66°North Impact Report 2022

66°07'44.9"N 23°31'20.1"W

2 Contents

66°North / Impact Report 3 Introduction Footprint Design Materials People & Places End of Life Milestones & Data Glossary 01 02 03 04 05 06 07 4 13 21 39 51 65 72 Contents

4 Introduction

2022 was a seminal year for 66° North. It was the year we became the first Icelandic company to receive a B Corp certification, as well as the year we launched our European flagship store on London’s Regent Street.

When we became guardians of the brand a decade ago we were very aware of our responsibility; 66°North is such a big part of Icelandic life. Almost every Icelander has something by 66°North in their wardrobe, and we had to prove to the nation we were right for the job!

Now our responsibility increases, as we reconcile international growth with our new status as a leader in the global movement for an inclusive, equitable and regenerative economy as part of the B Corp community.

66° North embodies Icelandic values, and these values are the bedrock of our approach to responsible business.

Founded in 1926 to serve Icelandic fishermen and Icelandic Search and Rescue teams battling the near-mythical challenges of the Icelandic climate - as a small island nation - our customers were our friends, family and colleagues. Our DNA began here, making high quality outerwear that was durable and repairable, to protect our community risking their lives at sea.

In our recent history resources were scarce, so making use of what we have and making it last is deeply embedded in our value system. This heritage gives us a unique perspective to share with the world and our hope is to drive a re-education through our clothing; promoting resourcefulness over waste, and durability and repair over endless consumption.

Launching our inaugural impact report this year felt right.

Now, with new European legislation on the horizon in areas such as transparent clothing labelling and greater restrictions on the use of forever chemicals, we cannot stand still. Working with our partners and creative collaborators, we are investing in the tools and innovation we need to evolve with the changing landscape.

For us, responsible business is not a destination or an end point - it’s a journey. We are already working on our B Corp recertification bid for 2025 and through this report, we want to share our progress through an honest narrative that covers all the social and environmental impacts of our business. From here, we will report year-on-year, sharing our developments and the challenges we face along the way.

Óskarsson, CEO Bjarney Harðardóttir, Head of Brand

5 North 66 / Impact Report

Bjarney and Helgi at head office, 2022

Helgi

Mission Statement

Our mission is to inspire the global community by championing Icelandic values that foster: a culture of protection - of people and environment; gender equality in business and society; a reevaluation of the role of clothes through the concept of úlpa - living with fewer garments that work harder for longer.

Introduction

“Iceland has no global consumer brand, believe it or not, but 66°North - with its history and approach to sustainability - has all the ingredients to become just that."

Bjarney Harðardóttir.

Bjarney Harðardóttir.

“

1928

We start making protective clothing for Search & Rescue teams

1926

The company was founded by Hans Kristjánsson under the name Sjóklæðagerðin to make protective clothing for fishermen Repair service launches

1951 Kids’ clothing launches

1977

2011 Helgi Óskarsson and Bjarney Harðardóttir take over the company

1930

Workwear is developed into everyday wear

1999

1972 Everyday wear is developed into fashion

Our first factory outside of Iceland is opened in Latvia

First use the brand name 66°North 1926–2013 Introduction

2016

Indestructible clothing take-back program launches in collaboration with the Icelandic Red Cross

2020

66°North becomes a member of Festa, the Center for Sustainability

We receive an Equal Pay Certification

2022

66°North becomes the first Icelandic company to receive B Corp™ Certification

66°North X UN Women receive grants from the Sustainable Development Goals Partnership Fund to create jobs for refugee women

We collaborate with Plastplan to create recycled plastic fastenings from our own operational waste

66°North x Studio Flétta collaboration recycles textile offcuts from the manufacturing of our outerwear

Erm X 66°North upcycling collaboration transforms our clothing into household furniture

2014

66°North School launches, becoming the foundation of the Academy

2019

Upcycled Collection launches, made from unsold products and leftover fabrics

We launch Glacier Friday to fundraise for glacier protection

2021

We begin growing the 66°North Forestry

We become a certified system partner of BlueSign

We start using recycled down in part of our Dyngja collection

Valdís X 66°North collaboration enables us to rethink clothing manufacturing methods

Shygirl X 66°North put sustainable fashion centre stage at The Fashion Awards with a custom-made dress using upcycled deadstock

2014–2022

Certified B Corporation ™

In January 2022, we became the first Icelandic company to receive a B corp certification, awarded to business leaders in the global movement for an inclusive, equitable, and regenerative economy. The certification demonstrates high social and environmental performance, along with transparent reporting through a publicly available online profile.

The process took two years and involved assessment across five key areas - outlined here with our scores - as well as a legal commitment to adopt a corporate governance structure that is accountable to all stakeholders (as well as shareholders). Achieving certification is not a final destination; we are already on the journey to recertify in 2025, with a target score of 120, or above, for the next assessment. This score would place 66°North among the top tier of B Corp certified businesses in the world.

Governance 9.8

Governance evaluates a company's overall mission, engagement around its social/ environmental impact, ethics, and transparency.

Mission & Engagement 2.2

Ethics & Transparency 5.1

+ Mission Locked 2.5

Workers 27.6

Workers evaluates a company’s contributions to its employees’ financial security, health & safety, wellness, career development, and engagement & satisfaction, as well as business models designed to benefit workers non-executive ownership and workforce development programs.

Financial Security 4.8

Health, Wellness, & Safety 8.6

Career Development 3.0

Engagement & Satisfaction 7.2

Customers 4.0

Customers evaluates a company’s stewardship of its customers through the quality of its products and services, ethical marketing, data privacy and security, and feedback channels.

Environment 33.1

Environment evaluates a company’s overall environmental management practices as well as its impact on the air, climate, water, land, and biodiversity. This includes the direct impact of a company’s operations, product, supply chain and distribution channels.

Environmental Management 5.0

Air & Climate 9.2

Water 3.1

Land & Life 7.2

+ Land/wildlife Conservation 0.4

+ Toxin Reduction/Remediation 6.5

Community 18.8

Community evaluates a company’s engagement with and impact on the communities in which it operates, hires from, and sources from. Topics include diversity, equity & inclusion, economic impact, civic engagement, charitable giving, and supply chain management.

Diversity, Equity, & Inclusion 5.6

Economic Impact 1.3

Civic Engagement & Giving 4.1

Supply Chain Management 6.2

Customer Stewardship 4.0

10 Introduction

Maximum score

120

(Our target score for 2025)

93.5

(Our overall B Impact Score 2022)

80

(Qualifies a business for B Corp)

““We are proud to be the first Icelandic brand to receive this distinction and look forward to continuing to build a purposedriven brand. Earning a score of 93.5 validates 66°North’s longtime commitment to doing business in a way that’s thoughtful and considerate of the planet.”

Helgi Óskarsson, CEO

50.9

(The average score for ordinary businesses)

66°North / Impact Report 11

140

Footprint

Operational Scope

While 66° North grows internationally as a company, our HQ and the majority of our stores reside in Iceland.

Since 2019 we have been reporting on our emissions and each year our scope evolves with the business - be that new hybrid vehicles in our domestic market, or opening a new premises in the UK.

The geographical footprint for our scope 1 and 2 emissions in 2022 is itemised overleaf. Some considerations to note; our US warehouse and UK store were launched very late in the year - October and November respectively. Therefore, the data from these sites will feed into 2023 reporting.

Scope 3 currently includes data for ecommerce shipments, business flights and waste (see more on page 68). We are actively investing in the systems we need to enable us to report on our whole value chain; this will include emissions generated by materials by 2024, and emissions from third party suppliers by 2025. In the interim all suppliers receive an annual questionnaire engaging them on adherence to internationally accepted environmental, social standards and compliance.

14

Footprint

Iceland

1 office

11 stores

6 electric cars

9 hybrid vehicles

2 diesel vans

Denmark

2 stores

1 petrol car

Definitions

Scope 1 emissions

Emissions from sources that an organisation owns or controls directly

Scope 2 emissions

Emissions that a company causes indirectly

Scope 3 emissions

Emissions not produced by the company itself, but are generated in its value chain

Latvia

2 factories

2 petrol cars

2 petrol vans

66°North / Impact Report 15

UK

Carbon Reporting 2022

We are pleased to report that our scope 1 emissions decreased, and our scope 2 emissions remained static, between 2021 and 2022.

In areas where we have invested resource and implemented action plans we can see positive results in the data. For example, as we develop our electric fleet, employee fuel consumption lowered and carbon emissions reduced by 26% to 171.4 tCOz over the year period. Additionally, through tighter monitoring and control of our waste intensity (see more on page 68) we have reduced our impact by 35% in 2022 to 1,345.8 kg/FTEs.

Unlike many other outerwear brands, more than half of our production emissions fall under scope 1 & 2, as we own the factories where the majority of our styles are produced.

The rise in scope 3 emissions is in line with our expectations, as between 2021 and 2022 we further expanded the scope of upstream emissions to include more business impacts. For example, this year we included employee commuting emissions into the data for the first time at a total of 92.1 tCO2.

Our scope 3 remit will continue to expand each year, as we report on a greater number of downstream emissions in the next 2023 assessment. We'll also continue to develop our suite of reduction strategies across scope 1, 2 and 3 and look forward to reporting on developments next year.

16

Footprint

2022

171.4tCO2

Scope 1

Fuel from vehicles Heating with natural gas

67.5tCO2

Scope 2

Electricity Heating Water

609.1tCO2

Scope 3

Business travels Sorted waste in HQ and selected stores

Transportation and distribution

848tCO2

(Total operational GhG emissions)

2021

Scope 1, 230.7tCO2 Scope 2, 60.3tCO2 Scope 455.3tCO2 Total, 746.3tCO2

Our Path to Net Zero

Product efficiency & circularity

Better waste management

From design through to end of life, we produce clothing in a way that minimises environmental impact. On average around 70% of our collections are made with recycled materials (fully or partly) and we actively participate in material innovation through our partners Gore and Polartec, and varied collaborations. We focus on timeless designs and multi-purpose products that last a life-time, constantly exploring ways to reduce our inventory. We avoid over-production through careful product control in our factories and never participate in Black Friday. We have a strong track record for resell in our home market, and we're exploring rolling this out to market worldwide. 98% of our products are repairable and we take-back worn out garments through our ´Indestructible´ program in partnership with the Red Cross.

This year we signed an agreement with plastic recycling and waste management system, Pure North. This involves a comprehensive waste audit and action plan for all our facilities with the aim of rescuing waste; increasing recycling rates; ensuring a better quality of raw materials generated in our day-today operations, and making sure our waste is disposed of using the right channels in a transparent way.

Active reduction of emissions

We run our headquarters and the majority of our stores on clean energy. Outside of Iceland, we use 78.9% renewable energy in our owned operations and are working hard to increase this. We annually report on our carbon emissions and are exploring ways to reduce our footprint, like developing our hybrid and electric vehicle fleet, and adding solar panels onto the roofs of our two Latvian factories during 2024/5. We have also been transitioning to LED lighting across all of our operations. Our stores are already converted, and our target is to be 100% LED across the business by 2025.

18 Footprint

0

Working with suppliers to address impact Educating employees and customers

Every year we send out a questionnaire to our supplier network to engage them on continuous improvements and adherence to internationally accepted environmental and social standards and compliance. This includes a safe and healthy work environment as well as environmental and social responsibility. The purpose of these questionnaires is to establish a measurable path within the company’s supply chain, identify gaps, and offer education and share best practice.

We regularly educate about the importance of reducing waste, recycling, and other sustainable practices. This can include training employees to sort waste correctly or encouraging them to use public transportation, carpooling, or bike to work. We also use our social media to widen the reach of our sustainability ethos and messaging.

Accounting and reporting

We have been using the Klappir Sustainability Platform since 2019 to collect and process environmental, social and governance data across the company’s value chain to facilitate transparent sustainability accounting and reporting.

This helps us keep a close track of our resources with real life data and set action plans for improvement where it is needed. For the year 2022 we have purchased third party certified credits to invest in carbon removal through our partner Klimate to offset unavoidable emissions. This will cover all of scope 1 and 2, and will include soil sequestration (13.4%) and forestation (86.6%) methods, supporting high quality agroforestry, afforestation and reforestation projects.

About Klimate

Founded in 2021 Klimate is a climate tech start up providing access to high-quality, innovative, and verifiable carbon removal solutions aligned with science. Their core purpose is to scale and accelerate the development of carbon removal methods and technologies needed to achieve the targets set forth by the Paris Agreement.

What is carbon removal?

Carbon Removal refers to a suite of activities that lower the concentration of CO2 in the atmosphere. This is done by removing CO2 molecules and storing the carbon in plants, trees, soil, geological reservoirs, ocean reservoirs or products derived from CO2.

66°North / Impact Report 19 0

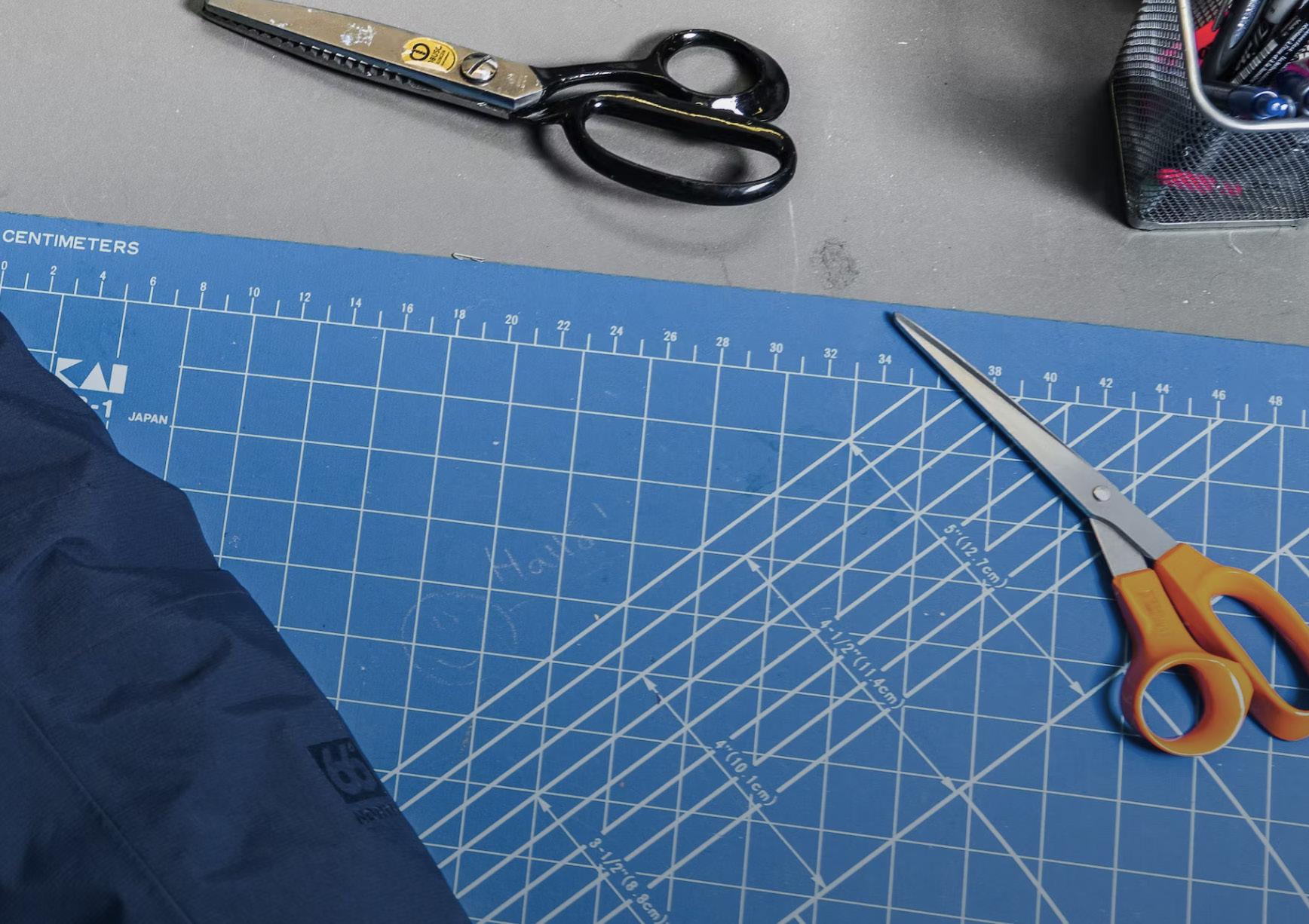

Design

Design Philosophy

Since 1926, we have been creating quality, repairable garments that are versatile in use - made to withstand the most challenging conditions. Nearly 100 years on, our approach to designing outerwear is unchanged.

Historically in Iceland, over-consumption has largely been a foreign concept. In our recent past, simply staying alive was a struggle and resourcefulness (using what you have and making it last) is ingrained in our culture.

Here, everyone has an úlpa; a single jacket that, whatever the weather, ensures you are ready for anything. We wear the same jacket up a mountain as we do out in the city; and treasure our úlpa for a number of years, often passing it down through the generations.

This is why we specialise in multi-purpose garments, like our 3-in-1 Tvioddi, or multisport shells like Snaefell which are suitable for cycling, skiing, or hiking, kayaking and other outdoor activities. Our best-selling shell jacket, Snæfell Neoshell Jacket, was introduced back in 2010, and it still looks exactly the same as when it was first made.

Nothing makes us happier than when we see someone in a 20 year-old-plus 66˚North jacket, whether that’s in the Icelandic highlands, on the streets of London, or in our offices.

Our challenge today is to take the concept of úlpa to the world, and encourage a cultural shift in the way we relate to clothes: living life with fewer garments that you love and not buying more than you need. We are proudly part of the slow fashion community, turning the tide on mass consumerism.

Úlpa is an Icelandic cultural and social relationship to one’s «jacket», it broadly means a piece protective clothing (often with hood).

22 Design

Úlpa [oul-pa]

ANYWHERE IN THE WORLD

KEEPS YOU WARM AND PROTECTS YOU

YOUR COMPANION FOR LIFE

UP A MOUNTAIN OUT IN THE CITY AT WORK

PASS ON THROUGH GENERATIONS

66°North / Impact Report 23

November 25th 2022

Glacier Friday

25% of all online sales fund the proteciton of glaciers in Iceland

We never participate in Black Friday. In 2019 we started a tradition of donating a percentage of sales on this day to environmental protection in Iceland. Icelandic glaciers are one of the reasons we exist as a company, and since 2021 we have partnered with the Icelandic Glaciological Society to support research on Iceland’s disappearing glaciers.

Design

Made to last Limited style count

Our designers’ primary goal is marrying a garment’s purpose with longevity. Durable clothing stays in use for longer, merits repair and can be passed on through the generations. Before any of our clothing is manufactured, it is designed and tested in Iceland by our outdoor community of trained mountaineers and rescue team members.

98% of the products we make are repairable, and we have been running a repairs service for our customers since 1926.

The creation of new styles — from design, technical specification development, sampling, preproduction, and production -- is one of the most wasteful parts of manufacturing.

Between 2018 and 2022 we reduced the number of product styles we produce by 42%.

Because we design products which are multi use with a timeless aesthetic, we are able to keep the variety of styles low, many of the which have been around for more than a decade. Each year we make subtle performance or sustainability improvements, rather than overhauling designs, to reduce environmental impact.

Responsible production volumes

For many clothing brands and retailers, overproduction is a business strategy that fuels Black Friday events.

Our aim is not to produce more than our customers need. We plan to sell 90% of our products at full price and manage our production volumes according to this goal.

What’s left over fills our Icelandic outlet store, is donated to a charity partner or goes back into the

2019 – 25% of online sales from Friday-Monday, totalling £15,000 went to Landvernd, The Icelandic Environmental Association

2020 – 25% of online sales from Friday-Monday, totalling £29,500 went to Votlendissjóður, The Icelandic Wetland Fund

2021 – 25% of online sales on Friday, totalling £9,500 went to Jöklarannsóknafélag Íslands, Iceland Glaciological Society

2022 – 25% of online sales on Friday, totalling £13,000 went to Jöklarannsóknafélag Íslands, Iceland Glaciological Society

66°North / Impact Report 25 Designing Out Waste

Reinvention through collaboration

GANNI 2019 - Current

Sölvhóll, 2021

Founded in 2000, Danish fashion label GANNI has developed exponentially over recent years with its Scandi 2.0 sense of style - full of personality, contrasts and experimentation. Infused with the Nordic heritage of both brands, GANNI X 66°North produce functional outdoor clothing for women with a unique aesthetic.

Handmade in Iceland in limited quantity, the Sölvhóll bum bag was designed to salvage shearling off-cuts leftover from the production of the Sölvhvóll coat. All shearling used by 66°North is an ethically sourced byproduct from family farms in Iceland. Until modern fabrics were created in the 20th century, it was the only source of protective clothing in Iceland and we regard it as a heritage fabric to preserve.

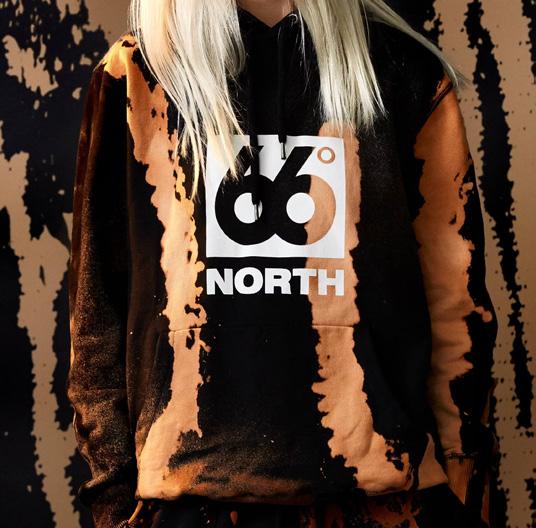

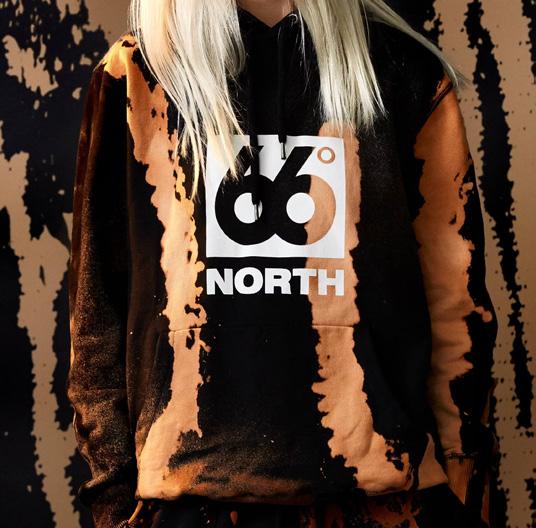

Bergur Gudnason, 2019

Kria, 2020 – Current

Our circular design approach involves testing new ideas, and exploring new uses for waste materials within our collections. We have become known for collaborating with like-minded brands and creatives to push the boundaries of what’s possiblewhether that’s creating something original from unwanted offcuts, experimenting with recycling materials, or trialing innovative design processes. Here we share products and partnerships that have defined the last 5 years.

We partnered with designer Bergur Gudnason to create a capsule collection of upcycled hoodies and sweats. With no two designs alike, the reworked cotton pieces were either merged together, bleached or even embroidered with brand embroideries dating back to the early 90s.

"My idea was to inspire people and emphasize - we don‘t always need to buy new things. We can use what we have and still make something new and exciting out of it."

— Bergur Gudnason, Designer

"The Kria Collections represent 66°North‘s design values: highly functional and technical, yet playful and eye-catching. Kria embodies our commitment to circularity and zero-waste, going beyond the use of leftover fabrics, to encompass how a jacket is made to last for decades - from a durability, performance and style standpoint."

— Rakel Sólrós Jóhannsdóttir, Designer

26 Design

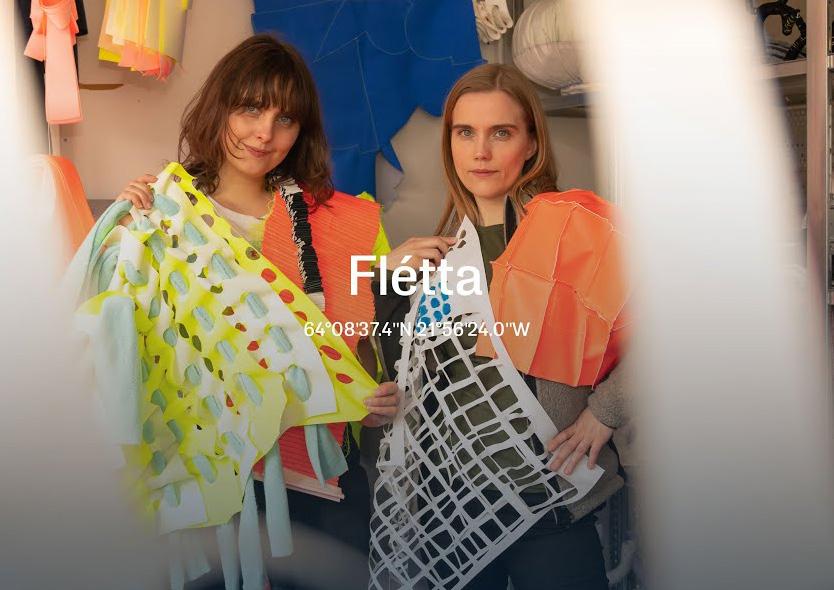

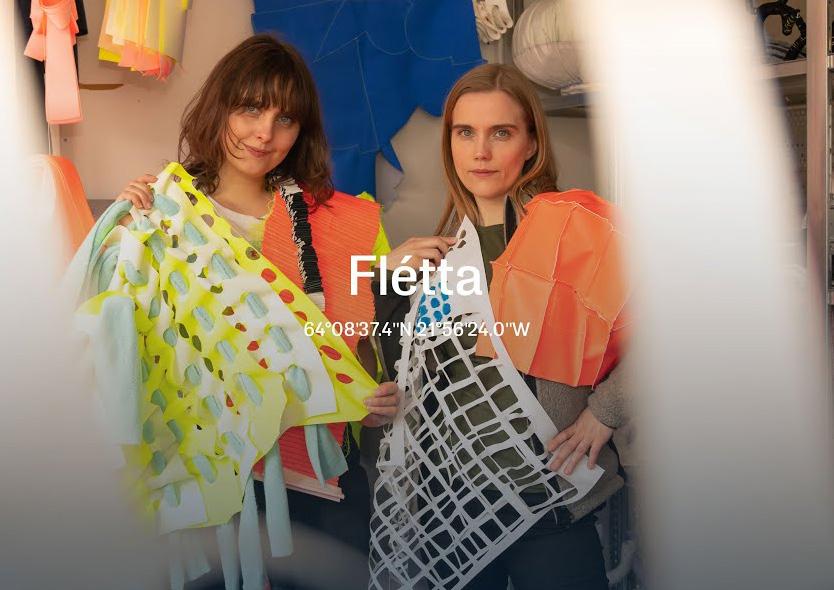

Studio Flétta X 66°North

Designers Birta Rós Brynjólfsdóttir and Hrefna Sigurðardóttir founded Icelandic design studio Flétta at the beginning of 2018, having worked together on projects related to recycling and upcycling waste materials since 2014. In Flétta’s hands, materials and objects that have served their purpose and are no longer ‘useful’ in their previous role are given new life in a new context.

In March last year we teamed up with the duo; they selected textile offcuts from the production of 66°North clothing for experimentation - melting, sewing, and wrapping fabric together in different ways in search of the right context for the textiles. The collaboration culminated in an exhibition that conveyed their playful and experimental approach to material research, inviting the public to observe this design process, often hidden from public view.

28 Design

MARCH 2022

Valdís Steinars X 66°North

Valdís Steinars is an independent Icelandic designer, who uses recycling and organic matter in her practice.

We joined forces with Valdís to explore a new model for making clothes enabling us to stop and rethink our current clothing manufacturing methods. Her approach uses a two-dimensional mold to shape the clothing with natural liquid material, instead of cutting and sewing. This technique eliminates excess scraps, using the exact amount of material needed for each garment, allowing manufacturers to measure with millimeter precision, rather than meters.

Our collaboration was exhibited at Design March 2022 and provided a window into the possibilities that exist in this exciting area. The project has since received a grant to take it to the next level and we are supporting Valdís in this development. Stay tuned for the next chapter.

30 Design

MARCH 2022

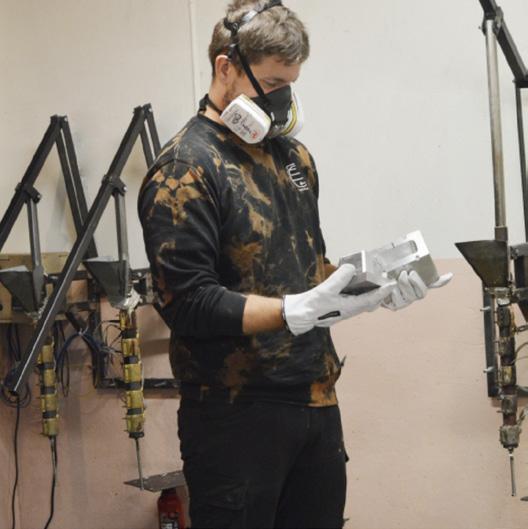

Erm X 66°North

We worked with designers Arnar Ingi and Valdis Steinars to explore how the life cycle of a product could be extended by giving it a new life beyond its original role.

How can a puffy coat become a chair? And can it become something else after that?

Erm (Icelandic for “sleeve”) aimed to creatively transfer an object’s intended purpose between categories, from a wearable clothing item to household furniture. The project was an examination of how product categorizing can be used as a starting point instead of a restriction when designing innovative solutions for discarded products.

Damaged and non-repairable coats and parkas from 66° North were given a new life and became chairs that could be re-fitted again and again. Made from a single metal rod covered with sleeves of discarded material, the chairs are the first outcome of an ongoing exploration of how upcycling can be achieved between product categories, tailored by Nína Guðrún.

32 Design

MARCH 2022

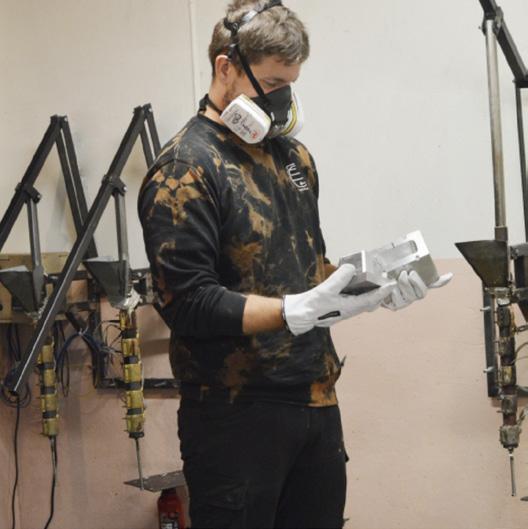

PlastPlan X 66°North

Icelandic design studio and recycling company Plastplan is no stranger to partnering with progressive companies like 66°North to expand their application of innovative solutions in plastic.

Last year, Plastplan designed and developed a 66°North snap buckle along with musician and product designer Logi Pedro. Each snap buckle was produced from plastic that had been recycled and collected from our operations, creating a valuable circular solution for the plastic by-product in our manufacturing.

The buckle was used on the classic 66°North Bum Bag which is made from leftover fabric and continues to be retailed, with plans to make this a permanent collection.

34 Design

MARCH 2022

Shygirl X 66°North

In December of 2022, English artist Shygirl brought a part of Iceland to the stage at The Fashion Awards during her performance, wearing a custom-made dress crafted using upcycled deadstock.

Building on our long-term sustainability commitment to never throw away product or materials, the coat was handmade by our design team in our studio in Iceland, using over 40 Dyngja down jackets.

After it was premiered at The Fashion Awards, the dress was displayed in our stores in London and Reykjavik for 4 weeks, and will eventually be donated to a special cause.

36 Design

MARCH 2022

Materials

Material selection & sourcing

The materials we choose are a direct response to our design approach. We select durable fibres and fabrics to make garments that last - minimising harm to the environment and best serving our customers. We would rather make a garment that can be worn for a decade or more, than a more short-term “sustainable” alternative that might break down after two or three years, creating waste and driving consumption.

Alongside this, we are constantly testing and experimenting, working with leading partners and certification bodies - ready to explore the newest and the best options on the market that deliver high performance and least impact. As a company, we are really open to innovation and this approach has served us well; gathering information from experience overtime.

55% of the SS22 collections are made with preferred materials (43% in 2021)

We are committed to working with respected suppliers that deliver outstanding quality, sourcing materials that are certified and traceable wherever possible. We are actively expanding our use of preferred materials, including organic, natural materials, recycled and PFA-free fabrics.

Our ambition is to be transparent with our customers about our raw materials and their origins, and in 2024 we are investing in material data systems to unlock greater insights and measurements to enable more detailed reporting. This will form the database for our customer product labelling to ensure we are in step with legislative changes in the area.

What is a preferred material?

A fibre or raw material that delivers reduced impacts and increased benefits for climate, nature, and people against the conventional equivalent.

40 Materials

Cotton

All of our cotton styles are made with organic Global Organic Textile Standard (GOTS) certified cotton.

95-100% of the cotton we use is grown in India, and the remainder comes from Turkey. Since 2014, all of our cotton production is carried out in Porto, Portugal.

(GOTS) is an international processing standard which means that it regulates the manufacturing stages of the textile supply chain such as the ginning, spinning, knitting/weaving, cut, make & trim for traders and retailers. The standard stipulates requirements for both ecological and labour conditions in addition to ensuring the integrity of organically produced raw materials.

Why organic farming is better for people and the planet?

Organic farming builds healthy soils which sequester carbon and helps to mitigate climate change. Healthy soils act like a sponge, soaking up water during floods and holding it for longer in times of drought. Hazardous synthetic pesticides and fertilisers are banned in organic farming, so rivers, lakes and drinking water are kept cleaner too.

Organic farmers always grow other crops alongside their cotton, which encourages wildlife and protects topsoil, as well as delivering social benefits for cotton farmers, providing more stable, accessible and abundant food supply and income for their families and communities.

Conventional cotton alone is responsible for 16% of all insecticides sold worldwide that damages ecosystems, poisons waterways and endangers workers. Organic farmers use natural methods like crop rotation to control pests and diseases. Genetically modified (GM) seeds are banned, so organic farmers are not reliant on powerful GM companies. Instead, they use their seeds year after year, working with the environment in a long-term, enriching way.

41

NATURAL FIBRES

Down

All down used in 66°North products is from our long-term partner in Germany who holds certificates for the Responsible Down Standard, Downpass and The OEKO-TEX® Standard 100. The standards guarantee a chain of custody from farm to final product and uphold The Five Freedoms in animal management, ensuring the welfare of birds and geese from hatching to slaughter. Force-feeding is prohibited as well as the removal of down or feathers from live birds (live-plucking or moltharvesting).

We have been purchasing certified down since 2011, and 43% of down styles from our AW22 collections are made with recycled down, which also meets the Global Recycling Standard.

42 Materials

NATURAL FIBRES

Wool

All the merino that features in our core collection is sourced from New Zealand and meets the Textile Exchange’s Responsible Wool Standard that guarantees: animal welfare protection in line with The Five Freedoms; land health preservation that protects soil health, biodiversity, and native species; social welfare protection, working conditions, and the health and safety of workers.

We produce the majority of our wool garments, including our 100% lambswool styles and our merino wool, base layer Básar, in China.

Some styles, like Ögri, Askja and our workwear heritage Dyngja sweaters, are produced in Portugal and Romania.

For some special lines like the Sölvhóll shearling collection, Dyngja wool capsule and Kaldi Gore Jackets (new for 2022), we use Icelandic sheep breeds from traditional Icelandic farms.

A closer look into the manufacturing process of our Kaldi Gore Jackets:

1. The yarn used for the outer layer is grown and spun in Iceland

2. The yarn is shipped by us directly to our producer in China where it is knitted into wool fabric, and then washed and boiled to become felted

3. The fabric is cut and sewn into the Kaldi Gore jacket (the Gore stands for the windstopper lining used inside the jacket)

The finished garment is shipped back to iceland. *Currently in Iceland we do not have a factory that can convert the knitted fabric into boiled wool at the scale needed for garment manufacturing; we are looking into solutions closer to home.

Icelandic Wool

This hardy wool is ideally suited to outerwear as the fleece has evolved over 1100+ years to be optimal for the unpredictable Icelandic weather, maintaining favourable body temperature (for sheep and people!). Icelandic sheep farming uses non-intensive, traditional farming methods that prioritise animal welfare, careful land management and heritage grazing techniques.

66°North / Impact Report 43

NATURAL FIBRES

Performance Materials

70% of the SS22 collections are made with recycled materials (40% in 2021)

There are trade offs involved with recycled synthetics. Their processing creates environmental impact and they release microfibres, in the same way virgin does.

“Our approach is that of Scandinavian pragmatism. Instead of diving in headfirst for an easy sound bite, we strive to best serve our customers and be respectful to our planet at the same time. We often don’t pick fabrics that are 100% recycled, maybe they’re 80% recycled as keeping some virgin fibres in there is going to increase the durability and lifetime of the product.”

- Guðbjörg Jakobsdóttir, Apparel Designer

A large part of our performance material is sourced from Polartec and Gore-Tex and we follow their lead on industry best practice in synthetic performance fabrics. Both companies are actively investing in innovation to reduce the impact of their materials.

All of our recycled materials meet the Global Recycling Standard from Textile Exchange.

44 Materials

Forever Chemicals

We take our responsibility for the environment and human health seriously and are following the lead of our partners Gore-Tex and Polartec in the removal of harmful PFAS (perand polyfluoralkyl substances) in our clothing.

All of the performance fabrics we source from Gore-Tex and Polartec are OEKO-TEX® and Bluesign® approved and we are privileged to be sharing our partners’ journey in this important area as one of their selected suppliers.

A challenging factor is our procurement process as it typical to buy performance fabrics 1 to 2 years in advance. Despite this, many of our products are already PFA-free and those that are not, are in planned phase out.

Why are PFAs called “Forever Chemicals”?

Because of how PFAS are constructed—using a chain of carbon and fluorine atoms, which is one of the strongest chemical bonds possible—they do not break down in the natural environment, thus earning the nickname.

66°North / Impact Report 45

Polartec

Over the company’s 30 year history, Polartec has established itself as the world’s foremost innovator of performance fabrics engineered for all conditions. The brand’s dedication to environmentally sustainable products continues to push the market forward.

From inventing the process of turning post-consumer plastic into performance fabrics and leading the use of recycled content across all categories––to innovating products with non-PFAS DWR treatments and leading the way in circularity––sustainable science is the innovation force behind the brand, keeping them ahead of the curve in legislation.

In 2021 Polartec announced the elimination of PFAS in its DWR (durable water repellent) treatments across its line of performance fabrics. Their in-house engineered non-PFAS treatment, offers zero loss of durability or water repellency, is the latest in Polartec’s growing EcoEngineering™ initiative.

In 2022 they launched a proprietary solution constructed from all non-PFAS polymers and plant-based building blocks that do not compete with human food sources. At the center of Polartec Power Shield’s revolutionary functionality is a major advancement in membrane technology. The highly durable monolithic membrane is a barrier specifically engineered to be impermeable to outside weather, while transporting moisture vapor from skin-to-surface via molecular diffusion.

“It is our commitment to reduce reliance on petroleum while producing a membrane that offers greater water-resistance performance than we’ve ever brought to market,” said Former Polartec President, Steve Layton

46 Materials

Gore–Tex

Founded in 1969, Gore-Tex is synonymous with waterproof outerwear. Their sustainability journey aligns with the SDGs and ecompasses:

Protecting people and planet combined with prolonging product life, Gore delivers performance to the benefit of the environment, individuals, society and its business. They see this as performance redefined – beyond technical product features and financial results. Gore is committed to measure its performance by these abilities.

Gore Fabrics Division 2022 status on Forever Chemicals

• On track to eliminate PFCEC from laminates that correlate with 100% of finished consumer product units (jackets, shoes, gloves and accessories) by 2025

• Over 80% of their general outdoor and lifestyle product portfolio utilizes PFC-free DWR, and they continue to pursue opportunities to expand deployment where it can meet requisite performance and durability requirements for intended end-use. further develop these new materials.

• Gore has developed new PTFE membrane prototypes for fabrics that no longer require PFCEC in manufacturing. Work continues to further develop these new materials.

• Gore is pursuing the development of new materials at pace, currently focussed on ePE, an entirely new membrane material platform for consumer applications. The first products were launched in 2022.

• Gore is exploring end of life impacts, and recently commissioned the Technical Chemistry at the Karlsruhe Institute for Technology to conduct a PTFE incineration study.

Straumnes and Skaftafell Windblockers are PFA free, Bluesign and meet the OEKO-TEX® 100 standard.

47 66°North / Impact Report

Packaging

We recognise the impact that packaging can have on the planet and have implemented a four-step strategy to reduce our environmental footprint in this area.

Since 2020, all of our shopping bags and packaging have transitioned from plastic to 100% environmentally friendly recyclable paper bags, made from responsibly sourced paper that carries the Forest Stewardship Council (FSC) certification. This certification guarantees that the wood used to produce the product comes from forests that are sustainably managed. In FSC-certified forestry, no more trees are cut down that can be replaced, allowing the forest to regenerate. Moreover, FSC certification ensures the protection of animal and plant life, and that forestry workers receive adequate equipment and fair wages.

All of our packaging is sourced from Embacollage who are pioneers in circular packaging solutions. Our reusable bag, pictured, is crafted using recycled plastic materials, and we are currently exploring the use of compostable packaging, and will continue to report on our developments.

48 Materials

share our commitment to sustainability 4 Use 100% reusable, recyclable and/or compostable packaging 3 Encourage customers to recycle and reuse 2 Reduce packaging waste by optimising packaging size 1

Partner with sustainable suppliers who

49 66°North / Impact Report

People & Places

Gender Equality: Iceland as a case study for the world

We are proud to be acknowledged as one of the world’s most gender equal countries. Supported by an extensive welfare system, Iceland also has extremely low inequality, which has allowed the nation’s creativity to thrive. Our team is a product of this cultural and political landscape, and we count world-class designers and innovators in our team and network.

Our company ethos and management style reflects Iceland’s gender and human rights laws, which are also echoed in the joint ownership of 66°North by husband and wife team Helgi Óskarsson and Bjarney Harðardóttir.

In 2022, 63% of management positions are currently held by women, with women making up 80% of the total workforce.

52 People & Places

Our Equal Rights Program

Our policy is prepared in accordance with Act No. 150/2020. The Equal Rights Committee, which operates within the company, supports management and ensures that the policy is followed.

Efforts will be made to ensure that the gender ratio in management positions, departments, and stores is as equal as possible.

Emphasis is placed on flexibility in work and the balance between work and personal life.

There are equal opportunities for career development, vocational training, and education.

Snapshot of Iceland’s gender policies and laws

• Women’s equality is protected by law

• 'Equal Pay For Equal Work' is mandatory

• The boards of larger companies must include at least 40% women

• Iceland has one of the best parental leave policies in the world

• From preschool to college, children learn that gender equality matters

• There is a ‘Ministry of Gender Equality’

Bullying, gender-based violence, genderbased harassment, and sexual harassment are not tolerated.

Job satisfaction, work facilities, and accessibility are exemplary.

Equality exists in the company as a whole, regardless of gender, national origin, religion, age, place of residence, sexual orientation, race, or other.

53

1 2

4 3

5 6

66°North / Impact Report

UN Women Iceland and 66°North, in cooperation with the Ukrainian artist Iryna Kamienieva, who arrived in Iceland following the Russian invasion into Ukraine, designed a t-shirt with all profits from sales going directly to UN Women’s projects in Ukraine.

The t-shirt is decorated with a combination of traditional Vyshyvanka patterns and a poem by the Ukrainian poet Lesia Ukrainka. The pattern carries a strong symbolical meaning as it's believed to have the power to protect its owner from all harm.

The poem is a manifest of hope, stating the desire to live, smile, and work despite the bitterness of life and any difficulties that appear on the way.

The project’s objective was not only to raise funds for Ukrainian women and girls, but also to raise awareness of the importance of gender-responsive assistance and services for women refugees, and women’s participation in peace negotiations.

54 People & Places

66°North X UN Women Projects

It was a real pleasure to see this partnership become a reality and it would not have been possible without support from the Sustainable Development Goals Partnership Fund. 66°North has always had equality and sustainability at the forefront, with the circular economy as a guiding principle for the business. Through this project we are supporting the empowerment of refugee women, while at the same time putting these principles into practice.”

Bjarney Harðardóttir

In 2022, 66°North and UN Women also received grants from the Sustainable Development Goals Partnership Fund to cooperatively develop a job creation project for refugee women from developing countries in Turkey. Þórdís Kolbrún Reykfjörð Gylfadóttir, Minister for Foreign Affairs and International Development Cooperation, and Bjarney Harðardóttir from 66°North, signed an agreement for a grant of over £175,000 from the Ministry against an equivalent contribution from the company.

The project aimed to create jobs for women fleeing Syria, Afghanistan, and Iraq. They received training in clothing manufacturing, with financial independence as a core principle. They learned to reuse materials and thereby strengthen the circular economy within the SADA center that houses them.

This cooperation project is the first of its kind in Turkey, and UN Women in Iceland will be contributing to the project and monitoring it.

Minister Þórdís Kolbrún stated that the contribution of 66°North and UN Women in Iceland illustrates what companies and civil society organisations in Iceland are capable of when it comes to development cooperation.

“Most of the refugee women have lost their spouses and are the breadwinners of their households. They are in distress and their rights are limited. This project generates revenue for the ongoing activities of the SADA Centre, which is their sole source of revenue, support network and shelter,” stated Þórdís Kolbrún at the signing of the agreement.

66°North / Impact Report 55 “

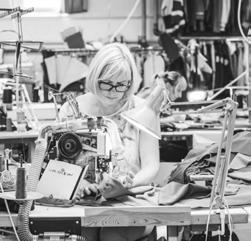

A look inside our HQ

“We know that great employees are a company’s most valuable resource. We believe in giving talented people, of all ages, career opportunities, and recognise the importance of a work environment that supports personal development and a healthy work life balance."

66°North Academy

Our Academy creates space in the working day for employees to grow their knowledge and take care of their health. This is achieved through a varied schedule of activities and courses that promote both physical and mental health, including yoga, hiking, meditation, and self-empowerment.

Inside the offices of 66°North, natural colours, textures and plenty of natural light create a relaxed atmosphere. A large canteen space is often alive with the hubbub of children visiting their parents for lunch. You’ll also see faces that have worked at the company for decades, often working their way up from the shop floor.

For Bjarney and Helgi, their team’s participation in shaping the company’s future is extremely important to them. The company holds an annual event where all employees come together, and brainstorm as a team about how to go further as a workplace, and as a company.

The results from these meetings have been utilized in formulating some of our most important strategies, including our sustainability strategy.

56 People & Places

“

HR Performance 2022

Internal and external HR assessments ensure that our peoplecentered approach is lived in real terms by our employees. We are pleased to say, the stats speak for themselves. However, we do not take our high social standards for granted and continually monitor and review our performance.

We conduct an annual employee satisfaction survey provided by VR, the largest union in Iceland, with the aim to improve our employee satisfaction from year to year.

HR Monitor is like a heart rate monitor that measures how healthy the company is in real time, every month. We conduct a monthly employee satisfaction survey that spans our teams in Iceland and Denmark.

We listen and track what our employees have to say to improve our work environment and engagement. Every month we view the results with our staff and managers to celebrate the good and we react to any improvements needed.

HIGH

CLIENT

TRAINING & DEVELOPMENT, 4.41 ENTHUSIASM, COMMITMENT & RESPECT, 4.51 LONG-TERM ORIENTATION, 4.46

STANDARDS, 4.54 JOB SATISFACTION, 4.31

RELATIONS, 4.62

66°North / Impact Report WAGES 3.40 OVERALL RATING 4.38 WORKING CONDITIONS 4.05 MANAGEMENT 4.52 FLEXIBILITY IN WORK 4.40 WORKING SPIRIT 4.54 COMPANY IMAGE 4.63 PLEASURE AND PRIDE 4.53 EQUALITY 4.66 INDEPENDENE IN WORK 4.57 RESPONSE RATE 50-59%

EMPOWERMENT,

SUPPORT FROM MANAGERS, 4.45

4.41

57

Out in the Community

Ambassadors

Every year we sponsor young athletes and artists to help them reach their personal goals and unlock their talent. This year was no exception, and it was a pleasure to support athletes Þorbergur Ingi Jónsson, Elísabet Margeirs and Sara Björk Gunnarsdóttir, as well as artists Laufey Lin, Kaleo and Celebs from Suðureyri.

Tree planting

In early October 2021, our team and their families got together at the 66°North forestry and planted over 2000 trees. The effort was a part of a larger initiative with a target of planting 11,000 trees over the next five years. This year we sustained our efforts with another 2000 trees going into Icelandic soil - well done team!

Internships

66°North has a rolling internship programme for business students, art students and technical students at university level. Internships are an invaluable way to provide students with real industry knowledge, and this year we welcomed 6 interns on placement, two of which progressed to permanent employment.

Donations

As an apparel brand we recognise we can do a lot of good with the products we make and every year we use our clothing to help those in need. In 2022 we produced a Ukraine T-shirt and through this initiative, raised £25,554 for UN women.

58 People & Places

66°North / Impact Report 59

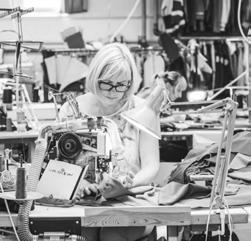

A look inside our owned and operated factories...

60 People & Places

We are incredibly fortunate to make the majority of our clothing in factories that we own, giving us direct control over our footprint and social and environmental management. This is very unusual in our sector where the majority of brands rely on third party facilities.

61% of the styles we sell are manufactured in our European factories, in Latvia. Through our close relationship with our Latvian factories, we have the great advantage of knowing each step of our production processes - from material inputs, to product management and traceability. Both factories are visited every 8 weeks by our production team as well as visits from our design and development teams throughout the year.

Our facilities are run under EU regulations relating to labour laws and workplace health and safety.

66°North / Impact Report 61

(Knitwear)

Porto, Portugal

(Down)

Povoa de Varzim, Portugal

(Accessories)

Borås, Sweden

(Wool & Accessories)

Campina, Romania

(Down)

Nantong, China

(Wool)

Hong Kong, China

62 Section Name People & Places

World supplier network

The next best thing to owning your own factory, is working with longstanding, trusted suppliers. We have known all of the suppliers who produce the remainder of our lines for a decade or more, in all cases. We only work with partners that ensure employee well-being and follow the labour, health and safety regulations of their own country.

All suppliers receive an annual questionnaire to engage them on continuous improvements and adherence to internationally accepted environmental and social standards and compliance. This includes a safe and healthy work environment as well as environmental and social responsibility. The purpose of these questionnaires is to establish a measurable path within the company’s supply chain, identify gaps and offer education and share best practice.

We are also working hard to strengthen our auditing of third-party suppliers. Currently auditing and inspection relates primarily to product quality. Portugal: Both factories undergo an external audit when production takes place

Sweden and Romania: Ad hoc auditing

China: Ad hoc auditing with additional quality control inspection

63

End of Life

(Start of another)

Repair

Our design philosophy, outlined earlier in the report, reduces waste at the design stage - through garment longevity, multi-purpose use and avoiding over production.

98% of our products are also repairable.

Our clothing repair service has existed since the company was launched in 1926 and is very much a part of our DNA. In early 2016, we launched our ´Indestructible´ program where customers bring in their worn 66°North products in exchange for a discount off their next purchase. We evaluate the state of the product, repair it if needed and give it to the Icelandic Red Cross.

Every year we repair around 4000 garments from all over the world, at our own repair centre in Reykajvík.

66°North also guarantees that it will take back any product at any time and ensure its recycling, or donation, whether done by us or with help of partners such as the Red Cross.

“66°North products are extremely popular in our stores. The tourists are often very happy when they find one of your jackets when searching through the rails.”

Guðbjörg Rut Pálmadóttir Sorting Manager

Icelandic Red Cross

66 End of Life

“

Hófí Saumastofa Repair Department Leader

Hófí takes an artisan’s pride in her work. As a master of tailoring and dressmaking, the simple notion of putting a garment back together has an intrinsic satisfaction. “I think it’s the fact that I’m not sitting in front of the computer all day,” she says. “I’m running around and fixing problems.

On a good day, Hófí and her team might process dozens of repairs; “We will repair any product we´ve ever made, whether it’s from a few seasons ago or sometime in the last century. The oldest garment that the repair shop has received is over 30 years old, and still in good shape.“

No matter how long a garment stays with her team, all but the truly irreparable come back to life. “66°North customer service is in contact with people all around the world,” she explains. On intake, garments are sorted by hand and evaluated. It’s Hófí’s job to make sure more involved repairs (like rips in waterproof materials which require special seam-welding machines

to fix) are tasked accordingly so repairs can keep flowing.

Once a repair has been sized up, materials are gathered. Over decades, 66°North has intentionally accumulated nothing less than an archive of textiles, fasteners, and materials - all in the service of making more true repairs.

“When we order fabrics for the factories, they make sure to order a few meters for us here,” Hófí says. “We get the same fabric, same colors, everything.”

With materials in hand, philosophy can turn into practice. In skilled hands, smaller repairs like rips in puffers and broken zippers may take just 10 minutes. Truly immense tasks, like reconstructing an advanced waterproof membrane jacket? Well, those might even take a few hours or more. “We always try to make the garments look as if nothing was done. We can’t always make it perfect, but the team aim to do the best job possible.”

Revived garments are then processed and collected, or sent back to their original owners. A simple, efficient outpatient procedure - but one with extraordinary results.

67 66°North / Impact Report

Reuse

Combining timeless design with durability, our clothing has long been popular for resale in our home market of Iceland, and many of our styles have become collectors’ items.

Second-hand purchasing is currently run through Facebook page Notaður 66° norður fatnaður til sölu/óskast. We are exploring ways to take resell to our growing global audience of buyers and sellers.

As part of our expansion of circular solutions, we are also considering rental as a model to drive down the environmental footprint of our clothing - with a focus on usage instead of ownership.

68 End of Life

Nearly 10% of the Icelandic population takes part in the purchase of second (or third, or fourth) hand 66˚North clothing.

69 66°North / Impact Report

Waste

While developing circular solutions remains a top priority for the business, responsible waste management runs alongside this and we are working hard to improve recycling rates and eliminate waste-to-landfill at our stores and offices.

In 2022 we signed an agreement with waste management consultancy Pure North, involving a comprehensive waste audit and action plan for our facilities.

Action plan objectives:

• Rescuing waste

• Increasing recycling rates

• Ensuring better quality of raw materials generated in our day-to-day operations

• Disposal in appropriate channels

2022 is our benchmark year and results include our headquarters in Garðabær and 4 stores: Hafnarstæti, Skipagata, Faxafen and Miðhraun (this is because we are able to accurately track the waste from these stores, unlike other stores that are part of larger entities e.g shopping complexes).

The consultation is ongoing and the remit will expand to include more of our premises overtime.

In 2022 we achieved a ‘waste sorting rate’ of 75%. Out of the remaining 25%, 22% constituted mixed waste that cannot be recycled, which is well below industry average. In 2023 we aim to bring down this figure to 15%, and 10% the following year, working towards our goal of zero waste-to-landfill.

All LDPE plastic packaging is sent to recycling at Pure North in Hveragerði, Iceland where it is mechanically recycled into plastic pallets, to be reused in various product manufacturing.

70 End of Life

MIXED RECYCLABLES

ORGANIC WASTE

Evolution of quantity: all locations

CORRUGATED CARDBOARD MIXED WASTE

PAPER PLASTIC PACKAGING

Divison of quantity: all locations

Data source: Pure North annual report 2022

Cost split: all locations

71 66°North / Impact Report

BULKY WASTE 2022–01 1,500KG 3,000KG 4,500KG 6,000KG 2022–05 2022–09 2022–03 2022–07 2022–11 2022–02 2022–06 2022–10 2022–04 2022–08 2022–12

SORTING RATE RECEIPTION OF RAW MATERIALS, 28% WASTE DISPOSAL, 48% EQUIPMEMENT RENTAL, 17% OTHER, 17%

TOTAL WASTE 37.297KG WASTE

Milestones & Data Glossary

• 66°North becomes the first Icelandic company to receive B Corp™ Certification

Design Collaborations

• Plastplan: Creating recycled plastic fastenings for our products from operational waste

• Studio Flétta: Extending material use by recycling textile offcuts from outerwear

• Erm: Turning clothing into household furniture

• Valdís Steinars: Rethinking clothing production methods

End of Life

• Circa 4000 garments are repaired at our repair centre in Reykajvík

• 10% of the Icelandic population takes part in the purchase of second (or third, or fourth) hand 66˚North clothing

• Waste action plan with Pure North achieves a ‘waste sorting rate’ of 75%

Footprint

• 171.4tCO2, Scope 1, fuel from vehicles, heating with natural gas

• 67.5tCO2, Scope 2, electricity, heating, water

• 609.1tCO2, Scope 3, business travels, sorted waste in HQ and selected stores, transportation and distribution

Materials

• 55% of the SS22 collections are made with preferred materials

• 70% of the SS22 collections are made with recycled materials

• 43% of down styles from our AW22 collections are made with recycled down

• Nearly 50% of collections material is sourced from Polartec and Gore-Tex and work continues to eliminate PFAs from our ranges

• On target for 100% environmentally friendly packaging by 2024

People & Places

• 4.46 (out of 5) rating in HR Monitor

• 4.38 (out of 5) rating from VR external employment satisfaction survey

• 66°North X UN Women receive grant of £175,000 from the Sustainable Development Goals Partnership Fund to create jobs for refugee women

• Glacier Friday raises £13,000 in online sales on Friday 25 November 2022 for Jöklarannsóknafélag Íslands (The Iceland Glaciological Society)

72 Glossary B Corp

73 66°North / Impact Report

Thanks for reading Conducted by This Way Next Sustainability Division Future Nature 6b Brownlow Mews London WC1N 2LD hello@futurenature.world 66°North 66north@66north.com +354 535 6600 Midhraun 11, 210 Gardabaer

Bjarney Harðardóttir.

Bjarney Harðardóttir.