The development of the OMEGA Marine was user-oriented, as was evidenced by a feature that has become a must-have on modern diving watches: the folding clasp. This innovative system included a length-adjustment device designed to allow the strap (made of seal leather) to be worn over a wetsuit, mak-

ing this buckle the very first extension mechanism specifically designed for diving! The Marine was also available in 18K yellow gold, paired with a bracelet in the same metal. It was moreover distributed by Tiffany & Co and Cartier New York, which placed their names on the dial.

The strap fastening was a folding clasp with an adjustment system ensuring a precise fit over a diving suit, the very first extension device specifically designed for diving

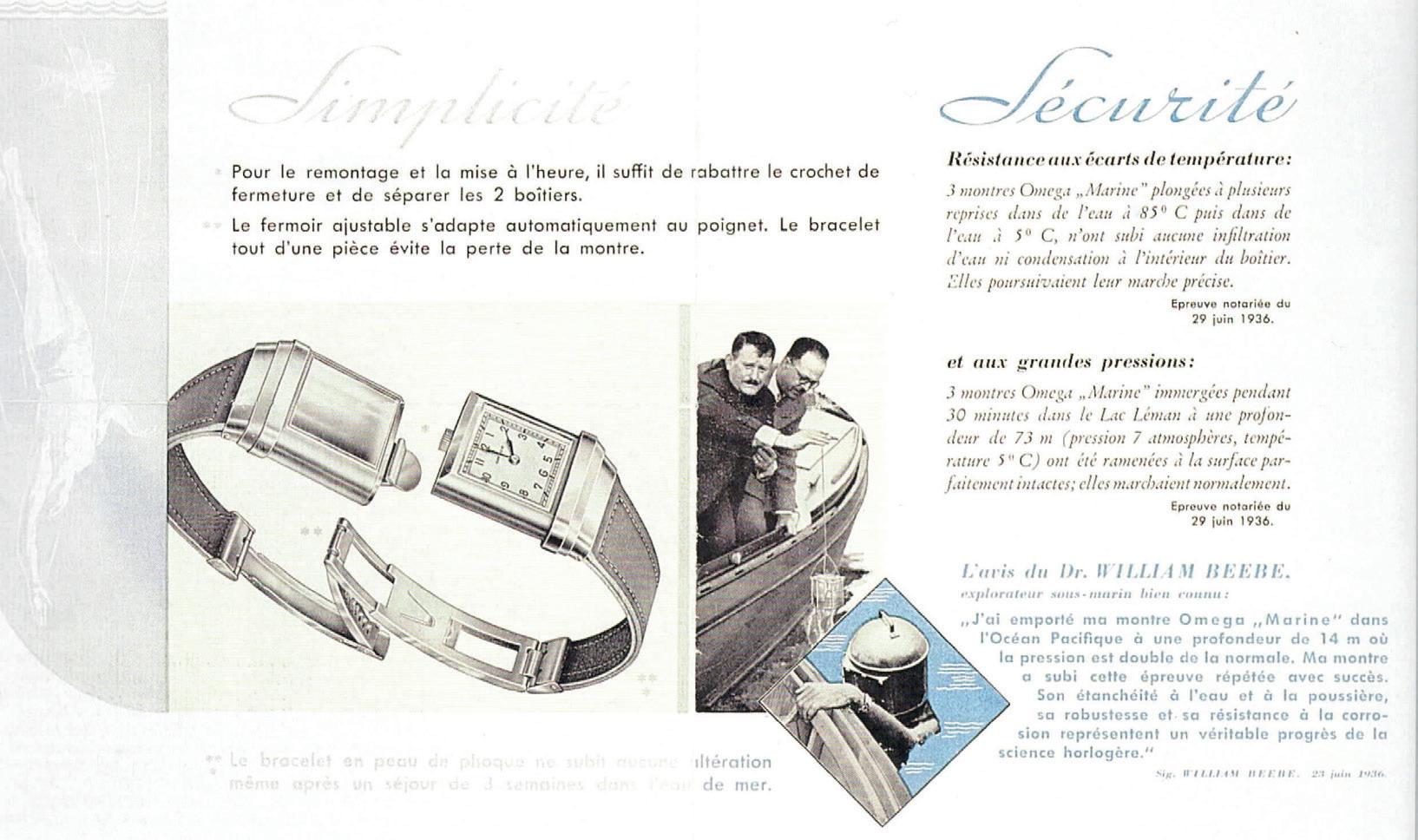

Right: Brochure detailing the characteristics of the Marine, along with a testimonial by Dr William Beebe and an illustration of the three watches being lowered into the water from a boat

In 1936, the Marine underwent a rigorous test conducted aboard a boat and which demonstrated the exceptional water resistance of its double case. Three watches were attached to a rope and plunged to the bottom of Lake Geneva at a depth of 73 meters, where they remained submerged for some 30 minutes. When they emerged from the water, the watches were not only perfectly watertight, but also as accurate as before (see the

excerpt from the brochure reproduced below). Later, further tests were carried out at the Laboratoire Suisse d’Horlogerie, where the Marine was subjected to depth simulations by means of gradually increased pressure. These unprecedented tests showed that the Marine was completely water-resistant at a pressure corresponding to a staggering 135-meter depth.

Below: Advert for the Marine showing the features and price in francs: CHF 800 for the Staybrite stainless steel version and CHF 2,900 for the yellow gold version

After 1968, development of the PloProf One continued until at least 1972, with a view to its eventual commercialization. The project was put on hold however before being unexpectedly relaunched around 1975. Thanks to technical advances, notably including the adoption of a 5 mm-thick glass, the production model offered guaranteed water resistance to 1,000 meters, a record for a watch at the time. Christened the Sea-

master 1000 by OMEGA, it was nicknamed “The Grand” by enthusiasts and collectors alike.

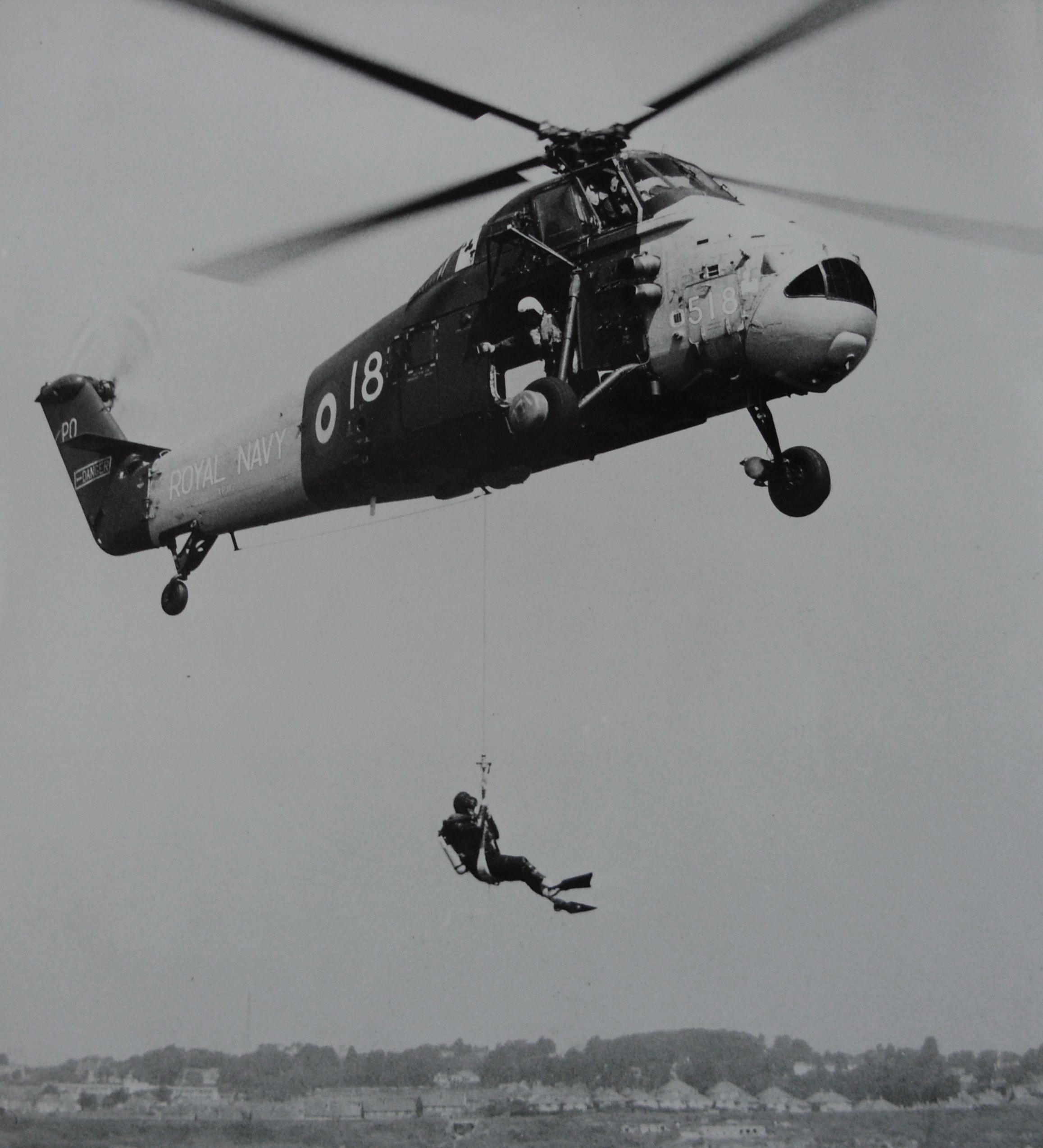

The Seamaster 1000 quickly established itself as the tool of choice for many professional divers, including Captain Cousteau and several members of the Calypso crew. It was also tested in extreme conditions at a real-life depth of 1,000 meters, attached to the robotic arm of the Beaver Mark IV submarine.

Seamaster Skin Diver from the 1970s and 1980s

During the 1970s and 1980s, OMEGA produced a wide range of “standard” diving watches under the Seamaster name, alongside its “ultra-professional” line. These models met the varied needs of a consumer base ranging from amateur divers to military personnel and explorers, while remaining accessible to the general public. Robust, reliable and sufficiently water-resistant for swimming or recreational diving, these watches

belong to the “skin divers” category: instrument-watches with designs that are often lighter and more versatile than professional models.

The first of these was the Seamaster 120, Reference ST 166.073, nicknamed “Deep Blue”. Marketed from 1970 onwards, it is often considered the natural heir to the Seamaster 300 and was used by the Israeli armed forces. In 1973, OMEGA introduced the Seamaster 200, Reference ST 166.0177, featuring an angular case typical of bold 1970s

Seamaster 120 “Deep Blue”, Reference ST 166 073, produced from 1970 onwards Considered the natural heir to the Seamaster 300 Date, it shares several of the latter’s features such as self-winding Caliber 565 as well as the same rotating bezel, date display, hands and screw-down crown

design trends. This model is now known by its nickname “SHOM”, a reference to the Service Hydrographique et Océanographique de la Marine française , which ordered a batch in 1979. The caseback of these watches was engraved with these initials. French Navy divers also acquired this model, recognizable in this instance by the initials “MN” (Marine Nationale) on the caseback. Other models were produced and are detailed in Part 6. The Legacy of the Seamaster 300

Seamaster 200, Reference ST 166 0177, nicknamed “SHOM” This model with its angular case emblematic of the 1970s was adopted by the French Navy’s Service Hydrographique et Océanographique de la Marine française (Hydrographic and Oceanographic Service), whose initials are engraved on the caseback

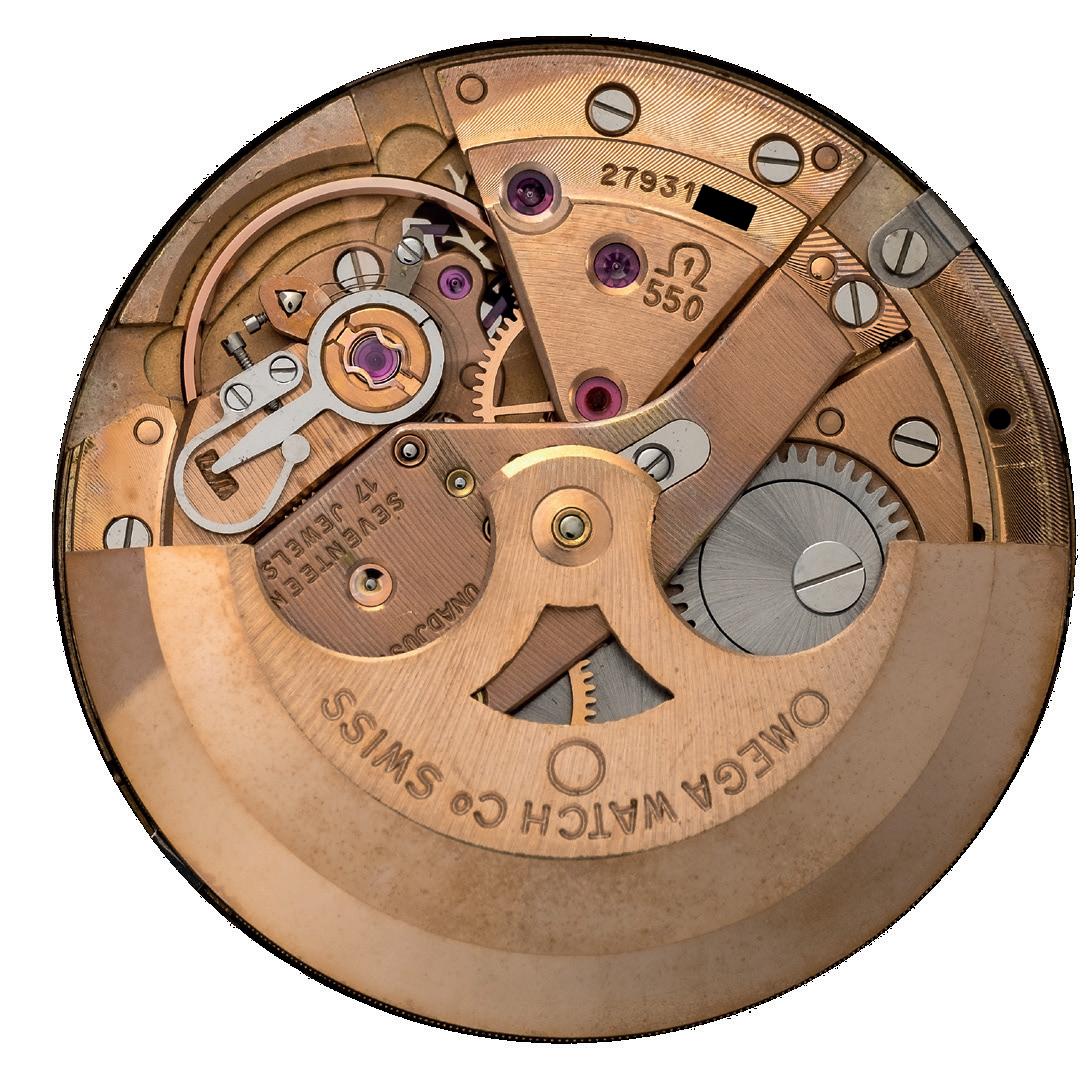

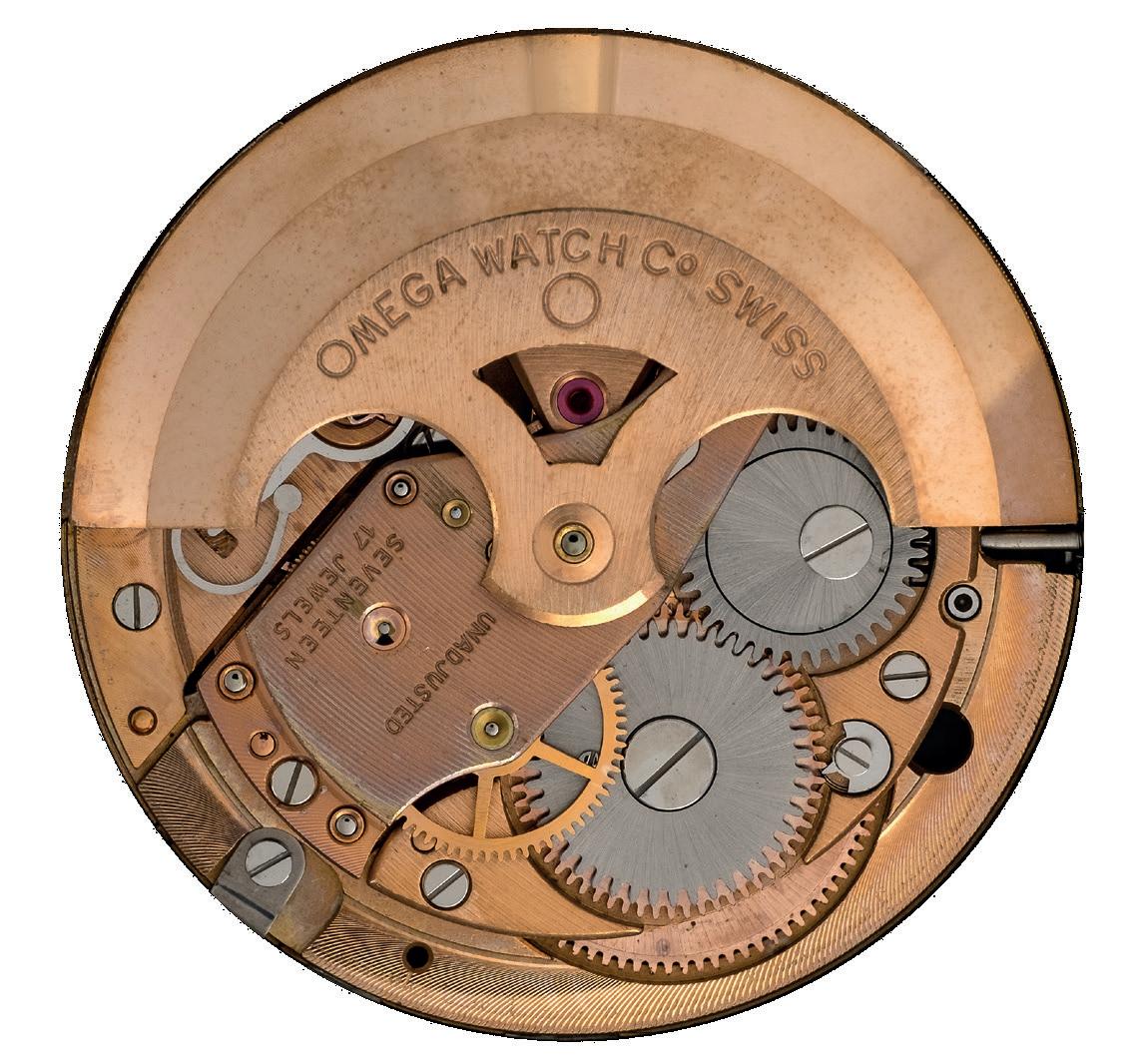

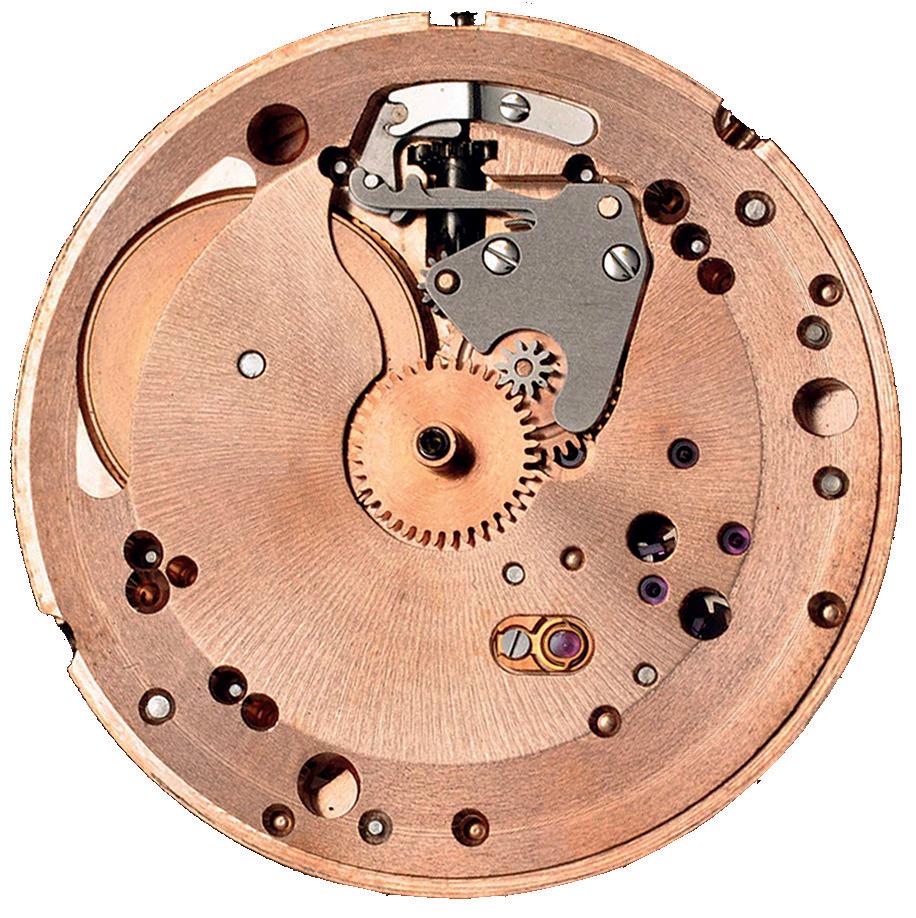

Throughout its production, the Seamaster 300 was powered by OMEGA’s in-house automatic mechanical movements from the 5xx series. This highly regarded range of calibers featured a full-rotor automatic winding mechanism with central seconds, a frequency of 19,800 vph/2.75 Hz and a Glucydur balance. Glucydur is an alloy known for its exceptional elasticity, hardness, antimagnetic properties and resistance to corrosion. The movement parts were crafted using brass or beryllium bronze: this copper alloy contains up to 3% beryllium, a metal highly suited to this application due to its ease of machining, resistance to oxidation, non-magnetic properties and remarkable durability. These qualities have also made it valuable in industries like precision tooling, aerospace and even armor-piercing bullets. To enhance durability further, the base material was electroplated with copper, providing additional protection and imparting the distinctive copper hue familiar to collectors of vintage OMEGA watches. The pinion wheel shaft sizes for the hands remained constant throughout the entire manufacturing period, at 1.5 mm for the hours hand, 0.8 mm for the minutes hand and 0.18 mm for the seconds hands.

This uniformity ensures that hands from all Seamaster 300 models are compatible with the movements originally fitted to the various references.

During the Seamaster 300’s production, the United States imposed higher taxes on imported watches with movements containing more than 17 jewels and/or adjusted to more than two positions. In response, OMEGA adapted by equipping U.S.-bound models with movements limited to 17 jewels and adjusted to no more than two positions. These modified movements were assigned unique caliber numbers and marked accordingly to comply with import regulations. The omitted jewels, all from the winding mechanism, were replaced by metal bearings.

Movements used in the first three Seamaster 300 references – CK 2913, CK 14755 and ST 165.014 (the symmetrical-case models) – were housed within the case using a stainless steel movement holder ring. In contrast, all subsequent references secured the movement directly to the case, eliminating the need for a holder ring. Notably, the screw-hole positions for attaching the ring to the movement differ between the Caliber 50x and 55x series.

Adjustment spring for regulator

Movement serial number

Caliber reference

Rotor end

Number of jewels

Adjusted or Unadjusted

Upper bridge

The caseback is a component of the watch case, much like the caseband. It follows that these two elements would logically originate from the same manufacturer. All evolutions of the vintage Seamaster 300 feature a screw-down caseback, designed with six slots around its circumference to accommodate a tool for easy fitting and removal (such as illustrated p.201). The caseback securely screws into the caseband, where a rubber gasket is held in place by pressure to effectively prevent the ingress of moisture and dust.

Each example is marked on the inner side with an engraved case reference number and additional engravings (such as the case maker), as well as a decorative circular-grained finish (with a few rare exceptions).

The outer side is adorned with varying styles of engravings, depending on the specific model. Except the very first version (A1),

all casebacks bear the seahorse emblem, introduced by OMEGA engraver Jean-Pierre Borle in 1958, inspired by the seahorse sculptures adorning gondolas in Venice (see image below).

The majority of these casebacks are crafted from Acier Staybrite, a corrosion- and heat-resistant formerly trademarked stainless steel alloy. This material contains 18% chromium, 8% nickel and 0.2% carbon, offering exceptional durability and resistance to the elements. Staybrite steel is a specific form of stainless steel, prized for its superior quality. In later production runs, Staybrite steel was replaced by more generic steel, probably for cost reasons. These later casebacks were inscribed with Acier inoxydable (stainless steel). The dimensions on the following pages, measured by us, may vary slightly – especially if the caseback has been polished.

We have classified the casebacks in three categories:

• Category A: small flat area and fitted to Seamaster 300 models equipped with Calibers 500 and 501

• Category B: larger flat area and longer slots

• Category C: smaller flat area and shorter slots than Category B.

Note that this chapter only covers civilian versions. The serial ranges and production years do not include military-issue watches, which extend beyond those of the civilian models. For more details, (see Part 5. MilitaryIssue Seamaster 300). Furthermore, all inside engraving variations have been compiled in Part 7. Appendix.

Maker’s mark

Circular graining External diameter Internal diameter

The Def Stan documents from 1968 & 1971 also required that a clearly visible circled “T” (to denote the use of tritium lume on the hour-markers and hands as opposed to the more dangerous radium lume used previously) was printed on the dial. We believe it likely this was not done at the factory, but once again by the MoD watchmakers. However, the first watches issued – those marked W10 and destined for the Army –did not initially feature the circled “T” and the dial fitted was a standard civilian version known as C5 in our classification. This is probably because they were ordered and supplied before the Def Stan requirements laid out in 1968 had been determined. It wasn’t until the subsequent batches of watches issued to the Royal Navy (marked 0552) that the M.C5 (Pinholes) and M.D1

(Big Triangle) dials printed with the circled T were fitted. However, given the extremely harsh working conditions, these watches were subject to regular repairs and servicing were necessary, so it is fairly common to see later dials fitted to earlier watches and vice

versa

Other updates were also made during the production run, including changing the Naiad crown system to the more reliable screw-down crown in 1968. This update was regularly retrofitted during maintenance service, so it is common to see earlier watches fitted with screw-down crowns, whereas issue watches that retain their original Naiad crown are quite rare. Replaced and updated components are in fact quite common on all the issue watches and are perfectly acceptable to collectors as long

as they conform to original military issue standards.

Despite the factory modifications, all the MoD-issue watches carry the same 165.024 case reference number as the civilian versions. The cases were manufactured for OMEGA by Huguenin Frères (HF) and La Centrale Boites (CB.)

Beside the military-issue watches, Seamaster 300s were also sold in military base stores around the world for private purchase by military personnel and the archival records held by OMEGA occasionally show delivery to base stores such as the US Army & Navy exchange (PX), the Royal Canadian Airforce (RCAF) and the UK’s Navy, Army and Air Force Institute (NAAFI) among others. These watches were regular civilian models and not modified for military use.

The printed circled “T” appears in a high position above the dial center and just beneath the word “AUTOMATIC” However, on some dials this marking is placed lower, below the center These markings were applied locally to indicate the presence of tritium, a radioactive substance used on the dial hands and hour-markers

REFERENCE

Material

Movement

Caliber

Functions

Water