Massive brand relaunch ticks off every box with package design masterclass Story on page 14

At Paxiom ® , we deliver automated packaging solutions for the demands of today and tomorrow while never losing focus that our customers come first. We are driven by solving problems, providing exceptional value and taking turnkey responsibility.

Move away from conventional pre-made pouches and produce stunning packaging at a lower cost per unit, less storage space and with lower transport costs.

new Videojet 1860 Continuous Inkjet Printer

True predictability

Industry-first ink build-up sensor provides true predictability and warnings of possibly degrading print quality, even before a fault occurs.

True remote services*

Multiple access options (Ethernet™, WiFi) and secure VPN communication meet highest standards in the industry as part of VideojetConnect™ Remote Service, and help to improve machine uptime and customer experience.

* Subject to availability in your country

True IP rating

Optional IP66 rating for entire cabinet and hygienic design following industry guidelines; easier integration with slanted printhead design.

True scalability

Workflow modules help to customize the printer to perform the exact need required. It is easy to adapt the printer with new capabilities and functionalities, and to meet growing demands.

APRIL 2019

VOLUME 72, NO. 4

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

ASSISTANT EDITOR

Alanna Fairey • (416) 510-5228 afairey@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

CIRCULATION MANAGER

Anita Madden • (416) 442-5600 x3596 AMadden@annexbusinessmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbusinessmedia.com

PRESIDENT & CEO

Mike Fredericks

ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

e-mail: rthava@annexbusinessmedia.com

Tel: 416-442-5600 ext. 3555

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year, USA $138.00 US per year, Outside Canada $156.50 US per year, Single Copy Canada $10.00, Outside Canada $27.10. From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2019 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional

editor, press releases, promotional items and images) from time to time. Canadian Packaging, its af liates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any

On its own, a thin strip of aluminum is just a thin strip of aluminum. But as an extra layer of product protection— as with aluminum cans of the popular Steam Whistle brand or premium pilsner lovingly crafted in Toronto by Steam Whistle Brewing—it is the latest in a long series of thoughtful packaging innovations that have helped Steam Whistle to evolve into Canada’s largest and possibly best-known craft brewer.

tional packaging real estate to get its brand logo into the consumers’ eyes all within the same package, which Steam Whistle accomplishes with its usual graceful elegance and subtlety. (See Picture) As for any sustainability concerns over introduction of yet another packaging feature that will need to be disposed of, McLaughlin rightfully points out the foil liner’s 100-percent recyclability.

In fact, innovation may arguably be too strong a praise for the liner, as the San Pelegrino brand of sparkling fruit beverages has actually employed the same technique for its canned products in Canada for several years now.

But to the best of our knowledge, Steam Whistle is the first major Canadian beer brand to adapt this “purity seal” for its product, and hence deserves whatever consumer acclaim and brand loyalty it erans from it.

“When you take a case of Steam Whistle home, we want you to enjoy it as fresh and pure as it was when it left our brewery,” says Steam Whistle’s vicepresident of marketing Tim McLaughlin.

“Our purity seal ensures that your can remains free of potential contaminants it may pick up during shipping and storage before you buy it,” McLaughlin explains.

“When you open that can, we want your Steam Whistle to be as pure as it was when it was filled.”

As a side marketing bonus, the extra packaging component also provides Steam Whistle with addi-

“With a recyclable can, recyclable packaging and recyclable foil top, you can enjoy your Steam Whistle without putting added stress on landfills or the environment,” he notes.

“It’s vitally important to us that we protect and preserve our beer without generating extra waste.”

With a benefit of hindsight, some packaging ideas often prompt the natural urge to inquire: “Why has this not been done before?”

The truth is that it is often the simple and straightforward things that tend to hide in plain sight in the larger endless quest for profound and dramatic solutions to problems that may not need excessive elaborateness just for its own sake.

And while the odds of anyone ever getting seriously ill from a contaminated can end not covered with a foil seal are astronomically remote, it’s hard to make a case against enjoying the total peace-of-mind that such a little thing can provide.

At the end of the day, that’s really what consumer safety is all about in its purest form. Cheers!

Innovative

Family-owned producer of upscale European-style deli meats and sausage upgrades its food safety credentials with advanced X-Ray inspection technology.

How

Adapting product labeling to achieve maximum payback in e -commerce retail channels. 37

orrugated industry event offers an insight into the industry’s future.

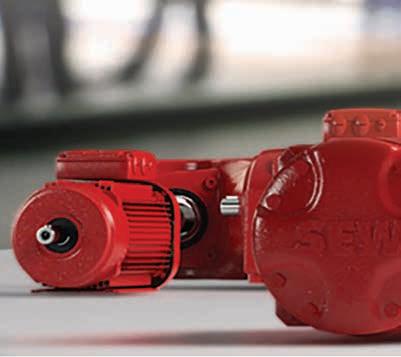

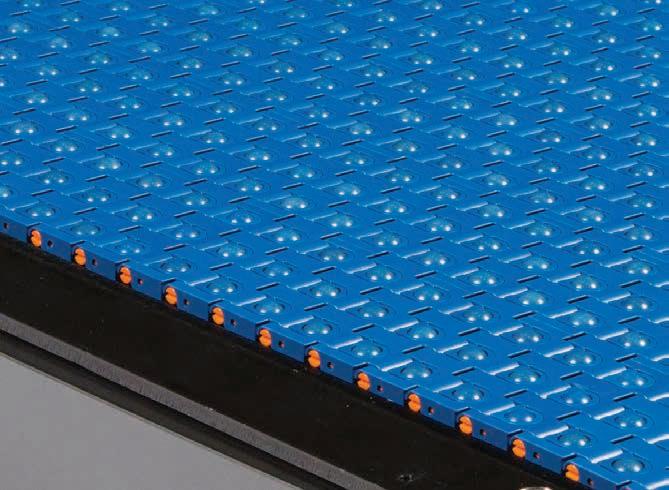

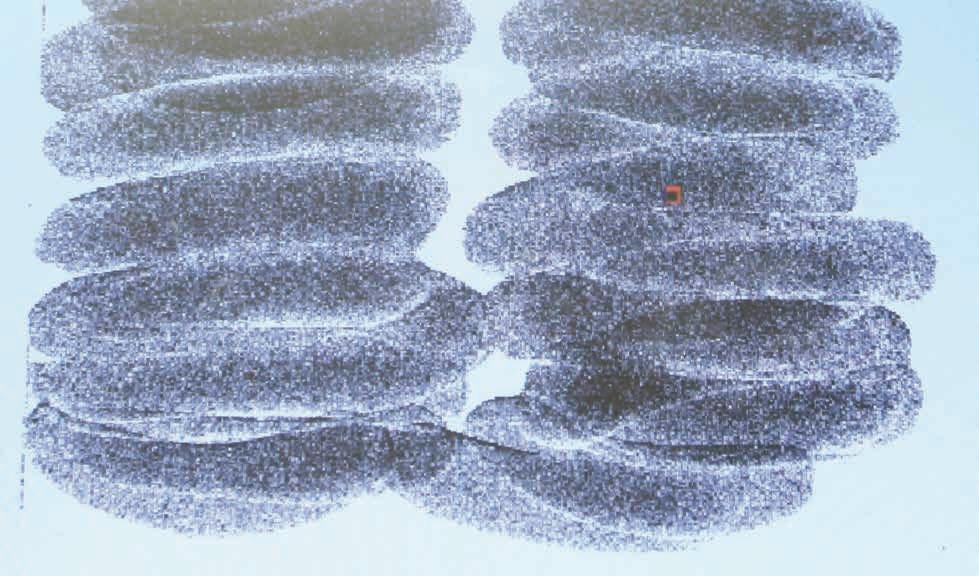

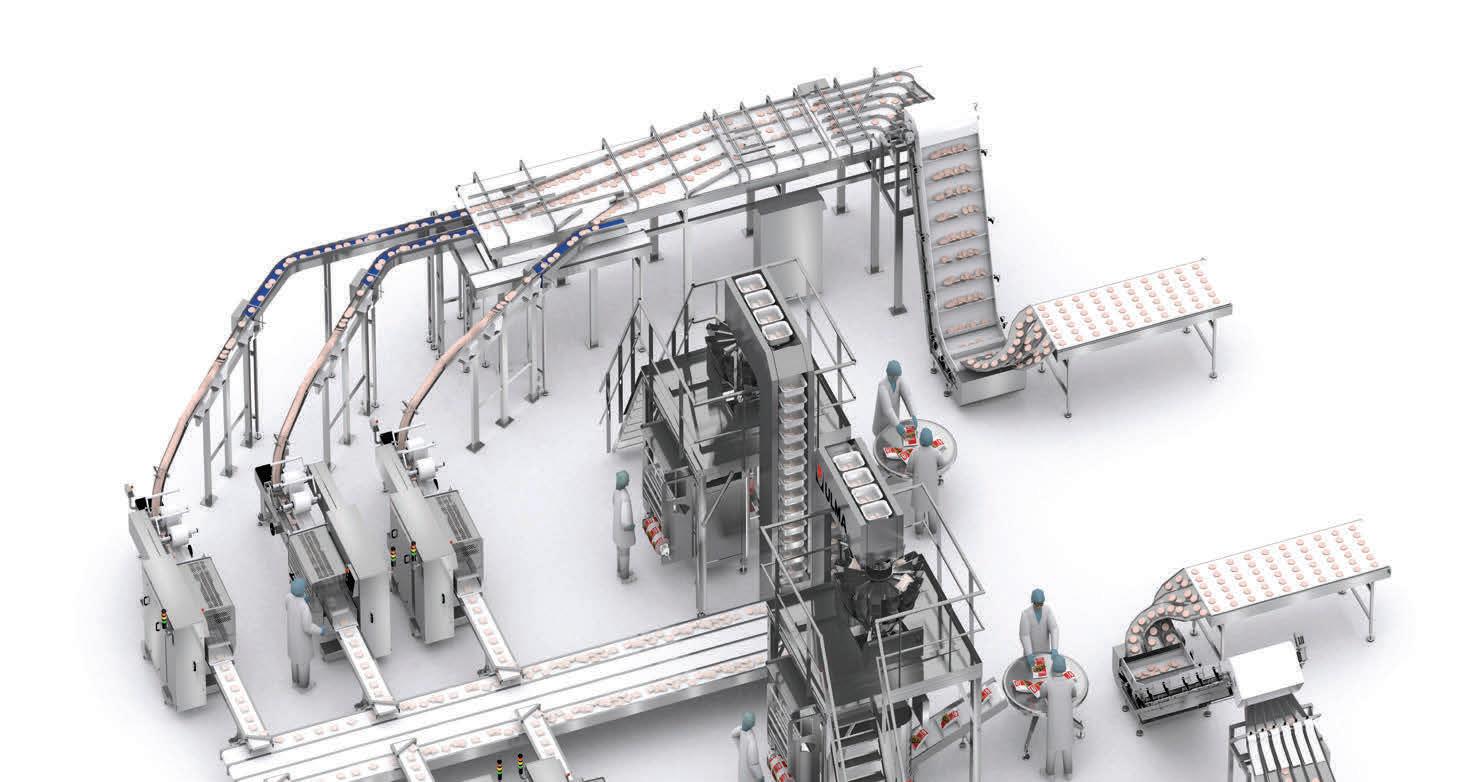

Industrial conveyor systems manufacturer and integrator Storcan International of Châteauguay, Que., has been awarded nearly $810,000 in loans and grants from the provincial and federal governments to help keep the company’s $4.3-million investment initiative on the right track.

Announced last month, the additional funding will enable Storcan to proceed with the purchase of various digital equipment and corporate management systems to support its ongoing efforts to improve productivity and optimize customer relations, as the company works to build up its export markets across North America.

According to local officials, Storcan’s expansion projects are expected to result in the creation of 10 new full-time jobs in the Montérégie region in the southwest part of Quebec.

in Montérégie and elsewhere in Quebec,” Chassé adds.

More than half of the financial assistance for Storcan will be provided by a $500,000 loan from the provincial Investissement Québec agency mandated to promote investment in Quebec-based businesses, with an additional $200,000 loan provided by federal government via Ottawa’s REGI (Regional Economic Growth through Innovation) program.

“I am thrilled with the support provided to Storcan, a well-established Montérégie company that carries out projects requiring expertise, precision and efficiency, and that comes up with innovative solutions,” says Brenda Shanahan, member of parliament for the Châteauguay–Lacolle riding.

“Our government’s priority is to make Quebec companies aware of the growth potential generated through investments, especially those aimed at integrating new technologies and developing exports,” says Marie-Chantal Chassé, member of the National Assembly of Quebec for Châteauguay.

“In fact, it is through projects like the one by Storcan that we can help build a strong economy that is open to the world, while also creating more wealth and more jobs locally

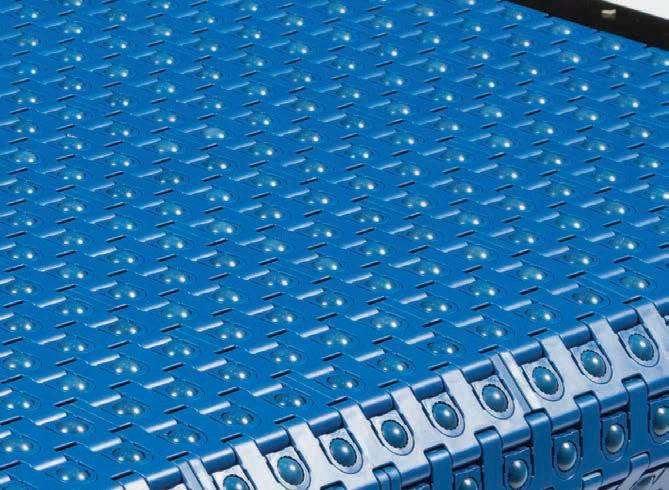

A close-up of a Storcan conveyor system in operation at a Quebecbased dairy products plant.

“In keeping with our commitment, the government of Canada is helping local businesses by making investments that enhance their productivity and strengthen their competitiveness in export markets.”

Founded in 1976, Storcan manufactures a broad range of conveyor systems used in the food-and-beverage industries—including roller, belt, inverted, air, spiral and other conveyor types—while also offering expert integration services to provide end-use customers with turnkey automated solutions.

According to the company, a portion of the additional investment funding announced last month will be used to will support the installation of enterprise-wide digital CRM (customer relationship management) and ERP (enterprise resource planning) systems, as well as for strengthening the company’s marketing efforts in the U.S. and Ontario.

the harshest conditions

speed

eed coding

–take it to the limit

IP65 rating – ready for the humid, sugar-laden beverage environment

◆ Non-stop production at temperatures up to 45° C

ation

medium

◆ Make the can your marketing m

Unique power concentr short, intense pulses increase

◆ marking speeds and quality

100,000 cans/hour – each coded with over 20 characters

Get creative with content to engage with customers

Exceptional productivity on concave surfaces

◆

Code over 60 high-resolution characters in a variety of formats

Class-leading

Code quality eliminates waste

◆ Sustainable production without consumables

◆ Reduced energy consumption with innovative cooling system

Permanent readability and traceability

With big soda brands continuing to cede market share to the fast-growing array of trendier beverage alternatives, CocaCola Canada Bottling Ltd. is pulling all stops to stem the tide through far-reaching packaging innovation.

Having recently competed a $20-million investment at its sprawling bottling facility In Brampton, Ont., to upgrade a production line with breakthrough shelf-life extension technology, the venerable soft-drink giant is

launching a new range of smaller, resealable PET (polyethylene terephthalate) plastic bottles for its bestselling brand across Canada.

Decorated with eye-catching product labels designed by Perennial Inc., the new Mini bottle containers is the latest addition to Coca-Cola’s growing roster of smaller package sizes in Canada,

Retiling in single 250-ml bottles or in eight-packs of 300-ml containers, the Mini-bottle range includes the company’s flagship Coca-Cola, Diet Coke, Coca-Cola Zero Sugar and Sprite soft-drink brands—now available across Canada grocery and convenience stores, as well as some foodservice outlets.

Make your machines even more flexible. Easily.

Achieve business excellence with future-ready machine solutions

“Mini bottle is one of the most exciting innovations we’ve seen in packaging in a long time,” says Darlene Nicosia, president of Coca-Cola Ltd. in Toronto. “Mini bottle is an example of how Coca-Cola is focused on accelerating momentum as one of the fastest-growing consumer goods companies in North America.

“We know that people want more drink options,” Nicosia states, “and Mini bottle is just one way that we’re meeting that desire.

”And it’s not just smaller package sizes, we’re also working to bring more lowand no-calorie drinks to the market to help Canadians choose the package size and sugar content that makes sense for them.”

Said to be the first of its kind in North America, the, the Mini bottle uses an innovative coating called FreshSafe to increase shelf-life by up to four months, compared to conventional PET packaging.

According to Coca-Cola, the FreshSafe PET technology effectively addresses all the technical carbonation issues related to the bottle’s smaller size dimensions, with all the packaging still remaining 100-percent recyclable.

The installation of FreshSafe technology at the Brampton plant is credited for creation of three new fulltime jobs at the state-of-the-art facility.

As a pioneer in smart automation technologies, Schneider Electric makes it easier for you to offer your customers more flexible machines. Our future-ready machine solutions help quickly and easily adapt machines to changing production and operator needs. So you and your customers can meet continuously evolving market expectations. Both today and tomorrow.

How can you improve machine flexibility? Find out, today!

“We are so proud that one of our first announcements as an independent bottling company is that we have invested back in our Brampton facility,” says Coca-Cola Canada Bottling president Todd Parsons.

“Having a local spirit and supporting our communities is very important to us,” Parsons states, “and our aim is to grow our capabilities in Canada that will, in turn, grow jobs.”

n Montrealheadquartered flexible packaging producer TC Transcontinental Packaging has won the Gold award in the Sustainability category of this year’s Flexible Packaging Achievement Awards competition of the Flexible Packaging Association for the Harney & Sons Master Tea Blenders pouch. Said to be the first 100-percent recyclable multilayer barrier stand-up pouch in the market, the pouch also picked the competition’s Gold award in the Packaging Excellence category and a Silver award in the Technical Innovation category. Developed in collaboration with partners Dow and Charter NEX Films, the pouch was designed to meet Harney & Sons’ commitment to sustainability while still protecting the flavor and the freshness of the product. “It is a great honor to be recognized by our industry colleagues for, once again, setting the bar high in packaging innovation and sustainability,” says TC Transcontinental Packaging’s vice-president of business development Todd Addison, noting this is the second year in a row that the company has won FPA’s top prize for sustainability. “These awards celebrate our commitment to sustainability as we strive to design products that take into consideration the environmental impacts of the product during its entire life-cycle.”

n Edmonton-based label application systems distributor Jet Marking Systems (JMS) has been appointed as a Certified Partner for the product identification and traceability solutions manufactured by Markem-Imaje following an extensive vetting process under Markem-Imaje’s Partner Program. According to JMS, the new partner status will significantly increase parts, servicing and machinery availability for MI customers in Jet Marking Systems’ main territory of western Canada, while providing JMS with access to nearly 200 new customers. “We are honored that Markem-Imaje chose to leverage

our strong presence throughout western Canada for a partnership that will benefit not only both companies, but also our customers,” says JMS general manager Dan Stickney. “With the overarching goal of enhanced service and increased availability, the collaboration is a smart combining of resources that improves both companies’ market positions.”

n Baltimore, Md.-headquartered Barcoding, Inc. has announced its expansion into the Canadian market with formation of the company’s Barcoding-Canada subsidiary, which will operate three regional offices in Montreal, Toronto and Vancouver to offer Canadian-based clients a broad range of technologies and services for various data

capture, labeling, printing, and mobile computing technologies supporting supply chain automation. “Canada is a fast-growing market with high demand for our industry services [and] we’re excited by the opportunity to grow our business and improve our services to existing clients in the country,” says Barcoding, Inc. president Shane Snyder. “With a Canadian team that understands the local market and culture, Barcoding’s expansion will further the company’s mission to deliver efficiency, accuracy and connectivity to all clients.” The Barcoding-Canada offices may be reached at (604) 260-1446 (Vancouver); (438) 800-8009 (Montreal); and (437) 538-3185 (Toronto).

n Leading Canadian paper products manufacturer Cascades Inc. has announced the launch of the company’s IMGN brand of retail solutions comprising a broad portfolio of POS (point-of-sale) displays, consumer and shelf-ready product packaging designed

to improve in-store brand impact. According to the Kingsey Falls, Que.-headquartered Cascades, the IMGN brand of products offers superior color intensity and printing precision ensured by the use of most advanced flexographic, lithographic and digital printing technologies to help brands make the products stand apart at the store and shelf level. “Our packages don’t just protect the products they contain; they’re also a source of infinite creative possibilities for capturing the consumer’s attention,” says said Charles Malo, president and chief operating officer of Cascades Containerboard

Packaging. “They’re custom-designed and manufactured using the highest industry standards in order to attract interest and create the desired impact by sending consumers a powerful message through innovative, environmentally-friendly solutions.”

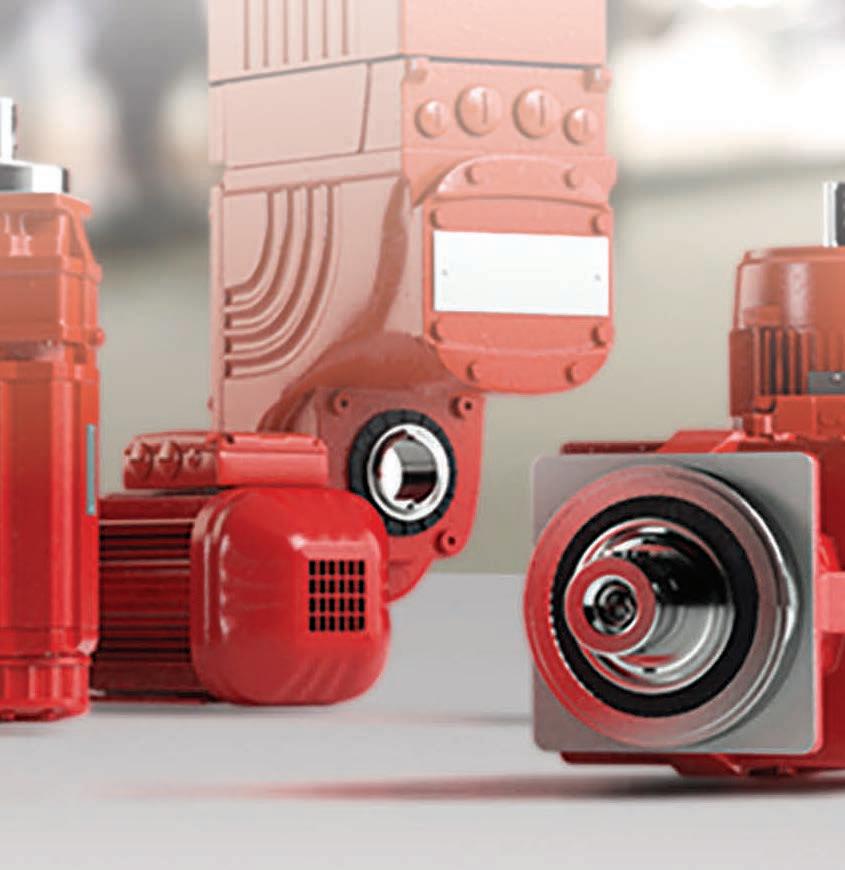

n Lenze SE , leading German manufacturer of electrical and mechanical drives, motion control and automation technologies, has commenced construction of its new state-of-the-art Mechatronic Competence Campus (MCC) in Extertal, Germany, to consolidate the company’s three different operations at one centralized production and product development facility. The estimated US$57-million investment, the largest in the company’s history, involves construction of an ultra-modern 81,000-squre-foot factory on a 323,00-square-foot campus that will also house the company’s service and storage operations—ultimately employing a total of about 800 people. “With the MCC, we are not only creating one of the most groundbreaking mechatronics production facilities in Germany, but above all an important reference project for the future of collaboration,” says Lenze’s chief executive officer Christian Wendler. “In years to come, our employees in Extertal will come together in open-plan spaces to collaborate in agile, interdisciplinary teams, developing the best mechatronic solutions and services for our customers around the world.” Founded 70 years ago, Lenze services the North American market via its Lenze Americas subsidiary headquartered in Uxbridge, Ma., along with an assembly and logistics center in Glendale Heights, Ill.

n Milliken & Company, Spartanburg, S.C.based manufacturer of specialty chemical for a broad range of industrial application, has announced plans to build its largest clarifier plant in Blacksburg, S.C., to keep up with growing market demand for the company’s Millad NX 8000 brand clarifier. Scheduled for startup in 2020, the new plant will boost Milliken’s production capacity for Millad NX 8000 —a polypropylene additive widely used in food packaging applications—by at least 50 per cent, according to the company.

The new semi-manual Cumulus SLPP-15 case-packer from NJM Packaging is high-performance integrated system—combining innovative technologies from fellow ProMach brands Wexxar Bel and OPTEL —featuring a twoaxis pick-and-place robot to pack up to 10 cases per minute, and it comes ready to comply with serialization requirements, if needed for pharmaceutical traceability applications. Well-suited for a broad range of OTC pharmaceuticals, nutraceuticals, cosmetics, foods, beverages and other product packaging applications, the versatile Cumulus system can case-pack up to 180 bottles per minute, depending on the number of layers and bottles in the case. As the bottles enter the SLPP-15 on a conveyor, a pneumatic pusher moves one row onto a stainless-steel tray—repeating this movement until the desired array/pattern is formed. Meanwhile, the operator inserts a case into Wexxar Bel’s BEL 5252u semi-automatic case former, which forms the bottom of the case and holds it in place. The operator then slides the case over to activate the servo-driven, Y-Z vacuum pick-and-place system from NJM, which inserts the layers into the case. Once the case is lled, the operator then slides it through the sealing section of the BEL 5252u to seal the top and bottom of the case. Designed to facilitate very quick

changeovers for new bottle and case sizes without any tools, the Cumulus SLPP-15 system is equipped with a high-performance B&R control system and HMI (human-machine interface) terminal.

NJM Packaging (Div. of ProMach, Inc.)

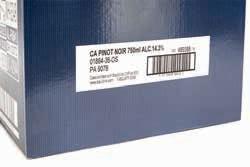

The new solvent-based CoPilot 500 inkjet printing system from Squid Ink Manufacturing, Inc. is designed to print superior quality high-resolution characters on non-porous surfaces such as coated corrugate, polystyrene and more. With up to 2.8-inch print height per printhead and the ability to run up to two printheads from one controller, the CoPilot 500 o ers a versatile, yet cost-e ective solution for coding, marking and product identi cation, according to the company. Equally adept at running either oilbased or solvent-based inks to print up to 5.6 inches (2.8-inch from a single head) of high-resolution characters, razor-sharp text, scannable barcodes, and great looking logos at 205-dpi, the versatile printer allows users to con gure it in multiple positions—including horizontal, down-shooting and side-shooting—with the system’s 4.3-inch full-color touchscreen providing easy access to the system’s internal messages and

print functions. The messages are created and edited on Squid Ink’s easy-to-use Orion PC software and transferred via Ethernet or USB device. For larger applications, a virtually unlimited number of CoPilot 500 printing systems can be connected wirelessly or via Ethernet and controlled through one central Orion print station, while users on-the-go can utilize an optional 10-inch full-color Windows tablet with Orion software for mobile programming within the facility. Squid Ink Manufacturing, Inc.

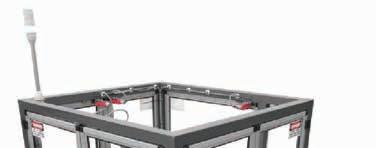

The new 2200 Precision Move Pallet System conveyor from Dorner Mfg. Corp. is designed to provide accurate positioning and routing of parts for a broad range of inspection, assembly and robotic and applications across a diverse range of manufacturing environments. Now available with several new features such as heavy-load corners, tight-turn corners, low-prole lift-and-locate modules, elevators, etc., 2200 Precision Move Pallet System operates while integrated with a Universal Robot (UR) robot to move and orient products using an elevator, while also passing over a lift-and-locate station and navigating through a 180-degree heavy-load corner.

Dorner Mfg. Corp.

Inductive Sensors with IO-Link

Rugged Ø4, M5, M8, M12, M18 and M30 housings, offering extended ranges up to 22 mm. Easily configured, providing advanced functionalities such as the detection counter (RPM) and the speed controller. Each sensor is fully programmable, providing the means for hundreds of configurations in a single device.

IO-Link Smart Configurator

Configure any IO-Link sensor or actuator via a wireless device that replaces the need to program via a USB IOLink Master connected to a PC or via a network connected master device. The portable Smart Configurator can be used anywhere, as it’s battery powered and equipped with WiFi for IODD files, sync and cloud storage.

Capacitive Sensors with IO-Link

Popular M18 and M30 diameter sensors provide the ideal solution for applications where flexibility or sensing performance needs to be constantly and accurately monitored and logged. IO-Link mode provides added functions such as: QoR (Quality of Run), QoT (Quality of Teach) and Diagnostic Parameters.

Matthews Marking Systems has launched a new product line geared towards OEMs (original equipment manufacturers) who want to integrate marking and coding equipment into their machines—comprising an automation software controller; an enclosed drop on demand (DOD) valve jet technology driver; and an enclosed thermal inkjet (TIJ) technology driver. According to Matthews, the company’s MPERIA controller is the only universal controller designed to work with virtually any print technology, thereby enabling OEMs to easily change the printers on the line as per their

customers’ needs. Available in Lite, Standard, and Advanced con gurations, the MPERIA OEM controller can be manages remotely via VNC and and integrated by the end user with either XML or Command Line Protocol. For its part, the enclosed V-Link OEM drop-on-demand (DOD) valve jet technology driver controls Matthews’ 8000+ series valve jet printheads, designed to deliver high print quality with exceptionally low ink consumption. Finally, the enclosed L-Link thermal inkjet (TIJ) technology can simultaneously operate up to four of Matthews’ high-speed L-Series L1 printheads that are capable of printing up to half-inch marks and codes at up to 1,600 feet per minute to match the demands of fast, high-volume serialization applications. Matthews Marking Systems

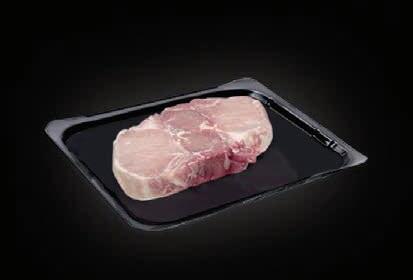

The new Evolve S and Elite brand trays and lm from the kp Food & Consumer Products division of Klöckner Pentaplast Group were developed to provide more sustainable and recyclable packaging solutions for protein packaging applications, according to the company. Speci cally, the new Evolve S tray and lm is said to deliver signi cant improvement in vacuum skinning cycle times over standard VSP (vacuum skin packaging) trays while also increasing shelf life. Moreover, the trays are made from 95-percent recycled post-consumer rPET (recycled polyethylene terephthalate) plastic, o ering signi cant sustainability advantages in applications requiring the use of peelable lms. For its part, the Elite series protein trays and lms are designed as a recyclable MAP (modi ed-atmosphere packaging) solution engineered for superior sealing performance to prevent product contamination or leaking.

“I’m Mike McCann and I’m part of the Reiser team of Packaging Specialists who work with customers to improve the packaging of their products. I can help you every step of the way –from evaluating your product, your customer, and your goals to assessing your various packaging machine options. With decades of experience, I can help you select the very best packaging solution for your specific application. Are you ready to produce a better package? Let me show you how.”

Watch Mike’s video

Klöckner Pentaplast Group

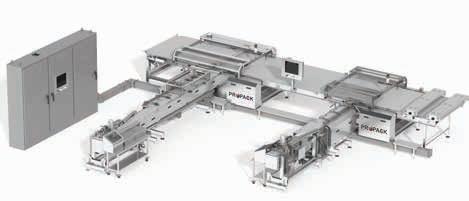

The new Propack Row Distribution System (RDS) is designed as an an economical, safe product delivery system that empowers the use of AC motors and servo technology to receive rows of products from upstream processing equipment and synchronizes product delivery on-time, on-demand to low-, medium- or highspeed wrapping machines. According to Propack Processing & Packaging Systems, Inc., the system accomplishes high-accuracy row distribution by intelligently monitoring product row position (bars, cookies, snacks, etc.) on a number of motion-controlled delivery sections feeding anywhere from a single or up to six wrapping machines. Moreover, the Propack RDS can be con gured to user-de ned requirements accommodating either direct delivery, accumulation, or automated refeed back into the system without operator intervention by using integrated communication throughout the line. Featuring sanitary stainlesssteel frame standard construction and equipped with high-performance Rockwell Automation AC motors and servo technology, the exible RDS has the capability of handling product ranges from two to eight inches in length, for products as thin quarter-inch, at rates of up 750 pieces per minute per single outfeed leg. Propack Processing & Packaging Systems, Inc.

When it comes to shaving, the Gillette brand razors and accessories have long set the standard for product and packaging excellence, but not so much when it came to sustainability and waste diversion.

However, that shortcoming appears to be finally addressed in a big way by its progressive brand-owner Procter & Gamble Inc., which is hooking up with leading product upcycling services provider TerraCycle, Inc. to collect and recycle all of its disposable razors, replaceable-blade cartridge units, and razor plastic packaging right across the U.S.

like park benches, bike racks, petfood bowls, recycling bins, etc.

Under the program, businesses, gyms, colleges, cities and community organizations will be actively encouraged to become designated drop-off points for the returned waste, whereby they will by supplied with special razor recycling bins that they can simply seal and return via UPS to TerraCycle, which will promptly send a new bin back to them.

“We are proud to partner with this forward-thinking company to offer consumers a way to divert razor waste from landfills,” Szaky states.

Under the recently-launched Gillette Razor Recycling Program , individual participants and organizations can sign up on the program page (www.terracycle.com/en-US/brigades/ gillette) to download pre-paid TerraCycle tracking labels for shipping their used razors and packaging directly to the recycler—ultimately to be made into broad range of useful new products

For every shipment weighing at least 15 pounds, collectors will earn points that can be used for charity gifts or converted to cash and donated to charities of their choice.

“Through this innovative, first-of-its kind program, disposable razors, replaceable-blade cartridge units and their associated packaging are now nationally recyclable through the Gillette Recycling Program,” says TerraCycle founder and chief executive officer Tom Szaky.

“We are very excited about our partnership with TerraCycle to offer recycling for Gillette, Venus or any razor brand across the U.S,” adds Gillette’s chief executive officer Gary Coombe.

“This is an important first step towards sustainable solutions for shaving products and the start of an exciting journey with Gillette and TerraCycle,” Coombe states.

“We are thrilled to bring this option to our consumers in the U.S.,” Coombe proclaims, “and we are already working on plans to roll out this importnt initiative to more countries very soon.”

Montreal-headquartered flexible packaging producer TC Transcontinental has become the first Canadian-based to formally join the Ellen MacArthur Foundation’s New Plastics Economy Global Commitment by pledging to make 100-percent of its packaging reusable, recyclable or compostable by 2025.

“We want to leave behind the legacy of a responsible corporate citizen, mindful of how today’s decisions will impact our collective tomorrow,” says TC Transcontinental’s president and chief executive officer François Olivier.

“We look forward to inspire change by pioneering the development of sustainable products and driving innovation to support our customers in their own sustainability journey,” says Olivier, adding the company has also committed to achieving at least 10-percent use of post-consumer content on average by weight across all plastics in its product portfolio.

“By joining the Ellen MacArthur Foundation’s commitment, we are furthering our corporate social responsibility leadership to ensure that plastic is effectively managed from sourcing to end-of-life,” Olivier states.

Adds TC Transcontinental’s chief strategy officer Magali Depras: “Integrated into the mandate of our Corporate Governance Committee, TC Transcontinental’s social responsibility priorities will continue to align with our

business strategy.

“With our three-year Corporate Social Responsibility plans presenting quantifiable targets, coupled with our 2025 pledge to the New Plastics Economy Global Commitment, we are poised and determined to make strides towards a Circular Economy—benefiting not only our industry as a whole, but also the communities in which we operate.”

Emerson is a global technology and engineering company, providing innovative solutions for customers in packaging markets. Emerson's expertise and technologies enable manufacturers in the food and beverage industries to gain flexibility, reduce losses, and improve safety.

Emerson offers key products for the packaging industry that were developed for use in extreme temperatures, as low as -40°C. Whether it's preparing the air for your other instruments, the need for reliable safety dump valves, or the ability to actuate various applications – Emerson has the solutions.

Visit us at PackExpo in Toronto to learn more about our solutions!

The PAC Packaging Certificate is the most flexible and comprehensive program in North America, offering maximum value in it’s Canadian pricing. It has been specifically designed to meet the needs of all professionals with an interest in the packaging industry and value change.

Course 1:

Packaging Essentials

• Package Brand Design & Innovation Winners

• Introduction to Packaging

• Perspectives of Packaging

• Packaging Development

• Brand/Graphic Design

• Prepress/Print Processes

• Digital Printing

• Design for eCommerce

• Smart Packaging

May 7-9, 2019

Toronto Airport

Includes a tour of

Course 2:

Complete Plastics

Packaging

• Package Brand Design & Innovation Winners

• Introduction to Polymers

• Design Basics for Plastics

• Rigid/Semi-Rigid Plastics

• Flexible Packaging

• Biopolymers

• Plastics and the Environment

June 18-20, 2019

Toronto Airport

Includes a tour of

Course 3:

Paper Packaging Plus

• Package Brand Design & Innovation Winners

• Paperboard/Folding Cartons

• Corrugated Fibreboard

• Micro-flute Alternatives

• Distribution Packaging

• Glass/Aerosols/Metal

• Packaging Machinery

September 24-26, 2019

Toronto Airport

Includes a tour of

Course 4:

Packaging Circularity

• Package Brand Design & Innovation Winners

• Sustainability/Optimization

• Life Cycle Approach

• Material Recovery Facility

• Circular Economy

• Consumer Trends

• Packaging for Food Waste Reduction

• Managing Trade Offs/ Setting Up For Success

October 22, 2019

Toronto Airport

Courses have been designed to offer maximum flexibility. Our professional students are encouraged to take all four courses or individual ones that suit their interests and career goals. For

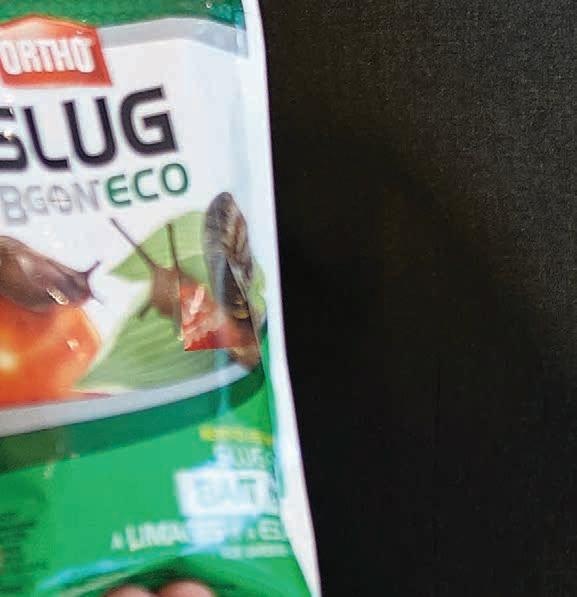

Comprehensive brand relaunch ticks all the right boxes with a compelling package design helping consumers navigate through a complex and chaotic product category

BY GEORGE GUIDONI, EDITOR

PHOTOS BT MARIE-EVE GREGOIRE

Humans and insects don’t make for good housemates. Never have, never will.

In fact, keeping nasty bugs at bay may well be one of humankind’s most ancient painstaking chores that, for many reasons, amounts to an endless war of attrition.

And while it’s true that only a mere fraction of all living insects gives the entire species a bad name and reputation, that’s little consolation to millions of Canadians overwhelmed by the seasonal arrival of ants, earwigs, spiders, beetles, wasps, mosquitoes and other unwanted creepy-crawly houseguests at the rst signs of spring.

Happily for them, there is no shortage of commercially available insecticides and other bug repellents widely sold across Canada to help them deal with the seasonal onslaught, thanks to companies like Scotts and other producers of pest control products formulated to help keep the nuisance insects at arm’s length, at least.

However, this ready availability and multitude of choices can often translate into consumer rage at the shelf level because shoppers often have a hard time selecting the most e ective remedy for their speci c insect issues on their own, in a reasonable amount of time.

“Historically, this is the one product category that has caused the most confusion among consumers, resulting in one of the biggest walkaway rates for any product category,” says Glenn Martin, director of marketing at Scotts Canada Ltd., Canadian subsidiary of multinational manufacturer of lawn, garden and home protection products Scotts Miracle-Gro Company.

“The insect control category has a plethora of both large and small competitors, and that’s part of the problem,” Martin told Canadian Packaging during a recent visit to the company’s head o ces in Mississauga, Ont.

“Unlike lawn and garden products, where you see big bags of similar products from two or three companies to choose from, you may be looking at seven or eight

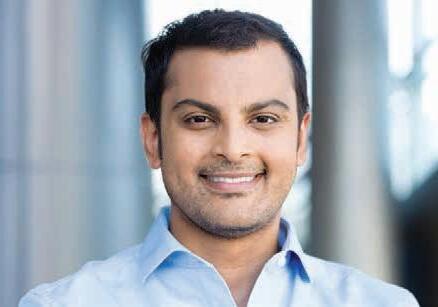

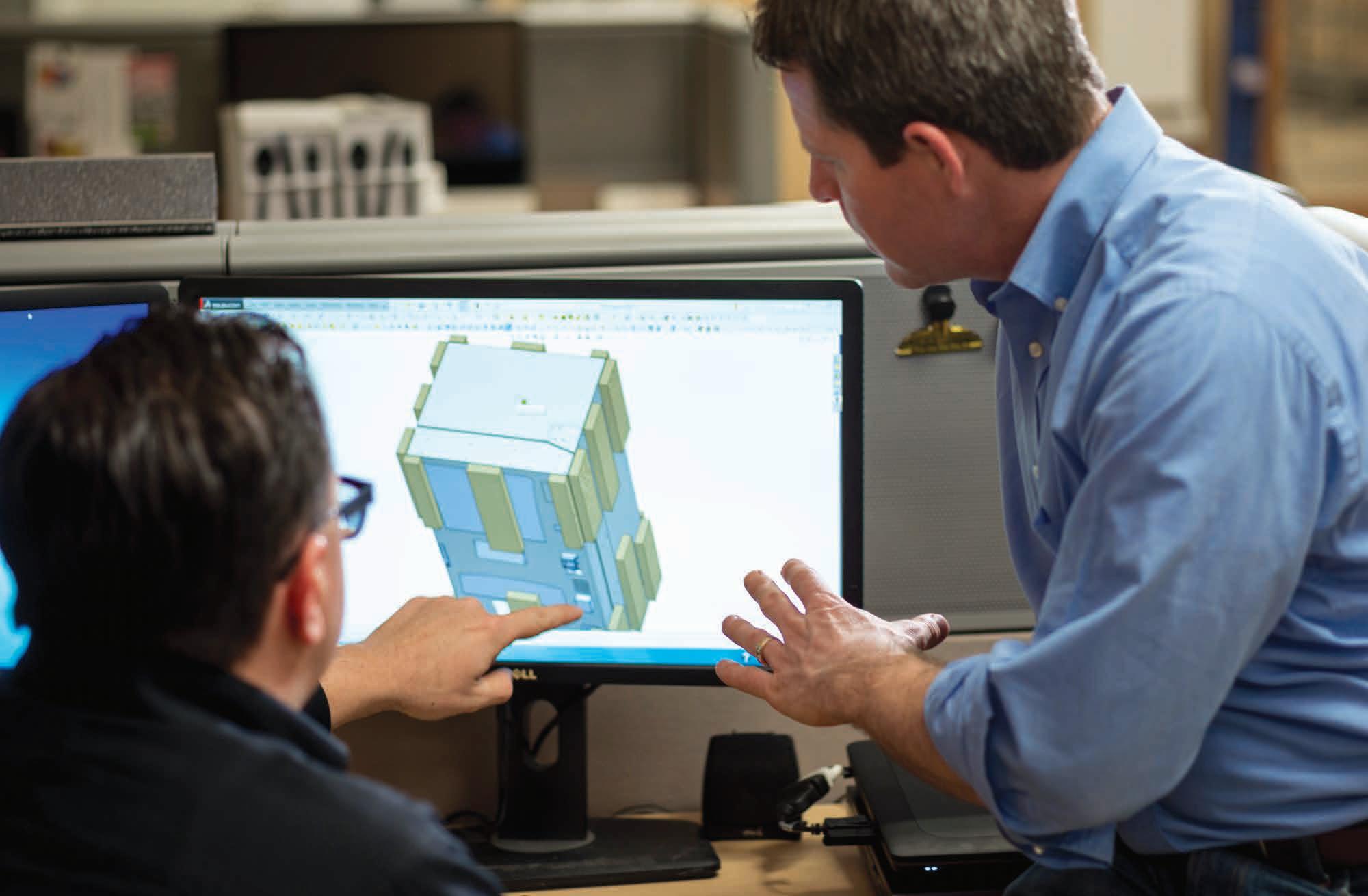

Pigeon Brands founder and president Thomas Pigeon (left) and Scotts Canada’s director of marketing Glenn Martin share a light moment while discussing the many nuances and intricacies of the new high-impact packaging design used to drive the highly successful relaunch of Scotts Canada’s B Gon brand of insect control products across Canada.

di erent insecticide product brands on a single shelf, o ering three or four di erent ways to kill wasps, for example.

“So it can get very frustrating to nd a solution that you need to remedy your speci c problems,” Martin explains. “When you nd yourself looking at the sea of colors and images, and there’s no knowledgeable store sta nearby to help you out, it’s very easy to get lost and exasperated.”

Whereas in the past insecticide producers skimped around the issue by o ering more general-purpose formulations to repel a broader variety of bugs, “This one-

size- ts-all approach was actually part of what caused all the confusion at the shelf level from a consumer standpoint,” Martin asserts.

“There is a strong emotional connection between consumers and these types of products because they are trying to resolve a problem that can potentially cause harm to themselves, their family or their home,” Martin explains.

“So they don’t want to buy a product that ‘might’ work,” he states. “They want to buy a product that will work the rst time and every time thereafter.”

A couple of years ago, Scotts Canada resolved to turn

this marketing shortcoming into an opportunity to establish a stronger and more uni ed shelf presence for its products through a comprehensive relaunch of its oncepopular Bug B Gon brand of insect control solutions.

“We were struggling to have a real impact on the shelves and grow our business, so we decided to do a brand relaunch project,” Martin recalls.

“And rather than start from scratch, we decided that we already had an asset with brand equity with the B Gon brand, so we decided to bring it back in a much more powerful, modern and aggressive way.”

As part of the extensive e ort to return Bug B Gon back to Canadian retail channels—where the brand once enjoyed notable success in the mid-2000s—Scotts commenced rapid development of several new e ective formulation targeted at speci c bug species, as well as more innovative and user-friendly ways of applying them.

“We have done a lot of product innovation in the last couple of years, which notably includes nding a way to package diatomaceous earth inside aerosol cans, as well as developing animal repellents to ward o problem raccoons, deer and other nuisance animals through learned behavior,” says Martin, citing new types of spray, gel, liquid, foam, powder and other product varieties, along with novel dispensing mechanisms such as prelled syringes and handheld wand applicators.

“The main idea was to provide more e cacious products and more innovative application technologies to make those products easier to use and apply to the problem areas.”

Martin relates that Scotts released the rst wave of reformulated B Gon brand products into the market last year, with many more others being launched into the market this spring to maximize the initial stellar success that, according to Martin, is a direct result of the superior package design work for the brand expertly executed by leading Canadian branding consultants Pigeon Brands Inc.

Having had considerable prior professional experience working with Pigeon Brands for over 20 years, Martin says he knew his marketing team would greatly bene t from working with a renowned design agency that has worked on thousands of brand launches and relaunches over the last 42 years—creating a vast track record of outstanding packaging designs for a multitude of SKUs (stock-keeping units) for well-known consumer brands every year.

And with the relaunched B Gon brand being ultimately expanded to comprise 26 di erent SKUs—

packaged in a diverse range of formats, substrates and sizes—Pigeon Brands founder and president Thomas Pigeon also knew that his company had a fairly unique and intense creative challenge on its hands.

“Working in a multi-SKU environment in a complex product category, subject to many regulatory requirements, was a di erent proposition from a lot of our other work we have done for food and beverage brands,” says Pigeon.

“It’s a lot di erent from other CPG categories where you want to take it slow and nurture the product experience that consumer has with the packaging.

“This is a real ‘get-in, get-out’ kind of category, where you have products intended to make a signi cant problem go away as quickly as possible,” Pigeon explains, “so your packaging has to be able to let consumers to locate the solution to their problems as fast as possible.”

As Martin reiterates, “This being a real problem-solution category—be it problem ants, wasps, mosquitoes

or whatever else—you want to nd a quick solution that’s going to work immediately after the problem has been identi ed.

“The impetus for us was to take a very intuitive brand that still had tremendous consumer awareness and acceptance, and bring it back in a way that really made sense to the consumers by helping them to navigate the shelves, whereby package design would do all the heavy lifting,” Martin explains.

“So if you have a wasp problem, let’s say, you can immediately locate the solution you’re looking for at the store by looking at the hero bug (wasp) image on the package for easy navigation.”

Says Martin: “ “We needed to create a common family look across a number of di erent product iterations within the category, but with enough product di erentiation, through distinct colors and graphics, that would also make the subbrands stand out on their own onshelf and, eventually, online as well.”

Adds Pigeon: “All new projects at Pigeon begin with a full discovery phase, with context being such an important part of a strategic design.

“And because we haven’t worked in this space before, this phase was even more important this time around, as we had to immerse ourselves in the market dynamics to make sure we would create a compelling idea and design to drive sales.”

After that market familiarity was established, the Pigeon design team and Martin’s marketing sta began evaluating all the di erent design strategies to achieve the intended result, ultimately settling on the “Be big, be bold” approach proposed by Pigeon Branding.

“The Bug B Gon portfolio is a brilliant brand with a brilliant trademark,” Pigeon explains,“but it needed navigational simplicity that would allow consumers to nd the product they need through quick understanding of the product via the packaging,” Pigeon explains.

“Hence the use of big bold images of the hero bugs; contrasting colors for strong product di erentiation for each of the speci c bugs targeted by the product; bold and simple typography to make it easier to read; and unique visuals that would be able to talk to all the demographics.”

As Pigeon points out, “In a multicultural environment like Canada, many consumers may be new Canadians with a di erent cultural set, speaking di erent languages.

“Hence the big graphic images of the mosquitoes, wasps, ants and earwigs become the icons that facilitate virtually global understanding and navigation of the brand message being communicated.

“One of the biggest driving principles at Pigeon Branding is creating ideas that travel,” Pigeon states, “and that’s where the big bold insect graphics play a key role.

“Naturally, you have to consider color, typography, iconography and photography as parts of a larger toolkit to use when building any brand,” Pigeon acknowledges.

“But at the end of the day you want to project a core idea with a core set of symbols and values that can travel through the brand’s entire eco-system with a harmonized, systemized and disciplined brand identity,” he states.

“In this instance, where you’re dealing with a lot of visual chaos and clutter on the retail shelf to cut through, iconography trumps photography any day of the week.”

Martin concurs, pointing out that the hero bug graphics developed by Pigeon to decorate the di erent products are now widely used as key consumer touchpoints for all the promotional e orts used to market the B Gon brand, including television, social media and other communication platforms.

“As the product line-up kept expanding throughout the whole design process, we were able to adapt those graphics to carry a consistent brand message on just about every packaging material out there,” says Martin, pointing out the expansive range of

packaging materials and components incorporated into the B Gon masterbrand.

“Pigeon enabled us to take those graphics and apply them to folding cartons, blister-packs, exible pouches, aerosol cans, polybags, pressure-sensitive labels and so on, while arranging them so that they look consistently strong and powerful on metal, plastic, paperboard or just about any other packaging substrate out there,” he says.

“That was probably the biggest design challenge—having a powerful master design and making it work across all the di erent permutations and color combinations, while also accounting for all the di erent sizes, shapes and structures.”

Naturally, none of this happened overnight.

“This project unfolded over many months,” Pigeon recalls,“involving tremendous amount of creative talent at Pigeon, a lot of walking through many di erent store environments, and constantly dialoguing with Glenn and his marketing team—often pushing back and challenging each other on some of the ideas put forth.

“But the net result,” Pigeon proclaims,“is an e ective design system that will survive for this brand anywhere on the planet, and win against any competitor on the shelf.”

Says Pigeon: “Great brand design only happens if you have a fearless client who allows you to do great things.

“It takes a great strategy, great thinking, and great insights to create a great collaboration,” he concludes, “and Glenn and his team have been exemplary in facilitating the successful outcome of this project.”

For his part, Martin is full of praise for the high level of creative talent and tireless dedication to the cause demonstrated by Pigeon Brands throughout the entire endeavor right from the outset.

“In all the years I’ve been in marketing and out of all the di erent businesses I have worked for, this is probably the strongest and most impressive brand relaunch I have ever been involved in,” Martin extols.

“We are thrilled to be able to stand back and look at this whole broad range of products that works so well as a family, but still maintaining a unique identity for individual packs so that they do not get lost on the shelf amongst each other or competitors,” he states. “We saw our POS (point-of-sale) numbers surge by 50 per cent as a result of the Bug B Gon relaunch,which is pretty hard to do for any product in this day and age.

“Moreover, the new design has also had a huge impact in terms of product listings, with most retailers now listing our products across Canada,” Martin points out.

“For all that, package design that can’t close the deal at the shelf level is not worth its salt,” Martin concludes, “and we have seen huge gains in the last year since this new package design was introduced into the market—enabling us to close the deal better than we ever had before.”

PHOTOS BY NAOMI HILTZ

Halal meat manufacturer changing frozen meal industry thanks to innovative thermoformer

BY ALANNA FAIREY, ASSISTANT EDITOR

rowing up as a child, Kebab Factory founder and owner Adnan Khan spent his summers working in his father’s butcher shop, and continued to do so throughout his university career.

A born entrepreneur, Khan saw an opportunity that went beyond the back room of his father’s butcher shop, where they were making kebabs by hand.

“I saw a lot of potential in this business, especially with all of the halal aspects and the ethnic growth in Canada,” Khan says.

“People liked it, they wanted it, they wanted more and now we’re here.”

Founded in 2012 as a subsidiary of NMK Foods , Kebab Factory is a readyto-cook, frozen foods brand that manufactures the titular kebabs, tandoori chicken, meatballs and, more recently, burgers.

Most of their products are stocked in independent markets, as well as in stores in the likes of Oceans , Sunny Supermarket , in addition to ve Walmart locations.

As a Halal-certi ed brand, Kebab Factory is in a market that has plenty of room to grow, but as a smaller sh in a big pond, a vital component of their business is making sure that they deviate from the status quo.

“The halal market is de nitely growing, but we need to stand out,” Khan told Canadian Packaging during a recent visit to the Mississauga, Ont.-based

7,000-square-foot facility.

“We are a halal brand and we are also an ethnic brand, but we are trying to market our products to the wider population.

“We’re not just trying to market towards the Halal or ethnic demographics. Palates are changing—we want to get our products out there more.”

Packaging has played a signi cant role in how Kebab Factory separates itself from other brands.

While most conventional frozen food products are enclosed in paperboard packaging, the chicken and beef kebabs are in clear, recyclable vacuumsealed bags with a pre-printed lm.

Khan had noticed that such boxed products would have attractive packaging and the food displayed on the box would look enticing, but the contents in the box would not have the same quality as the packaging conveyed once it was cooked.

“That’s why I wanted people to see the actual product before they bought it,” Khan explains.

“You can see it, there’s no freezer burn, it looks like it’s fresh and you take it straight out of the package and put it on the barbeque or in the oven, cook it from frozen and you won’t notice a difference.”

To improve how they operate, Khan began to search for a machine that would not only guarantee product freshness, but also be able to package the kebabs in a timely manner.

When he coincidently stumbled upon the Multivac R 085 thermoforming packaging machine at an OIMP trade show and talked with a sales representative from Multivac Canada , it was a moment that Khan describes as “love at rst sight”.

Coming primarily from a nancial and marketing background, learning about food processing and acquiring the proper machines had been a learning curve for Khan.

“Once I saw that machine, I knew that purchasing and installing it was the next step for Kebab Factory,” Khan recounts.

Even though it is an entry-level machine, the Multivac R 085 still has the ability to o er an extended con guration level for standard applications.

A compact machine that demands little space, The Multivac R 085 runs both rigid and exible lms up to 350 μm, with maximum forming depths of 88-mm and maximum cut-o lengths without preheating up to 300-mm.

As the R 085 e-concept model, the thermoforming machine operates exclusively with electricity and does not require a compressed air or cooling water connection.

This means that it can be used very accommodatingly in a plethora of di erent areas within the production process, a major sell for Khan and his team.

Before purchasing, Khan and his team had been using premade pouches from Duropac and had a friend who owned the print shop New Era Print Solutions supply the labels , including nutritional information as well as the UPC code. In some instances, Khan’s mother would help to place the labels on the bags at home during her free time.

Since installing the machine back in August of 2018, the Multivac R 085 has sped up production at almost a three-fold, since it is able to package in pre-printed lm and applying labels after vacuum sealing the kebabs was no longer feasible.

“We had at peak times we would have about ve people in the production room working about

days,” Khan explains. “This year, it was two people working two days.”

master cases.

Before the kebabs are packaged on the Multivac R 085 , they are put on the Handtmann VF 608 Plus , a state-of-the-art vacuum ller from Handtmann Canada Ltd. Khan had it retro tted and added a conveyor belt to pump out the kebabs to ensure that they are well proportioned.

The kebabs are taken from the Handtmann VF 608 Plus and are then frozen before being taken to the Multivac R 085

Workers then put the frozen kebabs into lm purchased from Packall , where it goes through the Multivac R 085, where it forms the pouch around the kebabs, and vacuum seals the product.

The machine can also add the compulsory information such as the date, a best before date stamp as well as production stamps.

Once packaged, workers then take the nished product and put them in

Having been praised for its pro ciency and easy-to-use interfaces, the Multivac R 085 produces about 80 boxes of product a day, an upgrade from the approximate 50 boxes Kebab Factory was producing when they were manually packaging the kebabs.

Khan estimates a possibility of producing upwards of 150 boxes of product a day with the addition of two more employees.

Adds Khan: “We’re very happy with the Multivac, and we hope to grow with it.”

Khan is especially happy with the experience that Kebab Factory has had working with Multivac.

Going against big name competitors in the likes of Maple Lodge Farms and Maple Leaf Foods , Khan appreciates the fact that Multivac sales repre -

sentatives prioritize their needs and concerns in a timely, professional, and friendly manner.

Prior to installation, Khan and his team faced a hiccup when the Multivac R 085 was not optimized. After letting a Multivac sales representative know about the situation, someone was at the facility to repair the machine within a day.

“Since then, we have been running great,” Khan extols.

“A very small percent of packages get returned or are broken, and there have not been any reject packages.”

Khan adds that the sales representative that he has worked throughout the buying and installation process makes frequent calls to see not only check in on the machine, but to also see how Khan and his business are doing. Khan describes him as acting like a second dad in a way.

“The team at Multivac are very diligent and they want to see us happy,” Khan says.

“They want to see us be successful with our product launches and they have worked tirelessly to make that happen.”

With Multivac Canada located in Brampton, Khan appreciates that they are close enough to get to the facility should anything happen with

Technical Support Before and after sales support includes same-day

Demonstration +

www.heatandcontrol.com

Heat and Control® offers a complete line of metal detectors, checkweighers, and X-ray inspection systems for pharmaceutical and food products from the leading manufacturers: Ishida and CEIA®

CEIA Metal Detection

The world’s largest manufacturer of metal detectors, with more than 90,000 units installed. Systems include THS/MS21 for food products, with optional USDA-certi ed construction (e.g., dairy, meats, poultry) and PH21-Series for pharmaceutical products (e.g., pills, tablets, capsules); both deliver unparalleled accuracy and sensitivity to all metals and provide high throughput rate.

Ishida X-ray Inspection

Find foreign objects, including metal, glass, bone, plastic, hard rubber, shell, and stones. Or detect product defects, like cracks, voids, missing items, and improper weights.

Ishida Checkweighers

Verify product weight, count, or missing items with DACS checkweighers. User-friendly controls include advanced data collection and management features.

the machine.

In fact, Khan is so impressed with how well the Multivac R 085 has performed at the facility that he would consider buying machines from Multivac again.

“We are always looking for new machines that we then utilize in an innovative unique way to create a new innovative unique product,” Khan explains.

“We’re looking at getting a label applicator and a banding solution, which applies a polymer band around a nished product so it adds a little level of packaging but people can still see the goods.

“We’re likely to buy sometime next year.”

Machinery aside, the next big focus for Kebab Factory is to work towards attaining their SQF (Safe Quality Food) certi cation and a federal license designation, which would assist Kebab Factory in getting stocked into bigger retail stores.

With the increase in demand for halal and ethnic foods, the future is looking promising for Khan.

“It’s about getting out there, getting more shelf space in stores, differentiating your product in whatever way we can, which we hope that we’re doing with the Multivac and with our packaging,” Khan extols.

“I think Canadian meat and ingredients are de nitely superior and people around the world will appreciate it for their families.

“Now since buying power is gearing up around the world, shoppers are will be looking for better tasting and healthier food options from different parts of the world and hopefully Canada can be a world leader on this front.”

BY GEORGE GUIDONI, EDITOR

PHOTOS BY NAOMI HILTZ

Life is not always a bowl of cherries for companies making their living in today’s ercely competitive Canadian red meat market. But for brothers Hershel and Micheal Snajdman, president and vice-president of Jadee Meat Products Ltd. in Beamsville, Ont., putting healthy high-quality meat products on the consumers’ plates is a labor of love, passion and pride that makes all the hard work along the way a joyful life-long endeavour.

Literally born into a family meat business started up by his grandfather Joseph and father Danny back in the 1950s in London, Ont., making his mark in the meat industry always seemed like a natural career path for Michael, who remembers helping his dad and grandpa out as a little boy at the company’s original processing plant in Hamilton, Ont.

Ditto for Hershel, born shortly after his father and grandfather selected Beamsville as the strategic location for consolidating their existing old-school butcher shop operations in southern Ontario at one main federally-inspected meat processing facility to serve the entire Canadian market.

“When they rst started building this facility in 1977, there was not a lot more than cherry and apple trees in the area, and while driving around looking for the perfect spot, my mom and dad heard an old ballad

Family-owned Ontario meat processor leverages advanced X-Ray inspection technology to let its uncompromising focus on high product quality shine from plant to plate

‘Cherry Pink and Apple Blossom Time’ on the radio,” says Hershel Snajdman, relating the original inspiration for the name of company’s agship Cherry Pink brand of processed deli meats, European-style hams and sausage, bacon, and a wide range of meat toppings and ingredients sold by the company to the Canadian quick-service restaurant industry, leading food distributors, and select retail channels across Canada.

Explaining the company’s Jadee Meat Products moniker as a playful rst-name tribute to founders Joseph and Danny (as in J.D.), Snajdman says the original 40,000-square-foot plant has enjoyed steady and consistent growth in sales and market share since it commenced operations in 1979.

Over the following years, the meat processing operation has undergone three signi cant facility expansions

that more than doubled its processing square footage, while enabling it to evolve into a well-respected and reputable supplier of premium-quality products safely manufactured at a fully-accredited HACCP (Hazard Analysis Critical Control Points) plant that today also boasts the globally-recognized BRC food safety certication developed by the U.K.-based British Retail Consortium

Running a steady two-shift operation on a vedays-a-week schedule, Jadee Meats has built its success on a solid foundation of innovation and time-honored European recipe authenticity and tradition to establish an exceptionally loyal client base and industry-wide respect for its Cherry Pink product brand family.

“Today we make toppings for most of the largest pizza chains operating in Canada,” Snajdman relates,

“ranging from pepperoni and bacon to diced, sliced, julienne, quartered or shredded pork and beef toppings.

“We also do a lot of specialty custom work for larger food manufacturers by supplying them with the meat ingredients used in their frozen food products and other dishes, such as veal cordon bleu for example, as well as many other cooked and smoked meat products for deli operators and private-label customers.”

As Snajdman explains, the Beamsville plant operates multiple large-capacity smokehouses on-site—supported with world-class processing and packaging machinery assembled on the shop oor—to help provide many of its creations with the unrivalled taste and aroma that virtually let the Cherry Pink products sell themselves.

“The recipes we use today are very much the same recipes that the company started out with originally,” Snajdman says, “except we now do it with modern equipment and technologies.

“Our bacon is arguably of the most popular premium products we supply to the market,” Snajdman sates, citing the popular Ontario grocery retail chain Longo’s as one of its loyal retail customers stocking its shelve with Pink Cherry bacon and other processed meats.

“Most plants making bacon in Canada take about a day to produce the nal product,” he points out, “whereas our bacon-making process takes well over a week.

“The result is a truly unique product that has a rich avor, terri c texture, and very little shrinkage during the cooking process.

“We also do a lot of custom ham work, whereby we ship our hams to customers in bulk, have, sliced, quartered, diced, half-moon or whatever format the customer requires … there are so many things we can do with one primary product,” Snajdman extols.

“It’s a customer-driven business,” he states, “and we take pride in giving our customers exactly what they want.”

Snajdman explains that about 60 per cent of the plant’s output is derived from pork meat and the rest from beef, with all of the large primary cuts of meat shipped to the Beamsville plant already de-boned and de-fatted at the suppliers’ slaughterhouses—allowing the Jadee plant to focus on its core “further processing” operations.

Says Snajdman: “We are helping our customers to improve their business by supplying them with custom solution that some of the larger meat processors may not want to do, for various reasons.

“We are pleased with our client mix of branded products, the co-packing work we do for our meat market customers, and the many QSR (quick-service restaurant) operators that we supply,” Snajdman states.

In addition to keeping the plant’s production machinery constantly updated to keep up with the times, Snajdman says he takes a lot of pride in the family-like work culture fostered at the Beamsville plant, which is one of the larger industrial employers in the Niagara region.

“We always stress to our sta the importance of treating others like they would want to be treated themselves,” he says, “and hopefully that extends right up to the management level.

“Our average tenure among sta at this plant is over 20 years,” he points out. “People who join us tend to stay with us, and we’re very grateful for that—they are great people.”

Having been part of the local community’s business landscape for such a long time has also enabled Jadee Meat to build and cultivate a highly favorable public image among the locals, according to Snajdman, who cites several local Chamber of Commerce awards given to the plant over the years for its various proactive community and business initiatives that include generous donations to local food banks and other like-minded community causes.

“Our storefront at the building’s entrance is a good example of this community bridge-building,” Snajdman states.

“It is only open for business three days a week, but you’d be surprised how many people come through here in those three days,” he remarks. “Some of the customers will even drive from a long way out to buy up to two cases of meat at a time that they can take up north with them to the cottage or camping.”

Says Snajdman: “It’s a very nice and tight community here, and we’re happy to serve it by being able to o er people really high-quality meat products at very affordable prices.

“People here really appreciate it,” he says. “It is actually a very small part of our business, but if we were to shut it down, a lot of people around here would be upset with us.”

With premium product quality being one of the meat processor’s biggest calling cards and competitive advantages, the plant leaves nothing to chance to allow its stellar industry reputation be tarnished through any accidental quality defects or product recalls.

While the operation has long enjoyed a virtually spotless product safety record, Snajdman is a rm believer that there is no such thing as too much safety when it comes to food.

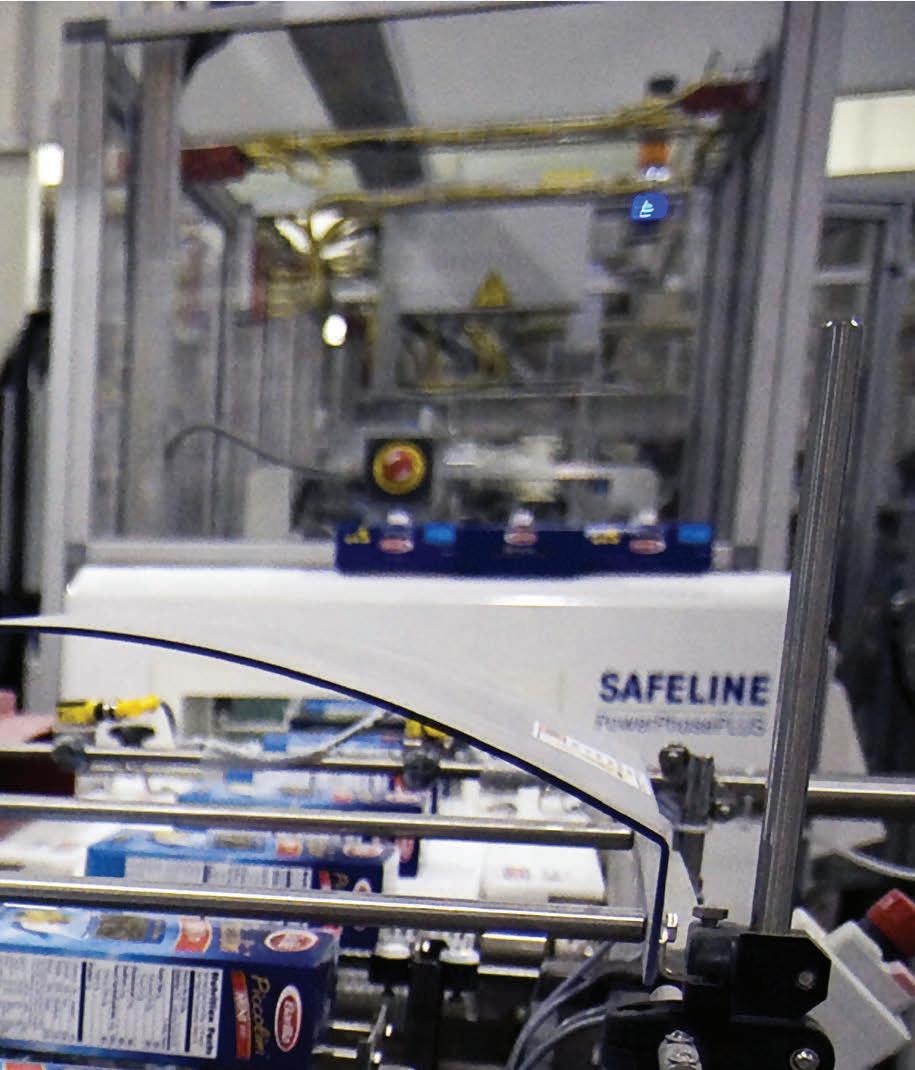

This mindset played a large part in the company’s recent decision to invest in additional advanced X-Ray inspection technology to complement its existing X-Ray system and a series of high-quality metal detectors installed throughout the plant at

all the usual critical points to ensure uncontaminated nished products.

“We wanted to go with X-Ray technology because there are some products that are more likely to contain bone fragments within them,” Snajdman explains.

“Just the thought of someone out there chipping their tooth because they bit into a bit of bone in our meat product is unacceptable to us,” he states.

“We felt that investing into a technology to prevent that kind of thing from happening is well worth the expense,” he states.

“We want people to enjoy eating our products, not to get hurt doing it,” says Snajdman, “and XRay inspection is a wonderful technology for detecting bone particles within the meat.

“In addition to bone detection, the X-Ray technology also allows us to detect metal particles much smaller than most conventional metal detectors can do,” Snajdman notes, “and we really enjoy that additional peace-of-mind it o ers.”

As Snajdman relates, all nished packaged products processed at the plant that are prone to harboring bone fragments pass through one of the plant’s X-Ray inspection units at the end of the line prior to being cased and shipped out.

To help Snajdman obtain his peace-of-mind, the plant’s long-time technology partners PLAN Automation, Orangeville, Ont.-based supplier of packaging automation products and line integration services, proposed the installation of a highly advanced Eagle Pack 430 PRO X-Ray inspection system manufactured by Eagle Product Inspection in Tampa Bay, Fla.

After assessing other options, Snajdman said he became quickly convinced about the Eagle Pack 430 Pro model being a perfect t for his plant’s needs.

“We just felt that the Eagle unit was more robust compared to the other X-Ray systems in the market,” he states.

“Combined with our long and productive relationship with PLAN Automation, who also supplied us with many of our metal detectors over the years, we felt very con dent about obtaining an optimal food safety solution for our premium products.”

Installed about a year-and-a-half ago, the Eagle Pack 430 PRO X-Ray inspection system has lived up to all its promises, according to Snajdman, who

credits Plan Automation’s vice-president and chief operating o cer Mat Bédard for overseeing a smooth and awless system installation at the plant, while also providing all the necessary training and technical support.

According to Bédard, the key to the Eagle Pack 430 PRO’s exceptional performance lies in the system’s proprietary Eagle MDX (Material Discrimination X-ray) technology designed to enable highly accurate detection of lower-density contaminants such as bone, glass shards, rubber, plastic, etc., by discriminating inspected materials by atomic number (chemical composition) to process “busy” images with high variation in image density.

Originally developed for use in the security sector, the innovative Eagle MDX is now widely available for food and beverage producers to trace and pinpoint traditionally undetectable contaminants such as bone fragments, plastics bits and glass shards.

Moreover, the Eagle MDX technology uses Easy MAT software that facilitates faster installation and simpli ed set-up by auto-learning the material composition of the product, according to Eagle.

Unlike many food companies who have been mandated by their customers to install X-Ray inspection at their packaging lines as part of larger food supply chain safety initiatives, “Investing in this Eagle unit was simply a case of us being proactive,” according to Snajdman.

“We were already meeting and exceeding out customers’ expectations for quality and safety with our current practices,” he points out, “so it wasn’t a case of us having a problem that we needed to x.

“We were guided purely by our desire to ensure that there is no bone getting shipped out with our product to the customers,” says Snajdman, praising the Eagle system’s operational exibility that allows it to perform high-speed inspection of a diverse range of packages—from 500-gram thermoformed packs to 2.5-kilogram vacuum-packed whole hams and other large cuts.

“It works just as well on fully-sealed products as it does on loose packs, depending on the products,” Snajdman says.

“We do a lot of MAP (modi ed-atmosphere packaging) work, vacuum-sealed barrier packaging, skin-packs and all the other common meat packaging formats,” says Snajdman, adding the company

only purchases high-quality packaging from reputable suppliers to produce nal packaging on its state-of-theart meat packaging machinery.

While Snajdman says he thoroughly enjoys being in the meat business, “It is de nitely an industry that has a fair share of challenges.

Says Snajdman: “I love our product, I love the idea of providing fresh and local products to the market, and I love the idea of being a Canadian meat producer.

“But food safety continues to be a huge challenge,” he states, “and the industry as a whole is very competitive.

“The industry has shrunk signi cantly in the last few years, with many medium-sized operations like ourselves being consolidated into fewer but much bigger meat-packing operations.

“There are not that many mid-sized meat processors like us left in Canada nowadays,” he re ects, “but we have many reasons to feel positive about the future going forward.

“A lot of Canadians are eating our products on a weekly basis, often without realizing where these products came from, but that is perfectly alright with us,” he says.

“A lot of our large QSR customers have been with us for over 25-plus years,” he states, “ and that would not be the case if we did not provide them with the right competitive solutions for their business that solve their speci c problems and challenges.

“We’re not trying to be everything to everybody,” Snajdman concludes, “but having established ourselves as a reliable supplier of custom solutions for our customers’ many di erent needs, we are con dent about being able to rise to whatever challenges the market throws our way.”

BY ALAN SPRECKLEY

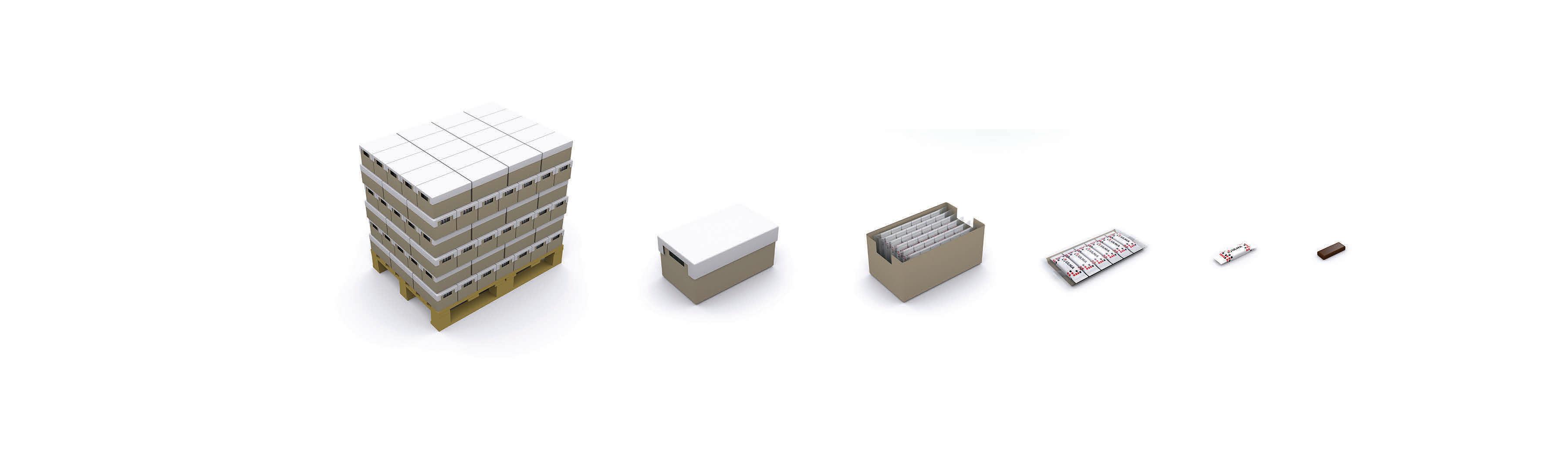

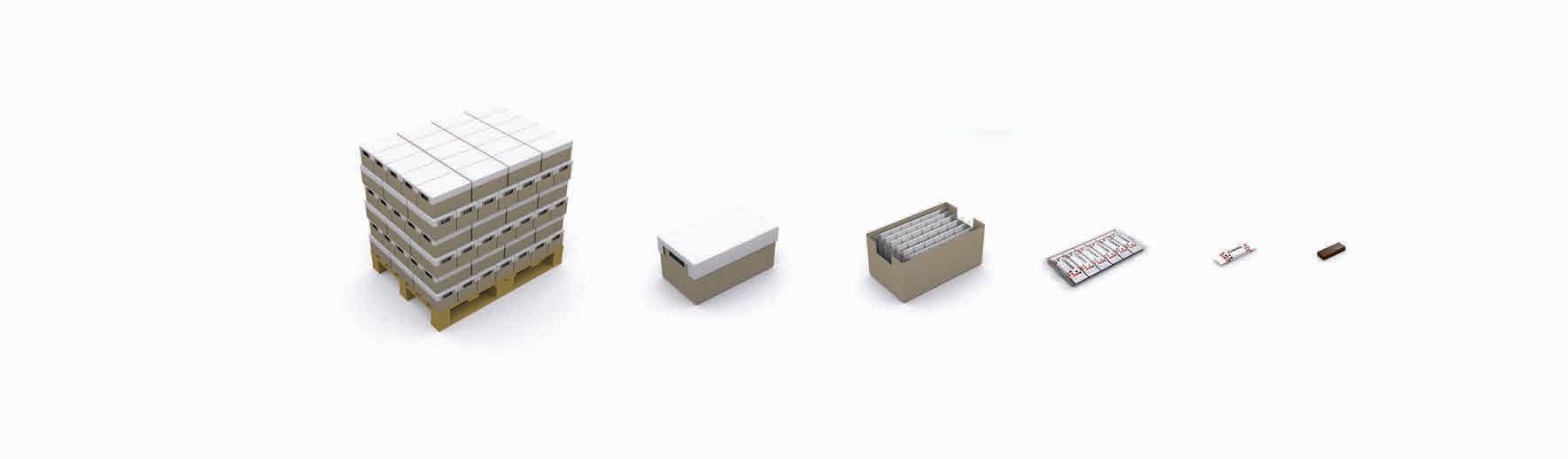

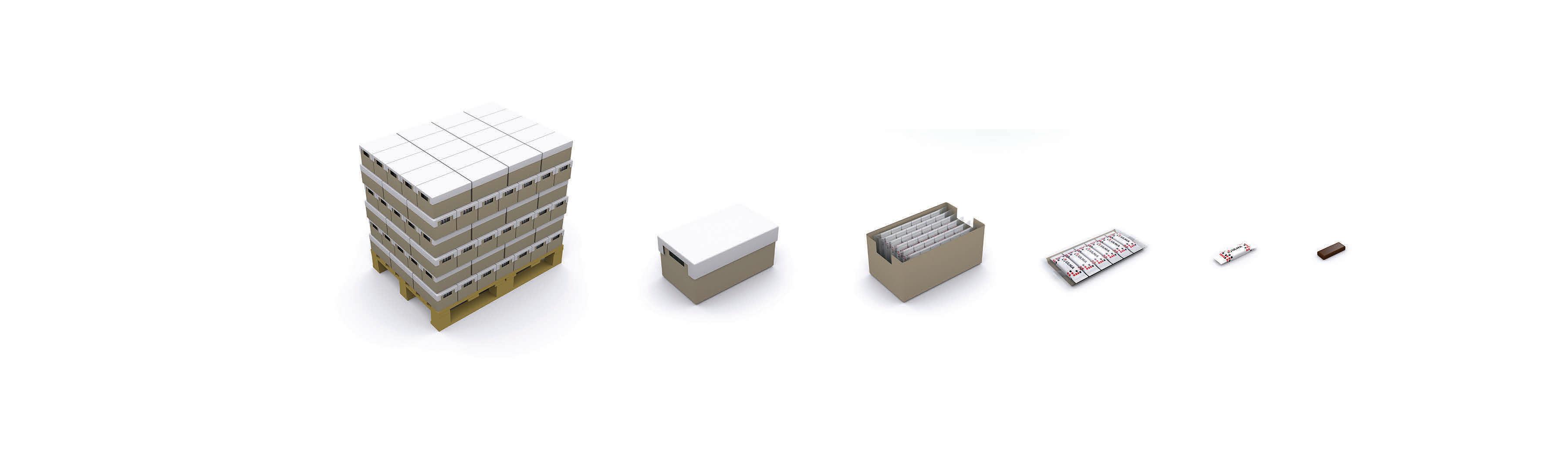

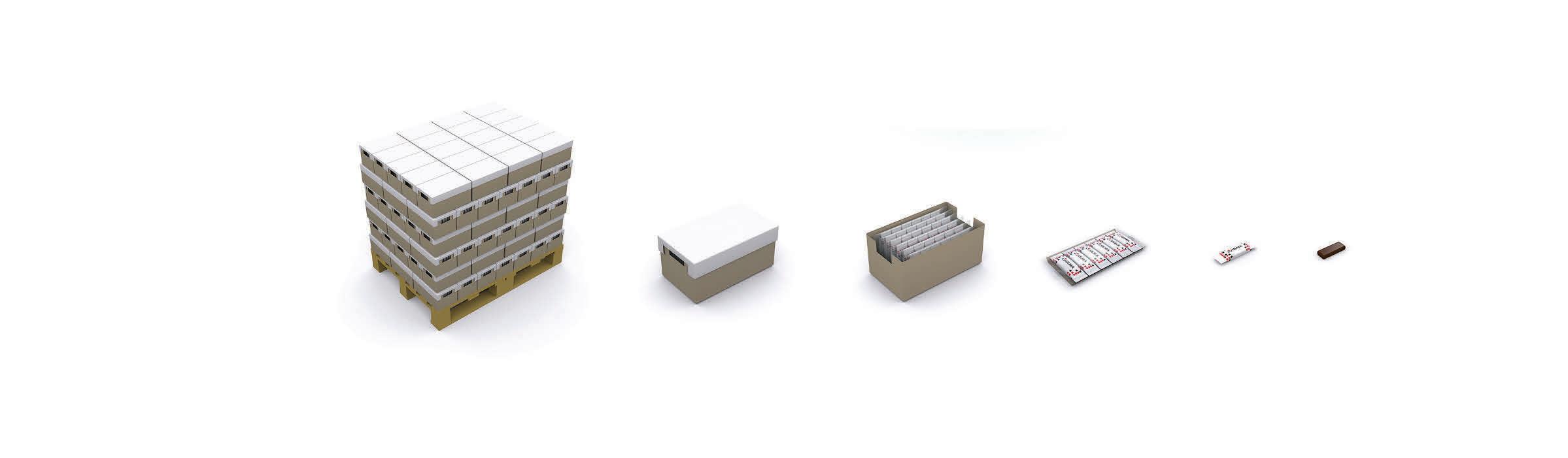

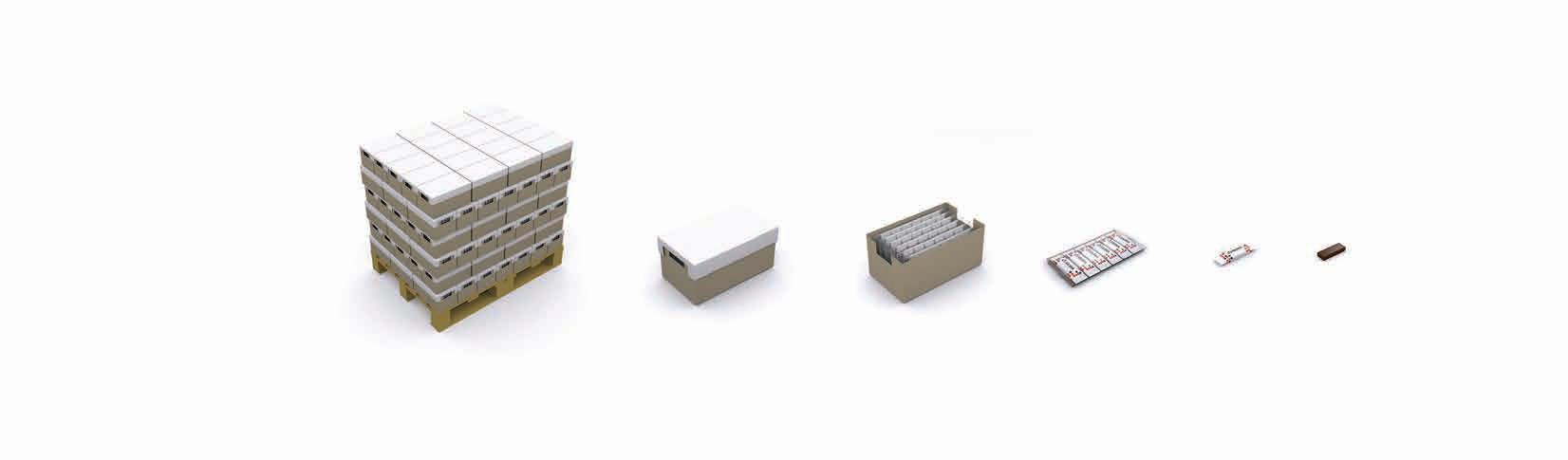

he technological and social revolutions of the past few decades have completely reshaped many industries, and the food packaging and palletizing industry is no exception. In fact, the last 10 years alone has seen the adoption of advanced technologies at an unprecedented rate, and this will only accelerate as the unfolding trend to digitalization makes its way into food palletizing.

As always, shifting demographics are at work. The last two decades have seen a decline in the nuclear family and a global rise in the number of private households with only a single resident.

This growing trend places a higher demand for single-portion servings of preprepared and pre-packaged food on the food industry, which makes the packaging and palletizing processes less linear than they have previously been.

Similarly, the unstable economy of recent years has nurtured a generation of savvy customers, eager for the special o ers and deals that retailers regularly provide, further complicating the palletizing process.

This leads to scenarios where manufacturers will be required to change palletizing patterns quickly and cost e ciently to deliver this.

To keep pace with this changing demand, plant managers and process engineers must ensure that the palletizing process is as e cient and e ective as possible.

This means keeping systems maintained and palletizing patterns up-to-date, while minimizing any risk of downtime or hindered performance.

To make these processes easier to manage, plant managers have been increasingly turning to new technological solutions that go a step beyond the traditional automation systems or machines.

In the 21st century, digital technologies and software are proving to be the unconventional ally of the modern plant manager.

Robots have been a staple of the food industry since the 1980s, with most businesses using at least one robotic system for some part of the production line.

Palletizing robots have proven particularly popular among plant engineers as they increase productivity, improve working conditions and can be easily integrated into existing production systems.

However, the process of integrating palletizing robots has traditionally relied on computer-assisted design (CAD) drawings and involved a lot of estimation.

Food plant managers provide approximate dimensions to robot manufacturers for the robot and leave the rest in the hands of the manufacturer, who tests the product in its own facility before nalizing and installing on-site.

While this approach is su cient for some businesses, it can open up several performance problems. For example, CAD drawings alone do not necessarily provide an accurate representation of the operating environment and the robots still need to be programmed after installation.

This lengthens periods of unproductive downtime to accommodate the placement and programming of a new robot.

To minimize unproductive downtime, the process of virtual commissioning is becoming increasingly popular among plant managers, often using ABB’s innovative suite of virtual commissioning tools.

Instead of using CAD drawings and developing robots in an external environment, the process is modeled in 3D, which provides an accurate visualization of a factory layout. This allows plant engineers to see a digital representation of how the robot will integrate and move within the process, and allows them to discover and resolve any potential technical issues before they become a reality, reducing commissioning time by up to 25 per cent.

For example, one of the most common causes of damage to palletizing robots is collision with a cell’s support pillar during operation. By using a virtual commissioning platform, such as ABB’s RobotStudio, these instances of collision can be fully discovered and resolved in a time and cost-e cient manner on the computer. This helps minimize the actual, physical commissioning.

Once commissioned, robots are machines like any other and they are susceptible to component wear over time. As such, regular maintenance is required to ensure that everything is functioning e ectively and safely.

This doesn’t pose much of a problem for plants that are ahead of the curve and running on an Industrial Internet of Things (IIoT) network, which allows engineers to access Cloud data to assess the performance of machinery remotely and schedule maintenance work accordingly.

While virtual commissioning and remote monitoring technologies both keep factories running, it is the development of o ine programming software that yields e ciency bene ts for plant managers.

This is software that allows the remote programming of palletizing robots without interrupting production.

For example, if a retailer usually asks for four-packs of tinned soup but decides to o er a 50 per cent-extra-free o er for a period of time, the palletizing robot will be required to change palletizing patterns accordingly.

Failure to do this e ectively could result in businesses being unable to supply a su cient amount of product to retailers, which leads to lost contracts and the risk of heavy supplier nes.