When Agweek brought Sugarbeet Grower Magazine under our umbrella earlier this year, I felt like I was getting a chance to go back to my roots … my sugarbeet roots.

My earliest memory is of standing in a sugarbeet field, looking at the line of food my Grandma Marguerite had delivered for the harvesting crew. It’s a fuzzy memory, from more than three and a half decades ago, but it’s a reminder that sugarbeets were a part of my life long before I ever could have imagined myself working on a publication dedicated to the sugarbeet industry.

After that early memory are many others, far clearer in my mind. Helping irrigate the long rows. Helping hoe the rows, which then seemed even longer, in the days before Roundup Ready technologies. Riding in the truck with Dad or Grandpa Bob to take loads to the factory in town. Tossing up beets that had missed the box of the truck. Watching the crew clean the equipment every night. Taking sugarbeets into school for show and tell.

My family still farms in south central Montana, though sugarbeets left the rotation during my teenage years. I distinctly remember riding with Dad when he hauled his last load of beets into town. I’m in North Dakota now, and the sight of a field of sugarbeets in the Red River Valley never fails to take me back in some way to those early memories.

And now I’m excited to reacquaint myself with all things sugarbeets and help serve the growers and the industry around the continent.

Mike Spieker, who served previously as the editor of Sugarbeet Grower Magazine, has decided to focus on other career interests. We are happy for him and wish him the very best in his venture. I have taken over as editor, in addition to serving as editor of Agweek.

Our staff is committed to serving the needs of agriculture. In Sugarbeet Grower Magazine, we will strive to continue to provide the latest information you need on sugarbeet agronomy, technology

and policy. We will introduce you to new techniques and ideas. We will put on display the personalities of the industry.

We also want you to know that our sugarbeet coverage is not relegated strictly to the pages of this magazine. At https://www.agweek.com/sugarbeet, you can catch up on the latest in sugarbeet news all year long.

Please reach out to me with ideas about topics you’d like to see covered. I’d also love to hear from you about your farm and your crops. We will continue the Photos from the Field feature in the magazine, so if you have any photos you’d like to see published, send them my way. You can reach me at jschlecht@ agweek.com.

Thank you for reading! I look forward to becoming part of the sugarbeet world once again.

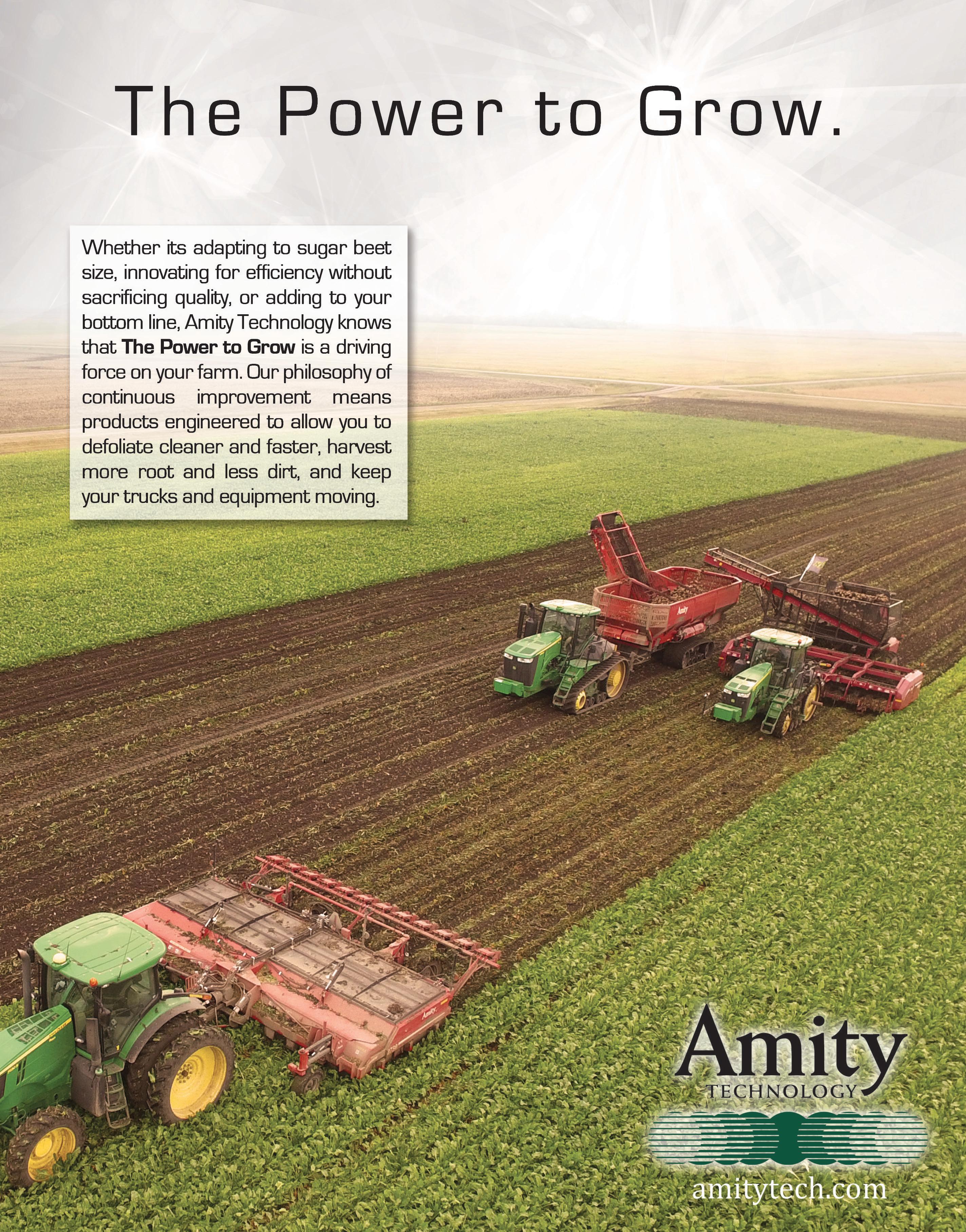

EDITORThe 2021 sugarbeet crop near Foxhome, Minn., shows potential for a healthy, 30-ton-per-acre yields, but cercospora leaf spot can quickly cut yields, reduce sugar content from 18% sugar down to 15%, and increase the processing costs of removing impurities.

FOXHOME, Minn. — New sugarbeet varieties resistant to cercospora leaf spot disease were commercially available for growers to plant in southern North Dakota and Minnesota in 2021.

The improved varieties will save tens of millions of dollars in spray and processing costs and could save hundreds of millions in crop losses.

Mohamed Khan, a professor and Extension sugarbeet specialist for the University of Minnesota and North Dakota State Unviersity, said he expects to see most farmers to adopt the technology in the next three years. He thinks its use in the next two or three years will extend to Michigan, Montana, Nebraska, Colorado and Wyoming.

CONTINUED ON PAGE 6

FARGO, N.D. — Cercospora beticola is the most economically damaging foliar disease farmers face, says Mohammed Khan, a Fargo-based Extension sugarbeet specialist at North Dakota State University and the University of Minnesota.

Khan has been doing his job for 22 years but the Cercospora history goes back a long time before that. Here is his look back on its history:

• 1926 — Farmers started producing sugarbeets in East Grand Forks, Minn., with seeds supplied by the company. Europeans improved varieties for yield, but with susceptibility to cercospora. American Crystal Sugar and other private companies prevented varieties that had higher cercospora susceptibility, even those which limited tonnage yields.

• 1974 — Farmers buy American Crystal, making it a cooperative. The farmer owners changed to an “open policy,” with higher yield potential but with cercospora controlled by fungicides. They used “tin” and Benlate fungicides. After two years of use, cercospora developed resistance and overtook Benlate.

• 1981 — The first major cercospora “epidemic” occurred in Minnesota and North Dakota.

• 1998 — A second big Cercospora epidemic cost American Crystal growers $40 million, and a total of $100 million for the region’s three co-ops. “We were going toward more susceptible varieties, but using one or two fungicides,” Khan said. Growers sprayed an average of 3.7 times across the growing region. Some applied fungicides nearly every week — 12 applications a year.

• 1999 — Environmental Protection Agency approves a Section 18 exemption for a QoI fungicide trade named “Quadris,” and then “Eminent,” a triazole. “That was that was the product that saved the industry,” Khan said.

• 2003 — EPA approves Headline and by 2005 fully approved Eminent and other triazoles. Fungicides controlled the disease at two applications in the northern Red River Valley, three in the southern Red River Valley, and four in Southern Minnesota.

• 2016 — Excessive and continuous rains and heat, increased the Cercospora incidence and the potential for fungus mutations that would make them resistant to fungicides. NDSU and growers asked seed companies to speed up development of resistant varieties that were becoming commercially available in 2021.

• 2021 — Growers in Minn-Dak Farmers Cooperative in Wahpeton, N.D., and Southern Minnesota Beet Sugar Cooperative at Renville, Minn., were among the first in the country to start using CR+ (cercospora resistance plus performance) beet seed.

CONTINUED FROM PAGE 5

Sugarbeets are the most prominent specialty crops from southern Minnesota to the Canadian border through the Red River Valley, accounting for some $5 billion in economic activity. But that activity can be hurt by cercospora, which turns green leaves brown, shutting down yield potential.

The new CR+ (cercospora resistance plus performance), from KWS, parent company for Betaseed, commercialized seed for some growers in the southern Red River Valley of North Dakota and into southern Minnesota.

German-based genetics company KWS Saat (parent of Betaseed) in its website on the topic says about twothirds of global sugarbeet acreage has a moderate to high cercospora pressure. Cercospora is the most destructive leaf disease of sugarbeets, sometimes cutting crop yield by 50% in some places, the company says on its website..

Khan said the new technology will prolong the usefulness of other fungicide treatment.

“It’s a real game-changer,” he said, describing the technology in a private tour of his cercospora research plots near Foxhome, Minn., about an hour east of Fargo, N.D.

Khan manages research/demonstration plots annually of about 25 acres on land farmed by Kevin Etzler of Foxhome. The research is open to the public, usually replicated four times, on a scale similar to typical farm fields. Here, the MinnDak Farmers Cooperative of Wahpeton, N.D., and American Crystal Sugar Co., of Moorhead, MInn., evaluate (blind)“coded” varieties they test for various seed companies to ensure they meet minimum standards for cercospora vulnerability. Much is at stake.

Infested fields hit can easily lose 40% of their yield and about 2 to 3 percentage points of sugar — a loss of millions of pounds of sugar and millions of dollars throughout the growing regions.

“You can easily lose $300, $400, $500 per acre,” Khan said.

Cercospora since 2016 in the Minnesota/ North Dakota region has been most prevalent in the two southern coops: Minn-Dak Farmers Cooperative andSouthern Minnesota Beet Sugar Cooperative. The areas where those coops operate generally get more rainfall and heat units, which increases yields but also creates more problems with cercospora. Over the past two decades, sugarbeet yields have increased nearly 50%.

Beets are a high investment crop in the three closed cooperatives. Farmers in North Dakota and Minnesota together produce 650,000 acres of beets. Diseased plants can produce 1 trillion spores per acre.

“That’s trillions and trillions of spores are circulating. The larger the number of spores, the more mutations that can lead to fungicide resistance,” Khan said. “We are trying to kill the fungus and the fungus wants to live.”

CONTINUED ON PAGE 8

A weather station at the sugarbeet cercospora leaf spot research plot near Foxhome, Minn., provides temperature (air and soil), relative humidity and precipitation data that is correlated with a spore trap to help scientists recommend the best way to fight yield- and qualityrobbing disease. Photo taken July 16, 2021, at Foxhome, Minn.

Harvestisn’t alwayseasy. It’saprocess that requirespassiontopersevere. At SESVanderHave, we’re continuously workingtodevelopsugarbeetvarieties thatthrivedespitethepressuresfrom diseaseandthechallengesofnature sothat youcanendeachharveston ahigh-note.Becausesharingthe prideofsuccessstartswithsharing thepassiontoachieve it.

From 2000 to 2015, farmers got excellent control by applying two to four fungicide applications per year, depending on the farms’ locations.

One fungicide type is the “quinone outside inhibitors” (“QoI”), a fungicide that specifically stops the production of energy. The main QoI for sugarbeets has been “Headline,” a pyraclostrobin (from the strobilurin class of chemistry). Because of its high specific activity, it has been effective against target fungi. But Headline suddenly became ineffective.

“If you sprayed the field in 2016, and went back to that fields three to four weeks later, it started to turn brown,” Khan said.

The reason? Mutations. One mutation resulted in complete resistance to the QOI fungicides.

“All the fungus had to do was change an amino acid at one position (in its genes)for another — an alanine changed to guanine,” Khan explained. And that was that.

At the same time, it developed “reduced sensitivity” to another previously effective fungicide group — triazoles (also called “demetallization inhibitors”). This puts holes in the fungi’s cell membranes.

Khan started recommending using one new fungicide with another mode of action — “especially an older chemistry.” (The older fungicides are “multi-site” types, used since the 1970s.)

The most popular older fungicides were ethylenbisdithiocarbamates. The EBDCs included trade names Mancozeb and Penncozeb. Other old chemistry are known as “tins” — triphenyltin hydroxide (TPTH). The common “coppers” were copper hydroxide and copper oxychloride..

The 2016 season was the warmest and wettest in the 121-year weather record history for Minnesota. This was good for growing beets but devastating if you had cercospora that had become resistant to the previously most-effective fungicides.

Mohamed Khan, a North Dakota State University and University of Minnesota sugarbeet specialist, says new “improved cercospora leaf resistant” beet varieties were used on 60% of Minn-Dak Farmers Cooperative acres and 15% of Southern Minnesota Beet Sugar Co-op, and should be available to most growers nationwide in two to three years. Photo taken July 16, 2021, at Foxhome, Minn.

“Because the best modes of action were no longer effective in 2016 our growers lost close to $200 million — less income to producers in North Dakota, Minnesota and Michigan,” Khan said.

From 2016 to 2020, growers in Southern Minnesota applied six to seven fungicide applications per year, always in mixtures, with mixed success, depending on the amount of rain.

QOI fungicides worked well until years like 2019 when repeated rains washed them off and they had to be reapplied. “The disease will overtake the plants. You will have low yields, very little to harvest,” he said.

In 2020, the southern Minnesota growers had effective disease control — nearly 30 tons per acre, with 17% sugar.

NDSU started urging seed companies to speed up work they already were doing to incorporate tolerance. The new cercospora improvements came through conventional breeding, not genetic modifications. KWS breeders had been finding strong cercospora tolerance in a broad range of wild beets.

K han and his research team inoculate plots to allow cooperatives to rate sugarbeet varieties for their cercospora leaf spot resistance. He also studies fungicides for their effectiveness, as well how they work in mixes and rotations.

Mike Metzger, vice president of agriculture for Minn-Dak Farmers Cooperative at Wahpeton, N.D., has had the new CR+ varieties in his company’s research plots for two years. He describes cercospora as the co-op’s “No. 1 production problem.”

Metzger said that 60% of seed planted by Minn-Dak Farmers Cooperative at Wahpeton this year were the improved cercospora-resistant sugarbeet varieties. Khan said about 15% of the crop for Southern Minnesota at Renville also also are the new varieties.

All of Minn-Dak’s members this year were offered an opportunity to buy the new seed, and Metzger estimates that 80% to 85% did. The new seed came at about a $40 per acre cost above the typical seed price, which ranges from $200 to $250 an acre.

“It’s going to offset three sprays,” which Metzger and Khan say is at about $25 to $30 per spray.

Metzger likened the new variety impact to the to “herd immunity” when it comes to COVID-19. Going to resistant varieties could drastically reduce the amount of fungus over a two-or three-year period.

“We don’t have to worry about that massive cercospora cloud hanging over our head. It gives us a chance to take a breath, hit the reset button,” he said.

Khan said the new cercospora-tolerant varieties appear to have tonnage yield comparable to approved sensitive varieties. The sugar concentration may be a little lower. “But overall the recoverable sucrose is as good as the other varieties we’ve had,” he said.

He said other seed companies (Crystal Beet Seeds, SESVanderHave, Hilleshog and Maribo) also are working toward commercializing resistant varieties.

While the cercospora-resistant varieties so far have come through conventional breeding, Khan said the industry is looking at developing other traits through genetic modification. Some on the horizon include triple-stack resistance to glyphosate (Roundup) glufosinate (Liberty) and dicamba perhaps in 2025 or 2026. The only sugarbeet GMOs now approved for use are for Roundup (glyphosate) resistance.

Khan and his technicians in late June intentionally inoculate the entire site with cercospora leaf spot disease, accumulated from infected leaves from growers’ fields the previous year, mixed with a talcum powder.

Also, Khan’s larger job is to determine which fungicides are effective in combating the disease.

The researchers apply the fungicides in applications in 10- to 14-day intervals

six applications across the entire season from late June into September. Khan applies the combinations to beets with varying levels of cercospora resistance. Those include varieties more susceptible than the “conventional, susceptible” growers would normally use.

“If something is working in my research site, it will work in a grower’s field,” he said.

Part of Khan’s research is using fungicides with the improved varieties to see if he can reduce the fungicide applications and still get high yields. In some of the improved varieties he thinks he can use as few as one — or zero — applications in some years.

In the end, the samples are analyzed at an American Crystal Sugar Co. tare laboratory at East Grand Forks, Minn.

“We do calendar sprays — for growers who don’t want to scout,” he said. “If they want good yields they’ll probably have to

Cercospora first attacks the oldest leaves, which produce the most sugar. The disease doesn’t hit younger leaves until late in the season. Those who scout do so based on leaf spots and daily infection values, some relying on scouts or consultants to determine disease severity and the best time to apply fungicides.

In a related study at the research plots, Khan is working with drones to aerially collect images to determine the amount of “brownness” that would indicate an infestation. That will be correlated to infestation data on the ground, and eventually cut the time and cost of scouting fields.

If the drone technology proves itself, Khan is working with an engineering colleague at NDSU to develop a sensor for agriculture that is also usable for detecting weeds, both in sugarbeets and other crops.

The site has a plot tour on Aug. 24, 2021.

SER VICE Save time and maximize profit

Michigan Mike, 1-810-705-0297

Idaho Kent, 1-208-280-0079

Nebraska 21 st Century Equipment

Minnesota

Award-winning 35 & 40 ton capacity & 40 ton BIG BEAR www.r opan ortha merica.com info@r opanorth america .com Nor th America

Midwest Machinery Co.

In he first six months for any new administration, there is a flurry of activity to oversee. Dozens upon dozens of Presidential Executive Orders are issued to modify or reverse what the preceding administration put in place and to push their agenda without congressional approval.

Getting the political appointees in place to provide the leadership in the agencies across the government is a slow process because of very lengthy security clearance background checks and review and approval of the nominees by the Senate. Until the political appointees are in place, the career staff are loath to make critical regulatory or policy decisions. The president has to push his big agenda items early and hard for congressional consideration, negotiation and approval.

Of course, all of this is shrouded in the politics of the 2022 elections. There is only a four-vote margin in the House and new congressional districts are being drawn this fall, adding even more dynamics in forging legislation. The president faces one or both of the chambers shifting to Republican control, dramatically limiting his agenda. Thus, the President must move quickly on his key priorities such as infrastructure, taxes, climate and various other social issues. The political theater over the next few months will be equivalent to a roller coaster ride.

Taxes: We see many threats to the status quo on taxes. The debate over infrastructure funding brings welcome and long overdue attention to roads, bridges, waterways and rural broadband but introduced potential tax threats with respect to stepped-up-basis, capital gains taxes, and changes to 1031 likekind exchange taxes. Agriculture rallied together to make it clear the devastation

such proposals would bring. Clearly your concerns have been heard and we shall see how they are eventually heeded. Waters of the U.S. (WOTUS): On June 9, the EPA and Army Corp of Engineers announced their intent to revise the definition of “waters of the United States.” EPA and the Army notes that under the current rule put in place by the Trump Administration they have “determined that this rule is leading to significant environmental degradation.” This is a major concern for all of agriculture.

Trade: As of early July, the Biden administration had not yet announced their nominee for the Agriculture Ambassador who is the lead negotiator in the office of the U.S. Trade Representative. This is a critically important position for American agriculture. On June 30, the Trade Promotion Authority expired, which essentially halts negotiations on pending trade agreements by the Biden Administration until Congress passes it again. The Administration has given no indication when it will seek to have Congress renew TPA. The World Trade Organization, which is in great need of reform, has a Ministerial meeting scheduled for the first week of December in Geneva, Switzerland. The WTO has been mired in a quagmire of dysfunction for several years and we must be vigilant on what reforms may be considered that could have a direct impact on our sugar policy.

Sugar Policy: Our traditional policy opponents have drafted a bill and are seeking cosponsors that would essentially gut U.S. sugar policy. The bill would drop the loan rate by a cent per pound, increase imports, continuously oversupply the market and keep prices

Luther Markwart has been the executive vice president of the American Sugarbeet Growers Association since 1982. Luther can be reached at lmarkwart@ americansugarbeet.org.

depressed. A similar bill was rejected by the House by a 141-vote margin in the 2018 farm bill and not allowed to be considered in the Senate at that time. However, there are many new members of Congress so we must constantly educate them as to why the U.S. sugar industry is critically important and is designed to support farmers, keep the market adequately supplied and operate at no cost to taxpayers. Given the experience of supply chain disruptions in various industries during the COVID-19 pandemic, the last thing Congress should be giving any time or attention to are proposals that would undermine domestic producers, put good rural jobs in jeopardy and increase dependence on unreliable foreign suppliers.

Initial work on the next farm bill is already underway by your industry leaders. They look at what the needs of growers are and see if current policy is meeting those needs. Farm policy cannot solve all problems, but it is the epicenter of what helps us survive and care for the nation’s sweetener needs. Once again we thank your grower leaders for the time and effort they put forth on your behalf to chart the course for our industry.

LUTHER MARKWART Executive Vice President American Sugarbeet Growers Association

New research shows consumer attitudes about real sugar are increasingly positive, while the favorability of artificial sweeteners has declined. A significant majority of consumers understand real sugar originates from plants and is naturally-occurring, according to the research conducted by Quadrant Strategies for the Sugar Association, the scientific voice of the U.S. sugar industry.

“The shift in consumer attitudes about sugar over the last three years shows consumers have a much deeper and clearer understanding of sugar’s plant origin, as well as its role in a balanced diet,” said Dr. Courtney Gaine, president and CEO of the Sugar Association. “That is good news and progress for facts, nutrition science and common sense over a lot of the misinformation around sugar we have seen in recent years.” The study, based on feedback provided by a national, statistically representative sample of 1,500 adults across the U.S., shows:

• 80% of consumers agree that “real sugar” is naturally occurring. 54% put “table sugar” in this category.

• More consumers (57%) associate sugar with the fun and happiness it provides in their lives, rather than the guilt (43%) some associate with eating sugar.

• Only 7% of consumers believe sugar CANNOT play a role in a balanced diet, as compared to 23% who say artificial sweeteners CANNOT play a role in a balanced diet.

• Consumers rank sugar higher than artificial sweeteners on almost all attributes they identify as important for foods and beverages they purchase.

• The top two food ingredients consumers now avoid are High Fructose Corn Syrup and sugar substitutes. In 2018 the most avoided ingredient was sugar, which has now slid down the list of ingredients being avoided, falling to number eight.

• More than 70% of consumers say they avoid products that contain artificial sweeteners — including bread, yogurt, peanut butter, canned fruit and children’s cereal.

• 70% of consumers avoid or moderate their sugar intake. The top three ways consumers limit sugar is by consuming products with sugar less often, consuming smaller portions and consuming reducedsugar products.

Taken as a whole, the new research, when compared to the 2018 findings, shows a significant increase in consumers’ positive perceptions of real sugar and increased consumer skepticism of sugar substitutes. “Real sugar is an ingredient that consumers know and recognize, and increasingly, consumers understand where real sugar comes from. In addition to its roles in many nutritious foods, sugar remains a source of fun and enjoyment for American families, playing a part in a balanced lifestyle,” Gaine said.

SPONSORED ARTICLE

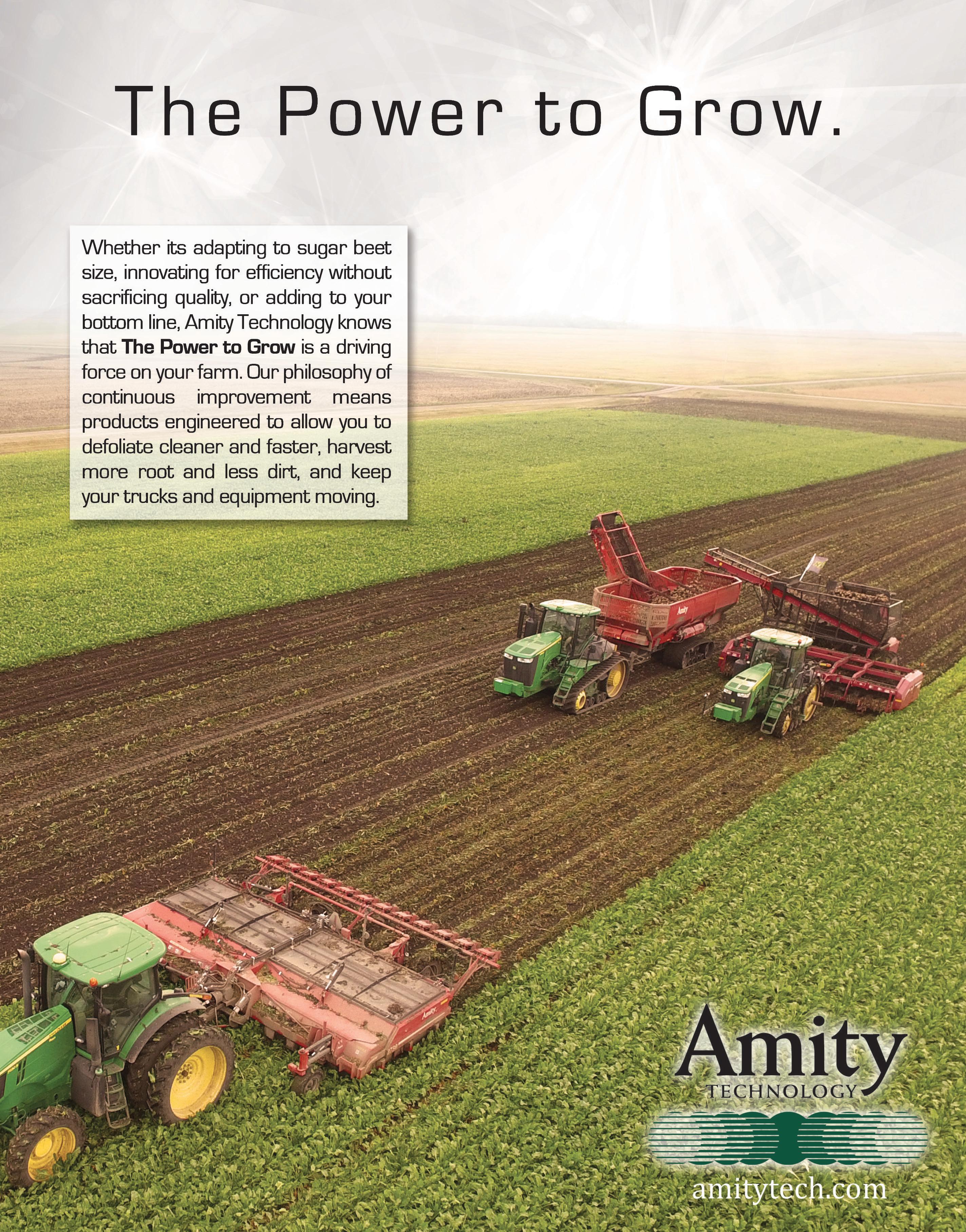

As most growers already know, the Crop Shuttle is the largest, fastest and most versatile crop cart on the market. New for 2021, STP Manufacturing based in Park River, ND has added even more diversification to the Crop Shuttle line-up with an all-new spreader attachment. The dual pan spinner is hydraulically driven, meaning you still will not need a PTO to operate the Crop Shuttle.

“This new attachment is a major deal for us” say Jacob Kringstad the Vice President at STP Manufacturing. “It allows our customer another option to diversify the use of their equipment making their investment go further.”

“Diversification options for our customers Crop Shuttle investment has been a major focus of ours for the past couple of years and we have some real groundbreaking things to come out in the next year or two.” The company worked closely with Ron and Nick Adams from Reynolds, ND to test and enhance the design in the Fall of 2020. The testing unit was outfitted on a 4600 series Crop Shuttle allowing it to load up 30+ tons of lime ash. The attachment is out of the way at the rear of the cart allowing farms to move from harvest operations to spreading with no down time to switch over.

“This year we harvested around 1,500 acres of sugar beets and then spread over 12 million pounds of lime ash in the Grand Forks area with the Crop Shuttle” says Nick Adams. “The Crop Shuttle’s Bluetooth scale system really made it easy to keep track of our spread rates and to adjust accordingly. Not only that, but our loader and harvester operators had the app on their phones allowing us to get the perfect amount in the Shuttle every time.” Through the product testing phase, “Adams were helpful during the development of this spinner, they have been awesome to work with while we work out the kinks” said Kringstad.

The Crop Shuttle has a modular design allowing you to customize your cart to fit your needs. You can maximize your payload up to 46 ton or 2400 cubic foot capacity and discharge speeds up to 30 tons per minute. Customers can customize various components of their cart, including capacity, side wall height, scales, cleaning tables and boom widths.

The Crop Shuttle is extremely versatile allowing you to use it in multiple crops such as sugar beets, potatoes, carrots, onions, red beets, cucumbers, and even corn silage.

The Crop Shuttle started as a product from Kringstad Ironworks Inc. but since has been moved to a sister company, STP manufacturing where it is currently manufactured.

“The Crop Shuttle got its roots when we introduced the first one into vegetables in 2016. The Beet Shuttle was my

father’s project that dates to the first prototype in 2012 to help Michigan farmers tackle the need to load large trucks, at tall heights at an efficient rate” explains Jacob. “After about 3 main designs the current hopper raising design was the most efficient and laid the groundwork for my brother, Alek, and I to take it to the next level and introduce it to more crops. Currently we have tried it in more than 15 different crops and adding more versatility each year.”

Currently STP has 5 main products that they manufacture. “We started with just Safe-T-Pull in mind back in 2014 but our focus to diversify quickly added more product lines” says Alek Kringstad production manager. “In 2015 we worked to develop the Slingshot Kinetic Energy Ropes, 2016 we added the Crop Shuttle under our roof, 2018 we purchased Strong Box Live bottoms, 2019 Prairie Plastics and last year was our 1st year as a dealer for the Holmer self-propelled harvester. All of these product lines compliment each other and share common parts and customer base.”

“We have always been big on innovation and there usually isn’t many things we aren’t willing to try. We have some big prototypes coming up this harvest and 2022 holds some promising innovations“ exclaims Jacob. “We have a few new items to debut so we look forward to the 2022 trade show circuit and getting back out in front of our customers.”

If you have any questions on the Crop Shuttle or any other product that STP manufactures, check out www.stpmfg.com or give them a call @ 1-701-284-6100.

We have always been big on innovation and there usually isn’t many things we aren’t willing to try.

– ALEK KRINGSTAD, production manager

This edition of the Sustainability Spotlight features Nate Hultgren. Hultgren is vice president of the American Sugarbeet Growers Association and farms with his brother and father in west central Minnesota near Willmar. His business, Hultgren Farms, raises 1,200 acres of sugarbeets, as well as corn, soybeans, alfalfa, sweet corn, peas, kidney beans and beef cattle on 6,000 acres. The farm is also a partner in neighboring Meadow Star Dairy, which milks 8,000 cows. Nate is a fourth-generation farmer. He and his wife, Jaime, have 5 children: Lily, Nora, Elias, Ruby and Oliver. Nate also serves on the board of directors at Southern Minnesota Beet Sugar Cooperative.

When asked what sustainability means to him, Hultgren replied, “When I think of sustainability, my definition is more holistic. It has gone back and forth between the ability for our family farm to thrive and to survive. If we don’t maintain a healthy relationship with the land, water, and people around us, our business and way of life would become unsustainable.”

Hultgren described measures he has taken to enhance his efficiency and sustainability: “While serving on the board of directors and as president of the Minnesota Corn Growers, my brother Noah had some good discussions with several soil health groups and started to give some thought as to ways we could improve our land while also reducing inputs. At the same time, I was fortunate to have a working partnership with a large dairy operation adjacent to our farm. Noah and I were able to carve a path forward that involved reducing the amount of both spring and fall tillage while steering a portion of our fertilizer plan away from commercial fertilizers by adding manure from the dairy. We participated in forage crops for the dairy as well, which in silage years allowed us to go away from moldboard plowing prior to planting beets due to the reduced corn residue. This also allowed us to do one less spring tillage pass before planting beets since we didn’t have

to level out heavy plowing. By reducing heavy tillage and limiting ourselves to no-till and minimum-till strategies on our sandy, irrigated soils, we have seen a noticeable reduction in the amount of wind and water erosion while retaining more spring soil moisture for planting our beets into.

“We have also added alfalfa to our crop rotation to extend the years between beets. Of course, alfalfa adds some nitrogen credit back to the soil, but we also knew it helped reduce winter wind erosion, preserved moisture and improved soil aggregates.

“In the interest of reducing labor, fuel and soil compaction, we added a self-propelled harvester and track beet cart. This keeps trucks out of the field and allows us the option to do very little tillage after beet harvest and prior to the next crop. We are able to harvest with about half the people required under the conventional system we had five years ago, with 25% less fuel and a similar reduction in maintenance.

“As do most SMBSC growers, we use cover crops on our beet acres at planting. But we have also been experimenting with cover crops (mostly winter rye) on fields of any crop that are harvested early enough in the fall to get established before winter. This year, we are harvesting and cleaning winter rye for seed to use on more of our acres in 2022. We are planning to seed more of this cover crop if we get the opportunity this fall, and also planning to no-till plant sugarbeets into the stubble next year.

“Like most SMBSC growers, we are adding pattern drainage tile whenever possible to extend the soil water holding capacity while making our land more workable in tough weather conditions. We have added GPS and variable rate controls as we’ve built irrigation systems to only apply water when and where it is needed most.”

Scott Herndon serves as the Vice President and General Counsel of the American Sugarbeet Growers Association (ASGA) in Washington, DC. He represents growers on all issues that impact the sugar industry, including sustainability. On sustainability policy, he works with Farmers for a Sustainable Future, www.sustainablefarming. us, a coalition of twentyone farm and ranch groups committed to environmental and economic sustainability. Scott can be reached at sherndon@ americansugarbeet.org.

Hultgren also explained what sustainability practices have been successful versus which have not been successful: “We have found that no-till has its limitations for us in our heavier soils. Sugarbeets need the soil temperature to warm quickly in the spring, and having too much residue seems to be a limitation. We have not properly vetted strip-till to see if this gets us around that issue. There are challenges surrounding beet production and no-till, such as incorporating residual herbicides (which have become a must for fighting resistant weeds) and fertilizer. While building up fertility with manure has worked well in areas, we still have a large number of acres that cannot be reached by manure. We are far more convinced that the tillage reduction is a success on the sandy, irrigated soils.”

Hultgren explained whether he sees the potential for his work to be rewarded by private industry or the government: “Our farm has a business venture that deals in wetland credits. We build credit banks by converting marginal crop land into permanent wetland easements with the Minnesota Department of Natural Resources. We are using this environmental credit model to develop carbon credits and sell them on a secondary platform.

CONTINUED ON PAGE 16

CONTINUED FROM PAGE 15

We would rather see private industry buy these credits so that there is a more needbased market for them.

I am maintaining a healthy skepticism until we start seeing actual payments going to farmers. There are a lot of companies jumping on the bandwagon, and we don’t want to sign up for anything that doesn’t have a realistic and reliable compensation schedule attached to it.

“Whether I agree with the existence or urgency of addressing climate change or not, as regulatory bodies continue to squeeze businesses to offset their carbon footprint, we want to be ready to implement logical and effective practices to improve farm profit opportunities while also making sure that we are not hamstrung at the farm or cooperative level by these same climate regulations. We want to be out in front to be sure we can use carbon sequestration to keep running.”

Hultgren continued the discussion by addressing how his sustainability efforts have improved his bottom line or made his crops more resilient to weather issues: “Reducing tillage and overall trips across beet fields has saved us dollars on the expense side, and by pairing this with pattern drainage tile and using large tire and track harvesters and carts, we have been better able to deal with extremely wet conditions to get our beets harvested. While the jury is still out on whether we see any yield INCREASES from reduced tillage, the fact that we have not seen a DECREASE while reducing our inputs is encouraging. Plus, we realize the value of the soil moisture we maintain when very dry conditions occur. Wind is also a factor on the prairie, and by retaining some residue and using cover crops, we are able to retain the value of precious topsoil.”

When asked to describe past and potential future sustainability changes, he stated, “On a per-acre basis, our tractors and harvesters use 25% less fuel than they did a decade ago. In the case of seed and fertilizer, we have been using variable rate technology for 10 years and while this doesn’t typically cut the total usage, it places more of these expensive inputs in areas of the field with more of a yield ceiling while conserving them in places

with a low yield potential. In this end this is more efficient because we end up yielding more for the same input level.

“Of course, GE crop traits such as Roundup Ready beets were a huge addition to our portfolio, but even as weed resistance has crept in and RR isn’t the ‘catch-all’ herbicide it once was, new weed fighting technologies are emerging to help fight these resistant weeds and we will certainly embrace them. To me, using GE crops has been a no-brainer for our farm as we attempt to implement minimum tillage because they allow us to plant into higher-residue environments or no-till in some cases. And since we are able to control the weeds without stirring the soil, we release less carbon, preserve moisture, use less labor and fuel, and require less equipment.

When I started farming in 1999, a 22-ton beet crop was the norm … now we feel that our yield target should be closer to 30 tons per acre and we are doing this with the same amount of fuel, fertilizer, seed and labor. So, on a per-ton basis, today’s beet farmers have reduced resource consumption on by over one-third! Much of this change can be attributed to advancements in seed genetics and biotechnology.

“As we attempt to reduce herbicide use and increase its effectiveness, the use of smart sprayers and drones will help.

As labor gets harder to find, I think that automation in areas such as chemical and fertilizer application will need to evolve. Transportation of harvested crops could also have added automation, whether it be the carting in the field or even trucking to the receiving site. There is already some automation taking place at our beet co-op’s piling sites, and I only see that continuing there and in our factories.

“In order to protect our soil during the offseason (winter), we will need to develop ways to seed cover crops before harvest. Perhaps seed companies could develop a hearty, cold-weather germination winter wheat or rye variety that could be planted after bean harvest in October so that it gets established enough before freeze-up in order to hold soil during the winter.

Sugarbeets are shown being no-tilled into standing rye cover crop. The rye will be sprayed off once the beets emerge and provide soil and seedling protection. This rye was planted the September of the prior fall and provided soil cover over the winter as well.

These sugarbeets couldn’t be harvested due to freezing during 2019 at Hultgren Farms near Willmar, Minn. The beets were left in the ground and soybeans were planted directly between the rows the next spring, no tillage required. Contributed photos

“As nutrient application continues to be more and more regulated, the use of time-release and urase inhibitors will become more commonplace. We currently use a product called ESN (time-release urea) on our irrigated land to assure that nutrients aren’t washed through the soil by frequent irrigation.”

When asked what innovations the industry needs the most he responded, “I think that innovations that reduce labor requirements would be the most beneficial. Sugarbeets are a very laborintensive crop, and we will need to continue to utilize telemetry, GPS and robotics to lower the headcount of our harvest staff.”

“In order to be more efficient, seed genetics can continue to focus on pushing more sugar into the root so that we are bringing in more sugar versus every pound of non-sugars to make our factory run more efficiently and deliver a higher margin back to the grower. We have learned that economics work best when the fixed costs of our processing facilities are spread out over more pounds of sugar, and every ton of non-sugar adds to expense.

“I imagine that most farmers feel the same way as I do in that they would prefer not to spray more chemicals or apply more fertilizer if they can help it, so if I could wave a magic wand of innovation, it would be to have GE developments that augment fertility and continue to fight disease and weeds through plant traits.” Hultgren offered the following advice to fellow growers: “You are going to see a lot of players surfacing in the carbon market — at this point, focus your efforts and money on things that affect your bottom line on their own.

If you’re going to engage in a practice that uses someone else’s definition of sustainability, make sure there are well-defined timelines, expectations and most of all, that there’s a clear path to getting a payment that is profitable for you after jumping through all of the hoops.” He then described ways growers

Webco manufactures quality welded stainless steel specialty tubing products for evaporators, vacuum pans, juice pre-heaters and more

can better communicate their efforts: “At Hultgren Farms, we’ve found that engaging in frequent social media posts, a website and a newsletter hit several demographics that potentially care about what we’re doing.

CONTINUED ON PAGE 18

Welded Stainless TubingGradesmill test reports provided: A249-439, 249-304/304L, A249-316/316L

For moreinformation, please contact:

MikeJamison: 918-630-0982

mjamison@webcotube.com

Jerri Lauderdale: 918-241-1037

jlauderdale@webcotube.com

www.webcotube.com

LI ST ING# 15 592: 157. 35 AC RES M/ LINCAS SC OUNT Y, ND

15 6. 62 es ti mat ed FS Acroplandacr es car ry in gaP roduct ivi ty Indexof8 0.1.

Loca ted ju st sout hwes tofGra nd in ,N D.

LI ST ING# 15 607: 74 .05ACR ES M/ LINT RA IL LC OUNT Y, ND

74 .05 es ti m ated FS Acroplandacr es car ry ing aP roductiv it yI nd ex of 85.9

Loca ted af ew mi le ss ou th of Mayv ill e, ND.

LI ST ING# 15 59 0: 32 0ACR ES M/ LINCAS SC OUNT Y, ND*

Of fe re di nt wo se para te trac ts .2 95.1 FS Acroplandacr es car ry ing aP roduct ivi ty Indexof6 6. 2. Located jus twes tofA lice,N D. *Co-listed with JamesJensen of RE/MAX Now

CONTINUED FROM PAGE 17

Having a ready-made portal to subscribe outside parties to, whether they are friend or skeptic, makes it easy for you to be honest and open about what you’re doing on the farm to sustain your family’s legacy and take care of the land, water, crops and animals.

“We have also found that making our facility tour-ready at all times makes employees think more about the facility as they want to be proud of where they work. It enables us to tell our story to outside groups by letting them walk around and actually see what we do every day. It opens a lot of eyes, and once a skeptic sees that these are family operations, pouring their heart and soul into their family legacy, those attitudes can often be disarmed.

“This fall, we are planning a community picnic and inviting neighbors, landlords, family and friends to learn more about our sugarbeet operation and the other things we do here on our farm. Having this one-on-one face time with folks allows them to ask questions and better

understand who we are and what we do.” In describing additional education efforts, Hultgren said, “We have hosted political candidates and sitting members from federal and state offices here from both sides of the aisle to talk about farm issues. The chairman and ranking member of the U.S. House Ag Committee were here several times. It was important for them to see that in order to do business the right way, it requires more effort and financial investment and so maintaining strong farm programs for efficiency improvements that benefit the U.S. sustainability landscape as a whole are important. We let them know that when farmers are strong, their rural communities are strong as well.

“I think the most critical thing for the food supply chain to understand is that sustainability as they define it comes at a financial cost. As I discussed at the opening of this piece, farmers have no problem understanding how to be sustainable. But if food companies or the regulatory agencies connected to those food supply chains want to see something

specific implemented as a product feature or source, farmers are willing to do it but they’ll need to capture a premium for doing the extra work.”

When asked whether he has been able to change misconceptions he said, “The most vivid example I can think of is when we hosted a group of junior high kids from inner city St. Paul at our farm. These kids were so excited and in awe of our farm equipment and the amount of food we produce here … and they left with huge smiles on their faces. I think a bunch of them said as they were leaving that they wanted to be farmers someday! I could tell by the questions they were asking me that day that they had been fed several inaccuracies about how farms operate and it gave me a good feeling to be able to dispel those misconceptions.”

In closing, Hultgren said, “I am very fortunate to be a part of the sugar industry which is very unique. We do a lot of great things and I hope that growers will join me in telling of the story of how we are constantly trying to improve.”

David Kragnes farms near Felton, Minnesota

David Kragnes is a former board member and chairman of American Crystal Sugar Company, he currently serves on the CoBank Board of Directors.

The first tractor that I drove Was grey with axels red, Purchased new in ‘50 Or so my father said.

I wouldn’t know, I wasn’t there Till nineteen fifty two, Then a few years had to pass, With not much I could do.

The next tractor in our yard, A yellow Moline Z, With a Rumley in the trees, How colorful were we?

We added next a Cat on tracks, Not quite a color new, Close to Moline yellow, But a slightly different hue.

Our combine at the time was orange, Before Case went to red. Redlin wouldn’t paint our yard, Picasso might instead.

One day when an H showed up, In shiny IH red, I thought the time had come when Towards one color we would head.

A couple drills, a Vibrashank, It seems we had a trend. With a Massey combine We’re red from end to end.

But somehow that green tractor, There popping in our yard,

Began to win us over, Though color change is hard. Like the grass along the ditch, Or an algae bloom, The green spread out across the yard, And did the red consume.

Red never gave up easy, The lifter stayed to fight. And I’ve always tried to keep A red pickup in sight.

But green had taken over, There seemed no turning back. Everywhere you looked were Wheels of yellow, tires of black.

I felt I was a traitor, My father took it hard, The day that big red combine First showed up in my yard.

One day to scratch a burning itch I bought myself a Quad. I like it though sometimes it seems, A parts man’s gift from God.

They all break and they wear out, Though red or green or blue. Change the oil, grease the zerks, It’s all that you can do.

Over years I think I’ve learned, From parts men you can’t hide. Machinery, just like grass, Is greener on the other side.

DURA-PUMP EASY CADDY

• Can be mounted in 6 different configurations on a variety of tank/tote & drum types

• Use it mounted on top of tank or top of 55 gallon drum, on side of tank, or off the ground

• Conversion Kits are available to mount system on Monsanto & Snyder type tank

• Tank/tote not included

DURA-PUMP EASY CADDY WITH AUTO-BATCH SYSTEM

• Intuitive interface allows for the selection of manual or automatic operation with the flip of a switch

• Optimized for repeatable batching; returns to the last volume amount dispensed

• 100% moisture sealed circuitry

• Includes Dura-Meter and Dura-Pump

• Suction port has 2” Male NPT and 1” Female NPT

DURA-METER

• Made of impact resistant Lexan faceplate

• 100% moisture sealed circuitry

• Menu driven backlit display

• Plumbed both for in-line and 90 degree applications

DURA-PUMP

• High-Flow with up to 15GPM

• Self-priming diaphragm pump w/ internal by-pass

• Motor thermally protected from overheating

• 30 minute duty cycle

• Suction port has 2” Male NPT and 1” Female NPT

Every week, members of the Forx Roller Derby League team, the “Sugar Beaters,” meet up to practice. Recent temperatures in the 90s did not deter them from skating in the parking lot of the old medical school in Grand Forks.

The casual observer might think they were a group of women out roller-skating. However, a closer look at the extensive amount of padding they wear, including helmets, mouth and wrist guards, and knee and elbow pads, indicates something much more serious is about to go down.

The Sugar Beaters say they are nice people but that there is nothing “sweet” about roller derby.

“It’s a full-contact sport,” said head coach Jules Amundson. “Injuries happen. We get bruises and we’ve also had some head injuries, torn muscles and broken bones.” However, all 13 members of the Sugar Beaters say that the health benefits of physical activity and strong bonds of friendship far outweigh the risk of injury.

The Sugar Beaters are celebrating 11 years of roller derby this summer. They are the sole team within the Forx Roller Derby League, started in 2010 by Cheryl Lawsen and Kelly Grey. “We all wanted a name that would reflect this region. The sugarbeet industry is something that is really unique in this area. That’s why the

BY LAURA RUTHERFORD

BY LAURA RUTHERFORD

team is called the ‘Sugar Beaters,’ and the American Crystal Sugar Company has sponsored us from the very beginning,” said Amundson.

The team’s name and the names of the players reflect the one-of-a-kind culture of roller derby. Name selection is serious business because the name a player chooses will be their name for as long as they are a derby skater, and becomes their persona in the sport.

“We pick a name that is unique and individual, and shows attitude. It tends to be puns or plays on words, and expresses your personal interests,” said Jo No Mercy, 28, of Grand Forks. “Names are also a rite of passage. You get your name after you learn how to skate, learn the skills and understand the rules of roller derby.”

Roller derby prides itself on inclusivity, and any woman who is at least 18 years old is welcome to join the Sugar Beaters. According to Amundson, the only requirements are a sassy attitude, enthusiasm and a strong desire to learn.

New team members are referred to by the team as “fresh meat” or “sugar babies,” and must successfully pass Amundson’s six-week boot camp held in June and July. “‘Fresh Meat’ is level one.

You learn basic skills like standing, moving forward safely, falling the right way, and skating backwards,” said Mighty Mouse, 24, of Grand Forks. “Coach Jules decides when you have generally mastered all the skills and can pass this level. When I started the Fresh Meat boot camp, I had to take it twice in order to pass. When you pass, you get your derby name.”

Mighty Mouse and teammate Sky describe roller derby as having the

footwork of hockey combined with the speed of speedskating and the blocking of basketball. Roller derby is played on a flat, oval track, and matches are called “bouts.” The bout is broken up into two 30-minute periods, and those periods are broken up into units of play called “jams.” A jam can last from 10 seconds to two minutes, and there are 30 seconds between each jam.

Each jam starts with five players from each of the two teams playing. There is one “jammer,” who has a star on her helmet, and four “blockers.” There is one blocker with a stripe on her helmet, called a “pivot.” The blockers are collectively known as “the pack,” and skaters are not allowed to be more than 10 feet apart in a pack.

The jam begins with the players skating counterclockwise around the track. Each team’s jammer starts behind the pack and scores a point for each opposing blocker they pass on each lap. Points can only be scored by the jammers, who must get through the pack and then all the way around the track to be able to score.

CONTINUED ON PAGE 22

KB Manufacturing, LLC has designed a new aid for loading trucks, carts or other vessels with a primary purpose to more evenly place product for improved stability.

Light indicators provide dual signals to both the loader and loadee Every unit is measured with sonar prior to loading, establishing a customized center point A green light indicated optimal load zone. A red light indicates the load zone is too far out • System is designed to help reduce operator fatigue and allow more attention on proper harvestor settings

Wireless Direction Light KB-LINX (1 TRANSMITTER, 2 RECEIVERS)

FEATURES:

Transmitter runs off of a 9-volt battery Receiver powered by plugging into a cigarette lighter

Easily transfer from one piece of equipment to another Units are small and install in minutes

Visual light shows direction of movement desired

PRODUCT USES:

Loading trucks, grain carts,beet carts for harvest

Loading and unloading of railcars and trucks at elevators and warehouses

Communicate between two or more vehicles when visibility is obstructed

The opposing team’s main objective is to play defense and stop the other team’s jammer, while helping their own jammer make it around the track successfully. During a bout, blockers will play both offense and defense simultaneously. The team with the most points at the end of the bout wins.

Players always rotate between jams, because of the sheer physical effort required. “Each jam is like a sprint. Because of this, people from other teams called ‘foster players’ will come on to the team to play and help out,” said Mighty Mouse. “We’re all competitive and want to win, but we all love playing the game, and that is what always comes first.”

There are three to seven referees at each bout. Play that is unsafe or illegal will send a skater to the penalty box for 30 seconds of jam time, or result in expulsion from the bout. A typical practice for the Sugar Beaters consists of drills to build endurance and work on game strategies.

“We do planks and sprinting, which is the team’s least favorite activity. We’ll do 50 laps in a row, 20 minutes of sprints, and footwork drills. We also work on transitions, which is switching between skating forward and backward,” said Shernobyl, assistant coach of the Sugar Beaters. “During the last part of the practice, we do a scrimmage. On our team, every player learns every position. We go through the rulebook and enact every possible scenario, and the veterans help the beginners learn. We also spend a lot of time teaching new members the rules…so many rules.”

Shernobyl, 47, owns and operates

Mike’s Pizza and Pub in East Grand Forks with her husband. She joined the Sugar Beaters in 2016. “I was going through a time in my life when I just needed something new. I saw an ad for roller derby in the paper and then I saw the team practicing outdoors on the greenway. I just started seeing them everywhere,” she said.

Shernobyl said her favorite parts of roller derby are the friendships she has formed with teammates and the confidence she has developed from participating in the sport. “I had never skated before doing roller derby and am still learning all the skills. We surprise ourselves by what we

Lauracan learn to do. The confidence you get in roller derby carries over to all other parts of your life,” she said. “We all have busy schedules, but make time to practice. I also love the encouragement we give each other on and off the track.”

The Sugar Beaters are a diverse group who range in age from 19 to 47. Sky, originally from Fairbanks, Alaska, is currently working toward her doctoral degree in clinical psychology at the University of North Dakota. She is also very close to earning her roller derby name, which will be “Psycho Sis.”

Sky, a former middle school football player and collegiate volleyball player at Rocky Mountain College in Montana, said roller derby is an excellent way to relieve stress and find new friends. “It’s hard coming to a new state and making friends as an adult,” she said. “It’s a great way to meet people.”

The friendships are also what make the long drives to practices well worth it for blocker and third grade teacher Crash Bandicoot, 24, of Dazey, North Dakota. She is also part of Triple H Simmentals with her husband and his family in Hannaford, North Dakota, and fits in

skating between teaching and hauling hay. My teammate Rachael brought me to a practice last summer and I had so much fun that I kept coming back,” she said. “The whole team are nonjudgmental, supportive friends.”

Blocker Kitty Blockins, 29, of Grand Forks and jammer Artie, 30, of Hallock, Minnesota, are both busy moms who juggle roller derby with their kids’ schedules. “I love the physical activity. Roller derby is good for your mental health and it always makes me smile,” said Kitty Blockins, who works for Easter Seals and has two children in elementary school. “My younger kid wants to try skating, which is really exciting. I can’t wait to take the kids to a bout.”

Other Sugar Beaters include Rachael, a social work student, Thumper, a pilot, and Violet Tendencies, a veterinary assistant.

The Sugar Beaters are a lot like the plant they are named after. Many things have tried to “block” the sugarbeet crop this year, such as lack of rain and excessive heat. However, the sugarbeets skate around it and keep on rolling, just like the Sugar Beaters.

ADDABOOSTOFPOTASSIUM TO YOUR FORINCREASEDSUGARS&DROUGHT

Increasingsugar contentinsugarbeets hasalwaysbeena challenge forsugarbeet growers.Overthe past two years we have seenthe challengebecome easier to overcome. Theuseof Aqua-Yield® NanoK®onsugarbeetsduringotherspray applicationshasshown to increasesugar by asmuchas .75pointsin two years oftrial work in Elbow Lake,MN. Theproducerhasseen thisincrease by addingNanoK® to thespray tankwiththelast herbicideapplication andatleastoneor twoapplicationsduring Cercosporaspraying.Thehighly available nanoparticlesofpotassiumgetintothebeet leaves very quickly followingapplication becauseofthesmall parrticlesize. Potassiumhaslongshown to have apositive influenceonsugarin mostcropsincluding sugarbeets.

Increasingsugar contentinsugarbeets hasalwaysbeena challenge forsugarbeet growers.Overthe past two years we have seenthe challengebecome easier to overcome. Theuseof Aqua-Yield® NanoK®onsugarbeetsduringotherspray applicationshasshown to increasesugar by asmuchas .75pointsin two years oftrial work in Elbow Lake,MN. Theproducerhasseen thisincrease by addingNanoK® to thespray tankwiththelast herbicideapplication andatleastoneor twoapplicationsduring Cercosporaspraying.Thehighly available nanoparticlesofpotassiumgetintothebeet leaves very quickly followingapplication becauseofthesmall parrticlesize.

®

Potassiumhaslongshown to have apositive influenceonsugarin mostcropsincluding sugarbeets.

The payback for theproducer hasbeena $17 investmentanda returnper acre of over $100 forthe additional sugarharvest.

ADDABOOSTOFPOTASSIUM TO YOUR PROGRAM FORINCREASEDSUGARS&DROUGHT TOLERANCE

The payback for theproducer hasbeena $17 investmentanda returnper acre of over $100 forthe additional sugarharvest.

Increasingsugar contentinsugarbeets hasalwaysbeena challenge forsugarbeet growers.Overthe past two years we have seenthe challengebecome easier to overcome. Theuseof Aqua-Yield® NanoK®onsugarbeetsduringotherspray applicationshasshown to increasesugar by asmuchas .75pointsin two years oftrial work in Elbow Lake,MN. Theproducerhasseen thisincrease by addingNanoK® to thespray tankwiththelast herbicideapplication andatleastoneor twoapplicationsduring Cercosporaspraying.Thehighly available nanoparticlesofpotassiumgetintothebeet leaves very quickly followingapplication becauseofthesmall parrticlesize. Potassiumhaslongshown to have apositive influenceonsugarin mostcropsincluding sugarbeets.

$17 investmentanda returnper acre of over $100 forthe additional sugarharvest.

Callus for recommendationson how we can maximizesugarand your bottomline by usingNanoK®

Increasingsugar contentinsugarbeets hasalwaysbeena challenge growers.Overthe past two seenthe challengebecome easier to overcome. Theuseof NanoK®onsugarbeetsduringotherspray applicationshassh to increasesugar by asmuchas .75pointsin two years oftrial Elbow Lake,MN. Theproducerhasseen thisincrease by addingNanoK® to thespray tankwiththelast herbicideapplication andatleastoneor twoapplicationsduring Cercosporaspraying.Thehighly available nanoparticlesofpotassiumgetintothebeet leaves very quickly followingapplication becauseofthesmall parrticlesize.

Callus for recommendationson how we can maximizesugarand your bottomline by usingNanoK®.

Callus for recommendationson how we can maximizesugarand your bottomline by usingNanoK®

Potassiumhaslongshown to have apositive influenceonsugarin mostcropsincluding sugarbeets.

Callus for recommendationson how we can maximizesugarand your bottomline by usingNanoK®.

These days who doesn’t want more? More bang for your buck. More time for what matters most.

Seedex Sugarbeet Seed provides the top genetics with time-tested traits to help you get more out of your fields. It’s our way of helping make things just a little more sweet.

seedexseed.com | #hellosugar