5 minute read

A PASSION THAT GROWS

by agweek

Harvestisn’t alwayseasy. It’saprocess that requirespassiontopersevere. At SESVanderHave, we’re continuously workingtodevelopsugarbeetvarieties thatthrivedespitethepressuresfrom diseaseandthechallengesofnature sothat youcanendeachharveston ahigh-note.Becausesharingthe prideofsuccessstartswithsharing thepassiontoachieve it.

From 2000 to 2015, farmers got excellent control by applying two to four fungicide applications per year, depending on the farms’ locations.

One fungicide type is the “quinone outside inhibitors” (“QoI”), a fungicide that specifically stops the production of energy. The main QoI for sugarbeets has been “Headline,” a pyraclostrobin (from the strobilurin class of chemistry). Because of its high specific activity, it has been effective against target fungi. But Headline suddenly became ineffective.

“If you sprayed the field in 2016, and went back to that fields three to four weeks later, it started to turn brown,” Khan said.

The reason? Mutations. One mutation resulted in complete resistance to the QOI fungicides.

“All the fungus had to do was change an amino acid at one position (in its genes)for another — an alanine changed to guanine,” Khan explained. And that was that.

At the same time, it developed “reduced sensitivity” to another previously effective fungicide group — triazoles (also called “demetallization inhibitors”). This puts holes in the fungi’s cell membranes.

Khan started recommending using one new fungicide with another mode of action — “especially an older chemistry.” (The older fungicides are “multi-site” types, used since the 1970s.)

The most popular older fungicides were ethylenbisdithiocarbamates. The EBDCs included trade names Mancozeb and Penncozeb. Other old chemistry are known as “tins” — triphenyltin hydroxide (TPTH). The common “coppers” were copper hydroxide and copper oxychloride..

A $200M hit

The 2016 season was the warmest and wettest in the 121-year weather record history for Minnesota. This was good for growing beets but devastating if you had cercospora that had become resistant to the previously most-effective fungicides.

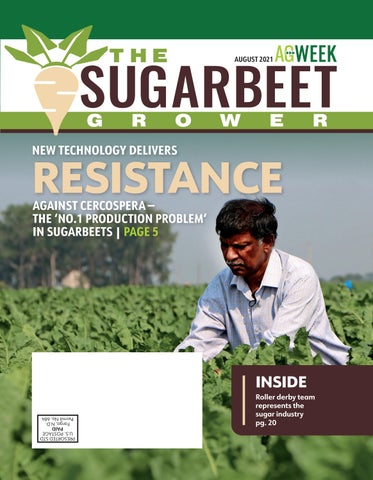

Mohamed Khan, a North Dakota State University and University of Minnesota sugarbeet specialist, says new “improved cercospora leaf resistant” beet varieties were used on 60% of Minn-Dak Farmers Cooperative acres and 15% of Southern Minnesota Beet Sugar Co-op, and should be available to most growers nationwide in two to three years. Photo taken July 16, 2021, at Foxhome, Minn.

“Because the best modes of action were no longer effective in 2016 our growers lost close to $200 million — less income to producers in North Dakota, Minnesota and Michigan,” Khan said.

From 2016 to 2020, growers in Southern Minnesota applied six to seven fungicide applications per year, always in mixtures, with mixed success, depending on the amount of rain.

QOI fungicides worked well until years like 2019 when repeated rains washed them off and they had to be reapplied. “The disease will overtake the plants. You will have low yields, very little to harvest,” he said.

In 2020, the southern Minnesota growers had effective disease control — nearly 30 tons per acre, with 17% sugar.

NDSU started urging seed companies to speed up work they already were doing to incorporate tolerance. The new cercospora improvements came through conventional breeding, not genetic modifications. KWS breeders had been finding strong cercospora tolerance in a broad range of wild beets.

K han and his research team inoculate plots to allow cooperatives to rate sugarbeet varieties for their cercospora leaf spot resistance. He also studies fungicides for their effectiveness, as well how they work in mixes and rotations.

Mike Metzger, vice president of agriculture for Minn-Dak Farmers Cooperative at Wahpeton, N.D., has had the new CR+ varieties in his company’s research plots for two years. He describes cercospora as the co-op’s “No. 1 production problem.”

Metzger said that 60% of seed planted by Minn-Dak Farmers Cooperative at Wahpeton this year were the improved cercospora-resistant sugarbeet varieties. Khan said about 15% of the crop for Southern Minnesota at Renville also also are the new varieties.

All of Minn-Dak’s members this year were offered an opportunity to buy the new seed, and Metzger estimates that 80% to 85% did. The new seed came at about a $40 per acre cost above the typical seed price, which ranges from $200 to $250 an acre.

“It’s going to offset three sprays,” which Metzger and Khan say is at about $25 to $30 per spray.

Metzger likened the new variety impact to the to “herd immunity” when it comes to COVID-19. Going to resistant varieties could drastically reduce the amount of fungus over a two-or three-year period.

“We don’t have to worry about that massive cercospora cloud hanging over our head. It gives us a chance to take a breath, hit the reset button,” he said.

Khan said the new cercospora-tolerant varieties appear to have tonnage yield comparable to approved sensitive varieties. The sugar concentration may be a little lower. “But overall the recoverable sucrose is as good as the other varieties we’ve had,” he said.

He said other seed companies (Crystal Beet Seeds, SESVanderHave, Hilleshog and Maribo) also are working toward commercializing resistant varieties.

While the cercospora-resistant varieties so far have come through conventional breeding, Khan said the industry is looking at developing other traits through genetic modification. Some on the horizon include triple-stack resistance to glyphosate (Roundup) glufosinate (Liberty) and dicamba perhaps in 2025 or 2026. The only sugarbeet GMOs now approved for use are for Roundup (glyphosate) resistance.

Research plots

Khan and his technicians in late June intentionally inoculate the entire site with cercospora leaf spot disease, accumulated from infected leaves from growers’ fields the previous year, mixed with a talcum powder.

Also, Khan’s larger job is to determine which fungicides are effective in combating the disease.

The researchers apply the fungicides in applications in 10- to 14-day intervals six applications across the entire season from late June into September. Khan applies the combinations to beets with varying levels of cercospora resistance. Those include varieties more susceptible than the “conventional, susceptible” growers would normally use.

“If something is working in my research site, it will work in a grower’s field,” he said.

Part of Khan’s research is using fungicides with the improved varieties to see if he can reduce the fungicide applications and still get high yields. In some of the improved varieties he thinks he can use as few as one — or zero — applications in some years.

In the end, the samples are analyzed at an American Crystal Sugar Co. tare laboratory at East Grand Forks, Minn.

“We do calendar sprays — for growers who don’t want to scout,” he said. “If they want good yields they’ll probably have to

Cercospora first attacks the oldest leaves, which produce the most sugar. The disease doesn’t hit younger leaves until late in the season. Those who scout do so based on leaf spots and daily infection values, some relying on scouts or consultants to determine disease severity and the best time to apply fungicides.

In a related study at the research plots, Khan is working with drones to aerially collect images to determine the amount of “brownness” that would indicate an infestation. That will be correlated to infestation data on the ground, and eventually cut the time and cost of scouting fields.

If the drone technology proves itself, Khan is working with an engineering colleague at NDSU to develop a sensor for agriculture that is also usable for detecting weeds, both in sugarbeets and other crops.

The site has a plot tour on Aug. 24, 2021.

SER VICE Save time and maximize profit

Michigan Mike, 1-810-705-0297

Idaho Kent, 1-208-280-0079

Nebraska 21 st Century Equipment

Minnesota

Award-winning 35 & 40 ton capacity & 40 ton BIG BEAR www.r opan ortha merica.com info@r opanorth america .com Nor th America

Midwest Machinery Co.