EQIPMENT

The practical advantage of precision planting

FEATURE

Bale Wrappers, Bale Handling Equipment and Telehandlers

FEATURE Hay and Silage Consumables

OCTOBER/NOVEMBER 2025

The practical advantage of precision planting

FEATURE

Bale Wrappers, Bale Handling Equipment and Telehandlers

FEATURE Hay and Silage Consumables

OCTOBER/NOVEMBER 2025

02 From the Editor: Spring momentum across the sector

INDUSTRY NEWS

03 Getting smart with nitrogen this spring

07 Rural professionals Erica van Reenen and Isabel Schmahl win top industry awards

08 Mentors behind the machines are driving the next generation of talent

10 Take the ‘aggro’ out of safely managing your agrichemicals

13 Innovation abroad, opportunities at home

17 Latest plantain trial results again show role in reducing nitrogen leaching

18 “Farmers are ecologists at heart”: an Auckland farm going big on predator control

TECHNOLOGY

21 Slugs – the ‘sniffer dogs’ of the mollusc world

22 Built in New Zealand. Built for you.

24 The practical advantage of precision planting

26 Autonomous tractors: innovation meets reality on the farm

28 A review of bale wrappers, bale handling equipment and telehandlers

54 A review of hay and silage consumables

60 Across the ditch: Dairy farming duo still ahead of the herd

66 Growing a legacy in Northland’s landscapes

72 Quietly getting it done in the South Waikato

Editor Angus Kebbell 022 052 3268 angus@agrimedia.co.nz

Advertising Manager

Michael Lightbourne 021 403 853 michael@agrimedia.co.nz

Advertising Sales

Lisa Phelan 021 782 228 lisa@agrimedia.co.nz

Circulation

Hilary Armstrong 027 443 3477 admin@agrimedia.co.nz

Production Design and Layout

Hannah Kincaid art@agrimedia.co.nz

Contributors

Jacob Quinn, Roz Beaver, Barry Dyer, Emma McMulkin, Jaimee Knight, Adam Sole

Printed by Blueprint Ltd

Read our magazine online ruralcontractor.co.nz/read-online

Spring always feels like a season of both urgency and possibility. For contractors and farmers alike, the ground is waking up, stock are demanding more and decisions taken now will echo through the months ahead. The stories in this issue capture that sense of momentum across our industry, from machinery that lifts and loads with ease to the finer details of how we manage landscapes, nutrients and even the people who make it all happen.

The first reminder comes from JCB’s telehandler story. Few machines in our sector are asked to do as much, day in and day out. To see the evolution from the early 520 model through to today’s Agri-Super and Agri-Pro variants is to see how engineering has responded to the needs of working farms. The mix of power, visibility, operator comfort and service support matters not just on paper but in the reliability operators need when the work is stacked up and the weather is pressing.

Follow us facebook.com/nzrclsf instagram.com/nzrclsf ruralcontractor.co.nz

Scan here to sign up to our digital newsletter

PO Box 36753 Merivale, Christchurch 8146 ph 03 329 6555 www.agrimedia.co.nz

Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping, Australian AG Contractor & Large Scale Farmer, NZ Novachem Agrichemical Manual.

Reliability and efficiency also sit at the heart of ProAg’s story. Born from frustration at poor silage wrap, their Protect 5 and Maxxcord products are about reducing downtime, minimising waste and ensuring the bale that is made today is still secure and feeding stock months down the track. It is a lesson in how local companies, by listening to contractors, can deliver simple but critical improvements that shift the bottom line.

Spring is also when nitrogen comes into sharp focus. The article on getting smart with fertiliser reminds us that the difference between a smooth lambing and hungry mouths can come down to timing, placement and product choice. Contractors bring not just spreaders and aircraft to the task but also the advice that ensures money is spent where it has the greatest impact. With prices still high and environmental expectations rising, the margin for error has narrowed. That makes the role of skilled operators and their judgement more valuable than ever.

Further north, the work of Northland Vegetation Control shows what contracting looks like when it stretches beyond the farm gate. Controlling weeds, stabilising slopes and planting natives are not side-issues; they are central to keeping land productive and communities resilient. Chance and Rochelle Campbell’s story is one of family, systems and steady professionalism. It is also a reminder that contractors are increasingly the bridge between regulation and results, taking policies on freshwater,

© RURAL CONTRACTOR AND LARGE SCALE FARMER - No part of this publication may be reproduced in any form without the prior written permission of the publisher. Opinions expressed in this publication are not necessarily that of the publisher and suggest independent advice be sought before acting on information or suggestions contained herein.

Angus Kebbell, editor.

emissions and biodiversity and turning them into real, measurable outcomes on the land.

And then there is Voltrac – an electric, autonomous tractor conceived in Europe but already stirring debate here. The potential is clear: labour savings, modular versatility and the promise of precision. But so too are the questions: will it cope with our terrain, our margins, our need for on-the-spot judgement? Technology will keep pushing and early adopters may find opportunities. Yet for now, it is worth remembering that machines complement people; they do not quickly replace the skill, adaptability and resilience that define this industry.

Together, these stories show a sector that is both grounded in practical realities and open to change. Machinery evolves, products improve, science sharpens our decisions and technology points towards new horizons. But at the core remains the same truth: it is people –contractors, farmers, families who carry the responsibility, make the calls and put in the hours. That is where resilience lies and that is what this magazine will keep telling.

Contributions - Editorial and photographic contributions are welcomed and should be sent directly to AgriMedia Ltd. Editing of submissions is at the sole discretion of the editor and will accept no responsibility for unsolicited material.

Spring on New Zealand’s hill country farms is always a balancing act. It is the time of year when demand for feed surges, with lambing and calving in full swing, yet grass growth struggles to keep pace under cool soil temperatures. For contractors and farmers alike, the weeks before and after lambing are decisive. Get the timing and management right and stock hit the ground running with a good supply of quality feed. Get it wrong, and the season begins with hungry mouths and pressure that is difficult to recover from. Within this context, nitrogen fertiliser becomes a tool that can tip the balance, lifting pasture growth just when it matters most.

The science is simple enough. Cold soils in late winter slow the mineralisation of nitrogen from organic matter, meaning grasses lack the nutrient they need for strong growth. Legumes such as clover are also sluggish at this time of year, leaving animals short of the lush feed they require. Applying nitrogen strategically in late winter or very early spring can give pastures the kick they need, closing the gap between feed demand

and supply. For contractors, this is one of the busiest and most valuable services they provide. The spread of nitrogen by air or ground is directly tied to lamb survival, milk production and farm profitability. Placement makes a difference. Not all paddocks respond equally to nitrogen, and hill country is especially variable. On shady

Proven and trusted by kiwi farmers for almost two decades.

Trusted drum after drum, season after season.

Superb Results. From the formulation flow through to the performance in the field

Precision spreading ensures nitrogen is used where it delivers the greatest return.

southern slopes and easy ground, clover often thrives and naturally feeds nitrogen into the soil. But on steep, north-facing

Magister® CS Herbicide is built for consistency—because when time’s tight and conditions are unpredictable, you need a product that performs without question.

That’s why more Kiwi farmers trust Magister® CS to deliver when it matters most.

slopes legumes are limited by dryness and shallow soils. Here, nitrogen applications can show the most dramatic response. Contractors with aerial capability can differentially apply fertiliser to these blocks, ensuring money is spent where it makes the most impact. It is a shift away from blanket spreading and towards precision, something increasingly valued as fertiliser prices and environmental scrutiny rise.

Timing is everything. The advice is to apply nitrogen four to six weeks before lambing or calving, particularly on north-facing country that warms more quickly. This ensures feed is available at the point when ewes and cows are at peak demand. A response of extra green feed at this stage can be the difference between smooth lambing and stock under

The rate of application is also well established. The sweet spot is between 30 and 50 kilograms of nitrogen per hectare at one time, roughly 65 to 110 kilograms of urea. Beyond this, the response tapers off and the economics become questionable. Contractors often find themselves advising farmers on this point, drawing on experience as well as research. With global fertiliser markets still volatile and prices in recent years at record highs, the value of every kilogram matters. Strategic application means not just spreading fertiliser but doing so in a way that maximises return.

Product choice plays its part too. Standard urea remains common, but its weakness is volatility when rainfall is not guaranteed. In these situations, stabilised products such as Sustain or N-Protect can make a difference holding nitrogen in the soil until rain arrives. They cost more, but they reduce the risk of losses to the atmosphere. In ryegrassdominant pastures, sulphate-sulphur can add another edge to efficiency particularly in early spring. For colder soils lacking phosphorus, blends such as di-ammonium phosphate deliver a more balanced response. These are details contractors understand well, and their ability to offer tailored advice is increasingly part of the service.

Environmental pressure cannot be ignored, and spring only sharpens the debate. Nitrogen leaching and greenhouse gas emissions are high on the political agenda, and farmers are being asked to demonstrate responsible use. Blanket spreading across hill blocks without thought to slope, soil type or timing is difficult to defend. But targeted applications aligned to animal demand and pasture response,

strengthening the sector’s licence to operate. Pasture cover adds another layer. Nitrogen applied to bare or overgrazed paddocks is far less effective than when applied to areas with at least 1,200 kilograms of dry matter per hectare. This makes grazing management inseparable from fertiliser management. For contractors, it reinforces the importance of observation. Seeing pastures first-hand whether from a cab or cockpit, allows them to provide feedback to farmers that sharpens decisions beyond the spreading run itself.

Spring is also when the stakes are highest financially. Lambing percentages, calf survival and milk yield all hinge on early feed. When nitrogen is used wisely, it is not just about growing extra grass; it is about underpinning the productivity of the entire farm system. For farmers, that means stronger stock performance and greater returns. For contractors, it means delivering a service that is directly tied to outcomes on-farm strengthening relationships and securing ongoing work.

There is no silver bullet in hill country farming. Weather will always turn against you, and variability across slopes will never allow for uniform responses. But nitrogen, used with judgement, remains one of the most effective tools available to bridge the gap between demand and supply. It is about timing, placement and rate, and about aligning applications with both the science of response and the realities of farming life.

This spring, as ewes and cows demand more than pastures can naturally provide, nitrogen offers a chance to stay ahead of the curve. Used strategically, it helps farms emerge from winter in stronger shape, animals well fed and businesses on firmer

Agribusiness and Environmental consultant

Erica van Reenen has been named the FarmIQ Systems Rural Professional of the Year for 2025, while Isabel Schmahl, Agri-Manager with Ravensdown, has taken out the title of FarmIQ Systems Emerging Rural Professional of the Year.

The awards were presented at the New Zealand Institute of Primary Industry Management (NZIPIM) National Conference Awards Dinner, held in Christchurch on 26 August 2025.

Erica has expertise across farm systems design, environmental management, greenhouse gas modelling, nutrient efficiency and biodiversity. She leads diverse projects including farm systems analysis, strategy design, sustainable finance initiatives and advisory team management, with extensive experience supporting Māori agribusiness.

The judges said Erica’s breadth and depth of expertise made her a standout. “She shows enormous passion and is not afraid to ask the hard questions of both the sector and her farming clients. Erica is a futuristic thinker with strong international and policy awareness and is highly attuned to the issues, challenges and opportunities facing our sector,” they said.

They added: “Her professionalism and advocacy make her deeply trusted, both by farmers and across the industry. She cares immensely for the farming community and is exceptionally well positioned to help New Zealand agriculture embrace change and new technologies.”

Erica said she was humbled to be named the 2025 winner:

“It’s a real honour to be recognised as Rural Professional of the Year. This award isn’t just about my work; it reflects the communities, farming families, businesses and organisations I’ve had the privilege to stand alongside. Together we can honour our sector’s legacy while embracing new ways of thinking to build a resilient, thriving futureka mua, ka muri.”

Isabel provides advice across nutrient management, environmental planning, agronomy and farm compliance, working with a wide range of clients to improve on-farm production, profitability and sustainability.

The judges described her as a ‘true high achiever’, noting her recognition as ‘Rookie of the Year’ with Ravensdown and her top scores in the national nutrient management course. They praised her balance of technical expertise and emotional intelligence:

“She has a very good grasp of the future of agriculture and her pivotal role as a nutrient adviser. Her farming clients describe her as sincere, courteous and knowledgeable.”

They also commended Isabel’s community involvement and ambition to take on leadership opportunities, saying she would be a fantastic ambassador for New Zealand’s emerging rural professionals.

Isabel said receiving the award was a huge honour:

“I am honoured and delighted to win this award - it took me by surprise considering the calibre of the other finalists. I am incredibly grateful for the support I have received from my current employer Ravensdown and previous employer Pāmu, as well as Lincoln University, NZIPIM and Beef + Lamb NZ for the many professional and personal development opportunities. I am passionate about making a lasting impact on farm productivity, environmental sustainability and animal genetics and I am excited to see where our ag sector is heading and how I can help shape its future.”

FarmIQ executive general manager Gavin McEwen says the calibre of the 2025 finalists once again shows the strength of New Zealand’s rural professional sector:

“After 14 years of sponsoring excellence in rural professionals we never cease to be impressed by the calibre of both young and more experienced professionals in the agricultural industry. Providing support and service to New Zealand’s farm businesses

Erica van Reenen was recognised for her leadership, vision and advocacy across New Zealand agriculture.

is an essential ingredient as to why the ag sectors preform so well across many metrics. Good farm businesses don’t just happen, it takes a team to get results and the nominees in the awards demonstrate the value these people add.”

Jo Finer, chief executive of NZIPIM, says, “It’s fantastic to work alongside FarmIQ Systems on these awards, who recognise the critical role of both emerging and mid-career rural professionals in our sector.

“Isabel and Erica exemplify the very best of excellence and professionalism, at their respective career stages. Their dedication to the profession and their commitment to the clients they serve really do set them apart. We are proud to recognise their achievements and celebrate the impact they both make across the primary sector.”

The judges also recognised Ryan Luckman as Highly Commended in the Rural Professional category. Ryan was praised for his innovation, collaborative approach and leadership in helping farmers apply wearable technologies, and rumination insights. He was described as an “exceptional communicator” with a strong drive for continuous improvement and deep commitment to his local Waimate community.

Although separated by the Cook Strait, John Deere service technicians, Marcus Vine and Liam Gee, both grew up pulling things apart and putting them back together, a hands-on curiosity that set them on a path to similar careers.

Such has been their success that they now play an integral role mentoring those following in their footsteps. After he completed school, Marcus pursued a pre-trade light automotive course and mechanical apprenticeship, before making the “best decision he’s ever made” and signing up to work at a John Deere dealership in Foxton.

Nineteen years later, he’s now working in the Brandt dealership in Feilding, where he takes pride in helping mentor apprentices to diagnose and repair faults to keep machinery up and running.

“Looking back, my career definitely worked out better for me as cars are such a throwaway industry, whereas we get to dig deeper with technology and new solutions,” Marcus said.

“I enjoy passing that knowledge on to the apprentices we have in our branch. They come out on the road with me, and we work alongside each other.

“I show them how to diagnose faults and, importantly, how to communicate with our customers, to understand what they need, and when they need it.

“I get the biggest buzz when I see how much the apprentices are enjoying their job. It’s not just about a paycheck; it starts to become a real passion for them.

Liam Gee mentors apprentice

Jack Iles at the Drummond & Etheridge, Blenheim branch.

Down on the South Island in the vineyardrich Marlborough region, Liam Gee grew up around machinery and approached the service manager at his local John Deere dealership about the chance to undertake work experience after he finished school.

This developed into an apprenticeship, and seven years later Liam is now sharing his expertise with the apprentices at the Drummond & Etheridge John Deere dealership in Blenheim.

“We usually have three apprentices staggered along years of experience and I am always helping them, whether that’s in a formal course training or out in the yard with the machinery,” Liam said.

“I’ve delivered half a day training to the young apprentices on Service Advisor Remote, as well as teaching them all about the John Deere technology systems, which is always fun.”

While he started out on agricultural equipment, Liam now specialises in John

Deere’s range of construction and forestry machinery, which is a skill recognised by other branches across the dealership network.

“I have travelled down to Christchurch to meet with a colleague from Invercargill when they were taking pre-delivery of a new 959ML Shovel Logger,” Liam said.

“I was able to give him a rundown on the equipment so he was familiar with it, which is a great way to share knowledge and help build skills across the dealership.”

Both Marcus and Liam love the customer engagement that comes with their roles and have enjoyed working at their local field days.

ASK ABOUT OUR

JCB has been pioneering the telehandler concept since 1977. Since then, we’ve remained the world’s first choice, and the JCB telehandler range has come to epitomise the very highest levels of performance and productivity. Not only that but the JCB telehandler lineup is one of the most extensive in the world, with competitive running costs, industry leading build quality, enviable versatility and top residual values.

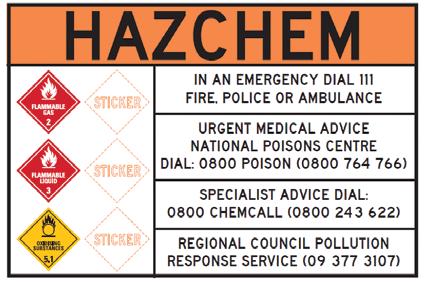

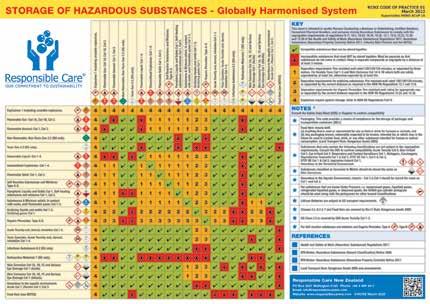

Safety is something most of us take for granted in our day-to-day work. Yet when it comes to the hazardous substances (chemicals) that keep modern farming and contracting moving, safety doesn’t just happen by chance. Agrichemicals, fuels, solvents and cleaning agents are a part of the landscape for farmers and horticulturists and, while essential, they also bring obligations that cannot be left to guesswork or old habits.

This is where Responsible Care New Zealand (RCNZ) delivers a vital service. As the not for profit chemical industry association, RCNZ implements the global Responsible Care initiative in this country, ensuring hazardous substances are handled in ways that protect people, the environment and businesses. RCNZ represents the majority of major manufacturers and importers of hazardous substances.

Chief Executive Barry Dyer is proud the national association, one of 66 worldwide, continues to help implement our complex chemical regulations.

“Our membership represents the entire product life cycle and we are a valuable resource for everyone seeking to meet their obligations under the Health and Safety at Work Act, HSNO, the HSW (Hazardous Substances) regulations and other chemical management requirements that govern every day operations.”

The most unique and arguably most important service RCNZ provides is Chemcall, a subscriber based, 24/7

emergency response advisory service available countrywide. Any farmer or contractor faced with a spill appreciates the importance of fast, informed advice. Chemcall responders are specialists who guide callers through addressing the incident until people and the environment are no longer at risk. This service is free to emergency services and schools, but its real value lies in the reassurance it offers to businesses that work with chemicals every day.

Training is another flagship service to members and non-members alike. RCNZ offers practical chemical education and safety training, reflecting workplace operations, from basic chemical awareness workshops through to our tailored Competent Chemical Handler Certification. For rural businesses where staff turnover can be high and seasonal labour is common, being able to put people through relevant

Responsible Care NZ delivers practical chemical safety training tailored to farming and contracting operations.

training without excessive downtime is a real advantage. The training is focused on helping participants understand their responsibilities and how to apply their knowledge in their workplace.

Supplementing emergency support and training, ReCNZ provides ‘compliance tools’ that make day to day chemical management easier.

Safety Data Sheet reviews, user-friendly codes of practice, educational posters, technical advice about transport regulations and checklists are all available to members and the public. These practical guides help businesses demonstrate due diligence, should WorkSafe NZ or the EPA come calling. For contractors working across multiple

“I quite like meeting new people and explaining what we do,” Liam said.

“Most of our customers are farmers in this region and it’s great to be able to talk to people at these events and let them know that we have a range of construction equipment that they can also use on their farms, such as diggers and skid steers.”

For Marcus, representing his dealership and John Deere at the Central District Field Days was a really positive experience.

“The Field Days is a great event for farmers and contractors and we also have lots of people from the community who want to come and see the big equipment,” he said.

“I really enjoy meeting with the range

of people and representing the service department and answering any questions about precision agriculture.”

No two days are the same

This time last year Marcus and Liam returned home to New Zealand after taking home trophies at the 2024 John Deere Technician of the Year Awards in Australia, a career highlight for both technicians who say the best part of their work is that no two days are the same.

“There is so much variety of work and range of equipment,” Marcus said.

“I have a different outdoor office every day and travel to places off the beaten track that

most of the public never get to see.

“There’s always something new to learn and a new challenge every day.”

From working in the workshop completing repairs and maintenance one day to attending an urgent breakdown in the field the next, Liam finds the challenge of getting a machine back up and running with minimal downtime especially rewarding.

“Every day is different,” Liam said. “Just last Friday, I was helping another branch fix a machine in torrential rain all day, in a location only a few people get to experience.

“Some of the sites I visit are located in amazing places. No two days are the same.”

KAITAIA Kaitaia Tractors 09 408 0670

WHANGAREI Piako Tractors Northland 09 438 1319

SILVERDALE Brandt NZ 09 427 9137

PUKEKOHE Brandt NZ 09 237 0043

MORRINSVILLE Piako Tractors 07 889 7055

MATAMATA Matamata Tractors & Machinery (07) 888 6292

HAMILTON Brandt NZ 07 847 0425

CAMBRIDGE Brandt NZ 07 827 5184

ROTORUA Piako Tractors Ltd 07 345 8560

TAUPO Taupo Tractors & Machinery 07 378 4533

STRATFORD FieldTorque Taranaki 06 765 8643

HASTINGS Stevenson and Taylor 0800 4273 2273

WAIPUKURAU Stevenson and Taylor 06 858 6041

DANNEVIRKE Lancaster Tractors 06 374 7731

PALMERSTON NORTH Transag Centre 06 354 7164

MASTERTON Brandt NZ 06 377 3009

NELSON Drummond & Etheridge 03 543 8041

BLENHEIM Drummond & Etheridge 03 579 1111

KAIKOURA Drummond & Etheridge 03 319 7119

GREYMOUTH Drummond & Etheridge 03 768 5116

CHRISTCHURCH Drummond & Etheridge 03 349 4883

ASHBURTON Drummond & Etheridge 03 307 9911

TIMARU Drummond & Etheridge 03 687 4005

OAMARU Drummond & Etheridge 03 437 1111

MOSGIEL JJ Limited 03 489 8199

GORE JJ Limited 03 208 9370

INVERCARGILL JJ Limited 03 211 0013

farms, having consistent documentation and processes also reduces the chance of chemical mishaps when working with various chemicals, in different environments.

RCNZ provided online advice to rural contractors during various Covid lockdowns and quarantine restrictions.

A very popular service is the ‘walk and talk’, an informal site visit to determine the extent to which the business is safely managing its chemical inventory. The assessor’s findings include advice to achieve the required remediation to demonstrate compliance. The visit report provides a road map for addressing SH&E compliance.

In an industry where reputation matters, being able to demonstrate a robust, independent verification of compliance and safe practices can be a real point of difference. The demanding Premises Inspection and Certification (PRINCE) initiative is a high level, comprehensive safety, health and environmental site assessment carried out by industry experts who tour the workplace, identify hazards and confirm that management meets and exceeds compliance. A business

that achieves PRINCE certification not only improves safety for staff but also gains recognition to show customers and regulators.

The complexity of rules around hazardous substances continues. What was once considered adequate chemical handling practice is now tightly regulated and the penalties for non-compliance can be severe.

RCNZ is keeping up with changes to legislation and ensuring its members and those seeking advice are informed and prepared. It works with regulators to help shape sensible rules, while also advocating on behalf of its members when new requirements are being developed. The industry voice is important because without it, rules are too often written in a way that overlooks the realities of rural businesses.

“For rural contractors in particular, the advantages of engaging with RCNZ are clear. Safely transporting, storing and applying chemicals in environments that change from job to job, while staying on top of compliance and delivering for clients is no easy task; having access to specialist advice,

On-farm ‘walk and talk’ assessments help rural businesses identify risks and strengthen compliance with hazardous substance rules.

emergency support and credible training makes the job safer and less stressful, resulting in safer workplaces and less time spent worrying about compliance.”

Barry notes membership is not just about ticking boxes for compliance. It is about participating in an internationally recognised SH&E initiative where safe chemical management is part of every day operations, protecting staff, neighbours and the environment. It is also about giving business operators the confidence that they are meeting and exceeding their legal obligations without undue disruption to the practical realities of their business. As a partner, RCNZ helps to ensure that the chemicals that drive productivity are used without compromising safety and environmental performance.

“As our world-leading agricultural sector continues to thrive, chemicals will continue to play a major role in our success. Public concerns and expectations about chemical safety continue to rise. This requires that the chemicals we all rely on for our quality of life are safely managed. Responsible Care practitioners continue to lead in striving to improve SH&E performance, rather than debating the need for more regulation.”

Those working on the land and looking beyond compliance to the continuing protection and future wellbeing of people and communities will benefit from the support and resources RCNZ offers. The role of rural contractors in supporting our dedicated farmers will only become more important as expectations around chemical safety and environmental protection continue to rise.

RCNZ is ready to help.

When a global dairy cooperative with more than 14,000 farmer members makes a major investment in Asia, it’s worth paying attention in New Zealand. FrieslandCampina Ingredients has opened a new state-of-the-art application centre in Singapore, expanding its research and development footprint in the Asia-Pacific by 30 percent. On the face of it, this may seem distant from our paddocks and farmyards but the implications reach right back to the New Zealand dairy sector and the wider rural economy.

The new facility is designed to be a hub for innovation in nutrition, building on Singapore’s role as the company’s Asia-Pacific headquarters since 2011.

FrieslandCampina, a cooperative of farmers in the Netherlands, Germany and Belgium is well known globally for turning milk into high-value ingredients and its Singapore base is its only development centre outside Europe. By enlarging its application centre, the cooperative is signalling that this region is central to its growth. For New Zealand farmers and contractors who already rely on Asia as a key export destination, the move underlines how much competition and opportunity is emerging in food and nutrition markets right on our doorstep. The facility is not just about building laboratories for the sake of science. It is equipped to develop functional foods such as yoghurts, snack bars, beverages and dietary supplements, and it brings together expertise in ultrahigh temperature processing, sensory science, packaging and analytical testing. In short, it is a full-service platform to speed

up the journey from concept to consumer. That’s a lesson worth noting for our own processors and exporters. Asia’s middle classes are increasingly focused on health, wellbeing and nutrition and they are willing to pay for products that meet those needs. FrieslandCampina Ingredients is betting that by being close to the market it can tailor solutions faster.

Tjalling Bekker, Regional Director APAC at FrieslandCampina Ingredients, put it plainly: “The APAC

Investing in research and development is key to moving beyond commodities into highervalue markets.

market is changing rapidly. Consumers are prioritising daily health, emotional wellness and beauty-from-within. Our new application centre will help our customers succeed in this fast-moving and growing market by accelerating application development and enabling

2026 Is Out Now -

• Over 110 new listings

• 70 discontinued products

• Numerous product label updates (new weed, pest & disease claims)

• All product labels reviewed for regulatory content and updated to GSH terminology. *

Storing Chemicals?

Print up-to-date SDS’s & Haznotes from novachem.co.nz to ensure you are compliant.

subscribe online at novachem.co.nz

closer collaboration so we can navigate these exciting opportunities together.”

For New Zealand exporters, that comment is both a warning and an invitation. If our co-operatives and food companies do not innovate, others will fill the space.

It is easy to see parallels with New Zealand’s own challenges and opportunities. We have long sold milk powders and basic commodities into Asia, but the direction of travel is towards functional foods, specialty nutrition and premium consumer products. Whether it is infant formula, performance nutrition, or health supplements, the competition is no longer about who can produce the cheapest volume but who can deliver sciencebacked tailored solutions. The rise of application centres like FrieslandCampina’s in Singapore highlights the importance of investing not just in on-farm productivity but in research, development and marketing that connects us directly with end consumers.

The Singapore Economic Development Board was quick to hail the investment, with

Melissa Guan, Vice President and Head of Consumer describing the centre as “a valuable addition to our vibrant food and nutrition ecosystem” and noting that it would accelerate co-development efforts with customers “to support health and well-being outcomes across all life stages”. That comment underlines another important point for New Zealand: governments in the region are actively working to attract and anchor global food companies. While New Zealand has deep agricultural expertise, our policy framework has not always kept pace with supporting innovation in food science and advanced nutrition. If we want to compete in these growing segments, it will take more than pasture and milk tankers; it will take alignment between science, industry and government.

For rural contractors and farmers in New Zealand, why does this matter? Because our long-term prosperity depends on where the value is captured in the supply chain. Selling milk as a commodity locks us into cycles of price volatility. Creating products that meet health and

lifestyle needs in Asia allows us to capture more stable and higher margins.

The Dutch farmers who supply FrieslandCampina are part of a cooperative model not unlike our own. Their milk is transformed into high-value ingredients that feed into the booming wellness and nutrition market. That model helps maximise the return for their members. For us, the challenge is whether we are equally committed to pushing beyond the commodity trap and investing in the partnerships and infrastructure that can get us into those higher-value niches.

It is also worth reflecting on how FrieslandCampina links its investment to community outcomes. The new centre will not just house laboratories; it will also create jobs, nurture local talent through internships and partner with organisations to promote healthy lifestyles. For instance, the company has signed a Memorandum of Understanding with Singapore’s Health Promotion Board and has worked with ActiveSG on initiatives to encourage healthy eating among children. In other words, it is embedding itself in the region not just as a seller of ingredients but as a participant in the health agenda. That is a reminder for New Zealand agribusinesses that in today’s marketplace, social licence and alignment with local goals are critical. It is no longer enough to sell a product; companies must demonstrate how they contribute to the wellbeing of the communities they serve.

The cooperative itself has a long pedigree. Formed from the collective efforts of more than 14,000 dairy farmers across three countries, FrieslandCampina processed 9 billion kilograms of members milk in 2024 and achieved revenues of 12.9 billion euros. It has operations in 30 countries and employs almost 20,000 people. That scale allows it to

New Zealand farmers face both competition and opportunity as demand for nutrition and wellness products rises.

invest in cutting-edge facilities like Singapore’s new application centre. For a smaller dairy nation like ours, the lesson is that cooperation and collective effort matter if we want to compete globally. Fragmentation weakens our ability to invest in the kind of research and development that can keep pace with international players. At the same time, New Zealand has its own advantages. Our reputation for grass-fed, pasture-based production remains strong. Our food safety systems are trusted. And our geographic proximity to Asia gives us a logistical edge. If we can match those strengths with innovation in nutrition and functional foods, we can maintain and even expand our role as a supplier of choice. But if we rest on the idea that bulk commodities will carry us forward, we risk losing ground to cooperatives like FrieslandCampina that are already embedding themselves more deeply in the region.

Ultimately, the opening of a new research centre in Singapore may not make headlines on-farm here in New Zealand, but it should. It tells us where the dairy world is heading: towards health, nutrition and value-added products. It also tells us that the competition is moving closer to our key markets and becoming more agile. For farmers and contractors, it reinforces the point that what we do in the paddock is only the first link in a chain that stretches all the way to consumers in Jakarta, Seoul, or Tokyo. How that chain is managed and how much value we capture along the way, will shape the future of our sector. The question, then, is how New Zealand responds. Do we double down on being a volume player, or do we take the harder road of innovation, science and partnerships to move up the value chain?

FrieslandCampina’s investment in Singapore is a reminder that the latter path is where the real rewards lie. It is a call for us to think not just about litres of milk produced, but about the nutritional solutions and wellbeing outcomes we can deliver to the world. That is the challenge and the opportunity that sits before us.

Merlo telehandlers and attachments deliver unmatched innovation, comfort, and performance across agriculture and construction. As Merlo’s exclusive partners in New Zealand, Ag & Civil Machinery Direct and JJ Limited provide the full range of compact, medium, highcapacity, stabilised, rotating, and telescopic models— plus specialised machines and genuine attachments to tackle any farm or jobsite task with ease.

Explore the technology trusted worldwide.

89 Kahikatea Dr, Hamilton

38 Progress Dr, Otorohanga

7 Heights Road, Pukekohe

*Terms & conditions apply. Contact your dealer for details.

Every new Merlo comes with a 2-year / 2,500-hour warranty*, giving you confidence that your machine is protected as you put it to work. It’s a commitment to the quality and durability Merlo is known for worldwide.

From farm jobs to construction sites, Merlo machines deliver consistent performance with advanced design, proven reliability, and trusted aftersales support. You get more than a telehandler. You get long-term peace of mind.

Discover the Merlo advantage — now with 0.99% finance available for a limited time* — and see why operators everywhere put their trust in green.

Visit us in Invercargill, Gore, Mosgiel, Cromwell, Timaru, Ashburton or Christchurch

Chat to our Specialists

DairyNZ’s Plantain Programme continues to deliver promising results, with new data confirming that modest levels of plantain in pastures reduce nitrogen leaching, offering farmers a practical science-backed tool to meet environmental goals.

With three years now complete, preliminary findings from the Lincoln University farmlet trial show 26% reduction in nitrate (N) leaching with an average of 17% Ecotain plantain in the pasture. Results from the Massey farmlet trial show over four years, N leaching was reduced on average by 26% where Ecotain plantain made up an average 25% in the pasture.

Monitoring on four mid-Canterbury farms shows that an average of 10-15% plantain across the whole farm is achievable by including plantain as part of the seed mix at pasture renewal and by broadcasting seed across the whole farm with fertiliser. The highest levels (20-40% plantain) are achieved in new swards 1-2 years after establishment.

The programme continues to show that plantain is a low-cost option to achieve significant reductions in N leaching without impacting the farm system, explains Kate Fransen, DairyNZ’s Plantain Programme

Lead:

“Nitrogen leaching is an issue for many dairy catchments, so we need practical affordable solutions. Including plantain in your pasture is ‘low-hanging fruit’ for reducing N leaching - and we now know you don’t need to have 30% plantain in your pasture to have the positive effect.

“Research shows that 17% plantain across the farm is enough to make a sizeable difference to N leaching and that between 10 and 20% plantain across the farm is achievable and practical for many farmers,” she said.

The final year of data collection is underway at the Lincoln site, while at Massey data collection is complete and final analysis is underway. The programme now turns its focus to adoption of plantain in targeted N sensitive catchments.

Farmers across New Zealand are adapting the science to suit their systems:

• Rotorua, Bay of Plenty: Farmers are achieving up to 20% plantain through broadcasting seed with their annual fertiliser and 17 of the 26 dairy farmers in the Rotorua

The Plantain Programme shows practical science in action, helping farmers meet environmental goals.

Lake Catchment intend to use plantain to meet their BOPRC regulated 2032 nutrient targets. Modelling estimates that farmers required to meet 2032 N leaching reduction targets will have 5-7% higher profit if using plantain compared to those using alternative strategies.

• Southland: Farmers are maintaining 8-10% plantain across their farms by including plantain in their re-grassing mix and have begun trialling broadcasting seed with fertiliser into existing pastures to push levels higher. Modelling estimates that farmers will have 7% and 9% higher profit/ha with 10% and 20% plantain respectively, relative to farmers reaching the same N leaching reduction via alternative strategies.

• Mid-Canterbury: Partner farmers are demonstrating success with plantain in mixed swards, achieving 10-15% across the farm.

Overseer estimates that every 1% of plantain in pasture reduces nitrogen leaching by about 0.6% by reducing N in the urine patch. Research has also suggested that plantain can further cut leaching through soil processes. It’s encouraging that measured leaching reductions at Lincoln and Massey

are greater than the modelled estimates, highlighting the potential benefit when both urine and soil processes are accounted for.

At the programme’s mid-term review, one of the key recommendations was to better understand these soil processes so the full benefits of plantain can be built into Overseer. This will be a major focus for the Plantain Programme over the next three years.

Plantain is recognised as an N leaching mitigation option by regional councils in Canterbury, Horizons, Waikato, Southland and Bay of Plenty where N leaching limits are in place.

The cultivar Agritonic, marketed by Agricom as Ecotain, has been used in Plantain Programme trials. An evaluation system is currently under development which will enable the efficacy of other plantain cultivars to be determined and may be extended to other species in the longer term.

The Plantain Potency Programme is a seven-year research initiative led by DairyNZ and using Agricom’s Ecotain environmental plantain. The funding partners are MPI, DairyNZ, PGG Wrightson Seeds Ltd., and Fonterra.

Even modest levels of plantain in pastures deliver measurable environmental benefits.

Shirley-Ann and Rick Mannering run a productive sheep, beef and dairy operation just south of Auckland. But alongside that, they’re leading a quiet ecological revolution - with traps, tech and a full-time farm ranger.

When the Mannerings first brought their Paparimu farm in 1991, one night’s shooting would turn up 120 possums, over just a few paddocks. Three decades later they’re not just managing possums, they’re running a tech-savvy campaign to remove all introduced predators threatening their bush, wetlands and birdlife.

Waytemore Farms has won many awards, mostly for their environmental efforts including a New Zealand Farm Environment Trust supreme award. But the real rewards are in the benefits to the farm itself.

“We’ve gradually progressed from shooting and poisoning on our own property to having a more formal eradication plan for pests on both properties that we now run,” says Rick, referring to their ‘home’ farm and a second nearby farm they inherited from Shirley-Ann’s father. But they didn’t get there overnight.

The tipping point

Their ‘home’ farm backs onto the Hunua Ranges Regional Park, home to Auckland’s only kōkako population.

In 2018, a large-scale 1080 operation knocked back the Hunua possum population. Auckland Council then installed a network of Philproof bait stations through Shirley-Ann and Rick’s bush block.

“You’d go out and you might only find a dozen, half a dozen or so [possums], so that was a bit of a game changer for this farm,” Rick says.

Seeing the difference the Auckland Council made was a huge motivator for Shirley-Ann and Rick to intensify their efforts massively.

They now have a network of bait stations alongside automatic resetting and manual traps. They have also employed a ‘farm ranger’ to help with maintaining traps, weed control and restoring their wetlands.

Years ago, the couple fenced off their native bush, but watched it continue to suffer despite the exclusion of cows and sheep.

With help from a QEII National Trust Auckland Council Fund grant, the Mannerings installed a suite of additional bait stations, DOC 200 and 250 traps and 12 AT220 self-resetting traps.

The early results were promising: chew card monitoring showed the possum numbers had halved.

So, they applied for the grant again, this time for their other larger farm. They followed a similar plan but doubled the number of AT220s they bought.

At $565 a pop, the AT220s are much pricier upfront than manual traps. “But the beauty of them is they just keep working. It’s a graveyard underneath the trap,” Rick says. Technology makes the job easier and Rick’s keen to see where it goes next. He has his eye on remote monitoring technology, especially for live-capture traps which must be checked daily by law.

Predator control at Waytemore Farms is protecting native bush, wetlands and birdlife.

But more gear meant more maintenance, so the couple made a bold move: they hired a full-time farm ranger to oversee trapping and restoration.

“You can’t farm unless you are a bit of an ecologist at heart. If you pug every paddock and wreck every hillside, the grass doesn’t grow, you’re not getting good production out of your animals and it just doesn’t work.”

Start small and watch it grow

“Everyone cares, and it’s just people’s ability to work on it that varies and some people can only do a small amount and some people can do a lot more. Everything counts.”

Rick and Shirley-Ann say once you start on predator control it’s so rewarding, it becomes addictive. And it doesn’t have to be complicated. They recommend starting with fencing off some bush, preventing stock from grazing. Then “chuck in” some traps. Take photos of the same vegetation every six months and “you’re away laughing”.

The rewards will be almost immediate. They saw this first in the canopy of their native bush. “As soon as something stops eating the trees, all the leaves come out on them,” Rick says.

It’s not just the native bush flourishing at Waytemore Farms, it’s also the birds and farmland.

“When you get a family of seven or so fantails fluttering around and k āk ā visiting from the Hunua Ranges, that’s just it,” Shirley-Ann says.

The Mannerings show how farming and conservation can thrive side by side.

Importing and supplying quality agricultural products New Zealand-wide for harvesting silage, hay, and straw.

Slugs have hidden talents, making them a nightmare for optimal crop establishment.

Pieter Van Der Westhuizen, UPL NZ Ltd Regional Manager Upper North Island, says front-footing slugs is essential. “Slugs have an acute sense of smell and are aware of seedlings, even as plants are just breaking the surface. By the time slugs are feeding on emerging seedlings, it’s already too late as seedlings damaged by slugs usually won’t recover.

“The goal is to protect the crop. Once feeding damage has stopped, that’s been achieved. We don’t have to see dead slugs to know we were successful.”

Ironmax Pro uses slugs’ multiple olfactory sensors against them.

The breakthrough Colzactive technology in Ironmax Pro makes it slugs’ favourite food. Colzactive is made up of specially selected oil seed rape extracts. Pieter says 20 different plant species were evaluated and 50 potential molecules identified for their attractiveness to slugs.

“Ultimately two molecules from oil seed rape were selected for their highly attractive and palatable characteristics from the slugs’ perspectives. These are the basis of the Colzactive technology, which enhances the Ironmax Pro bait taste and importantly, the speed at which the baits work compared to others.” Cage trials (2020) showed that slugs actively preferred feeding on Ironmax Pro to feeding on plant seedlings.

Pieter says feedback from contractors has been positive. “They’ve said it performs well and flows through machines - no problem at all.

“Contractors are finding that the product is also a good ecological match for the increasing number of clients, who would prefer not to use products that will impact the environment.

“Pet and stock safety is also an important consideration.

Stock break-outs and gates accidentally left open are part of farming life, no matter how careful you are. Similarly, the family labrador or huntaway needs to be safe when it’s stretching its legs or working on the farm. With Ironmax Pro, there’s no problem. It’s also safer for beneficial insects. And while the slugs will sniff the product out, it’s definitely more pleasant, in terms of odour for those working with it - especially in confined spaces.”

Ironmax Pro contains the optimized active ingredient 24.2 g/kg ferric phosphate anhydrous, referred to as IPMax. Iron (ferric) phosphate is a natural component of soil.

In Ironmax Pro, it works as a stomach poison on slugs and is fatal once ingested. Feeding stops almost immediately.

Baits are manufactured with the finest durum wheat using a unique slow drying process. This makes baits very rain fast (up to 60 mm of rain) unlike some baits which dissolve in the wet.

Ironmax Pro also has a consistent, wider spreadabiltiy with a recommended application rate of 5 to 7 kg/ha. With 60,000 baits per kilogram, Pieter says the product has excellent ballistic properties.

www.gaz.co.nz

Fuel Storage Limited has earned its place as New Zealand’s largest manufacturer of above-ground fuel tanks, with every unit designed, built and tested at the company’s Te Awamutu base. That local focus matters. Farmers, contractors and commercial operators need equipment that can withstand the tough, changeable conditions of this country and the team at Fuel Storage know what it takes because they live and work here too. Their tanks provide durability, compliance and convenience, keeping operations running when time and reliability are critical.

Among the most popular products are the trailer tanks, built with contractors and farmers in mind. Available in 1,350-litre and 1,800-litre tandem trailer options, these units are designed for mobility and efficiency taking fuel wherever it is needed. That might be a remote forestry block, an isolated job site or paddocks spread across a large property. The trailers are galvanised and robust, with lockable pump cabinets and a range of dispensing setups tailored to suit individual requirements. For contractors who often have multiple machines working across different sites, they save valuable hours otherwise lost to downtime. Farmers too can keep herds and cropping operations moving smoothly by having fuel on hand in the right place, when it is needed most. In both cases these trailer tanks have proven themselves as cost-effective, practical

Fuel Storage Limited builds every tank at its Te Awamutu base, ensuring durability and compliance for New Zealand conditions.

solutions that give operators control over their fuel supply.

For those who need fixed storage, the company also manufactures a wide range of farm and commercial tanks. These range from 600 litres through to 5,000 litres, providing permanent supply solutions for yards, workshops and farm bases. They are suitable for diesel, petrol and other fuel requirements offering safe and accessible storage on site. Bulk fuel on hand means contractors are not waiting on deliveries at peak times, while farmers gain the ability to buy in larger volumes at better rates. During busy periods such as planting, harvesting or stock movements, knowing fuel is there and secure provides peace of mind as well as cost savings.

The company’s reputation rests on more than just the size of its operation. Every tank is built in Te Awamutu with the understanding that it must stand up to hard daily use, whether that’s in farming, construction, roading or infrastructure projects. Fuel Storage has now manufactured more than 5,000 tanks, a track record that reflects both quality and consistency. That experience also allows them to offer versatility, with a product range that extends from mobile trailer tanks through to large permanent installations. Safety and compliance remain central to every design, giving operators confidence

Mobile fuel solutions save time and keep machinery running where it’s needed most.

that their fuel storage is both practical and secure.

Fuel Storage has always seen itself as more than just a supplier. For many contractors and farmers, the company has become a trusted partner in growth. A business may begin with a single trailer tank but as operations expand and demands increase, Fuel Storage can provide larger tailored installations to match. The pressures of modern contracting and farming are well understood by the team: time is money, reliability is non-negotiable and safety cannot be compromised. Each tank is built with those realities in mind.

For those looking to invest in New Zealandmade equipment that lasts, the company offers a clear proposition. Whether the need is for the mobility of a 1,350- or 1,800-litre trailer tank or the assurance of a 5,000-litre farm or commercial tank, Fuel Storage delivers on time, to specification and with service customers can rely on. Built in Te Awamutu and trusted nationwide, these tanks reflect a simple commitment: to keep New Zealand’s contractors and farmers moving, with fuel that is stored safely, securely and always close at hand.

Whatever your needs, Valtra has the working machine – made for you! Whether it’s the compact tractor that packs a powerful punch – the mighty little A Series, the gutsy all-rounder ready for any job – the G Series, the capable and award-winning N Series, the brains, brawn and beauty of the T Series, the smart and powerful Q Series, all the way through to the big new farm boss – the powerful and reliable S6, there’s a Valtra with your name on it!

Valtra tractors combine versatile features and innovative technology, with outstanding comfort in every model across the range. As a Valtra owner, you benefit from a reliable, high-quality tractor, that has been tailored to meet the needs of your farm or contracting business. Put simply, Valtra has the working machine – made for you!

TALK TO YOUR VALTRA DEALER FOR MORE INFO TODAY.

Precision Seeding Solutions (PSSAG) isn’t just another gear supplier - it’s the practical upgrade your planter’s been waiting for. If your focus is getting even germination, perfect singulation and maximising yield, then the tech they bring retrofitted onto the machinery you already own could make all the difference.

Headquartered in Inverell, New South Wales, with a New Zealand presence in Cambridge, PSSAG serves farmers across both countries as the premier dealer for Precision Planting, 360 Yield Center, Yetter Farm Equipment and GBGI. Their slogan ‘Straightforward Technology to Enhance Your Farm’ hits the mark: these aren’t gimmicks. They’re thoughtfully designed plug-ins born from farmer-led innovation and they speak to people who want better results without reinventing the tractor wheel.

At its heart, PSSAG offers ‘Build Your Row Unit’ solutions. If skips, doubles or uneven stands are denting your bottom line, their tools like the vSet meter that ensures accuracy without adjustment, DeltaForce which automates downforce row-by-row and SpeedTube that lets you double planting speed are crafted to eliminate guesswork and keep performance steady across varied conditions.

Take SmartDepth for example: adjusting planting depth from the cab as conditions change gives you real-time control and peace of mind. Or FurrowJet, which firms the seed and places fertiliser bands just right, giving roots immediate access to nutrients when they need them most. These sound like minor tweaks; in reality they’re yield protectors, tools that row-by-row shave margin from risk.

PSSAG goes beyond just sales. There’s a practical, side too ‘Planter Post-Season Inspection’. It’s a hands-on check that ensures your planter is tuned, tested and ready when the rains or the first seeding window arrive. That kind of proactive upkeep makes sense when the planting season can turn on a dime.

Importantly, PSSAG’s offering extends to industry presence and support. They’re not just pushing kit - they engage through events like the Australian Summer Grains Conference in July 2025, and they share on-farm success stories of customers reaping the benefits in real time. That kind of visibility builds trust and shows that these aren’t showroom solutions, but gear tested under real conditions.

Why does this matter to contractors and farmers in New Zealand and beyond?

Because productivity today isn’t just about planting, it’s about precision. Every seed counts. When equipment works seamlessly in varied terrain and changing soil, your crew moves faster, cover crops establish evenly

Precision Seeding Solutions technology delivers even stands and stronger germination across varied soils.

Tools like DeltaForce and SmartDepth give farmers real-time control over depth and downforce.

and yield potential stays high.

For operators juggling tight schedules and seasonal teams, vDrive, a maintenancefree electric drive, is a godsend, cutting mechanical hassle so planting runs smoothly. And consider CleanSweep, which allows row cleaner adjustments from the cab - not only a time-saver but a guard against downtime when weather or soil throws curveballs.

What’s more, investing in precision planting isn’t an overlay, it’s an upgrade that builds value into existing equipment. That matters on working farms where budgets are finite and ROI needs to be clear. PSSAG’s framework lets farmers iteratively step up performance without swapping tractors or planters wholesale.

Wired into innovation, grounded in practicality - that’s the essence of PSSAG. From mechanics built by farmers for farmers, to service built around planting calendars, they understand the rhythm of rural operations.

Here’s the bottom line: when planting window pressures collide with the need for consistency and yield, having a partner that brings precision without upheaval is a real advantage. PSSAG doesn’t talk a big tech game, they deliver tech that perform in the paddocks you know.

As New Zealand farmers face tighter margins, climate variability and growing demand for resilient yields, the ability to fine-tune planting, seeding, spacing, depth and delivery means more than efficiency; it’s about resilience. In that light, PSSAG isn’t just a gear supplier. They’re a row-unit enhancement partner and for those who believe every seed should count, that’s precision worth having.

End the damage from these three vile vermin in your forage brassica and fodder beet crops with SIVANTO prime. SIVANTO prime contains flupyradifurone, a powerful new insecticide providing rapid control of Nysius, green peach aphid and springtail.

• Rapid and effective control of key establishment pests in forage brassicas and fodder beet

• Can be effectively integrated into IPM programmes

• Innovative, odourless, liquid formulation that penetrates the plant quickly

• Can be applied by helicopter

Insist on SIVANTO prime from Bayer.

In the rolling fields of Spain, something quietly revolutionary is underway, Voltrac, a young startup has developed an electric autonomous tractor that doesn’t just aim to haul feed or plough paddocks. It has been engineered with dual-use in mind. While its deployment in agriculture holds promise for farmers the world over, the prospect of its use in defence applications underlines how the future of ag-tech is increasingly entwined with advanced, multi-use systems.

The Voltrac machine is no mere concept. It’s a 3.5-tonne electric tractor capable of carrying up to 4,000 kilograms, travelling

at speeds of up to 40 km/h and running for as long as 20 hours on a single charge. Its design allows for modular attachments - ploughs, mowers, cutters or a flatbed rig for transport. Swappable batteries stored in

the chassis keep downtime to a minimum.

The co-founders, Thomas Hubregtsen and Francisco Infante Aguirre, come with heavyweight credentials. Hubregtsen worked in artificial intelligence at BMW and Google X, while Aguirre is an aerospace engineer with family roots in farm machinery supply. Together they have built a tractor that learns, adapts and can turn its hand to more than one role.

In farming, that means the potential to fine-tune inputs. Even in its early development, the tractor is being designed to “experiment” in the field, treating patches differently, observing crop responses and adjusting treatments on subsequent passes. The promise is higher yields, reduced chemical use and more efficient management.

What catches global attention, however, is the tractor’s dual-use potential. Voltrac has been clear that with small modifications - anti-jamming systems, mine detection, or frontline supply roles - the platform could serve in conflict zones. Aguirre himself pointed to Ukraine as an example of where autonomous machines might save lives: “Many lives are lost in non-combat situations, including frontline resupply missions. That’s where we see

Voltrac’s autonomous tractor combines electric power with modular design for multiple farm tasks.

a machine like ours making a difference: it’s built for tough terrain, and it doesn’t risk human life.”

For New Zealand farmers and contractors, the technology invites both interest and caution.

On one hand, the possibilities are significant. Autonomous machines promise to ease labour shortages, improve precision in the paddock and cut emissions with their electric drivetrains. For contractors juggling a wide range of tasks, a modular platform that can swap between roles has clear appeal. Voltrac has raised millions in early funding, built its prototype and aims for first deliveries as early as 2026. The pace of change is breathtaking.

Yet for all the promise, scepticism is warranted. Farming is not conducted in laboratories or on test tracks.

New Zealand’s terrain, from steep hill country to heavy wet soils, is a tougher proving ground than most European farmland. Autonomous tractors may run for 20 hours on flat dry ground, but how will they cope with clay tracks in winter,

shifting stock across paddocks or working on slopes where judgement, instinct and caution matter as much as horsepower?

There is also the question of cost. Electric drivetrains and advanced AI are not cheap. Contractors already face tight margins and high capital costs. The idea that a robotic tractor will simply slot in and replace a skilled operator is far from straightforward. Farmers may well wonder whether the technology will pay for itself, especially when reliability and local servicing support remain untested in our conditions.

Regulation, too, poses questions. Remote operation across distances, or machines running without anyone in the cab raises safety, insurance and liability issues. Until the legal framework is clear, few will be eager to hand over their most important tasks entirely to an algorithm.

And then there’s the human element. Farming is not only about efficiency; it’s also about experience and judgement. A seasoned tractor operator can read the weather, hear when

Developed by AI and aerospace experts, the machine adapts and learns as it works.

a machine sounds ‘off’ and make on-the-spot calls that no software can yet match. Machines may reduce drudgery, but it is hard to imagine them fully replacing skilled drivers any time soon.

That doesn’t mean the technology should be ignored. Early adopters in New Zealand may find opportunities to trial these machines, especially in flat arable systems or controlled environments where logistics or repetitive operations dominate. Contractors might consider partnerships with suppliers or universities to test the potential in Kiwi conditions. But it would be unwise to assume this is a one-way road to replacing every driver with a robot.

There is also a risk of hype. Technology companies are quick to promise breakthroughs, but many prototypes never make it to mass adoption. We’ve heard predictions before that

machines will eliminate certain jobs, yet farming continues to demand human involvement at every level. The Voltrac platform is exciting but until it proves its mettle in real paddocks, under real pressure, the jury remains out.

Where the concept may have more immediate traction is in support roles - moving supplies, hauling loads or working in hazardous environments where the risk to people is high. In these spaces, the value of autonomy is clearer. But when it comes to the delicate, variable and unpredictable realities of

farm work, the role of people will remain central for a long time to come.

In the end, Voltrac’s autonomous tractor is a signal of the direction technology is heading: smarter, more modular more autonomous. But as we consider its relevance to New Zealand agriculture, we should keep our feet firmly on the ground. Machines like this may one day complement our work, but they will not quickly or easily replace the skill, adaptability and resilience of the farmers and contractors who keep this country fed.

Todays farming operations require top notch supplements and feed. To produce them, contractors and farmers need equipment that can handle the job with ease, precision and reliability. In this feature we review the products leading the charge in bale wrapping and handling equipment.

The Merlo telehandler range has carved out a reputation as one of the most versatile and dependable tool carriers available to farmers and contractors in New Zealand. Distributed in the North Island through Ag and Civil Machinery Direct, and JJ limited in the South Island, these machines bring together Italian engineering and operator-focused design in a package that fits comfortably into the demands of our agricultural and construction sectors.

For anyone who has worked with telehandlers, the basic expectation is simple: they must lift, reach and manoeuvre in ways that save time and add efficiency. Merlo has pushed that concept further by designing a family of machines that not only cover those fundamentals but also deliver a level of comfort, safety and reliability that stands out. From compact yard machines to high-capacity lifters capable of handling ten tonnes and reaching

heights of 18 metres, the range is structured to offer a solution for every scale of operation.

The compact machines have proven especially popular on farms where space is tight and agility matters. They give operators the ability to work in sheds or yards where larger equipment would struggle, while still offering the lift and reach expected of a telehandler. For contractors and larger farming businesses, the medium and heavy-capacity models step up with additional strength and stability. These machines

are designed for demanding work loading bulk materials, stacking bales high in a shed, or supporting construction jobs where the combination of lifting power and reach is essential.

What sets Merlo apart is not just the breadth of the range, but the attention given to operator safety and ease of use.

The adaptive stability control system is a good example.

It continuously monitors the load being handled, the boom position and the attachment in use automatically, managing machine movement to reduce the

risk of tipping. For operators who spend long hours in the cab, this offers peace of mind and ensures every job can be tackled with confidence.

Comfort is another area where these machines excel. The cabins are designed with wide visibility, sound and climate insulation and easy access, recognising that fatigue is not just uncomfortable but can also compromise safety. The control systems are intuitive, with a joystick that responds to operator touch and adjusts engine revs according to demand, reducing fuel use without sacrificing responsiveness. Attachment changes are also simplified with a locking system that can be managed directly from the cab. These details add up to a smoother workflow and less downtime.

Fuel efficiency is increasingly important, both for operating costs and environmental responsibility. Merlo’s Eco Power Drive system automatically manages the engine and transmission to cut unnecessary fuel burn, with savings that quickly accumulate over a season. For a contractor clocking up a thousand hours in a year, that can mean a meaningful

difference to the bottom line.

The rotating telehandlers in the Merlo range deserve particular attention. These machines give operators 360-degree boom flexibility, making them invaluable on construction sites or for large-scale farming operations where access angles can be difficult. Instead of repositioning the entire machine, the operator can rotate the boom to place loads precisely where needed. Combined with stabilisers and advanced suspension, the result is a machine that feels steady and predictable even in challenging terrain.

Looking ahead, Merlo is also investing in electric technology. Their e-Worker machines are the first fully electric telehandlers, offering zero emissions while still delivering useful lifting capacity. For businesses conscious of environmental impacts or working in enclosed areas where diesel engines are impractical, this development signals where the future is heading.

Of course, having the machines available in New Zealand is only part of the equation. Farmers and contractors also want the reassurance that comes

Ag & Civil Machinery Direct is New Zealand’s exclusive distributor for Kemper — the global leader in forage harvesting technology.

The Pro 400 Drum Maize Header series is engineered to deliver perfect chopping quality and smooth crop flow in all conditions. Built for contractors who demand reliability, efficiency, and uptime, this header has this header has set the benchmark for maize harvesting and is available in 6, 8, 10 and 12 row configurations.

from local backing. Ag and Civil Machinery Direct and JJ Limited provide that support, offering the full range along with servicing and a two-year or 2,500-hour warranty. That means operators are not just investing in a machine but in the confidence that it will be supported throughout its working life.

The appeal of the Merlo telehandler range lies in its ability to be many things at once. It is powerful enough for heavy lifting, refined enough for daily farm use, efficient in its fuel management and thoughtful in the way it supports the operator. Whether it is moving bales, shifting bulk loads, or placing materials at height

on a construction job, these machines have been designed to perform in the real world where time and safety matter most. For New Zealand’s farming and contracting businesses, versatility is not a luxury but a necessity. Every machine needs to justify its place by doing more than one job well. On that measure, Merlo telehandlers earn their reputation as an indispensable part of modern operations. They combine engineering that has been tested over decades with innovations that make life easier and safer for the operator. And with strong local support behind them they are machines built not only to work hard but to keep working, season after season. RC

Feeding efficiency has become one of the defining measures of performance on New Zealand farms, and the Kuhn Crossmix 2 CS mixer wagon has been designed to meet that challenge head on. The 18.2 cubic metre model in particular strikes a balance between capacity, manoeuvrability and fuel efficiency that makes it well suited to the realities of Kiwi farming.

At first glance the Crossmix 2 CS appears to be a compact wagon, yet its design conceals a wealth of clever engineering. The wheels are recessed and set outside the mixing tub, giving it a narrow overall width of just over 2.4 metres while still providing a generous ground clearance of close to 400 millimetres. It is a combination that allows the machine to travel comfortably across rough tracks and uneven terrain, yet still pass under low-roofed sheds and slip through narrow gateways that might challenge other mixers of similar capacity. The tyres

are stout and wide enough to carry the load with ease and the overall stance gives the machine a low centre of gravity that adds to its stability. That practicality continues when it comes to feeding out. At the front sits a wide cross conveyor that can deliver feed to either side of the machine. It is hydraulically driven and fitted with a PVC belt that moves rations cleanly and evenly without slop or spillage. The discharge door spans 1.2 metres

and is paired with a double bent scraper that keeps even fibrous rations flowing without blockages. For farms where layout or building design creates obstacles, the conveyor can be offset slightly to keep material clear of the wheels, adding another layer of adaptability. Inside the wagon, mixing is handled by twin vertical augers that create a figure-of-eight movement, pulling material continuously through the tub until it is thoroughly combined.

The polygonal design of the tub itself prevents any dead zones where feed might settle, ensuring a consistently homogeneous mix every time. This is particularly important when rations include a blend of silage, hay and concentrates as uniformity directly impacts animal performance. Kuhn’s augers are built with asymmetric, self-cleaning knives that cut long fibre material efficiently while maintaining constant torque,

meaning the tractor does not labour under sudden spikes in power demand. It all adds up to a machine that can mix thoroughly at a rate of around seven horsepower per tonne of feed, a fuel efficiency that makes a real difference when the mixer is in use day after day.

The 18.2 cubic metre capacity is well matched to medium to large herds, typically catering to between 70 and 150 cattle depending on the ration density. At just over seven metres long and with a tare weight of around 5.7 tonnes, the mixer fits comfortably behind a 90 horsepower tractor running a 540 rpm PTO. For most farms this strikes the right balance between size and practicality: large enough to handle substantial loads, yet not so big that it becomes unwieldy on smaller lanes or paddocks. Durability has been a clear priority in the design. The chassis and tub are built as a single structure, reducing overall height while strengthening the frame. The recessed wheels not only help keep the wagon narrow, they also protect against

wear and make access for servicing simpler. Anti-overflow extensions come standard on the 18.2 model, preventing spillage of long-fibre feeds during loading. The build quality and thought put into small details ensure the machine is prepared for the demanding workloads of New Zealand farms, where downtime is never an option.

For farmers and contractors, the Crossmix 2 CS offers more than just reliable performance. It is a wagon that adapts to