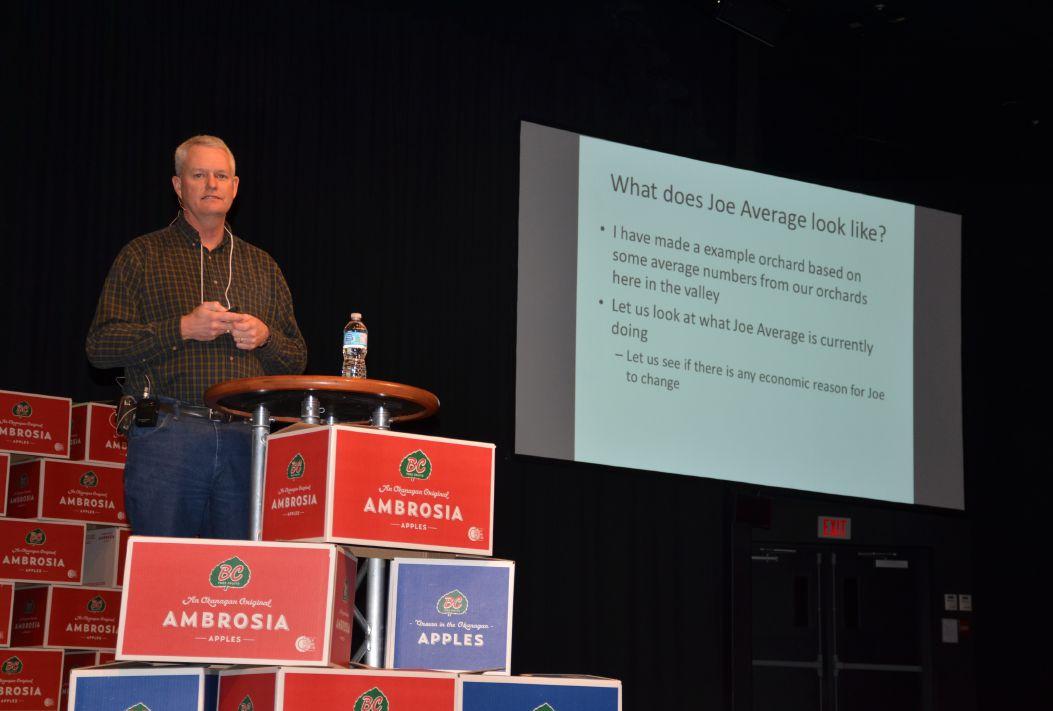

He spoke to producers at their annual horticulture symposium in February about increasing production potential in B.C. apple orchards. He described a hypothetical “Joe Average” grower and gave some strategies for improving grower returns.

“In my position, I have the opportunity to travel to other orchard regions in the world,” says Markgraf, who is also a second-generation Kelowna fruit grower. “They are starting to move their averages up, but we (in the Okanagan) are not doing that.

“This has become a bit of a pet project of mine. I’m going to talk about apples … but you could apply the same analysis to an orchard of pears or cherries.”

ABOVE

Back in the 1970s, the talk around the Markgraf family table was to get 40 bins of apples to the acre.

“That’s what Washington State was getting and we wanted to get that too,” he says. “My dad planted MacIntosh at 15 by 15 [foot] spacing. He worked hard, got 40 bins to the acre, and received the Golden Apple Award.”

The problem, Markgraf says, is that the average grower in the Okanagan has not moved much above that level.

“When I look at the B.C. Tree Fruits Cooperative data, which includes 85 per cent of the growers in the province, the average production today is 38 bins to the acre,” he says. “That’s not 1970, that’s today.

“When it comes to math, averages are just averages, but we do have the potential to increase. We need to be above 40, and a realistic target is 60 to 70 bins per acre. Despite

Planning not to replant is planning to get out of business, according to Hank Markgraf, grower services manager at the B.C. Tree Fruits Co-operative. Photo by

our northern climate, we have lots of examples of 80, 90, 100 bins to the acre that we can drive to right here in the Pacific Northwest. People are willing to share their expertise and there is lots of help available.”

“Joe Average” grower in the Okanagan valley has an 11.5-acre farm, says Markgraf. When you take out the footprint of his house, driveway and shed, he has 10 acres in production. Joe has done some replanting, but he is still working at converting over to highdensity plantings.

“Joe has five acres of Gala planted in the late 80s, early 90s, at 12 by 5 [foot] spacing,” Markgraf explains. “He also has 1.5 acres of Macs that are probably 45 or 50 years old, 1.5 acres of Spartans, and a half-acre of Reds [Red Delicious]. He’s been trying to get those Reds out but he isn’t there yet, and don’t lie cause I know you’ve all got them. And he has 1.5 acres of Ambrosia.”

This average orchard gets 45 bins to the acre for Galas and Ambrosia but the Spartans, that were likely planted in the 1950s, and the Macintosh only bring 25 bins to the acre with 30 bins for the Red Delicious.

According to Markgraf, if you look at the co-operative’s price averages for the last four years of 10 cents per pound for Red Delicious, 14 cents per pound for Spartans, 16 cents per pound for Macs, 21 cents per pound for Galas, and 41 cents per pound for Ambrosia, Joe Average is grossing $69,289.

“Almost $7,000 an acre is pretty good, at least we think it is,” he says. “A good industry target is a return of $10,000 per acre.”

But it’s not that simple, according to Markgraf, adding it’s important to look at Joe’s profit or loss per acre.

“Of course, Joe has costs,” he says. “He has to spray and prune and pick.”

Using a standard cost of $12 per hour for labour, those costs will range from $3,700 per acre for Macs and Spartans, $3,800 per acre for Red Delicious, and $4,100 per acre for Galas and Ambrosia.

“The numbers that are scary are the ones at the end,” Markgraf says. “He is losing almost $580 per acre on his Macs, $850 per acre on the Spartans, and nearly $1,290 an acre on the Reds.”

Given these costs, Joe’s net profit for the year would be $29,600.

“The last time I checked, the poverty line in Canada was around $24,000,” Markgraf quips.

The typical Okanagan grower is 52.5 years of age. He may have 12 years left to go before retirement but he’s probably more wary of going into more debt.

“I know replanting is expensive, but so is losing money every year,” Markgraf says. “And you don’t have to do it all at once.”

But Joe doesn’t have much extra to put into replant and that will also take five to 10 per cent of his orchard out of production for a good three years.

“Let’s increase production with the trees he has,” Markgraf suggests.

If Joe can just get more bins per acre – say 50 bins for the Macs, Spartans and Reds and 65 for the Galas and Ambrosia – with the same quality and the same price, his gross return can climb to $105,000. Considering input costs will go up – he will need

Markgraf has a strategy to help growers increase their production.

“You need to start with proper plantings,” he says. “If you muck up the first year, you are going to muck up the next 20. You need to start with good healthy trees, not 18-inches inches high, but four feet. You need to fill in the space quickly and you can’t crop for the first three years.”

Growers also need to prune and count buds.

“Loose the heavy wood,” he says. “We are not in the lumber business.

“If you are going to go from 40 to 60 bins and acre you need to look at your nutrient management program,” he adds. “More apples use up more energy and you need both ground and foliar management. You need to be replacing your calcium and your phosphorus.”

Bees are a grower’s friends, says Markgraf. At a minimum, at least one hive is needed per acre. The fruit should also be chemically and hand thinned and then counted on the trees.

“Why would you wear out your tractor and wear out yourself growing Red [Delicious]?” – Hank Markgraf

“If you have 2,178 trees per acre at 10 by two [foot] spacing and 50 apples per tree, you are getting 50 bins per acre.”

The grower also has to get them off the tree in a timely manner.

to prune and fertilize more – with this average of nearly 60 bins per acre, he’ll see a net profit of $59,750.

“But he still lost $50 on his crop of Reds,” Markgraf says. “Why would you wear out your tractor and wear out yourself growing Reds?”

Joe is now in a financial position to do things. He can buy a new tractor, he can buy new trees, he can buy an automated irrigation system or he can buy the more expensive fertilizer and save himself some time.

“You have a grant program to help with replant,” Markgraf points out. “If he did nothing else but pull out the Reds and an acre of Spartans and put in 1.5 acres of HoneyCrisp and manage 50 bins per acre at 41 cents a pound, in four years, Joe’s net return would be $76,460.”

“Joe and his wife used to be able to pick 12 bins a day over his 30 day harvest window. But now, with his 500 to 600 bins, he will need four pickers, he will need housing for four pickers, and he will need to be sure he can get four pickers. He will need someone to drive the truck. Joe is not the labourer in his business, he will become a manager.”

Growers need to learn drive their business, not let the business drive them, Markgraf says.

“This is not a one year fix for an orchard,” he concludes. “You need to plan for that five to 10 per cent renewal every year. That may go into Ambrosia, it may go into Cosmic Crisp, it may be variety XYZ but you are always looking to improve. You need to analyze the returns for each block or each variety every year. And you need to be honest with yourself when you see the true numbers.”

With demand for sweet potatoes on the rise in Canada, growers will be able to ramp up production with better varieties propagated here

BY TREENA HEIN

Sweet potato consumption is on the rise across the nation and Canadian horticultural growers will soon have the chance to get more of the action.

According to Statistics Canada, in 2015, more than 55 million kilograms of sweet potato were imported into Canada – in excess of 120 million pounds – valued at more than $59 million. And, although during the last 15 years the sweet potato crop in Ontario has grown from just over one million pounds to 30 million pounds, there are only an estimated 680 hectares of the crop currently being cultivated across Canada, mostly in southern Ontario and Nova Scotia.

To help grow the acreage, the Canadian sweet potato industry sorely needs locally adapted varieties (more on that later) and high quality, comparatively priced propagative material. Commercial growers in Canada currently source almost all of their slips [cuttings from the shoots of mature sweet potato roots that are planted directly into the field or simple hoop houses] from propagators in the southern United States, spending about $2 million on them

ABOVE

annually. According to the Vineland Research and Innovation Centre – based in southern Ontario – this is challenging for growers in terms of both the quality of the slips [with logistics and timing issues] and the fact that these varieties are not well suited to Canada’s shorter growing season.

That’s why Vineland’s Vegetable Production Research Scientist Dr. Viliam Zvalo is partnering with industry to make sure interested Canadian propagators have the research results they need to successfully grow locally adapted slips. Dr. Zvalo believes that by partnering with the industry to develop an effective propagation system, growers will be able to purchase superior slips at a reasonable price – and at the right time of year.

“Sweet potatoes are an easy plant to propagate,” he says. “The challenge is to ramp up slip production so that there are large numbers of slips available for a relatively narrow planting window in May or early June.”

With several industry co-operators, Dr. Zvalo is testing various methods of producing slips from

Dr. Zvalo, the vegetable production research scientist at the Vineland Research and Innovation Centre, is testing various methods of producing sweet potato slips in Canada. Contributed photo

the perspective of technical, hands-on practices as well as the economics. Dr. Zvalo is far from a novice with sweet potato production, having almost 14 years of experience developing the sweet potato industry in Nova Scotia from scratch in a position he held with Perennia, that province’s agriculture agency. In terms of the industry partners, Dr. Zvalo says he is working with grower-propagators in Nova Scotia and Manitoba who want to propagate sweet potatoes for their own uses, and with one commercial propagator in Ontario.

“We are examining two propagation methods, one of which is the standard U.S. method of getting slips from bedding the whole sweet potato root,” he explains. “The other, more novel method is to root vegetative cuttings over the winter in a high-density greenhouse. These cuttings are spaced to achieve desired plant density. Through intensive pruning, these plants will create a solid mat of plants from which slips will grow.”

Dr. Zvalo is also experimenting with LEDs to improve the slip production

process.

“We need to present the industry with a proven method to produce large numbers of slips of consistent quality, that in the end will still be price competitive,” he explains. “There is value in the short-season varieties themselves that we will have for Canadian growers starting in 2018, but the slips must be available at a reasonable price point and quantity for the growers.”

He will have a summary of the propagation feasibility study available to industry later this year.

Interested propagators, however, must have greenhouse space available.

“Greenhouse space is at a premium during the February-to-June timeframe with very high-value vegetable and flower crops, and these greenhouses are designed for these specific crops,” Dr. Zvalo notes. “There may be more opportunity for propagating sweet potatoes in greenhouses that are set up to grow shrubs and tree seedlings, and in their production cycles, they might have room to propagate sweet potato.”

“We need to present the industry with a proven method to produce large numbers of slips of consistent quality.” – Dr. Villiam Zvalo

Vineland has also been hard at work developing short-season cold-climate sweet potato varieties. In 2015, they conducted yield trials at multiple sites in P.E.I., Nova Scotia, Ontario, Manitoba, and B.C. One variety, likely to receive its name this spring, will be commercialized in 2018. This year, field tests will focus on how to boost yield through factors such as optimized spacing, irrigation after transplanting and optimized fertility management, said Dr. Zvalo.

He notes that most sweet potatoes are consumed in Canada at Thanksgiving and Christmas, making it hard for growers to supply the Thanksgiving market.

“That would require harvest in midSeptember, which is too early for the current U.S. varieties. Shorter-season varieties will enable growers to widen the planting window and plant first for early harvest, and then follow with later planting for winter storage.”

Uni-orange Design, a Chinese provider of integrated industrial design solutions, recently revealed its first orchard operation machine to the public – the Apfel AP150. The semi-automatic operation platform can handle most spherical fruit and accommodate eight people on the platform. It is equipped with a conveyor that leads to the bucket. Once the picker drops the apples on the conveyor, no apple will touch another all the way to the bucket, helping to reduce bruising. The machine can walk on a variety of landscapes, including hill areas, with controllable walking speed. The AP150 is also modular, which allows for more customized requests including spraying and pruning. uni-orange.com/en

Errors occurred in the New Varieties section on pages 27 & 28 of the January/February 2017 issue of Fruit & Vegetable Magazine. AgroHaitai is the proper source for the CC1460/CR Happy Spring Chinese cabbage variety while Norseco is the proper source for Prospector onions. We apologize for the errors and any confusion they might have caused.

Chinese Cabbage

CC1460/CR HAPPY SPRING

CATHY BARTOLIC | cathy@ontariofarmfresh.com

Incredible. Unbelievable. Disneyland.

These were the words that came out of all our mouths as the Ontario Farm Fresh Marketing Association tour group visited Le Vignoble du Ruisseau last November. It is a vineyard and winery near Sutton in the Eastern Townships of Quebec. The area is known as a pastoral playground for the wealthy from Montreal. It is incredibly picturesque and many towns and businesses have decided to focus their marketing dollars on attracting Montrealers to their establishments.

Le Vignoble du Ruisseau is no exception. The property was purchased in 2007 by a magnate in the Quebec road construction industry. His goal was to grow grapes so he could make his favourite French wines in Quebec. In order to do that, he needed to grow grape varieties not acclimatized to Quebec winters. So he went about developing a patent pending process that has kept the vineyard alive and grapes growing since before the first harvest in 2013.

Geothermal pipes were laid deep below the ground on the 15-acre property. Corresponding pipes were laid beside the actual grape vines above ground, the idea being that with the heat coming out of the ground during the winter, the vines will never experience temperatures

actual winery and parking lot are separated by a ravine. To overcome this, the owners built a quaint covered bridge to connect the two entities. The winery’s boutique has soaring 12foot ceilings and offers several local artisanal products in addition to the farm’s wines and maple sap and syrups. The cellars harken back to days of yore and the lunch we had was exquisite. Every part of the property has been created to reflect elegance and taste.

I also appreciate that the winery is willing to open their gates to everyone. The cost of the activities offered range from nothing to over $100 per person for a planned “countryside excursion,” knowing that some of their customers would think nothing of paying top rate for a personal tour. The winery is also available for weddings and special events.

Our visit included a wine tasting in the cellars. The chardonnays we tried were lovely but I don’t trust my taste buds to be discerning enough, so I did a quick search online. Interestingly enough, the reviews are all over the map with no clear consensus one way or another.

“A mini greenhouse is erected over each row in the fall.”

less than -10 Celsius. In order to keep the geothermal heat somewhat contained, a mini greenhouse is erected over each row annually in the fall. Red grape varieties are grown in more permanent greenhouse structures year round to increase the amount of heat they receive. There are other vineyards that go to great lengths to make certain their vines survive our increasingly unpredictable winters, but this seemed outlandish in comparison. Upon further consideration, maybe it is just the upfront costs that seemed outlandish and the annual efforts of other vineyards may eventually actually cost more in the long run. (This could be a PhD project that someone might want to explore.)

The vineyards were not the only incredible part of the Le Vignoble du Ruisseau. The

We were told the owner had already invested $15 million in developing this, his semi-retirement project. Having been given that tidbit, my mind automatically tried to guess what the price of one of their bottles of wine would be. How would they ever get that investment back? How could they make money when the upfront costs were so high? Why would we even visit an operation of this nature?

On-farm marketers don’t generally have easy access to $15 million but my hope is that every stop on the bus tour offers a nugget that can be implemented in order to make an operation more efficient, tweak a marketing plan to gain a greater audience or perhaps offer a display alternative that can be adapted by the participants of the tour. It is not to suggest that this type of operation be replicated exactly as offered.

A bottle of chardonnay, by the way, was $24.95. We agreed, as a group, that making money was not a high priority for this vineyard.

DuPont™ Altacor® insecticide delivers long-lasting insect control for cranberries, blueberries and raspberries in addition to other fruit crops. Say goodbye to oblique-banded leafroller, raspberry cane borer, raspberry crown borer, cranberry fruitworm and many other pests. Powered by Rynaxypyr®, Altacor® gets rid of damaging pests while having minimal impact on beneficial insects and pollinators when applied at label rates.1

Experience the Altacor® advantage.

Questions? Please contact your retailer, call your local DuPont rep or the DuPont™ FarmCare® Support Centre at 1-800-667-3925, or visit altacor.dupont.ca