THE PROFESSIONALS GUIDE TO CULTIVATION AND CROP ESTABLISHMENT

THE PROFESSIONALS GUIDE TO CULTIVATION AND CROP ESTABLISHMENT

FINANCE *

2 .5 P.A. FOR 36 MONTHS

ACROSS THE KRONE HAY TOOLS RANGE

ACROSS THE KRONE BiG TOOLS RANGE BUY NOW! PAY LATER NO REPAYMENTS FOR 6 MONTHS

BiG PACK Square Baler’s

The HDP 6 knotter 5th generation machine, with new hydraulic fan for the cleanest machine from top to bottom. Engineered for excellence, these balers redefine efficiency in hay and straw baling. Experience the pinnacle of productivity with Krone big pack square balers where you will achieve optimal bale density and uniformity with every pass, ensuring top-quality fodder for your livestock.

Keoghan appointed chair of Animal Evaluation Governance Group

takes out global award for Claas after sales excellence

running four free roadshows in June

Technologies and Good Earth Cotton: powering sustainable cotton

Farming now the home of JCB

campaign getting a re-run

GM of the machinery division at Power Farming brings a wealth of real world experience

place like home for dairy sector scientists

adoption, robots and the future of food feature at evokeAG. 2025

shows strong progress in half-year results

Ora decision could mark turning point for NZ Wool sector

NZ submissions on gene technology bill

Where New Zealand farmers can find value through PTx solutions

Väderstad proceed V 24 brings new technology to seeding machines

UK maize expands despite dairy decline

Transforming unproductive land: the ELHO Scorpio 550 in action

Truck scales of the highest quality thanks to durable load cells

How the AT220 is innovating pest tech

Handle with care for great results every time

boosts frontline staff to improve agrichem wait times

Kubota’s VT1100 Turbo-Max and HT1100 Terra-Max redefine soil preparation

FarmShop mowing to market leadership

Co-creation with the IoT and agriculture: solving agricultural issues with soil sensors

Advanced steering system improves accuracy and simplifies field operations 34 Heading-off one of autumn pastures’ biggest threats at the pass 36 Maximising efficiency and sustainability in farming with the Kverneland iXtra LiFe 38 The all-new Deutz-Fahr 6C 40 Power Farming expands precision ag offering with Topcon partnership 41 The slug solution 42 With all the different camera options -what's the best choice for my property? 45 Cirrus trailed cultivator drill more than just sowing 46 Innovation in cultivation: the future of strip-till, discs and roller drills

49 John Deere’s precision essentials to save dollars and drive tech adoption

50 Rollmax Roller Drills 52 Amazone Ceus the all-in-one machine

53 Stunning optics combined with strong internal qualities

53 Game-changing speed tillers from Tulip 54 Horsch and Grange optimising productivity in primary cultivation

56 Power Farming service, buyback schemes, bolster new business owners 60 Across the Ditch: Holm family continues family legacy 02 From the Editor: Hello and welcome

Editor Angus Kebbell 022 052 3268 angus@agrimedia.co.nz

Advertising Manager

Michael Lightbourne 021 403 853 michael@agrimedia.co.nz

Advertising Sales

Lisa Phelan 021 782 228 lisa@agrimedia.co.nz

Circulation

Hilary Armstrong 027 443 3477 admin@agrimedia.co.nz

Production Design and Layout

Hannah Kincaid art@agrimedia.co.nz

Contributors

Heather Chalmers, Kathy Davis, Elisabeth Johnston, Andrew Olsen, Mark Devlin, Celine Walters-Gray, Marcia Welch.

Printed by Blueprint Ltd

Read our magazine online ruralcontractor.co.nz/read-online

Whether you like or loathe Donald Trump and his policies, he certainly does not muck around in terms of making change.

ANGUS KEBBELL, EDITOR.

Follow us facebook.com/nzrclsf instagram.com/nzrclsf ruralcontractor.co.nz

Scan here to sign up to our digital newsletter

PO Box 36753 Merivale, Christchurch 8146 ph 03 329 6555 www.agrimedia.co.nz

Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping, Australian AG Contractor & Large Scale Farmer, NZ Novachem Agrichemical Manual.

The United States' decision to withdraw from the Paris Agreement once again under President Trump’s leadership is a bold move that raises questions about New Zealand’s own commitments under the accord. The Paris Agreement has long been touted as a landmark international effort to combat climate change, but, in reality, one could argue it has proven to be more of a political instrument than an effective mechanism for meaningful environmental progress. The question New Zealand farmers must now ask is whether our own commitments to the agreement are serving our best interests or simply placing an undue burden on our agricultural sector. Farmers in New Zealand are no strangers to the pressure of meeting stringent environmental regulations. While we are among the most efficient food producers in the world, our sector continues to face increasingly restrictive policies aimed at reducing emissions. These policies often ignore the fact that New Zealand’s agricultural emissions profile is vastly different from that of industrialised nations, where fossil fuels are the primary culprits. Instead, and as it currently stands, we have ambitious climate targets that could place unnecessary strain on rural communities, affecting productivity, profitability, and ultimately food security. Trump’s move to withdraw from the Paris Agreement is centred around the notion of prioritising national interests - an approach that New Zealand could consider more seriously. The United States is essentially rejecting an agreement that imposes costly commitments while offering little in return, particularly when other major emitters such as China and India are not held to the same standard. This raises the question: Should New Zealand, a country responsible for a minuscule fraction of global emissions, continue to bear the financial and operational costs of a system that does not recognise our unique circumstances? New Zealand farmers are already among the most sustainable in the world. Our pasture-based systems, efficient water use, and world-leading research

© RURAL CONTRACTOR AND LARGE SCALE FARMER - No part of this publication may be reproduced in any form without the prior written permission of the publisher. Opinions expressed in this publication are not necessarily that of the publisher and suggest independent advice be sought before acting on information or suggestions contained herein.

in methane mitigation place us at the forefront of sustainable farming. The United States’ withdrawal could prompt our own government to reassess whether our commitments align with both our economic and environmental goals.

This is not a call to abandon environmental responsibility. New Zealand’s farmers know better than anyone the importance of protecting the land and waterways that sustain their livelihoods. However, any climate policy should be grounded in pragmatism rather than ideology.

Like every edition of Rural Contractor and Large Scale Farmer this one is full of people and businesses striving to be better not only in terms of efficiencies for farmers and contractors but also working hard for positive environmental outcomes - from articles on improving crop establishment and cultivation, to gene technology, innovation in pest control, to name a few. It is heartening to see an industry so dedicated to constant improvement across the board.

Contributions - Editorial and photographic contributions are welcomed and should be sent directly to AgriMedia Ltd. Editing of submissions is at the sole discretion of the editor and will accept no responsibility for unsolicited material.

Keoghan has been appointed as Independent Chair of the Animal Evaluation Governance Group.

DairyNZ Chair Tracy Brown welcomed the appointment noting that Rebecca comes with the right mix of senior governance experience paired with a strong dairy background.

“As a fifth-generation dairy farmer Rebecca understands the importance of our industry and its challenges. I am excited to see this governance group now fully formed and set up to progress the workstreams to accelerate the rates of genetic gain in the New Zealand dairy sector,” she said.

Rebecca says she’s excited to take up this position, outlining her clear priorities. “I have been tasked with leading the governance group to achieve the objectives of this report,” says Rebecca.

The governance group was formed in 2024 to tackle the issues identified in the Industry Working Group's (IWG) final report.

“The report highlighted real opportunities for improvement for New Zealand. We know we’ve got plenty of work ahead of us to make the progress we need. We simply can’t sit on our laurels, or we will slip backwards,” she says.

The IWG report said the current system for genetic gain in New Zealand was not fitfor-purpose and that New Zealand’s genetic herd has lagged relative to other advanced dairy industries.

The IWG report noted its confidence that New Zealand can catch up to fully harness

gain, unlocking increased profitability and improving environmental outcomes.

“We’ve formed a road map for improving the genetic gain system for New Zealand’s dairy herd, and my job is to move us along it, providing the independent perspective and ultimately drive the work streams forward, working with my fellow members and their partner organisations,” Rebecca says.

DairyNZ, LIC and CRV have each committed to making changes for the sector’s benefit and are participating in the governance group and working with industry stakeholders, to take the report’s recommendations forward.

The governance group is overseeing a programme of work to strengthen animal evaluation for the purpose of accelerating genetic gain in the dairy sector that includes:

- establishing a future-looking National Breeding Objective

- developing a solution to have one Breeding Worth Index

- developing mechanisms to provide transparency and confidence in the system

- improving the volume and quality of phenotypic data collection

- bringing in relevant international expertise, and

- engagement and extension activities to increase the value for farmers of animal evaluation.

Rebecca joins Cam Henderson (DairyNZ), Corrigan Sowman (LIC), James Smallwood (CRV), and Steve Howse (NZAEL) on the Animal Evaluation Governance Group.

Rebecca is Chair of Fire & Emergency NZ and a director of Alpine Energy Limited and

Tai Poutini Polytechnic and deputy chair of Timaru District Holdings and has held multiple other directorships.

In 2016, Rebecca was awarded Dairy Woman of the Year, in 2017 she received a New Zealand Order of Merit (MNZM) in the Queen’s Birthday Honours for services to business, and in 2018 she was awarded the Rural Westpac Woman of Influence award. She has been appointed as independent

Landpower and its network of Claas Harvest Centre dealerships took out the foundational Global After Sales Excellence award in Bielefeld, Germany, during the annual Claas After Sales meeting last week.

Christian Radons, Claas Global Sales Director, said, “Service is the backbone of our success. Our global aftersales network maximises our machines' uptime, increasing customer service efficiency, and supporting our business with machine servicing, spare parts, service, and digital products.

"We give our customers the promise of harvest, and through our strategic objectives - customer loyalty, growth and profitability - our team members and partners deliver.

"Landpower is an outstanding ambassador of our brand values and a high-performing

distribution partner who is always professional in what they do to benefit New Zealand and Australian farmers.”

The Claas Global After Sales Excellence Award was developed to express Claas’s general appreciation for their global after sales network, which spans 134 countries and wholesale partners. The criteria of the award is based on performance within the four after-sales core functions: Customer Service Efficiency, Business Development, Product Portfolios and Supply Chain Management.

Claas products set a global standard for operating

33 Harvest Centres and 20 independent dealerships provide essential backup and support to customers across New Zealand and Australia.

performance and smart technology. Their machinery is distributed through the Landpower developed Claas Harvest Centre network across Australia and New Zealand. Represented by 33 Harvest Centres and 20 independent dealerships, they sell machines and provide essential backup and support to customers.

“We are delighted to have been recognised by Claas as an outstanding ambassador of the Claas brand values and a highperforming distribution partner.

We have proudly represented Claas since 1987 and we’re committed to providing worldclass service and after sales support, to go with the worldclass machinery we sell,” says Landpower CEO, Richard Wilson.

The award, accepted by Mike Parris, Technical Service Manager, followed his presentation to an audience of 200 attendees at the Claas Future is Calling conference in Germany, and was presented by Christian and Ulrich Timcke (SVP Global After Sales).

Rural Contractors NZ will kick off its 2025 roadshows in four centres in June and like the organisation’s conference, attendance will be largely free.

The RCNZ Board confirmed the dates and venues at its February meeting.

CEO Andrew Olsen says the first roadshow will be held at the Distinction Hotel in Hamilton on Tuesday June 17 with another the following day at Palmerston North’s Distinction Hotel.

The following week sees roadshows at the Croydon Lodge in Gore on Tuesday June 24 and the following day at the Commodore Hotel in Christchurch.

He says the roadshows, which were initiated in 2022, provide RCNZ members with an alternative to attending the organisation’s now bi-annual conference.

“We’ve got more than 600 members around the country and fewer than a third are able to

attend our conference. So, we're putting together the roadshows are as a way for more members to engage.”

The roadshows will each kick off with an early afternoon session sponsored by Nufarm, which is dedicated to members who are agricultural sprayers. It will then merge with those focused on grass harvesting and other cropping-related activities.

Andrew is planning for some short industry updates, including one on health and safety in rural contracting which will reinforce the RCNZ’s summer campaign on the risks of fatigue. The afternoon will finish with an opportunity to have a drink and catchup with old mates as well as some sponsor prize-draws.

Andrew says any Rural Contractor NZ member is entitled

to attend and also bring three other family or staff members for free. Any further attendees are welcome but there will be a modest charge.

“Our balance sheet and the support of our partners allows us to put this on for our membership

at no cost. We know that it’s a challenge for all of our members to get to our conference every second year, so we are bringing the roadshows to their regions.”

The 2026 RCNZ conference will be held in June next year in Christchurch.

AUTHORISED DEALERSHIPS THROUGHOUT NEW ZEALAND

KVERNELAND PLOUGHS

COMPACT DISC HARROW

• 2-8 furrows

• Robust and reliable construction

• Variomat Vari-width® system for furrow width adjustments that save fuel and time as standard

Ask about seamless integration with the Value Line Steering package

KVERNELAND U-DRILL SEED DRILL COMBINATION

Front & rear tyre packers present a uniform seed bed

CD coulter ensures consistent seed depth for greater germination

Seed & Seed & fertiliser options

3m, 4m & 6m models

“I’ve been in this space for nearly eight years, and I can’t find anything more compelling than this technology.”

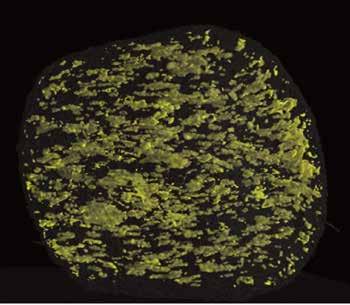

Danielle Statham describes her discovery of Downforce Technologies’ remote measurements of soil organic carbon (SOC) which provide historic data and annual monitoring of carbon at 10m resolution, as a “game changer”.

Danielle and her husband David co-own Sundown Pastoral Company and their cotton brand, Good Earth Cotton®, is a global leader in regenerative cotton farming, producing cotton that is designed to restore ecosystems by improving soil health and capturing carbon.

Since starting the venture, the pair has been driven by a mission to lift the environmental profile of cotton and provide their supply chain with a climate beneficial fibre, but they needed a way to measure carbon levels at scale and monitor the progress throughout the growing season.

“Downforce gives us the metrics we need to prove our environmental claims,” Ms

Danielle said. “It’s not just about saying we’re regenerative; it’s about showing it with real data and transferring that knowledge with integrity.

“Soil tests are essential for NPK testing, but we’re only positioning one point with a soil test. With Downforce, you get thousands of points.

“We thought it was too good to be true at first. But we gave Downforce a few blind tests in a biochar trial paddock where we had multiple soil test results. The Downforce figures came back as pretty much identical.

“The technology itself is a game changer for agriculture and environmental recordings at scale and having someone like Jacquie (McGlade, Downforce co-founder and chief scientist) and her intel in this space provides tremendous support.

“We work directly with many global brands. Greenwashing is an issue in the fibre industry as much as the textile and garment industry and legislative changes are tightening with what can and cannot be claimed. We can stand side by side with honest GHG protocol-aligned environmental data, supported by real scientific research

from experienced scientists.”

By delivering greenhouse gas emissions data through a three-year central moving average, Downforce enables Good Earth Cotton to quantify the positive outcomes of their farming practices.

Full transparency across the cotton supply chain is another key area where Downforce’s data helps Good Earth Cotton substantiate their claims.

Good Earth Cotton has partnered with FibreTrace®, a technology that provides full traceability for every bale of cotton. By embedding a luminescent pigment to the cotton at the gin, FibreTrace provides full fibre integrity and transfers the fibre intel when scanned at every stage of the supply chain, providing both physical and digital verification.

“Traceability has come a long way in recent years, but many brands still have no idea where their cotton comes from or the origin of the fibre it may have been blended with,” Danielle said.

“FibreTrace is like tracking a package, or putting an air tag on the cotton. By combining real-time digital monitoring with physical scanning of the garment, it gives visibility across the supply chain, so brands know exactly where their cotton comes from and where it ends up.”

With cotton traveling across continents and blending with other fibres, FibreTrace ensures that Good Earth Cotton’s product can be traced back to the source, maintaining the integrity of the product through to the finished garment or through to recycle.

Watertight traceability requires tangible, verifiable scientific data - which is where Downforce comes in. The data on greenhouse gas emissions, carbon sequestration, and soil health provided by the platform is a safeguard for Good Earth Cotton to verify its product across the supply chain.

Rodd and Gunn’s shift to verified cotton New Zealand-based menswear brand Rodd and Gunn relies heavily on cotton, which makes up more than 80% of its product range. While the brand has long used highquality cotton, achieving full traceability back to the farm has proved challenging in the past.

Samantha Helmold, Rodd and Gunn’s Sustainability and Ethical Sourcing Manager,

David and Danielle Statham, co-owners of Sundown Pastoral Company and Good Earth Cotton.

Downforce’s data flows through to the shopfloor, giving brands like Rodd and Gunn full traceability to verify claims on their product labels.

said that changed when Rodd and Gunn partnered with Good Earth Cotton.

“Good Earth Cotton were extremely transparent from the moment we met, providing a level of verified traceability that we previously struggled to achieve,” Samantha said.

“In 2019 when we started voluntary reporting under the Australian Modern Slavery Act, we were becoming increasingly concerned about the allegations of forced labour linked to certain cotton growing regions. With the oncoming global supply chain legislations and increased NGO scrutiny, being able to confidently verify the origin of our cotton became our number one priority.

“Good Earth Cotton, backed by Downforce Technologies, provides us with a complete solution - physical and digital traceability with verified environmental data to support our claims.”

By integrating Good Earth Cotton into its products, Rodd and Gunn now have full transparency across a large majority of their cotton supply chain. FibreTrace ensures the cotton can be scanned and verified at every stage, while Downforce provides environmental impact reports that quantify its footprint.

“We won’t make a claim on our products that we can’t support with verified data,” Samantha said.

“The combination of FibreTrace and Downforce’s data gives us the confidence to know that we’re meeting our commitment to responsible sourcing.

“It provides the consumer with a level of trust and assurance, empowering them to make a purchasing decision based on their own social and environmental values.”

The investment has been significant. In the first season, Rodd and Gunn sourced 300 tonnes of Good Earth Cotton to pilot across some of their core products. Due to an overwhelmingly positive response, the

brand increased its order to 1,300 tonnes the following season, enough to produce over 1.5 million garments across their polo, tee, sweat and knitwear categories in the coming year.

The partnership with Good Earth Cotton has also strengthened Rodd and Gunn’s ability to prepare for future challenges, including global regulatory pressure, climate disclosure reporting and growing scrutiny over supply chain practises and partnerships. By leveraging the tools provided by Downforce and FibreTrace, the brand is well-positioned to meet these demands while continuing to deliver highquality products into the future.

Power Farming is excited to announce a new chapter in its partnership with JCB. Having represented JCB Construction equipment for over three years, Power Farming is now expanding its relationship to include the renowned CB Agriculture product range.

From February 1, 2025, Power Farming officially began its role as the exclusive distributor of JCB Agriculture in New Zealand. The product line-up includes models such as the JCB Fastrac icon, telehandlers and 435/457 wheel loaders.

Comprehensive workshop, parts and warranty support is already in place to ensure a seamless transition for existing JCB owners.

“Power Farming is a family-owned business with its global headquarters in Morrinsville, Waikato. With over 75 years of operation across New Zealand, Australia, and more recently the United States, the addition of JCB Agriculture is a significant milestone in our ongoing growth,” said Tom Ruddenklau, CEO of Power Farming New Zealand.

This partnership not only enhances Power Farming’s product portfolio but also ensures

continuity and innovation in serving JCB Agriculture customers. The JCB Agriculture brand is already well established in New Zealand, and Power Farming extends its gratitude to the Landpower team for their exceptional care and leadership in developing the brand and setting a high standard for customer service. Power Farming is committed to ensuring continuity and a seamless transition for JCB.

With a world-class portfolio of agricultural

and construction equipment – including leading brands such as McHale, Kverneland, Deutz-Fahr, Kioti, and Maschio – Power Farming is uniquely positioned to meet the diverse needs of farmers and contractors.

“Our customers deserve the best - whether it’s cutting-edge machinery, tailored solutions, or reliable after-sales support. We’re confident this partnership with JCB Agriculture will deliver exactly that,” said Tom.

The summer campaign against fatigue run by Rural Contractors NZ is being refreshed in time for those working on the autumn maize crop.

RCNZ CEO Andrew Olsen says there’s been great feedback on the campaign which was fronted by veteran rural contractor Steve Murray.

He says the campaign was only able to have the reach it achieved because of the videos which were produced with the support of Power Farming.

“There are other organisations

promoting health and safety with financial backing from government agencies but nobody has tackled fatigue like we have.”

The decision to re-run the campaign for the maize season came from RCNZ Board member Julie Clark.

“I made all of my staff watch the videos before Christmas as

part of a Toolbox meeting and then we talked about the risks,” she says. "This made it more personal.”

She acknowledges that employers can only do so much to encourage their workers to avoid fatigue risks.

“You can’t control what they do as they go out the gate.”

However, she says it is important to reinforce messaging, particularly to younger staff to ensure they are eating properly and drinking enough fluids.

Julie said maize cropping started in early February in her home region of south Waikato and would continue through March/April.

Andrew says his members take their health and safety

Former RCNZ Chair Steve Murray fronted the fatigue campaign.

responsibilities very seriously and the campaign includes a video aimed at them.

“They’ve faced the usual summer weather challenges and crop deadlines and these now continue with the maize harvest.

The message is not to put themselves and their staff under too much pressure.”

Building in breaks is a key to avoid anyone getting fatigued, which can have terrible consequences.

A second video is aimed at employees reminding them of their responsibilities including being in a fit state when arriving at work and looking out for other workers.

The third video gives tips on avoiding fatigue, including eating good food, drinking lots of fluids and taking breaks. The videos are supported by more detailed material on the RCNZ website –ruralcontractors.org.nz

You deserve technology that’s both compatible with your existing fleet and easy to use. That’s why PTx Trimble leads the way in engineering solutions – including displays, steering systems and guidance control – that allow you to connect your farm, your way for seamless work all season long.

This farmer uses: GFX-1060™ display with Precision-IQ™, Autopilot ® steering system, NAV-900 guidance controller, and Trimble ® CenterPoint ® RTX correction service. Scan to learn more and contact a local dealer.

From the workshop floor to the boardroom, Bevin Wolland's career has been one of evolution, learning and leadership. Now, as General Manager of the Machinery Division at Power Farming New Zealand, he is focused on bringing technology and efficiency to the forefront of the agricultural sector.

Born and raised in Pahiatua, in the lower North Island, Bevin was immersed in agriculture from a young age. His parents, Maurice and Christine, established Wolland Contracting 50 years ago, and Bevin spent countless hours in the passenger seat of farm machinery, observing and learning. "I spent a lot of time sitting on that dreaded armrest next to the old man, taking in every move and function he did to operate the equipment,” he recalls.

This early exposure led to an interest in mechanics, and he quickly became adept at repairing machinery. "Growing up, I spent a lot of time in the workshop fixing gear and teaching myself how to weld," Bevin says. This hands-on experience translated into a career in heavy diesel mechanics, where he trained at Jackson Enterprises under the guidance of Trevor Jackson and his team. From 1995 to 2007, he honed his skills at Jackson Enterprises, Wolland Contracting, Cable Price, and Fonterra.

Despite his demanding career, Bevin has always been grounded by family. He and his wife Janine have been together for 26 years, raising three children – Josh, Harry, and Ella. Beyond his professional commitments, he serves as a volunteer station officer for Fire and Emergency in Fielding and will soon transfer to the Morrinsville Brigade.

His transition from hands-on mechanical work to management began in 2007 when he took on a role managing Fonterra’s tanker build business in Morrinsville. This role involved overseeing the construction and delivery of new tankers, ensuring efficiency and reliability in milk collection. Later, he returned to the family business, managing Wolland Contracting alongside his parents. "Growth was front of mind to succeed, being more strategic about what equipment we built and purchased, which in turn gained efficiencies and grew profits,” he explains. Leaving the family business was a difficult decision, but Bevin knew he wanted to expand his management experience. "It was probably the hardest call I made,” he admits. "As every son wants to take over their family

business, there was more than one of us, so we decided to do our own thing. The business is still successfully running with Maurice, Christine, and my younger brother Jamie.”

His career progressed through management roles at Cable Price and Cervus Equipment before joining John Deere as a product and systems specialist for New Zealand and Australia. Working across five key product lines, including mid-range tractors, foragers, and balers, Bevin gained a deep appreciation for agricultural technology. "Technology is key to farmers’ success,” he says. "It’s about gaining better efficiencies and profitability while ensuring compliance with local body regulations.”

This belief in technology’s role in agriculture is what drew him to Power Farming. "I see huge opportunities in building our customers’ knowledge on technology, helping them be more accurate in what they do, and documenting data to report compliance regulations,” he says. "Collaboration is key to building a business, and for me, working closer with our customers is number one.”

The agricultural sector has faced significant challenges in recent years, but Bevin sees reasons for optimism. "Some real positive news for our customers – our beef market is strong, Fonterra has announced a record payout, and the industry is getting back on track. This has started some good enquiry, and I see our industry turning a corner.”

As he settles into his new role at Power Farming, Bevin is focused on building relationships and supporting farmers through

innovation. "We’re bringing in the right products to meet customer needs,” he explains. "The Covid era created a stock surplus, and now it’s about getting the right equipment into the hands of the right people.”

Looking ahead, Bevin is excited about the company’s recent acquisition of the Topcon franchise for New Zealand, a move set to enhance technology adoption across the sector. "This is a massive boost for our customers,” he says. "Technology is about improving efficiency and profitability, and we’re committed to supporting farmers on that journey.”

With a wealth of experience spanning mechanics, contracting, management and technology, Bevin is well-positioned to lead Power Farming’s Machinery Division into the future. His approach remains firmly rooted in the values he learned growing up – hard work, strategic thinking, and a commitment to supporting farmers in their pursuit of success. "We are seeing positive signs for 2025”, he says. "Spring next season, I think we’ll be in a better space, and that’s good for the economy and good for farming.”

For Bevin, the journey has come full circle – from a young boy watching his father operate machinery to a leader in agricultural technology, shaping the future of farming in New Zealand.

On the 10th anniversary of the International Day of Women and Girls in Science, globally celebrated on February 11, we speak to published DairyNZ scientist Dr Lucy Hall about a day which recognises the vital contributions women and girls make to the fields of science, technology, engineering, and mathematics (STEM).

Among the women helping shape the future of agricultural science is Dr Lucy Hall, a post-doctoral scientist at DairyNZ. With a deep passion for providing research that not only supports dairy farmers but also considers the entire farm system, Lucy’s work has positioned her at the forefront of research aimed at keeping New Zealand’s dairy industry internationally competitive.

With an under-graduate degree in animal science and agriculture from Massey University and a PhD from Lincoln University, alongside experience working on dairy farms and as a consulting officer, Lucy brings practical, hands-on experience to her research, and a strong farm systems understanding. Her field knowledge and scientific expertise makes her an invaluable asset to the industry.

“I am lucky to work in a role which brings together my passion for animals, science and wellbeing. The science allows us to look at things in new ways while also giving back to farmers, the sector and the wider country, which is important to me,” says Lucy.

"If you’re interested in grass-based dairy farming systems, there is no place like home. You won’t get access to more impactful projects or credible people anywhere else in the world.”

Lucy’s research focuses on areas vital to the wellbeing and productivity of dairy farmers, including workplace productivity, flexible milking schedules, the impact of safety improvements on farms, and the relationship between farmers' sleep and milking frequency.

This is part of DairyNZ’s accelerating on- farm productivity strategic priority,

“If you’re interested in grass-based dairy farming systems, there’s no place like home.” On the 10th anniversary of the International Day of Women and Girls in Science, we speak with DairyNZ scientist Dr Lucy Hall about her passion for research that supports farmers, enhances workplace productivity, and keeps New Zealand’s dairy sector globally competitive.

with research focused on increasing workplace productivity. Other current research includes 24-month extended lactation to reduce the spring workload peak, understanding workplace productivity practices of leading farmers and assessing the impact of wearables on herd reproductive performance.

One of Lucy’s most recent achievements was having her PhD journal article, a novel study on sleep deprivation in dairy farmers, selected by the leading peer-reviewed international publication Journal of Dairy Science as a featured article. The study was the first of its kind, offering quantitative data on the sleep patterns of dairy farmers—an area that had been largely overlooked in research until now.

“With dairy farmers working with machinery and large animals, sleep deprivation can have serious implications for their health and safety,” Lucy explains. “Farmers often work in isolated conditions, which only increases the risk of severe consequences after an accident.”

The work looked to determine whether farmers were getting sufficient sleep quantity and quality over the spring calving period and identify how different factors affected the sleep quantity and quality as well.

The research findings will have widereaching benefits, providing critical data that could influence the design of safer and more effective working conditions for dairy farmers.

"I’m looking forward to progressing this research more, with our next project using Garmin watches to better understand farmer

"With dairy farmers working with machinery and large animals, sleep deprivation can have serious implications for their health and safety.”

sleep and energy exertion over a full day, rather than focusing on evening sleep.”

From 2020 to 2023, Lucy was a DairyNZ PhD scholar. Today, she continues her important work as a post-doctoral scientist, focusing on further investigating factors affecting workplace productivity including farmers’ sleep, energy exertion, and technology use.

evokeAG. 2025 in Brisbane has seen record attendance, with just under 2,000 delegates, 40 startups and 12 scaleups, and a program of more than 95 speakers, making it the largest AgriFutures evokeAG. event to date.

On Day 1 of the two-day event, attendees heard from speakers, including:

• Mike Casey, CEO of Rewiring Aotearoa, the world’s first fully electric farm

• Jack Bobo, Executive Director of the UCLA Rothman Family Institute (Food Studies) and author of ‘Why Smart People Make Bad Food Choices'

• Sarah Cragg, Head of the Earthshot Prize for the Asia Pacific, an award founded by the Prince of Wales to recognise innovation for sustainability

• Robert Boyd of Boeing Asia Pacific, working to accelerate aerospace decarbonisation

• Anthony Lee, CEO and director, Australian Country Choice, one of the world’s largest family-owned cattle and beef supply chain enterprises.

Hailing from 27 countries, close to 2,000 people descended on AgriFutures Australia’s evokeAG. 2025 event at the Brisbane Convention and Exhibition Centre.

The largest agrifood technology and innovation event in the Asia-Pacific, evokeAG. brings together the brightest minds in the sector to catapult Australian agriculture towards its ambition to be a $100 billion industry by 2030 and discuss the most pressing issues facing global food and fibre production.

This year’s conversations were centred around four important threads: economics

and trade, exploring global market competitiveness and investment trends; innovation and future technology, showcasing innovation in robotics, AI, and next-gen technologies; sustainability and environment, inspiring agriculture’s and agritech’s role in climate and environmental solutions; and workforce and skills gap, tackling innovative strategies to attract and retain the brightest talent for a growing agriculture sector.

Representatives from the world’s most dynamic and successful agrifood producers, retailers and investors were in Queensland to share their insights as part of the bold two-day program and its sideline events.

Over fifty start-up and scale-up businesses showcased cutting-edge technologies, from autonomous robots to vertical farming, AI-powered insect monitoring, and dronebased livestock management.

evokeAG. is the largest agrifood technology and innovation event in the Asia-Pacific.

Finding common ground to drive innovation

AgriFutures Australia Managing Director, John Harvey said AgriFutures was thrilled to be able to deliver its most interactive evokeAG. to date, uniting the agri-food sector on the 2025 theme, ‘Common Ground’.

“Agriculture in Australia – and across the Asia-Pacific – plays a critical role in feeding a growing global population. In light of shifting environmental, trade and market conditions, evokeAG. is more important than ever. The industry can’t stand still,” John said.

“The agrifood sector has always been at the forefront of innovation. The role of evokeAG. is to bring all the masterminds together, the people who can turn ideas into action – the investors, the makers, the scientists and the primary producers,” he said.

For the fifth consecutive time, Elders joined evokeAG. 2025 as the Platinum Partner.

Elders Managing Director and CEO, Mark Allison, echoed the opportunity for the agriculture sector to thrive through collaboration and innovation.

“Our agriculture sector’s advantage is having a resilient mindset and curious approach to farming, hardened by decades of innovating to produce food and fibre in one of the most environmentally challenging landscapes on earth,” Mark said.

“evokeAG. encourages us to continue to innovate by promoting connection and knowledge sharing to help address the modern challenges faced by farmers and the wider agricultural supply chain.”

Turning traditional keynote on its head: delegates ask the tough questions.

A highlight of Day 1 was an innovation in itself, with the traditional keynote flipped on its head. Delegates were handed the microphone to ask provocative questions of panellist experts on the future of food production.

As part of the ‘Tough questions – you ask, they answer’ session, change-makers from industry and government were asked on the spot questions ranging from workforce and trade to the impact of innovation and research.

On trade, founder and Chief Scientific Officer, Downforce Technologies, Prof. Jacqueline McGlade said it was important that Australia gets ahead of the game.

“Politicians are fickle, and trade relations come and go – but farmers stay,” Jacqueline said.

“Countries must be better prepared to change the diversity of goods coming out of that country.

“When you look at Australia, you are unfortunately on the cutting edge of climate issues – therefore, being ready and knowing what the rest of the world is going to experience because you already have, gives an advantage.

“You are far more likely to make a success of crops and products that are going to be needed to meet global demand for food. So, let’s get our shop in order, be ready and grow the things that we know we are going to need in the future.”

On ag-tech adoption, CEO and Director, Australian Country Choice, Andrew Lee said that when it comes to scale and commercial viability, individual businesses operating in the agriculture supply chain had an important role to play.

“For ag-tech companies, I would encourage them to approach individual businesses first,” Andrew said.

“Work with a reputable company, and if

that company likes your tech you can then approach a research and development corporation together and that will have a far greater impact.”

In the spirit of collaboration, thought leaders from the grains, horticulture, livestock, fisheries, processing, retail and logistics sectors all contributed to the day’s bold discussions. This included Regional Head for Boeing, Robert Boyd, and General Manager of Agribusiness for CommBank, Natasha Greenwood.

The excitement continued with Day 2 of evokeAG. as speakers delved into robotics, quantum computing, sustainable 3D ocean farming and the war on waste.

Improved half-year results from Farmlands show that the co-op’s tight focus on supporting New Zealand’s farmers and growers is working. This result reinforces the strategy that’s guided the organisation for the last three years.

A 14% increase in revenue, to $477.6 million, for the half-year shows that customers are buying more from their Kiwi-owned co-op. An improved half-year EBITDA (up 49% to $17.7m) is the realisation of operational improvements made over the last 36 months – indicating that Farmlands is growing smarter and more efficiently.

“Delivering a strong first-half result is vital as it includes Spring – the most important season for rural supplies. This result means we are in a good position to continue to support our farmers and growers in the second half of the year, while holding our financial position,” says Farmlands CEO, Tanya Houghton.

Tanya adds that the co-op’s focus on operational efficiency is delivering these positive results and that they are not coming at the expense of customer service and benefits.

"We're building a stronger Farmlands that's better equipped to serve our shareholders. These financial numbers show we're moving in the right direction, and the improved customer sentiment we’re seeing is just as important.”

Farmlands customers and shareholders are demonstrating that they understand what the co-op is working to do: provide key farm

inputs at the best possible price, delivered when they are needed.

Customer sentiment is 27% up on the same period last year. Satisfaction with product range and pricing has improved significantly, which demonstrates the effectiveness of the recently-completed three-year product and supply-chain transformation. Customer perception of staff knowledge and expertise has also grown through a period where Farmlands has been investing in its frontline teams, including in key sectors like horticulture and agronomy.

Tanya says, “We are just beginning to see the improvements that were baked into our transformation strategy, and our customers and shareholders are set to benefit even more in future as a strong financial position becomes our foundation for growth.”

There are several other key indicators of smart investment, innovation and growth from Farmlands:

• Digital innovation is at the heart of Farmlands' strategy. Over 7,000 shareholders have downloaded FarmlandsPRO, a new order placing and managing app, and $70 million in sales have been processed through it. 10,000 shareholders have downloaded the Farmlands Card app – which is supporting them to find the best Card Partner deals and better manage their accounts.

• The acquisition of SealesWinslow and follow-up purchase of the Winton mill facility to establish a national feed business are already releasing significant operational efficiencies. Fern Energy, Farmlands’ jointventure bulk fuel business, is only into its third year and continues to grow.

• Farmlands’ new Southland regional hub, the first of a model to be applied in other parts of the motu, is creating savings in freight costs and improving on-farm deliveries.

• Direct sourcing of products is providing greater choice and better pricing for customers. New ranges include agrichemical brand Agstar, and the soon-to-belaunched Top Paddock rural supplies range.

• Three new retail stores in the North Island will be opening in the second half of the year in Hastings, New Plymouth and another North Island location soon to be confirmed. This follows the recent opening of Farmlands' first Horticulture Hub in Hastings. Tanya adds, "The relationship between Farmlands and our shareholders is built on mutual support. As the farming sector strengthens, having a strong cooperative that consistently delivers value will be more important than ever.”

The decision by Kainga Ora to reopen a multi-million-dollar tender for the supply of carpet to over 5,600 homes could mark a turning point for NZ’s wool sector, according to an industry expert.

The move comes at a time when the price of strong wool reaches $4 per kg, an eight-year high - driven by a reduction in supply and an increase in demand.

Previously, Kainga Ora issued a Request for Proposal for the national supply of carpet and underlay materials to support Homes and Communities’ maintenance and construction work which stated they “are not looking to procure wool carpet”.

The exclusion of wool carpet as part of the tender process conflicted with a government directive that stated they would “prefer the use of woollen fibres over synthetic ones” in its buildings, where practical.

At the time of the Kainga Ora tender wool advocates voiced their concern at the lack of consultation with the sector.

Greg Smith, CEO of wool carpet manufacturer Bremworth, says he welcomes the change to the tender process and says it is now up to the wool sector to take advantage of the new opportunity.

“As an industry, we need to prove to the government and consumers that wool has all of the features to be competitive on durability and price and win on sustainability because of the natural attributes of wool.

“As New Zealand’s biggest landlord with over 75,000 properties, the government is signalling a massive shift away from synthetics and showing us that it is prioritising the New Zealand primary industry over plastics.

“If they opted for synthetic carpet, this

would require importing around 1.7 million kilos of plastic for its production. In contrast, if the choice is made to buy a locally sourced natural fibre such as wool, we not only improve the country’s trade balance but also reduce the need to deal with this volume of synthetic material when it reaches the end of life and enters the waste stream.

“With a potential contract of this volume for wool suppliers, we also need to consider the broader economic benefits for the country by supporting our farming sector and the precedent it sets for other government agencies, commercial and residential developers,” he says.

Smith says wool is naturally stain-resistant and a fire retardant, unlike synthetic yarns.

“The properties of wool carpets mean they are better suited to provide a healthier and safer home for some of Aotearoa’s most vulnerable community members. Wool carpet is hypoallergenic, durable, easily maintained and can regulate humidity by releasing moisture when the air is dry or absorbing it when the air is moist.

“It is also a very efficient thermal and acoustic insulator and is naturally well adapted to helping to keep homes and office spaces warm and quiet.

“The expansion of this tender is a step in the right direction for the wool sector and environment as we know synthetic yarns do not biodegrade whereas wool does break down naturally. It is also a signal to the New Zealand sheep farmers who have been

struggling for a while that there could be better times ahead for them.

“It is great to see that common sense has prevailed and that there has been a move to publicly support this important primary sector,” he says.

Gene technology is a subject that continues to provoke debate across New Zealand’s primary sector, and the government’s gene technology bill represents a critical moment for the industry.

DairyNZ has made a comprehensive submission to the Health Select Committee, supporting the bill’s intent but highlighting significant areas that need refinement. The submission makes clear that while gene technology offers opportunities, careful regulatory settings are essential to protect farmers, trade, and the country’s reputation as a high-value food producer.

DairyNZ Chief Science Advisor Dr Bruce Thorrold has reiterated the organisation’s backing for a balanced regulatory approach, one that enables safe testing and use of gene technologies while ensuring farmers retain agency and choice. The bill establishes a foundation, but five key concerns have been identified that require urgent attention: trade and market access, co-existence, primary sector input, Māori rights and interests, and transparency. Addressing these will be vital to ensuring a system that serves farmers while maintaining confidence in New Zealand’s exports.

New Zealand’s dairy sector contributes $25 billion annually in export earnings and accounts for a third of all goods revenue. Ensuring that gene technology regulations align with trade and market access requirements is paramount. DairyNZ is calling for an explicit commitment within the bill to safeguard these considerations. International markets have stringent rules around genetically modified products, and any misalignment could risk the competitiveness of the sector. Greater clarity is also needed around how nonnotifiable and exempt activities are determined and registered. Without clear parameters, there is a risk that regulatory gaps could expose the sector to unforeseen consequences. Another central issue is co-existence. The ability for farmers to choose between conventional, organic, and gene technology-based systems must

be preserved. The bill needs to ensure that the definition of ‘environment’ includes primary production systems so that regulators can effectively oversee co-existence strategies. The production of high-grade seed crops already follows established practices that allow different systems to operate side by side, providing a model for future regulatory settings. However, without explicit recognition in the legislation, the risk of unintended gene flow and its associated market implications remains a concern.

A further challenge is the limited role currently outlined for primary sector expertise in the regulatory process. DairyNZ is advocating for a dedicated primary sector sub-committee within the Technical Advisory Committee. This would ensure that industry knowledge informs decision-making, strengthening the regulatory framework. The current composition lacks sufficient agricultural expertise, an omission that could lead to regulatory decisions being made without adequate consideration of real-world farming impacts.

Māori rights and interests form another crucial aspect of the discussion. The government has proposed a Māori advisory Committee, but DairyNZ is urging officials to explore a broader range of options to ensure Māori perspectives are meaningfully incorporated. The relationship between gene technology, indigenous species, and kaitiakitanga requires careful handling. The submission calls for a more robust approach that respects these concerns while ensuring the regulatory framework remains effective for all stakeholders.

Perhaps the most pressing issue raised is transparency. Trust in the regulatory system will be critical for industry and public acceptance. DairyNZ is pushing for a two-to-five-year transitional period during which greater transparency is required

in regulatory decisions. One key recommendation is ensuring that no technologies or organisms are automatically deemed exempt during this period. This would allow for a measured approach, ensuring that decisions are made with full visibility and stakeholder engagement. It would also help build confidence in the new system, preventing unintended consequences from hasty regulatory approvals. Beyond the legislative framework itself, the process by which the bill has been developed has also raised concerns. Consultation with the primary sector has been limited, with industry engagement largely restricted to a small number of meetings. Farmers have had little opportunity to digest the details of the bill or provide meaningful feedback. Given the potential implications, DairyNZ is calling for a more inclusive approach that allows the sector to contribute effectively.

While DairyNZ supports the intent of the bill, it is clear that refinements are necessary to protect New Zealand’s dairy sector. The risks associated with poorly structured regulations are significant. Trade access, farm management practices, consumer confidence, and environmental integrity all hang in the balance.

Farmers are no strangers to innovation. Advances in breeding, pasture management, and herd genetics have all played a role in improving

productivity and sustainability. Gene technology has the potential to be another tool in this progression, offering solutions for disease resistance, improved nutrition, and environmental benefits such as reduced greenhouse gas emissions. But its adoption must be guided by a framework that maintains New Zealand’s competitive edge while safeguarding the interests of all farmers, whether they choose to adopt gene technology or not. The government now has a responsibility to refine the bill in a way that reflects these concerns. Ensuring trade considerations are embedded in the legislation, strengthening co-existence measures, increasing primary sector input, and improving transparency will be essential. The dairy sector operates in a global marketplace where perception matters as much as production, and regulatory settings must reflect that reality.

DairyNZ’s submission lays out a roadmap for a more effective approach, one that balances innovation with caution, opportunity with protection. The challenge for policymakers is to ensure that this balance is struck. Farmers deserve a system that gives them choices, protects their markets, and upholds New Zealand’s hardearned reputation as a producer of premium dairy products. With the right adjustments, the Gene Technology Bill can be a positive step forward, but only if these critical issues are addressed.

2.8-5.6m working widths

Suits 80-170HP

Fixed or folding hydraulic models

4.05 – 5.85m working widths

Suits 150-350hp

Hydraulic folding models

For over 150 years GASCON have built gear that lasts.

3.05 – 3.55m working widths

Suits 100-180hp

Fixed width models

KAITAIA Kaitaia Tractors 09 408 0670

WHANGAREI Piako Tractors Northland 09 438 1319

SILVERDALE Brandt NZ 09 427 9137

PUKEKOHE Brandt NZ 09 237 0043

MORRINSVILLE Piako Tractors 07 889 7055

MATAMATA Matamata Tractors & Machinery (07) 888 6292

HAMILTON Brandt NZ 07 847 0425

CAMBRIDGE Brandt NZ 07 827 5184

ROTORUA Piako Tractors Ltd 07 345 8560

TAUPO Taupo Tractors & Machinery 07 378 4533

STRATFORD FieldTorque Taranaki 06 765 8643

HASTINGS Stevenson and Taylor 0800 4273 2273

WAIPUKURAU Stevenson and Taylor 06 858 6041

DANNEVIRKE Lancaster Tractor Services 2022 Ltd 06 374 7731

PALMERSTON NORTH Transag Centre 06 354 7164

MASTERTON Brandt NZ 06 377 3009

NELSON Drummond & Etheridge 03 543 8041

BLENHEIM Drummond & Etheridge 03 579 1111

KAIKOURA Drummond & Etheridge 03 319 7119

GREYMOUTH Drummond & Etheridge 03 768 5116

CHRISTCHURCH Drummond & Etheridge 03 349 4883

ASHBURTON Drummond & Etheridge 03 307 9911

TIMARU Drummond & Etheridge 03 687 4005

OAMARU Drummond & Etheridge 03 437 1111

MOSGIEL JJ Limited 03 489 8199

GORE JJ Limited 03 208 9370

INVERCARGILL JJ Limited 03 211 0013

Advances in precision agriculture technology continue to shape the future of the industry, presenting new opportunities for farmers to produce more while using fewer resources.

As pressures mount to increase efficiency and optimise operations, solutions that enhance accuracy and streamline processes are becoming essential. Precision agriculture technologies provide critical resources to meet these challenges, offering real-world benefits that improve outcomes in the field.

Success in modern farming depends on focusing investments on big ideas and innovations that create efficiencies. However, it is just as important to stay focused on return on investment to ensure that the right solutions are implemented for each specific operation. Farmers cannot afford to spend their budgets on buzzwords or technology that does not deliver quantifiable results. Instead, investment should be directed towards solutions that drive measurable improvements and move the operation forward.

One area where farmers can see significant benefits is in the adoption of smart spraying systems. These technologies increase machine efficiency in the field while ensuring the accuracy of applied products, reducing waste and optimising input use. Similarly, natural resource management, including landforming projects, can create yield-enhancing advantages. PTx Trimble’s WM-FieldForm solution is one such tool that enables farmers to manage land more effectively, improving productivity over time.

The integration of camera-based AI solutions is also laying the groundwork for future autonomous applications. These advanced systems allow sprayers to distinguish between weeds and crops,

transforming what has traditionally been a manual and skill-intensive operation into an automated process. With this level of precision, farmers can ensure targeted application, reducing chemical use and enhancing sustainability.

Beyond these advancements, guidance and steering systems remain fundamental to modern precision agriculture. Ensuring machinery follows optimised paths in the field not only improves efficiency but also reduces overlap and input costs. Product control technologies, such as spreaders and air seeders, provide further enhancements by delivering inputs more accurately, ensuring even distribution and better crop establishment.

The integration of Precision-IQ and PTx Trimble Ag Software connectivity allows farmers to maximise steering paths and make the most out of every field. This level of connectivity ensures that all elements of an operation are working together seamlessly, enabling better decision-making and overall management of the farm’s resources.

The bottom line is that farmers must focus their efforts on projects that deliver measurable outcomes, keeping a close eye on their return on investment. Any technology adopted should either create cost savings through enhanced capabilities or provide greater control over variables that impact profitability. By focusing on solutions that deliver tangible benefits, farmers can ensure their investments drive meaningful improvements in efficiency and productivity.

New Zealand’s agricultural sector has long been at the forefront of innovation, with farmers in the region demonstrating a strong willingness to adopt emerging technologies. This early adoption of precision agriculture tools positions the industry as a leader in shaping the farms of the future. As global challenges continue to evolve, the advancements driven by New Zealand’s farming community will play a vital role

The integration of Precision-IQ and PTx Trimble Ag Software connectivity allows farmers to maximise steering paths and make the most out of every field.

in influencing the direction of agriculture worldwide.

The company continues to be a trusted name for New Zealand farmers, building on a long history of making farm work easier, conserving resources, alleviating labour challenges, and delivering solutions that enhance productivity. As a result of a joint venture between Trimble and AGCO, PTx Trimble now operates under the AGCO brand PTx. This transition has not changed the company’s focus. Instead, the emphasis remains entirely on agriculture and retrofit solutions, with farmer success at the core of every product brought to market. No matter what type of equipment is used, PTx Trimble provides tools to help farmers improve outcomes at every stage of the growing cycle. With a portfolio designed for precision technology at scale, it ensures maximum impact for farmers, delivering new innovations and advancements in retrofit technology solutions that enhance efficiency and productivity.

Justin Van Viersen, commercial director for PTx Trimble, leads operations across the AsiaPacific-Africa region from his base in Perth. His work with the company underscores a commitment to providing industry-leading smart farming solutions that support farmers in achieving better results. With precision agriculture continuing to evolve, the ability to harness these technologies effectively will be key to ensuring long-term success in farming operations across New Zealand and beyond.

Väderstad’s latest seed drill technology, Proceed V 24, will improve precision and increase planting efficiencies for New Zealand farmers and growers from the 2026 season.

Since the first public showing in 2021, Proceed has been awarded for its innovation all over Europe. In both 2022 and 2023, it won the international Farm Machine award, previously known as ‘Machine of the Year’. It has also been recognised at SIMA in France, LAMMA in the UK, AGROmashEXPO in Hungary, and Agrosalon 2022 in Slovakia.

Designed to plant a variety of crops, the Proceed V 24 represents a new category of seeding machines where one machine can increase the yield potential across multiple crops, including wheat, barley, oilseed rape, sugar beet, peas, maize, and sunflower. Greg Moore, Norwood Brand Manager –Equipment, explains that the machine merges seeding and planting technologies, bringing the precision of planters to grain crops while maintaining the ability to plant at wider row distances. The result is unprecedented crop quality and great versatility. Previously, there had been a clear distinction between grain seed drills and precision planters for row crops, but every component of Proceed

is built to ensure the exact same start for all seeds.

A technological leap forward, the Proceed V 24 is built around a variation of the familiar Gilstring seed metering unit from the Väderstad Tempo precision planter. It ensures even the smallest seed is planted at the perfect depth with millimetre precision, resulting in a 50% lower seed rate for the same yield. “The heart of Proceed is its high-precision row units and PowerShoot technology,” says Greg. Available with 24 rows and a working width of six metres, the machine operates with either 225mm or 250mm row spacing

Optimal seed-to soil contact at the selected depth across the entire working width.

and a 2,200-litre seed hopper. A front hopper can also be used to enable in-row fertiliser distribution.

To guarantee consistent conditions for each seed, individually mounted preconsolidation wheels work alongside the Väderstad PowerShoot system, which uses air pressure in three ways.

Proceed V 24 represents a new category of seeding machines.

Positive air pressure ensures each seed is placed individually on the rotating seed discs. As the seed is released, air pressure is cut, allowing precise placement into the seed tube before

Maize production continues to expand in the United Kingdom despite a declining dairy industry and weather issues limiting yields, say two visiting UK maize experts.

Jon Myhill and Kate Baker of the UK Maize Growers Association (MGA), told the Foundation for Arable Research’s maize field day at its research site near Hamilton in February that 250,000 hectares is now grown in maize.

Despite the UK losing a dairy farm a week because of low milk prices, maize plantings continue to expand by 3000 to 5000ha a year as demand grows from anaerobic digestion plants, where maize silage is a key input. Encouraged by UK government support, these plants produce renewable electricity and bio-gas.

Digestion plants now absorb 30 per cent of maize production, with 60 to 65 per cent grown for silage for beef cattle and dairy.

“Fifteen years ago, this industry didn’t exist,” says Jon Myhill, MGA’s technical agronomist.

Anaerobic digestion plants generally take maize, as well as grass silage and fodder beet, that has been grown within a 30km radius. Plants process about 50,000 tonnes of organic matter a year, providing nearby growers with a stable income at prices comparable to those paid by dairy farmers for maize silage. Digestate, a by-product, is returned to paddocks for fertiliser and organic matter.

While most UK maize is utilised as silage, maize for grain is also steadily increasing, making up 5-8 per cent of the cropping area. However, maize grain growers struggle with plant genetics and yields, which average 8-9 tonnes/drymatter/ha.

“The best harvest moisture growers can get is 30 per cent, so there are big drying costs.”

The UK climate is the biggest issue when growing maize, with a short growing season and fewer heat units compared with big maize growing countries. Increasingly erratic spring weather patterns make achieving timely planting and subsequent early autumn harvests more difficult. “This compressed growing season puts pressure on yields and quality.

“Maize in the UK is typically planted in

mid-April, but last year nothing had been drilled by May 20. Twenty per cent of crop hadn’t emerged by the longest day (June 23). So that’s five weeks of heat units we lost.” Maize silage yields are typically 16-17 tonnes/drymatter/ha.

With chemistry, particularly neonicotinoid insecticides being lost in other crops, growers are turning to maize as it doesn’t have a lot of pest and disease issues. “So, from a crop management point of view, it is relatively straightforward for cereal growers.

“If we can improve maize genetics for UK conditions, I can see a rapid increase in growing areas.”

In contrast, canola (oilseed rape) plantings have dropped by half in the last four years because of a lack of control options for cabbage stem flea beetle, which can cut yields by 40 to 50 per cent. Sugar beet has also lost a key seed treatment.

A significant concern for maize is the increasing difficulty in managing bird damage, with growing restrictions on available seed-applied bird repellents and a lack of new effective alternatives coming to market. This leaves crops vulnerable during establishment, impacting yields.

The MGA provides a platform for growers to share best practices, access the latest

research and technical advice, and collectively address the challenges and opportunities within the maize sector. MGA operations and trials manager Kate Baker says that reducing maize’s environmental footprint is a key consideration, with the crop not having a good reputation in UK, often attracting “bad press”, particularly after substantial rain. Issues include soil compaction, as well as soil erosion and nutrient run-off because of the crop’s late harvesting period. To address these issues, MGA has an extensive programme of trials on under-sowing and cover cropping, (practices which attract environmental incentive payments for growers). Minimum tillage and strip till are also slowly being adopted.

Dairy farming in the UK continues to decline, with the next generation often choosing not to take on family farms. In addition to low milk prices, dairy farmers face the risk of bovine tuberculosis spread by badgers and other animals, as well as new laws around inheritance taxes.

resuming to shoot the seed down to the soil. A stop wheel then receives the seed, ensuring optimal seed-to-soil contact at the selected depth across the entire working width.

Extensive field testing has been part of

the Proceed V 24’s development journey. Väderstad’s engineers and testing department carried out trials across Europe to understand how farmers could maximise the machine’s potential, while independent researchers assessed results throughout

the entire growing period. After a year of full-scale field trials and product refinement, Proceed V 24 is now ready to hit the market. New Zealand customers can place orders now, with deliveries expected for Spring 2026.

Clearing stones from paddocks is a tough but necessary task, one that needs to fit in between other jobs around the farm.

For contractors and farmers alike, efficiency is key, and finding a machine that can reliably handle the job makes all the difference. The ELHO Scorpio 550 stone picker has become a valuable addition to farms and contracting businesses, proving its worth in challenging conditions.

With a fully hydraulic drive system, the Scorpio 550 operates smoothly and efficiently. It requires a hydraulic flow of 85 litres per minute, with an optimal working pressure between 110 and 150 bar. The machine is designed to run on a tractor’s standard dual-function hydraulic coupling, making it a straightforward attachment without requiring additional modifications. Its maximum continuous power use is 24 kW, and the tractor’s own cooling system ensures oil temperatures remain at an optimal level, preventing overheating during extended operation.

One of the standout features is its automatic depth adjustment, allowing the machine to follow the ground’s contours while maintaining consistent working pressure. This not only ensures an even collection of stones but also makes operation easier, even in dusty conditions. When needed, the hydraulic system increases pressure to a second pickup motor, ensuring no loss of efficiency when dealing with heavier loads. The lifting force at the end of the tines reaches 700 kg, providing the power needed to clear even the most stubborn stones.

The Scorpio 550’s tines are made from Hardox 500 steel, which is more durable than traditional steel spring tines. This allows them to rotate at higher speeds, improving the sieving process and breaking

down organic material more effectively. The pickup drum has a diameter of 1.8 metres and rotates at 80 revolutions per minute, while the tines themselves spin at 125 revolutions per minute. The design incorporates rubber bushings, allowing the sieve bars to flex laterally, preventing blockages and ensuring a smooth operation. If needed, the tines can flex up to 500 mm, lifting out of the sieve to avoid obstructions. With a working width of 5.5 metres, the Scorpio 550 is capable of handling significant areas efficiently. It can pick up stones ranging from 25 mm to 400 mm in size, ensuring a comprehensive clearing process. Its large hopper, with a capacity of up to two cubic metres, allows for extended work periods without constant emptying. The machine’s tipping height of 2.7 metres makes unloading straightforward, whether into a trailer or directly onto the ground for further handling.

For contractors like Ben Scott of Hakatere Valley, the Scorpio 550 has become an essential part of the business. Having added the machine to his fleet in 2024, he quickly saw its potential. With the abundance of rocks in the area, many paddocks that were

previously left untouched are now viable for cultivation. “It’s proven its place where a lot of guys that probably wouldn’t bother with some paddocks, it’s an option – we can clear it, it’s feasible,” he says. “It’s worthwhile getting into and is a big part of my business now.”

One of the features he appreciates most is the machine’s width, allowing him to cover large areas efficiently. Since adding the Scorpio 550 to his operation, he estimates he has moved between 3,500 and 4,500 tonnes of stone. The volume varies depending on the job, but in one instance alone, he cleared between 2,000 and 2,500 tonnes. With an average capacity of 30 to 35 tonnes per hour, the machine has significantly boosted productivity, turning previously unworkable ground into productive farmland.

Designed for durability and ease of maintenance, the Scorpio 550 features bolted hopper components that can be easily replaced if necessary. The entire support structure follows the same principle, ensuring longevity and reducing downtime. Large 560/60 R22.5 bogie wheels provide stability across uneven terrain, while the rake wheels are designed to turn with the machine, improving manoeuvrability.

The addition of optional extras like a hydraulic unit, a screen for smaller stones, and a K80 towing eye further enhance the machine’s versatility. With its combination of power, precision, and efficiency, the ELHO Scorpio 550 is more than just a stone picker –it’s a solution for making unproductive land usable, helping farmers and contractors get the best from their land.

The Scorpio 550 is capable of handling significant areas efficiently. It can pick up stones ranging from 25 mm to 400 mm in size, ensuring a comprehensive clearing process.

Truck scales play a critical role in ensuring precise and reliable weight recording across various industries, particularly in the food sector, where accuracy is essential for quality control and traceability.

At the forefront of this precision weighing technology is Waagen Dammaschke, a company that has built a reputation for delivering high-quality truck scales tailored to individual customer needs. A key component of their offering is the PR 6221 load cell from Minebea Intec, a globally recognised leader in weighing and inspection technologies. Reliable and accurate weighing is crucial, especially in demanding environments such as food production facilities, where truck scales are often positioned at the entrance and exit points. These scales measure the weight of incoming lorries carrying raw materials such as grain, sugar and flour, as well as live animals and various liquid products. A second weighing on departure ensures that the exact weight of unloaded materials is documented, facilitating complete traceability throughout the production chain. This process is instrumental in maintaining transparency and ensuring stringent quality control.

Waagen Dammaschke is committed to providing customised weighing solutions, leveraging its expertise and innovative approach. The company manufactures precast concrete elements to accommodate a wide range of scale dimensions, ensuring that customer-specific requirements are met with precision. The PR 6221 load cell, available in 30-tonne and 50-tonne capacities, is central to these solutions. Known for its durability and high accuracy, this load cell offers a class C3 rating, ensuring precise measurements even under the most

challenging conditions.

A significant advantage of the PR 6221 load cell is its ‘Matched Outputs' feature, which eliminates the need for corner adjustment in most cases. Each load cell is precisely calibrated, reducing the time and effort required for installation and maintenance. Fabian Müller, Managing Director of Waagen Dammaschke, highlights this benefit: "With new builds, we see that the load cells are perfectly matched to each other, so that corner adjustment is usually no longer necessary. This feature also proves invaluable during servicing, as it minimises the need for adjustments even after years of use."

Designed for heavy-duty applications, the PR 6221 load cell incorporates a special measuring element that effectively counteracts errors caused by weighbridge deflection. This ensures that even under the weight of heavy lorries, the load cell maintains its precision. Its high restoring force allows it to quickly return to its centred rest position, enhancing repeat accuracy.

In addition to the PR 6221 load cell, Waagen Dammaschke also utilises self-centring thrust pads with an anti-rotation mechanism (PR 6021/06N), further improving stability and accuracy in truck weighing applications. These components contribute to the overall reliability of the weighing systems, ensuring consistent performance even in adverse conditions.

"We are committed to the load cell PR 6221 from Minebea Intec because the quality and the fact that it is ‘Made in Germany' offer clear added value for us and our customers. Thanks to its durability and reliability, using the PR 6221 from Minebea Intec pays off,” says Fabian.

By offering truck scales that require minimal maintenance while delivering consistently high accuracy, Waagen

Designed for heavy-duty applications, the PR 6221 load cell incorporates a special measuring element that effectively counteracts errors caused by weighbridge deflection.