FEATURE

What’s new in Tractors 90hp+

PROFILE

& LARGE SCALE FARMER

Letting the air and water in!

EQUIPMENT

Latest LiuGong loaders now a step ahead

FEATURE

What’s new in Tractors 90hp+

PROFILE

Letting the air and water in!

EQUIPMENT

Latest LiuGong loaders now a step ahead

PO Box 36753

Merivale, Christchurch 8146

ph: +64 3 329 6555 www.agrimedia.co.nz

Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping, Australian AG Contractor & Large Scale Farmer, NZ Novachem Manual.

EDITOR

Scott Wilson

Mob: +64 21 725 061

Email: scott@agrimedia.co.nz

ADVERTISING SALES

Pulse – Media Sales

Justin Bowler

Ph: 0429 699 553

Email: justin.bowler@mmg.com.au

CIRCULATION

DDI: +64 3 329 6555

Email: admin@agrimedia.co.nz

PRODUCTION, LAYOUT & DESIGN

Mark Winstanley

Email: agc_art@agrimedia.co.nz

Contributors: Gerhard Uys.

Printed by PrintGraphics Pty Ltd

AC © AUSTRALIAN AG CONTRACTOR AND LARGE

SCALE FARMER - No part of this publication may be reproduced in any form without the prior written permission of the publisher. Opinions expressed in this publication are not necessarily that of the publisher and suggest independent advice be sought before acting on information or suggestions contained herein.

CONTRIBUTIONS - Editorial and photographic contributions are welcomed and should be sent directly to AML. Editing of submissions is at the sole discretion of the editor and will accept no responsibility for unsolicited material.

02 FROM THE EDITOR: Farmers face fallout from US tariffs

03 Top Case IH dealers rewarded for outstanding performance at annual awards ceremony

04 1st Place to CropScanAg for the CropScan 4000VT ISOBUS Integrated On Combine Analyser TECHNOLOGY

06 World first: Solar-powered smart hydraulic cattle crush revolutionises farming industry

07 Kuhn Australia launches next-generation interactive technology, revolutionising consumer engagement

08 New Rate Controller 3 enhancing efficiency and precision of liquid applications

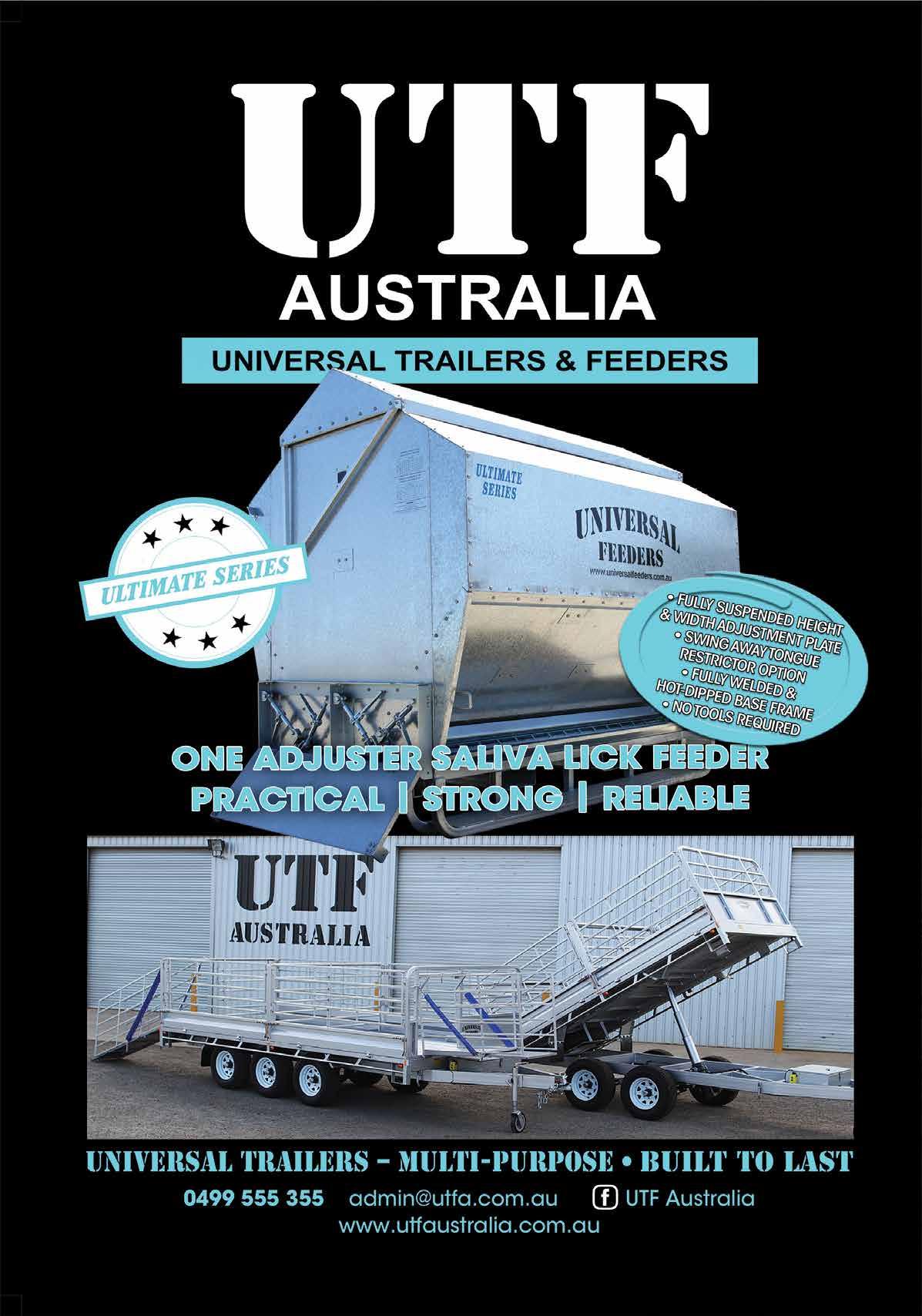

08 Trimble and PTx Trimble expand innovative tech

10 Precision application a double winner

12 Letting the air and water in!

20 Across the ditch: Dryland contractor in for the long haul

16 What’s new in Machinery Finance

26 What’s new in Tractors 90hp+

40 Non-arable sheep country now producing big crops

41 New range of bale wrappers and farm machinery

42 Optimal seed placement by working smarter together

43 Latest LiuGong loaders now a step ahead

44 New spot-spraying technology on Case IH Patriot just makes good sense when it comes to savings

45 Is it time to upgrade your seeding setup?

46 New sprayer updates maximising yields and minimising costs

47 Kubota’s new RTV-X is built to be tough and dependable

48 One-pass soil structuring turns heads

CASE IH HAS CELEBRATED ITS OUTSTANDING DEALERS OF THE PAST YEAR AT A GALA CEREMONY AT THE WESTERN SYDNEY CONFERENCE CENTRE.

Held during the brand’s annual dealer conference, the top awards went to a mix of Australian and New Zealand Case IH dealerships.

Boekeman Machinery in Western Australia took home the award for dealers with three branches or more, while St George Machinery Centre in Queensland claimed the title for dealers with one or two branches.

The Parts and Service Dealer of the Year was Three Rivers Machinery from NSW, and Kenway & Clark, with dealerships in NSW and Queensland, claimed the CNH Capital Case IH Dealer of the Year award.

For the first time, there was an award for CNH Dealer of the Year, which was taken out by Stevenson & Taylor, with dealerships in Waipukurau and Hastings on the North Island of New Zealand.

The Dealer of the Year results are based on a number of different criteria, including finance and business management, performance in sales and marketing, and parts and service, a precision technology focus and total market share.

CNH Business Director - Agriculture ANZ, Aaron Bett, congratulated the winners, highlighting their outstanding efforts and ongoing commitment to Case IH and their customers.

STEVENSON AND TAYLOR AWARD: FROM LEFT, DALE HOLMES AND KARL HARVEY FROM CNH, GRAHAM WILLAN AND ROBBY SMITH FROM STEVENSON AND TAYLOR, AND JEAN-PIERRE VAN HEERDEN, CRAIG HODGETTS AND DAVID KNOWLES, FROM CNH.

“It’s no surprise these dealers have risen to the top in the past 12 months, all of them demonstrating a standard of service and performance that CNH is very proud of and which customers welcome and have come to expect from such highly skilled, knowledgeable and passionate dealer teams,” Aaron said.

“Boekeman Machinery, St George Machinery Centre, Kenway & Clark and Three Rivers Machinery have all worked hard in recent years to raise the bar on business excellence. Kenway & Clark and Three Rivers Machinery have also undergone significant expansions and it’s gratifying to see them rewarded for their efforts.

“We’re also excited to introduce the new award, CNH Dealer of the Year, and to have it won by one of our New Zealand dealers, after such big changes for our brands in New Zealand in the past few years, is really outstanding. Stevenson & Taylor is a well-respected name in the North Island, building a very successful dealership with a very loyal customer base,” he said.

Boekeman Machinery has dealerships in

BOEKEMAN MACHINERY AWARD: FROM LEFT, BRUCE HEALY, GLEN FRASER AND DEAN SMART FROM CNH, AND ANDREW BOEKEMAN, BEN BOEKEMAN, TIM BOEKEMAN AND DILLAN ELLIOT, FROM BOEKEMAN MACHINERY.

Brookton, Dalwallinu, Northam, Wongan Hills and Dowerin, and Dealer Principal Tim Boekeman said it was a privilege to accept the award on behalf of his entire team.

“I’d really like to thank our team for all of their wonderful efforts – this award really is for them. All of the effort that they’re put in, all the hard work, the afterhours calls that they’re taking for our clients to deliver parts and service.

“I’d also like to thank Bruce Healy, Dean Smart, Glen Fraser and Steve Ogden for all of their support, we’re really grateful for them,” said Tim.

Cameron Small, branch manager at St George Machinery Centre, in St George, Queensland, said it was a great honour to be recognised for the award, and a credit to his team.

“It’s all a team effort really, we’ve got a great team that work very well together and are passionate about what they do. Our CNH reps are a big help too. And of course, a big thank you to our clients and customers,” Cameron said.

For Robby Smith, General Manager of Stevenson & Taylor, the thrill of winning the inaugural CNH Dealer of the Year is still sinking in.

“Big things from my team in little old Hawke’s Bay. It’s so great to be a part of this business. I’m just going to take this award and remember it for the rest of my life,” he said.

CROPSCANAG WAS PLEASED TO ACCEPT THE FIRST PLACE AWARD FOR AG TECH AT THE MANITOBA AG DAYS HELD IN BRANDON, MANITOBA, CANADA, JAN 23, 2025.

Dean Scrivens, CropScanAg Technical Specialist for Western Canada and Victoria Morris, CropScanAg Marketing Manager and USA Manager, Denver, Co, accepted the award and proudly displayed the banner on their stand during the show.

This award is the third in the last 12 months for CropScanAg. The first was an Australian Agritech Association (AAA) award for Precision Agriculture awarded in Melbourne, June 6th, 2024.

The second was the ‘Innovation in Agronomics Award’ from the Ag in Motion organisers at the 2024 Ag in Motion, Western Canada’s Outdoor Farm Expo held at Langham, Saskatchewan, Canada, July 17-19, 2024.

The Australian designed and manufactured CropScan 4000VT ISOBUS On Combine Grain Analyser is the world market leader in on combine grain analysers.

Victoria Morris has been working in the North American market for several years and in 2023, Dean Scrivens was

appointed to provide technical and sales support to dealers in Western Canada.

These awards are a credit to the efforts made by both Victoria and Dean, as well as the CropScanAg team in Australian, to position the CropScan as the world’s premium system for measuring protein, moisture, oil and starch in grains and oil seeds as they are harvested.

The CropScanAg technology provides farmers with a simple and reliable means of generating variable rate nitrogen fertilisation applications which ensure an increase in yield, reduction in fertiliser usage and an optimization of protein and oil in grains and oilseeds.

At the Manitoba Ag Days, the competition in the Ag Tech category has previously included technologies focused on controlling sprayer efficiency, using spray drones, as well as some automation for weed control.

he 2025 judges saw CropScan as a brand-new approach to managing nitrogen. An agron -

omist attending the event commented, “I wish every farmer had the CropScan system on his combine. This would help agronomists to advise the farmer with recommended fertiliser inputs, which is a major

part of what agronomists do”. For more information on the CropScanAg technology please visit the CropScanAg web site: www.cropscanag.com or contact CropScanAg at sales@ cropscanag.com.

LIVESTOCK PRODUCERS ACROSS AUSTRALIA NOW HAVE ACCESS TO A GROUNDBREAKING SOLUTION SET TO TRANSFORM CATTLE YARD OPERATIONS.

Morrissey & Co and Land Watch Australia, two trusted names in agtech innovation, have joined forces to launch the world’s first solar-powered smart hydraulic cattle crush system.

The system combines Morrissey & Co’s hydraulic crush system, powered by solar technology, with, for the first time, the seamless integration of advanced Wi-Fi and camera connectivity by Land Watch Australia.

And the good news? There isn’t a yard in Australia that cannot be connected to this smart tech solution.

The Morrissey & Co and Land Watch tech is already delivering connectivity to some of the most remote yards in Australia, where communication was once impossible. Whether 100km from the homestead or in a connectivity blackspot, the Morrissey Solar Smart Hydraulic Crush, connected by Land Watch, ensures producers can now operate safely and stay connected in realtime, offering peace of mind and connectivity wherever the yards are located.

The Morrissey Solar Smart Hydraulic Crush, connected by Land Watch products, offers a suite of features that address key challenges in modern cattle handling:

- Wi-Fi connectivity: Seamlessly integrates mobile phones, Wi-Fi-enabled scales, and other wireless tools into yard operations.

- Instant data transfer: Farmers can instantly upload weight, genomic, and EBV data to the cloud, improving efficiency and decision-making.

- Enhanced safety and productivity: Hydraulic operation streamlines cattle handling while removing the need for noisy generators, boosting worker and animal welfare. Live-streaming camera technology enables monitoring and emergency assistance from anywhere, anytime.

Powered by a 12-volt lithium battery, the crush runs on two solar panels, ensuring reliable operation even on cloudy days. It can run for 5–6 hours on battery power alone,

THE MORRISSEY SOLAR SMART HYDRAULIC CRUSH, CONNECTED BY LAND WATCH, IS AVAILABLE IN THREE VARIATIONS, ENSURING EVEN THE MOST REMOTE YARDS CAN BE CONNECTED.

Morrissey Solar Smart Hydraulic Crush with Wireless Link Wi-Fi and Camera System (Medium Range):

- Wi-Fi access with a 100m radius around cattle yards

- Extends Wi-Fi coverage up to 5 km (line of sight) from the homestead.

- Includes a camera for monitoring cattle during processing.

- Ideal for operators near their homestead where 4G or mains power is unavailable.

Morrissey Solar Smart Hydraulic Crush with Wireless Link Wi-Fi and Camera System (Long Range):

- Wi-Fi access with a 100m radius around cattle yards

- Allows connection to existing internet up to 15 km (line of sight) from the homestead

- Includes a camera for monitoring cattle during processing.

- Designed for operators with cattle yards up to 15 km from their homestead

Morrissey Solar Smart Hydraulic Crush with Starlink Wi-Fi and Camera System (Longest Range):

- High speed internet connectivity anywhere on the property via Starlink

- Camera system for monitoring cattle during processing.

- Ideal for operators in extremely remote locations where 4G and mains power are unavailable.

without any solar input, making it ideal for remote locations without mains power.

Even on overcast days, solar input continues to top up the battery, which can be monitored through the Victron Connect app.

Producers can check battery life at the start of the day and track solar input in real time, ensuring uninterrupted operation. The much-loved Land Watch technology also delivers advanced connectivity to even

PRODUCERS CAN NOW TAILOR THEIR MACHINERY TO MEET ON FARM DEMANDS, WITH A REVOLUTIONARY NEW TOOL FROM KUHN AUSTRALIA.

The first in its field, KUHN Australia has launched an interactive and immersive experience for customers, the Kuhn configurator. Combining innovation and cutting-edge technology, the configurator is an easy-to-use online tool.

As a dedicated customer portal, the configurator allows customers to select their desired Kuhn Machine and further personalise it with the various accessories and features made available by Kuhn. The configurator encompasses the entire purchasing journey, providing personalised machine customisation and clarity on pricing, connecting customers to their nearest Kuhn dealer for actioning.

Kuhn Australia’s Managing Director Bruno Fetiveau said “Our new configurator marks a significant leap forward in the realm of agricultural machinery customisation.

“By putting the design directly into the hands of our customers, we’re providing solutions perfectly attuned to their unique farming needs and environments.

“This level of personalisation ensures optimal productivity and performance, setting a new standard for the industry.”

Offering real-time pricing, the configurator brings a new level of transparency to the machinery industry, allowing customers to make accurate comparisons and more informed decisions about their high involvement machinery purchases.

“We’re excited to offer this interactive technology to our customers and be the first in our industry to do so,” Mr Fetiveau said.

By putting the power of personalisation in the customers hands, the configurator enables buyers to build a machine fit for pur-

the most remote yards, allowing producers to monitor and control yard operations in real time, no matter how isolated their location.

John Hill, co founder of Land Watch Australia, highlights the value in working with likeminded partners, “The partnership with Morrissey & Co has been an incredibly rewarding experience. As two family-owned

pose, by adjusting the make, model, features and optional extras.

“At KUHN, we understand the critical role our machines play in the success of producers worldwide.

“That’s why we have a dedicated portal

businesses with a shared commitment to innovative, high-quality, and smart solutions, we’ve worked hard to deliver a product that truly meets the needs of Australian farmers. Highlighting the power of combining tradition and innovation to create something that’s both practical and groundbreaking for the industry.”

Sally Morrissey, Business Development Manager of Morrissey & Co added, “Our solar-powered crush now seamlessly integrates with Land Watch cameras and connectivity solutions, helping producers stay

that will enable customers to customise a machine that will meet their requirements,” said Mr Fetiveau.

To experience the KUHN configurator, and ‘Build Your Dream Machine’ visit: configurator-au.kuhn.com/

connected, upload and analyse herd data in real time, and improve safety in case of accidents by allowing staff to call for help, even in remote areas. The silent operation also reduces stress for both producers and cattle. Combined with our robust crush design, this is a game changer for livestock producers in remote areas.”

To learn more about the Morrissey Solar Smart Hydraulic Crush systems, connected by Land Watch, please contact the team at Morrissey & Co, https://www.morrisseyco. com.au/hydraulic-cattle-crush.

JOHN DEERE CUSTOMERS NOW HAVE THE ABILITY TO APPLY TWO LIQUID PRODUCTS SIMULTANEOUSLY FOLLOWING THE RELEASE OF THE NEW RATE CONTROLLER 3 AT COMMODITY CLASSIC IN DENVER, COLORADO.

The John Deere Rate Controller 3 gives customers an option to control two liquid and/or anhydrous ammonia (NH3) products and up to 16 different sections.

The innovation builds on the strong foundation of several precision agriculture technology components, including the Precision Essentials kit containing the G5 or G5Plus universal display, StarFire 7500 receiver and JDLink M or R modem, which work together to improve overall performance and ease of use.

John Deere Australia and New Zealand Production and Precision Ag Marketing Manager, Royce Bell, said the Rate Controller 3 would deliver an integrated user experience by featuring a new rate controller app within the John Deere display menu.

“This app will give farmers a similar experience to operating a self-propelled sprayer with a controller with a built-in base from the factory,” Royce said.

“With this new experience, farmers can now monitor their

IONOGUARD IMPROVES RTK GNSS POSITIONING PERFORMANCE DURING SOLAR STORM EVENTS.

Trimble and PTx Trimble announced today the availability of Trimble IonoGuard for the precision agriculture industry. IonoGuard is a next-generation technology engineered to enhance RTK GNSS signal tracking and hardware positioning performance. IonoGuard helps ensure more reliable and accurate positioning by reducing the risk of signal loss and maintaining signal integrity during challenging ionospheric conditions.

Every 11 years, solar activity peaks, causing ionospheric disturbances such as scintillation and signal noise that can result in unreliable positioning. Solar Cycle 25, which began in 2024 and is expected to last through 2026, could pose significant challenges with the potential for global disruptions. While solar

cycle disturbances are a phenomena noticed by few in most occurrences, high-precision RTK GNSS users in equatorial regions are regularly impacted by solar activity year-round, inflicting costly interruptions on agricultural operations.

“There was no question when asked if we wanted to test IonoGuard,” said Michael Munro, General Manager, Sales and Marketing of Vantage Australia.

“Knowing we can better weather the next major solar storm with less risk for signal loss and improved signal availability and precision during such a disturbance provides peace of mind knowing we can still get the work done.”

JOHN DEERE CUSTOMERS NOW HAVE THE ABILITY TO APPLY TWO LIQUID PRODUCTS SIMULTANEOUSLY WITH THE RELEASE OF THE NEW RATE CONTROLLER 3.

rate controller functions on one screen on the display and execute easy adjustments.”

With input costs rising and an increasing need for farmers to deliver more from less, the controller is designed for ease of use to help farmers of all types improve their precision and efficiency.

“The Rate Controller 3 is versatile and suitable for a variety of customer segments, including row crops, small grains, high-value crops, dairy and livestock, and golf courses,” Royce said.

“It is also fully compatible with Gen 4 v2 server CommandCenter

displays, 4640 displays and G5 displays.”

The product features a new harness and 48-pin connector, which expands the compatibility with third-party equipment improving serviceability and installation of the Rate Controller 3. This connector also creates a strong seal to protect the harness and the controller from weathering or other damage.

The Rate Controller 3 will be available to order late 2025. For more information on the new Rate Controller 3, contact your local John Deere dealer or visit deere.com.au/co.nz.

“The solar storm experienced in May 2024 put IonoGuard to the test and, based on feedback from our beta testers like Vantage Australia, demonstrated the value of this technology to enable uninterrupted work in the midst of significant solar activity,” said Andrew Sunderman, Vice President, Product and Customer Experience at PTx Trimble.

“When a solar storm hits, work might be stopped due to signal loss, resulting in downtime, increased labor costs and potentially wasted inputs during planting and spraying. We’re extremely proud to offer a solution that truly minimizes this risk by

decreasing downtime, reducing costs for the farmer and keeping the agriculture industry up and running all day, every day.”

Trimble IonoGuard is available on the PTx Trimble NAV-900 guidance controller via the latest PTx Trimble Precision-IQ firmware release and Trimble base stations that support the ProPoint GNSS positioning engine, sold and distributed by PTx Trimble. When combined, users can achieve maximum RTK performance. To learn more about IonoGuard, visit https://ptxtrimble. com.

THE ADOPTION OF A PRECISION AGRICULTURE TECHNOLOGY HAS SIGNIFICANTLY IMPROVED THE EFFICIENCY OF FERTILISER AND CROP PROTECTION INPUTS ON AN ISAAC REGION CANE FARM.

Bryce and Emma Jackson, together with mother, Jane, and siblings, Monique and Mark, grow about 350 ha of cane across six properties totalling 1600 ha in the Carmila West district, about 50 km south of Sarina.

In 2022, the Jacksons were invited to participate in a three-year project to adopt decision-making technology and management practices to improve their nitrogen use efficiency and minimise the run-off of dissolved inorganic nitrogen into waterways.

The project was conducted by LANDhub information systems and Liquaforce liquid fertilisers with funding from the Mackay Whitsunday Water Quality Program, and in turn, the Australian Government’s Reef Trust and the Great Barrier Reef Foundation.

Over the past three years, the Jacksons have adopted a range of soil and crop monitoring techniques and the use of farm spatial data, including soil sampling, drone imagery and electromagnetic mapping.

At the same time, they have switched to sub-surface, split-stool application of liquid fertilisers.

“Going to sub-surface application was a no-brainer for us,” Bryce says.

“We want the fertiliser to stay where we want it to improve nutrient use efficiency and

reduce nitrogen loss after rainfall.

“We treated about one third of our ratoon cane in the first year; the next year we treated all of our ratoon cane; and the next year we did plant cane as well.

“We apply about 100 to 150 kg/ha nitrogen, in addition to growing soybeans, cowpeas and sunn hemp as green manure crops before planning.

“We have a farm nutrient budget that tells us now much nitrogen we can apply across our properties, so we have to make the most of that.

“I have learnt a lot through the program and

now we have all the data I need to achieve Smartcane BMP accreditation.

“It’s more than being compliant with the reef regulations – we want to make sure we have something to leave for our kids.”

In February, the Jacksons took delivery of a custom-made ‘high rise’ spray tractor fitted with precision spraying technology.

Constructed by Donnelly’s Welding in Mackay, the unit is based on a New Holland T5.100S tractor, reimagined with a two-metre clearance and a three-wheel configuration.

“We have always wanted a high rise sprayer

because it allows you to effectively spray at the ‘out-of-hand’ stage,” Bryce says.

“This is your last chance to get on top of vines and weeds

“If you can get that last spray in, you can get six month’s weed control.”

The spray system incorporates an eight-row flat boom and seven inter-row droppers.

The 1400 L main tank, powered by a 140 L/ min pump, is used to apply an ‘over the top’ spray of 2,4-D or fluroxypyr to control vines, such as cucumber, morning glory, convolvulus, passion vine and Star of Bethlehem.

The 700 L secondary tank, powered by a 70 L/min pump, is used to apply an inter-row spray of pre-emergent herbicides, such as flumioxazin or isoxaflutole.

The two booms are controlled independently using RightSpot precision spraying technology from Ag Leader.

RightSpot utilises ‘pulse width modulation’ technology and high-tech switching gear to independently open and close each spray nozzle 10 times a second, meaning the spray solution is emitted as a pulse rather than as a stream.

Boom pressure remains constant regardless of operating speed, ensuring consistent droplet size and minimising the potential for spray drift.

By comparison, the boom pressure in conventional flow-based spraying systems is determined by ground speed.

Any reduction in speed will produce a larger droplet size and reduce coverage, while any

increase in speed will produce smaller droplets that are more prone to drifting.

“I went to a RightSpot field day two years ago and I knew that’s what we wanted on our new sprayer,” Bryce says.

“I immediately approached the local Ag Leader dealer about getting a RightSpot system fitted to our spray tractor during the build.

“If we were going to spend $250K on a high rise spray tractor, then it made sense to spend another $80K and do an even better job.

“We’d already fitted Ag Leader InCommand automated steering in our harvester and three tractors, so we were already down that path.”

All spraying operations are controlled using the Ag Leader InCommand 1200 universal display, which provides real-time monitoring of operating speed, boom pressure, droplet size, nozzle status and diagnostics.

“I can change application rates on the go or switch from broadcast to band spraying by flicking a switch,” Bryce says.

“It automatically calibrates itself – doing this manually would take me at least an hour.”

Bryce particularly likes the AutoSwath function, which eliminates over- or under-application, and the BoomLoop reticulation system.

“Every nozzle turns off as it passes over any previously-applied row and it automatically starts wherever you left off,” Bryce says.

“BoomLoop allows the spray to flow from

the boom ends directly back to the spray tank, which eliminates ‘dead spots’ and the potential for the build-up of residues and blockages.

“There’s not a bad thing to say about it.

“You can flush your lines as you’re running up to the crop and then prime your nozzles, so you’re good to go the moment you enter the crop.”

Bryce says the combination of the high rise spray tractor and RightSpot technology has greatly improved the efficiency of spraying operations.

“I used to get really stressed by the amount of work associated with spraying,” he says.

“The spray tractor and RightSpot make spraying so easy.

“This is the first year I feel on top of things.”

The spraying system was installed by precision ag specialists, DMD Ag Solutions.

Company director, Darren Deguara, trained as a fitter and turner and worked as a farm machinery operator before establishing a hydraulics repair business in 2003.

In 2008, he and wife, Maree, established GPS Solutions Mackay with Tony Crowley, a well-known agronomist, to install GPS guidance systems.

Two years ago, DMD Hydraulics and GPS Solutions Mackay merged to become DMD Ag Solutions.

A third-generation cane grower, Darren also finds time to manage his own 40 ha cane farm at North Eton, about 30 km south-west of Mackay.

BRENDAN KING FROM CQ AG EARTHWORKS HAS DEEP RIPPED MORE THAN 30,000 ACRES IN THE PAST FOUR YEARS.

With a Komatsu bulldozer leading the charge, a TTQ deep ripper to do the hard yards, an air cart fertiliser/seeder in tow and a Trimble GPS to add precision to his work, he has seen improvements in soil, pasture and farm land wherever ripping exposes soil to water and air.

Brendan worked in coal mining for a decade, but always had the goal of being a self-starter.

He launched CQ Ag Earthworks, located in Springsure in the central highlands of Queensland, in 2020, with the purchase of a Komatsu bulldozer.

However, before getting started, he had to work with Komatsu to modify the machine to meet his specific needs. This involved adding five auxiliary hydraulics to enable the operation of deep rippers and an air cart.

The changes included installing a Trimble hydraulic rate controller on the air cart, as well as bigger oil coolers to keep the ‘dozer

BRENDAN KING, 30,000 ACRES DEEP RIPPED AND COUNTING!

running cooler in hot conditions.

This was important, as the hydraulic system’s long distance from the air cart to the coolers could lead to overheating issues.

For the first two years, he had a business partner, but then bought the partners 50% share and is now sole operator.

GRAZING CATTLE FOR EXTENDED PERIODS ALSO CREATES SOIL DEFICIENCIES, AND TO THIS END BRENDAN EMPLOYS THE AIR CART TO DEEP RIP FERTILISER.

As a service, Brendan offers deep ripping, with the option of also fertilising with granulated fertiliser, and seeding. He also offers contouring services, either redoing existing contouring on farmland, or recontours completely, depending on what the client wants.

In pasture blocks Brendan says he mostly deals with soil compaction. Deep ripping aerates

DEEP RIPPING AERATES SOILS AND LETS WATER AND AIR BACK INTO SOILS.

avoiding unnecessary expenditure.

“You’re not wasting money by applying the wrong product,” he says.

In farming country Brendan deals mostly with heavy soils that compact over years. Pasture land is often clay country that turns hard with compaction, and water simply runs off it, with no grass growth.

BRENDAN ALSO BUILDS DAMS, THE BEST PART OF THE WEEK IS TO SEE ONE COMPLETELY FULL.

“You want as much of the water getting into the ground, especially in grass country.”

Brendan relies on TTQ deep rippers to get the job done. He says gear from other companies were too small for his needs.

The way the TTQ deep ripper shanks retract out of the ground when it encounters something hard, like a rock or tree stump, and are under pressure, is really good, he says.

The shanks first move back, and then up and over an obstacle. This prevents it from breaking. And with the thousands of acres he rips every year, he isn’t easy on the ripper.

“Most of what I do is pasture land, it’s pretty rough going”.

In cases where there is too much strain and something does snap, a shank is also easy to

replace as they are bolted on.

This means a bolt gives way first and can easily be replaced, and work continues.

TTQ offers clients versatility. Having a shear pin and hydraulic option with a large number of different shank sizes and shapes.

The frames are also bolted together in a fashion that allows a buyer to design their own machine.

Three designs of shank, which are cut from 450 grade ‘hardox’, allow deep ripping up to 450mm, 620mm and 840mm. These all come in either shear pin or hydraulic options.

After 30,000 acres of deep ripping and seeing good results, Brendan says the recipe is straightforward.

To create good land and ideal pasture or growing conditions

A KOMATSU BULLDOZER LEADING THE CHARGE, A TTQ DEEP RIPPER TO DO THE HARD YARDS, AN AIR CART FERTILISER/SEEDER IN TOW.

you need deep penetration. Enough penetration means you let in water and air and break up any nutrients that are in roots that you rip through.

“Open up the soil and let the water in.”

Brendan says he relies heavily on the accuracy of a Trimble GPS.

Fertiliser is a costly input, and farmers aim to optimise usage. For a 200-hectare paddock, applying 250 kilograms per hectare means a specific amount is required, with no desire to exceed that.

FARMERS AND CONTRACTORS FACE PLENTY OF UPS AND DOWNS IN THEIR BUSINESSES, ESPECIALLY WHEN THE WEATHER TURNS DRY. IT IS VITAL TO PAY ATTENTION TO THE BOTTOM LINE AND CONSIDER ALL MACHINERY FINANCE OPTIONS. IN THIS FEATURE, LEADING MACHINERY DISTRIBUTORS TELL US ABOUT SOME OF THEIR FINANCIAL PRODUCTS.

BACK YOUR PRODUCTS WITH FINANCE THAT WORKS FOR YOU

Every farming operation or agricultural contracting business is different. Claas Financial Services offer tailor-made financial packages to suit your individual needs. We can work out a plan, factoring in the deposit and repayment schedules, to best suit your cashflow situation.

While we may advertise low promotional rates, these often require a high deposit or shorter term. Our no-deposit option may suit contractors better as they scale up their fleet when they pick up additional work, or perhaps you want to have a repayment holiday when income is lower, or outgoings are higher. While these different structures may increase your interest rate, as the rate subsidy doesn’t go as far – more important is that they match your income cashflows.

Our dealer sales team can do a basic quote at the dealership, and we have a finance specialist

in each of the North and South Islands for more complex structures. Whether you want to source finance for your Claas Greenline products, Tractors, Scorpion Telehandlers, Jaguar, Lexion or used equipment our dealerships and Financial Services team can provide a repayment schedule to suit your income periods.

Established in 2010, Claas Financial Services is a division of De Lage Landen (DLL) a proud member of the Rabobank Group, a leading provider of equipment

and technology financing to the Agriculture and Food industries. Drawing on deep industry knowledge, DLL creates sustainable finance solutions for asset and input manufacturers, dealers, and farmers and contractors in over 30 countries.

With Claas Financial Services backing the products we sell, the Claas dealership network is your first point of contact for machinery lending requirements. Talk to our team today to see what we can do for you! https://claasharvestcentre. com/finance-leasing/

The Brimblecombes have been farming in Queensland’s salad bowl, the Lockyer Valley, for close to 150 years with a story that begins with a shipwreck and very nearly ended during World War One.

For family patriarch Linton Brimblecombe, a key attribute that has been shared down the years has been keeping an eye on the future.

“Empowerment of the next generation is just something so key to this conversation,” Linton said.

Each steward of the family property has brought their own approach, starting with grazing and fodder production, before transitioning to cotton and later vegetables.

“My great, great grandfather came in with the gold rush heading to Ballarat in the mid-to-late 1800s but he got shipwrecked off the coast of Newcastle,” Linton said.

“He met a lady, got married and had two boys, John and William, and they made their way to Queensland to farm the black soil plains of Forest Hill.

“The call of war came with World War One and my grandfather, who was student teacher,

joined the light horse in 1917.”

His campaign ended in a bloody battle which killed five of his eight men and left him with gunshot wounds to his wrist and hip. In 1925 he bought the block that remains in the family almost a century later.

“Grandpa lived with the challenge of his war wound for the rest of his life,” Linton said.

“He retired in his fifties and said to my dad, ‘Allan, I want you to have this and I think that expression of faith in the next generation started at that point.

“And in the same way, I guess I’m a little tired now and my son Mitch has taken over the management of the farm.”

Mitch said it was a daunting challenge at the age of 20 but he had wanted to be a farmer for as long as he can remember.

“When I’d get home from school I’d want to go out and follow dad around and probably was more of a hindrance than a help,” Mitch said.

“But it’s always been a passion. It’s a great industry with a lot of great people and there’s so many different aspects of the business whether it’s agronomy, machinery operation, earthworks, finance or future direction.”

Planning has been a critical part of the Brimblecombe’s management at Moira Farming, particularly with the operational

needs of a farm that grows cotton and vegetables across hundreds of hectares.

“To be a farmer you need a few more tools in your toolkit and they’re generally big and expensive,” Linton said.

“So you need someone like John Deere Financial to go on that journey with you.”

John Deere Financial Territory Finance Manager, Shaun Procter, said it was important to make the process simple but also tailored to each business.

“We like to make life as simple as possible, so we use things like e-signatures and online application processes,” Shaun said.

“We’re really trying to find a way to give them ease of operation and do things on their own time because they don’t have the time throughout the day.”

Mitch, who recently completed the purchase of a John Deere 8R tractor, said he valued the effi-

ciency of the online application process.

“The reason I recommend John Deere Financial to other people is I was lying in bed at 9pm in my pyjamas when I signed the deal on my iPhone to buy this tractor, and then went to sleep,” he said.

“It’s easy, it’s convenient and we can see them being part of our business for a long time to come.”

To see the Brimblecombe’s story watch the video here at the John Deere Australia and New Zealand YouTube channel: https://www.youtube.com/ watch?v=mKhR69F6MzE.

To find out more about how John Deere Financial can help your operation, including with online applications, paperless contracts, fixed rates, and no early exit fees, head to https:// www.deere.com.au/en/finance/ financing/.

AGCO Finance provides crucial financing solutions to support the agricultural industry, helping farmers across Australia purchase the world-class machinery they need to stay competitive. As one of the global leaders in the design, manufacturing, and distribution of agricultural equipment, AGCO’s financing options extend across its popular brands, including Fendt, Massey Ferguson, PTx, Valtra, and AGCO Parts & Service. For Australian farmers, AGCO Finance is a valuable resource to ensure they can access top-tier equipment while managing the challenges of an unpredictable farming business. Farming is inherently subject

to seasonal variations, fluctuating commodity prices, and unforeseen costs. AGCO Finance understands the unique financial landscape farmers face. The company offers flexible, tailor-made financing solutions designed to match the cash flow fluctuations common in agriculture. Whether it’s the unpredictable nature of the weather or sudden market shifts, AGCO Finance adjusts to the demands of the industry by offering customized payment plans that align with each business's financial cycle.

In the agriculture sector, financing has become an integral part of the equipment purchasing process. For many farmers, the decision to acquire new machinery depends as much on the financing options available as on the mechanical features

and technological benefits of the equipment itself. AGCO Finance recognises this shift and offers a range of financial products to suit different needs. The available financing options include chattel mortgages, finance leases, and operating leases, ensuring flexibility for all types of farming operations.

AGCO Finance’s comprehensive programs provide Australian farmers the opportunity to purchase and utilise the best agricultural equipment available. The power, efficiency, and cutting-edge technology offered by AGCO’s brands play a crucial role in helping farmers increase productivity and operate profitably. With these financing solutions, farmers can obtain

machinery that will ultimately enhance their operational capabilities, boosting efficiency and profitability.

An extensive network of AGCO dealerships across Australia makes accessing AGCO Finance straightforward. These dealerships offer financing not only for AGCO products but also for non-AGCO and used equipment, ensuring that farmers have a variety of options to choose from. With the support of knowledgeable dealership staff, farmers can easily navigate their financing choices and find a solution that meets their needs. Additionally, AGCO Finance representatives are available to provide personalised assistance, offering valuable insights into

SMART MACHINERY

FINANCE: WHY PFG CREDIT STANDS OUT

Farmers and contractors have many machinery financing options, but looking beyond traditional banks and brokers can offer unique advantages, says Scott Maxwell, PFG Credit Account Manager at DLL.

The role of DLL in agriculture financing

DLL offers asset finance solutions for equipment and technology around the world. Part of the Rabobank Group, DLL has been providing equipment finance solutions for more than 50 years across 25 plus countries.

Scott notes that Australian agriculture has long benefited from accessible and affordable finance options. For over 20 years, major machinery manufactures have provided financing solutions.

“Many farmers and contractors have strong relationships with their bankers and brokers, but there are some great alternatives available that can preserve your existing credit lines for other business expenses,” Scott explains.

About PFG Credit

“PFG Australia, a major machinery distributor, has a specialist equipment finance company behind their brand called PFG Credit.* It’s widely recognised for having a quick, simple and competitive finance package which is an important part of the purchase process.”

PFG Australia is a family-owned distributor that sources leading tractor and agricultural machin-

ery brands from around the world such as Deutz Fahr, Kioti, Versatile, McHale and Mascho and distributes them through an extensive dealer network in Australia.

Competitive rates and unique advantages

Scott says that PFG Credit has competitive interest rates in the marketplace. “Many machinery companies subsidise finance interest costs to attract buyers, rather than lowering equipment prices or offering a service package,” he says.

“Buyers may not realise that $1,000 spent on your interest bill will often go further than $1,000 off the purchase price of a tractor. That’s why you see low interest rates that are well below traditional lenders. The distributors see the benefits of spending their money on special finance offers rather than on discounted mudguards.”

“More farmers and contractors are spreading their risk, whether it’s between insurance or buying equipment from different manufacturers. The same applies to finance; if you have all your eggs in one funding basket then you may not be getting the best value deal.”

Using a specialist financier for your next equipment purchase can offer several advantages: Tailored financing options: PFG Credit can provide customised financing plans that align with your specific needs and budget. This flexibility can make it easier

to manage payments and obtain the equipment you need.

Streamlined process: PFG Credit is proud to offer a quick and efficient low-doc approval process . This can save you time and help you get your equipment sooner.

Enhanced customer support:

PFG Credit has a long standing relationship with the equipment distributor so they can offer high quality customer service and support, ensuring a smooth overall experience.

“PFG Credit understands machinery. We understand what the machinery does and how important it is to the farming

programme. Having people who understand the business makes a big difference.”

Scott emphasises the importance of exploring different finance options that include a fixed rate and tailored repayments, helping buyers get a personalised funding package with their new machinery.”

*DLL and PFG Credit are trading names of De Lage Landen Pty Limited (ABN 20 101 692 040). Finance is provided by DLL and is available for business purposes only. Applications are subject to credit approval, fees and terms and conditions apply.

local agricultural conditions and financial options specific to the region.

One of the key benefits of AGCO Finance is the ability to lock in rates and payments on forward orders. This feature provides farmers with certainty, knowing exactly what their payments will be when their new machinery arrives in the spring. This predictability allows farmers to plan ahead and manage their cash flow more effectively, eliminating financial uncertainties that

can arise with large equipment purchases.

For Australian farmers looking to expand or upgrade their machinery, AGCO Finance offers an essential and flexible financing solution.

With its deep understanding of the agricultural sector and a commitment to providing tailored financial products, AGCO Finance helps ensure that farmers have the tools they need to thrive in a competitive and ever-changing industry.

WITH ITS UNEVEN RAINFALL, LACK OF IRRIGATION AND HARSH NOR’ WEST WINDS, IT IS NOT EASY TO FARM IN THE HAWARDEN DISTRICT OF NORTH CANTERBURY.

Because farmers face so much uncertainty, a contractor who provides services to them must be both efficient and frugal.

In the case of Waitohi Ag Ltd, it helps that the contracting business has plenty of local knowledge. This is because it was initially a machinery syndicate that six local farmers formed to do their own baling and cultivation.

It was back in 1974 that they set up the syndicate. Today members of two of the original families who started the business (the Zino and Costello families) are still shareholders.

bury, Ben joined Waitohi Ag Ltd in 2016 and never left. Not only is Ben now a shareholder of the business, he is also operations manager.

Waitohi Ag is based at the small settlement of Masons Flat, not far from the Waitohi River. In fact, they have converted the historic Masons Flat Hall into their workshop.

The shareholders who formed the business did so primarily to make the best use of their own capital and equipment to do their own work in a timely manner. Now, however, most of the work

WAITOHI AG MAINLY USES THEIR TWO KVERNELAND OPTIMAS TO PRECISION PLANT FODDER BEET, BUT THEY ALSO DO SWEDES AND SOME MAIZE.

it does is for other farmers.

“About 30 percent of the work we do is for shareholder farmers and 70 percent is external. We travel up north to Culverden, east to Cheviot and down south of Amberley, but 80 percent of our clients are within a 25 minute drive from our yard,” Ben says.

across ditch the PROFILED IN NZ’S RURAL CONTRACTOR & LARGE SCALE FARMER APRIL/MAY 2025, WE VISIT WAITOHI AG IN NORTH CANTERBURY, NEW ZEALAND.

They now run the business with other shareholders who have bought into it. One of them is Ben Clarke, a transplant from the UK who arrived in New Zealand in 2012.

After working for contractors in the Waikato and Mid Canter-

A MCHALE BUTTERFLY AND A PÖTTINGER FRONT-REAR COMBINATION DO THE MOWING. BEN SAYS BOTH MOWERS DO REALLY GOOD JOBS.

WAITOHI AG CAN WRAP INDIVIDUALS AS WELL.

From the beginning the services Waitohi Ag has provided are cultivation, drilling (grass, cereals and green feed crops), and baling. Today they also do bulk silage, precision planting and strip tillage.

“We have about 35 dryland sheep and beef farmers on our books. They tend to be very conservative farmers because they have to be. Most of them do not have irrigation, so everything depends on rainfall and the price of lamb and beef.

“Often they do not have a lot of cash flow, and if they do have access to water, they need to use it strategically. It is difficult farming and it means that our contracting business has massive peaks and troughs. We might be flat-out when we have rain, but when we don’t we might not turn a wheel for a month or six weeks,” Ben says.

To succeed they keep overhead costs to an absolute minimum. This is not easy because the uncertain weather makes it hard to budget and plan.

For example, in 2024 the Hawarden area had no significant rain from the beginning of the year to mid-October. A good front at that point saved the season, but it only brought the year’s total rainfall up to 390 mm. That is just over half of the yearly average, which is 680700 mm.

Ben says to monitor costs his team keeps track of everything they do – engine hours, staff hours, hectares covered, bale numbers and tonnes harvested.

Currently they do this by hand but they are checking out apps that will make it easier.

“A lot of what we face is out of our control such as the weather and what farmers are going through. So we have to focus on what we can control. We have to be as flexible and as efficient in the paddock as possible.

"One of the most important things we do is to have experienced drivers who deliver a good bang for the buck.

“We are also anti debt. We like to buy our tractors new, but a lot

of our other gear is second hand.

Also we keep it working longer than some other contractors might. We do about 70 percent of our own mechanical repairs.”

The Waitohi Ag season generally kicks off in late August with cultivation of ground coming out of winter crops. When the ground is ready they start to establish crops. This includes spring-sown barley, which sheep and beef farmers can hold for grain or cut for whole crop silage.

By early October drilling is in full swing and they start to strip till and precision plant fodder beet as well as some maize. This is the crux of the season because balage and bulk silage get underway at the same time.

Once the new year begins, they are into combine harvesting barley and wheat. In February and March it is a time to sow oats, Italian ryegrass and other winter green feed crops.

Because of the dry climate, pit silage is the most economical way for farmers in the area to

preserve supplemental feed, Ben says.

“We make pit silage from grass, whole crops and maize. When there is good bulk and good quality in the crops, pit silage is the best option. It is the cheapest way to preserve feed, and it will last. One of our farmers recently opened a pit that had been buried for seven years.”

Bales still have their place, of course, and Waitohi Ag produces

WHEN THERE IS PLENTY OF RAIN AND THE GRASS IS GOOD QUALITY, FARMERS IN THE HAWARDEN AREA PREFER TO MAKE PIT SILAGE RATHER THAN BALAGE.

ALL DRIVERS DO THE DAILY MAINTENANCE ON THEIR MACHINES AT THE END OF THE DAY.

12,000-15,000 rounds and medium squares of balage each year, depending on how kind Mother Nature has been, as well as 4000 to 5000 big squares of hay and straw.

The economics of kale make

TODAY IT IS A BUSY CONTRACTING BUSINESS, BUT WATOHI AG LTD STARTED OUT 50 YEARS AGO AS A MACHINERY SYNDICATE FOR DRYLAND FARMERS IN THE HAWARDEN DISTRICT OF NORTH CANTERBURY.

it a good winter feed option for sheep and beef farmers. In the past couple of years the interest in fodder beet has dropped off and kale has replaced it.

Ben says fodder beet is more expensive to grow and it needs to deliver 8-10 tonnes/ha to break even. In a good year it can deliver 16 tonnes/ha in the Hawarden district, but in a dry year yields can be down around 3-4 tonnes/ha.

Waitohi Ag Ltd gives the option of running their PTO-powered strip tiller in front of the precision planter. Not only does strip till preserve moisture in the soil by only cultivating part of the paddock, it can cut out two weed

sprays over the life of the crop.

In a typical season they precision plant 600-700 ha of fodder beet (and some swedes).

Given the dry conditions, maize is not really an option for mostfarmers in the area, but they do plant 60-80 ha of it for a large irrigated dairy farm in the Culverden area.

The equipment you will see at the Masons Flat Hall is something of a rainbow, which includes a couple of shades of green.

Their five tractors include three John Deeres (a 6150R, a 6170R and a 7210) and two Claas (an Axion 870 and an Arion 610).

These are not the only tractors you will see pulling Waitohi Ag Ltd. They also lease a Massey Ferguson 8660 for the two months of the year when baling and drilling overlap, and they hire a Valtra from a local farmer during the same period. With the operation’s emphasis on efficiency, the three main tractors

have Greenstar GPS.

John Deere is also the brand of their two self-propelled forage harvesters. They are a John Deere 7350 and 7400.

Doing the square baling are a Case IH LB 334, which generally does medium squares for balage, and a Krone 1290C 4x3 baler, which does straw, hay and some balage. Most bales are tube wrapped with a Webbline tube wrapper but they have a Goweil individual wrapper as well.

A variable chamber McHale V8950 does the round baling while a McHale butterfly and a Pöttinger front-rear combination do the mowing. Ben says both mowers do really good jobs, and he runs two four rotor Claas Liner rakes.

For precision planting Waitohi Ag Ltd runs two Kverneland Optimas. One is a 12-row and the other is a six row, which can run in tandem with their six-row Precision Cultivation strip tiller.

“We got one of Paul Linklater’s Precision Cultivation strip tillers

because one of our drivers was familiar with them. We can put fertiliser down with both precision planters. When doing strip till, we can cultivate the strips, put down fertiliser and plant the crop in one pass,” Ben says.

An eight-year old John Deere 750A disc drill does direct drilling while a Taege tine drill does the drilling in cultivated ground. Like the planters, the Taege can apply fert with the seed.

“We work in lots of different types of soils, from riverbed flats with lots of stones to heavy clay. The amount of ground we direct drill versus the amount we cultivate and drill depends on the weather.

“In a dry year we do more direct drilling because it preserves moisture. This year we direct drilled 40-50 percent of the crops we sowed. In the spring we have to cultivate ground coming out of winter crops.”

A variety of well-proven tillage tools are used to prepare ground for crops. They include a Taege Maxitill, a Hubbards chisel plough with a wavy disc combo, a Simba X-Press compact disc harrow, and an Austins Cambridge roller. There are also several Kverneland tillage tools in the mix, including a five-furrow reversible plough, a power harrow and offset discs.

All drivers do the daily maintenance on their machines at the end of the day and Ben gets them involved in any repair work that needs to be done.

“The more familiar they are with the machines, the better able they are to fix something if they have a breakdown.

“We always hire Kiwis. This is the first year we have had an overseas driver. He is Dutch and he contacted us right after one of our best drivers, who is a woman, took a job in the North Island. So that worked out well.”

In addition to hiring local drivers, Waitohi Ag takes part in Hurunui College’s Gateway Programme. Students can sign up to work them for a day a week during part of school term. Then, if they are keen, they can work full-time during the summer holidays.

WAITOHI AG LTD HAS TURNED THE OLD MASONS FLAT HALL INTO THEIR PRIMARY WORKSHOP.

USES THIS CASE IH LB 334 TO PRODUCE MEDIUM SQUARES OF BALAGE AND A KRONE 1290C TO DO STRAW AND HAY

Ben is making an effort to reduce fatigue by hiring an extra driver this season. He is also trying to do less driving himself, but he still gets roped in during the busy spells.

“Sometimes I get home to sleep five or six hours and have a shower, and then it is time to get back out. But we know fatigue is dangerous. Over the last two years we have hired another operator, so everyone can do a bit less.

“Our drivers are young guys and they have a life to live. They still do some big days though.

It is a massive cost to hire an additional driver, but it means our staff can have a day off or a weekend off during the busy part of the season. It brings in a bit of balance.

“We also feed the staff during the busy times. They are crucial to our business and we want to look after them as best as we can. The meals are delivered to the paddock, which gives everybody a chance to get out of the tractor and stretch their legs. We have found it to be a real morale booster.”

While Ben and his crew maintain the equipment, they still depend on the product support

they get from their suppliers. In particular, they get a lot of help from Power Farming Canterbury and their parts manager Roger Hunter, as well as the Claas branch in Waipara.

“Roger is very knowledgeable and we would not be able to run without the parts we get from them for our Kverneland, McHale and Simba gear.”

Ben developed a love of farming and machinery growing up on a farm near Shepperton, which is just 24 km southwest of Central London. The area got caught up in plans to expand Heathrow Airport, so Ben, headed off to New Zealand.

He has been with Waitohi Ag for nearly a decade and on top of managing its day-today operations for the past two years he has also been a representative on the board of Rural Contractors NZ.

“I like being on the board. It feels good to give something

Ben Clarke says fortunately Waitohi Ag has a solid base of long-term customers. Some have been on the books for over 35 years.

“Loyalty is a big thing. Repeat customers are so valuable. We are working with some families who have been with us for two or three generations and those working relationships are invaluable.”

back to the industry. All contractors are under a lot of pressure and we can get caught in our own bubbles. Being on the board is a chance to sit with other contractors and see what the different issues are.

“As the Zone 3 rep I do get calls from other contractors who are looking for a bit of help. The contracting world is facing a lot of negativity and contractors are under financial and work pressure.

“It is hard to get skilled drivers and the weather can be an issue. Interest rates are high and the cost of machinery is eye-watering. If you have to replace a trac-

tor and a drill, for example, you ask: How can we do this? But then again, if you are going to stay in business, you have ask: How can we not do it?”

Among the issues Rural Contractors NZ is working at a national level are immigration and a campaign to remind contracting business owners and drivers about the dangers of fatigue.

Fatigue can be dangerous both in the short term, when people are operating machinery, but also in the longer term, when business owners get burned out or collapse under all the pressure they face.

TRACTOR MANUFACTURERS CONSTANTLY REENGINEER THEIR MACHINES AND DEVELOP NEW MODELS. ADVANCED FEATURES SUCH AS FUELEFFICIENT ENGINES, CONTINUOUSLY VARIABLE TRANSMISSIONS, FACTORY-FITTED PRECISION FARMING TECHNOLOGY, AND LARGE COMFORTABLE CABS ARE AVAILABLE ON MORE AND MORE MODELS. IN THIS FEATURE THE LEADING COMPANIES TELL US ABOUT THEIR NEW HIGH HORSEPOWER TRACTORS.

POWER, PRECISION AND PERFORMANCE

HIGHLIGHTS OF 715

Since hitting the Australian market last year, the Steiger 715 Quadtrac, the brand’s most powerful Steiger ever, remains one of the highest horsepower tractors available in the local market.

With an engine rated for 715 continuous horsepower and 778 peak HP, the Steiger 715 delivers “power with purpose”, putting more power to the ground to do more in a day, while being agile and versatile enough to navigate a single lane of traffic.

“With the arrival of the Steiger 715 Quadtrac, which was launched to the local market last year, it positions the range as one of Case IH’s most flexible tractor offerings,” said Justin Bryant, Case IH ANZ Steiger Product Manager.

Features include:

- New heavy-duty undercarriage with a longer track

design for improved traction and flotation to match the tractor’s high horsepower, while still reducing soil compaction and delivering more power to the ground;

- New FPT 16L TST twin-stageturbo Tier 2 engine with 23% increase in displacement over the 13L delivering more power and more torque;

- Higher three-point linkage capacity and full engine power through the whole work-

ing range of that three-point linkage;

- Improved visibility from the operator’s cab with newly re-styled cab interior, redesigned bonnet and exhaust and increased LED lighting power;

- 16-speed PowerDrive powershift transmission;

- Increased fuel capacity to allow longer stints in the paddock;

- Easier daily service with 31% greater access from re-de -

With the completely newly developed Fendt 600 Vario series, Fendt, for the first time in the 150-200 hp category, is presenting a compact and manoeuvrable 4-cylinder tractor with high performance and payload at a low power-to-weight ratio.

With four models (Fendt 614 Vario, 616 Vario, 618 Vario and Fendt 620 Vario), the new series occupies the from 149 to 209 hp (110 – 154 kW) power range according to ECE R120. For the first time, Fendt DynamicPerformance (DP) added-performance concept is available for all models in the 600 series. DP releases up to 15 hp of additional performance on each model via demand-based control exactly when it is needed. The extra power concept is not tied to driving speed or special operating tasks. It functions purely dynamically – even when carrying out stationary PTO work or, depending on the operating conditions, during tillage.

Exclusively for Fendt, the completely, newly developed 4-cylinder 5 litre AGCO Power CORE50 engine enters the market with the Fendt 600 Vario series. Exhaust gas after-treatment takes place via a diesel oxidation catalytic converter (DOC), diesel particulate filter (DPF) and with selective catalytic reduction (SCR) without exhaust gas recirculation. The CORE50 engine is also prepared for alternative

fuels, such as HVO, to operate with lower CO2 emissions in future. There are also maintenance-free hydraulic tappets built into the engine. The newly developed, single-stage Fendt VarioDrive transmission is made up of the engine and the matching VarioDrive drive train.

Fendt VarioDrive refers to a completely new generation of continuously variable transmission technology. The foundation is the single-stage drive train with independent control of the front and rear axles. The transmission continuously measures the slip on all four wheels and sensitively regulates the power output. For the first time, Fendt VarioDrive combines the four key functions of maximum tractive force, simultaneous ground protection with minimum wear and ground-breaking manoeuvrability. Dynamic control prevents wheel slip, with maximum traction regardless of the surface. The drive train eliminates the need for manual switching when changing between field and road operations. In this way, VarioDrive automatically combines maximum tractive force, high ground protection on any surface without distortion, loss of performance or tyre wear.

The so-called pull-in-turn effect pulls the machine into the curve during turns due to the axle-independent control. The result: a particularly small turning circle of just 10.2 meters with 540/65 R30 tyres.

The innovative low-speed Fendt iD concept is available for

the first time in this compact performance class.

All components, such as the engine, transmission, hydraulics and cooling system, were designed according to the so-called “high torque – low engine speed” principle. In this way, the Fendt 600 Vario achieves high torque even at low engine speeds and saves fuel. The rated engine speed is only 1,900 rpm. In the main working range, the speed is a quiet 1,350 to 1,800 rpm.

With a power-to-weight ratio of just 34.4 kg per hp and compact external dimensions, the Fendt 620 Vario is particularly manoeuvrable and exerts as little pressure as possible on the ground.

Depending on the work application, the range can be flexibly ballasted at the front, as well as at the rear on the rear wheels. A gross vehicle weight of up to 13.5

t allows it to be used as a heavy towing tractor and ensures operational safety during transport. Optimally adjusted tyre pressure reduces slip and ground pressure and increases soil fertility. The fully integrated Fendt VarioGrip central tyre inflation system increases the contact area of the tyres, boosts tractive power by up to eight percent, and at the same time reduces fuel consumption by up to eight percent, thus increasing the overall productivity of the machine. Higher air pressure during road travel reduces rolling resistance, thus another two percent fuel* can be saved (*South Westphalia University of Applied Sciences, Agricultural Economics Soest 2014). In the terminal, the driver can conveniently control the tyre pressure via the dual-line tyre pressure control system. Fendt VarioGrip can be ordered directly from the factory for both flanged and stub axles, for row-crop with dual tyres and also with wheel weights.

For the first time in this performance class, Fendt is offering the Fendt 600 Vario as a 60-inch (row-crop) version for all models in the series. For row-crop use, both single and twin tyres are available from the factory.

Fendt is committed to keeping tractors up to date for customers. Further developments can be made through continuous updates of the vehicle’s operating system as well as functional enhancements for machines. This is exactly what the Fend-

The new Claas Arion 600C EVO F facelift series has arrived at Claas Harvest Centre.

This stylish model has been refreshed for 2025 with a range of new features to deliver the next-level experience in productivity and comfort.

Introducing hydraulic system upgrades with load sensing circuits (110 l/min or 150 l/min options) for better efficiency and fuel savings, reduced RPM for similar oil flow and noise reduction, and Cemis 1200 digital guidance system and machine connect capability can now be added as a factory fit option.

The in-cab experience has been amplified with a new ergonomic steering wheel, both driver and passenger seating upgrades offering premium comfort, and new air outlets to increase ventilation.

“Tractor operators will want to experience the most comfortable cab on the market”, says Kevin Walker - Product Business Manager, Tractors ANZ.

“The new 3D Front grille, on a modern bonnet design with new Claas branding, is sure to draw attention to our stand”, he says.

Claas Cemis 1200, its new generation steering system designed to deliver advanced precision farming solutions to farmers globally.

With improved accuracy and user-friendly features, the Cemis 1200 simplifies field operations for farms of all sizes.

The new functions and features of the Cemis 1200 Universal Terminal provide the ability to define multiple reference tracks and field segments using field boundaries marks a significant gain in convenience, especially during cultivating and drilling. Furthermore, tramlines can now be flagged with colour and acoustic signals and master data can be created and processed directly on the terminal.

The Cemis 1200 offers 1200 offers +/- 15cm accuracy with Satcor 15 as standard with optional Satcor 3 offering +/3cm accuracy or RTK ready, ensuring precise navigation for efficient fieldwork. This Satcor 15 comes standard with five years of use, providing long-term reliability and cost savings for farmers.

By reducing overlaps and missed areas during field operations, the system helps improve productivity and resource efficiency.

Complementing the Cemis 1200 is the Cemis terminal, which offers a similar user experience for smooth and intuitive operation. Both systems are designed to be easy to use, allowing farmers to adopt and integrate them effortlessly into their daily routines.

A standout feature of the Cemis 1200 is its ISOBUS functionality, which ensures compatibility with all ISOBUS-ready implements.

This plug-and-play capability eliminates complications, allowing farmers to connect and operate implements seamlessly with the steering system. Whether working with planting, tillage, or harvesting tools, the system streamlines operations across the board.

Class recently introduced Claas Connect creating the basis for virtually connecting all key elements of your farm. The powerful interface provides instant access to performance data, service information and the location of your machines.

The digital platform from Claas

is the key to managing your farm and fleet efficiently and streamlining your business. Connect your tractor, automate your documentation and boost your performance in the field. You can find out more information about registering for Claas Connect here: https://claasharvestcentre.com/digital-solutions/

Challenge accepted! Claas has responded to market demands with the new Night Edition for the continuously variable, Arion 660 CMatic and the Axion 870 CMatic tractor.

The tractor has the most substantial emotional connection with the driver of all farm machines. After all, most drivers spend from a few hundred to over a thousand hours a year in the cab, so opportunities for a premium driver package are becoming increasingly important for driver wellbeing, and for identifying ‘their’ tractor.

The catchphrase for these special limited-edition models is ‘Strong on performance, design

Inside the cab of the Night Edition, lettering appears on the steering wheel badge, seat headrest, and floor mat. What’s more, drivers can enjoy a firstclass entertainment experience thanks to the Apple Carplay/ Android Auto radio. The cab equipment features high-quality materials, additional accents,

transmission, and a Cebis multi-function armrest and offers opportunities for design customisation.

The Night Edition exterior features custom grey paint on the rims, roof, and side engine panels. The Claas logo on the side of the bonnet is white on a custom grey background. The Night

placed on the side of the bonnet, with the emblem above the LED road lighting, which provides the finishing touch to the external design and flexibility for working hours.

Farmers and contractors can now purchase the exclusive Night Edition with enhanced optics, by contacting their local

The latest enhancements to the Fastrac 8330 ensure it is the largest and most powerful JCB tractor yet.

Faster, more comfortable, extremely versatile and fitted with more safety features than any other tractor in its class, the Fastrac 8330 guarantees operators can get more done in a day than ever before.

With its speed, comfort, productivity, safety and versatility, the Fastrac 8330 can make a big difference to any operator. Thanks to its faster road and field speeds plus unique allround suspension, the Fastrac 8330 is a great machine for any farming operation.

Fastrac 8330’s engine combines the advanced powertrain and suspension systems to deliver the ultimate in power, torque and traction making the difference in any situation. It can also achieve road speeds up to 70 kph.

An 8.4-litre, six-cylinder engine delivers up to 348 hp with twin turbochargers that give quick responses and high torque ratings across a wide range of engine speeds.

A CVT transmission with improved cruise control functions also ensures optimum use of power and torque.

On the road, the Fastrac 8330’s steering is precise and well weighted. It can provide the ultimate control when travelling at 70 kph. A Rapid Steer option

reduces the lock-to-lock turn of the steering wheel by 50 percent and makes headland and other field manoeuvres quick and easy.

A road performance package is an option to provide further traction control plus a ‘hill-hold’ feature that is unique to JCB.

External brakes on the axles allow the Fastrac 8330 to consistently stop up to 15 percent quicker than conventional tractors.

At the same time, the hydrostatic dual steering system significantly reduces operator effort whilst meeting the safety standards for high-speed tractors.

The advanced anti-lock system (ABS) retains stability and steering while optimising braking performance on the road, on dirt tracks and in the field.

An added safety feature is Fastrac’s fail-safe system, which ensures the brakes are applied in the event of a loss of pressure. A transmission disc park brake holds the tractor securely and applies air brakes on a trailer, tanker or spreader.

Fastrac 8330’s advanced suspension quickly responds to changing loads from front- or rear-mounted implements. This distributes the load evenly across the machine.

With near 50:50 weight distribution and suspension on both axles, there is plenty of traction for heavy draft work. Rough terrain is no deterrent to Fastrac operators as the all-round suspension and air seat ensure

a smooth ride during baling, spreading and spraying.

The heavy-duty axles can also be used at a track width of 3m track for controlled traffic and row crop work.

JCB has designed the chassis to give plenty of options when mounting a variety of implements. Powerful hydraulics can meet the demand of implements through five rear double-acting electric spool valves and a Power Beyond hydraulic connection.

Fastrac 8330’s powerful Category III rear hitch can lift 10,000 kg to handle large capacity three-point linkage spreaders, ploughs, cultivators and mounted drills.

Sensitive electronic draft control helps the tractor maintain traction under heavy load. For added productivity operators can also use the optional Category 3N front hitch with 3500-kg capacity, external lift/lower control and optional power and lighting sockets.

Optional rear deck-mounted 900-kg or 1600-kg ballast weights provide additional trac-

tion. This load is suspended, providing additional comfort over wheel weight systems. The rear deck weights are quick and easy to fit or remove, encouraging the efficient use of ballast.

In the cab, Fastrac 8330 delivers high levels of tractor and implement control through a simple, easy to use interface. It easy-to-use touchscreen terminal has large icons and intuitive navigation so operators can easily adjust settings.

Operators can also create and save up to five sequences each with up to 15 steps in the Headland Turn Assist section to minimise control workload at the end of each run across a field.

Four configurable joystick buttons can also be assigned different tasks. Factory fit GPS is available and it is compatible with a wide range of third party systems.

During spraying and spreading, the Fastrac can minimise overlap at speeds of up to 40 kph.

To find out more about the JCB Fastrac 8330, with advanced suspension speak to your JCB CEA dealer today.

Australia’s agricultural landscape is diverse, spanning vast open plains, rolling hills, and arid outback regions.

The New Holland T9 series is a high-performance tractor that offers both reliability and cutting-edge technology and is designed to meet the growing demands of the Australian agricultural sector.

Whether it’s the extensive cropping areas of the Murray-Darling Basin or the pastoral lands of Queensland, the T9 is a versatile, powerful machine equipped with advanced features to enhance

productivity, reduce downtime, and increase farm efficiency.

Unmatched power for largescale operations

The T9 tractor series offers some of the most powerful tractors in the market, with horsepower ranging from 467 to 699. These tractors are designed for large-scale farming operations, making them ideal for tasks like heavy tillage, seeding, planting, and hauling large implements. The sheer power available in the T9 models is unmatched, ensuring Australian farmers can tackle even the most demanding tasks with ease.

The T9’s robust capabilities are complemented by its choice of transmission systems, including the Ultra Command full power-

shift transmission and the Auto Command Continuously Variable Transmission (CVT).

These options provide Australian farmers with the flexibility to choose a transmission system that suits their operation’s needs.

The Ultra Command transmission is perfect for operators who prefer the control and efficiency of a powershift, while the Auto Command CVT offers a seamless driving experience for those who need continuous speed adjustment, making it ideal for tasks that require precision and responsiveness.

One of the standout features of the New Holland T9 is its integration of Precision Land Management (PLM) Intelligence, a system designed to optimize every aspect of farm management.

With PLM Intelligence, farmers can access a suite of tools that enable them to remotely monitor and manage their machines. This technology helps farmers track operational data in realtime, from fuel consumption to field performance, and make informed decisions to enhance efficiency. It allows for better machine and crop management, boosting productivity while reducing unnecessary waste.

For Australian farmers dealing with the challenges of wideopen spaces and sometimes remote locations, the ability to monitor their operations from a distance is a game-changer. With PLM Intelligence, operators can access data on their mobile devices or computer, making it easier to plan, adjust, and even troubleshoot from anywhere. The system also allows for precise documentation of every field activity, which is invaluable for compliance with regulations and improving sustainability

practices. Remote diagnostics further reduce downtime, as technicians can remotely identify and address issues before they turn into costly problems, ensuring that the tractor is always performing at its best.

Long hours in the field are a reality for many Australian farmers. As the tractor is often the primary tool for most farming tasks, operator comfort becomes a crucial factor in improving productivity and reducing fatigue. The New Holland T9 series rises to this challenge by offering a redesigned cab that sets a new standard in comfort.