Abbr.Abbreviated Phrase

MAXMAXIMUM

MBMARKER BOARD

MECHMECHANICAL

MISCMISCELLANEOUS MPMETAL PANEL

MTDMOUNTED MTLMETAL MULLMULLION MWKMILLWORK

NNORTH NICNOT IN CONTRACT NO, #NUMBER NRNOISE REDUCTION

NRCNOISE REDUCTION COEFFICIENT NTSNOT TO SCALE

OCON CENTER

OFFOFFICE

OHOPPOSITE HAND

OPNGOPENING

PEDPEDESTAL, PEDESTRIAN, PEDIATRIC

PERFPERFORATE(D)

PFBPREFABRICATE(D)

PFNPREFINISH(ED) PL, PLAMPLASTIC LAMINATE

PLASPLASTER, PLASTIC

VENTILATION, AND

IBCINTERNATIONAL BUILDING CODE

DIAMETER

(ING)

(ING)

PLWDPLYWOOD PNLPANEL

PNTPAINT(ED) PRPAIR

PTPRESSURE TREAT(ED)

PTNPARTITION

QTQUARRY TILE, QUART

RBRUBBER BASE

RBTRUBBER TILE

RECRECEPTACLE

REFREFERENCE, REFER

REFRREFRIGERATOR

REMREMOVE

REQ'DREQUIRED

RMROOM

RSRESILIENT

S&RSHELF AND ROD

SCWSOLID CORE WOOD

SECTSECTION

SFSQUARE FEET

SFRMSPRAYED FIRE RESISTIVE MATERIAL

SHRSHOWER

SIMSIMILAR

SPECSPECIFICATION(S)

SSSTAINLESS STEEL

SSMSOLID SURFACE MATERIAL

STSTONE STDSTANDARD

Abbr.Abbreviated Phrase

SUSPSUSPENDED SUSP CLGSUSPENDED CEILING SVSHEET VINYL SYSSYSTEM

TEMPTEMPERED, TEMPORARY TMETO

4041 Hiddenbrook Dr

S000Cover Sheet12/20/2024

S001StructuralNotes12/20/2024

S100Foundation Plan12/20/2024

S101FirstFloorFraming

S102Second

S103RoofFraming Plan

S200Sections12/20/2024

S300Typical Foundation Details

S310SteelDetails

S330Typical Wood Details

S331Wood Shear WallDetails

S332Typical Wood Details12/20/2024

S400Stair Details

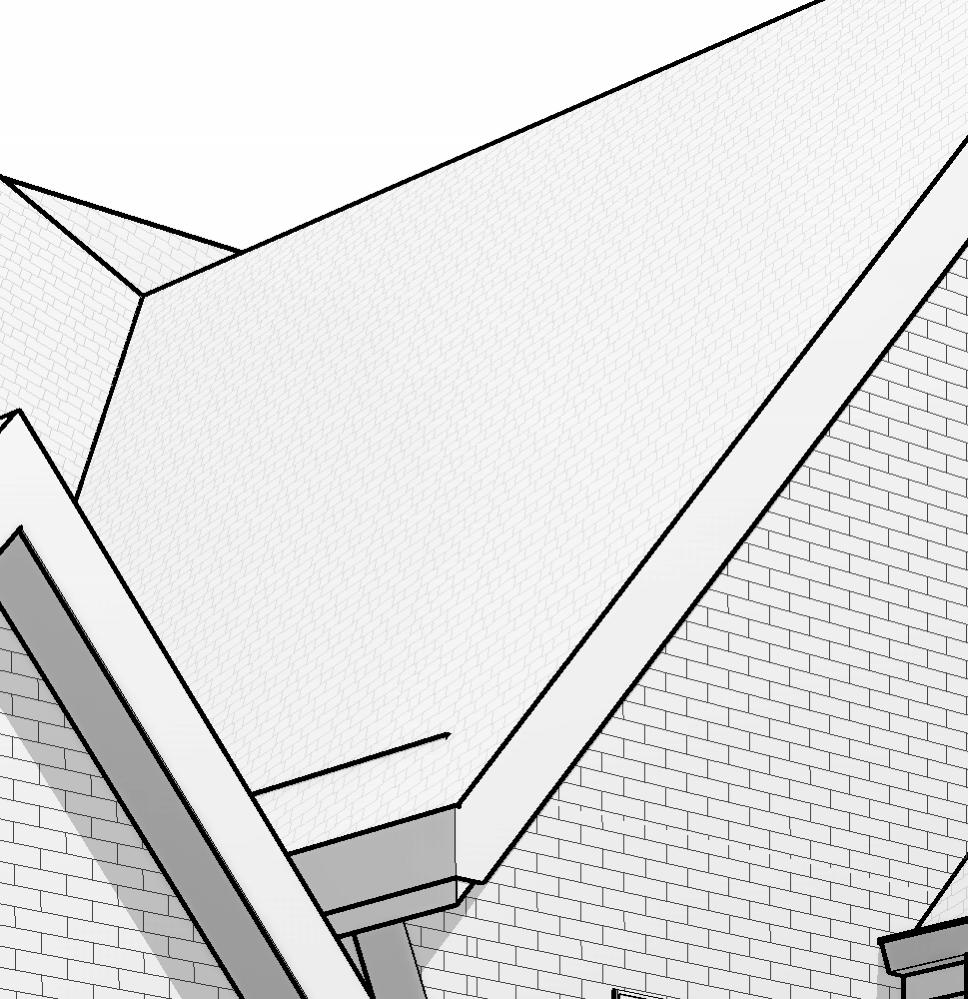

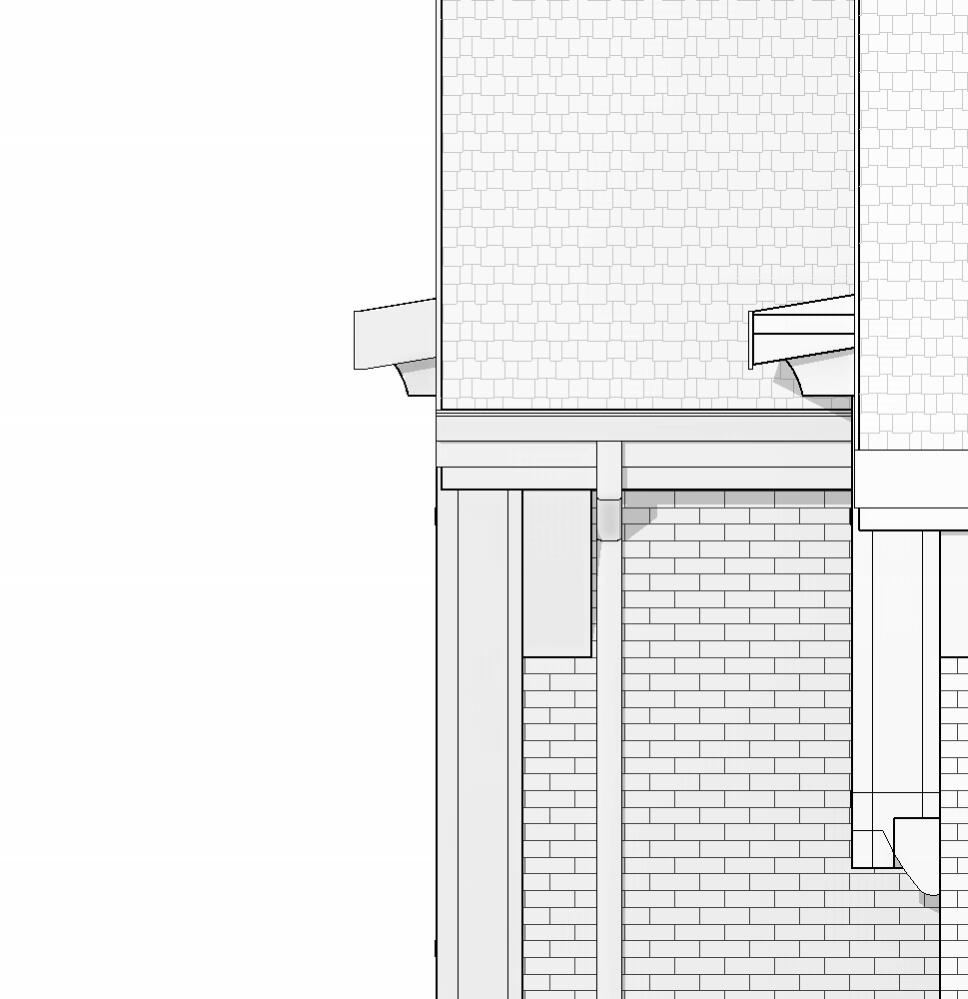

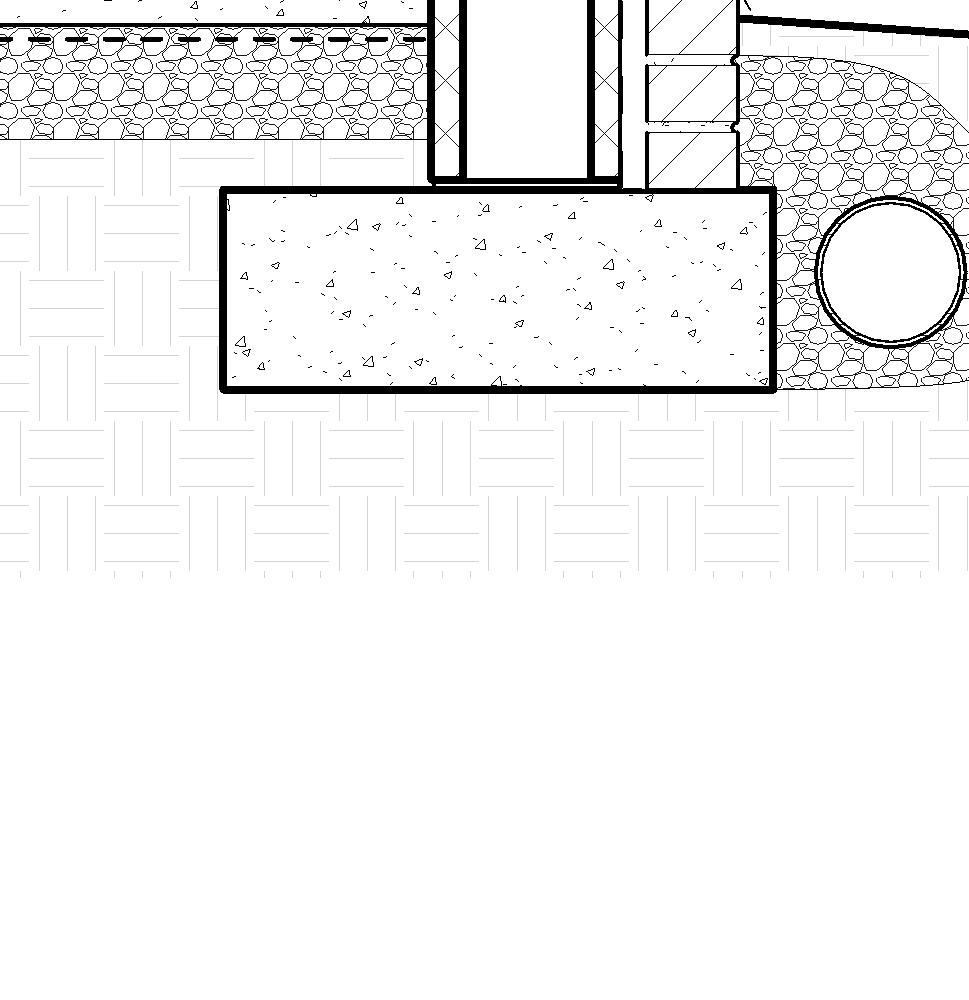

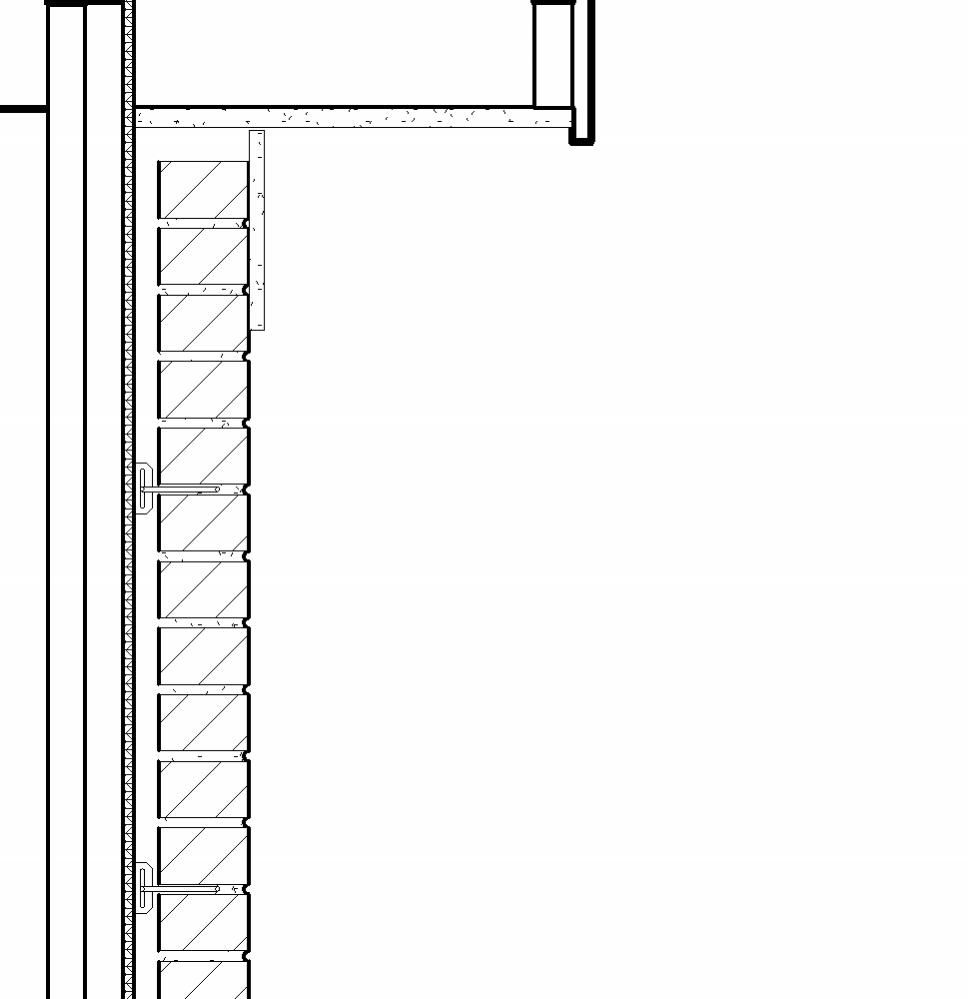

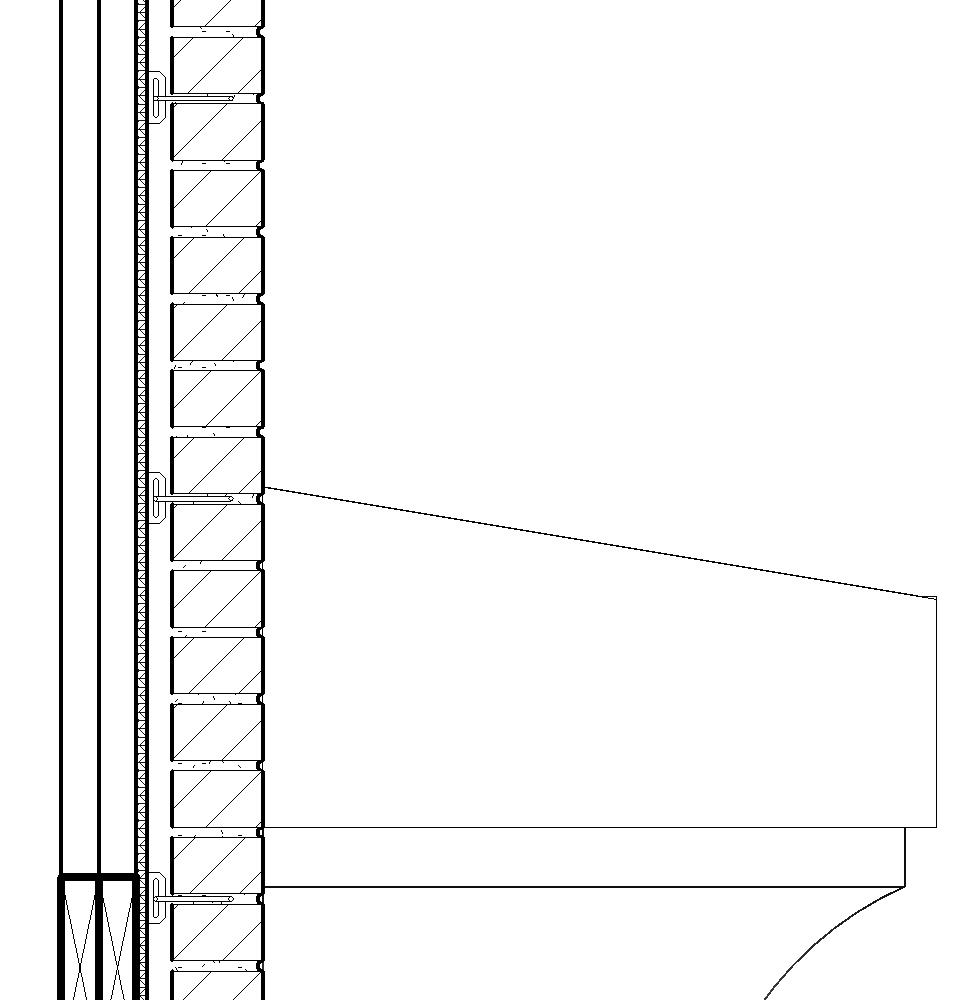

1 L=5' - 0" WOOD SHEAR WALL TAG WOOD SHEAR WALL HOLD DOWN TAG

STEEL

PLATE CONNECTION

FACE MOUNT JOIST HANGER

CONCEALED FLANGE JOIST HANGER BH0 BH0 MOMENT CONNECTION

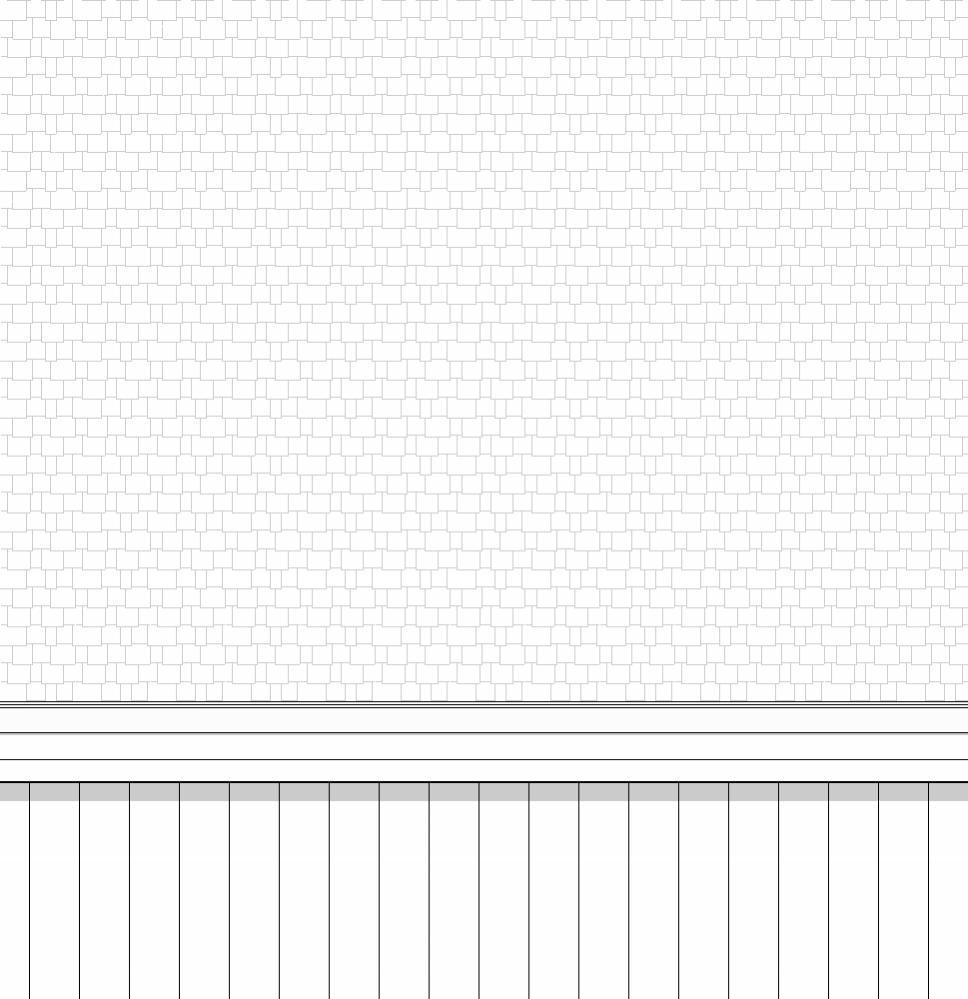

NOTE: THIS DETAIL SHOWS BARS REQUIRED AT SSTB ANCHOR BOLTS

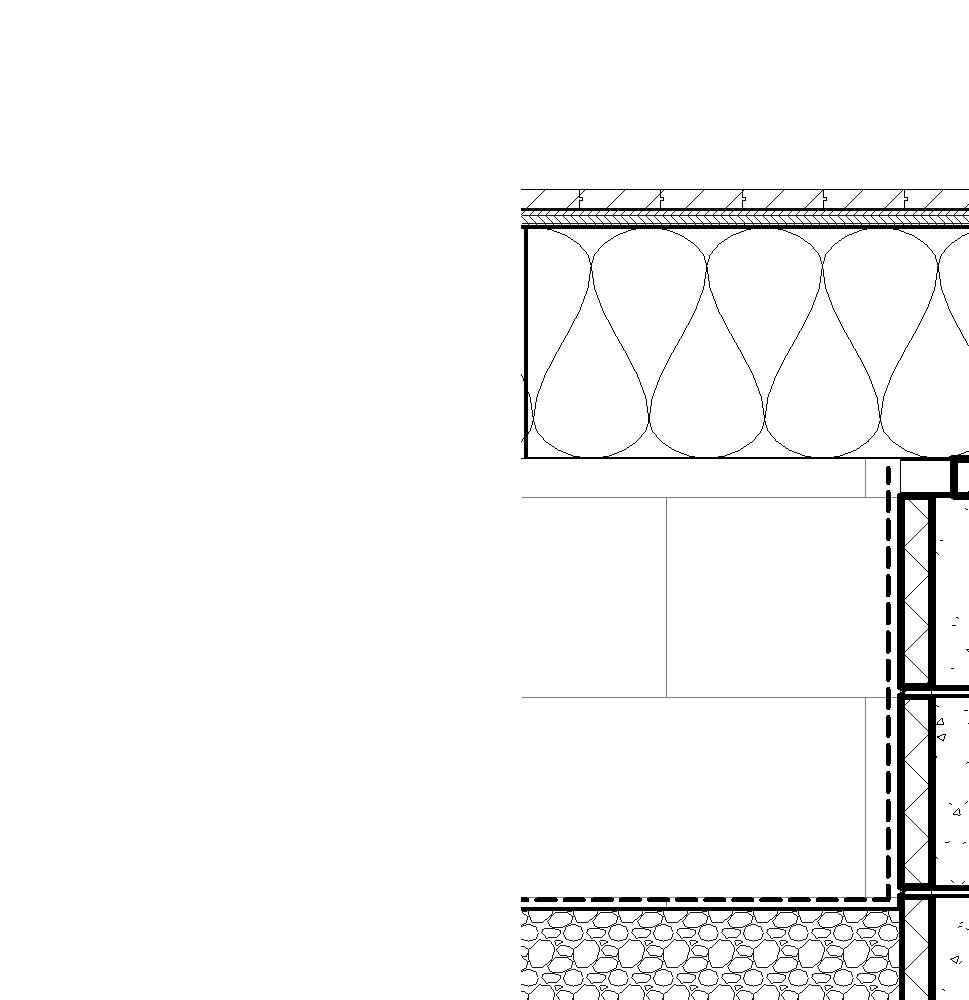

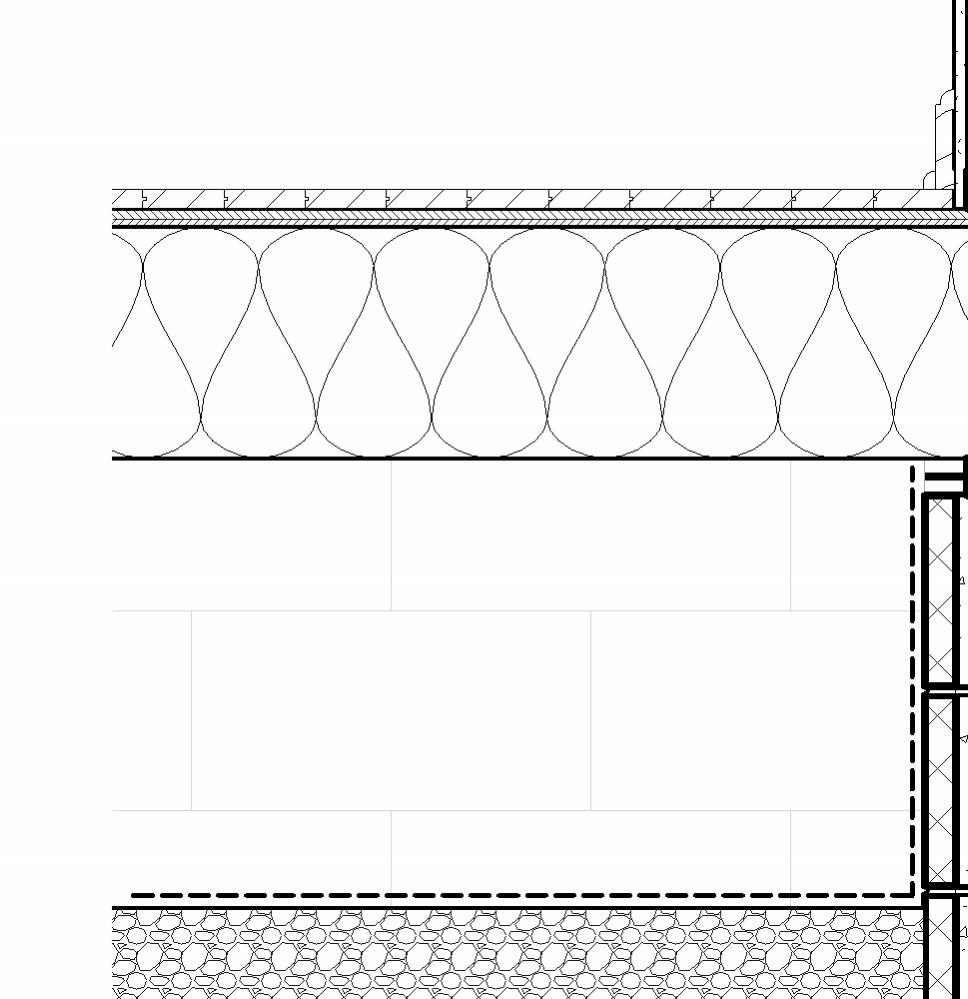

CMU WALL PER PLAN

IN CELL ADJACENT TO ANCHOR ROD

• AT SSTB28/34, PROVIDE (1) ADD'L BAR IN CELL ADJACENT TO ANCHOR ROD & (1) BAR AT 24" OC • 2 ADD'L BARS TOTAL AT SSTB28/34 END WALL LOCATIONS

• 3 ADD'L BARS TOTAL AT SSTB28/34 CORNER/INT WALL LOCATIONS

BUILT-UP

COLUMNFASTENEREND DISTANCE MAX SPACING

2-2x10d NAILS2 1/2" 6" OC

3-2xSDW*3 1/2" 6" OC

4-2xSDW*3

>4-2x1/2" BOLTS4" 8" OC

NAILS SHOULD BE STAGGERED.

5. SEE NDS CHAPTER 15 FOR SITUATIONS NOT COVERED.

6. PROVIDE MIN 4" END DISTANCE AND MIN 1 1/2" EDGE DISTANCE AT BOLTS.

7. ALL NAILS ARE COMMON. PROVIDE HOT DIPPED GALVANIZED NAILS AT PRESSURE TREATED LUMBER.

8. PROVIDE A WASHER AT BOLT HEAD AND NUT. TIGHTEN NUTS TO BRING ALL PLIES INTO CONTACT.

GROUTED CMU HOLD DOWN TYPE TYPE ANCHOR ROD THROUGH ROD HDU2HDU2-SDS2.5SSTB165/8"

NOTES:

2.

1. ALL HOLD DOWNS SHALL BE SIMPSON STRONG TIE.

(DETAILREMOVED)

5.

6.

7.

REINF*W/ REINF*