NEWS

Case IH’s biggest ever Steiger makes debut on Aussie soil

PROFILE

Getting the system right — from paddock to pit

& LARGE SCALE FARMER

EQUIPMENT

Optimal seed placement by working smarter together

Case IH’s biggest ever Steiger makes debut on Aussie soil

Getting the system right — from paddock to pit

Optimal seed placement by working smarter together

Think big, think smart – with the sixth generation Valtra S Series. No task is too big, no detail too small for the Boss. The S Series pushes, lifts and pulls through the toughest work days with ease, and does it with precision and intelligence. This is power and performance that reaps rewards.

PO Box 36753

Merivale, Christchurch 8146

ph: +64 3 329 6555

www.agrimedia.co.nz

Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping, Australian AG Contractor & Large Scale Farmer, NZ Novachem Manual.

EDITOR

Scott Wilson

Mob: +64 21 725 061

Email: scott@agrimedia.co.nz

ADVERTISING SALES

Pulse – Media Sales

Justin Bowler

Ph: 0429 699 553

Email: justin.bowler@mmg.com.au

CIRCULATION

Email: admin@agrimedia.co.nz

PRODUCTION, LAYOUT & DESIGN

Mark Winstanley

Email: agc_art@agrimedia.co.nz

Contributors: Delwyn Dickey, Gerhard Uys

Printed by PrintGraphics Pty Ltd

AC

© AUSTRALIAN AG CONTRACTOR AND LARGE

SCALE FARMER - No part of this publication may be reproduced in any form without the prior written permission of the publisher. Opinions expressed in this publication are not necessarily that of the publisher and suggest independent advice be sought before acting on information or suggestions contained herein.

CONTRIBUTIONS - Editorial and photographic contributions are welcomed and should be sent directly to AML. Editing of submissions is at the sole discretion of the editor and will accept no responsibility for unsolicited material.

02 FROM THE EDITOR: Weather whiplash: A tale of two seasons for Australian farmers INDUSTRY NEWS

03 Ten harvests in, and still terminating the problem at its source

04 Case IH’s biggest ever Steiger makes global debut on Aussie soil

06 Esperance cropping business has its challenges so quality machinery, experienced team critical for success

07 CEA announces significant expansion

08 John Deere’s Technology Bootcamp seeding series delivers expert insights and tangible on-farm impacts

10 Rising dairy stars: Meet Australia’s best young dairy paraders

TECHNOLOGY

20 New product a ‘game-changer’ for customers wanting tech upgrade for their Case IH, New Holland fleets

12 Getting the system right — from paddock to pit

16 Dairy farming duo still ahead of the herd

22 Across the ditch: Rooted in the land, driven by service: The story of Quigley Contracting

FEATURES

28 What’s new in hay and silage consumables

36 What’s new in bale wrappers, bale handling equipment and telehandlers

EQUIPMENT

48 New header front design turning heads

49 Fast chaser bin boosts big harvest efficiencies

50 Jumbo 5000 – the success story continues

52 Daybron Farms double down with new seeding rig

53 Speed and efficiency from new Fendt Slicer mower range

54 Is It time to upgrade your seeding setup?

55 Smart and completely newly developed: The Fendt Former C two-rotor central delivery rake

56 Rock crushing demo big hit at Goondiwindi

57 Pöttinger Top VT 12540 C four-rotor rake - now with Profiline comfort control system

58 Optimal seed placement by working smarter together

60 Claas Rollant; your solution wrapped up in one machine

63 Smaller has become better for WA grower

64 John Deere’s most powerful tractors exceed all expectations

THIS SEASON HAS BROUGHT A STARK REMINDER OF JUST HOW DIVIDED AUSTRALIA’S AGRICULTURAL FORTUNES CAN BE.

On one side of the country, Western Australian growers are talking about one of their strongest seasons in recent memory, with rainfall arriving right on cue and crops showing excellent promise. On the other, farmers across South Australia, Victoria, and particularly the Mallee regions, are contending with a season that’s off to a frustratingly slow start.

For many in SA and VIC, the story of the past nine months has been one of waiting. Much of the region endured prolonged drought conditions, with rainfall charts flatlining for the better part of a year. Nine months without meaningful rain has left soils parched and moisture profiles depleted. When the autumn break finally did arrive, it came late—too late for a smooth start to the season.

As a result, sowing has been pushed back

ers are facing the dual challenge of shorter growing windows and the knock-on effect this has on yields. In areas that missed out on early rainfall, many growers have had to make tough calls about whether to cut back on sowing, switch to shorter-season varieties, or in some cases, write off paddocks altogether.

The frustration is all the more acute when compared with WA’s outlook. There, timely autumn rains soaked soils just as seeders rolled out, setting up what could be a bumper harvest. The contrast is striking: two agricultural regions of the same country, living completely different realities.

This variability underscores both the resilience of Australian farmers and the ongoing volatility of our climate. While one state celebrates strong prospects, another braces for a season of compromise. It also raises wider questions about how the industry adapts— through improved water management, better access to seasonal forecasts, and ongoing investment in crop varieties built to withstand harsher conditions.

Farmers are no strangers to tough sea

SCOTT WILSON

mercy of weather patterns beyond our control. The challenge, as always, will be how we prepare for the next season while making

Designed to work harder, so you don’t have to.

IT’S HARD TO BELIEVE IT’S BEEN A DECADE SINCE THE FIRST SEED TERMINATOR ROLLED OUT ACROSS AUSTRALIAN PADDOCKS. IN THE REAR-VIEW MIRROR, THOSE FIRST GENERATION MACHINES MIGHT SEEM PRIMITIVE. BUT EVEN THEN, THEY CARRIED THE SAME CONVICTION: THAT STOPPING WEEDS AT HARVEST WAS NOT JUST POSSIBLE—IT WAS ESSENTIAL. TEN HARVESTS LATER, THAT CONVICTION HAS ONLY DEEPENED.

Much has changed in the last decade. New chemistries have come—and in some cases, already gone. Integrated Weed Management (IWM) and Harvest Weed Seed Control (HWSC) have become mainstream. There are new crop varieties, advances in soil amelioration, precision ag, even the occasional curveball—like a global pandemic. And through it all, one thing has remained clear: weeds adapt, but so do farmers.

The Seed Terminator journey has never been about chasing shiny objects or the next agtech wave. It’s been about digging in—refining, upgrading, and responding to what’s happening in the paddock, not just in the lab.

Even in a globally depressed machinery market, Seed Terminator has doubled down—not on selling, but on building. With reduced spend on sales and marketing, resources have gone into product development, testing, and performance upgrades. So when farmers are ready to invest again,

the value is already waiting for them—more capacity, smoother installs, tougher components, better outcomes.

This season, the full suite of new models is a testament to that focus. From the latest AF10 and CR11 platforms, to John Deere’s S & X series, and now the new S7 range. From Claas Lexions, to upgrades for the New Holland’s 8.90–10.90 range, and of course Case IH’s Flagship series, there aren’t many headers Seed Terminator doesn’t fit.

One of Seed Terminator’s early commitments was building a future-proof platform—and they’ve delivered on that promise. Through backwards-compatible upgrades, retrofit kits, and continuous R&D, they’ve ensured that the earliest adopters aren’t left behind—they’re leading the way. Because progress shouldn’t

leave the early believers behind.

That evolution is also reflected in the heart of the technology: the AeroIMPACT mill, now in its fourth generation. The latest variant lands just in time for this year’s harvest, built on stationery testing, real-world data, and farmer feedback.

While herbicide resistance continues to be a major driver of adoption, there’s a deeper truth underpinning harvest weed seed control: a Seed Terminator acts on all cohorts— not just the ones that emerge early. Where a knockdown might achieve 95% control,

CASE IH IS DOUBLING DOWN ON POWER AND PRODUCTIVITY WITH THE NEW STEIGER 785 QUADTRAC, AND VISITORS TO THIS YEAR’S AGQUIP FIELD DAYS NEAR GUNNEDAH, NSW WERE THE FIRST IN THE WORLD TO SEE IT.

This new Steiger model is now the most powerful in the Case IH range, with the horsepower boosted by almost 10% over the previous model, offering increased power for farmers who are looking to get even more out of their businesses.

The higher horsepower takes productivity to a new level, allowing farmers to handle larger implements, or pull the same implements deeper to maximise yield potential. Designed to provide more power to the ground, the Steiger 785 Quadtrac also offers a superior operator experience and cab comfort.

Farmers can access integrated precision technology with Connectivity Included, delivering automation-driven features such as AccuTurn Pro and AccuSync, along with

it’s often only targeting 40% of the season’s weeds—delivering, in practice, closer to 38% overall control.

“This idea that you only get 50%, so it’s not worth it—that mindset needs smashing,” says Dr Nick Berry. “It’s a globally important shift.”

And the data backs him up. The RIM model, developed by AHRI and CSIRO, has shown that even moderate reductions in the seedbank at harvest can dramatically change the weed seed bank trajectory over time—especially when combined with other integrated tactics.

clear, actionable data through FieldOps— all designed to meet the unique needs of their operation.

“To be able to bring this exciting new tractor to Australia and unveil it at our largest field day event is an amazing opportunity. AgQuip visitors will be the first in the world to see this latest evolution of the Steiger range, and really get a sense of what it can offer to Australian farming operations,” said Justin Bryant, Case IH ANZ High Horsepower Product Manager.

“Our farmers deal with some of the most challenging conditions in the world, so their equipment needs to withstand these pressures and deliver in terms of performance and reliability. The Steiger 785 Quadtrac will not only meet those demands, but with

As the old saying goes: one year’s seeding is seven years weeding. At harvest, there’s no ifs. You collect the weed seeds, or you don’t. You crush them, or you spread them.

And for those watching from afar, it seems the word is spreading. A recent Instagram like from Kaleb Cooper of Clarkson’s Farm may not be a scientific endorsement—but for many in ag, it’s a life goal unlocked.

Of course, behind every bit of progress— every chassis, screen, and mill—is a community of farmers who took a punt, backed the idea, and helped shape it into what it is

this increase in power and productivity, it will exceed them.”

Even with the increase in horsepower, the Steiger 785 Quadtrac is impressively agile, offering excellent visibility and manoeuvrability for an optimal driving experience.

For those seeking enhanced performance, an optional heavy-duty suspended undercarriage delivers a smoother ride, superior traction and flotation, helping to minimise soil compaction in the field.

The Steiger 785 Quadtrac holds strong value thanks to long-term advantages such as Connectivity Included, providing access to machine and agronomic data without subscription fees, and a simple engine design that focuses on producing power.

today. Seed Terminator’s tenth Australian harvest isn’t just a milestone. It’s a quiet tribute to those who believed a better system was possible—and made it happen.

Here’s to the legends who made it possible. And for those still considering it—maybe this is your season. What have you got to lose, apart from another year of spreading weed seeds?

Speak to your local Seed Terminator dealer. Get it sorted now in time for harvest. Because the best decisions are the ones you don’t have to second-guess at the end of the season. seedterminator.com.au.

TOP 882 C FLOWTAST

The best reliability in challenging ground conditions

Better footprint than wheels - ideal for soft and peaty soils

Thanks to the large surface area of contact with the ground, deep wheel marks, holes or furrows no longer present a problem.

Hydraulic weight alleviation for maximum soil conservation and low wear to the glide bar

Special wear-resistant plastic (PE 1000) for a long service life

For more information on our product line contact us at (03) 8353 2770, www.poettinger.com.au

ANDREW FOWLER LIVES IN A BEAUTIFUL PART OF WESTERN AUSTRALIA, BUT THE LOCATION AND ENVIRONMENT CAN BE CHALLENGING WHEN YOU’RE RUNNING A LARGESCALE CROPPING OPERATION, SO HAVING THE RESOURCES AND STRATEGIES TO CHANGE DIRECTION WITH LITTLE NOTICE IS CRITICAL.

Andrew runs Chilwell Farms, about 90km east of Esperance in the south of WA. It’s 80% cropping with canola, wheat and barley and sometimes lupins, and 20% pasture, running sheep and cattle. A lot of the country is rotated with a vetch, serradella or clover-based pasture for a year or two, before returning to canola and wheat.

“There’s quite a bit of variation as you move around the property, so there’s some quite heavy clays and loams close to the coast, lots of typical Esperance sand over clay … and then as you head north and you go back into the more traditional Mallee country, it can be quite heavy. So there are differences, but fundamentally, for this Esperance area, there is a sort of a duplex nature to the soils with a tight clay subsoil,” Andrew said.

“The other thing to note is that the rainfall changes a lot. So right on the coast, we’re at 650mm because we go down to 2km from the beach. And then at the top of the farm, 45km to the north, it’s 400mm.”

Currently, Andrew and his team are managing 15,000 hectares of canola, the same of wheat and 8ha of barley. And they’ve seeded about 5000ha of vetch and rye grass pastures.

“With a variation in both rainfall and soil type, that requires different management strategies and different focuses,” Andrew said.

Some of the soils are relatively low in quality, he says, with a fairly low water-holding capacity, sodicity at depth and prone to compaction. On the sandier soil, there’s a non-wetting quality to it.

“So, we’ve spent a lot of time soil-improving and really, I think, the big leap up in productivity from a cropping perspective has come from soil-improvement programs over the last decade or so. And that’s a combination of everything,” he said. “It includes deep-ripping to about 500mm on the sandier soils, and a lot of lime to get the pH levels up to where you need them.”

For this task, Andrew has nine Case IH Magnum Rowtracs among his fleet, and three

Case IH Steiger tractors. The Rowtracs were well suited to the sandier soils, Andrew said, particularly when it got wet.

“We’ve put a lot of effort into decompacting with the sandier soil, and it’s a relatively expensive, slow operation, ripping to 500mm. We’re running a full 12m match CTF system and spraying and spreading on 36m, seeding and harvesting on 12m. The Rowtracs are really important for being able to start on 3m and have the capacity to pull the seeder bars, particularly when it’s a bit wet or if it’s soft sand that’s been deep ripped. Once you start getting bogged, it gets pretty painful and turns into hard work really quickly, so the Rowtracs help keep us moving,” he said.

Andrew also has eight Case IH Patriot sprayers split into two teams. There’s a core group of staff who support the spraying operation, which Andrew says is important when running a large number of sprayers and needing to prioritise particular tasks as the need arises.

The Patriots are running reasonably regularly – between 1000 and 1200 hours annually – with three of the Patriots equipped with spot-spraying technology.

“It’s a fairly high workload per sprayer. But we have a relatively intensive input program with our cropping when you consider multiple applications of fertiliser, applying fungicides, weed control – it certainly adds up to a lot of passes. And then there’s also activity around managing pastures as well, both in pasture and desiccation at the end of the season, and preparation at the start,” Andrew said.

“So, I don’t know that we could do it with any fewer sprayers. That’s the reality. We’re pretty busy all the time, particularly given our spraying windows are sometimes compromised with wind. Esperance can be a windy

part of the world.”

Chilwell Farms is going into its third season with the Patriot fleet, and Andrew said they had been reliable and efficient to date.

“The individual nozzle control and the predictability and accuracy of application is really good. There’s no wasted chemical anywhere, which is so important for planning and for the efficiency of our operation.”

He also praised his local dealer, Farmers Centre in Esperance, for their quality service and support.

While there were challenges with the diversity of the area he’s farming, Andrew said that it also offered a degree of security, further supported by an expert team and large machinery fleet.

“It offers a bit of stability from a business perspective because, while you know it’s probably not going to be great everywhere, you also know it’s unlikely to be really bad everywhere. So that gives you a bit of security, and from an operational point of view, it provides flexibility,” he said.

“There may be some areas that are too dry or some areas too wet, but you can manage your operations by being nimble. So, we don’t have farm managers, we have operational managers who run the fleet of machinery where they need to be operating. You might focus on getting the heavy coastal country in before it gets wet and hard to manage, or you might be focused on getting the northern country in while the moisture is still in the slot.”

The season to date has been good, Andrew says, with most of the property getting between 30 and 50mm through April, and then after a fairly dry May, welcoming about 30mm towards the end of June.

“For this time of year, things are looking pretty promising, but there’s still a long way to go,” he said.

CEA, A LEADING PROVIDER OF EQUIPMENT TO THE AGRICULTURE, CONSTRUCTION, MINING, EARTHMOVING, INFRASTRUCTURE, DEFENCE, WASTE MANAGEMENT, MINING, AND RECYCLING SECTORS, IS PLEASED TO ANNOUNCE A SIGNIFICANT EXPANSION OF ITS BUSINESS TO INCLUDE TWO NEW BRANCH LOCATIONS IN CENTRAL QUEENSLAND: ROCKHAMPTON AND MACKAY (FORMERLY TERREQUIPE).

This strategic move emphasises CEA's unwavering commitment to growth while reinforcing its focus on supporting core industry segments throughout metropolitan and regional areas.

The official handover for the branches took place on 24 June 2025, with both locations now operating under the CEA business trading name. This expansion will substantially broaden CEA's reach throughout the region and enhance its capacity to deliver unparalleled service and robust after-sales support to customers across these vital sectors.

The new Rockhampton and Mackay branches will form part of CEA's Northern Region, with CEA’s Brisbane-based operation providing extensive support to ensure a seamless transition for the highly experienced staff currently at both locations.

As part of the acquisition employees previously working for the Terrequipe branches in these locations have transitioned to CEA, ensuring key product knowledge and strong customer relationships are retained within the business.

"The expansion into Rockhampton and Mackay is an exciting move for CEA,” said Wes Henshall, Executive General Manager Northern Region. "It's a testament to our focus on growing the business and our dedication to working with customers across industry segments we know well and are highly proficient in supporting. We are also pleased to welcome the experienced teams at these locations into the CEA business and look forward to strengthening our relationships while providing exceptional service to customers within the region.”

Hylton Taylor, CEO of CEA, commented on the strategic importance of the expansion: "Our decision to expand into Rockhampton and Mackay reflects CEA's long-term vision for growth and our commitment to being closer to our customers in critical regions.

“By integrating these additional branches into the business, we are not only expanding our footprint; we are reinforcing our position to deliver superior service, comprehensive after-sales support, and to be a reliable partner for customers within the agriculture, construction, mining, and earthmoving industries.

“We are confident that this move will create new opportunities and further solidify our position as an industry leader.

“There will be a period of transition over the coming months as we integrate CEA systems and procedures into the new locations, but I am confident we can complete this quickly and with minimal disruption,” Hylton added.

“Since announcing the acquisition, we have received extremely positive feedback from the market, and with over 45+ years of industry experience we are confident our business understands the market requirements, and how best to meet the evolving demands of the customer base going forward.”

BRANCH LOCATIONS:

ROCKHAMPTON 1011-1021 Yaamba Rd Parkhurst QLD 4702, Australia Phone: 07 4936 3577

MACKAY 6 Longwall Place Paget QLD 4740 Phone: 07 4952 6061

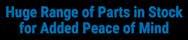

JOHN DEERE DEALERS AND CUSTOMERS FROM ACROSS REGIONAL AUSTRALIA HAVE JOINED THE LATEST IN A SERIES OF ‘TECHNOLOGY BOOTCAMPS’ DESIGNED TO SHOWCASE THE CAPABILITY OF JOHN DEERE’S TECHNOLOGY OFFERING AND THE COMBINED POWER OF ITS INTEGRATED SEEDING SOLUTION.

John Deere Australia and New Zealand Director, Marketing, Ben Kelly, said these bootcamps have been developed to deliver an “up close” look at how tech can be practically implemented on-farm for greater performance and productivity.

“Developing technology and equipment is just part of our role within Australia’s agriculture industry – we’re equally focused on sharing knowledge and expertise, and having conversations with our dealers and farmers,” Ben said.

“By collaborating with our dealer network throughout the Technology Bootcamp series, we’ve not only been able to talk about the new innovation we’re bringing to market but also how farmers can use the existing technology they have on their machines to optimise their operations.”

John Deere Australia and New Zealand Production and Precision Ag Marketing Manager, Royce Bell, said the Technology Bootcamp experience had included detailed demonstrations of the entire John Deere seeding line-up.

“We’ve really wanted to demonstrate what happens when you combine the power of the 8 and 9 Series Tractors with the accuracy of the new C-Series air cart and P640 precision air hoe drill – products that deliver a total seeding solution that works smarter together for Australian farmers,” Royce said.

“The Technology Bootcamp is the perfect opportunity to explore the integration of this solution in diverse cropping enterprises across the country, and examine John Deere’s digital tools, such as John Deere Operations Center and Connected Support, which harness the power of data and analytics to improve outcomes and simplify farm management.

“Dealers and customers have also been

ALEX CONTERNO, PRODUCT AND SYSTEMS SPECIALIST, JOHN DEERE SHOWCASING THE C-SERIES AIR CART AND P640 PRECISION AIR HOE DRILL TO DEALERSHIP STAFF AND CUSTOMERS.

particularly interested in the improvements to See & Spray Select, which now has in-season variable rate capabilities via the camera processing and ExactApply technologies.

“Rounding out the bootcamp sessions were discussions about our new Precision Essentials program, which allows customers to select the Precision Agriculture technology

BROTHERS, DAVID AND JIM MAITLAND (FRONT RHS OF IMAGE) CO-OWNERS OF MAITLAND FOODS, A 3,000-HECTARE BROADACRE CROPPING ENTERPRISE AND CONTRACT FARMING BUSINESS, TRAVELLED FROM SOUTH AUSTRALIA’S CLARE VALLEY TO ATTEND THE WIMMERA REGION BOOTCAMP.

they see as most impactful for their unique farming operation.”

In early April, Jim and David Maitland, co-owners of Maitland Foods, a 3,000-hectare broadacre cropping enterprise and contract farming business travelled from South Australia’s Clare Valley to attend the Wimmera region bootcamp.

Their operation consists of a mix of owned, leased share-farm and other hybrid agreements, where they focus on lentils, export hay and wheat production using an extensive stable of John Deere equipment.

Jim Maitland said the recent delivery of a John Deere 616R sprayer was the catalyst for their bootcamp attendance, enabling them the opportunity to further unpack the benefits of the See & Spray Select system, as well as learning more about other technology that could enhance their operation.

“It was great to meet the specialists who look after this product in Australia and hear about some of the upcoming features being released and utilising the See & Spray sys-

tem to apply at a variable rate,” Jim said.

“I was also keen to learn about the P660 and C Series air cart, and through the bootcamp, I now have a better understanding of its functionality and how it might fit into our future operations.”

With John Deere’s bootcamps designed to support customers to make the most of their equipment and understand what’s ahead in the technology pipeline, Jim said he was impressed by the value delivered by the experience.

“I was amazed at how high the ratio was in

regard to John Deere representatives versus customers,” he said.

“It was great to meet those representatives responsible for the various John Deere categories and I was also fascinated to learn that the See & Spray technology was developed in Australia.”

The Technology Bootcamp Seeding Series will be complemented by a Harvest Series later in the year as part of John Deere’s focus on helping customers to maximise the value of their equipment’s technology and enhance on-farm profitability and sustainability.

Rigid or 3-section frame and flexible cutterbar (Razor)

Widest centre section allows greatest wing flexibility

Exclusive, fully integrated air system behind knife for lowest losses

Floating, mechanical drive intake auger

Slim side panels for minimal disturbance of high value crops

Industry leading design to improve harvest

efficiencies with capacities of 150 and 225T

Unload and load at ease without holdups

Exclusive data management system with HIVE Connect and Pro

THE BEST YOUNG DAIRY CATTLE PARADERS IN AUSTRALIA HAVE BEEN ANNOUNCED BY AGRICULTURAL SHOWS AUSTRALIA AND WILL COMPETE IN THE NATIONAL FINALS NEXT MONTH.

Murray Findlay, 22, Albany

Murray Findlay grew up on and around farms and spent school holidays working on a local dairy farm where he met Russell Hall who introduced him to the world of cattle showing. After a gap year on the farm, Murray moved to Perth to study a Bachelor of Agribusiness, graduating in 2024.

“Since 2019, I have shown for multiple exhibitors at the Albany Show, Harvey Show/ WA Autumn Fair and the Brunswick Show as well as showing beef cattle while I was at ag school. I have competed in a number of state finals and last year I competed in the National Dairy Paraders competition representing Western Australia in Melbourne. My show highlights are winning the Highest Dairy Achiever at Cattle Camp and my first handlers class at the Brunswick Show.”

Patrick English, 20, Malanda

Patrick has been hands-on with the preparation and presentation of his family’s large show teams from a young age. He works full-time at the Mareeba Saleyards and parttime on the family’s dairy farm. A standout moment in his show career was the Royal Queensland Show when his family claimed both Supreme Intermediate Female and Supreme Champion Cow in 2019.

“My family are multi-generational dairy farmers and have exhibited dairy cows at every Malanda Show since 1916. Our family has always been competitive - with six siblings there is always competition - and I have enjoyed parading animals since I could walk.”

Lilly Eagles, 15, Forbes

Lilly was born into dairy life and now co-owns Savvy Ayrshires with her two sisters. She proudly parades her own Ayrshires - Savvy Deluxe Blossom and her dam Paschendaele Ash Blossom - and has been showing cattle since she was little.

Currently in Year 9 at Forbes High School, Lilly is a regular on the show circuit, helping clip and prepare cattle for her school and family friends. Her favourite event is International Dairy Week in Victoria, where she and

The 2025 National Championships is being hosted by the SA Country Shows at the Royal Adelaide Show from 1-6 September 2025 and includes paraders of beef and dairy cattle, young judges (beef and dairy cattle, grain, Merino sheep and fleece, meat breeds sheep, and poultry), the Australian Young Farmers Challenge, and National Rural Ambassador Award.

Young judges and paraders aged from 15 to 25 in each state will gather to compete in the annual competition. Qualification is via success in competitive regional and state competitions.

Meet the six finalists in the Dairy Cattle Parading final.

her sisters show their cattle and lend a hand to other exhibitors. She also enjoys getting involved with beef cattle at local shows like Trundle, Grenfell, and Eugowra.

“My two best moments at a show would have to be winning Junior Champion at the Forbes Show with my Ayrshire, Ash, when she was a heifer - and then taking her to International Dairy Week where she won Reserve Junior Champion. The other was at the Sydney Royal Easter Show earlier this year - I won my paraders class with my heifer Deluxe, then went on to be named Reserve Champion Parader. Now, I get the amazing opportunity to represent New South Wales at the Adelaide Royal.”

VICTORIA

Sienna Ross, 17, Katamatite

Sienna is a proud first-generation dairy farm kid growing up milking cows, rearing calves, and driving tractors. Now in Year 12 and School Captain at Sacred Heart College Yarrawonga, Sienna hopes to one day become a qualified embryo technician.

“My family definitely are the main reason I now have such a love for showing dairy. I have dad’s love of cows, mum’s support and her determination for me to succeed, my brother’s skills building all my new gear, and my sister by my side at all the shows to learn new things.”

SOUTH AUSTRALIA

William Phillpot, 19, Murray Bridge

Showing dairy cows has been a big part of William’s life since age 12, when he attended the SA Dairy Youth Camp and met mentor Bridget Liebelt. Today, William regularly shows top-quality stock alongside Bridget at local and interstate events, and works at Daish Irrigation and Fodder in his hometown.

“I started competing with dairy cattle at a young age, with what first started as a small hobby, and quickly grew into a lifelong passion and skill. My dedication and willingness to learn helped me progress my talent and skills into the show ring. I have had so many amazing opportunities to compete in handlers classes, with much success along the way.”

TASMANIA

William Dudfield, 22, Somerset

William Dudfield has been part of the show ring since he was three years old, and joined paraders competitions at just nine. Growing up on a dairy farm sparked his love for cattle, and even though he now works in civil construction, showing remains a big part of his life. He has been to several national championships and is a successful competitor at the highest levels.

Jacqueline (Jac) Wilson-Smith, Chair of Agricultural Shows Australia - the peak body representing 572 agricultural shows that attract six million visitors annually and contribute nearly $1 billion to the national economydescribes the competition as a celebration of emerging talent in livestock judging across the country.

“This is an incredibly prestigious event, and earning a spot in the nationals is highly sought after,” Jac said.

“These young competitors represent the future of agricultural show competitions, which play a vital role in advancing Australia’s food and fibre industries. The nationals offer an exciting chance for participants to grow both personally and professionally while testing their skills against the very best.”

The winner will also receive a halter from sponsor, The Cattle Shop. Based in Goulburn, NSW the store supplies and stocks cattle grooming gear. Owner Daryl Holder has been involved in the cattle industry for more than 30 years.

“As a business who deals with these young people I want to give back in some way to them. All these young people give up so much to be part of an industry that Australia needs. It is only a small part but hopefully goes a long way,” Daryl said.

For more information, please contact Katie Stanley, Executive Officer, Agricultural Shows Australia: execofficer@agshowsaustralia.org.au | 0402 127 001.

NORTHERN VICTORIA

DAIRY FARMER BRADY HORE SAYS THE KEY TO PUTTING THE BEST FEED IN FRONT OF HIS COWS IS THROUGH THOROUGH PLANNING, BACKED BY A STRONG WORKING RELATIONSHIP WITH HIS CONTRACTOR.

Brady is the fourth generation dairying on the farm, and operates in partnership with his parents, Steven and Deanne, and multiple staff.

Brady milks 700 cows, with about 10 million litres of milk going through the 44 unit rotary every year.

Cows are all housed in sand bedded freestalls, with young and dry stock on manure compost bedding. The entire herd, from young stock to lactating cows, are barn fed total mixed rations (TMR).

Brady feeds an average 26-28kg dry matter intake per cow per day.

All the feeding is done at first light, with the first job of the day being shaving the pit face for fresh feed.

Brady crops 1700 acres, aiming to harvest 2400 dry tonnes of corn and a few thousand tonnes of winter cereals and vetch for feed.

“Depending on the season and how much storage ahead we would like, we are trying to build a feed bunk,” he says.

Brady says, because he barn

feeds TMR year round, he does not treat feed differently during specific seasons or for specific cow production stages, but constant monitoring of what goes into the pit and comes out of it is crucial for sustained productivity and good animal health.

“We are looking and learning all year round,” he says.

“We make sure the quality is top notch, especially what’s

BRADY’S SILAGE MIX IS MADE UP OF CORN, CEREAL OR VETCH SILAGE, LUCERNE HAY, ALMOND HULLS, COTTONSEED, CANOLA MEAL AND GRAIN.

coming out of the silage pit. Our contractor checks in with us and we discuss any problems we pick up and make sure it doesn’t hap-

ALL THE FEEDING IS DONE AT FIRST LIGHT, WITH THE FIRST JOB OF THE DAY BEING SHAVING THE PIT FACE FOR FRESH FEED.

pen the next season. I am also in constant contact with an animal nutritionist.

“Compaction, moisture content, dry matter, any mould or contamination, it’s a daily check,” he says.

Good feed quality translates into high milk production, production gain and healthy cows.

For the last five years, Brady has been contracting out silage chopping and packing to Monk & Son Ag Services, doing the rest himself.

Sam Monk started the business when he was only 16, and had only a Case IH Maximum 155 tractor and a New Holland BR7060 round baler.

The business has now grown

THE ENTIRE HERD, FROM YOUNG STOCK TO LACTATING COWS, ARE BARN FED TOTAL MIXED RATIONS (TMR).

to a fleet of tractors, forage harvesters, silage trucks and a host of other implements, with staff reaching 100 plus in peak silage season.

Brady says he maintains a good relationship with Sam at Monk & Son by regularly checking in and talking about how the season is tracking, and by catching up both on and off-site.

“We’re talking all the time.”

Timing is critical to securing good feed, with weather condi-

tions in the lead-up to harvest playing a key role in determining silage quality. Talking about timing has everyone putting their minds together to assure the best quality result is possible.

Maximising the timing of dry

COWS ARE ALL HOUSED IN SAND BEDDED FREESTALLS, WITH YOUNG AND DRY STOCK ON MANURE COMPOST BEDDING.

BRADY MILKS 700 COWS, WITH ABOUT 10 MILLION LITRES OF MILK GOING THROUGH THE 44 UNIT ROTARY EVERY YEAR.

matter is the most time critical factor, as it allows for making the best quality silage that will impact intake and production and enables him to get the most production from his feed.

The consistency of silage comes a close second, also leading to maximum intake, as cows like consistency in feed.

His silage mix is made up of corn, cereal or vetch silage, lucerne hay, almond hulls, cottonseed, canola meal and grain.

“Getting a consistent product with the right dry matter in a total mixed ration is the key. Over the years we’ve gotten better and better.”

The right mix is one cog in the farm profitability machine, because cows that eat well are healthier, produce more milk, and they consume all their feed, which means less wastage.

“In conjunction with our nutritionist and agronomists and

contractors, we are learning and improving. We’re all on the same page and want to get the most production out of our animals and crops, and have good animal health.”

Asked what is the most critical time for feeding in an animal’s life, Brady says, “From the day it’s born to the day the animal leaves the farm, it’s all important and because we lot feed on a full TMR everything is critical.

“We monitor animals and their growth rates from when they start TMR at five months old.”

Brady takes on TMR mixing himself and relies on ONEFeed, an electronic feeding system, to track daily mixes, with dry matter intake and quality being particularly important.

Dry matter also helps maximise intake and consequently he gets higher production.

A cow eating a well-balanced

“GETTING A CONSISTENT PRODUCT WITH THE RIGHT DRY MATTER IN A TOTAL MIXED RATION IS THE KEY. OVER THE YEARS WE’VE GOTTEN BETTER AND BETTER.”

diet of TMR and silage is able to produce optimally.

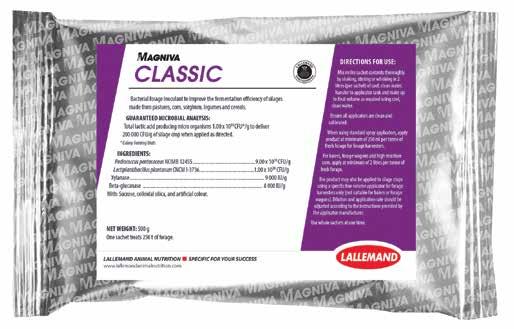

Brady also relies on Lallemand to keep his cows healthy.

Lallemand develops microorganisms, yeasts, bacteria, fungi and their derivatives.

Their theory is that a dairy farm has several microbial ecosystems, from the forage to the cow’s rumen, all hosting natural microflora.

“By managing these microbial ecosystems, producers can optimize performance, quality, and safety while contributing to sustainable dairy production.”

Brady says Lallemand has a good product offering covering inoculants and production advice. He says Dave Lewis, Technical Service Manager at Lallemand, has helped him achieve his production goals and boost animal health.

“I’ve learned a lot from him. He has helped me make and manage silage.”

Brady also relies on a GEA CowScout collar that tracks rumination and will send a notification of reduced eating and rumination times, which helps Brady identify health problems early on.

The collar also tracks heat and identifies animals entering the milking shed.

Brady says attention to detail, teamwork, and consistent monitoring are what keep the system running smoothly from paddock to pit.

With the right people and practices in place, he’s confident his herd will keep performing at its peak for seasons to come.

HAD HIS BOILERMAKER FATHER NOT DECIDED ON A CAREER CHANGE, DAIRY FARMER ALEX ROBERTSON MIGHT HAVE HAD A VERY DIFFERENT CAREER AFTER GROWING UP IN MELBOURNE CITY.

With his father Ian’s own childhood spent on a dairy farm in Thomastown, after years in the trade he’d had a hankering to get out of the city and return to rural life.

This had seen the house in suburbia sold and the hunt for a farm further west.

Weekends regularly spent with his cousins came to an end as the family moved a two-hour drive away, to a farm in the Colac area.

It was a big adjustment for the entire family, especially his mother Bev who had always lived in the city.

The change of pace out in the countryside and lack of other family around were initially a bit daunting for the then nine-yearold Alex.

“I found it a bit of a challenge,

ALEX ROBERTSON (MIDDLE LEFT) AND BROTHER ROBERT (MIDDLE RIGHT) WITH THEIR LATEST ACQUISITION – A STRAUTMANN VM4501 MIXER WAGON.

but eventually it sort of grew on me,” he reckons.

After five years or so, a “blank canvas” farm of 400 acres came up for tender at Simpson and the family moved again. With just a house and a shed on it, and a single fence running up the middle of it, the farm became a work in progress for some years. Getting a dairy shed up and running was the first priority, but that was just the start.

HARD WORK AND KEEPING UP WITH INNOVATION HAS CONTRIBUTED TO THE SUCCESS OF THE ROBERTSON BROTHERS DAIRYING OPERATION.

“We had to break it in. The dairy, a 14-unit herringbone, went up and then we had to put fences on, track it, and laneway it. Basically, start from scratch,” Alex says.

SANDY LOAM SOIL IS WELL SUITED FOR FARMING IN THE HIGH RAINFALL AREA.

By the time he left school, Alex was fully immersed in agriculture and rural living, with few thoughts of a return to the city. While his brother Robert worked on the farm with his father, Alex moved more into agricultural contracting.

An interest in all things mechanical saw him thrive in that business for around 12 years.

But when his father died 23 years ago, he had to rethink the long irregular hours involved with contracting. Plagued by an injury for years this also made the change easier.

“I had a back injury that just wasn’t getting any better, so pretty much had to get out of it,” he says.

“So, I ended up taking over the farm with Robert. I still like tractors and farm equipment – it’s pretty much my forte. Whereas my brother, he’s breeding the [Holstein] cows.”

The partnership between the brothers has been a successful one with more land added to the dairy farm over the years, now covering 850 acres.

Another farm, about 50kms away has also been added. At a couple of thousand acres and considered the main farm, its role is to back-up the dairy operation.

“We rear heifers and feed the cows when they get dried off.

They go out to there for around six weeks and then come back to the home farm. During the summer months we grow a lot of silage out there and irrigate maize as well.”

With calving in January, May and September and a peak of around 1200 milking cows, the operation is too big for Alex and Robert to handle by themselves which requires six or seven other staff members on site.

These days other contractors do the maize and silage work on the property, but Alex keeps up with what’s going on through friends still involved with the industry. His love of machinery and engineering has also shifted sideways to the mechanics and technical side of milking.

“I went over to Mystery Creek [Fieldays - New Zealand agricultural show] recently with some contracting friends. I wanted to have a look at the dairy side of

things as I’m into building dairies and it’s always good to look at new innovations.”

Doing his home-work a couple of years ago had been behind the decision to replace the older 44-bail rotary dairy they’d been using for 20 years with a new 80 bail Waikato rotary dairy.

When his father died, the original herringbone shed was demolished with the 44-bail rotary taking its place. At the time, they were only milking around 300 cows and it was ample. But as time went by and their operation increased in size, they found they could be spending up to 10 hours a day in the milking shed. The long hours were becoming untenable.

So, the new two-hour milking sessions in the morning and again in the evening that the new

PORTABLE IRRIGATION AROUND THE FARM IS SUPPLIED VIA A IDROFOGLIA IRRIGATION SYSTEMS TURBOCAR EXTREME.

shed provides, has been more than welcomed.

The new shed has also seen a digital upgrade for the farm. This sees the multiple digital components of the operation connected, with the various computers “talking” to each other.

“We have the JanTec monitoring system with reading and identification, and then we have the Allflex collars also linked into that setup, and the Waikato platform.”

Alex felt an integrated system, favoured by some brands, could restrict another brand’s tech being added into it further down the track. This ability to add and

WITH 40 TONNE OF SILAGE FED OUT TO DAIRY COWS DAILY A HUGE STOCKPILE IS KEPT ON SITE.

adapt as newer tech becomes available into the future should give the overall system more longevity, he reckons.

The ease and simplicity of the Waikato system really appealed to him as it would be easier to understand and operate by new staff, including short-term backpackers.

“Instead of guys touching numbers and stuff on the table codes

and getting confused, they’ve just got colours. Sometimes the colours flash different colours or they don’t flash.”

Along with recording fat, litres, protein and cell count, the system picks up information including if a cow is on meds/antibiotics and if their milk needs to be separated.

Data conveyed from the collars can see different coloured lights flashing depending on what the data is telling the computer.

“With the drafting gates also connected to the computer, if the collar detects something, it will talk to the computer and that ani-

ALL MAIZE GROWN ON THE FARM IS USED IN THE DAIRY OPERATION.

mal can be drafted off. If she’s in heat so that she can be AI’d, or if she’s got any diets, or if she’s not well.”

If a cow doesn’t milk out to its average, the computer will automatically send the cow around again.

One feature Alex particularly likes is when the cow has finished and has been logged off by the computer, a worker can’t then accidently put her back on again as the table won’t allow her on.

“It’s quite efficient, quite simple, and quite easy to train people to use. If something needs to be changed about the track, it’s not going to be a hard thing to recognise.”

The shed also sports new solar panels paid for with a grant from the supermarket chain he supplies.

“They have programs that will give you a subsidy if you want to increase the safety of your farm or you want to do something environmentally that improves your environmental footprint,” says Alex. “And then the government kicked in with another grant for it.”

Alex estimates the panels have cut his power bill in half in the six months he’s had them.

This push for both efficiency and simplicity on-farm as the operation has grown, also extends to a new feed mixer. Although there have been a few headaches finding the one that could handle the mount of silage they feed out each day.

Increasing stock numbers saw them outgrowing an initial twin screw mixer after a few years. A triple screw replacement also

became too small after another four years. This mixer has remained on site. Originally planned as Plan B - a backup - it has been called upon more than anticipated. A move to a different brand didn’t increase the feed volume as expected and another change saw another machine that ejected feed onto the ground while mixing.

So, it was with some relief when Alex and Robert took charge of their new Strautmann triple auger VM4501 mixer wagon six months ago - the largest available and the first one of its kind in Australia.

Holding 20 tonnes of silage, this is an increase of three tonnes on the last mixer they owned, and sees them feeding out with it usually twice a day - although this creeps up to three times a day when there isn’t much feed about.

“It seems to work really well and does a really good job. We don’t have feed spilling all over the ground like we used to. The dealer is also in close proximity to us and has a good reputation,” says Alex.

An added bonus has been that, despite the extra capacity, they haven’t had to upgrade their Massey Ferguson 8470 tractor which has a 230HP motor.

The augers are also stepped along the spiral which lifts and loosens the fodder without over-processing and uses less power. With the gap between these steps now reduced to every 60 degrees of angle, this sees a further reduction in power required to drive it.

Alex reckons it still takes more power than the smaller wagons they’ve used.

“If you’re putting up to 20 tonnes in it, you’ll use pretty much all that power. If you’re doing light loads, you won’t use as much,” Alex reckons.

The Colac area in Victoria has a reputation for being fairly wet, with the many lakes in the area testament to the ample rainfall. The farm has had a lot of subsurface drainage put in to help deal with that abundance.

But there hasn’t been much need of drainage recently as Alex and Robert have had to adjust to one of the worst dry spells they have experienced.

The last 16 months have been

tough going for large parts of south eastern Australia, which has experienced the lowest rainfall on record. This, coupled with some of the highest recorded summer and autumn temperatures, has seen many farms struggling.

While there has been some rain, it has often come at the wrong time, and rain over winter came too late to provide the usual autumn flush. Autumn rains would normally have seen solid pasture growth before the cold

of winter, which largely sees the end of grass growth.

“It’s been very different I can tell you. I’ve never seen anything like it. Cattle just dropping for no reason and dying.”

Water has been tight at times though, with most water coming from bores they have managed. Even so, the grass hasn’t been growing, and they are going through the silage and other feed more quickly.

Alex is hoping for rain and a mild spring to warm the soil

for grass growth as he expects they will run out of silage, with off-farm feed getting harder to buy.

He recalls another drought back in 2006 which saw lake levels in the area dropping to very low levels and revealed the intact wreckage of a World War II RAAF Wirraway in Lake Corangamite. After skimming the water’s surface as it came down and with enough time for the pilot to escape, the plane then sank and rested submerged on the lake

A SERIES OF TRIAL AND ERRORS WITH MIXER WAGONS HAS SEEN THE STRAUTMANN VM4501 GET THE THUMBS UP FROM ALEX AND ROBERT.

bottom for over 50 years. The two-seat planes were used as trainers for hundreds of pilots during the war at the flying training schools in Uranquinty and Deniliquin.

With the plane finally recovered in 2021 for restoration, it’s no longer a gauge of how severe this drought is in comparison to the 2006 one.

Though the lack of rain is hitting the southern region hard, Alex is philosophical about the drought which he reckons is just part of the highs and lows of farming. How long this dry spell is likely to last is uncertain.

“Well, everyone’s an expert. Everyone’s blaming climate change.”

Regardless, droughts have always been part of the mix for agriculture in Australia, he says. “I think it probably will come good, but it will take a little while, as it always does in farming,” he says.

FARMERS ARE ALWAYS ON THE LOOK-OUT FOR SOLUTIONS TO BOOST BUSINESS EFFICIENCY AND PRODUCTIVITY, AND NOW CNH HAS LAUNCHED A NEW PRODUCT THAT PROMISES TO BE A ‘GAME-CHANGER’ FOR MANY FARMING OPERATIONS.

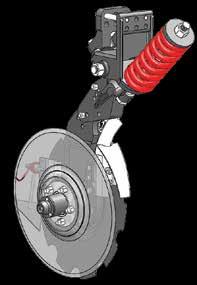

CNH has launched RS1, the most powerful high-speed steering system in the industry, designed to be fitted to earlier model Case IH and New Holland machinery to allow for the latest technology around positioning, speed and performance.

For CNH, RS1 is a result of the acquisition of Raven Industries in 2021, which allowed it to leverage Raven’s 50 years of innovation in the precision agriculture technology space to enhance its machinery offering to Case IH and New Holland customers.

“We’ve been able to bring this level of technological expertise in-house, which has given

us the ability to accelerate the delivery of automated solutions to our customers; faster than we would have been able to through the conventional mechanism of using third parties,” said Jeremy Duniam, CNH Head of Precision Technology.

RS1 is an intuitive, easy-to-use unit, with exceptional precision at both high and low speeds, improving efficiency and giving the operator the opportunity to cover more ground in a day.

“RS1 is helping modernise the legacy fleet as we go further down the road of increasing automation. This latest technology paves the way for customers

to accelerate a lot of this automation around steering, implement control, and agronomic data sharing via our FieldOps platform – it’s equipping their older machines with current levels of technology,” Jeremy said.

“Equipped with the industry’s most accurate steering system, the receiver enables rapid line acquisition and smooth operation at both high and low speeds. It’s an ideal solution for all farming applications—from raised bed horticulture to broadacre cereal production.”

With a receiver that fits to the roof of the machine, and a stateof-the-art 12-inch wide, high-resolution screen, RS1 has been described as a gamechanger.

“The new screen and receiver will give our existing custom-

ers greater flexibility and speed around the tasks they’re completing. RS1 is a highly robust solution, with access to more satellites that increases its usability and reliability in the field. Overall, it’s just a better, faster solution for customers in the market today,” Jeremy said.

Customers wanting more details on RS1 and the current promotion on offer can find out more from their local dealer, who can also install the product.

“This is certainly an attractive offer for customers looking to upgrade the performance of their machinery fleet. The RS1 is a guaranteed high return on investment that will deliver time savings and higher productivity all day, every day, for your business,” Jeremy said.

You deserve technology that’s both compatible with your existing fleet and easy to use. That’s why PTx Trimble leads the way in engineering solutions – including displays, steering systems and guidance control – that allow you to connect your farm, your way for seamless work all season long.

This farmer uses: GFX-1060™ display with Precision-IQ™, Autopilot ® steering system, NAV-900 guidance controller, and Trimble ® CenterPoint ® RTX correction service. Scan to learn more and contact a local dealer.

QUIGLEY CONTRACTING’S ROOTS RUN DEEP IN MID CANTERBURY, WHERE THE QUIGLEY FAMILY HAS BEEN FARMING SINCE 1961.

What began as a family commitment to the land at Punawai, Westerfield, has grown into one of the region’s most reliable and well-respected agricultural contracting businesses. Quigley Contracting officially launched in April 2003, but the real story starts long before that. It starts with a young farmer, supportive parents, a few key pieces of machinery and a simple goal: to support the needs of the family sheep farm.

ness, both in terms of practical backing and the confidence it gave to build something meaningful. At the outset the vision was humble - simply to service the home farm. But like many ventures that grow out of necessity and passion, it didn’t stay small for long.

MODERN GEAR AND EXPERIENCED OPERATORS ENSURE EVERY JOB IS COMPLETED TO THE HIGHEST STANDARD.

The first couple of seasons were a tight-knit affair. It was very much a family effort, with everyone rolling up their sleeves to get the work done. It quickly became clear that one-size-fits-

all wouldn’t work in this region. Clients wanted choice and reliability, and they needed a team that could turn up on time and get the job done right. By the end of year two, the baler fleet had grown from one to four, with Quigley Contracting adapt-

In those early days, the equipment list was modest - a 3x3 square baler, a tractor, vee rake, wrapper and a couple of old truck trailers. Additional tractors and vehicles were leased from the Managing Director, Andrew Quigley’s parents, David and Jill Quigley, who helped get things off the ground. Their support was foundational to the busiacross ditch the

PROFILED IN NZ’S RURAL CONTRACTOR & LARGE SCALE FARMER AUGUST/SEPTEMBER 2025, WE VISIT QUIGLEY CONTRACTING IN MID CANTERBURY, NEW ZEALAND.

INNOVATION ON SHOW: MODERN MACHINERY EQUIPPED WITH THE LATEST TECHNOLOGY FOR PRECISION AND PERFORMANCE.

ing rapidly to meet demand. In 2006 the company added its first silage harvester, following a long round of discussions with local farmers. It was clear that chopped silage would play a key role in the region, offering the most efficient way to move large volumes of feed. That insight came not from watching competitors but from listening directly to clients.

By 2008, Quigley Contracting had added a second forage har-

vester, expanded the baler fleet to eight and acquired trucks and gear to support the growing demand.

A management team had also stepped up helping manage day-to-day operations. That support was critical as the business grew, and it signalled a shift from a family operation to a well-structured company capable of servicing large areas and diverse farming operations.

In 2011 the business expanded

again, this time into cultivation and drilling. The catalyst was land ownership. With land to manage, it made sense to invest in the equipment needed to do the job properly.

But like many good ideas, what started as a way to service their own land quickly became a commercial service for others. Equipment availability was stretched, and the demand from clients for reliable cultivation and drilling soon eclipsed the original plan.

FROM DRILLING TO HARVESTING, QUIGLEY CONTRACTING HAS THE GEAR AND EXPERTISE TO MEET EVERY CLIENT’S NEEDS.

That same year, the company invested in a fodder beet planter. The crop was emerging as a strong performer for winter grazing, and Quigley Contracting could see the potential early.

INNOVATION ON SHOW: MODERN MACHINERY EQUIPPED WITH THE LATEST TECHNOLOGY FOR PRECISION AND PERFORMANCE.

The following year, they imported their first fodder beet harvester from the UK, one of only two in the country at the time. Fodder beet rapidly gained popularity in the region and has since become a staple diet for winter feed in Mid Canterbury and beyond.

PRECISION CULTIVATION UNDERWAY AS PART OF QUIGLEY CONTRACTING’S COMPREHENSIVE SERVICE OFFERING.

In 2013, further innovation arrived in the form of effluent umbilical systems. One of the management team at the time pushed for the investment. Like many things in contracting, it was a slow burn at first. The system took time to master, but perseverance paid off.

The slurry side of the business has continued to progress and adapt over the years. They are currently operating two large volume tankers which meet the demands of their clients.

Across the two decades since it started, Quigley Contracting has seen the region and the industry change. Machinery has become more advanced, more efficient and significantly more reliable.

The early days of Freeman balers are long gone, replaced by Claas and Krone balers capable of delivering higher density bales with better throughput. Autosteer has become the norm in

many of the tractors, increasing precision and reducing operator fatigue. Embracing technology has not been about chasing trends but about finding ways to deliver a better outcome for clients - and that has remained a consistent focus.

Mid Canterbury itself has also transformed. Irrigation is now widespread and sophisticated. The shift from border dyke systems to ponds, roto-rainers and now pressurised pivot systems has changed the productivity and potential of the landscape. That evolution has come with new challenges and expectations, especially around service delivery, compliance and health and safety.

These days, Quigley Contract-

AT ITS CORE, THE BUSINESS REMAINS GROUNDED IN THE VALUES IT STARTED WITH - RELIABILITY, SERVICE AND DOING THE JOB RIGHT.

ing is no longer just about a run of the mill contracting service. It is about people - those who work in the business, those who rely on it and who are trying to bring forward the latest in innovation and technology to the agricultural community. Recognising the need to maintain a high standard of service, a management team has continued to grow through the business with each member

TRANSPORT IS ANOTHER KEY SERVICE AREA WITH 15 TRUCK UNITS IN THE FLEET.

a crucial part of the structure, enabling the business to maintain the consistency and quality that clients expect.

“The clients make the business, but it all starts from the right foundations,” says Sam Nelson, sales and account manager. “We stand by our team, constantly in pursuit of providing the best service to our clients to be a key partner in their progress.”

A proud quality of Quigley Contracting is providing a pathway to success for its people. This steams across the entirety of the business with many success stories from the workshop, management and admin team who have all progressed their careers often from an operational roll or from a work experience position. As the business has continued to grow it has explored several

structures around client facing and sustainability. Quigleys has found itself a core, experienced management team, allowing the time and headspace to think strategically and innovate ideas, which ensures operational improvements are implemented and carried out.

“Capacity and scale is only

IT IS ABOUT PEOPLE.

achieved by having the right people in the right places,” says Tim Pearce, chopping and transport

manager. “In order to provide success, the key is building a team of like-minded people to ensure every job is done to the best possible standard.”

As agriculture has progressed, health and safety has become more of a major focus on- and off-farm. Quigley Contracting takes that responsibility seriously, making sure everyone in

QUIGLEY CONTRACTING’S SUCCESS IS BUILT ON TEAMWORK AND DEDICATION.

the business understands their role in creating a safe working environment. The management team plays a key part in embedding those values and practices, ensuring that every job is done with care and that everyone gets home safely at the end of each day.

At its core, the business remains grounded in the values it started with - reliability, service and doing the job right. From mowing and baling to wrapping and transporting, Quigley Contracting offers a comprehensive start-to-finish service across

all types of forage. Whether it is rounds, square or bulk fine chop, they can do it all.

Their silage services are equally flexible. With three forage harvesters and loader wagons in the fleet, they can cater to both short and long haul situations.

Additional technology, such as a silage bagger, adds another layer of efficiency and storage flexibility. Stack quality is a point of pride, with experienced stack operators, quality control and a focus on presentation that goes beyond just getting the job done. Covers are supplied as needed,

A HARVESTER AT WORK ON A CANTERBURY PROPERTY, DELIVERING EFFICIENCY AND QUALITY FEED.

and stacks are regularly finished and covered by the team.

From maize and grass to cereal and lucerne, all crops are handled with care and the right gear. On the cultivation and drilling side, the company has assembled a wide range of equipment to ensure the right tool for every job. There is no one-size-fits-all solution in farming, and Quigley

Contracting has responded by offering versatility and depth.

The list is long and impressive. They offer a range of primary and secondary cultivation machinery, which is capable of dealing with the various soil types Canterbury has to offer, from light silty soils through to more challenging rocky soils. This then leads on to their drilling and planting fleet, with equal amounts of flexibility ranging from direct drills, cultivation drills, precision planters and broadcasting drills. This fleet has been built deliberately, to offer a solution for every soil type, farm system and seasonal condition.

Transport is another key service area. With 15 truck units, of which are high productivity motor vehicles carrying in excess of 32 tonnes, the business can move silage, bales, grain, fertiliser, pig manure, wood chip and more.

Augers and grain vacs add flexibility across product types, and knowledge of inter-island freight networks ensures that North Island logistics are efficient and cost-effective.

A FAMILIAR SIGHT ACROSS MID CANTERBURY, QUIGLEY MACHINERY GETTING THE JOB DONE.

Matched with high density baling, this makes for an unbeatable transport solution. Quigleys are excited to be adding a purpose-built bulk blower unit which offers another layer of service for their clients.

As any business would admit, it takes the right team to keep the wheels turning and the business successful on a day-to-day basis.

Quigleys have found themselves in a fortunate position where full-time and season-based labour is filled by passionate and energetic people from around the world. Quigley Contracting recruits a skilled team of operators every year from September through March.

“Every year is a different rollercoaster ride,” says operations

manager Rob Raisbeck. “You get to meet a huge amount of people from all backgrounds while watching the agricultural industry develop in exciting ways.”

Quigley’s are now operating out of their new purpose built yard, based in Winslow, five minutes out of Ashburton, just an hour south of Christchurch. Support is provided from the outsetfrom airport pickup, fully catered accommodation and a friendly welcoming team of people with similar interests in the agricultural industry.

That focus on looking after people is one of the reasons the business has sustained success for over two decades. Loyal clients have stood by the company, and loyal staff have built a cul-

ture of pride, performance and teamwork. Running a business like this is a privilege and it is not one taken lightly. In the words of the owner, the business is only as good as its people - and in this case those people are making a lasting difference to the farms they support and the region they serve.

The future for Quigley Contracting looks strong. With the right gear, the right people and the right approach, they have a constant pursuit to innovate whilst maintaining the roots of what the company was built on. They continue to prove that a local business with deep roots and a clear purpose can not only survive in a changing agricultural landscape but thrive.

AUSTRALIAN FARMERS AND EXPORT CUSTOMERS RELY ON SUPPLEMENTAL FEED TO ACHIEVE PEAK PERFORMANCE FROM THEIR ANIMALS. CONTRACTORS WHO FOLLOW BEST PRACTICE AND USE THE LATEST TECHNOLOGY CAN MEET THEIR CLIENTS’ DEMAND FOR HIGH QUALITY HAY AND SILAGE. HERE ARE SOME OF THE LATEST TWINES, NETWRAPS, SILAGE FILMS AND INOCULANTS THAT WILL HELP YOU PRODUCE TOP QUALITY FORAGE.

The quality of silage is a critical factor in the success of livestock farming. Whether feeding dairy cows, beef cattle, or sheep, the quality of preserved forage directly impacts animal health, production efficiency, and profitability. Central to achieving high-quality silage is the fermentation process, which transforms harvested forage into a nutritious and stable feed. However, the fermentation process is highly dependent on the exclusion of oxygen—a factor that premium silage covers play a crucial role in controlling. At Tama, we understand the vital role of oxygen management in the preservation of silage, which is why we provide Silacover, a high-quality silage cover specifically designed to form an effective barrier against oxygen infiltration.

The fermentation process begins once forage is compacted in the silage pit, a crucial step in creating anaerobic conditions. In the absence of oxygen, naturally occurring lactic acid bacteria break down sugars in the forage and convert them into lactic

acid. This lactic acid is key to preserving the forage, reducing its pH, and preventing spoilage by undesirable microorganisms. A successful fermentation process results in nutrient-dense silage that can be stored and fed to livestock throughout the year. However, oxygen is the enemy of effective fermentation. When oxygen enters the silage pit, aerobic organisms, such as moulds and yeasts, proliferate.

These organisms consume the valuable nutrients in the silage and cause spoilage. Not only does this reduce the nutritional value of the feed, but it also increases the risk of feeding spoiled forage to livestock, which can have severe health implications. Therefore, it is essential to prevent oxygen from entering the silage pit at all costs.

Recent studies have emphasized the critical importance of selecting high-quality silage covers to enhance feed preservation. Research highlights that modern multi-layer silage films can reduce dry matter losses by up to 50% compared to traditional single-layer covers. These findings underline how advancements in production techniques, such as the development of oxygen barrier films, contribute to maintaining optimal fermentation conditions. By investing in premium covers, farmers can prevent oxygen infiltration more effectively, safeguarding

the nutritional integrity of their silage. Tama’s Silacover incorporates the latest innovations in material science, ensuring that farmers benefit from the most advanced and reliable oxygen barrier technology available.

At Tama, we recognize the significance of creating an oxygen-free environment for the fermentation process. Silacover is designed to provide a robust barrier against oxygen ingress, ensuring the success of the anaerobic process. Manufactured with advanced multi-layer technology, Silacover is durable, tear-resistant, and capable of withstanding Australia’s varying weather conditions. The flexibility and strength of Silacover make it ideal for covering large silage pits, sealing them tightly, and maintaining the essential anaerobic environment throughout the entire fermentation period.

Our silage covers have been specifically developed with

UV protection, meaning they retain their integrity under prolonged exposure to sunlight. This is essential, as many silage pits remain sealed for extended periods. The high puncture resistance of Silacover ensures that it remains intact even when subjected to rough handling or environmental hazards such as animals or debris.

Tama is proud to have a relationship with Lallemand, a global leader in animal nutrition and forage inoculants. This partnership allows us to understand the finer points of developing fodder that meets the criteria for milk and beef production.

Effective silage preservation is not just about storage—it’s about ensuring that the nutritional quality of the feed meets the needs of high-performing livestock. By using Silacover, farmers can have confidence that their silage will support optimal milk yields and weight gains, maximizing the value of their forage investment.

The use of premium silage covers is not just about preventing spoilage; it’s about protecting your investment.

The forage you harvest represents a significant portion of your farm’s resources, and by investing in high-quality covers from Tama, you ensure that your silage retains its full nutritional value.

By preventing oxygen ingress, Silacover helps to minimize wastage and ensures that you’re feeding your livestock with the best possible forage, leading to better animal health, higher productivity, and ultimately, improved profitability for your farming operation.

In conclusion, the fermentation process is the foundation of high-quality silage, and protecting this process from oxygen exposure is critical. Tama’s Silacover provides the best defence, ensuring that your silage remains nutrient-rich and spoilfree, offering peace of mind that your livestock are receiving the best possible feed.

For many Australian producers, fodder storage is no longer just about getting through a single season. Weather volatility, shifting markets, and feed security concerns have made long-term storage a key part of farm planning. While silage and hay storage methods vary, one factor remains central to success: the integrity of the bale from the day it’s made until the day it’s fed out.

Bale netting plays a critical role in this process. It’s the first line of defence against the elements, pests, and physical damage during transport and storage. A well-formed, securely bound bale is less likely to lose shape, shed material, or allow moisture to penetrate — all of which can compromise feed quality. It’s no surprise that New Holland, known for its high performing hay equipment, would partner with the world’s best netwrap manufacturer Tama.

“Last year, areas with prolonged dry conditions reminded everyone just how important high-quality silage and hay is,” says Andrew Makin, Sales Manager for Zeus Australasia.

“With feed costs rising to fill forage shortfalls, it’s not about finding the cheapest wrap — it’s about protecting the feed your herd depends on.”

The Zeus Epicrop range of

The latest generation of New Holland round balers has earned a reputation for producing dense, perfectly formed bales — and New Holland Infinet + netwrap is designed to protect those bales in even the toughest conditions.

While bale netting may look similar across brands, there can be significant differences in performance. Tensile strength, weave structure, UV stability, and edge-to-edge coverage all influence how well a net will protect a bale over time. Lower-quality nets may perform adequately in the short term but are more likely to fail when bales need to be stored for extended periods or handled multiple times. This is where ongoing research and development by net manufacturers is vital. Testing net performance in different crops, climates, and storage conditions allows manufacturers to understand how materials and construction affect product integrity. From there, design

improvements can be made — whether that’s adjusting tensile strength to better resist tearing or optimising the stretch characteristics for uniform coverage.

In some regions, bales are stored for 12 months or more, often outside in open paddocks. In these conditions, UV exposure is a major threat to net integrity. High-quality nets incorporate UV stabilisers tested to withstand prolonged Australian sunlight, reducing the risk of netwrap breaking down before the bale is fed.

Ensuring nets remain intact throughout storage — and choosing nets designed to retain

their bale binding ability under stress — can mean the difference between high-quality feed and waste.

With the industry’s push toward greater efficiency and reduced wastage, the role of bale netting will only grow in importance. Producers who prioritise net quality — and who understand the benefits of ongoing product innovation — are better placed to protect their investment in stored fodder.

After all, good fodder storage doesn’t start in the shed or paddock where bales are kept; it starts in the paddock on baling day, with the choice of net, Infinet+ by New Holland.

wraps is made with high-grade C8 polymers for strength, consistency and a reliable airtight seal.

Produced on advanced machinery, each multi-layer film delivers tight tolerances and top performance in impact resistance, tear strength, UV protection and tack.

“Trying to save a few bucks on a cheaper silage wrap can cost you more if it’s not keeping the air out,” Andrew warns. “Poor sealing allows mould to grow

and increases losses in the valuable grass you’re trying to store. When your forage affects milk yields and weight gain, cutting corners is a false economy.”

New to Australia this season, Epicrop Oxystop covers offer a true one-sheet silage solution. With a 7-layer structure and EVOH technology, Oxystop delivers one of the lowest oxygen permeabilities in its class. Lightweight, ultra-resistant and easy to handle, it helps reduce waste, limit Dry Matter losses and create the ideal environment for anaerobic fermentation, preserving more nutrients

in your silage. From wraps and covers to net and twine, the Epicrop focus is on reliability and ease of use.

“Your investment in fodder doesn’t stop at planting,” Andrew says. “Quality crop packaging reduces downtime at harvest and delivers a better-quality end product.”

With over 25 years of crop-packaging expertise, Zeus Epicrop is recognised worldwide for its quality and consistency.

Contact Andrew on 0488 528 599 or andrew.makin@zeuspackaging.com.au and follow Zeus Epicrop.

With sheds completely empty and reserves all but depleted, the 2025 season calls for smart strategies and top-quality homegrown feed.

It is time to rethink how we manage what we grow and getting ahead now means securing every tonne of quality feed while minimizing losses — because in a season like this, there’s no room for waste.

Quality feed = cost savings

In tough seasons like this, nutritional value is everything. Whether you’re making hay, bale silage, or storing up in bunkers, preserving the goodness in every tonne means spending less on expensive supplements later. While weather plays its part, there’s plenty you can control — starting with the right tools and products.

but a premium bale net is just as critical. Tight, well-shaped bales ensure your wrap creates a true airtight seal. Venus Packaging’s TotalCover nets are built for Australian conditions, with European-made strength and high UV protection. Choose from a wide range of specs to suit your machinery and crop type.

Wrap it right