3 minute read

FLOW AND OCCUPATION

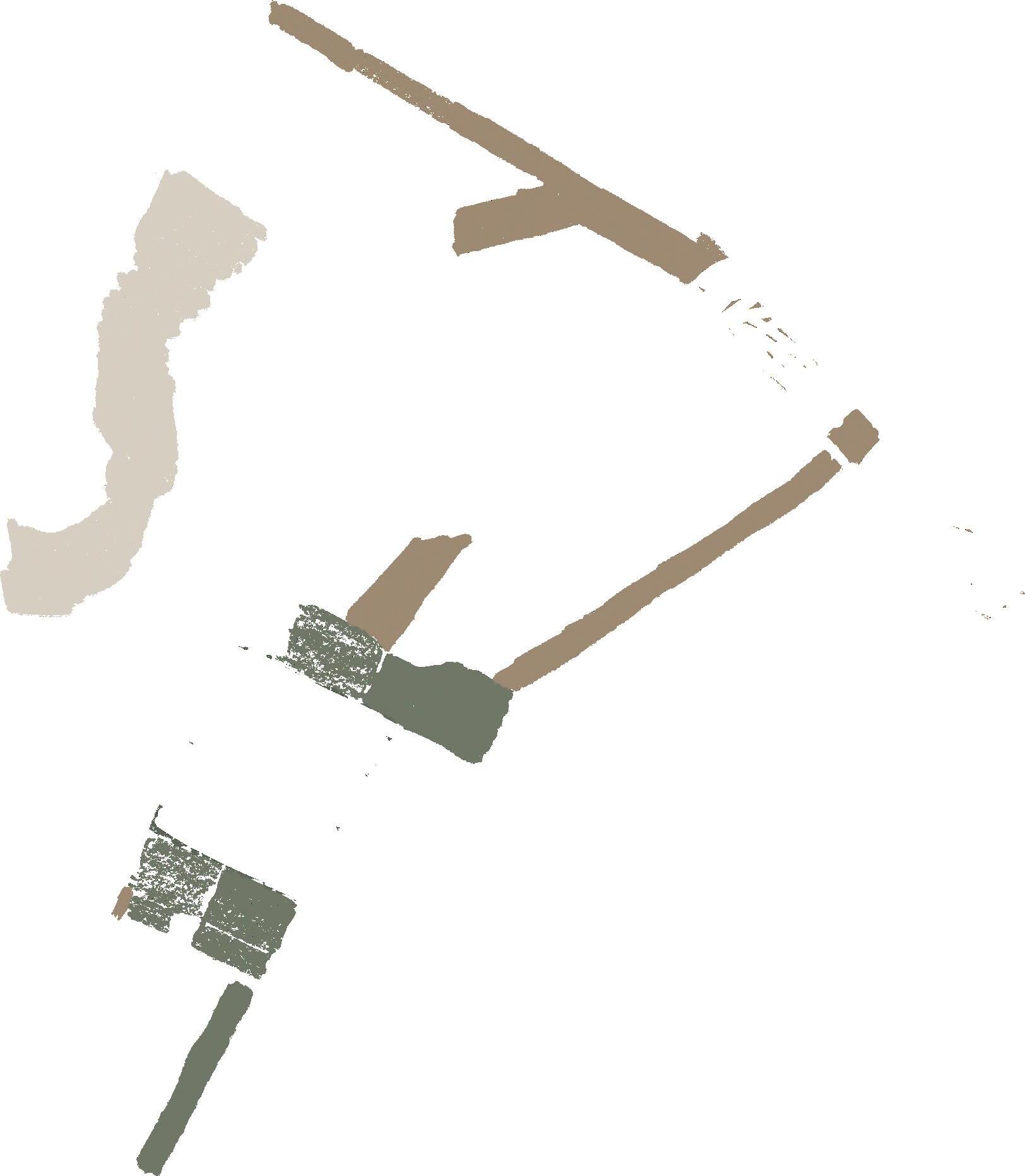

Actors Of The Project

Advertisement

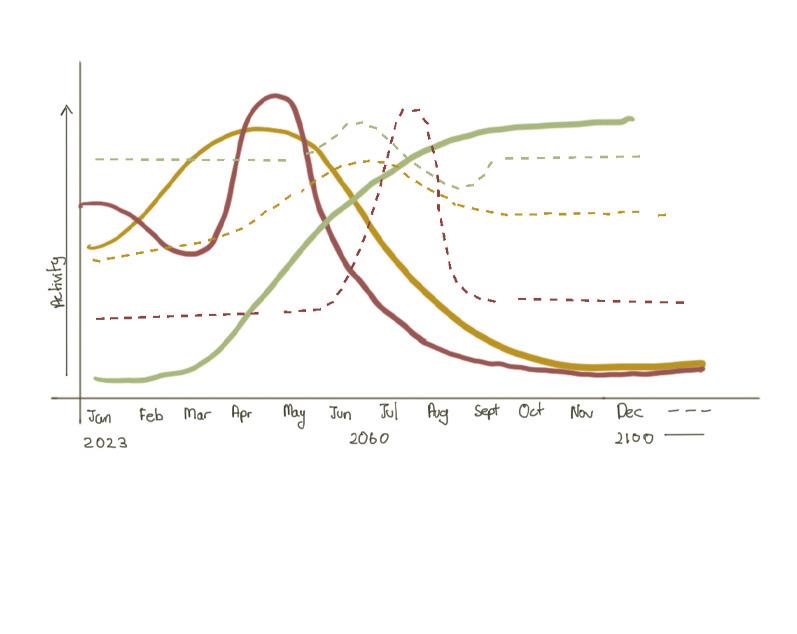

Activity Across Time

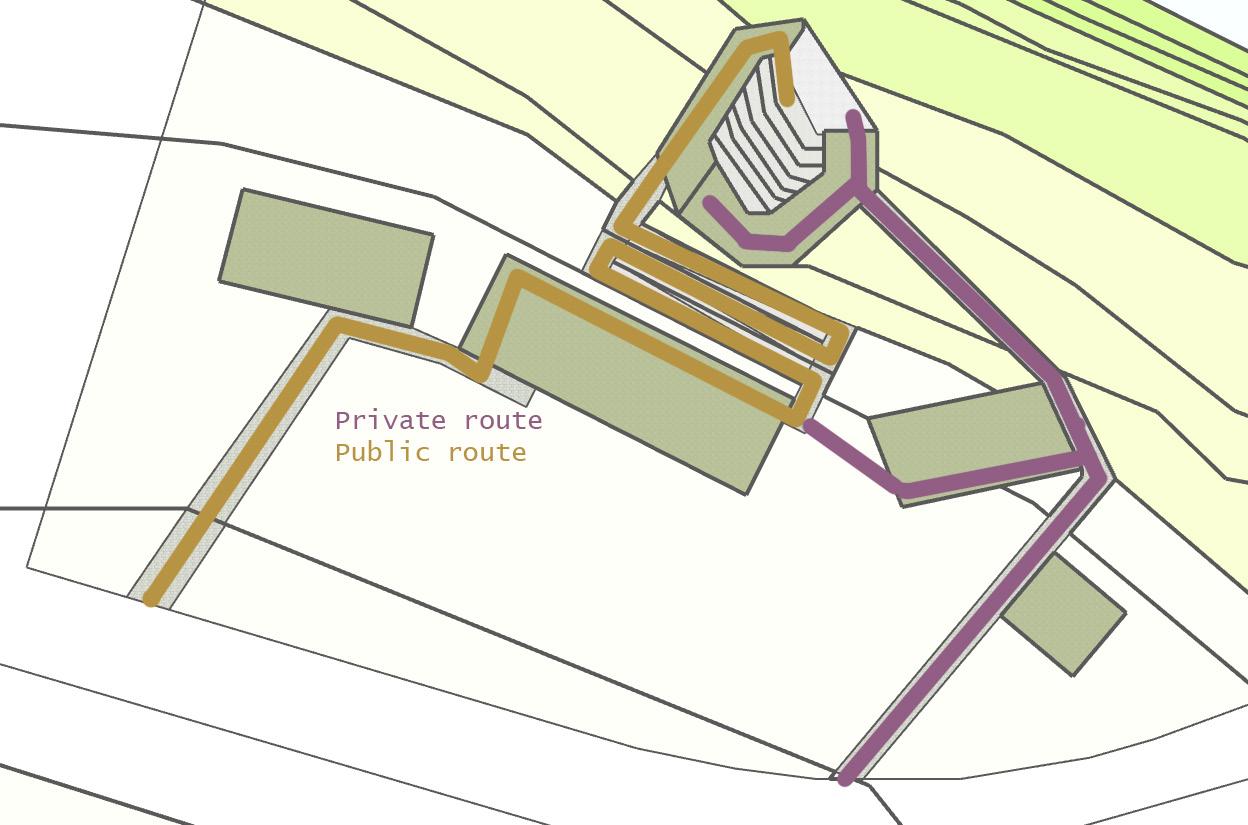

Over time there is a shift in those who use the space and the way it is used. It starts of with being highly used by people in the way of constructors, landscape, then teaching and students. As the space growns, performance and radio grows, more publics engage with the space to get involved and visit. Eventually however, other spaces inspired by school of language develop and there is no more need for it. Here it become a refuge for the environment.

Annually, winter times are reduced usage for the public with auditorium spaces being too cold. This is intentional as bats hibernate then and it will be used for them

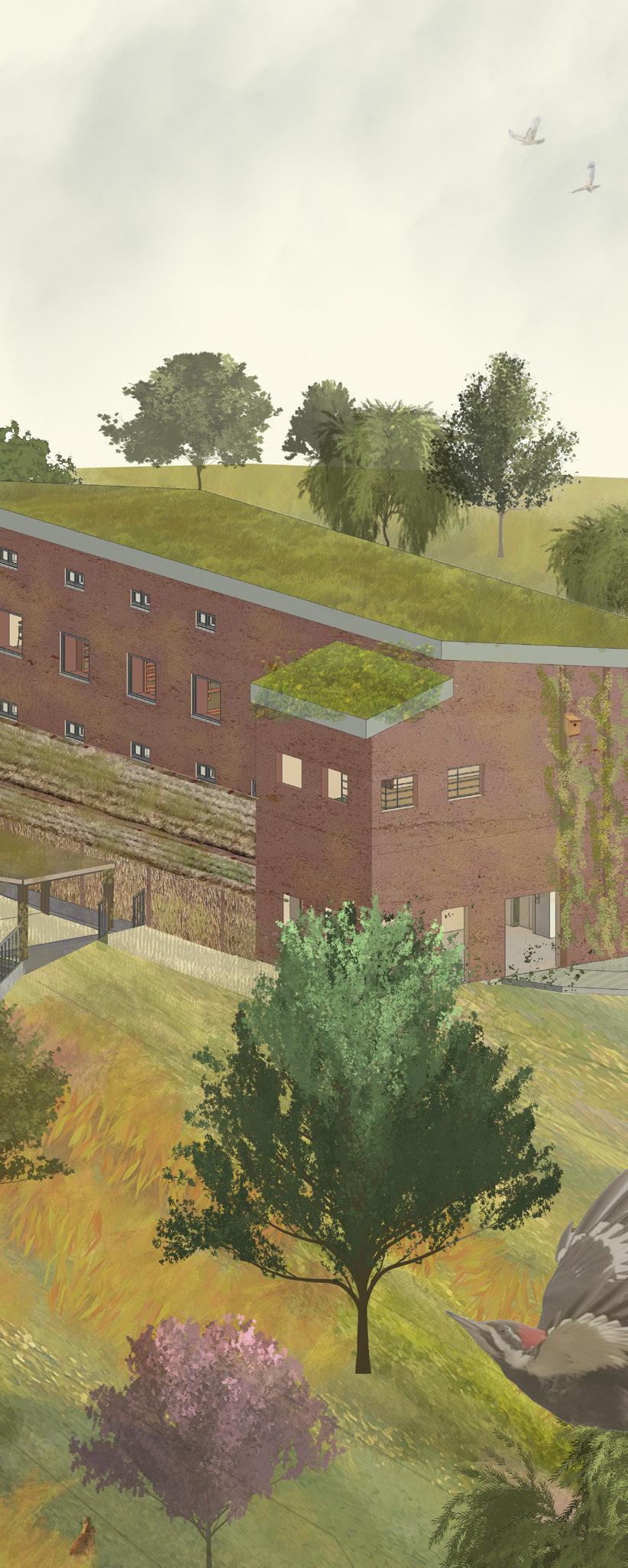

The Library is quiet with the ocassion discissions taking place. The cener of the library is the quietest spot, the edges, however, welcome the sounds of birds from thatch. Sheeps woll insulation, however, is a great sound insualator so helps with preventing it from getting too loud.

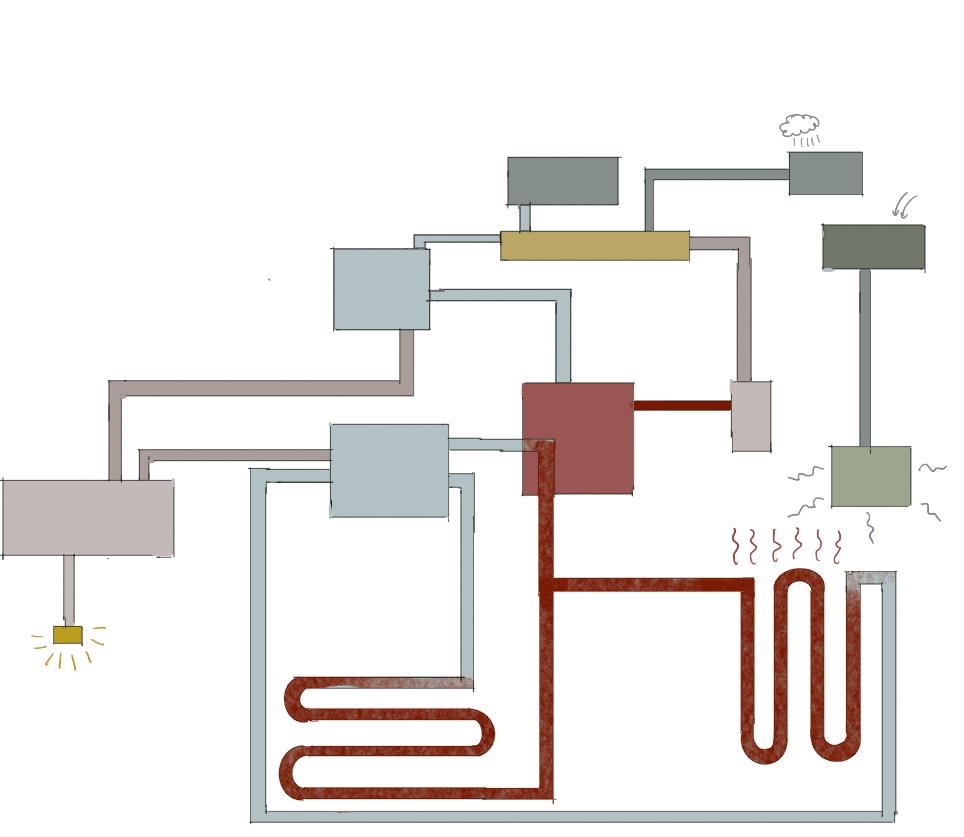

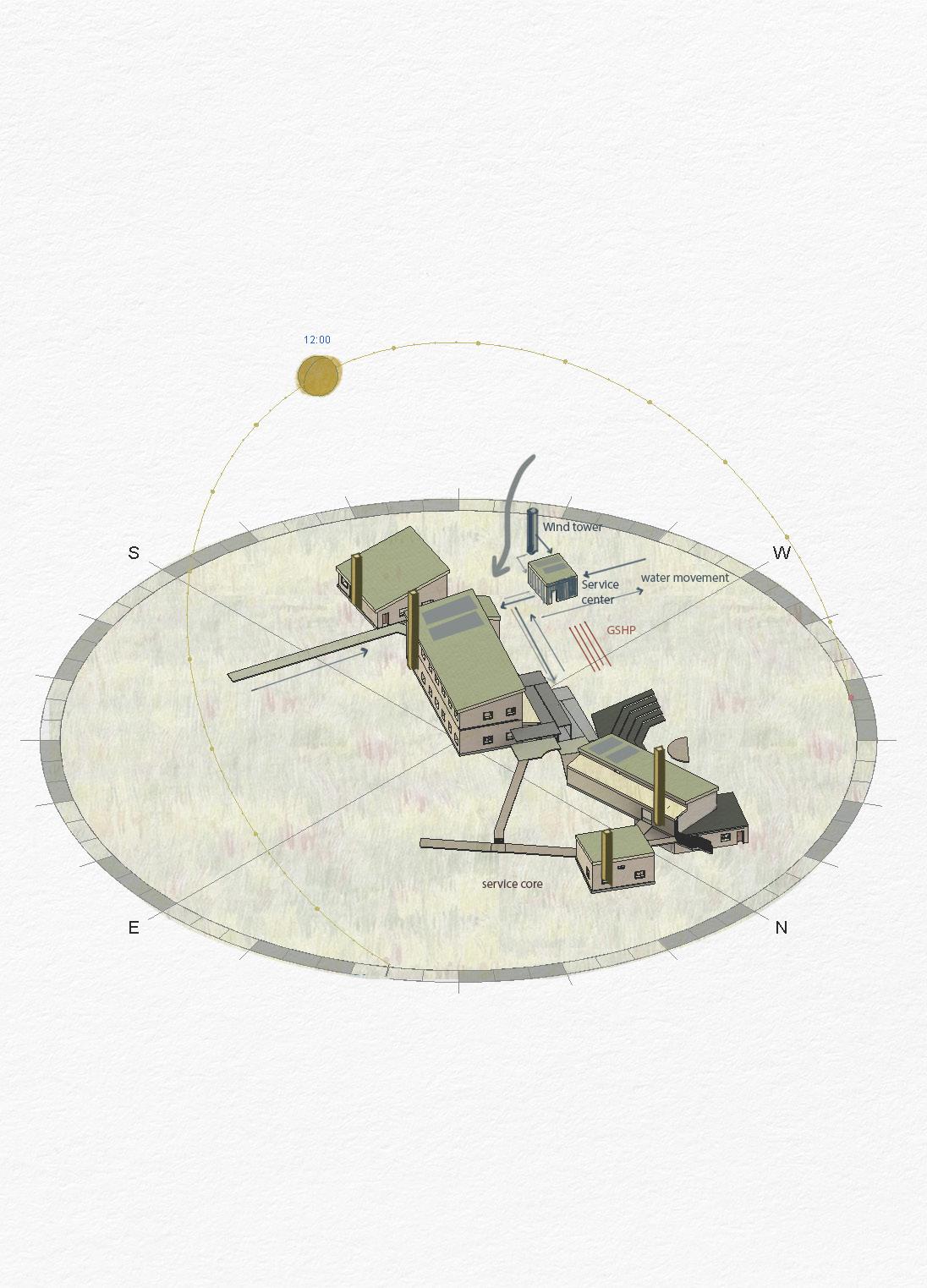

Energy And Utilities

A no-carbon waer cycle stratergy water, and reusing water, was a driving for for the majority of the energy decisions made in this proposal. For heating, closed loop ground source heat pumps are used which takes hotwater into underfloor heat pipes. The GSHP also heats water for kitchen and bathrooms through a boiler.

Grey water is filtered through the reed bed system before either going to storage or redirecting to pond based on levels of water. Rainwater joins grey water in this step.

Clean water is pumped back to the building for use in the supplies. It is this recycled waer that is also supplied to the boiler to become hot water

Solar panels

Solar panels are strategically placed and oriented towards the sun. The electricity generated goes onto supplies, but also runs the pumps, cutting back carbon at that stage. There is a service core in every building for it

Earth tube

Vents are placed in the floors of all spaces to provide an operable source of ventilation. THe air for the ventialtion comes from earth tubes that take air, put it through pipes in the ground (to cool/ heat it), and then comes out through vents in the floor. Clerestory windows allow air to grow, creating a passive ventilation stratergy.

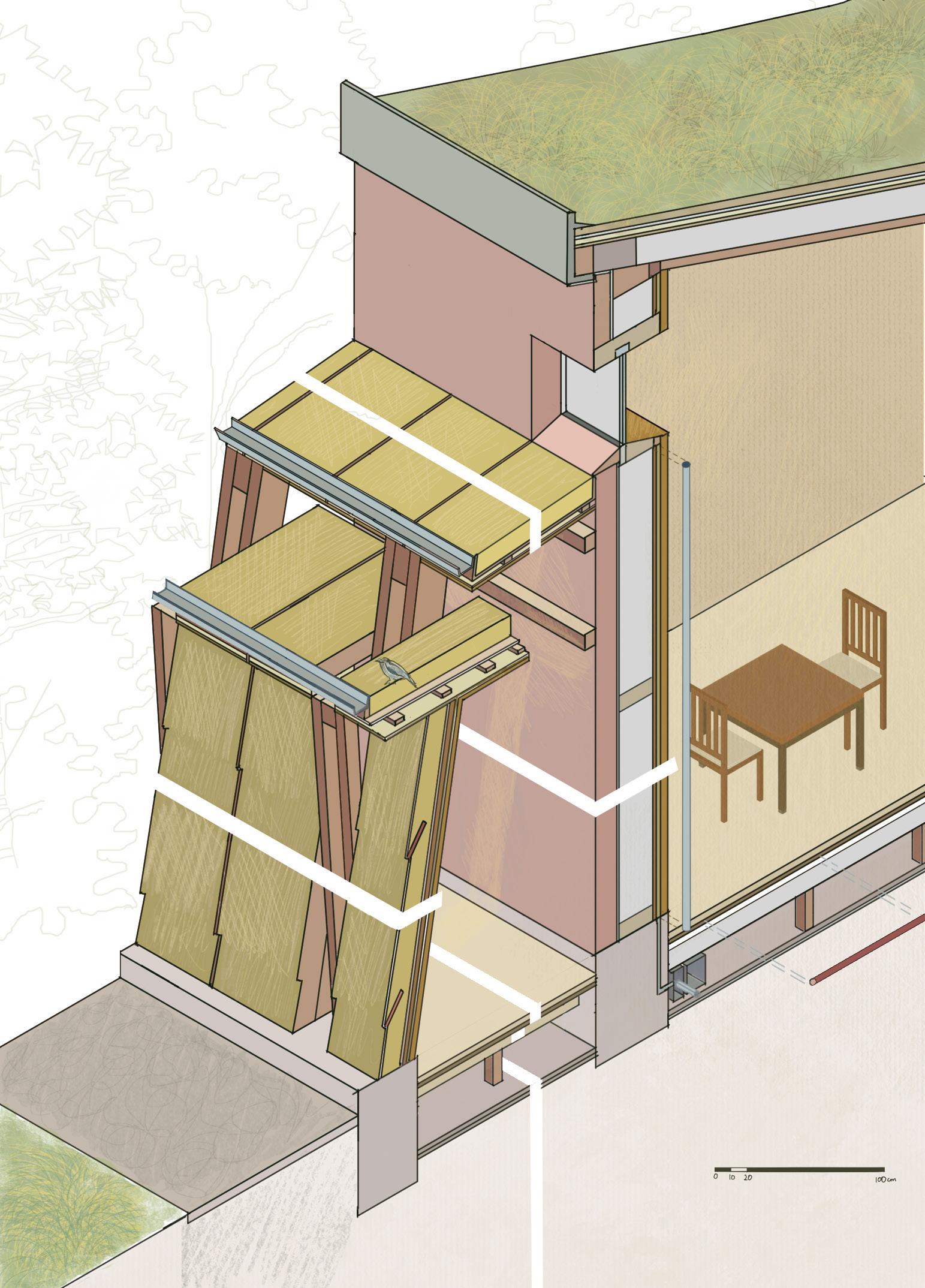

1. Thatch structure:

• 22mm clay impregenation (Prevents exterior horizontal fire spread)

• 230 mm prefabricaed thatch (using water reeds and hazel sways) on a 20mm mdf frame with clay fire stopper plates screwed in, (reduces vertical fire speread)

• 30/50mm horizontal timber battens (made with birdsmouth join to reduce screwes being used)

• 16mm woodfiber board,

• 25mm Clay plaster interior rough (prevents interior fire spread)

• 3 mm clay plaster interior fine (prevents interior fire spread)

2. Insulated wall

• 200 mm rammed earth make with recycled gravel from concrete on site, sand, silt, and clay. Silicon dioxied mixed in to balance PH levels and promote growth

• DPM

• 9 mm OSB board, 300mm sheeps wool insulation on a 300/100 timber frame, 9 mm OSB board

• Vapour control membrane

• Vertical timber battens (30/50) that creates a cavity for services

• 16mm woodfiber board

• 25mm Clay plaster interior rough (prevents interior fire spread)

• 3 mm clay plaster interior fine (prevents interior fire spread)

3. Service riser

• For electric cables, outlets, and water pipes, with fire resistan fastenings following IET Wiring Regulations (BS 7671:2018)

• Grey water goes through pipes into reed beds where they will be filtered and feed into a small habitait pont

• Rain water will be stored for reuse and for hot water ground source heat pumps will be utilised

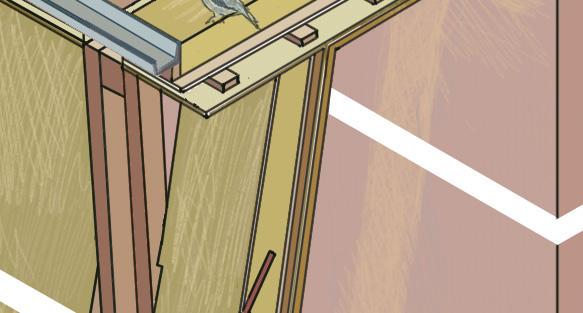

4. Wall window joint

• Wooden window sill

• DPM that extends over rammed earth wall to create a continous water barrier layer achived using a projecting rib

• TImber stud with a rammed earth block to create sealing

5. Clerestory ventilation window, double glazed no coating, 300mm/ 600mm

• Operable to create a natural ventilation path in classrooms and add both physical and psychological comfort

6. Aluminium gutter 150mm with galvanised steel rain chains to guide water down for storage. Rain chains exposes water and creaes a language from it.

7. 200/125mm glukam beams screwed into rammed earth wall

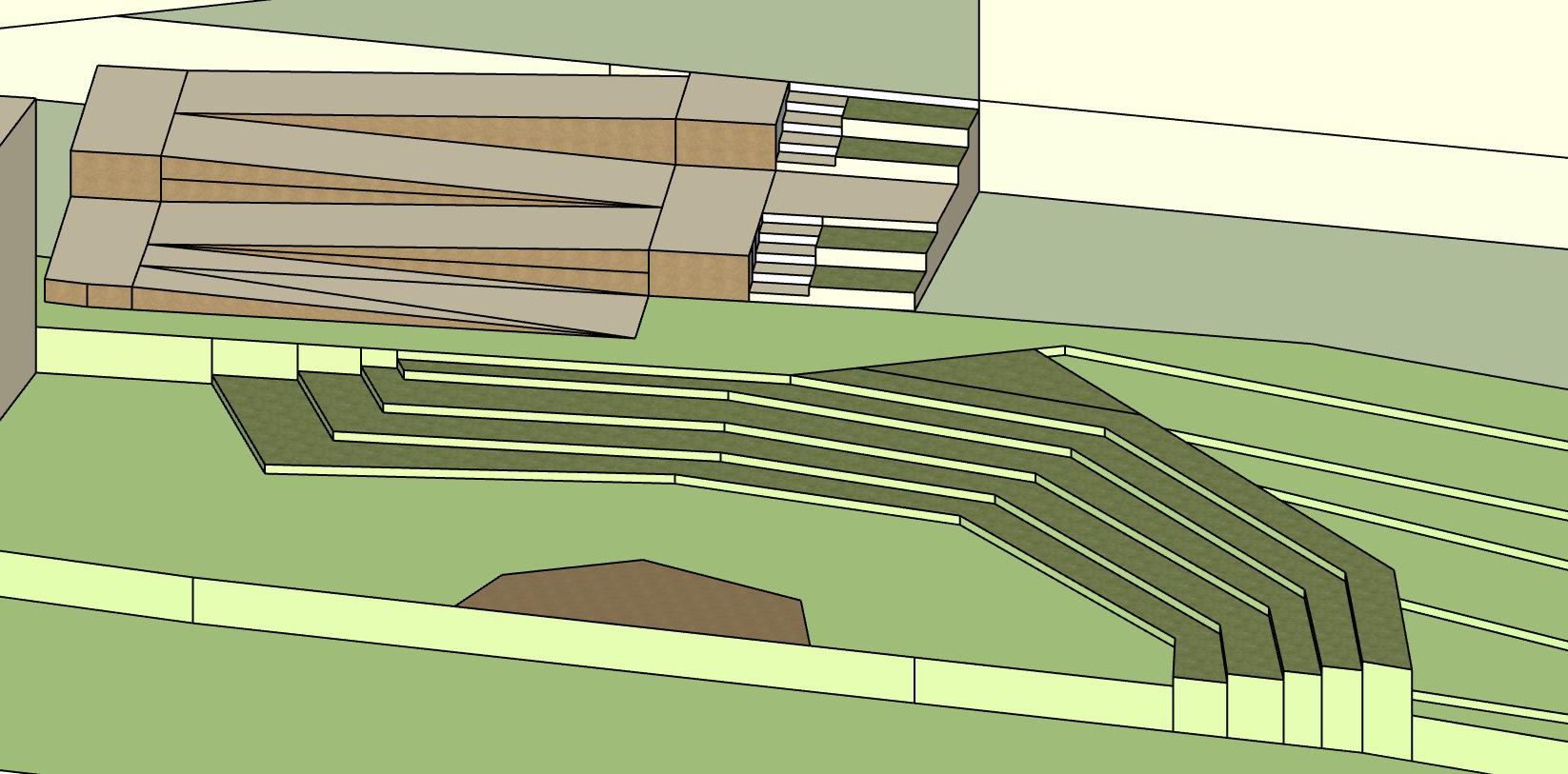

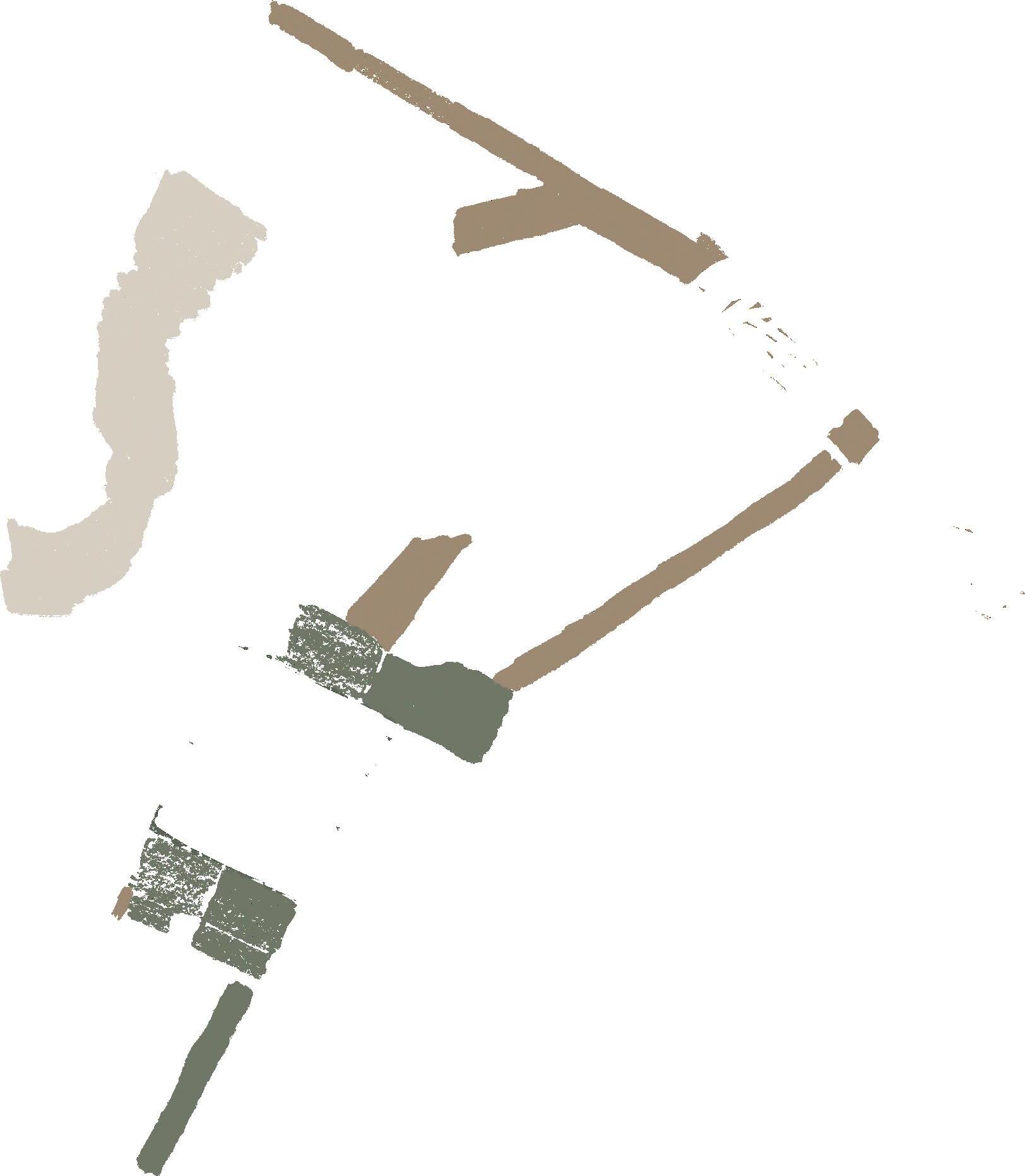

8. Prefabricated glulam timber structure made out of:

• 2 300/125 columns,

• 2 200/125 colums (vertical to join lower roof to foundation and add more stability by principles of triagnulation)

• 1 200/200 column,

• 1 300/200 column

These components are screwed in together and then transported on site.

Quality Of Light

Slits in the timber structure allow streams of light to enter the thatch corridor