& LARGE SCALE FARMER

FEATURE

What’s new in fertiliser technology and spreaders

PROFILE

George Stevenson –Embracing lower emission rice

EQUIPMENT

Henty visitors glimpse special edition Steiger tractor

FEATURE What’s new in grain harvesting equipment

FEATURE

What’s new in fertiliser technology and spreaders

PROFILE

George Stevenson –Embracing lower emission rice

EQUIPMENT

Henty visitors glimpse special edition Steiger tractor

FEATURE What’s new in grain harvesting equipment

PO Box 36753

Merivale, Christchurch 8146

ph: +64 3 329 6555

www.agrimedia.co.nz

Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping, Australian AG Contractor & Large Scale Farmer, NZ Novachem Manual.

EDITOR

Scott Wilson

Mob: +64 21 725 061

Email: scott@agrimedia.co.nz

ADVERTISING SALES

Pulse – Media Sales

Justin Bowler

Ph: 0429 699 553

Email: justin.bowler@mmg.com.au

CIRCULATION

DDI: +64 3 329 6555

Email: admin@agrimedia.co.nz

PRODUCTION, LAYOUT & DESIGN

Mark Winstanley

Email: art@agrimedia.co.nz

Contributors: Delwyn Dickey

Printed by PrintGraphics Pty Ltd

AC © AUSTRALIAN AG CONTRACTOR AND LARGE

SCALE FARMER - No part of this publication may be reproduced in any form without the prior written permission of the publisher. Opinions expressed in this publication are not necessarily that of the publisher and suggest independent advice be sought before acting on information or suggestions contained herein.

CONTRIBUTIONS - Editorial and photographic contributions are welcomed and should be sent directly to AML. Editing of submissions is at the sole discretion of the editor and will accept no responsibility for unsolicited material.

02 FROM THE EDITOR: The modern farmer’s balancing act INDUSTRY NEWS

03 Light green turns local heads

04 Australia’s top technicians recognised at 2025 John Deere Technician of the Year Awards

06 Ten harvests in, and still terminating the problem at its source

07 New Holland celebrates a half-century of Twin Rotor combines TECHNOLOGY

10 JDLink Boost enhances Machine Connectivity on Australian Farms

11 Maximising the advantages of technology: Data and Autonomy PROFILES

12 George Stevenson - Embracing lower emission rice

16 Across the ditch: Quietly getting it done in the South Waikato FEATURES

22 What’s new in fertiliser technology and spreaders

32 What’s new in grain harvesting equipment EQUIPMENT

46 Flexibility, precision and performance in one machine

47 New features for Flexcare V row crop cultivators

48 Bergmann: new steered pick-up ActiveLoad 2: more power, greater stability and optimised material flow

49 Case IH debuts Optum tractors with 3-metre centre option at Henty Machinery Field Days

50 John Deere’s most powerful tractors exceed all expectations

52 Seeding success: first ever Flexi-Coil 7200 in Australia helps crops take off

53 New from Pöttinger: Terradisc HT 12000

54 One pass machine improving southern WA soils

56 Renovated YP limestone lifts lentil yields up to 70%

57 Special-edition Steiger tractor provides Henty visitors a glimpse of the past and vision for the future

58 Fendt introduces completely new 800 Series Gen 5 Tractor Series

THERE’S AN OLD SAYING THAT FARMERS ARE THE ETERNAL OPTIMISTS — THE ONLY PEOPLE WHO BUY SEED IN THE HOPE IT’LL RAIN.

In Australia, that optimism has been tested more times than anyone cares to count. Between the weather, rising costs, and red tape, it’s a wonder anyone still has the energy to get out of bed before dawn. Yet, somehow, they do - and thank goodness for it.

Right now, Australian farmers are facing a perfect storm of challenges, each as unpredictable as the next.

The weather, for starters, is doing its usual impression of a moody teenager - too hot, too cold, too dry, too wet, and never at the right time.

One day you’re watching your crops bake, the next you’re watching them float away. And through it all, the forecasts remain as reliable as a politician’s promise.

Then there’s the cost of running a farmup, up, and away.

Diesel prices have taken flight, fertil -

ting it to market often costs more than it’s worth. And speaking of markets, global price swings make farming feel a lot like gambling - only the casino doesn’t have to worry about drought.

Add to that a chronic labour shortage, and things start to look even tougher.

Good help is hard to find, and the average age of Australian farmers is creeping steadily upward.

The next generation, it seems, would rather be coding apps than chasing cattle or fixing pumps. Can’t really blame them - coding doesn’t usually require pulling a bogged ute out of a paddock at 2am.

And let’s not forget the paperwork. Between environmental regulations, compliance forms, and the ever-changing rules around water, farmers now spend nearly as much time in the office as they do in the field. It’s hard to grow food when you’re buried under forms.

Still, for all the challenges, the resilience of Australian farmers remains remarkable. They keep going, season after season, with grit, humour, and the occasional curse at the clouds. Because at the end of the day, feeding a nation - and a good chunk of the world - is no small feat. And if anyone’s earned the right to complain about the

CORRIGIN FARMER CRAIG LARKE IS BASED IN THE CENTRAL WHEATBELT

REGION OF WESTERN AUSTRALIA, 229KM EAST-SOUTHEAST OF THE STATE CAPITAL, PERTH.

As a third-generation farmer, Craig and his wife, Peri, raise their four children on a 4100ha property, with an additional 1100ha shared-farm. Their operation is 100% continuous cropping, which is 40% canola, 30% wheat, and 30% barley.

The owner of two new Claas Lexion 8800TTs with Convio 1380 fronts, that are now in their second harvest season, he can often be found speaking to neighbours about the performance he gets out of the European-made machines.

“It’s so easy these days to be a follower and support the largest brand, but it was more important to me to do the research before I was ready to buy my machinery. I wanted to know that I would invest my money in something that would increase my on-farm efficiency and be the best spending outcome for my business.

I also wanted to guarantee that after the sale, I would be backed by a team of professionals who cared about keeping me going, particularly through the peak period.”

Craig’s relationship with the local Northam, Claas Harvest Centre (CHC), started five years ago with the purchase of an Amazone Spreader, well before he was ready to invest money into his new grain harvesters.

When it was time to upgrade his three John Deere combines, Craig’s goal became to reduce losses and improve automation. He took the time to be analytical and pair the mathematical results he sought before purchasing, with the right product and to him, the Claas combine seemed superior to the competitors. Placing a call to Melvyn at the Northam CHC, Craig said, “I’m done with the

single-rotor machines. I want to buy two Lexion combines to reduce our rotor losses and improve residue spreading.”

And he hasn’t looked back!

“We are very happy with how the Lexions perform; their reliability has been exceptional. We knew the Lexion platform had been well proven over the years and continues to develop.”

“We’ve reduced our losses and improved throughput - all through the Lexions ability as a true small grains combine (which is what we grow in WA). Early threshing and separation, twin rotors, an even cut, and a spread residue system are a priority. The Claas Cemos automation has provided us with an efficiency gain with inexperienced staff, when running multiple machines. It gives confidence in the correct combine setup for a learner driver and for loss control, whilst still maintaining capacity.”

Craig is an avid fan of pre-season maintenance being conducted by the Claas Harvest Centre team.

“I prefer Claas Harvest Centre Northam

to come out and check over my machines to prepare them well before harvest and check for any potential future issues. Doing repairs myself Isn’t practical these days. Qualified, experienced mechanics that see these machines every day typically know what fails and when.

“I’m happy to do this ASAP post-harvest taking advantage of early offer promotions and not leaving it to the latter half of the year where dealerships get under time pressure pre-harvest.”

When speaking about the qualified technicians from his local Claas Harvest Centre, he is particularly impressed with their meticulous service and detailed explanations.

“They take a lot of pride in what they do.

And with parts and consumables, I like to keep a really good supply on-hand on my farm. The hour-and-a-quarter drive to the CLAAS Harvest Centre can be time-consuming, but Mel will often drop them off to us if he is coming our way.”

Since purchasing the Lexion machines,

FIVE OUTSTANDING AUSTRALIAN TECHNICIANS HAVE BEEN HONOURED AT THE FIFTH ANNUAL JOHN DEERE TECHNICIAN OF THE YEAR AWARDS, ANNOUNCED AT A GALA DINNER IN BRISBANE.

From a technician who began their career in Romania to another now based in Roma, the winners demonstrated exceptional skill and commitment over two days of rigorous testing at John Deere’s Crestmead headquarters. This year also marked a first, with New Zealand’s Bryce Dickson becoming the only person to win a trophy in three separate years.

The 2025 awards recognised:

- Australian Agriculture & Turf Service Technician of the Year

- New Zealand Agriculture & Turf Service Technician of the Year

- Australian and New Zealand Parts Technician of the Year

- Australian and New Zealand Construction & Forestry Service Technician of the Year

- Australian and New Zealand Service Apprentice of the Year

- Australian and New Zealand Parts Apprentice of the Year

John Deere Australia and New Zealand Managing Director Luke Chandler said the awards highlighted the technicians’ vital role in supporting key industries.

“Congratulations to all our Australian winners, who have shown exceptional technical knowledge, customer focus and ability to solve problems under pressure,” he said. “They are the people who keep our customers moving every day and it’s fantastic to see their talent and hard work acknowledged.”

Luke also commended the finalists. “The finals process is rigorous and designed to test even the most experienced technicians. To reach the finals is a huge achievement and speaks volumes about the capability and

Craig has added a new Claas Xerion 12.590 Tractor and a second-hand Scorpion telehandler to his fleet.

“I’m happy with all of the gear that I have purchased and the support that I have from the team.”

Craig has also been pivotal in spreading his thoughts on light green.

“Several neighbours rang me, there are very few new Lexions in this area, so everyone was inquisitive. Two was a big upgrade,

commitment of each participant.”

He said this year’s technicians represent the next generation of service excellence in agriculture, construction and forestry. “Their professionalism and problem-solving ability ensure farmers, contractors and businesses can achieve more with their equipment,” he said.

He also congratulated Bryce Dickson, from Brandt, Whangarei, New Zealand, for taking home the New Zealand Agriculture and Turf Service Technician of the Year Award for the third time. “Bryce is committed to being the best in his field by consistently challenging himself and continuing to grow his technical expertise in John Deere’s suite of precision ag technology and equipment.”

John Deere Customer Support Business Manager Marko Koelln said this year’s finalists reflected the diversity of people entering and excelling in technical careers.

“Our finalists come from a wide range of backgrounds, with many starting their careers in different industries before finding their calling as technicians,” he said. “What unites them all is a passion for learning, a drive to deliver great service, and a genuine connection to the customers and communities they support. That’s what makes these awards so important. They shine a light on the people who keep our customers running.”

Daniel Popovici, AFGRI Equipment, Albany, WA

Starting his career with a John Deere dealership in Romania more than a decade ago, Daniel Popovici grew up surrounded by machinery, developing a fascination for engines and technology that shaped his future. Now based with AFGRI Equipment in Albany, his enthusiasm and technical excellence earned him the 2025 Australian Agri-

but the aim was simplicity and efficiency. A lot of guys ask me how they are going, as they are built in Europe, and they expect them not to work in our conditions. I tell them they are performing fine, with no overheating or cooling issues.”

Craig has replaced only normal everyday consumables in the two seasons, and with the rising cost-of-living, questions why people are still going with single-rotor corn harvesting machines.

culture & Turf Service Technician of the Year title.

Daniel said it was an honour to be recognised. “This is a huge boost,” he said. “As a technician, we do our jobs and don’t always receive thanks. This event is amazing, and it really feels good to be recognised for those long hours through harvest and those long weekends – it’s seven days a week and it’s absolutely amazing to win.”

His success will also be celebrated back home in Romania, where both his father and brother work at a local John Deere dealership. “My father will be extremely proud as he already was when the finalists were announced,” Daniel said. “He actually went to a job and the customer said, ‘hey I saw Daniel on John Deere’s Facebook’. That day exploded. I got so many messages and calls from people I haven’t spoken to for years.”

Poppy Blohm, AFGRI Equipment, Narrogin, WA

A year after winning Parts Apprentice of the Year, Poppy Blohm has gone one better, taking out the 2025 Australian & New Zealand Parts Technician of the Year award. Her exceptional customer service and technical knowledge have cemented her reputation at AFGRI Equipment in Narrogin.

“I was surprised last time I won, and I’m surprised tonight too,” she said.

Originally from Perth, Poppy’s journey into agriculture began when she attended an agricultural school in Harvey and later worked at a grain handling facility. When an opportunity arose with AFGRI Equipment, she seized it – and has thrived ever since.

Poppy has also won a WA Regional TAFE Trainee of the Year Award, reflecting her dedication and empathy for her customers.

“Farming is these people’s livelihoods,” she said. “When they’re broken down, it affects

“I now do the work of the three machines with only two, with less fuel, less labour, less losses - it just makes sense.

I like to think I’m opening other people’s eyes to the possibility of changing from other brands,” Craig says.

Craig was instrumental in converting another local customer to two Claas Lexion 8800TTs, two Convio 1380s, a Claas Arion 630 C-Matic tractor and a Claas Liner 2900 Trend.

their mood and mentality. Giving them a tiny little part that might get them up and running again means a lot to them – and that’s the biggest reward.”

Outside work, Poppy enjoys time with her animals: horses Magic and Flora, and her miniature Dachshund, Brandy – a passion inspired by her mum, a vet.

Damian Aspinall, RDO Equipment, Roma, QLD

When Damian Aspinall moved to Roma, his cricket debut earned him a light-hearted “duck trifecta” – but his career as a John Deere technician has been a resounding success. The RDO Equipment technician took out the 2025 Australian & New Zealand Construction & Forestry Service Technician of the Year award.

Growing up in Richmond, North West Queensland, Damian was surrounded by machinery through his family’s earthmoving business. His interest deepened when his father bought a grader when he was 12, leading to an apprenticeship with the local council and his first exposure to John Deere equipment.

After relocating to Roma two and a half years ago, Damian said he was thrilled to build new skills and work with an outstanding team. “I’m over the moon,” he said. “This

award is a big thanks to all the team back in Roma. Without them I wouldn’t be here. Everyone in the team relies on everyone and we all learn from each other.”

Mentoring young apprentices is his next goal. “I just want to continue doing what I am doing and helping the apprentices come along and reach their best potential,” he said. “We’ve got three apprentices back at Roma –all good young fellows – and it would be great to sign them all off.”

Henry Barkley, Haeusler’s, Mildura, VIC

For Henry Barkley, time spent helping on his uncle’s Barossa Valley farm and a week of work experience at a John Deere dealership set his path.

After a school-based apprenticeship, Henry joined Haeusler’s in Mildura, Victoria – a decision that led to him being named the 2025 Australian & New Zealand Service Apprentice of the Year.

He credits advice from his uncle for shaping his work ethic. “My uncle always said, ‘don’t give up when times are tough’. Jobs can be challenging, and you get tough customers, but just keep pushing through. There’s always a solution.”

This year has been especially significant for Henry – he not only claimed the award but also bought his first home with partner Jaymee Ireland, the 2022 Agriculture & Turf

Service Technician of the Year. “I’m pretty excited and honoured and feel like I’ve come a long way,” he said. “I’m quite blown away and proud of the journey I’ve taken.”

Olivia Barsley, Hutcheon & Pearce, Cowra, NSW

Perth-born Olivia Barsley grew up far from the paddocks but found her passion for agriculture through showing livestock. After finishing school, she moved to New South Wales to study a Certificate III in Agriculture at Tocal College and gain hands-on experience across cattle stations and mixed farms. Her determination led to a role with Hutcheon & Pearce in Cowra, where her commitment and teamwork have now seen her named the 2025 Australian & New Zealand Parts Apprentice of the Year.

“I really still can’t believe it,” she said. “But it’s really thanks to everyone at work pushing me to get out and have a go.”

Olivia’s colleagues also encouraged her nomination for the NSW Training Awards, where she won Trainee of the Year for the Western Region. She enjoys the fast-paced nature of her work. “The most rewarding part of my day is probably seeing that customer satisfaction,” she said. “Seeing the customer walk through the door and leave with a smile and never knowing what’s going to come in the door.”

IT’S HARD TO BELIEVE IT’S BEEN A DECADE SINCE THE FIRST SEED TERMINATOR ROLLED OUT ACROSS AUSTRALIAN PADDOCKS. IN THE REAR-VIEW MIRROR, THOSE FIRST GENERATION MACHINES MIGHT SEEM PRIMITIVE. BUT EVEN THEN, THEY CARRIED THE SAME CONVICTION: THAT STOPPING WEEDS AT HARVEST WAS NOT JUST POSSIBLE—IT WAS ESSENTIAL. TEN HARVESTS LATER, THAT CONVICTION HAS ONLY DEEPENED.

Much has changed in the last decade. New chemistries have come—and in some cases, already gone. Integrated Weed Management (IWM) and Harvest Weed Seed Control (HWSC) have become mainstream. There are new crop varieties, advances in soil amelioration, precision ag, even the occasional curveball—like a global pandemic. And through it all, one thing has remained clear: weeds adapt, but so do farmers.

The Seed Terminator journey has never been about chasing shiny objects or the next agtech wave. It’s been about digging in—refining, upgrading, and responding to what’s happening in the paddock, not just in the lab.

Even in a globally depressed machinery market, Seed Terminator has doubled down—not on selling, but on building. With reduced spend on sales and marketing, resources have gone into product development, testing, and performance upgrades.

So when farmers are ready to invest again, the value is already waiting for them—more capacity, smoother installs, tougher components, better outcomes.

This season, the full suite of new models is a testament to that focus. From the latest AF10 and CR11 platforms, to John Deere’s S & X series, and now the new S7 range. From Claas Lexions, to upgrades for the New Holland’s 8.90–10.90 range, and of course Case IH’s Flagship series, there aren’t many headers Seed Terminator doesn’t fit.

One of Seed Terminator’s early commitments was building a future-proof platform—and they’ve delivered on that promise. Through backwards-compatible upgrades, retrofit kits, and continuous R&D, they’ve ensured that the earliest

adopters aren’t left behind—they’re leading the way. Because progress shouldn’t leave the early believers behind.

That evolution is also reflected in the heart of the technology: the AeroIMPACT mill, now in its fourth generation. The latest variant lands just in time for this year’s harvest, built on stationery testing, real-world data, and farmer feedback.

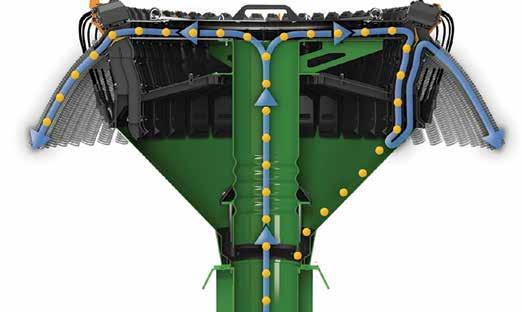

WITH HARVEST SEASON BEGINNING ACROSS AUSTRALIA, NEW HOLLAND IS MARKING THE 50TH YEAR SINCE INTRODUCING THE FIRST COMBINE FEATURING THE BRAND’S TWIN ROTOR THRESHING AND SEPARATION TECHNOLOGY.

New Holland’s twin rotor product line has grown from the launch of the TR70 combine in 1975 to a complete range today, led by the new CR10 and CR11.

CNH Product & Portfolio Manager – Crop Harvesting ANZ, Marc Smith said New Holland has refined the twin rotor concept for five decades.

“The twin rotor technology represents a significant innovation in combine harvester design, showing how a machine can harvest grain more efficiently,” he said.

“The twin rotor system can tackle any type of crop, producing large amounts of centrifugal force creating grain on grain threshing, superior grain quality and high performance in small grains.

“IntelliSense automation can alter the pitch of rotor vanes without completely changing the concave setup, so it can slow crop material down if needed, keeping it in there longer or speeding it up if over threshing the material.

“The twin rotor design continues to be the cornerstone of our product performance, helping farmers maximise their combines efficiency,” Marc said.

Over 70,000 TR and CR Twin Rotor combines have been produced globally to date.

New Holland’s Centre of Harvesting Excellence in Zedelgem, Belgium, has recently undergone significant investment and upgrading for production of the latest CR10 and CR11 models.

While herbicide resistance continues to be a major driver of adoption, there’s a deeper truth underpinning harvest weed seed control: a Seed Terminator acts on all cohorts— not just the ones that emerge early. Where a knockdown might achieve 95% control, it’s often only targeting 40% of the season’s weeds—delivering, in practice, closer to 38% overall control.

“This idea that you only get 50%, so it’s not worth it—that mindset needs smashing,” says Dr Nick Berry. “It’s a globally important shift.”

And the data backs him up. The RIM model, developed by AHRI and CSIRO, has shown that even moderate reductions in

Well-known for its expertise in grassland farming products such as balers and forage harvesting equipment, New Holland, then primarily a US-based manufacturer, entered the combine market in 1964 when it acquired

the seedbank at harvest can dramatically change the weed seed bank trajectory over time—especially when combined with other integrated tactics.

As the old saying goes: one year’s seeding is seven years weeding. At harvest, there’s no ifs. You collect the weed seeds, or you don’t. You crush them, or you spread them.

And for those watching from afar, it seems the word is spreading. A recent Instagram like from Kaleb Cooper of Clarkson’s Farm may not be a scientific endorsement—but for many in ag, it’s a life goal unlocked.

Of course, behind every bit of progress— every chassis, screen, and mill—is a com-

Belgian company Claeys, which had introduced its first self-propelled combine in 1952.

Over the decade that followed the acquisition, New Holland continued to develop the conventional straw-walker combine line it had acquired, but during the 1960s began to investigate new ways of threshing and sepa-

munity of farmers who took a punt, backed the idea, and helped shape it into what it is today. Seed Terminator’s tenth Australian harvest isn’t just a milestone. It’s a quiet tribute to those who believed a better system was possible—and made it happen. Here’s to the legends who made it possible. And for those still considering it—maybe this is your season. What have you got to lose, apart from another year of spreading weed seeds?

Speak to your local Seed Terminator dealer. Get it sorted now in time for harvest. Because the best decisions are the ones you don’t have to second-guess at the end of the season. seedterminator.com.au.

rating grain to boost output, increase cleanliness and reduce losses.

To do this, New Holland engineers studied centrifugal force and its potential for separating grain from plant matter, an innovative concept distinctly different from the drum/ concave and straw-walker traditional method of threshing and separation.

The first development machine, adapted from a 985 straw-walker model from the Claeys factory in Belgium, was trialled in corn in 1968, and wheat the following year.

The trials showed benefits from splitting the incoming crop flow from the elevator/ feeder house into two streams, feeding it into two counter-rotating longitudinal rotors working against longitudinal concaves that consisted of threshing sections followed by separation sections.

The high speed of the rotors meant centrifugal force ejected much of the grain through the concaves, minimising grain damage when compared to conventional drum and concave threshing, and minimising losses when set against straw-walker separation.

By 1969, a totally new combine design with these internal elements was under test, and in 1975 the first production model, the TR70 with a 145hp engine and 5,550-litre/158-bushel grain tank, was launched – the first New Holland combine

built in the USA. In 1979 it was replaced by the upgraded TR75, and joined by a larger companion, the TR85. Over the next two decades the range evolved, with the 25,000th TR combine produced in 1997.

European high-capacity combine development had taken a separate path with the development of the Twin-Flow combines introduced in 1983. These used a conventional drum and concave followed by a large beater and rotary separator and then a lateral Twin Flow rotor that split the crop into two streams to separate the final grains.

However, by the late 1990s New Holland engineers in Europe and North America began work on a totally new Twin Rotor design that would meet the needs of farmers around the world in all types of combinable crop.

Introduced in 2002 and blending key features from the TR and TF machines with new developments and styling, the new 333hp CR960 and 428hp CR980 were initially built in the USA, before production was transferred in 2005 to the Zedelgem plant in Belgium.

The CR960 featured twin rotors of 432mm/17in diameter, with larger 560mm/22in diameter units on the CR980, which had a 12,500-litre/355-bushel grain tank. Operators benefited from a completely new cab design. The range was gradually expanded, and introduced features including IntelliSense combine automation, Dynamic Flow Control remotely adjustable rotor

vanes, Dynamic Feed Roll technology and Opti-Spread Plus residue management.

Development of the Elevation models in 2007 introduced IntelliCruise feed rate control for maximum output, and Opti-Clean cleaning technology to further enhance grain cleanliness. These and other innovations have earned the TR and CR combines multiple industry awards throughout the world.

The next development was the CR7.90, CR8.90, CR9.90 and CR10.90 models, with the latter machine in 2014 taking the Guinness World Record for the most wheat harvested in eight hours, at 797.656 tonnes (29,308 bushels). The record still stands today.

The New Holland CR combine range is now topped by the recently introduced CR11 (775hp, 20,000-litre/567-bushel tank capacity) and CR10 (634hp, 16,000-litre/454-bushel grain tank) models.

Like their forebears, they continue to incorporate proven Twin Rotor technology, but have more capacity than ever, with greater power and tank volume matched by rotors with a diameter of 600mm/24in and a length of 3,600mm/142in, to maximise crop handling capacity, ensure thorough threshing and separation, and protect grain quality.

Global events and initiatives are planned during 2025 to celebrate #TwinRotor50, while owners and operators are encouraged to share their memories of working with these machines at https://wkf.ms/41evGY8.

John Deere’s combine and front-end equipment, precision automation technology, and real-time data keep your operation one step ahead.

Cover more ground, faster, with more throughput, adapting to conditions and delivering cleaner grain with fewer losses.

And with connected dealer support and your operations data, you get more uptime, less stress, and smarter decisions applied automatically.

Ask your local dealer today about how to make yours a smarter harvest.

AUSTRALIAN FARMERS HAVE PUT JOHN DEERE’S NEW JDLINK BOOST TO THE TEST AND IT HAS COME THROUGH WITH FLYING COLOURS IN PROVIDING SATELLITE CONNECTIVITY BETWEEN MACHINES, EVEN IN AREAS WITH NO MOBILE COVERAGE.

Connectivity is widely recognised as one of the biggest challenges facing farmers, but it is now being overcome through the power of satellite technology.

The new JDLink Boost option is the result of John Deere’s partnership with Starlink from the SpaceX network, providing farmers navigating rural connectivity challenges with the opportunity to fully leverage precision agriculture technologies.

John Deere Australia and New Zealand Production and Precision Ag Marketing Manager, Royce Bell, said the technology was put to the test in real-world conditions during seeding, spraying and cotton picking in Queensland and New South Wales, where farmers were excited by the ability to access John Deere Operations Center in real time.

“JDLink Boost is a game-changer for farmers in rural and remote areas – it streamlines connectivity and provides seamless access to critical data and your team at the time you need it most for informed and timely deci-

sion-making,” Royce said.

“Farmers in areas with marginal mobile service coverage on their farms can now connect and take full advantage of John Deere’s precision agriculture applications and all of their benefits.”

John Deere Manager of Production Systems Services, Max Cusack, said the team was excited to expand its initial testing program to all customers across Australia and New Zealand.

“From the testing we have seen the ability to stay connected to allow farmers to make better decisions from the cab thanks to the guest wi-fi,” Max said.

“And more importantly, it allows managers to see how connected machines are operating in real time across their farm and fleet.”

After revealing JDLink Boost on the 9RX 830 at Farmfest in Toowoomba, Qld, in June, it was clear farmers were eager to get it their hands on the technology.

“Farmers all around the country will be able to see JDLink

Boost on the 9RX 830 demo machines this year, but even better, they can put it into their own machines for this harvest and reap the benefits,” Max said.

JDLink Boost adds the next layer to John Deere’s precision technology strategy and will enhance the performance of a range of systems including:

- John Deere Operations Center to assist farmers to plan, monitor and analyse.

- Access to remote monitoring and alerts to identify issues as they occur to ensure equipment is running at optimal levels.

- In-field data sharing in real time for more efficient application of resources and reduced waste.

- See & Spray Select for realtime transmission of agronomic and machine data from sensors and cameras mounted on the sprayer, enabling immediate analysis and response.

- Harvest automation through integration of sensors and systems that control combines to improve harvest efficiency.

- John Deere Connected Support so customers and dealers can respond faster to

By Justin Van Viersen

A GENERATION AGO, A FARMER’S INSTINCTS DROVE MOST OF THEIR AGRONOMIC DECISIONS.

Today, Australian farmers have the benefit of advanced technology, real-time feedback and data, which has transformed the way farmers work and create success.

In fact, on-farm technology use has proliferated so much in the last decade that the majority of farmers today depend heavily on data to operate. We’ve seen this shift most significantly when we look at guidance control; a decade ago, maybe a few farmers on the cutting edge were casually exploring automated guidance. Today, most operations depend on guidance solutions to operate their machinery.

This is one of many examples we see where the use of technology is creating more data output and enabling farmers to make data-driven decisions. To stay competitive and maximise these advantages, farmers need to leverage their data more effectively. Here are three key steps to follow that can support better decision-making and improved results:

There is still a human element to farming when it comes to knowing the ground, understanding requirements for success and the ability for people –not machines – to make informed decisions. But, the scope and capabilities of machines using today’s technology continues to expand, and with it, so too does the amount and variety of data farmers collect. It’s critical to see the metrics and performances of

any issues, with access to solutions like Expert Alerts, Service Advisor Remote, and Remote Display Access.

Royce said the faster and more reliable connectivity would not only assist in responding to issues quickly, but also assist in

your technology – to actually use the data you’re collecting. When you do, you’ll gain an understanding of machine feedback, and ultimately be able to make profitable adjustments when opportunities arise.

For example, farmers can use their data to review a planter pass or a pass on a sprayer and overlay that with a yield map to see a fuller picture of what’s happening. Using data, farmers will have a clearer picture to make profit-generating adjustments.

Once you’re aware of the ways data can positively influence your results, it’s time to set up systems to ensure you’re collecting relevant information, and doing so in a way that will produce usable data. This includes integrating technology throughout your operation with tasks like building boundary lines, organising scripts into a software management system like the newly released PTx FarmENGAGE farm software product, and sending work orders even if you aren’t physically in the tractor. Taking time to build these data integrations during the offseason will give you confidence that you’re using technology effectively and set you up for a more seamless experience when planting season begins.

With better data, farmers can see the fruits of their labour

predicting maintenance recommendations, thereby reducing downtime and ultimately boosting operational efficiency.

“With real-time access to data we can help farmers schedule maintenance activities at convenient times, reduce unex-

come together and understand what was going on while they were in the cab. It can help explain and understand yield performance, for better or worse. Maybe there was an issue with your planter on a specific pass, or you experienced an issue with your sprayer, or your tank ran out of chemical on the last pass before you realized it was low. Having data tied to these operations will help you see anomalies that go against a historic yield map and provide answers to questions you might have about what happened, why you did or didn’t perform as expected.

A generation ago, farmers used yield maps primarily as a historical record of performance. Today, a yield map has much more utility with evidence to explain what’s happening in realtime, and where you can make adjustments and improve yield. You can make decisions faster while you’re planting or applying inputs. And in many cases, today’s technology can enable you to simplify what you’re doing in the cab by leveraging sensors to help inform your decisions and

pected breakdowns and ensure equipment is always operating at its best,” Royce said.

“JDLink Boost enables secure transmission to Connected Support, allowing technicians to remotely diagnose issues with equipment and speeding up

gain confidence. For example, using autonomous solutions, you don’t have to use brainpower to inform when you’re turning sections on or off, or identifying weed pressure. And better still, you don’t just have to believe you’re doing the right thing, as farmers did a generation ago. Today’s farmers using these technologies will know with certainty because the data tells them.

Using technology, the next generation of farmers have an exciting opportunity to change the game as they learn from their machines in real-time. They’ll need to keep up with rapidly generated data and expanding machine capabilities as operations become more automated. But, the payoff is worth it. Farmers will be able to understand what’s happening in their fields in real-time and make improvements immediately, rather than waiting until the next season.

repairs, saving farmers time and money.”

JDLink Boost is available to order now, in stock and ready for harvest this year.

For more information about JDLink Boost, contact your local John Deere dealership.

BETTER RETURNS AND AN OPPORTUNITY TO SUPPLY MORE SUSTAINABLE, LOCALLY GROWN RICE TO THE HOME MARKET ARE BEHIND A NEW VENTURE FOR RIVERINA RICE GROWER GEORGE STEVENSON.

“A lot of farmers really don’t appreciate how things are changing. Customers are looking for responsible lower emission products,” he says.

George is one of around 2,000 rice growers in Australia. Most of these rice producing farms are located in the Riverina region of New South Wales, and they produce more than 95% of the 600 -700,000 tonnes of rice grown in Australia each year.

Up until this year, the rice produced in the state was processed and sold under the SunRice brand, which held exclusive rights to selling out of the state both domestically and exporting.

While this saw growers dealing with a reliable and successful brand, it didn’t give them much leverage as far as payments for their crops went.

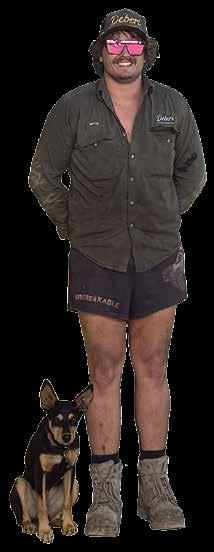

GEORGE, KARINA AND TWO-YEAR-OLD OLIVERFARMING WITH A LIGHTER TOUCH IN JERILDERIE, NSW.

With increasing costs, some growers were seriously thinking of leaving the industry.

“We felt as though there were diminishing returns, with the price at which we were growing rice, dictated by SunRice,” says George.

A change in legislation this year removed the monopoly seeing NSW growers able to pursue other options.

GEORGE IS AMONG A GROUP OF GROWERS LOOKING TO TAKE ADVANTAGE OF CHANGES TO RICE CROPPING SYSTEMS WHICH REDUCE METHANE EMISSIONS.

With a Bachelor of Ag Science from Melbourne’s La Trobe University under his belt, along with a Bachelor of Business in International Trade and Finance, George was in a better position than most to see where Australian rice production sat in the broader scheme of things.

DRILL SEEDING AND PERIODIC FLUSHING OF THE PADDOCKS UNTIL THE CROP IS ESTABLISHED REDUCES THE AMOUNT OF TIME THE RICE CROP IS PRODUCING METHANE.

SunRice is very export orientated, George says, and while they do supply the domestic market, they don’t sell all of the different varieties that growers produce.

“We grow long grain which is Jasmine rice, a myriad of short grain and medium grain rice. The majority of those varieties won’t retail in Australia.”

This saw most of the rice on local supermarket shelves

Rice as a crop has a particular problem with high methane emissions when grown traditionally.

With advances in cropping systems in Australia, reducing these emissions, George and a small group of local farmers felt there was a good opportunity to take advantage of the gap in the domestic market for their lower emissions rice.

“If you want access to a high-value market, you need to meet a certain minimum standard of production, but also in emerging premium markets that once upon a time anybody could play in. Now, we’re being held accountable and we’re seeing that in the pricing of our products.”

Grown in flooded fields or paddies, rice production accounts for nearly half of all the green-

“We wanted to set up a rice brand and processing facility that championed an environmentally and socially responsible system, where we’re growing rice in industry leading conditions using considerably less water than anyone else around the world,” says George.

Having a processing plant locally in the local Jerilderie area, with storage and drying facilities, would keep transport miles to a minimum.

“That way we could get rice onto people’s plates having travelled significantly less food miles, and with a lower carbon footprint.”

Even though they were cautious, research and setup costs were still considerably more than they anticipated, with the plant costing around $10 million, and funded mostly by themselves.

Water for irrigation is likely to become more of an issue as the climate warms making water security of special concern for

“We’re all competing for the same resource, so water is

FABA BEAN IS ONE OF THE WINTER CROPS GROWN ON THE FARM ALONG WITH WHEAT, BARLEY, CANOLA, AND VETCH.

obviously our largest environmental and production risk. ”

This made water a big consideration as new growers looked to come on board with the venture.

“We wanted to make sure that we had some growers across different water sources to spread that risk.”

This saw growers in the Murrumbidgee Irrigation area, the Murray Irrigation area along with some growers with groundwater.

When the new legislation came into effect, the co-operative of around 30 like-minded growers were really able to push ahead.

George is now a director of the business with the newly minted Nice Rice brand name. He is also a non-executive director of Honestly Riverina, the parent company.

And things have moved quickly for the brand. They have seen

early success supplying the major supermarkets in Australia, touting the environmental credentials of their products.

“Price -wise we’re certainly in the upper price bracket with other branded products. We’re marginally dearer, but we’ve got some really good sustainable packaging and a good story to tell.”

Like many in the Riverina area, George’s family farm had been a soldier’s settlement block. Developed by George’s great-grandfather, it was originally a livestock grazing farm.

The introduction of irrigation had seen a move into cropping with the 1000 acre farm in

SECURITY IS ONE THE TOP CONSIDERATIONS FOR RICE GROWERS WITH ON-GOING BREEDING HELPING TO PRODUCE VARIETIES THAT NEED LESS WATER BUT THAT ARE ALSO MORE TOLERANT OF A COOLER CLIMATE.

David’s day expanding to 4000 acres today with up to 500 acres of rice grown annually.

As part of the Murray Irrigation scheme, their water source ultimately comes from the Murray River with the catchment in the Upper Murray alpine regions of Victoria and NSW.

Along with the summer rice crop, George and father Lockie also grow a series of winter cereals - wheat, barley, canola, faba bean, and vetch, with about half these crops irrigated.

When they have dry seasons and less water is allocated, they move out of summer crops that require full irrigation, and the cereal program becomes either fully dry land or supplemented with irrigation.

Flooding fields for rice isn’t cheap and is one of the biggest costs with production.

The problem with methane arises when the paddock is flooded and water sits there for months.

Starved of oxygen the soil becomes anaerobic. This sees soil bacteria then start to break down any dead soil organisms, dead plant material, fertilizers,

and outputs from the roots converting it into methane. This is absorbed by the roots, carried up the plant and released into the air through the leaves.

Reducing the amount of water used in production has not only reduced water costs but also considerably reduced the amount of methane coming off the crop, seeing rice crops now producing more than 40% less methane than traditional growing methods.

In the past, the paddocks were flooded in October and stayed submerged for around five months before being drained.

That all changed about 12 years ago when drilling the rice rather than aerial broadcasting started.

“By drill sowing now, the seed is under the soil, and the paddocks aren’t fully ponded now until late November or early December - once the crop is well established.

“We’ll plant the crop in early October and then flush it three to four times to get it established. We can then apply fertilizer and then go to a full ponding system for the remainder of the projectabout four months.”

The water, drained in midMarch a couple of weeks before harvest, also now goes into on-farm storage, before being reused to help irrigate wheat and faba bean.

Native bird populations and ducks have also been big winners with the new system.

Ducks had been a considerable nuisance when the rice was broadcast over flooded paddocks. They would hoover up the rice sitting on the soil underwater.

Along with some shooting, various lights and gas guns were used every six hours or so to

scare them off. This had been noisy and cumbersome but was a practice his father and grandfather had been doing for years to help establish the crop, George reckons.

But it wasn’t just the ducks that were being frightened off.

“This was also scaring away native species as well, including endangered [Australasian] bitterns and a lot of other native birds that didn’t necessarily do any harm or any damage to the crop. While they were certainly never shot, they were less likely to make our patch of earth their home.”

So, the increase of native birdlife about the farm has been more than welcomed.

Other changes have come from breeding rice varieties that suit the Riverina climate better.

“The rice industry’s got a really strong breeding program led by Rice Breeding Australia. We can now grow grains and varieties that potentially we never would have been able to before.

“This includes varieties that were more suited to tropical regions closer to the equatorincluding Jasmine rice, which has always been grown in a tropical region and originates from Thailand, Vietnam, Cambodia,” he says.

The rice crop fits in with other cropping around the farm, with no extra equipment needed.

Once the soil surface has dried out after flushing, it is firm enough they can use their own gear for spraying and fertilising –further reducing their reliance on aerial contractors.

“Come harvest time, we use a normal combine harvester with just some slight variations. But for the most part they’re often four-wheel drives and a bit bigger tyres. We don’t need tracked tractors.”

Reducing spraying costs and being more mindful of the effects of chemicals in the environment has seen George using integrated pest management more.

Other growers in the co-op are also encouraged to use it.

“We expect our growers to grow rice within certain parameters. Some chemicals they’re unable to use because of potential issues environmentally. We like to use beneficial insects instead of sprays where possible

BEING ABLE TO USE THE SAME FARM MACHINERY FOR THE VARIOUS CROPS CUTS COSTS AND REDUCES RELIANCE ON AERIAL CONTRACTORS.

- trying to let the ecosystem balance itself.

“We used to just spray as a precautionary measure, but now there’s been a lot of work done on where the economic thresholds are, for when we should spray.”

“We don’t want to be too restrictive on our growers too, as sometimes you’ve just got to do things unfortunately, but, as far as our farm goes, it’s in our best interest to actually do the best thing by the environment.

“For our farm, we apply what we have to, but work on a combination of crop rotations, some cover crops, growing legumes and pulses in the system to have an overall healthier soil and that creates good, healthy crops that often compete well with weeds, and mitigate the need for spraying.”

Sticking to a fairly tight, well organised schedule is important in the two Stevenson households on-farm since Oliver came on the scene two years ago.

Mum, Karina, is a paramedic with Ambulance Victoria in Cobram - just across the state line and works 30 hours a week in 12-hour shifts.

This also sees Lockie and wife Kaye part of the family network as they all manage daycare dropoffs and pickups, with Oliver also spending time riding around in tractors.

Karina and Kaye are also involved in the farm, along with a full-time staff member.

While they do less of the tractor work, they act as support staff for George and Lockie, picking them up and dropping them off when needed, along with moving equipment, collecting fuel trailers and the like.

“When we’re flat out, they’re keeping us fed and clean and in the best shape to be able to work some pretty long hours. We certainly wouldn’t be able to get the output from the farm that we do now without their support,” George reckons.

Like many generational farmers, George has a deep emotional attachment to the farm his great-grandparents started, and the wildlife and biodiversity that shares the land with them.

Certain places on the farm have a lot of sentiment attached to them - the place where he and Karina got married, another spot where his Aunt got married, a tree that was one of his grandmother’s favourites.

Then there’s the small, 100 acre, red gum wetland that they’re immensely proud of because of the amount of biodi-

versity it holds – “a full ecological system going on in there.”

At the end of the day, one of George’s pleasures is to grab a stubby and watch the sunset with the family on a paddock barbecue, enjoying the water birds and kangaroos.

“That’s part of why we do what we do - because we get to live here.”

“I think most farmers, if they could do something that had less of an impact on the environment and achieve the same outcome, they’re happy to adopt,” he reckons.

“Where we need to make tradeoffs which potentially reduce production, as an agricultural industry as a whole we’re happy to do that - provided the consumer is prepared to pay a premium for it.

“That’s the challenge of food production globally - how do we feed the population and maintain a really healthy environment. State government policy doesn’t do a great job of that, but if the consumers start acting with their wallets, we can see more, broad scale change.

“It is coming, and we’ve got to embrace it.”

IN THE ROLLING COUNTRY OF THE SOUTH WAIKATO, WHERE THE LAND STRETCHES GREEN AND STEADY BETWEEN TOKOROA AND PUTARURU, A FAMILY BUSINESS HAS QUIETLY GROWN INTO ONE OF THE REGION’S MOST RELIABLE CONTRACTING OUTFITS.

Putt Contracting, founded and run by Chris Putt began in the most modest of ways nearly two decades ago with nothing more than a single truck and a willingness to take on whatever jobs came his way.

Today it has become a trusted operation built on hard work, steady investment and the strength of family ties.

business was as much about spotting a gap as it was about a determination to make something work. There was room for another contractor in the district, and Chris stepped into that space.

PUTT CONTRACTING’S FLEET OF FENDT TRACTORS PROVIDE THE BACKBONE OF THE BUSINESS WITH RELIABILITY, COMFORT AND POWER.

Growth came steadily but without fuss, and the business settled into the rhythms of silage, maize, cartage and the variety of jobs that keep contractors busy through the year.

Today, Putt Contracting runs a

fleet of nine tractors, dominated by Fendt – a brand Chris is loyal to. “Always been a lover of Fendt tractors,” he says with a grin. Among the line-up are three Fendt 930s and a 936, along

across ditch the

PROFILED IN NZ’S RURAL CONTRACTOR & LARGE SCALE FARMER OCTOBER / NOVEMBER 2025, WE VISIT PUTT CONTRACTING IN SOUTH WAIKATO, NEW ZEALAND.

Chris remembers those early days with a touch of understatement. “It started almost thirty years ago with just a truck,” he says. “Then I bought a tractor and a spreader to do a lot of chicken manure back in those days. I figured if I had a tractor, I might as well use it for more than just spreading. So I bought a loader wagon and it just grew from there. One loader wagon turned into another, then I needed someone to help me and it just blossomed.”

The decision to build out the

QUIETLY GETTING THE JOB DONE SEASON AFTER SEASON ACROSS THE SOUTH WAIKATO.

with 800 and 700 Series machines that cover the breadth of jobs across the business. For Chris, the 900 Series models are a particular favourite.

“The nine series are my favourite. They’re just a nice tractor to drive. They don’t seem to break that much, and they do the hours without giving trouble. A good tractor, no more problems than any other but a lot more comfort.”

The Fendt 936 Vario, part of the company’s backbone, is renowned for its combination of power and precision.

With up to 360hp on tap, it offers contractors like Chris a machine capable of handling heavy draft work, high-speed transport and the demands of running modern implements efficiently.

Fendt’s continuously variable transmission, the hallmark of the Vario system, allows seamless power delivery whether on the road or in the field.

For contractors working long hours in varied conditions, the 936 is as much about comfort as it is about productivity. With its spacious cab, intuitive controls and fuel efficiency it makes a long day’s work that much easier. It’s no surprise Chris rates it so highly.

While tractors form the core of the fleet, the real moneymakers come in the form of forage harvesting.

Putt Contracting runs a Claas Jaguar 970 self-propelled forage

STRONG CLIENT RELATIONSHIPS ARE THE FOUNDATION OF LONGTERM SUCCESS. FROM SILAGE TO CARTAGE, NO JOB IS TOO BIG OR TOO SMALL.

Claas,” he says. “It’s about keeping the work moving, getting through faster and staying reliable.”

In an industry where weather windows are tight and downtime is costly, having a chopper that can deliver on both speed and consistency is critical.

harvester, a machine that has set the standard globally for its class.

Claas has long been synonymous with precision, throughput and chop quality and the 970 continues that tradition.

Powered by 790hp and equipped with the Claas Shredlage crop processor, the Jaguar

970 ensures silage of consistently high quality. Contractors benefit not only from its ability to cover hectares quickly but also from its reliability under pressure.

For Chris, choosing Claas was about investing in performance he could trust.

“We’ve just bought a 970

The Jaguar’s advanced crop flow system coupled with intuitive operation from the cab, means Chris and his team can focus on the work rather than the machine.

The mowing side of the business is no less impressive. Putt Contracting runs a line-up of Pöttinger gear designed to get through large areas efficiently and deliver clean, even cuts.

The flagship is a Novacat V10000 Crossflow triple

BY BRINGING IN YOUNG WORKERS STRAIGHT FROM SCHOOL, THE BUSINESS HELPS TRAIN THE CONTRACTORS OF TOMORROW.

mower, which allows grass to be merged into swaths straight behind the mower cutting down on extra passes.

Two Novacat A9 triple mowers, one fitted with conditioners, add further flexibility depending on crop and conditions.

At the front end, three Alpha Motion 301 frontmounted mowers give Chris and his team the ability to set up powerful combinations that cover wide working widths while maintaining a smooth, groundhugging cut.

For clients, that translates to faster mowing, less wheel traffic and tidy swaths ready for the chopper or wagons.

TEAMS KEEP WORK MOVING SMOOTHLY, NO MATTER THE CONDITIONS.

- which Chris prefers for their ability to handle off-road conditions.

“Mercedes because they get off road real good,” he says simply.

The trucks haul silage, palm kernel, metal and all manner of loads across the district.

Having his own trucks gives Chris more control over logistics and keeps the work flowing smoothly from paddock to pit.

The real backbone of Putt Contracting though, lies not just in the machines but in the people who keep them moving. Chris is joined by his three sons – Corey, Keegan and Jakob – each of whom has carved out a place in the business.

Corey, the 2nd eldest, has been with the business for twelve years, while Keegan, the

eldest, came across after an apprenticeship in engineering 10 years ago.

Jakob, the youngest, joined four years ago and quickly established himself as a capable operator and engineer in his own right. “It makes my life a lot easier,” Chris says. “They know what they’ve got to do. They just get on and do it.”

Alongside the family are a team of long-serving employees, bolstered each season by extra hands to cope with peak demand.

The mix of family and loyal staff has created a steady culture where everyone knows their role and the work gets done with a minimum of fuss.

On the forage wagon side, Chris has built up a fleet that gives him options across job sizes and conditions.

Loader wagons, including Torro and Jumbo models, form an important part of the silage operation.

Known for their capacity and robust build, these wagons ensure grass is shifted from paddock to pit quickly and efficiently. In a district where weather can turn fast, the ability to move bulk forage without delay is a big part of keeping customers happy.

The fleet is supported by a stable of trucks, mostly Mercedes

GEAR, STEADY HANDS – INVESTING IN NEW MACHINERY LIKE THE CLAAS 970 ENSURES THE BUSINESS STAYS EFFICIENT WHILE AVOIDING COSTLY DOWNTIME.

Engineering skills within the team mean much of the day-today maintenance and fabrication is done in-house.

Keegan’s background as an engineer, along with Jakob’s knack for mechanics ensures that breakdowns are often shortlived and custom jobs like trailer decks and cages can be built to suit the business’s needs.

That said, modern tractors, choppers and mowers come with computers and diagnostics that require dealer support and Chris is pragmatic about this. “For the tractors we always use Piako tractors in Morrinsville, which we find pretty good. Contractors today, you can’t do everything yourself.

Claas Harvest Centre do the chopper work and we just look after the easy stuff.” It’s a balance of in-house know-how and trusted dealer relationships that keeps the wheels turning. The scale of the business means that during peak season, nine to ten people are working full tilt.

Outside of family members,

MANY OF THE SAME CLIENTS HAVE WORKED WITH CHRIS FOR DECADES, A TESTAMENT TO TRUST AND CONSISTENCY.

names like Cody Cherry and Blake Littin join the roster along with younger recruits brought in straight from school. It’s a mix of experience and fresh energy that keeps the team humming along.

For Chris, bringing in young workers is as much about moulding the next generation as it is about filling a gap in the roster.

The work itself is typical of a Waikato contractor but no less demanding.

Maize silage, grass silage, cartage and general contracting jobs keep the team busy through spring and summer with the shoulder seasons filled with palm kernel cartage and other haulage.

The South Waikato provides enough work within a relatively tight radius that Chris doesn’t need to send machines far afield.

“Most of our work is Tokoroa

leaf counts MERGENTO VT

Clean forage without disintegration losses even with leafy crops such as clover or alfalfa

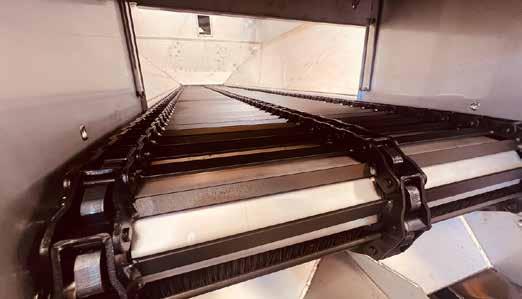

High pick-up performance and perfect crop transfer to the conveyor belt thanks to the six rows of controlled pick-up tines

Perfect crop flow along the pick-up thanks to the adjustable, damped crop swath roller with baffle curtain

and Putaruru, down Arapuni way. It’s quite close. I don’t see the point in travelling too far - that’s wasted time. If you’ve got enough work where you are, why would you?”

Farming clients in the district know Putt Contracting as a steady presence, someone who has turned up season after season. “I’ve worked for the same people for years and years,” Chris says.

That loyalty runs both ways, and it’s part of what has under-

pinned the business’s growth.

In a district where farming is still the bedrock of the local economy, contractors like Chris are integral to keeping things moving.

When asked what he enjoys most about the job, Chris is characteristically blunt. “Probably the smell of diesel to be fair,” he says with a laugh. “And as long as I’m outdoors doing something and contributing.”

That pragmatism sums up much of his approach – work

hard, keep the machines running and enjoy the satisfaction of a job done right.

Outside of work, fishing is his chosen escape with a particular fondness for chasing kingfish off the Waikato coast.

The business has weathered the ups and downs of contracting life.

There was a significant spendup pre-Covid, when new tractors and implements were added to the fleet to improve reliability and get through work faster. Another round of investment is happening now, with the

CHRIS PUTT’S LOYALTY TO FENDT TRACTORS REFLECTS YEARS OF RELIABLE SERVICE ACROSS SILAGE, CARTAGE AND CULTIVATION WORK.

new Claas 970 Jaguar chopper and Pöttinger mower line-up bolstering the operation.

The strategy is simple - keep the gear modern enough to stay efficient, but not so new that it creates unnecessary overheads.

Looking ahead, Chris sees the seasons as harder to predict.

Springs that once arrived reliably are now more variable, grass growth is patchy and frosts hang around longer.

“The seasons are all changing,” he says. “It seems like it’s reverting back to the old days, where it’s cold and frosty. You just don’t know until you’re

WITH NINE TRACTORS IN OPERATION, THE FLEET PROVIDES THE HORSEPOWER NEEDED TO KEEP SOUTH WAIKATO FARMS MOVING.

MERCEDES MUSCLE - THE COMPANY’S TRUCKS ARE RELIED UPON FOR CARTING SILAGE, PALM KERNEL AND METAL, CHOSEN FOR THEIR ABILITY TO HANDLE ALL CONDITIONS.

there.” It’s a reminder that contractors, like farmers, are at the mercy of the weather and success depends on being ready to move when the opportunity arises.

Beyond the nuts and bolts of machines and weather, Chris is

clear about the broader picture. Farming, he says, is vital to New Zealand. “It’s very important. They’re the only ones making money really for the country at the moment. Forestry is average, it’s up and down but dairy is always pretty steady.”

In his eyes, agriculture is still the backbone of the economy and contractors are an essential part of that chain.

Putt Contracting, is in many ways, a snapshot of the best of New Zealand’s rural contracting sector – a family business that has grown steadily, invested

wisely and built strong local relationships. It has done so without fanfare, relying instead on the strength of its work and the loyalty of its people.

Whether it’s a Fendt 936 pulling hard in the paddock, a Claas Jaguar 970 swallowing rows of maize, or a Pöttinger mower combination laying down clean swaths ready for the pit, the machines are only part of the story.

The rest comes from the people who keep them moving and the communities they serve.

For Chris, the formula is sim-

PUTT CONTRACTING IS PART OF THE BACKBONE OF THE SOUTH WAIKATO, SUPPORTING FARMERS WHO KEEP THE LOCAL ECONOMY STRONG.

ple and enduring - keep it local, keep it reliable and keep it in the family.

And in the South Waikato, that’s been more than enough to turn one man’s truck into a thriving contracting business that shows no signs of slowing down.

For over 40 years, Roesners have manufactured the all purpose Marshall Multispread,designed for Australian Agriculture.

The Marshall Multispread delivers proven performance and versatility with over 11000 units in the field across Australia, backed up by superior customer service and support.

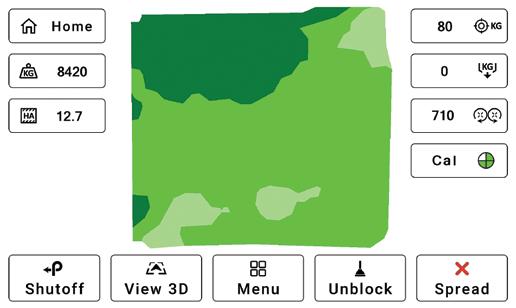

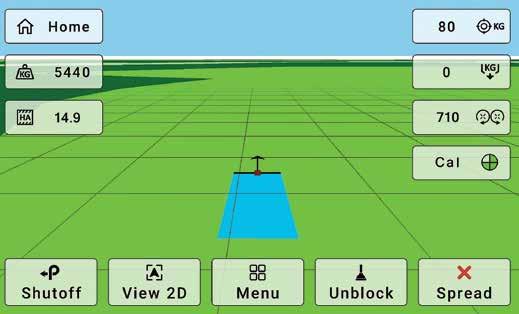

Multispread machines are available with advanced features such as the D3 spinner system for accurate spread patterns up to 36m and the latest version 3 i4M spreader controller, launched in June 2025, including a new auto-calibration feature.

To discuss your fertiliser spreading requirements, call Roesners today to speak directly to our dedicated sales, spare parts and support team.

WITH TODAY’S HIGH FERTILISER COSTS AND GROWING PUBLIC CONCERN PUSHING US TO PROTECT THE ENVIRONMENT, CONTRACTORS AND FARMERS NEED SPREADERS THAT ARE SOPHISTICATED, ACCURATE AND DURABLE. IN THIS FEATURE LEADING MANUFACTURERS TELL US ABOUT THEIR LATEST PRODUCTS.

BERGMANN XPERT SPREADER

Bergmann has a proven track record in putting innovative ideas into practice and driving vital developments. Even under challenging conditions, Bergmann manure and universal spreaders always work reliably with proven quality and functionality, along with outstanding spreading precision. Last year Bergmann celebrated “70 years of spreaders”.

Bergmann will be presenting its new generation of spreaders of the Bergmann Xpert series at Agritechnica 2025. On display will be the Bergmann Xpert 6.34, the latest-generation, top of the range three-axle model, and the Bergmann Xpert 4.22, the largest tandem model with mechanical chassis.

At Agritechnica 2023, Bergmann already showed a demonstrator from the new Xpert series of spreaders to witness initial reactions of visitors at the stand.

General development objectives were defined at the beginning of the new development phase. These are now reflected in the models of the new Xpert series:

- Increase in performance

- Optimisation of work quality

- Increased resistance to wear and corrosion

- Reduction of cleaning workload, avoidance of dirt deposits

- Simplification of maintenance and servicing

- Increased safety and convenience

- EU type approval in category R (transport vehicles – road transport possible)

- Modern, uncluttered design

- Modularity across the entire series

Explained below are a few examples of how these goals were implemented.

Among other factors, this objective was achieved through higher load volumes, increasing the milling unit passage to 1.55 m, 1.70 m and 1.90 m for higher throughput rates, along with practical cargo space lengths and load heights for faster and more uniform loading.

The patented V-Spread wide spreading unit with a disk diameter of 1,100 mm for larger working widths and fewer tram lines is also available as an option for all Xpert models.

The material feed point onto the spreader disks has been further optimised for an even more uniform spreading pattern and optimum lateral distribution.

Depending on the model, the diameter of the spreader disks of the standard T-Spread disk spreader unit has been retained (in models with 1,000 mm diam-

eter) or increased to 1,100 mm for even better spreading accuracy.

The entire body features high quality cathodic dip and powder surface coating. The floor of the bin is constructed of even more wear-resistant steel than the current models.

Seen from the front, the first thing you notice is the narrow drawbar of all models, which offers little room for dirt deposits and also significantly increases the manoeuvrability of the tractor-trailer combination.

The body of all models is completely self-supporting, does not require an additional subframe and is open at the bottom. The Xpert models are easily accessible from below and can be effortlessly cleaned after use. This design was until now not available on the market especially for spreaders with a gross vehicle weight of 18 t or more.

The mudguards are steeper

than on current models. They are also cathodic dip and powder coated which gives them a highly smooth finish. The mudguards thus reliably prevent larger deposits of material.

The contours of the sidewalls are also designed to avoid surfaces attracting material deposits.

The narrow LED lighting has been positioned above the spreader unit. This means falling material does not remain on or in front of the lamps. A further plus: this also increases road safety.

The round underride guard also offers little contact surface for material deposits.

To simplify maintenance, lubrication points have been sensibly grouped together and are accessible from just a few locations.

All Xpert models are equipped with a low-maintenance and smooth-running cardan drive as standard.

The hydraulic lines and cables are laid in a standardised, tidy and easily accessible way.

On all models, the control block is mounted on the right at the front in driving direction. Reliable LED lighting is fitted as standard for the Xpert series.

Increased safety and convenience

A completely new feature for spreaders is the ISOBUS-TIM option: trailer controls tractor. There are three different applications. Some of these applications can also be combined:

- TIM – SpeedControl: adjustment of the spread rate by varying the tractor driving speeds with a constant scraper floor speed (= constant spreading pattern)

- TIM – PTOControl: switching the PTO shaft on and off coupled with the scraper floor; PTO speed control to match the working width; automatic deactivation of the PTO if the spreader disks or beaters are blocked

- TIM – HydraulicControl: operation without control block via the control units of the tractor with an ISOBUS terminal

Another feature in terms of convenience is the electronic forced steering without a drawbar angle sensor. All you have to do is “Hitch and go”.

Adapting cylinders or steering rods (as is the case with conventional hydraulic or electronic forced steering systems) is not necessary because no additional elements are installed. This also increases the manoeuvrability of the tractor-trailer combination.

A removable storage box can be selected as an option, which is located at the front on the left in driving direction. This box can be used to store wear parts, tools etc. to secure these parts from lying loose in the tractor cabin.

The access ladder has also been redesigned to be more ergonomic. The ladder is set at an angle when folded out for use. This means the user climbs up like a ladder leaning on a wall or railing and not vertically, as is usually the case. This makes climbing up safer.

All Xpert models are designed to have a significantly higher tongue load than the current models. This provides the driver with more driving comfort and the transmission of tractive force is even better.

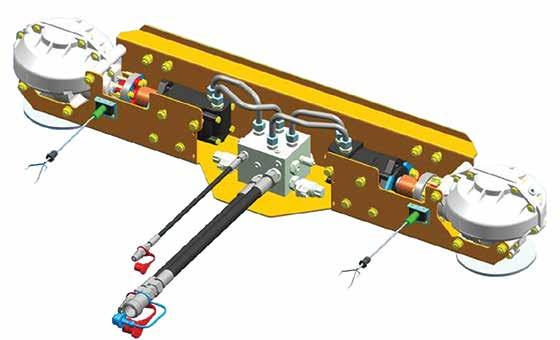

Liquid Systems (SA) has been at the forefront of liquid application technology for Australian farmers for over two decades. In early 2025, the company launched its latest Liquid Ready Kits for John Deere’s C-Series Air Carts.

In July 2025, Liquid Systems unveiled a bolt-on LQS P600 4000 L Liquid Bridge for John Deere’s P600 Precision Air Hoe Drills.

When paired with a John Deere C-Series Liquid Cart, the new Liquid Bridge is the perfect match—boosting liquid capacity of the C650 from 4800 L to 8800 L, and the C500/550 from 3720 L to 7720 L. That means longer

runs, fewer refills, and uncompromised precision.

Farmers can choose from two options:

- Tank-only Bridge – increases the liquid capacity of C-Series Air Carts.

- Tank Bridge + LQS120 Module – transforms a non-liquid cart into a liquid-ready bar configuration, with the added ability to apply dual, separate liquids alongside a liquid cart.

Designed to match the current hub capacity of the P600 Drill, the 4000 L Liquid Bridge mounts directly to the P660, P670, P680, and P690 chassis, integrating seamlessly with John Deere’s dealer-fit C-Series carts.

Looking ahead, larger hub capacities from John Deere will open the door to a 6000 L solution—an ideal fit for Western

Australia’s high-demand cropping regions.

With a reputation for build quality, reliability, and exceptional support, Liquid Systems continues to deliver turnkey equipment that helps Australian farmers work smarter, faster, and more efficiently.

The benefits of in-furrow liquid application are clear: targeted

nutrient placement, improved germination, and maximised input efficiency. With Liquid Systems’ precision technology, nutrients are placed accurately at seeding—optimising efficiency, protecting soil health, and boosting yield potential. Call (08) 8357 4437 or visit www.liquidsystems.com.au to find your nearest dealer.

EU type approval in category R

All Xpert models are certified as standard with full EU type approval in category R in accordance with the official regulation. The CoC (Certificate of Conformity) documents are also supplied. Especially when reselling within the EU, type approval is an advantage, as it removes the need for individual national approvals.

All these new features have been packaged in a standardised, modern and uncluttered design, thus clearly setting Bergmann apart from the competition.

The result of the development

work is the new Bergmann Xpert series made up of nine models and six sizes with a gross weight of between 12,000 and 34,000 kg.

The most compact model is the single-axle Bergmann Xpert 1.13. This is followed by seven tandem models with a gross weight of 13,000 to 24,000 kg. The Bergmann Xpert 6.34 with tridem chassis and 34,000 kg gross weight is the largest spreader in the new series.

We have also removed the distinction between manure spreaders and universal spreaders. Customers can choose between the standard T-Spread

disk spreader unit and the optional V-Spread wide spreading unit for working widths of up to 36 m (depending on the material) and the 2-Spread hybrid spreader unit with two vertical beaters for precise distribution at maximum throughput.

The Xpert spreaders have also been further developed in terms of tyres. The single-axle vehicle is available with a maximum tyre size of 800/45 R30.5. The XPERT 1.14, 2.16 and 3.18 models can be fitted with a maximum tyre size of 710/50 R26.5.

Tyre sizes up to 800/45 R30.5 are available for the Xpert 3.22,

4.22 and 4.24. The two top models Xpert 5.24 and 6.34 can even be ordered with the maximum size 750/60 R30.5.

The first demonstrator went into operation in the spring of 2023. Since then, further demonstrators and prototypes of various sizes have been intensively put to the test in the field by end customers in Germany and abroad.

The first vehicles from the Bergmann Xpert 4.22, 4.24 and 5.24 zero series were shipped to end customers in summer 2025. The zero series of all other sizes are to be rolled out by summer 2026.

When you see the majority of truck spreading contractors using a single brand you know they must be doing something right. Southern Spreaders in Ballarat are the brand trusted by contractors and high-end users to supply a product that performs every day, in all conditions and all materials.

From their Ballarat headquarters, Southern Spreaders design and build commercial

spreaders that are ready to hit the paddock the moment they leave the factory.

Every spreader body is built entirely in-house — engineered, fabricated, and fitted with precision to deliver a complete turnkey solution.

Whether you bring your own truck or want Southern Spreaders to supply the cab-chassis, they’ll handle everything from setup to finish. Customers can specify brand, load capacity, wheel and tyre options, tow bars, GPS and autosteer systems, section control, load cells, onboard

inflation, toolboxes, and more — creating a seamless, high-performance unit built exactly to spec.

“Every operator has different needs and Southern Spreaders understand that no two spreading businesses are alike. Southern Spreaders engineering team customises each build to suit terrain, regional conditions, preferred materials, and existing fleet configurations.” said Southern Spreaders General Manager Jarrod Keyte.

“From single-unit contractors to large-scale fleets, every truck represents decade of spreader

experience combined with the latest technology and design features to maximise accuracy and efficiency for the end users” said Jarrod.

Jarrod says the proof is in the paddock: “We’ve seen contractors start with one truck and grow to fleets of more than a dozen — all running Southern Spreaders gear. Some of our first units, built over 20 years ago, are still in daily operation. The only reason for replacement is usually new technology or truck age.

Jarrod added “We back every spreader with parts supply and

THE MULTI-PURPOSE

Precision application of inoculant solution for high-quality silage Liquido F is the newly developed, versatile front silage additive tank from Pottinger. It can be used easily and flexibly in combination with a wide variety of different brands of loader wagons and balers. The nozzle header is positioned between the pick-up and the rotor, where it applies the lactic acid bacteria solution directly and homogeneously to the flow of forage to produce high-quality silage. The application rate is matched to the flow of forage and the farms requirements. The Liquido F can also be used as a front bumper and as front ballast. Maximum utilisation of this versatile and cost-effective unit is

a given because it covers such a wide range of different applications.