LIGHTING CONTROLS LEGEND

FIRE ALARM SYSTEM SHALL BE INCLUDED. LOCATIONS OF ALL PANELS AND BOOSTERS SHALL BE COORDINATED WITH ARCHITECT. CONTRACTOR SHALL TEST THE SYSTEM IN THE PRESENCE OF LOCAL AUTHORITIES AND MAKE ALL REQUIRED MODIFICATIONS AND ADDITIONS TO HIS DESIGN AT NO ADDITIONAL COST.

A COMMISSIONING PLAN MUST BE DEVELOPED BY A REGISTERED DESIGN PROFESSIONAL OR APPROVED AGENCY. THE PLAN SHALL INCLUDE THE FOLLOWING ITEMS:

• A NARRATIVE DESCRIPTION OF THE ACTIVITIES THAT WILL BE ACCOMPLISHED DURING EACH PHASE OF COMMISSIONING.

• A LISTING OF THE SPECIFIC EQUIPMENT, APPLIANCES OR SYSTEMS TO BE TESTED AND A DESCRIPTION OF THE TESTS TO BE PERFORMED.

• FUNCTIONS TO BE TESTED.

• CONDITIONS UNDER WHICH THE TEST WILL BE PERFORMED

• MEASURABLE CRITERIA FOR PERFORMANCE

CONTRACTOR SHALL BE RESPONSIBLE FOR THE DEVELOPMENT AND IMPLEMENTATION OF THE COMMISSIONING PLAN.

LIGHTING COMMISSIONING NOTES

• LIGHTING SYSTEM COMMISSIONING ACTIVITIES INCLUDE BUT SHALL NOT BE LIMITED TO:

-SUBMITTAL REVIEWS

-FIELD OBSERVATION

-ENSURE ALL FIXTURES HAVE LAMPS AND ARE OPERATIONAL

-TEST EMERGENCY LIGHTING (INCLUDING EXIT SIGNS)

-ENSURE ALL OCCUPANCY & DAYLIGHT SENSORS HAVE BEEN INSTALLED PER THE MANUFACTURERS INSTRUCTIONS AND ARE OPERATING AS INTENDED.

-VERIFY STATUS INDICATORS ON DEVICES ARE CORRECT.

-CONFIRM SWITCHES AND DEVICES CONTROL LIGHT FIXTURES AS INDICATED ON THE DRAWINGS.

• THE LIST OF COMMISSIONED SYSTEMS INCLUDES, BUT SHALL NOT BE LIMITED TO:

-LIGHT FIXTURES

-EXIT SIGNS

-EMERGENCY EGRESS LIGHTING

-OCCUPANCY SENSORS

-DAYLIGHT SENSORS

-TIME-CLOCK & TIME-SWITCH CONTROLS

-DIMMER SYSTEMS

-BAS INTERFACE

• DOCUMENTATION CERTIFYING

WIRES + 1 CURRENT CARRYING NEUTRAL CONDUCTOR) ARE INSTALLED IN A COMMON CONDUIT, THE AMPACITY OF ALL CURRENT-CARRYING CONDUCTORS SHALL BE DERATED PER 2017 NEC ARTICLE 310.15 (B)(3)(A). EXAMPLE: (6)-20AMP CKTS WITH 8 CURRENT CARRYING WIRES IN A COMMON CONDUIT MUST USE MINIMUM #10 WIRE 70% X 35A = 24.5 AMPS. PROVIDE COMMON TRIP BREAKERS FOR MULTIWIRE CIRCUITS PER 2017 NEC ARTICLE 210.4 (B).

KEYED NOTES

1PROVIDE JUNCTION BOX FOR FORKLIFT CHARGING STATION

COORDINATE EXACT LOCATION AND REQUIREMENTS WITH OWNER/ARCHITECT PRIOR TO ROUGH-IN AND INSTALLATION.

2PROVIDE JUNCTION BOX FOR 2 CIRCUIT, ASTRONOMIC TIME CLOCK 'TC1'. TIME CLOCK SHALL BE INTERMATIC #E190215C OR EQUAL.

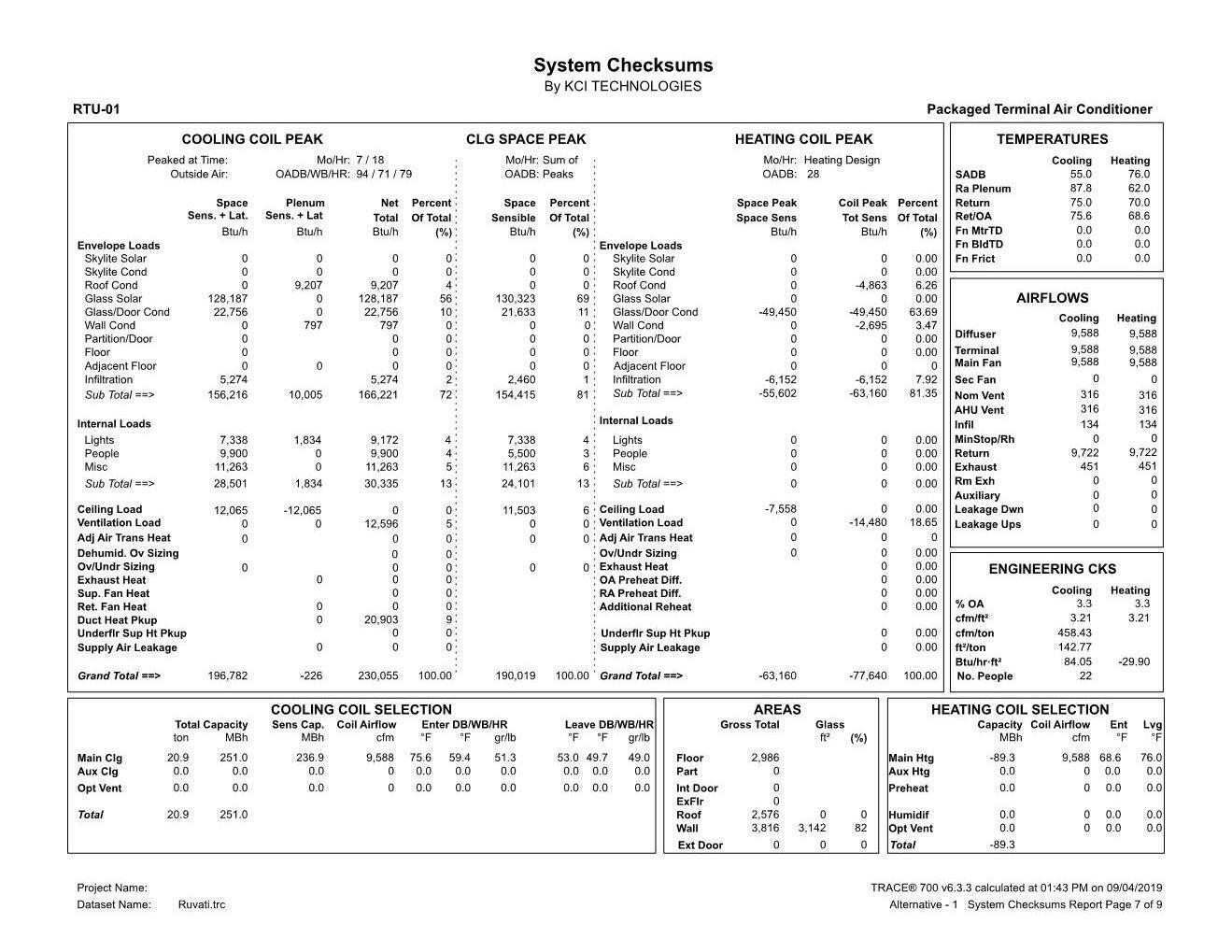

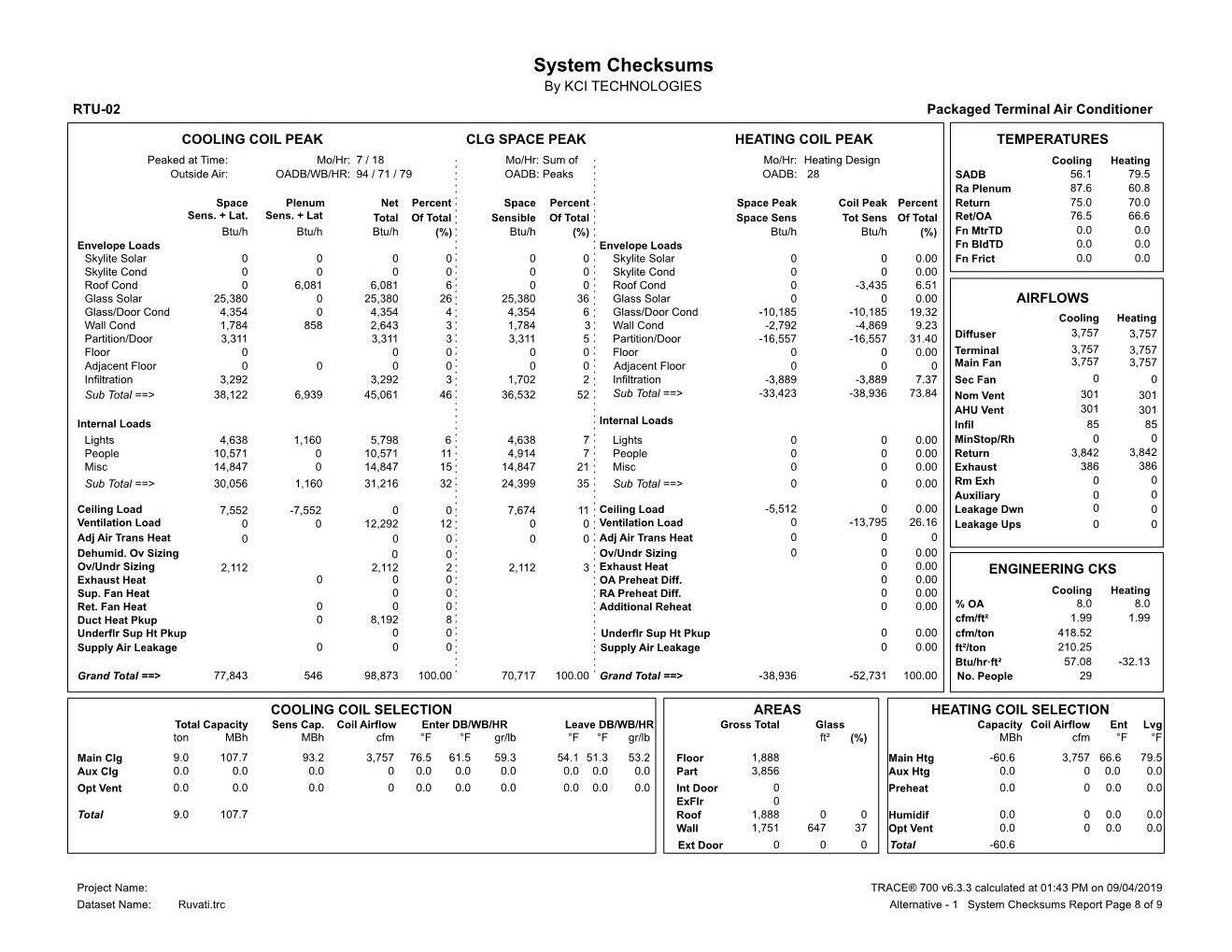

HVAC & PLUMBING EQUIPMENT CIRCUITING EQUIPMENT TAG PANEL-CKTNOTESEQUIPMENT TAGPANEL-CKTNOTES CU-1-01 LAC-2,41EUH-W-04HAC-25,27,291 CU-1-02LAC-6,81EUH-W-05HAC-31,33,351 CU-1-03LAC-10,121EUH-W-06HAC-37,39,411 CU-1-04LAC-22,241EUH-W-07HAC-14,16,181 CU-2-01LAC-14,161EUH-W-08HAC-20,22,241 CU-2-02LAC-18,201EUH-W-09HAC-26,28,301 EF-1-01LAC-212,5 EWH-1LA1-24,26,281 EF-1-02LAC-212,5 FCU-1-01LAC-1,31 EF-1-03LAC-212,5FCU-1-02LAC-5,71 EF-1-04LAC-212,5FCU-1-03 LAC-9,111 EF-1-05LAC-212,5FCU-1-04--1,7 EF-1-06LAC-212,5FCU-2-01LAC-13,151 EF-2-01LAC-232,5FCU-2-02LAC-17,191 EF-2-02LAC-232,5 HWRP-1 LA1-302 EF-2-03LAC-252,5 IWH-1 HA-2 1 EF-2-04LAC-272IWH-2 HA-4 1 EF-WO-01LAC-295RTU-01HAC-2,4,61 EF-WO-02LAC-295RTU-02HAC-8,10,121 EF-W-01LAC-262GV-W-01LAC-262,3 EF-W-02LAC-282GV-W-02LAC-282,3 EF-W-03LAC-302GV-W-03LAC-302,3 EF-W-04LAC-322GV-W-04LAC-322,3 EUH-W-01HAC-7,9,111GV-2-01LAC-13,152,4 EUH-W-02HAC-13,15,171GV-2-02LAC-17,192,4 EUH-W-03HAC-19,21,231

NOTES:

1.

2.

HA-15,17,19

HA-21,23,25

HA-14,16,18 1 1 1

EXCEPT WHERE SPECIFICALLY NOTED AND ALLOWED. WHERE MORE THAN THREE CURRENT CARRYING CONDUCTORS (EXAMPLES: 3 PHASE WIRES + 1 CURRENT CARRYING NEUTRAL CONDUCTOR) ARE INSTALLED IN A COMMON CONDUIT, THE AMPACITY OF ALL CURRENT-CARRYING CONDUCTORS SHALL BE DERATED PER 2017 NEC ARTICLE 310.15 (B)(3)(A). EXAMPLE: (6)-20AMP CKTS WITH 8 CURRENT CARRYING WIRES IN A COMMON CONDUIT MUST USE MINIMUM #10 WIRE 70% X 35A = 24.5 AMPS. PROVIDE COMMON TRIP BREAKERS FOR MULTIWIRE CIRCUITS PER 2017 NEC ARTICLE 210.4 (B).

KEYED NOTES

1PROVIDE UNISTRUT RACK FOR MOUNTING 120V WP/GFCI RECEPTACLE AND MECHANICAL EQUIPMENT EQUIPMENT DISCONNECTS. ONE RECEPTACLE CAN BE SHARED WITH MULTIPLE UNITS IF WITHIN 25' OF RECEPTACE. COORDINATE EXACT LOCATION OF RACKS WITH MECHANICAL EQUIPMENT PRIOR TO INSTALLATION.

HVAC & PLUMBING EQUIPMENT CIRCUITING EQUIPMENT TAGPANEL-CKTNOTESEQUIPMENT TAGPANEL-CKTNOTES CU-1-01LAC-2,41EUH-W-04HAC-25,27,291 CU-1-02LAC-6,81EUH-W-05HAC-31,33,351 CU-1-03LAC-10,121EUH-W-06HAC-37,39,411 CU-1-04LAC-22,241EUH-W-07HAC-14,16,181 CU-2-01LAC-14,161EUH-W-08HAC-20,22,241 CU-2-02LAC-18,201EUH-W-09HAC-26,28,301 EF-1-01LAC-212,5EWH-1LA1-24,26,281 EF-1-02LAC-212,5FCU-1-01LAC-1,31 EF-1-03LAC-212,5FCU-1-02LAC-5,71 EF-1-04LAC-212,5FCU-1-03LAC-9,111 EF-1-05LAC-212,5FCU-1-04--1,7 EF-1-06LAC-212,5FCU-2-01LAC-13,151 EF-2-01LAC-232,5FCU-2-02LAC-17,191 EF-2-02LAC-232,5HWRP-1LA1-302 EF-2-03LAC-252,5IWH-1 HA-2 1 EF-2-04LAC-272IWH-2 HA-4 1 EF-WO-01LAC-295RTU-01HAC-2,4,61 EF-WO-02LAC-295RTU-02HAC-8,10,121 EF-W-01LAC-262GV-W-01LAC-262,3 EF-W-02LAC-282GV-W-02LAC-282,3 EF-W-03LAC-302GV-W-03LAC-302,3 EF-W-04LAC-322GV-W-04LAC-322,3

EUH-W-01HAC-7,9,111GV-2-01LAC-13,152,4 EUH-W-02HAC-13,15,171GV-2-02LAC-17,192,4 EUH-W-03HAC-19,21,231

NOTES: 1. PROVIDE DISCONNECT FOR EACH UNIT. FIELD VERIFY LOCATION WITH MECHANICAL

(EXAMPLES:

CARRYING NEUTRAL CONDUCTOR) ARE INSTALLED IN A COMMON CONDUIT, THE AMPACITY OF ALL CURRENT-CARRYING CONDUCTORS SHALL BE DERATED PER 2017 NEC ARTICLE 310.15 (B)(3) (A). EXAMPLE: (6)-20AMP CKTS WITH 8 CURRENT CARRYING WIRES IN A COMMON CONDUIT MUST USE MINIMUM #10 WIRE 70% X 35A = 24.5 AMPS. PROVIDE COMMON TRIP BREAKERS FOR MULTIWIRE CIRCUITS PER 2017 NEC ARTICLE 210.4 (B). GENERAL NOTES KEYED NOTES

WIRES +

1NEW CONCRETE FLOOR BOX SHALL BE LEGRAND #880S2 OR EQUAL TWO GANG FLOOR BOX FOR POWER AND VOICE/DATA TO FURNITURE SYSTEMS. VERIFY EXACT FINISHES WITH ARCHITECT PRIOR TO INSTALLATION. PROVIDE 1"C FOR DATA AND 3/4"C FOR POWER IN SLAB TO NEAREST WALL, STUBBED TO ACCESSIBLE CEILING.

2PRE-WIRED FURNITURE IS 8-WIRE 4-CIRCUIT. PROVIDE A J-BOX AND CIRCUITING AS SHOWN FOR POWER CONNECTION AND ONE FOR DATA CONNECTION. PROVIDE QUANTITY OF WIRES PER VENDOR'S REQUIREMENTS. PROVIDE FLEX CONNECTION TO PRE-WIRED FURNITURE AS REQ'D.

3TELEPHONE TERMINAL BOARD: PROVIDE 4'X2'X3/4" THICK PLYWOOD BOARD, PAINTED AND TREATED WITH FIRE RETARDANT. PROVIDE AN ERICO #TMGB-A29L41PT (29"X4"X1/4") TELECOMMUNICATIONS GROUNDING BUS BAR (TGB) MOUNTED ON THE BOARD (COORDINATE LOCATION W/TELECOMMUNICATION CONTRACTOR). PROVIDE 1 #6 WITH GREEN INSULATION CONNECTED TO THE TGB. ROUTE THE #6 IN A 3/4" CONDUIT TO PANEL "LA1" AND CONNECT TO GROUND BUS.

4VERIFY ALL SERVER/IT ROOM EQUIPMENT ELECTRICAL POWER REQUIREMENTS, LOCATIONS, AND PLUG TYPES WITH ARCHITECT/TENANT/IT CONSULTANT PRIOR TO ROUGH-IN AND INSTALLATION.

5PROVIDE RECESSED TV BOX WITH RECEPTACLE, PHONE/DATA OUTLET, AND CABLE TV OUTLET FOR NEW FLAT SCREEN TELEVISION. LEGRAND #TV1WTVSSW OR EQUIVALENT. VERIFY EXACT MOUNTING HEIGHT AND LOCATION WITH TENANT/ARCHITECT PRIOR TO ROUGH-IN AND INSTALLATION

6NEW POKE-THRU: PROVIDE AND INSTALL WIREMOLD 4ATC WITH 3/4"C FOR POWER UNDER SLAB TO NEAREST WALL, STUBBED TO ACCESSIBLE CEILING. VERIFY EXACT FINISHES WITH ARCHITECT PRIOR TO INSTALLATION. COORDINATE EXACT LOCATION WITH TENANT/ARCHITECT PRIOR TO ROUGH-IN AND INSTALLATION.

HVAC & PLUMBING EQUIPMENT CIRCUITING EQUIPMENT TAGPANEL-CKTNOTESEQUIPMENT TAGPANEL-CKTNOTES

CU-1-01LAC-2,41EUH-W-04HAC-25,27,291

CU-1-02LAC-6,81EUH-W-05HAC-31,33,351

CU-1-03LAC-10,121EUH-W-06HAC-37,39,411

CU-1-04LAC-22,241EUH-W-07HAC-14,16,181

CU-2-01LAC-14,161EUH-W-08HAC-20,22,241

CU-2-02LAC-18,201EUH-W-09HAC-26,28,301

EF-1-01LAC-212,5EWH-1LA1-24,26,281

EF-1-02LAC-212,5FCU-1-01LAC-1,31

EF-1-03LAC-212,5FCU-1-02LAC-5,71

EF-1-04LAC-212,5FCU-1-03LAC-9,111

EF-1-05LAC-212,5FCU-1-04--1,7 EF-1-06LAC-212,5FCU-2-01LAC-13,151

EF-2-01LAC-232,5FCU-2-02LAC-17,191

EF-2-02LAC-232,5HWRP-1LA1-302

EF-2-03LAC-252,5IWH-1 HA-2 1

EF-2-04LAC-272IWH-2 HA-4 1

EF-WO-01LAC-295RTU-01HAC-2,4,61

EF-WO-02LAC-295RTU-02HAC-8,10,121

EF-W-01LAC-262GV-W-01LAC-262,3

EF-W-02LAC-282GV-W-02LAC-282,3

EF-W-03LAC-302GV-W-03LAC-302,3

EF-W-04LAC-322GV-W-04LAC-322,3

EUH-W-01HAC-7,9,111GV-2-01LAC-13,152,4

EUH-W-02HAC-13,15,171GV-2-02LAC-17,192,4

EUH-W-03HAC-19,21,231

NOTES:

C. CONTRACTOR

CIRCUITS (3 PHASE WIRES,

+

IN A COMMON CONDUIT, EXCEPT WHERE SPECIFICALLY NOTED AND ALLOWED. WHERE MORE THAN THREE CURRENT CARRYING CONDUCTORS (EXAMPLES: 3 PHASE WIRES + 1 CURRENT CARRYING NEUTRAL CONDUCTOR) ARE INSTALLED IN A COMMON CONDUIT, THE AMPACITY OF ALL CURRENTCARRYING CONDUCTORS SHALL BE DERATED PER 2017 NEC ARTICLE 310.15 (B)(3)(A). EXAMPLE: (6)-20AMP CKTS WITH 8 CURRENT CARRYING WIRES IN A

2.

3.

4.

1.

A2E HE WILLIAMS #LT-22-L39/840-AF-EM/10W-DIM-UMV 2X2 WITH 90 MIN. BATTERYBACKUP

B HE WILLIAMS #AX.5-P-DI-50/50-A-XXX-40K-8-UNV-S1-X-X-G-PC-24 PENDANT DIRECT/INDIRECT

C HE WILLIAMS #6DR-TL-L20-8-35-DIM-UNV-OW-OF-CS-N-F1 6" DOWNLIGHT

C2HE WILLIAMS #6DR-TL-L15-8-35-DIM-UNV-OW-OF-CS-N-F16" DOWNLIGHT

RECESSEDLED 13.8W UNV 1

RECESSEDLED 19WUNV 1

CE HE WILLIAMS #6DR-TL-L20-8-35-EM/10W-DIM-UNV-OW-OF-CS-N-F1 6" DOWNLIGHT WITH 90 MIN. BATTERYBACKUPRECESSEDLED 19W UNV 1

GHE WILLIAMS #75S-4-L50/840-QS-DIM-UNV STRIP LIGHT

SUSPENDEDLED 44WUNV 1

GEHE WILLIAMS #75S-4-L50/840-EM/10WLP-DIM-UNV STRIP LIGHT WITH 90 MIN. BATTERYBACKUPSUSPENDEDLED 44WUNV 1

H ATLAS #ILH-2-24L-L-5K-M HIGH BAY2X4

SUSPENDEDLED187W UNV1,4

HE ATLAS #ILH-2-24L-L-5K-M-EB HIGH BAY2X4 WITH 90 MIN. BATTERYBACKUPSUSPENDEDLED187W UNV1,4

PCORONET #LOOP LED -4-35-LTG1 -UNV-DB% -XX -ACARCHITECTURAL LED HALO

P2 CONTECH #CPL6-30K-MVD2-FC LED PENDANT

SUSPENDED LED 48WUNV 1

SUSPENDEDLED 65WUNV 1

P2E CONTECH #CPL6-30K-CDB-FC LED PENDANT WITH 90 MIN. BATTERYBACKUPSUSPENDEDLED 65WUNV 1

P3 CONTECH #CPL4-30K-MVD-FC LED PENDANT

W HE WILLIAMS #WPCL-L200-8-40-BZ-DIM-UNV WALL SCONCE

SUSPENDEDLED 50WUNV 1

SURFACELED 93W 277V1

WEHE WILLIAMS #WPCL-L200-8-40-BZ-EM/6W-DIM-UNV WALL SCONCE WITH 90 MIN. BATTERYBACKUPSURFACELED 93W 277V1

X1HE WILLIAMS #EXIT/EL-XX-R-CP-AN-EM-D EXIT SIGN WITH 90 MIN. BATTERYBACKUPSURFACELED3W UNV1,2

NOTES:

2.12.72.03.46.18.59.07.98.69.79.17.06.58.19.58.97.2

0.10.20.30.30.30.30.30.30.30.40.40.30.30.40.40.40.3

A. CONNECT ALL EXIT LIGHTS TO UN-SWITCHED POWER AHEAD OF ALL LIGHT SWITCHES. EXIT LIGHTS ARE SWITCHED AT PANEL ONLY.

B. ALL LIGHT SWITCHES TO BE GANGED TOGETHER WHERE POSSIBLE.

C. CONTRACTOR SHALL NOT INSTALL MORE THAN THREE CIRCUITS (3 PHASE WIRES, 1 NEUTRAL + 1 GROUND) IN A COMMON CONDUIT, EXCEPT WHERE SPECIFICALLY NOTED AND ALLOWED. WHERE MORE THAN THREE CURRENT CARRYING CONDUCTORS (EXAMPLES: 3 PHASE WIRES + 1 CURRENT CARRYING NEUTRAL CONDUCTOR) ARE INSTALLED IN A COMMON CONDUIT, THE AMPACITY OF ALL CURRENTCARRYING CONDUCTORS SHALL BE DERATED PER 2017 NEC ARTICLE 310.15 (B)(3)(A). EXAMPLE: (6)-20AMP CKTS WITH 8 CURRENT CARRYING WIRES IN A COMMON CONDUIT MUST USE MINIMUM #10 WIRE 70% X 35A = 24.5 AMPS. PROVIDE COMMON TRIP BREAKERS FOR MULTIWIRE CIRCUITS PER 2017 NEC ARTICLE 210.4 (B).

KEYED NOTES

1DAYLIGHTING ZONE. PROVIDE WITH PHOTOCELL CAPABLE OF DIMMING FIXTURES WITHIN DASHED BOUNDARY LINE IN RESPONSE TO AVAILABLE DAYLIGHT.

P0.01PLUMBING

P0.02PLUMBING

P1.00PLUMBING

P2.00PLUMBING

P3.00PLUMBING ENLARGED PLANS

P3.01PLUMBING ENLARGED PLANS

P3.02PLUMBING ENLARGED PLANS

P3.03PLUMBING

P4.00PLUMBING

P5.00WASTE AND VENT RISER DIAGRAM

P5.01DOMESTIC WATER RISER DIAGRAM

PLUMBING GENERAL NOTES

A. Drawings are diagrammatic; confirm dimensions and locations in the field. If conflicting dimensions are shown, use larger dimension.

B. All plumbing piping, equipment, and fixture installations shall be performed by a licensed plumbing contractor. All plumbing work shall be supervised by a licensed Master Plumber.

C. Guarantee labor and materials for 1-year. Warranties begin upon Owner’s acceptance of substantial completion of the installation.

D. All plumbing materials, installation, testing, cleaning, supports, and workmanship shall be in strict accordance with the below listed applicable codes:

E. 2015 International Plumbing Code

F. 2015 International Energy Conservation Code

G. 2015 International Fire Code

H. All exceptions or substitutions taken to specified materials, fixtures, equipment, or requirements of these documents shall be submitted to the owner, Architect, and Engineer for review prior to purchase and installation.

I. Refer to project contract documentation and architectural drawings for additional requirements and information.

J. See Architectural plans and elevations for exact location of fixtures and wall mounted devices.

K. Plenums are crowded and not all obstacles are indicated. Allow for additional pipe offsets, as required, and when not indicated on drawings.

L. Properly seal all penetrations of floors, exterior walls, and rated walls.

M. Secure all permits and provide any required temporary utilities.

N. All plumbing vents thru roof shall have the minimum separation from HVAC outside air inlets, per the applicable code; coordinate with HVAC contractor.

O. Contractor shall visit site prior to bid –no extras will be allowed for conditions that could be readily observed.

P. Piping shall not be routed over electrical panels or transformers.

Q. Provide water hammer arrestors per ASSE 1010 for maintenance free operation on all quick acting valves. Size as per PDI standards; or, as specified. The use of air chambers shall not be acceptable and are not allowed.

R. The general contractor shall make an allowance n his price to pay all gas company setup fees associated with installation of gas service and meter at the building.

PLUMBING SYMBOLS & ABBREVIATIONS

ABBREVIATIONS

DOMESTIC COLD WATER LINE CW DOMESTIC HOT WATER LINE HW DOMESTIC HOT WATER RECIRC LINE HWR

SANITARY DRAIN LINE SAN

SANITARY VENT LINE V

GREASE WASTE DRAIN LINE GW

GREASE VENT LINE GV

STORM DRAIN LINE ST OVER FLOW DRAIN LINE OD

NATURAL GAS LINE G

COMPRESSED AIR LINE A

NEW

BELOW FINISHED FLOOR B.F.F.

ABOVE FINISHED FLOOR A.F.F.

WALL CLEAN OUT WCO FLOOR CLEAN OUT FCO

CLEAN OUT TO GRADE COTG

NOT IN CONTRACT N.I.C.

BOTTOM OF PIPE B.O.P.

INVERT ELEVATION I.E.

HOSE BIB HB

VENT THRU ROOF VTR

PLUMBING SPECIFICATIONS

22 05 00 COMMON WORK RESULTS FOR PLUMBING

Shop drawings:

Submit all fixtures, trim, equipment, specialties and insulation for review by Engineer-ofRecord.

Operations and maintenance instructions:

Provide 3-copies of operation and maintenance manuals to Owner. Provide instruction on system operation to Owner’s representatives.

Record drawings:

Within 90 days after the date of system acceptance, provide record drawings in Revit/AutoCad Format (using the same software and version the project was designed in), plus full size hard copy. Project designed in Revit Electronic drawings may be available from Engineer for a fee. Record drawings shall include, as a minimum, the installed location and performance data on each piece of equipment and plumbing fixture. In addition, provide general configuration of all piping distribution systems, including sizes. For below grade sanitary piping, provide installed invert elevations.

Coordination:

Provide Electrical Contractor with electrical requirements of approved equipment in sufficient time to order panel boards, disconnects, and related appurtenances.

Access doors

Provide Milcor, or equal, for access to all valves, controls, water hammer arrestors, or other devices requiring maintenance. Doors shall match wall or ceiling rating. Architect must approve location and appearance of all access doors, prior to installation.

Sleeves:

Provide metal sleeves where pipes or control wiring penetrate walls.

22 05 23 GENERAL DUTY VALVES FOR PLUMBING PIPING

Ball valves: Nibco 585 Series with NIB SEAL –two piece, fullport, bronze body stainless steel trim, memory stop, with insulated handle; or equivalent in Scott, Kitz, or Milwaukee.

22 05 29 HANGERS AND SUPPORTS

Pipe and equipment hangers and supports shall be per local code.

Support all above floor piping utilizing support systems manufactured for the applicable installation. Wire or tape supports are not acceptable.

Provide 4”reinforced concrete housekeeping pad with chamfered edges for all floor or ground mounted equipment.

Isolate all water piping from direct contact with structural members (studs, joists, beams, etc.) to prevent the transmission of sound.

Flash and seal equipment, pipe stacks, and roof penetrations.

No wood sills allowed.

Roof supports compatible with existing roof system shall be portable pipe hangers or approved equal.

22 05 48 VIBRATION ISOLATION

Inline circulating pump: suspend or support with rubber or spring isolators.

22 05 73 PLUMBING COMPONENTS IDENTIFICATION

Equipment: permanent label (stencil, metal tag or engraved plastic) with unit tag or name and area or space served.

Piping: provide Brady or Seton pipe markers every 20 feet. Identify service, flow direction, and pressure. Install in clear view and align with axis of piping.

Valve tags: Install engraved metal tags with corrosion resistant chain. Number tags consecutively by location.

Valve Tag Chart: Typewritten letter size list in anodized aluminum, or plastic laminated, frame.

22 07 19 PIPING INSULATION

All insulation must have flame spread less than 25 and smoke developed less than 50 as per ASTM E84, NFPA 255, and UL 273.

Provide galvanized sheet metal shields at all pipe hangers for pipes 1½”or larger. For pipe 4”and larger, provide high-density insulation (calcium silicate) inserts at hangers.

Domestic cold water in exterior walls, attics above building insulation, or other areas subject to freezing –1”fiberglass.

Domestic hot water –For pipe sizes 1-1/4”or less, provide 1”fiberglass insulation with allservice jacket. 1-1/2”and larger, provide 1-1/2”fiberglass insulation with all-service jacket.

Roof drain bodies and horizontal piping –All pipe sizes, provide minimum 1½”thick, 0.75 lb. density fiberglass insulation with foil vapor barrier.

Insulate all exposed drain and water supply piping beneath handicap accessible sinks with closed cell insulating kit as manufactured by ‘Truebro’or equal by ‘McGuire.’

Floor drains receiving condensate from HVAC units or ice machines shall be insulated minimum 5-feet downstream of drain.

22 10 00 PLUMBING PIPING

Domestic hot/cold –ASTM B88 Type “L”copper with wrought copper or cast bronze fittings using lead-free solder joints. Or, press fit type copper fittings, up to 4”diameter and meeting ASME B16.18 and B16.22. Copper, or galvanized, grooved piping materials may be used with Engineer approval. System shall be drainable.

Testing: upon completion of construction, all domestic water piping shall be thoroughly flushed and sterilized. Submit Certificates of Testing for Engineer review.

Below slab Drainage piping below slab shall be service weight cast iron bell and spigot or schedule40 PVC with DWV no-hub fittings and clamps

Storm drains –Standard weight, cast iron soil pipe, ASTM A74 and/orSchedule 40 PVC. No hub above ground; bell and spigot below ground. Grade 1/8”per foot. Transitions between underslab PVC and above slab cast iron shal be as detailed on plans.

NOTE: PVC shall not be used for storm waste piping in any return air plenum.

Make connections between dissimilar piping materials with adaptors manufactured for the applicable type of transition.

Provide dielectric isolation device (dielectric union or coupling) where copper lines connect to ferrous lines or equipment.

Support piping every 10'-0”or less for 1”and larger pipe size; every 6'-0”for