Fieldays 2025: A Snapshot of New Zealand’s Premier Agricultural Event

TECHNOLOGY

Record cotton crop in WA’s far north benefits from attributes of high-performing Case IH planter

Fieldays 2025: A Snapshot of New Zealand’s Premier Agricultural Event

Record cotton crop in WA’s far north benefits from attributes of high-performing Case IH planter

DESIGNED BY FARMERS FOR FARMERS

The Massey Ferguson 8S Series was born from 8 years of interviews with hundreds of farmers all over the world to understand what they wanted.

MULTI AWARD WINNER

The MF 8S has won awards all over the world, including the prestigious AE50 Award and the Farm Machine Award for tractors in the 180hp to 400hp category.

100% CONNECTED

Free 5 year MF Telemetry Connect and optional precision farming suite for maximum uptime.

THE EFFICIENCY OF DYNA-7 AND DYNA-VT TRANSMISSIONS

Power to the ground where you need it most. Plus 25% increased efficiency and 5% better fuel economy.

THE ULTIMATE CAB ENVIRONMENT

Insulated from noise heat and vibration the MF 8S cab is one of the quietest on the market with just 68dB noise rating.

OUTSTANDING VISIBILITY

With 6.3m3 of glass area in cab and the slopping bonnet design further enhances the forward view.

From the Editor: Balanced progress for land and trade

Dairy sector 2025 People Expo: ‘focus on what you can control’ - economist

Nick Fisher appointed as the new chair of Meet the Need

Pöttinger celebrates 50 years of arable farming

Sir William Gallagher’s vision and legacy honoured with National Fieldays Life Membership

Building a sustainable future, the next step in farm plastic recycling

Gallagher takes full control of its European markets with acquisition of Gallagher Europe B.V.

IH partners with Meet the Need to support Aotearoa

study tour opens new doors for Harri Moss

Farming can help nature thrive and vice versa

Freeing the great outdoors from health and safety scope creep

Reducing the weed seed burden at harvest

Innovation through tradition: Amazone-Werke honoured again

Record cotton crop in WA’s far north benefits from attributes of high-performing Case IH planter

Ptx Trimble’s Nav-960 sets new standard for precision farming

Knowledge is (also) power

Mitas enhances HC2000 tyre range with advanced PFO technology

Grounded in growth: the Molloy agriculture story

Rooted in the land, driven by purpose

Across the Ditch: Derrick and Kerry Barnes - taking the heat out of volatile crops

40 Special feature: Fieldays 2025: A snapshot of New Zealand’s premier agricultural event 52 A review of tractors 90hp+ EQUIPMENT

64 Canterbury farmer reclaims farm life with spreader upgrade

SaMASZ has spoken: NZ in top 5

Award-winning precision:

Fendt 620 Vario takes top honours

Editor Angus Kebbell 022 052 3268 angus@agrimedia.co.nz

Advertising Manager

Michael Lightbourne 021 403 853 michael@agrimedia.co.nz

Advertising Sales

Lisa Phelan 021 782 228 lisa@agrimedia.co.nz

Circulation

Hilary Armstrong 027 443 3477 admin@agrimedia.co.nz

Production Design and Layout

Hannah Kincaid art@agrimedia.co.nz

Contributors

Courtney Lee, Silja Kempinger, Heather Chalmers

Printed by Blueprint Ltd

Read our magazine online ruralcontractor.co.nz/read-online

Minister of Agriculture and Forestry Todd McClay has confirmed that long-anticipated restrictions on full farm-to-forest conversions for LUC 1–6 land will take effect from 4 December this year.

The introduction of enabling legislation this quarter signals a commitment to protecting our most productive farmland and safeguarding the future of food and fibre in New Zealand.

Many in the sector have voiced concern about the loss of prime sheep and beef country to carbon farming. The government’s announcement sends a clear message that while forestry remains a valuable part of our land use mix, it cannot come at the cost of core agricultural production. A cap on LUC 6 conversions, a moratorium on LUC 1–5 land entering the ETS for full forest conversion and a limit of 25 per cent forest planting on productive farms are pragmatic steps in the right direction.

Follow us facebook.com/nzrclsf instagram.com/nzrclsf ruralcontractor.co.nz

Scan here to sign up to our digital newsletter

PO Box 36753

Merivale, Christchurch 8146 ph 03 329 6555 www.agrimedia.co.nz

Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping, Australian AG Contractor & Large Scale Farmer, NZ Novachem Agrichemical Manual.

The inclusion of transitional measures for genuine afforestation investments already underway and exemptions for specific categories of Māori-owned land, reflect a balanced approach - one that acknowledges existing commitments while still setting a firm policy direction. After a period of uncertainty, rural communities should now have a measure of clarity and reassurance.

Minister McClay’s calendar has also been busy abroad and the results are beginning to show. The New Zealand–European Union Free Trade Agreement is already delivering significant gains. In just a year, our exports to the EU surged by 28 per cent - proof that well-negotiated trade deals can unlock real value for our primary producers. The jump in sheepmeat and kiwifruit exports and the doubling of machinery exports signal that New Zealand’s rural economy is ready to step up to global demand when given fair access.

The UK trade relationship is also gaining momentum. Just two years after the NZ–UK FTA came into force, we’ve seen a 21 per cent boost in exports. Dairy exports alone have jumped 139 per cent, fruit and nuts are up more than 50 per cent and even travel and tech-related services are

© RURAL CONTRACTOR AND LARGE SCALE FARMER - No part of this publication may be reproduced in any form without the prior written permission of the publisher. Opinions expressed in this publication are not necessarily that of the publisher and suggest independent advice be sought before acting on information or suggestions contained herein.

Angus Kebbell, editor.

growing. It’s good news and it couldn’t come at a better time.

In this issue, we showcase the 90hp+ tractor feature alongside our National Fieldays preview - an event that remains a cornerstone of the rural calendar and a celebration of all that is innovative, practical and forward-thinking in our industry.

Add to that a solid mix of news, opinion and insight across technology, contracting, agribusiness and you’ve got plenty to chew over as the winter season sets in.

As always, we aim to inform, provoke thought and, above all, reflect the reality of life on the land for our contractors and farmers.

Enjoy the read.

Contributions - Editorial and photographic contributions are welcomed and should be sent directly to AgriMedia Ltd. Editing of submissions is at the sole discretion of the editor and will accept no responsibility for unsolicited material.

New Zealand farmers are facing an increasingly unpredictable global environment, but economist Shamubeel Eaqub delivered a clear message at Waikato’s 2025 People Expo, hosted in April by DairyNZ and the Dairy Women’s Network: focus on what you can control.

“The world is changing rapidly and nothing can be taken for granted,” said Shamubeel, who delivered a thought-provoking keynote on the economic and political shifts shaping the future of dairy farming. “We’re moving into a new state of the world, one that is less predictable, more volatile, and fraught with challenges like rising protectionism, economic slowdowns, and geopolitical tensions. But history shows us that this isn’t unusual, it’s just different from what we’ve experienced over the last two decades.”

Despite global uncertainty, Shamubeel pointed to positive signs in New Zealand’s economic landscape. Interest rates are stabilising, and the current high milk payout is providing a cushion against challenges like drought. However, he urged farmers to be prepared for cost shocks and to strengthen their financial resilience by focusing on productivity in new ways.

“Productivity is not about how much milk we produce, it’s about how much money we make and what we can pay our people,”

Shamubeel explained. “Farmers are businesspeople first. Profitability and wages are the true measures of success.”

Eaqub highlighted the rise of protectionism, drawing comparisons to the 1930s when tariffs disrupted global trade. He noted that future government policies, both in New Zealand and internationally, are likely to be erratic, with political cycles becoming shorter and more polarised. “We’ll see more one-term governments undoing each other’s work, making long-term planning harder for businesses,” he warned.

Climate policy shifts, trade disruptions and evolving social expectations also pose challenges for the dairy sector. “We used to take things like open trade and economic growth for granted. That’s no longer the case,” Shamubeel said. “Our supply chains will become less reliable, and we’ll need to work harder to maintain our social licence.”

While dairy remains a pillar of the New Zealand economy, consumer habits are shifting. In 2007, 90% of households bought milk weekly; today that number has dropped

to 50%. Additionally, 40% of New Zealanders due to affordability concerns, are not buying fresh food weekly and a quarter of the population sometimes skips meals due to cost.

“If we want to keep our social licence, we need to stay connected to consumers,” Shamubeel cautioned. “Dairy still has a strong public perception; around 65% of Kiwis hold a positive view but that could change if we don’t engage with the reality of rising food insecurity.”

On the farm, retention of skilled workers is becoming increasingly critical. With New Zealand’s core working-age population shrinking and net migration slowing, Shamubeel stressed the importance of investing in people. “Retention is where you get the biggest gains. The more people you can keep the stronger your business will be,” he said.

He encouraged farmers to focus on leadership and workplace culture, as well as ongoing training. “Technical skills are important, but future success will depend on communication, teamwork, problem-solving and critical thinking. If we know these skills will be vital in ten years, why not prioritise them now?”

Despite the challenges ahead, Shamubeel remains hopeful about New Zealand’s agricultural future. “We are more diversified than ever before. We have land, water and a climate well-suited to farming. We remain a successful farming nation and we will for a long time to come.”

Encouragingly, signs of economic recovery are emerging. Business investment is starting to pick up, lending conditions are improving and consumer confidence is slowly returning. “Hope is coming back,” Shamubeel said. “We’re going to have a good couple of years.”

However, he urged farmers to take a proactive approach: “Prepare for volatility, focus on your business fundamentals, invest in your people and adapt to the changing world. The more resilient and forwardthinking we are, the better positioned we’ll be for the future.”

Meet the Need, New Zealand’s farmerled food charity, has announced the appointment of Nick Fisher as its new Chair.

With a strong background in the meat industry and rural media, Nick brings a wealth of experience and a deep commitment to tackling food insecurity across the country.

Nick takes over from Julia Jones, a founding board member of Meet the Need who has proudly served as Chair for the past four years and who is stepping into a new role as General Manager of Agri-Women’s Development Trust (AWDT).

“ Outgoing Chair Julia Jones is proud to see a strong succession within the board, ensuring continued leadership and momentum for the charity.” Originally from Dunedin, Nick’s family founded Fishers Meats in 1915, giving him a lifelong connection to the agricultural sector. Nick transitioned into radio advertising in 2008, eventually becoming Head of Rural at MediaWorks, where he built strong industry relationships.

He joined the Meet the Need Board in April 2023.

“One of the reasons I joined Meet the Need is that I understood at a deeply personal level

that you never know when you’re going to need support,” says Nick.

“When our family business closed, I went from being a managing director of a large family business to having no job or income. You just don’t know what’s around the corner. Meet the Need gives us the ability to help those who need it most at an incredibly difficult and stressful time,” says Nick.

Nick sees public awareness as a key opportunity for Meet the Need.

“Not everyone knows who we are yet, despite the great work we do,” he explains.

“My goal is to use my network to help grow awareness of what we do and how we do it.”

He acknowledges the tireless work of Meet the Need’s co-founders, and outgoing Chair, Julia Jones, who has devoted four years to building Meet the Need into what it is today.

“Julia was an effective Chair who brought incredible energy and drive for outcomes to her role – we will miss her greatly,” says Nick.

“It’s an honour to take on this role and carry the charity into its next exciting phase. Our current Board Greg McSkimming, Cheyenne Wilson, Nicki Mackay, Shaheen Junge and Jo Hay – bring together a diverse set of skills and high capability, united by our vision that no one should go hungry or

New Chair Nick Fisher brings industry insight and personal experience to Meet the Need, aiming to grow awareness and ensure no Kiwi goes hungry.

malnourished in New Zealand.”

Nick urges farmers and supporters to remember that food insecurity isn’t always visible. “You don’t know who needs a little extra help putting dinner on the table,” he says. “It could be your neighbour, someone at your school, or a member of your community who needs access to nutritious food. The ability to provide quality protein to those in need is absolutely vital.

“Our responsibility is to ensure our longevity. I’d love for Meet the Need to still be here in 100 years, thriving and making an impact.”

Half a century of expertise in tillage and seed drill technology.

Pöttinger Landtechnik GmbH entered the arable farming technology market in 1975 following the acquisition of the Bayerische Pflugfabrik (“Bavarian plough factory”) in Landsberg Germany. Fifty years and countless innovations later, the family-owned business based in Grieskirchen, upper Austria, continues to deliver impressive results in grassland digital agriculture, tillage and seed drill technologies. Gregor Dietachmayr, speaker of the executive board, emphasises the strategic importance of the arable segment: “This dynamic market offers numerous opportunities and possibilities, which naturally we are making full use of. We are working intensively on the continuous development of our arable farming technologies for the success of our customers, and for the long-term success of the company.”

Founded in 1891, the Bayerische Pflugfabrik was one of the oldest manufacturers of soil preparation implements in Germany. With the 1975 acquisition, the Austrian manufacturer gained 85 years of experience along with valuable expertise in developing high-quality machinery for arable operations. Over the following decades the company introduced several notable innovations, including the

Servo generation of ploughs (1988), the rugged Lion power harrows (1991) and the Synkro linkage-mounted stubble cultivator.

In 2001, the business took over the Rabe seed drill plant in Bernburg Saxony-Anhalt, marking its entry into seed drill technology. This expansion brought mechanical, pneumatic and mulch seed drills into the product portfolio. More innovations followed, such as the Terradisc compact disc harrow (2003) and the next generation of Terrasem mulch seed drills (2004), both of which helped set new standards in tillage and sowing. In 2005 the three-row Synkro stubble cultivator was introduced, suitable for both shallow and deep tillage. The Vitaseem mechanical seed drill range was updated in 2011 with improved metering and placement for precision sowing. The Terrasem drill was upgraded in 2012 to support direct fertilisation and in 2013, the new generation of Aerosem pneumatic seed drills was named ‘Machine of the Year.’ The Terria stubble cultivator followed in 2020 and in 2021, crop care equipment such as rotary hoes row crop cultivators and tine harrows

Pöttinger marks 50 years in arable farming innovation, celebrating a legacy of ploughs, precision drills and smart soil technology since 1975.

were added to the range.

In 2022, the manufacturer acquired MaterMacc based in San Vito al Tagliamento in northern Italy. Known for its expertise in precision planting, mechanical and pneumatic seed drills, crop care machines and OEM components the Italian firm proved a perfect fit in terms of products, people and passion for agriculture. That same year the Amico flexible front hopper was added to the lineup. In 2024, the Plano became the first shallow cultivator in the company’s range. The anniversary year 2025 will be marked by a series of events, retrospectives and special offers on arable equipment, crop care machines, grassland tools and digital farming technologies. A dedicated anniversary website at www.poettinger.at/ go/50years-arablefarming will offer insights, stories and a look to the future.

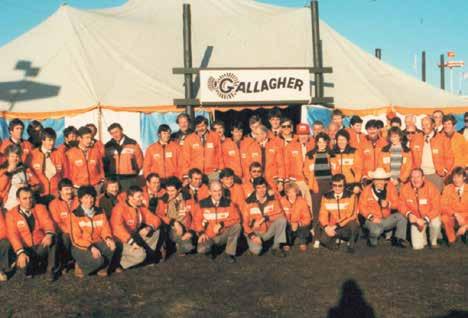

Sir William Gallagher has been awarded a National Fieldays Life Membership in recognition of his decades-long contribution to the event and New Zealand’s agri-tech industry.

He has been a part of Fieldays since its inception, playing a pivotal role in its foundation alongside other influential farmers in New Zealand.

Gallagher’s presence at the very first Fieldays in Te Rapa in 1969 was a milestone moment, as the company was already emerging as a leader in farm technology and export markets. Sir William, alongside his brother John, had been exhibiting at agricultural field days in Australia before 1968 and was an early advocate for establishing a national event in New Zealand.

A champion of agricultural innovation, Sir William has been instrumental in Gallagher’s success at Fieldays, using the event as a platform to introduce worldfirst products, engage with farmers and showcase the company’s latest technological advancements.

“Fieldays has been an important part of Gallagher’s journey,” says Sir William. “It has always been a place for us to connect with farmers, showcase new developments, and contribute to the growth of our farming sector. Receiving this recognition from the Fieldays Society is truly an honour.

“Our long-standing partnership with Fieldays goes beyond exhibiting,” says Sir William. “It’s a place and a community of people dedicated to fostering new ideas, supporting the primary sector and shaping

Sir William Gallagher has been honoured with a National Fieldays Life Membership, recognising his visionary leadership and unwavering support since the event’s founding in 1969.

the future of farming in New Zealand. It is something truly special.”

Over the years, Gallagher has launched numerous breakthrough products at Fieldays, won multiple innovation awards and used the event to gain valuable farmer feedback to make sure that new solutions met farmers’ needs.

“Having the support of an innovative company like Gallagher from the very beginning played a key role in laying a strong foundation for Fieldays,” says National Fieldays Society Chair Jenni Vernon.

“Sir William has consistently demonstrated visionary leadership - bringing together talented teams and maintaining a clear focus on progress within the industry. Even during challenging times, Gallagher remained

committed to investing in new technologies, fostering a steady stream of fresh ideas. This life membership is a modest but heartfelt tribute to Sir William’s profound impact in helping shape Fieldays into the world-class event it is today.”

Fieldays Head of Customer & Strategic Engagement, Taryn Storey, says Sir William’s leadership has reinforced Fieldays’ reputation as a global hub for agri-tech.

“Through Gallagher, Sir William has helped position Fieldays as a premier stage for showcasing world-leading innovation,” says Taryn. “His ongoing support has helped attract international interest, turning Fieldays into a truly global agricultural event. We are hugely grateful for his incredible vision and support.”

Gallagher has supported and exhibited at Fieldays every year since its launchnever missing an event. The company is a staple presence, not just due to its large site but also through its iconic orange stock sticks, sold to support the Westpac Rescue Helicopter.

For two decades, Gallagher ran the legendary fence-building competitions at Fieldays, which became known as the ‘Olympics of Fencing’. The tradition remains a strong part of the event today, reflecting the values of practical skill, forward thinking and community that Fieldays embodies.

“I am incredibly proud of and grateful for this recognition and what it represents,” says Sir William. “The Gallagher team is always looking for new ways to innovate, adopt the latest technology and we will continue to work alongside Fieldays to set up Gallagher’s future at the event and support the future of farming.”

Profi-Flo Pick-up

Increase crop intake through more efficient crop flow, with a high-performance pick-up.

Adaptive Intake

The adaptive intake automatically adjusts for light and heavy crops to facilitate a smooth crop flow into the chamber.

Isobus Compatible

All McHale Fusion 4 Plus machines are ISOBUS compatible as standard

New Zealand’s agricultural sector is on the cusp of a significant shift in its approach to plastic waste management. The government has just closed public consultation on the proposed regulation of Agrecovery’s Farm Plastics Product Stewardship Scheme, a move that signals a step towards a nationwide, coordinated recycling system for farm plastics. This long-awaited development aims to streamline existing efforts and ensure that farmers and growers have access to a consistent and effective way to manage plastic waste on their properties.

Tony Wilson, Chief Executive of Agrecovery, sees this as a crucial milestone. “This is a positive and long-awaited step forward for the sector. New Zealand farmers and growers want recycling systems that are easy to use and fit for purpose. Regulation will give Agrecovery the tools to scale up services, expand access to recycling, and deliver a more consistent nationwide system for managing the

complexity of plastic use in farming today.”

The scheme’s first phase focuses on four key farm plastics: agrichemical containers and drums, bale wrap and silage sheet, small seed, feed, and fertiliser bags, and large grain and fertiliser bags. Over time, it is expected to expand to include additional materials such as netting, irrigation pipe and plant pots, ensuring a more comprehensive

Agrecovery Chief Executive Tony Wilson says New Zealand farmers and growers want recycling systems that are easy to use and fit for purpose.

solution for on-farm plastic waste. While Agrecovery has already been running voluntary recycling programmes for many of

these materials, regulation will provide the necessary framework to enhance and extend these services.

Farmers have long struggled with the challenge of plastic waste disposal, often resorting to burning or burying materials that have no viable recycling pathway. Anders Crofoot, Agrecovery Board Chair and a farmer himself, acknowledges the need for a more accessible system. “It’s great to see us moving closer to a regulated scheme that’s simple, free, and accessible for farmers to use. We know the demand is there—this is about making sure every farmer has access to a service that makes doing the right thing the easy thing.”

The government’s commitment to improving farm plastic waste management is evident in the backing of Environment Minister Penny Simmonds, who underscores the benefits of a streamlined approach. “The proposal—an industry-led initiative—would bring the existing Agrecovery and Plasback programmes into a single national recycling system, making services simpler and more accessible for all users of regulated farm plastics.”

Public consultation will shape the final regulations and ensure they meet the needs of those directly affected. The scheme, provisionally named Green-farms, is designed to work not only for farmers and growers but also for industries such as forestry, manufacturing, hospitality and tourism. Local authorities and households are also expected to benefit, as the initiative includes take-back services for pest and weed control product containers.

Simmonds emphasises the importance of collective responsibility. “Plastic products are vital to New Zealand’s world-leading agri-economy, but rural communities know that waste like agrichemical containers and bale wrap can quickly pile up. These regulations will provide a unified system where producers, sellers, and users take responsibility for the entire product lifecycle, from design to disposal.”

The government aims to ensure that the scheme reflects the needs of those who will be using it while reinforcing its commitment to environmental sustainability.

A significant boost to the initiative came with the accreditation of Agrecovery’s Greenfarms Product Stewardship Scheme (GPSS) under the Waste Minimisation Act (2008). This recognition reinforces the programme’s credibility and signals a broader industry commitment to sustainability.

“This is a landmark achievement not only for Agrecovery but for the entire New Zealand primary industry. Our accredited GPSS underscores our dedication to stewardship and sustainable practices, driven by the demands and cooperation of New Zealand’s farmers and growers. We’re looking forward to expanding our schemes and fostering innovation and collaboration to ensure a sustainable future for all,” says Tony.

With new regulations on the horizon, the agricultural sector is moving towards a unified, accessible recycling system that supports both environmental goals and on-farm efficiency.

The scheme will operate on a voluntary basis until regulations mandate participation. Under the proposed framework, those selling targeted farm plastics would contribute levies to fund a free nationwide collection network, ensuring that all farmers and growers can access recycling services without financial barriers.

Industry leaders have welcomed the accreditation, recognising its potential to drive sustainable farming practices. Nadine Tunley, CEO of Horticulture New Zealand, says Tony. “The GPSS is a game-changer for our industry and will enable growers to recycle a more diverse range of plastic packaging. It is an example of the necessity of operational coordination and cost-sharing to manage the collection and treatment of farm plastics to improve the sustainability of our sector.”

Dr David Burger, DairyNZ’s General Manager of Farm Solutions and Policy, underscores the value of a structured recycling system. “New Zealand dairy farmers are committed to reducing their environmental footprint, including minimising plastic waste. The GPSS offers a solution to enable our farmers to progress further along this journey.”

Agrecovery’s vision extends beyond the initial scope of the scheme. Plans are already

in place to expand its reach over the next two to seven years, bringing more farm plastics into the recycling framework. This phased approach is designed to address the evolving needs of the agricultural sector and respond to feedback from farmers and growers.

Tony reinforces the long-term ambition of the programme. “The GPSS is a purposedriven solution to elevate New Zealand as a world leader in sustainable agricultural practices and represents a significant step forward towards a circular future led by innovation and purpose.”

Farmers and growers across New Zealand now have the opportunity to shape the future of farm plastic waste management. With a regulated scheme on the horizon, the industry has a chance to move beyond ad-hoc solutions and towards a system that works for everyone. As Anders puts it, “This is about making sure every farmer has access to a service that makes doing the right thing the easy thing.”

The next step is clear: farmers, industry stakeholders and rural communities need to engage in the consultation process to ensure the final framework meets their needs. With regulation on the way, the opportunity to build a future-focused, nationwide recycling system is within reach.

Gallagher Group is accelerating its commercial expansion across the European region with its acquisition of the Dijkstra family’s shareholding of Gallagher Europe, an agritech business headquartered in Groningen, Netherlands.

For nearly 50 years, the Dijkstra family has led Gallagher Europe, helping grow the brand into a trusted name across the continent. The agreement for Gallagher to acquire the Dijkstras’ shareholding was completed on 31 March 2025, welcoming the team of around 130 people into the global Gallagher Group.

Gallagher Europe has offices in the Netherlands, UK and Switzerland, with in-market teams based in France, Belgium, Austria, Germany, Italy, Denmark and Sweden. The team has strong distribution partnerships in Ireland, Spain, Iceland and Hungary and sells its solutions in every country in Europe.

The Dijkstra family says, “We are grateful for everything we have achieved together. We look back on a remarkable journey, with a dedicated team, loyal partners and a shared mission to make the agricultural sector safer and more future-proofed. With confidence, we pass the baton to the Gallagher Group. Together we have built the European market over many years, and we

are certain that they – along with the current team – will continue the culture, ambition, core values and vision.”

Gallagher’s Group Chief Executive Officer and Executive Director, Kahl Betham, based in New Zealand, says the Gallagher Group is proud to continue the legacy. “Over several generations, the Dijkstra family has built a strong business. We are committed to honouring that legacy and building on it to unlock even greater potential for the Gallagher Europe team, our customers and the wider farming and agriculture community.

“Owning our market distribution is a key part of our strategy, demonstrated through the acquisitions of Gallagher North America and the Australian Animal Management business in 2009 and 2011,” Kahl says.

Gallagher Animal Management Chief Executive Lisbeth Jacobs adds, “We have established many strong partnerships and made substantial investments in recent years to expand our portfolio of higher tech solutions and increase our geographic footprint. I’m looking forward to working with our European team to understand the nuances of their business and unique needs of their market.

“We believe this acquisition will allow us to grow our European business substantially, both in our core products and our portfolio of high-tech connected solutions, including eShepherd. The European market is one

Gallagher’s Group Chief Executive Officer and Executive Director, Kahl Betham.

where we see significant evolution and opportunity for growth, particularly as it undergoes changes driven by evolving regulations and shifting customer needs.” Customers are increasingly seeking intelligent, digital solutions to streamline their operations. The Gallagher ecosystem addresses these evolving needs through groundbreaking innovations in virtual fencing, liquid monitoring and remote paddock weighing systems. These solutions tackle the most pressing challenges customers face today. They strengthen their financial performance, deliver meaningful benefits to their quality of life and protect the natural environments they manage.

“This acquisition represents a pivotal moment in Gallagher’s European journey,” adds Lisbeth.

“By bringing together our innovative technology with deep local market expertise, we’re uniquely positioned to help European customers navigate changing regulations and embrace digital transformation. “We’re excited to build on the strong foundation the Dijkstra family established and write the next chapter of Gallagher’s success story in Europe.”

The move strengthens Gallagher’s ability to deliver high-tech agritech solutions across Europe, building on nearly 50 years of partnership with the Dijkstra family.

Whatever your needs, Valtra has the working machine – made for you! Whether it’s the compact tractor that packs a powerful punch – the mighty little A Series, the gutsy all-rounder ready for any job – the G Series, the capable and award-winning N Series, the brains, brawn and beauty of the T Series, the smart and powerful Q Series, all the way through to the big new farm boss – the powerful and reliable S6, there’s a Valtra with your name on it!

Valtra tractors combine versatile features and innovative technology, with outstanding comfort in every model across the range. As a Valtra owner, you benefit from a reliable, high-quality tractor, that has been tailored to meet the needs of your farm or contracting business. Put simply, Valtra has the working machine – made for you!

TALK TO YOUR VALTRA DEALER FOR MORE INFO TODAY.

As part of the initiative, $50 from the sale of every new Case IH tractor in New Zealand will be donated to Meet the Need, helping provide meals to families in need through local food banks and community groups.

Founded by farmers for communities, Meet the Need offers a practical way for the primary sector to give back - donating livestock, milk, or funds to deliver nutritious, protein-rich meals where they are needed most. Since launching in 2020, Meet the Need has already provided over 2.3 million meals to more than 130 food banks and community groups nationwide.

Meet the Need General Manager Zellara Holden said the partnership highlights a shared commitment to community support and helping those in need.

“Case IH is a brand we are proud to be associated with,” Zellara said.

“This sponsorship directly supports our mission - getting quality food onto Kiwi tables. When businesses like Case IH stand behind us, it helps create real, lasting change.

“Together, we can help build a better tomorrow for families across Aotearoa.”

Case IH Business Director – Agriculture ANZ, Aaron Bett, said the partnership was a natural extension of the brand’s longstanding commitment to rural New Zealand.

“As a brand deeply rooted in New Zealand’s rural communities, we believe in showing up for the people who support us,” Aaron said.

“Farmers are already doing so much to support their communities, and this is one more way we can stand alongside themsupporting a practical, farmer-led solution that’s making a real difference.”

With the partnership now underway, every new Case IH tractor sold in New Zealand will

Every new Case IH tractor sold in New Zealand now helps put meals on Kiwi tables, thanks to a partnership with farmer-led charity Meet the Need.

help nourish a Kiwi family - while the wider Case IH team continues to fundraise and advocate for a more food-secure future.

For more information, visit www. meettheneed.org.nz.

Profitability is an increasing concern for arable farmers, which is why the Foundation for Arable Research has chosen it as the theme of its 2025 conference.

Under the banner ‘Show me the money’ a range of international and local speakers as well as FAR staff will outline ways farmers can potentially reduce costs, improve productivity, diversify into additional income streams and adopt new tools and technologies.

The biennial event is being held at Lincoln University on Monday 30 June and Tuesday 1 July.

FAR Communications Manager Anna Heslop says that when organising the conference, FAR considered the key concerns that are front-of-mind for farmers. Regular feedback from growers is that Increasing input costs, flat crop contract prices, increased regulatory compliance and extreme weather events continue to challenge their profitability.

The conference keynote speaker is New Zealand’s Special Agricultural Trade Envoy and Methven arable farmer Hamish Marr.

Discussing how to make technology pay will be James Venning, a grain grower from the Yorke Peninsula in South Australia. Farming over varying soil types, he uses a wide range of technologies to aid in decision making and to micromanage areas in his cropping programme focussing on productivity, efficiency and cost effectiveness.

As well as the day to day running of Barunga Grains, James chairs his local grower group Northern Sustainable Soils, is a board member of the Hart Field Site Group and is a grower director of Grain Producers South Australia. Another speaker, United Kingdom arable farmer, entrepreneur and popular YouTuber Olly ‘Blogs’ Harrison left school at 16 having

struggled with dyslexia. Since then, he has grown his farm from 70 to 600 hectares. His farming business has 14 different income streams including dog walking fields, chipping wood for biomass, sunflower mazes, and office and holiday rentals.

He’s always seeking new ways to commercially exploit his land and assets.

Olly will be outlining his farming journey via video link.

Professor Nicola Randall, the founding director of the Centre for Evidence Based Agriculture at Harper Adams University in England will also appear via video link to discuss whether regenerative agricultural systems add value.

Farmer discussion panels will provide examples of the different approaches and technologies that growers are adopting to improve their farm business performance.

A conference dinner will double as a farewell to FAR chief executive Dr Alison Stewart, who steps down at the end of June.

Anna Heslop says that, as always, prices for the event have been pared back to the absolute minimum, with early bird pricing sitting at $220 for two-day attendance. Early bird

registrations close on 19 May, when the price goes up to $320.

To register for the conference, visit the FAR website, www.far. org.nz.

South Australian grain grower James Venning will discuss how to make technology pay.

With this season now ended, it’s time to put some thought into next seasons staffing.

Hanzon Jobs are currently interviewing. We have started to place drivers already.

If you are interested and would like to secure staff for this coming season, please get in touch, or register via www.hanzonjobs.co.nz/get-staff.

For more information please email us at work@hanzonjobs.co.nz

Hanzon Jobs will be back from the UK and in office from the 1st of July.

Harri Moss recently had the incredible opportunity to participate in a study tour to Nufarm and Croplands in Melbourne and Adelaide Australia, thanks to winning the Nufarm/RCNZ Spray Applicator Award for 2024. It was a fascinating experience, one he thoroughly enjoyed and learned a lot from.

The study tour, which Nufarm helped organise, was divided into two parts. The first focused on crop protection products and the technology behind their manufacture, while the second covered practical application technologies with Croplands in Adelaide.

There was so much to see and absorb throughout the week, but Harri captured a few of the key highlights from those few days. After arriving on the first day, he was given an introduction to the Australian crop protection market and how Nufarm engages with its customers from a marketing perspective. This was particularly useful, as SprayLink is exploring new ways to interact with and support its own customers. David RyanANZ Customer Marketing Lead shared some valuable insights, especially the idea that “keeping it simple wins every time, bullet points, clear benefits and links if people want to dig deeper”. It prompted Harri to think about how they could simplify and

strengthen their communication strategy.

One surprise was discovering the full extent of Nufarm’s seed business, formerly known as Nuseed. The innovation in new varieties was impressive, particularly their work with Omega-3 production and using grain as a base for aviation biofuel. It was eye-opening to see these kinds of technologies being integrated into agriculture. As one of the team explained, “It’s not just about protecting crops anymore, it’s about adding value at every step.”

A real highlight was the tour of the manufacturing plant and laboratory. Seeing the differences in production between various products like glyphosate and phenoxies - was incredibly interesting. With so much complex chemistry involved, it was a lot to take in.

One of the plants even looked like “an oversized whiskey distillery”, which made for a good laugh. What stood out most was the sheer attention to detail in testing

formulations. The team walked Harri through some practical mixing and compatibility tests and explained how these can vary widely between industry products. Their comment — “A good mix on paper can still be a bad mix in the tank”— stuck with him.

The visit to Croplands in Adelaide really stood out, especially given the work Harri and his team do day-to-day. Seeing some of the large selfpropelled rigs in action, along with the latest ‘Brown-on-Brown’ and ‘Green-on-Green’ optical spot spraying technology, was incredible. Watching it operate up close, he could immediately

see the potential for adapting some of this tech back home.

One of the team members joked about their workshop nickname, ‘Big Fridge’, written on a sign above one of the bays. That kind of camaraderie was great to see and added to the atmosphere of innovation and passion. It’s exciting to think about how they might one day integrate Greenon-Green tech into their trucks in New Zealand.

Overall, the study tour was an unforgettable experience that gave Harri valuable insights and knowledge. He remains incredibly grateful to RCNZ, Nufarm and Croplands for the opportunity.

Here’s how farmers can dig into practices that make economic sense but also contribute to biodiversity. Many farmers are already tapping into innovative resources, actively sowing the seeds of positive change for on-farm biodiversity.

Breaking ground together

Expecting farmers to do it on their own simply won’t work.

So, Farming with Native Biodiversity has undertaken comprehensive research and experiments to uncover economically viable farming practices that help biodiversity.

Managed by NZ Landcare Trust, the Farming with Native Biodiversity website is a gateway to inspiration. It showcases real-life examples of farm biodiversity plans customised for sheep and beef farms across the North and South Islands.

From engaging training modules, webinars, podcasts and videos to a comprehensive resource collection, it caters to farmers and advisors at every stage of integrating on-farm native biodiversity.

Topics range from ‘Biodiversity 101’, ‘Managing regenerating remnants’ to ‘Healthy Waterways’.

With half of New Zealand’s land cover used for pastoral farming, the advantages of protecting and enhancing farm biodiversity are undeniable.

It helps native species, obviously.

But it helps farmers by providing pollination for crops, enhancing water quality, reducing soil erosion and improving aesthetic values.

However, the reality is that farms are complex businesses and farm biodiversity and ecosystem management plans can be costly, with additional costs to implement.

Expert advice and resources take time to find and digest.

Who’s behind it all?

The pilot project, born out of the Biological Heritage National Science Challenge, aims to help a new farming era emerge. “Protecting and enhancing biodiversity should be a normal part of being a farmer, not something special or an extra task done at the end of the day.”

A 2021 study of 500 sheep and beef farmers around the country revealed that most farmers perceive many advantages in maintaining native biodiversity, primarily social and environmental.

The most frequently cited disadvantages were cost and time, which were also the barriers to managing biodiversity.

These barriers inform the resources offered. They are practical and technical, enabling the

Projects like Farming with Native Biodiversity are helping farmers balance economic goals with practical steps to restore native ecosystems on working farms.

farming community to take meaningful action on their land.

A case in point: farming with biodiversity on a sheep and beef farm in Canterbury

Hororata Farm, a 395-hectare sheep and beef breeding farm focusing on beef finishing, is redefining what’s possible.

The farm’s owners have set their sights on a future where habitat patches are restored to native vegetation, attracting native bird species like korimako and tūi. While this might sound like a far-fetched dream in the

Workplace Relations and Safety Minister

Brooke van Velden is announcing further changes to health and safety as part of the ACT-National Coalition commitment to reform health and safety law and regulations.

“This reform refocuses the work health and safety system by getting rid of over compliance, making sure there’s less paperwork and giving businesses, employers and workers clarity on their health and safety responsibilities. We want all New Zealanders to return home safely after every working day,” says the Minister.

“For many Kiwis, outdoor recreational activities are a way of life that has been enjoyed for generations. Unfortunately, New Zealand’s work health and safety settings have reduced the appetite to allow these activities, inadvertently creating a culture of fear amongst landowners who are now worried about their legal liability if someone gets hurt.”

“Many landowners, managers, councils, farmers and iwi allow access to their land for recreational use out of sheer goodwill. I do not think it is reasonable or proportionate for landowners, managers and iwi to be

prosecuted by WorkSafe if someone was to be hurt or injured during the course of a recreational activity just because they are responsible for the land.”

The Minister announced on April 1 changes to the Health and Safety at Work Act that: “Clarifies the law for landowners and will free up private and public land for recreational use. Landowners will not be responsible if someone is injured on their land while doing recreational activities. Health and safety responsibilities will lie squarely on the organisation running the activities.

“For example, a farmer might worry they are responsible for the risks of a horse trekking business on their land. I am making it clear in the law that in this case the health and safety duties sit with the horse trekking business. The farmer would only need to consider the risks from their work where that work is happening in the immediate vicinity of the horse trekking. They are not responsible for risks of the recreational activity itself.

“We all know that recreational activities aren’t without some risk, and sometimes it’s the risk that makes it fun. I want Kiwis to be able to hunt, fish, hike, climb, mountain bike, kayak and so much more without being caught up in health and safety red tape.”

The change will apply to both public and

Brooke van Velden says new reforms aim to lift the burden of liability from landowners, allowing more access to New Zealand’s great outdoors for recreational use.

private land, from farms and forestry to school grounds, local council land and regional and national parks.

This change will not impact private property rights, and it will still be up to the landowner to grant access to their land if they wish.

biodiversity-challenged Canterbury Plains, it’s anything but.

Hororata Farm presents a blank canvas with ample opportunities. With enthusiastic

owners and funding avenues, there are many opportunities to create biodiversity assets on the farm.

Farming with Biodiversity set up a work

plan that outlines the necessary tasks for achieving high-quality biodiversity management outcomes at Hororata Farm.

The plan is presented as a five-year calendar, with step-by-step goals and a draft budget to schedule biodiversity management actions into the working year.

Having a structured approach to planning biodiversity restoration work increases the likelihood of biodiversity management actions being undertaken.

Each goal serves both the farm business and biodiversity outcomes.

For instance, a goal to plant native trees in a specific area benefits the farm by providing shade and shelter for livestock, enhancing soil health, contributing to aesthetics and allowing customers to associate their products with the farm’s positive impact on native biodiversity.

At Canterbury’s Hororata Farm, a five-year biodiversity plan is showing how structured, affordable actions can benefit both livestock and local wildlife.

Solid, Liquid or Slurry Fertiliser

Put fertiliser in as you cultivate saving tractor passes, and it’s only placed where required.

The 3 key row elements are pneumatically adjustable from the cab Made on the fly and it’s clean and simple.

Adjustable Row widths

Use for a multitude of different crops

Up to 15kph working speed

Lowering tractor hours and creating a better seedbed.

Retain soil structure

Better moisture retention making harvesting simpler.

Canadian made Bale Baron Picks up small or conventional square bales and bundles them into packs of 9, 18 or 21.

Packs up to 1000 Bales/hr and keeps up with 2-3 balers!

The bundles are compressed and tightly bound with regular twine using a 4 string double knot - Rasspe Knotter, and are easily handled by loaders and forklifts.

A technique which significantly reduces the spread of weed seeds during harvest is being demonstrated by the Foundation for Arable Research in a bid to generate a conversation around whether it is time it was adopted in New Zealand.

Chaff decks and other similar technology, attached to the back of a combine harvester to reduce the weed seed burden, are widely used in Australia.

FAR technology manager Chris Smith says FAR wants to kick-start the conversation.

“This is to help New Zealand arable growers better understand what it’s about, and the pros and cons, to help them decide if it’s the right fit for them.”

Known as Harvest Weed Seed Control (HWSC), the techniques are all based around keeping the chaff separate from the straw during combine harvesting. This is because nearly all the weed seed is in the chaff, which is of much smaller volume than straw.

Chaff can be spread up to the width of the combine front (9-10 metres in some cases) during harvest, so technology which limits its spread, or crushes seeds, can substantially reduce the amount returning to the weed seed bank in the soil for following crops.

FAR senior field researcher Charles Merfield (Merf) says HWSC is proving a very valuable technique, now used by more than two-thirds of Western Australian growers. Australian research shows it is highly effective, with a 95% reduction in annual ryegrass plants in crop in three years.

“However, it has not made its way across the Tasman, despite herbicide resistance becoming an increasing risk, particularly in ryegrass, which is also the main problem in Australia,” syas Merf.

“In arable systems, a large proportion of the weed seed does flow through the combine. So, by stopping that, we can actually achieve considerable amounts of weed control without using herbicides.”

There are six HWSC techniques: narrow windrow burning, chaff lining, chaff carts, bale direct, impact mills and chaff tramlining. All have pros and cons regarding: capital cost, mechanical complexity, running costs, maintenance, power required from the combine and nutrient removal from the paddock.

Merf says a misconception exists that many HWSC techniques won’t work in New Zealand,

Chaff deck directs the chaff into two easy-to-manage rows behind the combine

because of our much larger tonnages a hectare compared with Western Australia, where 2-3 tonne/ha is regarded as a good yield. “It was believed that the likes of impact mills won’t cope with the volumes of chaff flowing through our headers.

“However, it is not the tonnages/ha that is the correct measure, it is the tonnes per hour going through the header. As Australian growers have bigger combines and faster driving speeds of up to 15 km/hr they can harvest up to 70 tonnes of grain an hour. So, there is actually less chaff, straw and grain per hour running through most of our headers than in Australia, so all their systems will work here, likely with greater headroom.”

To demonstrate chaff tramlining, FAR purchased a pair of chaff decks from Australia and fitted these to a New Holland twin-rotor combine in Canterbury during the 2025 harvest to gauge its performance under New Zealand conditions. The material comes off the sieves and instead of spreading the chaff, it puts it in two narrow rows behind the wheels. This concentrates weed seeds into tramlines for easy follow-up, if needed.

“So far, they have been coping very easily with the amounts of chaff being produced and putting it in the wheelings with no problems.”

Seed germination in the tramlines and its management will be monitored, particularly as the farm is on controlled traffic.

Ideally the chaff deck is used all the time during harvest, with different kits for different makes and models.

This is a much cheaper option than an impact mill, probably the most well known of HWSC techniques. All originating in Australia, these include the Seed Terminator and Harrington Seed Destructor. Impact mills grind up the chaff and weed seeds, killing them. Impact mills are integrated into the back of a combine, with manufacturers increasingly suppling them as an option at purchase. However, impact mills are complex and expensive, costing at least $120,000 and requiring a lot of power, up to 100hp, from the combine.

Innovation has always been the heartbeat of Amazone, and once again it has been recognised on the national stage. In 2025 the Amazone Group has been named Germany’s most innovative medium-sized company in the agriculture and agricultural machinery sector for the second year running.

The accolade follows a recent study commissioned by the news magazine Stern, which ranked Amazone first in its sector and an outstanding third across all industries in its top 500 list. It is a result that places the agricultural machinery manufacturer firmly among the elite of Germany’s most forward-thinking businesses.

With a clear focus on research and development, Amazone is committed to helping agricultural businesses move towards a more sustainable and future-ready model. The company continues to push the boundaries, not only advancing its equipment but also leading the way with digital and AI-supported technologies. These innovations are designed to adapt precisely to varying climate, soil and plant conditions, with the aim of conserving resources, reducing input levels and maintaining high yields. Achieving these goals requires a blend of technical expertise and a strong commitment to turning bold ideas into practical solutions.

The company’s long list of innovations highlights its determination to make a real contribution to the future of farming, helping to secure global food supplies with smarter technologies. As Christian Dreyer and Dr Justus Dreyer, CEOs and owners of the Amazone Group put it: “Innovation has characterised the progress of our family business throughout its history. The excellent result in this evaluation encourages us in our endeavours to strategically increase our innovative strength in the future and to further expand our position as a pioneer in the industry.”

Christian and Justus were quick to credit the people behind the success. “Our special thanks go to our employees, whose creative commitment constantly provides new impetus and turns ideas into reality. We would also like to thank our customers and partners for their trust, cooperation and valuable suggestions from the field,” they said. It is clear that

innovation at Amazone is not just about technology, it is also about collaboration, listening and responding to the needs of farmers on the ground.

This latest recognition follows on from a similar award last year, when Amazone was named Germany’s most innovative medium-sized company by WirtschaftsWoche magazine. Winning two years in a row is no small feat, and it shows that the company’s approach is more than just words. By combining

deep technical know-how with a forward-looking mindset, Amazone continues to set standards for the industry, proving that tradition and innovation can go hand in hand to build a stronger future for agriculture.

Gigante Pressure

Direct Seed Drill

Easily slices through soil, regardless of soil conditions or crop residue

Places every seed at the right depth for optimum growth

A record 4000ha of cotton has been planted by Kimberley Agricultural Investment (KAI) in the area’s Ord Valley, the largest cotton crop for KAI and the biggest in the valley’s history.

Planting finished in mid-March in an area with some unique challenges when it comes to cotton and its growing season.

The last of the 4000ha of cotton for KAI went in during March, using six Case IH Early Riser planters and Case IH Magnum 340 tractors to achieve the massive task over the three-month planting period, punctuated by regular periods of heavy rain.

“Because we’re planting during the wet season, you might only get a window of a few days, so to maximise that opportunity it’s great to have that many planters and tractors on hand to get as much done in a relatively short period of time,” said Luke McKay, KAI Farm Manager.

When the decision was made to dramatically increase the size of KAI’s cotton crop, four new Case IH Early Risers were purchased last year and Luke said they were impressed with the way the fleet performed this year.

“They went really well and did the job in pretty challenging conditions,” Luke said.

“We’ve got nearly 4000ha of cotton out of the ground and it looks outstanding in what is pretty hard conditions. We had 400mls of rain over the time and then weeks of 40-degree temperatures back-to-back, so it’s a wild environment.”

Luke said he appreciated the precision planting aspects of the planters and integration with the tractors, with the metering on the units a notable feature. Two of the Early Risers also have hydraulic downforce, which has been such a success that KAI is planning to upgrade the other units to include it in time for next season.

“It makes a phenomenal difference in the conditions we have. When you’re running six planters you can be changing fields every three hours so knowing you have repeatable ground contact and depth - that hydraulic downforce feature makes a huge difference to your emergence,” he said.

Luke went on to elaborate on its benefits, saying it was particularly useful in wet conditions.

“Because it’s wet, if you set the planter up and then put another 20kg of seed in, it changes the operation of the planter, whereas with hydraulic downforce it can hold the planter off the ground to where you had it set

A Case IH Early Riser planter at work in the Ord Valley, helping to establish a record 4000-hectare cotton crop under tough northern WA conditions.

up so it doesn’t matter how much seed is in there. The operator doesn’t have to stop and check as much and when I’ve looked behind the planter and seen how it is, I know that’s going to be repeatable for the rest of the day.”

Luke said the precision technology of the Early Riser planters and Magnum tractors meant it was straightforward to standardise the equipment, meaning if there were changes in operators – which there often are with such a large workforce and machinery fleet – they didn’t have to negotiate differences between one tractor and the next.

Planter closing systems are crucial for maximising seed-to-soil contact and ensuring even emergence, and the Early Riser features a two-stage system, providing for a perfect finish that gets the seed off to a fast, uniform start.

“In our environment there is a narrow window of good ground conditions. It’ll be too wet and then without blinking your ideal planting depth can be too dry not long after the field becomes trafficable. So you need to push the boundaries of operating conditions whilst trying to maintain the basics of planting – consistent depth and soil contact. So, the closing system is pretty important,” Luke said.

“And even though it can be really wet, you would think that would make it easier, but it does make a big difference and the Early Riser has proved its value in this area.”

KAI’s General Manager, Jim Engelke, said KAI had been operating in the region for the past 12 years, planting its first commercial crop of cotton in 2018 – 350ha that allowed the KAI team to test theories and systems related to growing cotton in the conditions.

They soon realised growing cotton to the east coast formula was not an option in WA’s north-east corner. So after looking at the seasonal conditions they determined planting through the wet season, from January to March and then picking from July to September was the best strategy.

Successful crops followed, but never more than a few hundred hectares because the nearest cotton gin was Dalby in Queensland, so freight costs and transport availability made growing any more than that economically unviable.

Following the decision in 2023 to build a cotton gin near Kununurra, which is due to start operating by the middle of this year, KAI has significantly increased cotton plantings. Built by Kimberley Cotton Co, the development has also opened up other regional development opportunities.

Jim said the building of the gin has resulted in major re-development upgrades for nearby Wyndham Port, with the state and federal governments committing funding for infrastructure upgrades and the port granted all-important First Point of Entry status.

The ability to export local products like cotton had the potential to usher in a “major economic shift for the region,” Jim said.

The cotton will be picked from July to September, and with the increase in the investment in KAI’s cotton crop this year combined with much more scope for maximising the crop’s profitability, the team is hoping for a bumper season.

“It’s an exciting time for the whole region, and the unique challenges agriculture faces up here just makes the outcomes all the more rewarding,” Jim said.

KAITAIA Kaitaia Tractors 09 408 0670

WHANGAREI Piako Tractors Northland 09 438 1319

SILVERDALE Brandt NZ 09 427 9137

PUKEKOHE Brandt NZ 09 237 0043

MORRINSVILLE Piako Tractors 07 889 7055

MATAMATA Matamata Tractors & Machinery (07) 888 6292

HAMILTON Brandt NZ 07 847 0425

CAMBRIDGE Brandt NZ 07 827 5184

ROTORUA Piako Tractors Ltd 07 345 8560

TAUPO Taupo Tractors & Machinery 07 378 4533

STRATFORD FieldTorque Taranaki 06 765 8643

HASTINGS Stevenson and Taylor 0800 4273 2273

WAIPUKURAU Stevenson and Taylor 06 858 6041

DANNEVIRKE Lancaster Tractors 06 374 7731

PALMERSTON NORTH Transag Centre 06 354 7164

MASTERTON Brandt NZ 06 377 3009

NELSON Drummond & Etheridge 03 543 8041

BLENHEIM Drummond & Etheridge 03 579 1111

KAIKOURA Drummond & Etheridge 03 319 7119

GREYMOUTH Drummond & Etheridge 03 768 5116

CHRISTCHURCH Drummond & Etheridge 03 349 4883

ASHBURTON Drummond & Etheridge 03 307 9911

TIMARU Drummond & Etheridge 03 687 4005

OAMARU Drummond & Etheridge 03 437 1111

MOSGIEL JJ Limited 03 489 8199

GORE JJ Limited 03 208 9370

INVERCARGILL JJ Limited 03 211 0013

When farmers look for technology to make their lives easier, reliability and precision are top of mind and anything that helps farmers work smarter, faster and with less stress is worth a closer look. The new Nav-960 guidance controller from Ptx Trimble, launched recently at Agrishow in São Paulo, Brazil, promises to do exactly that, bringing better accuracy, more power and greater durability to farms around the world.

Formed in 2024 as a joint venture between Agco and Trimble, Ptx Trimble has been quick to deliver on its goal of making precision agriculture easier and more profitable. The Nav-960 is the latest step forward, replacing the popular Nav-900 and raising the bar for what farmers can expect from their guidance systems.

Andrew Sunderman, Vice President of Product and Customer Experience at Ptx Trimble, said the company is committed to making life easier in the field. “As the precision ag industry evolves, we are focused on innovative solutions that make it easier for farmers to tackle the critical challenges they face and to do so in a way that creates added value,” Andrew said. “With the new Nav-960 guidance controller, farmers have access to some of the most advanced technical capabilities for GNSS positioning in the market, which ultimately helps to get the job done in less time and with more profitability.”

There is plenty under the bonnet to back up those words. The Nav-960 comes with a new cast aluminium base that is tough enough to

handle extreme heat, freezing cold, heavy rain and thick dust. It also houses a powerful quad-core processor for faster calculations and quicker data delivery, making it ready not just for today’s demands but for the future as well.

One of the big improvements is how well the system holds its line. Thanks to a new GNSS engine and better inertial sensors, farmers can expect up to fifty percent better vehicle positioning and line following compared to the previous model. Andrew said this is all about helping farmers work more efficiently. “Farmers who implement the technology can realise a myriad of benefits, including saving on inputs from reduced overlap and less downtime that decreases operational delays and improves machine utilisation,” he explained. “It is all aimed at reducing operator fatigue during long planting days and improving overall productivity.”

Technology like Trimble ProPoint and

The new Nav-960 guidance controller from Ptx Trimble offers farmers improved accuracy, better vehicle positioning and less downtime in the field.

With enhanced GNSS performance and rugged design, the Nav-960 sets a new benchmark for reliable, stress-free precision farming.

Trimble IonoGuard also make a difference, helping the system resist issues caused by solar events that might otherwise interrupt work. This extra resilience means more hours in the field and fewer unexpected stops, something every farmer can appreciate when weather windows are tight.

Ptx Trimble has not forgotten about practicalities either. The Nav-960 is compatible with all Gfx Series displays including the Gfx-350, 1060 and 1260, and uses the same cables as the Nav-900. Built-in Wi-Fi and Bluetooth mean easier support and room for future updates. Farmers can slot it into their existing setups without missing a beat.

There are plenty of reasons to take a close look. Farmers who make the move can expect better uptime, reduced input and labour costs and less stress in the cab. Spending long days in the tractor is always going to be part of farming, but technology like this helps make those hours more productive and less draining.

The Nav-960 is available now worldwide, both for aftermarket and OEM installations. For farmers looking to future-proof their operations while making everyday tasks easier, it looks like a very solid option. As Andrew put it, “This is about giving farmers the tools they need to get more done with less effort, and to keep moving forward with confidence.”

When the pressure is on to plant, spray or harvest, having a guidance system that can be trusted to perform could make all the difference.

With the Nav-960, Ptx Trimble is giving farmers one less thing to worry about.

The data behind adjuvants: the hidden ingredient in effective spray programmes.

Fear of failure can be a powerful motivator for farmers and growers. Reduced returns, the threat of tariffs and market uncertainty are keeping everyone on their toes. There’s no margin for error.

It comes as no surprise that farmers and growers expect to see scientific proof that a product is going to work for them. They want data and studies.

There are some great chemicals out there, and they tick a lot of the boxes in terms of efficacy and safety for the people using them.

But that’s only three-quarters of the story.

Working hard behind the scenes are the adjuvants that help get the most out of spray programmes.

Pieter Van Der Westhuizen, Regional Sales Manager Upper North Island for UPL NZ Ltd, says it’s all about proven deliverability. “While adjuvants don’t have an active, they are shown to improve spray programme outcomessometimes significantly.”

Adjuvants work by modifying the physical characteristics of spray solutions. They range from buffering agents, to spreaders, penetrants, stickers through to products which lower the pH of the spray or reduce water hardness.

Pieter says it’s no secret that the cost of insecticides, fungicides and some herbicides is increasing. That makes it prudent to adopt and integrate an adjuvant (or adjuvants) to maximise spray programme efficacy.

His confidence in adjuvants doesn’t come out of nowhere.

Elliott Chemicals Limited, now UPL NZ Ltd, began work on adjuvant development and marketing in this country more than two decades ago. Today, it has a portfolio of over twenty adjuvant products – each fulfilling a niche role with its own chemical partners, seasonal timings and uses.

Pieter says the UPL range has a research-based pedigree that

Adjuvants work by modifying the physical characteristics of spray solutions. They range from buffering agents, to spreaders, penetrants, stickers through to products, which lower the pH of the spray, or reduce water hardness.

not all products can boast. “A lot of research and trials went into proving that UPL’s adjuvants can do the job.

“We always go back to research and sticking to the label rates. Extensive work has gone into that. These products are not just a ‘she’ll be right’ kind of thing. You need to ask the questions and check the research, just as you would with anything you’re trusting with your business and livelihood.”

He says Li-700, for example, used to reduce off-target drift is one of the most researched adjuvants in the world and is proven in global trials. “Li700 adds value by providing contractors with a bigger window of opportunity when spraying, limits downtime, makes application more effective and reduces the risk of the unintended consequences of spray to neighbouring crops.”

In terms of contractors, Pieter says adjuvants also have a major role to play in rig hygiene and in avoiding cross-contamination of chemicals and stop costly crop harm, reduced yield, or underspraying due to clogged nozzles or lines.

He says even if separate rigs are used for particular chemicals only, having them thoroughly cleaned on a regular basis improves performance. “It’s just part of getting them serviced.”

He recommends All-Clear® 2X, which he says will out-perform

ordinary tank cleaners on the widest range of agricultural chemicals, even carfentrazoneethyl, which is notoriously difficult to shift.

“All Clear 2X has a three-way action, decontaminating, cleaning and neutralising. It’s the best way to remove even the

most ‘sticky’ chemistry.”

Talk to your local technical representative for more details on how to get the best from your spray programme by using databased adjuvants or contact Pieter Van Der Westhuizen, UPL NZ Regional Sales Manager Upper North Island at 021 392 740.

When it comes to tyre performance in the field, small changes can make a big difference. That’s the thinking behind the latest update to the Mitas HC2000 tyre range. Designed for high-horsepower tractors, sprayers and spreaders, these tyres are now available with Pressure Field Operation (PFO) technology. It’s a development that underscores Mitas’s ongoing commitment to practical innovation, and it’s one that will be welcomed by anyone serious about protecting their land while getting the most out of their machines.

The core benefit of the HC2000 Series has always been its ability to deliver greater performance through a higher load capacity and reduced inflation pressure. But with the introduction of PFO technology, Mitas has taken this a step further. This advanced feature allows the tyres to handle heavier loads at the same low pressure as standard VF (Very High Flexion) tyres. The result is a larger footprint that spreads the load more evenly, protecting the soil structure and enhancing traction in the paddock. For farmers, that means less compaction, better root development and improved long-term soil health. Where the HC2000 range stands out is in its ability to perform under pressure, quite literally. Working at reduced pressures helps minimise the damage caused by heavy machinery on soft or vulnerable soil, a key consideration in today’s more sustainabilityfocused industry. The HC2000 series doesn’t just tick boxes for performance, it addresses real-world challenges that farmers face day in and day out.

This is especially important for operations with consistent fieldwork under high torque at lower speeds, where traction and stability can make or break the day’s productivity. By leveraging PFO technology, Mitas enables these tyres to perform exceptionally well in the 5 to 15 km/h range, which is where many modern tractors spend much of their time during fieldwork. It’s a smart pairing of technology with reality. Lower working speeds often come with higher loads, especially when towing wide or heavy equipment. The HC2000 handles this with confidence and crucially, without compromising the soil beneath.

Roberta D’Agnano, Global Brand Director for Mitas at Yokohama TWS, summed it up clearly: “We are thrilled to bring PFO technology to our HC2000 tyre range. This development highlights our dedication to providing effective solutions delivering high performance, positioning Mitas as a trusted partner for the daily challenges.”

The availability of PFOequipped HC2000 tyres in sizes such as VF 600/70R30 PFO and VF 710/70R42 PFO, with more on the way, means operators now have access to a solution that combines durability, efficiency and agronomic sensitivity. It’s a modern response to the complex demands placed on today’s machinery and land.

Looking at the specifications, the performance gains are easy to quantify. For instance, the VF 710/70 R 42 PFO tyre can support more than 12,000 pounds at reduced pressures, a testament to the smart engineering behind the design. It’s not just about carrying more weight either. The larger contact patch also improves grip and reduces slippage, which contributes to fuel savings and smoother field operations. Less strain on the machine means less fuel burned, fewer maintenance issues and a more comfortable experience for the operator. Durability also plays a central role in the HC2000 design. The

deeper tread, robust carcass and increased number of lugs contribute to longer service life and reduced operational costs. It’s a combination that reinforces Mitas’s reputation for building tyres that are tough enough for work in the field, and smart enough to adapt to changing needs.

There’s also a noticeable advantage in road transport. With the ability to operate at higher speeds without sacrificing load capacity, the HC2000 reduces downtime and speeds up transitions between field and yard. That might seem like a small win, but when the days are long and the jobs are stacking up those minutes matter.

All of this feeds into a bigger picture. In a world where farmers are asked to produce more with less, any innovation that improves efficiency without compromising the land is worth a closer look. The HC2000

Mitas has a reputation for building tyres that are tough enough for work in the field, and smart enough to adapt to changing needs.

Series now with PFO technology, is a fine example of how tyre development is evolving to meet those demands. Mitas isn’t just adding a technical upgrade, it’s offering a meaningful tool to help farmers stay ahead. As technology continues to shape the future of farming, investments in kit like this become increasingly strategic. Choosing the right tyres isn’t just a matter of fit and size anymore. It’s about matching capability to conditions and ensuring that every component of the machine is pulling its weight. The HC2000 PFO tyres from Mitas do exactly that, while giving back to the land at the same time.

Leasing is made easy with Landini. Our fully maintained operating leases are available at highly competitive rates across the entire range of tractor models- from 60 to 310 horsepower. Your payments are fixed, easy to budget for, and tax deductible. Lease a brand new tractor for the term you want and hand in the keys when you’re done - easy as that.

Talk to your local Landini dealer today.

In 1985, David and Sonia Molloy took a quiet but determined step toward independence when they fitted their first spray unit to a J1 Bedford truck.

There was no grand marketing plan or long-term corporate strategy. It was a practical decision made by two people who knew their land, their region and the needs of the farmers around them. That decision grew into a business that now sprays over 130,000 hectares annually across Mid and Central Canterbury, employing more than thirty people and offering a seamless combination of agronomy, chemical supply, liquid fertiliser and recycling services alongside a fleet of sixteen highly specialised spray units.