From 18 to 50 tonnes, MAN TGS trucks are built for the toughest construction jobs, combining reliability, performance, and durability. Powered by fuel-efficient, high-torque engines and available with two to five axles, they offer tailored load capacities, wheelbases, and frame overhangs to suit any task.

06 CITB’s Employer Networks

Helped 50,000 - plus learners access construction training

14 Utility Machines fuel further growth at McHale Plant Sales

17 Finning UK & Ireland’s Parker Anderson retires after 50-year career

70 Eurofab exported one of the largest storage vessels manufactured in Northern Ireland

76 New Bobcat track loaders and graders at ECL Civil Engineering

78 A Develon DX62R mini-excavator has prepared a coastal resort for summer

25 Gordon Best, Regional Director, MPANI

Golda Burrows General Sales Manager

Sarah Nelson Editor

Martin Elliman General Manager

Joel Byers Production Manager

Catherine Bulling Accounts Administration

Helen Beggs Chief Operating Officer

Plant & Civil Engineer is Published by: 4 SM (NI) Ltd, The Old Coach House, 12 Main Street, Hillsborough BT26 6AE

CONTACT Golda: 07724 192032 or Martin: 07985 887171

Email: golda@4squaremedia.net

Email: martin@4squaremedia.net

4SM (NI) Ltd is part of the North West News Group

COPYRIGHT NOTICE: © Plant & Civil Engineer 2025. All material in this publication is copyright, including advertisements which have been prepared for advertisers. No part of it may be reproduced in any way whatever or stored in electronic retrieval systems without the written permission of the publishers. We are a completely independent voice and are not connected to any Institutes or Associations within the industry. Our aim is to publish accurate, specific and dedicated information, targeting each sector of the industry, throughout Ireland. The publishers cannot be held responsible for any inaccuracies supplied by the contributors. All rights reserved.

62 Karen McShane, Past President, CIHT

Welcome to the June-July edition of Plant & Civil Engineer – and what an exciting, important issue it is!

27 How R Heatrick Ltd is driving innovation in waste recovery

30 Behind Merlo’s sustainability mindset

44 Invest NI is helping firms seize opportunities in the green economy

46 Numac introduces eco-conscious waste compactor

54 Pat O’Donnell & Co. have been on a determined net zero journey

SALES AND SERVICES

105 Plant sales

108 Buyers’ guide

2025 PLANT & CIVIL ENGINEER AWARDS

83 Has your team entered yet?

From social media threads to newspaper headlines, the path to net zero is a journey that is rightfully driving significant dialogue and change. This is particularly the case in the construction, recycling and quarry sectors where minimising environmental impact and supporting a sustainable future are being ushered in as considerations more than ever before, as those on the frontlines seek to incorporate the reduction of emissions and promotion of eco-friendly building practices into their projects where possible.

Admittedly, it is a long-distance journey and we have a stretch still to go, but it doesn’t mean that we haven’t progressed far beyond the starting line. This is especially the case in our sectors, where net zero milestones are being realised every day, be it internal shifts to operations, or external offerings to customers.

To tie in with Net Zero Week in July, our special ‘building towards net zero’ feature is shedding light on the remarkable eco-conscious work being carried out across the sectors, as well as tapping into the improvements which are yet to be attained. This edition’s Cole Groundwork Contracts cover story is a shining example of sustainability – find out how the company has been cultivating a future-proof environment for generations to come.

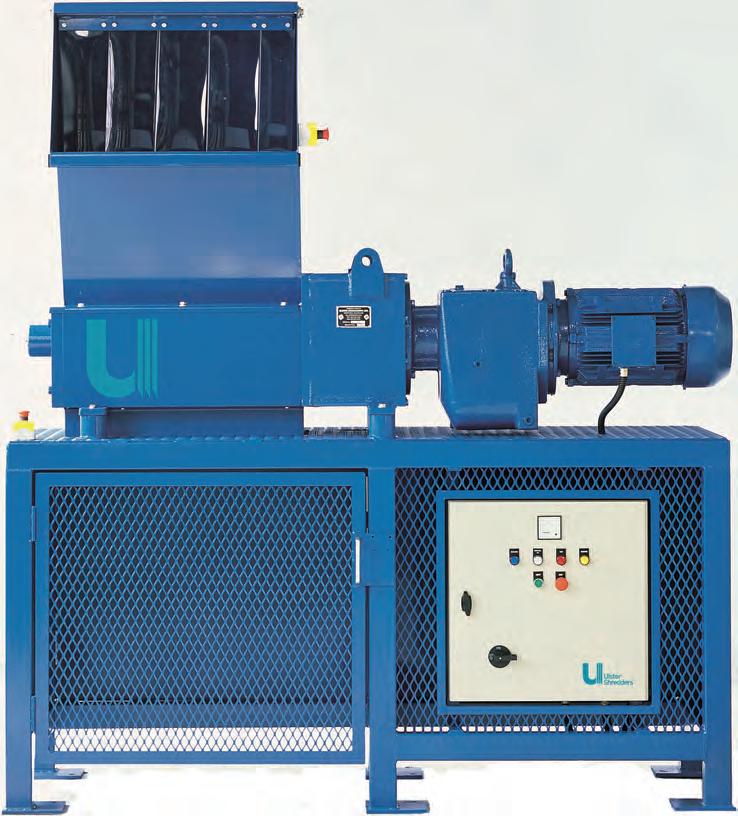

Just some of the other net zero inspiration which you can draw from this issue include the breakthrough in the production of low carbon concrete, Ulster Shredders’ installation of a 40kW solar panel system, how Invest NI is empowering businesses to focus on green, and many more net zero focus pieces. We’re also thrilled to reveal that we will be threading our transitioning to net zero focus throughout our subsequent issues too. Please get in touch if you would like to highlight your own achievements in the sustainability realm.

Elsewhere in this month’s instalment, don’t miss out on our plant hire feature, expert columnists’ insights, news stories, and Plant & Civil Engineer Awards details, including our brand new category – Transitioning Towards Net Zero. Enter now if you haven’t already!

I do hope you enjoy the read, and remember that you can remain on the pulse of the profession’s news 24/7 by logging on to our website at www.plantandcivilengineer.com. Our free weekly newsletter is also distributed every Tuesday – subscribe on our website now if you haven’t already.

See you next issue!

Sarah Nelson Editor

Email: pceeditor@4squaremedia.net

M: 07789 756 815

Maximising uptime and minimising costs are essential when managing an articulated dump truck (ADT) fleet. Here, Scott Pollock, Senior Product Manager for ADT manufacturer, Rokbak, shares strategies – from smarter maintenance and operator training, to cuttingedge on-board technologies – that help boost efficiency, cut expenses, keep your haulers moving, and leave you stress-free. Maximising productivity, minimising downtime, and delivering lasting value, is the name of the game when it comes to Rokbak haulers. In today’s competitive industrial landscape, articulated haulers are expected to do more than move material. They must operate efficiently, reliably and safely for the long haul. At Rokbak, the focus is not just on manufacturing our robust RA30 and RA40 trucks, but on helping customers get the most out of them throughout their operational life.

Unplanned breakdowns are a costly disruption in any fleet. The best defence against them is a solid strategy for planned, proactive maintenance. This goes far beyond routine filter and oil changes. Rokbak encourages regular inspections that can catch issues early – from worn suspension to minor leaks that could become major headaches. Like a good vehicle check-up, effective servicing looks for both current faults and potential problems on the horizon. A vigilant approach to diagnostics and servicing can keep trucks on-site and earning, rather than waiting on repairs. No truck is better than the person operating it. Well-trained operators not only maintain productivity, but the health of the hauler itself. Pre-start checks, basic diagnostics and awareness of operational anomalies make all the difference.

That’s why Rokbak invests in training programmes that empower operators and service personnel. When everyone understands the ‘why’ behind truck care, the result is longerlasting equipment and a safer, more efficient worksite.

Today’s articulated haulers are smarter than ever. Rokbak integrates automation and safety features that actively prevent misuse and mechanical stress. Technologies, such as anti-tip body controls and downhill retardation systems, protect the hauler and the operator.

Load monitoring and productivity tracking also ensure trucks are operating within their optimal range, saving fuel, reducing wear and avoiding costly errors. These built-in tools support smarter, more cost-effective operation.

Every Rokbak articulated hauler comes fitted with Haul Track as standard – an intuitive telematics system that gives fleet managers real-time access to vital performance data. This connected technology uses on-board diagnostics, GPS and wireless communication to track and improve truck performance across multiple sites. From any internet-connected device, fleet managers can monitor fuel consumption, idle time and machine usage. This helps them develop more effective maintenance schedules, reduce operating costs and avoid unexpected breakdowns. Maintenance alerts and fleet activity reports highlight potential issues before they become downtime-inducing problems. Haul Track also helps identify operational inefficiencies. By detecting patterns like harsh braking or excessive idling, it

allows for corrective actions, such as targeted operator training or rerouting – improving driving habits, protecting uptime and extending machine lifespan.

Using non-OEM components might save money in the shortterm but often leads to longterm losses. Rokbak haulers are designed with precision, and only genuine parts offer the fit, compatibility and tested durability the trucks demand. Every part plays a role in maintaining uptime and performance. By using OEM-approved components, operators gain the assurance of full compatibility with the truck’s systems and sensors. Understanding that no two job sites are alike, Rokbak works closely with a global dealer network to tailor parts strategies and service support for each application – whether it’s a construction site in America or a quarry in Australia. Rokbak parts availability planning and regional stocking strategies ensures fast response when customers need it most. Strong local support, combined with a robust global network, is key to keeping haulers running and delivering value.

Ultimately, achieving long-term ADT efficiency is not about a single factor – it’s a combination of great equipment, smart technology, reliable parts and, most importantly, skilled and committed people.

At Rokbak, there is a focus on this full ecosystem because we know that our customers depend on it. By partnering closely with operators, technicians, customers and dealers, we’re helping to ensure that every Rokbak hauler delivers maximum productivity, minimal downtime and lasting value.

For more information, visit www.rokbak.com

The end of an important chapter at the Construction Equipment Association (CEA) has been marked, with Joanna Oliver MBE completing her final day with the association after 30 years of service.

Joanna has played a central role in the CEA’s activities over the last three decades –shaping the export programme, contributing to the launch of events, including PlantWorx and Futureworx, and working with government and industry stakeholders. Recognised for her knowledge of international trade and policy, she has supported members across the sector and represented UK manufacturers around the world.

Joanna joined the CEA in the mid-1990s and became a key

contact for export-related matters. During her time with the association, she helped deliver numerous trade missions and UK Pavilions at international exhibitions, including bauma, Conexpo, BICES and M&T Expo.

Joanna was also part of the original PlantWorx project team and, more recently, helped launch Futureworx. She was awarded an MBE in 2011 by Queen Elizabeth II for services to the construction equipment sector and international trade.

Although Joanna has stepped down from her role at the CEA, she continues to work with AMPS and will be involved in PlantWorx 2025. She also plans to provide consultancy support to businesses using her experience in trade and policy.

Joanna reflected: “To borrow a line from a country song: ‘Don’t blink 30 years go by faster than you think.’ That couldn’t be more true of my time with the CEA. When I joined back in 1995, I was entirely new to both construction equipment and running UK Pavilions.

“Looking back, I’m struck by how much I’ve learned—not just about organising events, but about people, resilience and embracing challenges head-on. It hasn’t always been easy, but I’ve loved nearly every minute of it.

“To my friends across this remarkable industry – especially those who’ve travelled the world with me to some of the more ‘interesting’ corners of the globe – thank you. The memories we’ve made, the

challenges we’ve faced, the whisky we’ve drunk and the laughs we’ve shared mean more to me than I can say.

“Here’s to more adventures and more memories. I wouldn’t have missed it for the world.”

50,000-

The Construction Industry Training Board (CITB) has released its year-end figures for its Employer Networks initiative. It was the second full year of operation for the initiative, and figures demonstrate that the networks supported 50,966 learners in the financial year 2024-to-2025 – an increase from 11,468 the previous, inaugural year. The figures also reveal that in the financial year 2024-to-2025, Employer Networks supported:

• 4,097 employers – an increase from 1,284 the previous year

• 2,655 of the employers supported are small and micro

• 26 per cent of the employers supported had not claimed grant in the past 12 months

Employer Networks are an initiative set up and funded by CITB that offer bespoke, easy-to-access training and financial support for employers. They give employers a direct channel to communicate their training needs and advise on how funding should be prioritised and allocated in their local area. Additionally, they enable CITB to be more responsive to industry needs on both regional and national levels.

There is huge demand for skilled construction workers in the UK, with CITB’s Construction Skills Network report forecasting the need for over 250,000 new construction workers by 2028.

Deb Madden, Executive Director for Nations Engagement, CITB, commented: “It’s vital we have a firm grasp of what skills are required and where they’re needed

across the country. Employer Networks are designed to make the training and skills system easier to navigate for employers, in turn helping to address the skills gap.

“Our latest Employer Networks figures prove the initiative has been hugely successful, and we look forward to building on this success and continue providing much-needed access to training for more employers and learners.

“There is an increasing demand for construction work in the UK, and construction employers are clearly aware of the opportunity and the need for training, with 80 per cent of employers indicating they plan to increase their training efforts in the future. We’re always striving to improve our services and embed a culture of quality into what we do – Employer Networks are a prime example of this.”

Welcome to the sustainable way of working with the Merlo e-WORKER. Zero emissions, zero noise, zero use of fossil fuels. Fitted with a fully recyclable lead acid battery pack the e-WORKER demonstrates that at Merlo, green is more than just a colour. Contact your local Merlo dealer today. 2.5 4.8 8Hrs

A partnership between John Paul Construction and temporary energy solutions provider Aggreko has successfully achieved savings of over 66,000kg in carbon emissions and 20,357 litres of fuel at a prominent Galway construction site.

In early 2024, the industry-leading construction company was appointed as the main contractor for a Galway construction project. Having developed a close working relationship since 2020, John Paul Construction reached out to the team at Aggreko to seek their insight on integrating a decentralised energy solution.

The project required power for both a tower crane and site lighting. While a standard 250 kVA / 320 kVA generator would typically be able to support the site’s power demands, Aggreko’s goal of delivering greater efficiencies to customers and John Paul Construction’s ambition to reduce carbon emissions led to a low-carbon solution.

To reduce the environmental impact of the project, Aggreko suggested a hybrid system using a 125 kVA generator alongside a 150/75 kWh battery which provided an 700amp pass through current to allow for the impact motor start. This would allow the site’s energy requirements to be met, while also offering scalability in line with varying load demands, and even periods of zero-emissions power when the battery was operating independently.

To prove its capabilities, Aggreko tested the package at its site in Dublin for two weeks. The test package demonstrated that both the necessary power and the desired outcome was achievable, encouraging John Paul Construction to use the solution for the duration of the project – 201 days.

After being installed at the Galway site in August 2024, the battery and generator delivered a consistent power supply until the completion of the project in February 2025. During this time, the generator came on at 6am for a maximum of three hours to give the battery a boost and ran for a maximum of three hours at night so that it could recharge. This all resulted in John Paul Construction achieving a weekly emission reduction of 2,342 kg per week alongside a fuel saving of 712 litres. This is the equivalent to a weekly fuel cost saving of at least €600 euros.

Pat Enright, Sector Sales at Aggreko Ireland, said: “The construction industry is increasingly needing to balance power requirements with cost efficiencies and sustainability targets to reduce the environmental impact of the sector. We knew when John Paul Construction approached us that finding a low-carbon solution was a must, so our team set out to identify an alternative to a standard generator that could limit emissions and save on fuel. Our solution, a hybrid battery system, allowed John Paul Construction to incorporate its sustainability values into the Galway project.”

Schneider Electric, a leader in the digital transformation of energy management and automation, has appointed Jacqui Whitaker as its new Vice President of Finance, UK and Ireland (UKI).

Jacqui will lead the UKI finance team, focusing on maximising investment returns, supporting growth opportunities, and driving forward Schneider Electric’s broader sustainability goals.

She steps into the role with nearly a decade of international experience with Schneider Electric, having led the international business finance function across 100+ countries in South America, the Pacific, the Middle East, and Africa. Her business and commercial focus, coupled with expertise in dealing with hyperinflation and foreign exchange instability, have equipped her with the resilience and scenario planning skills necessary to navigate the current UKI

market. Prior to Schneider Electric, Jacqui held leadership roles at Eurostar in the UK. Speaking about her appointment, Jacqui Whitaker, Schneider Electric’s Vice President of Finance for UKI said: “Schneider Electric has a mature and very successful business here, but I am looking forward to finding additional growth opportunities and making it operate even more effectively as the demand for clean energy increases in the region.”

BAM, the main contractor for the landmark Narrow Water Bridge project, has brought together 148 pupils from four local primary schools across the Irish border to take part in The Big Bridge – an educational initiative designed to inspire the next generation of engineers.

As part of the event, pupils collaborated to build a 13-metre cable-stayed bridge, providing a fun and engaging hands-on experience that introduced them to the world of engineering and construction.

Organised in partnership with the Narrow Water Bridge Community Network, Louth County Council, Roughan & O’Donovan and social enterprise, The Big Bridge, the initiative aims to spark interest in STEM subjects among young people, while celebrating the transformative vision of Narrow Water Bridge. A vision, which is already becoming a reality – not only through construction, but through the communities it connects.

Once complete the Narrow Water Bridge will span 195 metres, offering sustainable transport options for vehicles, cyclists and pedestrians.

The schools – St Dallan’s and Dromore Road Primary School in Warrenpoint, and Scoil Naomh Lorcan and Scoil Naomh Bríd in Omeath – worked in mixed teams to construct the model bridge, sparking curiosity, confidence and cooperation. Pupils also learned about the historical significance of Narrow Water and the future potential of the landmark 195metre bridge being constructed across Carlingford Lough.

Speaking about the event, William Diver, Construction Director from BAM, said: “We are proud to partner with The Big Bridge to bring this innovative learning opportunity directly to schools. The Narrow Water Bridge is the flagship project of the Shared Island Fund, and our goal is to ensure that it delivers lasting social value

beyond the build. By engaging young people in STEM and construction, we are investing in the workforce of tomorrow. We thank all participating schools for embracing this initiative.”

Amy Dillon, Principal Engineer at Design ID and Project Director of The Big Bridge, added: “We’re passionate about helping young people experience the creativity, teamwork and problem-solving that underpin engineering. Through this workshop, we’re not only building bridgesthey’re discovering the wide range of careers that bring major infrastructure projects like Narrow Water to life.”

David Jones, Director of Services, Louth County Council, also commented: “The Narrow Water Bridge is a landmark project that symbolises connection, and

Bobcat CZ, a.s., the exclusive distributor of Bobcat machines in the Czech Republic, has announced the delivery of another 80 excavators and eight skid-steer loaders to Stavebniny DEK a.s. At DEK rental stores, domestic customers can now choose from more than 550 Bobcat machines.

Stavebniny DEK a.s. is currently focusing (within the Bobcat machine portfolio) primarily on expanding its fleet of mini excavators, which are among the very popular machines in its rental stores. The total of 80 Bobcat excavators in this delivery covers weight categories from one to five tonne including the E10z (30 units), E19 (30 units), E35z and E55z (both 10 units).

The mini excavators will be supplemented by eight new S650 skid-steer loaders.

“The rental segment remains a priority for us. We have been cooperating with Stavebniny DEK for many years. The repeated interest in Bobcat machines confirms the renowned quality of our service network across the entire Czech Republic. The current trend is the supply of machines with powertilts, which we supply for all machines from the E19 model upwards,” said Vladimír Hes, Sales Director of Bobcat CZ.

the Big Bridge workshop is a brilliant example of how major infrastructure can also deliver real educational and community value. By capturing the students’ interest in engineering and construction, we’re not only building a bridge, but we’re also hopefully building future careers and strengthening crossborder relationships that will last for generations to come.”

“Borders divide, bridges bring people together,” said Jim Boylan, Chairman of the NWBCN, a local community group based in Warrenpoint, which has campaigned for many years for the bridge.

“The number one objective of our campaign was to unite communities around the Lough. It was truly inspirational to see children from both traditions and both sides of the border coming together so easily to build a bridge. The real bridge, of course will transform these children’s lives, creating opportunities denied to previous generations.”

The Narrow Water Bridge project is being delivered by BAM on behalf of Louth County Council, designed by Roughan & O’Donovan and funded by the Irish government under the Shared Island Fund.

The Big Bridge is a not-for-profit social enterprise operating across Northern Ireland and Ireland. Its mission is to deliver memorable STEM experiences to schools, showcasing the realworld application of construction and engineering in a fun, inclusive and impactful way.

Stavebniny DEK a.s. has many years of experience with Bobcat machines and Bobcat CZ a.s. service, and has been purchasing them regularly since 2017. The current fleet of Bobcat machines, including the latest delivery, includes 444 mini excavators (E19/E35/E35z/E50/E55z/E85 models) and 117 skid-steer loaders (S530/S650).

Within the scope of this order, Stavebniny DEK a.s. relies on proven machines from the output of the Czech Bobcat factory in Dobríš, where the majority of production for the European market has been manufactured for more than 20 years. The location of the Bobcat regional headquarters in the Czech Republic is a clear advantage for customers – the machines are developed here to meet the requirements of not only Czech, but also all European customers.

Powered by the latest Stage V engines to give class-leading pushing capability combined with low fuel burn, Generation 8 dozers are engineered for efficiency. There’s a wide choice of blades, a unique tilting cab for easy servicing, and a new-look cab providing outstanding comfort and great views to blade and ripper.

Operators - need a little help? We offer Free Grade, Definition Grade or optional 3D Grade Assistance systems as well as optional factory fitted, GPS preparation for all popular systems.

It’s a Liebherr. Job done.

As jobsites grow in size and environmental regulations tighten, the need for adaptable, heavyduty equipment in the US is clearer than ever. That’s where a new venture between Hydex and Hills Machinery is stepping in with a solution that pairs proven articulated hauler performance with serious dust suppression capability.

At the core is a new water truck range. Rokbak RA30 and RA40 articulated dump trucks (ADTs) are being upfitted with high-performance water tanks to be deployed across quarries, mines and infrastructure projects under the Hydex banner.

The RA30 and RA40 are no strangers to tough jobsite conditions. Built in Motherwell, Scotland and part of the Volvo Group, Rokbak trucks are engineered for power, control and reliability in the harshest off-road environments.

However, their latest application showcases a new kind of versatility. The RA30, with its

370-horsepower engine, now carries a 6,000 gallon or 22,712.47 litre (AWT6) water tank, while the 444-horsepower RA40 is matched with a 9,000 gallon or 34,068.71 litre (AWT9) tank – both equipped with advanced spray and pumping systems for highperformance water distribution.

“This is about using a proven platform to meet a pressing and growing need,” said Robert Franklin, Director of Sales – Americas at Rokbak.

“The RA30 and RA40 give contractors the power, manoeuvrability and durability they need in a base machine –and now, with this adaptation, we’re showing just how far that platform can go.”

The idea to repurpose articulated haulers as water trucks came from the ground up – quite literally. Hills Machinery, a longtime Rokbak dealer based in North Carolina, saw firsthand how contractors were searching for tough, reliable machines that could do more than haul.

“We work with Rokbak on a daily basis and believe those to be the best two trucks to outfit these tanks with,” says Jim Hills, president of Hills Machinery and Hydex. “But we also recognise that some contractors will want to keep their fleet standardised so we’re happy to work with everyone to solve their dust suppression and water access needs.”

Hydex is supporting the rollout through Hills’ existing dealership network, with upfitting taking place at a joint facility in Seattle, Washington, and distribution coordinated through Hill’s location in Wilson, North Carolina. Each truck is backed by Hills Machinery’s Uptime Operations service, which includes lifecycle fleet management, real-time equipment monitoring and pre-stocked replacement parts – minimising downtime as trucks hit jobsites.

The tanks themselves are engineered to meet demanding performance specs. Water is shot from an Americanmade Elkhart water cannon to

distances of over 213 ft, while operators can adjust pressure to 320, 480 or 630 gallons per minute. Multiple spray bars and nozzles – including vertical, side, front bumper and rear dribble – offer complete customisation depending on site needs.

A rear-mounted electric hose reel, American-made Berkeley hydraulic water pump and optional suction system for drawing water from lakes or reservoirs round out the functionality.

“These tanks are serious pieces of equipment in their own right,” said Jim. “But what makes them truly effective is the machine underneath – the Rokbak hauler that keeps everything moving and delivers the power, even in the roughest terrain.”

Dust suppression isn’t just a jobsite concern – it’s a growing regulatory issue in many jurisdictions, particularly in states such as California, Texas and Arizona, where construction activity is booming in arid environments. Add to that the increasing size and activity level of quarries and mines, and the demand for large-capacity, offroad water trucks is rising fast.

With their articulated frame, powerful drivetrains and operator-friendly design, Rokbak trucks offer a more robust and stable solution than conventional rigid-frame water trucks – especially when offroad capability is a must.

As Hydex scales production and more water trucks hit the field, all eyes will be on how this versatile solution might open the door for further adaptations of the Rokbak platform. From fuel and lubrication service units to emergency response and haul support, the articulated hauler’s future may be even more diverse than its past.

“We’re just getting started,” Jim said.

“When you’ve got a reliable chassis and a clear market need, the opportunities are endless.”

Develon, formerly Doosan Construction Equipment, has officially opened its new Parts Distribution Centre (PDC) in Boom in Belgium, marking a major step in its strategy to enhance customer service and accelerate growth in the European market. The inauguration ceremony for the new PDC was attended by Develon CEO, Seung-Hyun Oh, key customers, logistics partners, and other distinguished guests.

In his keynote speech, CEO Seung-Hyun Oh stated: “The opening of our Belgium PDC represents a critical first step in our customerand market-oriented strategy. It is a strategic investment to deliver faster, more stable and

more responsive services for our valued European customers.”

Since the establishment of the first Europe-based operation in the UK in 1994, Develon continues to build on this and expand its presence in the European market, with the region now serving as a vital hub for technological innovation and sustainable growth. The company previously operated a PDC in Germany, which played a key role in improving its on-time delivery rate and logistics efficiency.

With a storage area of 24,000 m² and an inventory of 47,000 stock units, the new Belgium PDC is designed to bring services closer to customers and to allow Develon to respond more swiftly to diverse and evolving demands in the European construction equipment market. With improved supply chain optimisation and increased speed of parts delivery, the centre is expected to significantly enhance customer satisfaction and strengthen competitiveness for both Develon and its clients.

The Belgium facility will be operated in partnership with Fiege, a leading logistics provider with a long-standing relationship with the Develon range. Leveraging Fiege’s deep expertise and innovative logistics solutions, the new PDC aims to deliver exceptional service quality and reinforce customer loyalty across the continent. In line with Develon’s commitment to sustainability, the Belgium PDC was built with energy-efficient infrastructure and incorporates low-carbon operational practices. This reflects the company’s broader mission to pursue growth while fulfilling its environmental and social responsibilities.

A rise in demand for what Komatsu calls ‘utility machines’ is being reported by its distributor in Ireland, McHale Plant Sales.

Machines sheltering under that generic description include the micro-mini-midi size diggers and compact-size wheeled excavators popular among utility services providers and plant hire renters for whom the ‘shorthire, call-and-collect rental and DIY markets are paramount’.

Among Komatsu’s extensive portfolio, units classified within the segment are its PC 09, PC 16, PC 26, PC 33, PC 55 and PC 80 units.

Major deals that have raised its share of this important market sector include what McHale Plant Sales Director, Denis McGrath, calls “multiple

unit deliveries to customers, such as Kilkenny’s Total Highway Maintenance, Limerick’s Treaty Plant Hire, and Ballina-based plant rental specialist, Davy Tool Hire.”

Explaining its surge in sales, McGrath said: “in addition to a naturally arising growth in demand, the trend towards ‘contracting out’ by local authorities; gas, electricity and alternative energy suppliers,

and by major computer, communications and broadcast services providers has increased purchasing and rental activity.”

“Another explanation can be found in an increasing tendency on the part of ‘big plant users’ to include compact-size diggers in its inventory, there to perform minor ‘project finishing’ and final surface dressing, landscaping, rectification, and small-scale ‘second-thoughts’ applications,” he added.

Looking ahead, McGrath forecasts a ‘continuance’ of demand at the entry level.

“Echoing Komatsu’s own determination to build a bigger presence in the sector, helped by further upgrading, increases in specifications, and competitive pricing, we in McHale Plant Sales are placing even greater focus on this important segment, encouraged by feedback from the market generally, and the guidance of some of our committed customers,” McGrath said.

Uisce Éireann, in partnership with Water Stewardship Ireland and the Sustainable Enterprise Skillnet, has launched a new Advanced Water Stewardship Programme, now open to all trade effluent business customers.

This fully-funded training initiative is designed to support businesses in addressing trade effluent and water quality challenges, while also helping them prepare for upcoming regulatory changes and develop strategies to manage trade effluent charges effectively.

With water quality and sustainability becoming increasingly vital in today’s regulatory and operational landscape, this new programme offers direct, site-focused support. It empowers businesses to take proactive measures that protect water quality, lower operational costs, and enhance sustainability credentials. Programme benefits include:

• Protect water quality –gain practical training on improving water quality and implementing sitespecific actions that drive behavioural change

• Monetary cost savings – develop proactive strategies to mitigate future trade effluent charges

• Reputational benefits –stay ahead of evolving water-related reporting

requirements and strengthen your sustainability credentials

• Environmental impact –add a meaningful green initiative to your sustainability goals, reducing your environmental footprint The programme is delivered through a series of expert-led workshops. All participants will also create a Water Charter for their site – a tailored plan that identifies key risks and solutions, maps drainage and water use,

and supports reduction, reuse, and restoration of water on-site.

Geoffrey Bourke, Head of Customer Operations at Uisce Éireann, welcomed the new programme: “We are delighted to support our trade effluent customers and do our part to enhance water quality and protect the environment. At Uisce Éireann, we are responsible for the delivery of secure, safe and sustainable water services for the people of Ireland. This programme helps us to attain our vision of a sustainable Ireland where water is respected and protected for the planet and all the lives it supports.”

The Sustainable Enterprise Skillnet is co-funded by Skillnet Ireland and network companies. Skillnet Ireland is funded from the National Training Fund through the Department of Further and Higher Education, Research, Innovation and Science. For more information and to register, visit www.water.ie/advancedws.

A landmark celebration at Combilift’s global headquarters in Monaghan has occurred, marking the 10th anniversary of the highly-successful OEM Engineering Traineeship – a collaborative initiative between Combilift and the Cavan and Monaghan Education and Training Board (CMETB).

The event, which welcomed past graduates, current trainees and local educators, underscored the programme’s evolution from a local skills initiative to a cornerstone of regional industrial development.

Launched in 2015, the OEM Engineering Traineeship was born from a shared vision to tackle the skills gap in engineering and manufacturing with an industryled approach. Today, with over 150 trainees having passed through its doors to achieve a QQI level 5 qualification, and with job placement rates above

80 per cent, the programme stands as a model for how industry and education can collaborate to mutual benefit.

Combilift, a global leader in materials-handling solutions, has been central to this success.

As the primary industry partner, Combilift has not only provided cutting-edge workplace experience, but also ensured the course content remains aligned with real-world demands.

“We wanted to create more than just a training programme – we wanted to build a pathway into meaningful careers,” said Combilift Managing Director, Martin McVicar.

“This traineeship has delivered exactly that, time and time again.”

The nine-month programme blends 26 weeks of classroombased learning at Monaghan Institute with 12 weeks of hands-on work experience in Combilift. Over the years, the

course content has evolved to reflect changes in the manufacturing landscape, now including modules in hydraulics, lean manufacturing, and, more recently, mathematics to prepare students for greater work or educational opportunities.

CMETB has played a vital role in co-ordinating and delivering the educational aspect of the programme. Its ongoing commitment to adapting the curriculum, securing government funding, and expanding the scheme to include other regional employers from 2025 reflects its strategic approach to workforce development.

“It’s about staying ahead of the curve,” said Sinead McKenna of CMETB.

“We’ve created a flexible, forward-looking course that equips learners with in-demand skills and supports local industry at the same time.”

Parker Anderson, Product Support

Account Manager at Finning UK & Ireland, is set to retire at the end of July after a remarkable 50-year career in the plant and machinery industry.

Beginning his journey as a workshop mechanic, Parker has built a wealth of expertise and established vital relationships across the sector. Since taking on his current role in 1989, he has been a trusted resource within the company and the broader sector.

Stepping into his position will be Stephen Thompson, who currently serves as Customer Service Controller, ensuring a smooth transition.

Parker commented: “I have had too many highlights in the role to mention. With Stephen stepping into the role, I know that I’m handing over to somebody who is more than capable and going to provide the customers continuity.”

Speaking on his new venture, Stephen said: “I am very excited to take on the role –it’s something I’ve been building towards over the years. I have been in my current

job for the best part of 20 years, having started off as an engineer, and have built up customer relations during this time so it hopefully should be an easy transition.”

As the construction industry evolves, the importance of the incorporation of ecoconscious practices into civil engineering and groundworks projects can’t be overstated.

But this isn’t a revelatory finding for Cole Groundwork Contracts – as a long-time leader in the groundworks and civil engineering realms, the company has been consistent in its commitment to minimising environmental impact, adopting innovative methods, conserving resources, and ultimately cultivating a future-proof environment for generations to come through its work.

Given the mammoth strides secured by the company, it’s difficult to believe that Managing Director, Conor Cole’s, career could have taken any other turn – but it almost did.

“When still at school, I was originally going to go into Accountancy, believe it or

not. That seemed to be a common path, and I was always very good with maths and numbers,” said Conor.

That course of thinking shifted following Conor’s subsequent completion of his A-Levels, when he spent a few years working with a groundwork contractor – rising up the ranks to become the foreman and, indeed, leading many of his employer’s jobs. Equipped with this first-hand knowledge, Conor embarked on Civil Engineering studies at university.

“With my on-site experience, and passion for the industry becoming almost a hobby to me, in my first year the tutor of the course said that I was like a fourth year student because of all the experience I had already gained. I was so interested in the area that when I went home,

I continued researching it myself,” recalled Conor. However, it was after leaving university that the foundations of the business were firmly planted and Conor’s entrepreneurial spirit flourished.

“I started off doing private domestic projects, and it just really grew from there. At that point I thought of it as a shortterm job rather than a longterm company, but I went out and took a shot at it, and then a few contractors heard and contacted me about more jobs. I kept my head down and kept going. From

2015-to-2020, our turnover increased steadily every year.”

This hard work aligned with the accelerated pace of the company’s profile. Although originating as a dedicated team of professionals serving domestic and small commercial building contractors, Cole Groundwork Contracts has over the years expanded to offer a comprehensive range of groundwork and civil engineering services across the UK and Ireland.

COLE GROUNDWORK CONTRACTS LEADING THE WAY WITH SUSTAINABILITY...

Now, from its Northern Ireland office, the team proudly partners with many of the world’s leading companies, including Bouygues, Gilbert Ash, WHP and Mercury to name a few, delivering high-quality solutions on projects of all sizes.

Under Conor’s expert guidance, the company is currently actively engaged in a diverse range of sectors – including infrastructure, the education sector, sustainable fuel terminals, electrical generation sites, telecommunications, and the water industry, and more recently moved into the substation and mission critical sector.

This broad spectrum of projects was impacted by considerable reflection brought on by the onset of the pandemic.

“When COVID kicked in, we were defined as essential workers –and I realised that I wanted to be involved in not just groundworks and civils projects, but jobs that are crucial to society, and essentially recession-proof. We started looking more towards telecommunications, power generation and the mission critical sector – with particular interest in data centres, energy projects, wind turbines, and we were strategic in our approach – making a clear plan for making it happen,” explained Conor.

“Last year we commenced our first major data centre job which we currently have a large team working on. This project win has allowed us to look across Europe

at further data centres. Working in the mission critical centre has been a natural progression for us as a company and something we are very proud of. We are extremely interested in this sector, the hurdles to overcome, and the continual evolving progression in technology in this area, and we are excited to become more involved. ”

The company’s evolution over the years has very much been based on being the best at every turn.

“It sounds cliche but we strive to be the best we can and a genuine partner for our clients. Our rate of return clients is testament to how strong our work is. We have been able to evolve and grow by being the best in each sector we have worked in. Our core values aren’t just words on a page – they

are what we live by and what has contributed to our success.

“We deliver each project on our values and we even use them in our hiring process to ensure that anyone that joins our team is committed. We value honesty, motivation and genuinely care for our people, suppliers and partners.”

It is this mindset that has allowed Conor to win more and more projects year-on-year.

During the completion of each project, the company’s pursuit of eco-friendly solutions where possible is clear. A key step in the company’s sustainability strategy has been the adoption of advanced HVO – a renewable, low-carbon

alternative to traditional diesel which significantly reduces greenhouse gas emissions and air pollutants, which helps combat climate change and improve air quality on construction sites.

“In 2017 we started doing biogeneration projects in Scotland, and witnessed the team use HVO. The power that the team was producing was greater than what the factory required so they were selling the overspill of this back to the grid. It sparked my awareness of HVO and I started to ask questions. I then tried it myself and realised how transformational it is to improve emissions dramatically, without any need for changes to any plant or equipment.”

Cole Groundwork Contracts’ umbrella of environmental responsibility continued to expand in other ways, such as the adoption of smart tech to monitor fuel use, the encouragement of employing local labour in regions other than their home base, and sourcing materials as local to projects as commercially feasible.

“We’re making a statement in the industry with the quality and performance of a project we deliver, we are not just the normal civils contractor, we really believe we offer more to our clients and end users. We also want this to now reflect our commitment to sustainability.”

Conor is passionate that the company’s sustainability story continues to unveil new chapters and will never truly

be done – they are always looking for different eco-friendly approaches to their work both in the office and on-site.

“One of the core values in the company is ‘constant improvement’. This is for our people, our processes, the way we deliver, our attitudes, and this past few years has also been focused on our sustainability efforts. Everybody knows that as a business we either meet or beat the programme with

100 per cent dedication and at an extremely high quality standard – “Right First Time – Every Time”. We’re very flexible and will adapt to exceed clients’ expectations. ”

As well as recognition from the clients they collaborate with, the Cole Groundwork Contracts’ team have had their efforts highlighted on a wider scale – earning acclaim at many key industry events, including the recent Business Eye Sustainability & ESG Awards 2025 in which the company was shortlisted for two titles: Sustainability Project of the Year (Small-Medium), and Sustainable Business Leader of the Year (for Conor). Conor has also been listed as a finalist in the upcoming 2025 Responsible Business Awards as Responsible Business Ambassador.

“It’s great to be recognised, however our clients and customers are what are important. If there’s no business, we wouldn’t be able to go for awards, so that comes first. The thing that comes next is the team – there would be no Cole Groundworks if it wasn’t for the fantastic team. I am proud of everyone from our senior leadership team to our groundworkers, and everyone in between,” said Conor. “Awards may list my name but its testament to the work of the whole team.”

“We’re at the stage now where we’ve outgrown our offices so we’re actively looking at the next move. We’re also strategically looking at where it is next on the map in Europe. With our experience in France at present we are confident to move forward and become a dominant player in the mission critical sector in this region, and now look forward moving into other regions of Europe also. For now, we are waiting on a few very exciting projects hopefully coming to fruition, if we do, we can expect to see our turnover double in the next 18 months; which will align with a recruitment drive for the right people to support this.”

Creagh have developed a Net Zero Roadmap which strategically aims at removing carbon throughout the company (Scope 1&2 emissions) and influence supply chain (Scope 3 emissions).

Our base year is 2019 and we have aligned our objectives closely with our sector’s Net Zero Roadmap - 2050, with 5 yearly milestones to achieve Net Zero Carbon Emissions.

The sector faces significant challenges due to the nature of cement manufacturing which is a key ingredient in our products and is outside our direct control.

We will however continue to influence change and innovation in the sector through our memberships of several industry bodies.

We are collaborating with our longstanding supplier, Go Power. Creagh Concrete has established a 100% certified green electricity supply across our N.I. facilities. This move complements our UK sites, which commenced a green supply in January 2025.

Environmental Product Declaration

Our EPD’s provide transparency about the environmental impacts of our products and help support the adoption of sustainable building practices. They also facilitate the smoother approval processes for construction projects.

Our journey from CEM II to CEM III is ongoing and with recent testing involving low carbon concrete demonstrating carbon savings of over 70%. Our journey to a more sustainable concrete mix is fundamental in our pathway to net zero.

Creagh’s have a strict Policy criteria for Responsible Aggregates Sourcing. Aggregates are all sourced within a 25 mile radius of the main product facility at Toome, Co. Antrim, thereby eliminating significant transport miles.

Through a dedicated Predictive Maintenance Programme our site engineers optimised absorbed power from our electricity supply by replacing deteriorating capacitors. This step optimised power usage by 8%.

Through continuous investment in people & processes Creagh has eliminated 7,202 metric tons of carbon from its Spantherm product line. From 2017 to 2023, we have eliminated 3,848.2 tonnes of steel mesh from our Spantherm® product lines.

The project team led by the site continuous improvement lead has reduced the amount of virgin timber used within our business by 52% at one of our facilities and 27% at the our largest site.

Our Net Zero Roadmap plan illustrates our commitment to achieving Net Zero Emissions from our operations with 5 yearly milestones. These are designed to ensure our trajectory and strategy are in line with the objective.

Download a copy of

“Creagh are very aware of the environmental impacts of our products & activities. We have developed our Roadmap to Net Zero, which through strategy & innovation we will mitigate and eliminate our carbon emissions”

James Mc Keague Managing Director - Creagh Concrete Products Ltd

When we published our industry journal in mid-2024 I entitled it ‘Our 3D Transition of Decarbonisation, Diversity and Digitisation’. Given the sustainability focus of this edition of Plant & Civil Engineer, I thought the time was appropriate to give readers an update on the impressive progress being made across all our sectors on the journey to net zero, energy efficiency and security. So, if saving the planet from climate change is not a priority for you or you see the drive to reduce carbon emissions as misinformation, that’s fine. However, can I ask you to take a moment and think and take a purely selfish approach? Let me explain! Since almost the start of the last century our lives and economies have been all but dependent on either oil, gas or coal. Our transport, our heating, our energy and many of the plastic and bituminous by-products that come from those industries. Unfortunately, since the end of the Second World War our global politics and many of the conflicts we have witnessed have been caused by disagreements and vested interests in getting access to oil and gas reserves. At this stage I would certainly recommend an excellent read: “Blowout: Corrupted Democracy, Rogue State Russia, and the Richest, Most Destructive Industry on Earth”. For me, and I do believe that climate change is real and happening, all this effort and investment in decarbonisation is about cheaper energy prices, generating our energy locally and importantly securing clean energy from the limitless natural resources we have around these islands. My evidence is simple! Look what happened in the 1970s when the Arab countries overnight significantly raised the oil price, the impact during the two Gulf Wars and more recently the impact of the Ukraine war on the price of gas

imports. Or speak to the residents of the tiny Pacific and Indian ocean islands who are or have made plans to evacuate their homes because of rising sea levels, or the people of Blatten in Switzerland where the collapse of a glacier engulfed their village recently.

Many readers may have attended the MPANI Annual General Meeting earlier this year where we had an expert panel taking questions from our members. One particular question hit home the reality of how little control we have over the price of our electricity and other energy supplies. The question to the panel was simply: “What can we do locally as individuals and organisations to reduce energy prices?” John French’s, the Northern Ireland Utility Regulator, answer was short and chilling: “Not a lot”. John went on to explain that our electricity base line price movement is based on the wholesale price of gas, which of course is an internationally-traded commodity. We

operate within the All-Island Energy Market which is based on a European model. The good news is that discussions are ongoing at a European level to move away from fossil fuel indicators to more renewable sources, such as hydro and wind. Think of it! Northern Ireland has the highest nondomestic manufacturing electricity prices in Europe. We are four times the US level of electricity prices for manufacturing yet we have such huge potential to generate our own energy from wind, solar and biomethane. It needs to change and fast!

I firmly believe we have a vehicle in Northern Ireland to take a collaborative approach to reducing energy costs, decarbonising and helping productivity level. That vehicle is IDNI. Funded by Innovate UK, key partners include Manufacturing NI, Mineral Products Association NI, AMIC/QUB, Ulster University/

Smart Manufacturing Data Hub, and a GB consortium that successfully delivered the UKRI-funded RePowering the Black Country project. Invest NI has also secured support from all 11 councils, DfE, DAERA, DfI, SONI, NI Chambers and all major Northern Ireland utility companies.

IDNI has developed a free-to-use, Productivity Emissions Tool (PET), which has been adopted by 103 Northern Ireland high energy intensive businesses to date, helping them establish their Scope 1 & 2 emissions, plus benchmarking productivity against GB counterpart organisations, using ONS comparisons.

IDNI has identified nine industrial clusters of high-energy users, across six of the 11 council regions and a Mineral Products Sectoral grouping of more dispersed businesses, titled Community of Shared Interest (MPANI-COSI). Additionally, IDNI is advancing a mapping initiative to enhance visibility of Northern Ireland’s industrial sectors, linking these with infrastructure and renewable asset generation by integrating input from electricity and renewable datasets. Invest NI is also engaging gas and water utilities in this effort to enhance strategic planning, investment and policy delivery for decarbonisation. By taking a customer-first perspective, IDNI has identified three distinct levels at which industrial decarbonisation methodology needs to be pursued:

• Individual firm carbon reduction interventions

• Clustering of neighbouring companies to enhance shared energy infrastructure and waste streams

• Improved infrastructure planning, industry information-sharing and development for the whole of Northern Ireland

While Innovate UK funding has now stopped, hopes are high that following the UK Government’s Comprehensive Spending

Review in June new funding streams will become available to take forward the already excellent collaborative work and cluster development that has gone on over the past 12 months. Certainly, we in MPANI will want to develop the Toomebridge Mineral Products Cluster and the wider NI Mineral Products Community of Shared Interest (COSI). Already we are advising, directing and informing members about the benefits of understanding and utilising half hour electricity metres, the use of smart meters and sensors in the manufacturing process, the technology around developing digital twins and how it can be applied in the quarry and mineral products sector. Recently funding has been made available through the Belfast Region City deal to develop and install new 5G /6G infrastructure. This 5G innovation funding scheme came out recently and I immediately thought it would be of interest to our MPANI members in the Belfast city region. As you are no doubt aware, our industry’s digital and automation journey will be totally dependent on the availability of high performance 5G and 6G on our sites, located mainly in rural areas.

What is heartening now is to see and hear of the work going on within our sector. The work continues with Queen's University, AFBI, Agriad and our cement members on exploring the potential use of Biochar in cement with a number of trials taking place already showing positive results. The Biomethane Gas potential is huge across Northern Ireland and in particular for our industry for heating or transport purposes. The generation and use of small-scale green hydrogen gets ever closer through the ground-breaking work of companies like Catagen. The use of battery storage in tandem with wind and solar offers real opportunities for our minerals sector.

On the diversity front we are certainly beginning to see more women and young girls coming into our sector, not only in the administration side but on front line disciplines as well. We will shortly be launching our new “Women in Minerals” video and social media clips. A huge thank you goes to all the ladies who gave of their time to speak on camera about their careers in the minerals sector and why they would recommend it to others.

The association continues our day-to-day works representing members’ interests. MPANI will host a visit by the Infrastructure Minister, Liz Kimmins, to Northstone’s Craigantlet Quarry and in particular to view the new asphalt plant. We will take the opportunity to raise members’ concerns around budgets for structural maintenance, planning reform, NI Water and revenue raising. We recently published a press release entitled, ‘Road Conditions Set to Get Worse, and it’s Already Bad”. It’s a blunt message from MPANI.

The Department for Infrastructure’s annual resource and capital allocation was announced by the finance minister and agreed by the Executive on 19th December 2024. The decision relating to the final 2025 / 2026 budget is yet to be announced by the Minister and consequently DfI staff and the contracting industry are working to provisional unconfirmed allowances, causing grave uncertainty in the market as to whether there is a pipeline of work for the remainder of the financial year. At this point, MPANI are calling on the Minister to carry out a review of the allocations to ensure that our existing road network does not fall into further unsafe condition and disrepair, and to bring some certainty for all employed in the highway maintenance sector.

My view is that the proposed budget for Transport and Road Asset Management (TRAM) has dropped from £143 in 2024 to £121 million for 2025 / 2026. The levels of road structural maintenance funding of £68 million being proposed for this coming year is truly shocking. In real terms, allowing for inflation, it takes us back to levels of spend last seen in the late 90s. Our members can’t understand this given the Department’s draft 2025-26 budget outcome, for both resource and capital is showing a 14 per cent improved position in comparison to previous years. The reality is that this budget allocation is the largest capital budget ever proposed for any NICS Department. What is being proposed is grossly unbalanced and completely ignores previous professional advice outlined in the 2010 Snaith Report, 2019 Barton Report and the NI Audit Office Report. The policy is akin to building a new extension to your house while at the same time your roof is leaking. We need an urgent and serious discussion on how we fund and procure new capital funded roads and water infrastructure. We believe the Department have got the balance of spend all wrong. We have to be brutally honest here, the impact of these decisions will be a continued acceleration in the deterioration of the road network condition, an increase to the risks to all

road-users, whether in vehicles, or on cycles or other active travel, or on foot, and an undermining of the contracting and support organisations who rely on this sector for the sustained employment of their employees. The potential safety implications for the condition of an already deteriorating road network are enormous. MPANI, in partnership with HSENI, has written to all school principals in Northern Ireland asking for their support to spread the “Cold Water Safety Message” and trespassing dangers to children and young people. MPANI and HSENI have been writing this letter for 15 years and are grateful for the support and feedback that many school principals give to this important safety message.

MPA has published a new guidance document on work-related stress. The guide aims to provide clear, simple, smart guidance to employers and managers to help them complete a suitable and sufficient workrelated stress risk assessment of their workplace. Launched to coincide with Stress Awareness Month, the guidance document describes the importance of carrying out an organisational level risk assessment that addresses work-related stress. It also lays out the legal context and touches on the moral

and financial cases for managing work related stress and the practical steps that need to be taken during the risk assessment process. Statistics published by Health and Safety Executive show that 0.9m workers suffered from work-related stress, depression or anxiety in 2022/23, accounting for 17.1 million working days lost¹. Deloitte also reported that poor mental health, including stress, costs UK employers up to £56 billion a year. MPANI will be meeting with Local Council Senior Planners Group (SPG) shortly to discuss many issues of concern for our mineral products sector. Namely:

• Establishment of a skilled, wellresourced shared service for mineral and waste planning

• Time-scales for planning decisions

• Fast-tracking of renewable energy infrastructure on MPANI members sites

• Use of financial guarantees

• Recent involvement of the Public Health Agency (PHA) as a statutory consultee

If you’re interested in becoming a full or affiliate member of MPANI and get access to up-to-date industry news and guidance don’t hesitate to give me a call on 07876136929. It would be great to have you on-board. Take care and stay safe!

20mm

With more than half a century of experience in haulage, demolition, and recycling, R Heatrick Ltd (RHL) has carved out a prominent role as an environmental leader within Northern Ireland’s construction industry. As a family-run business founded in 1969 by Robert Heatrick, RHL has evolved far beyond its civil engineering origins to become a pioneer in sustainable waste management.

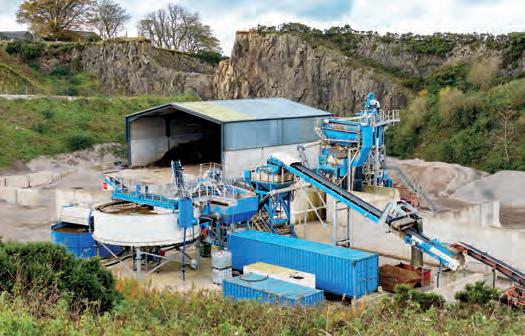

At the core of this transformation lies one of its most impressive innovations to date: a state-ofthe-art wash plant dedicated to processing recycled aggregates and trommel fines – an initiative that not only advances the circular economy but also sets a new standard in the region for environmental excellence.

Long before sustainability became a buzzword, RHL was finding ways to repurpose construction and demolition (C&D) waste. The company’s early demolition

projects involved crushing concrete and brick debris into hardcore material for reuse on-site or further processing at its own quarry. These surplus materials were tested under WRAP protocols and reintroduced into the construction market,

reducing landfill dependency and the need for virgin aggregates. That ethos continues today, embedded deeply in the company’s operations and culture. Still family-run, now by Robert’s sons and grandsons, RHL combines generational knowledge with modern innovation to tackle today’s most pressing environmental challenges.

In 2021, Managing Director, Trevor Heatrick, led a new initiative to solve a long-standing problem in waste processing – what to do with trommel fines. These materials, made up of fine sand, soil, and organic debris, are typically unsuitable for reuse and often relegated to landfill. Determined to find a sustainable alternative, RHL partnered with

engineering specialists CDE Global to build Northern Ireland’s first trommel fines washing plant at their quarry in Lisburn. The £2 million investment has proven transformative, enabling the company to recycle up to 98 per cent of all C&D waste it handles.

The 50-tonne-per-hour wash plant features a sophisticated process including an AggMax modular log washer, an EvoWash system with Counter Flow Classification Unit (CFCU), AquaCycle thickener, and static screens. This configuration enables the removal of lightweight organics – key contributors to Loss on Ignition (LOI) – and converts the waste stream into high-quality, sellable construction materials.

The wash plant currently produces a variety of in-demand materials, including paving and cable sands, drainage gravel, and two sizes of pipe bedding. These are sold back to the construction, farming, and

landscaping sectors, helping close the loop on material reuse.

RHL’s wide range of products in question also include:

• Crushed Concrete 75mm down

• Pipe Bedding 14mm & 20mm

• 50mm Clean Drainage

• Paving/Concrete Sand

• Fine Sand

• Screened Top soil

Notably, RHL doesn’t just sell these products – they use them too. In early 2024, the company constructed three new sheds at its Lisburn site, the largest measuring 25,000 sq. ft, using 100 per cent recycled aggregates from its wash plant.

Over 2,000 cubic metres of concrete made from recycled 20mm stone and grit sand went into these structures, underscoring RHL’s commitment to embedding sustainability at every level of its operations.

Continuing to expand its sustainability reach, RHL

recently began accepting street sweepings – a notoriously complex waste stream – after winning a contract with Ards and North Down Borough Council. The wash plant can process a 25-tonne load of sweepings in under 30 minutes, efficiently separating contaminants and converting residual materials into recycled aggregates.

“This marks the beginning of further exploration and testing of other waste streams that have the potential to contribute to the circular economy,” said Trevor Heatrick.

“We’re always looking at how we can push the boundaries of what’s possible in waste recovery.”

As the construction sector moves toward more sustainable building practices, the demand for recycled aggregates is growing – and RHL is well-positioned to meet it. The company continues to explore new technologies and partnerships to enhance its resource recovery capabilities

and increase the availability of high-quality recycled products across the region.

With plans to develop adjacent sites using its own recycled materials and expand the types of waste the wash plant can process, RHL’s long-term goals are clear: to lead Northern Ireland in recycled aggregate use and redefine how the construction industry approaches waste.

From humble beginnings to award-winning recognition for environmental and waste management excellence, RHL has proven that sustainability and profitability can go hand-in-hand. Through investment in innovation, commitment to the circular economy, and a forward-thinking family leadership, RHL stands as a beacon of environmental responsibility and a model for others in the industry to follow.

For more information about RHL, as well as pricing details for their products please email aggregates@skipway.com

How a sustainability mindset is shaping the future of construction and agriculture – starting from the factory floor.

Merlo is known across the world for its innovative handling solutions – but the company’s commitment to sustainability runs deeper than the green paint on its machines. From cutting-edge electric telehandlers to solar-powered facilities and circular waste systems, Merlo is driving a comprehensive, group-wide shift towards cleaner, smarter operations. And this transformation isn’t just happening in Italy. The UK team is taking the same ambitious steps, proving that sustainability is not a one-off project – it’s a culture.

At Merlo Group’s headquarters near Cuneo, Piedmont, sustainability begins long before a machine leaves the production line.

The site is powered in part by an extensive photovoltaic array, which in 2024 alone produced 1,150 MWh of clean energy – avoiding approximately 750 tonnes of CO2 emissions, the equivalent of planting over 4,500 trees. The goal? To reach energy parity generating as much electricity as the site consumes.

But green power is just the start.

Merlo has taken major steps to minimise its environmental impact through smart waste and resource strategies:

• Over 30 compacting presses manage the recycling of cardboard and plastic packaging

• Metal filings and scrap offcuts from sheets are systematically collected for reprocessing

• Employees are encouraged to shut down IT equipment when not in use – small actions that, collectively, lead to substantial energy savings

• Sensor-activated taps minimise waste water in restrooms, while digital transformation initiatives have drastically cut printed paper usage by transitioning communication and records to digital platforms These might sound like operational details – but they reflect a much larger ambition: to build machines sustainably, from the inside out.

Energy-saving measures continue across the facility:

• A site-wide transition to LED lighting is underway, with systems that use up to 90% less energy than traditional fixtures

• Dusk sensors and automated heating systems regulate lighting and temperature in key departments, using smart home tech to avoid waste

• New production buildings are being built with enhanced insulation, ensuring thermal efficiency and reducing heating and cooling demands

• Upgraded production equipment and streamlined logistics reduce internal fuel consumption and optimise operations

Every innovation within the factory is designed to do more with less – less energy, less waste, and fewer emissions.

Merlo’s environmental commitment doesn’t end at the factory gates. It’s carried forward into the machines themselves.

The eWorker, Merlo’s fully electric telehandler, is a standout. Zero-emission, near-silent, and packed with ecoinnovation – from regenerative braking and auto start-stop to a recyclable battery system – it’s proof that green performance doesn’t mean compromise. Also in the spotlight are the ROTO Plug & Play Hybrid, delivering full-size performance with significantly reduced emissions, and the eCINGO, a compact, electric tracked carrier built for clean operation in confined or indoor environments. But these are just the beginning. Several other models in the Generation Zero line are currently in concept development or preproduction, set to expand Merlo’s sustainable range even further. As these machines transition from prototype to production,

they will reinforce the group’s long-term commitment to offering a complete portfolio of low- and zero-emission handling solutions. Together, they signal that sustainable handling isn’t a distant goal – it’s an evolving reality. And Merlo is leading the way.

In the UK, the green ethos is equally strong. Merlo UK has embraced solar energy at its base in Ringwood, Hampshire, where rooftop panels now help power operations and employee vehicles. Any unused energy is fed back into the grid – closing the loop on responsible energy use. Where appropriate, the car policy is for hybrid vehicles, while recyclable packaging has replacing traditional materials in logistics and parts distribution.

In 2023, Merlo also began a gradual transition to more sustainable shipping methods for machines bound for the UK. Where possible, units are transported across Europe via electric freight trains, with sea crossings handled by hybrid LNG/electric vessels –further reducing the carbon footprint of every machine before it even reaches UK soil.

These are not just token efforts – they’re part of a long-term commitment to embed sustainability into every corner of the business.

Whether it’s a technician shutting down their workstation to save power, a manager reviewing LED retrofitting plans, or an engineer fine-tuning a new-generation electric telehandler, Merlo’s teams – across Italy and the Merlo group – are united by a shared goal: to create a cleaner, smarter, more sustainable future.

As Shaun Groom, Managing Director of Merlo UK, puts it: “We all have a responsibility to future generations. Sustainability is about more than the machines we deliver – it’s about how we build them, how we power them, and how we run our business day-to-day.”

It’s not just the machines that are evolving. It’s the mindset.

1,150 MWh of solar energy produced (2024)

750 tonnes of CO2 saved –equal to planting 4,500+ trees

Over 30 compacting presses across the factory

90% energy savings from LED lighting rollout

100% electric

eWorker telehandler in production

BY TOM BROUGH, GTC SALES AND MARKETING DIRECTOR

The UK housing sector is at the forefront of a digital transformation, as the nation pushes towards a sustainable net zero future. Digitalisation is reshaping the way homes are built, managed, and lived in, playing a pivotal role in reducing carbon emissions and enhancing energy efficiency. By leveraging smart technologies, digitalisation enables seamless integration between lowcarbon heating systems, the electricity grid, and user interfaces, making sustainable living both practical and accessible.

Digitalisation is transforming the UK housing sector by enabling data-driven insights, automation, and connectivity between systems. This shift plays a significant role in decarbonising homes, aligning with the Future Homes Standard, which mandates new homes to achieve high energy efficiency and low-carbon emissions. With the help of digital technologies, energy-efficient heating systems can now operate in harmony with the electricity grid, balancing energy demand and supply, while giving users greater control over their consumption. Heating, which traditionally depended on carbon-intensive sources, has become a critical area of focus in this digital transformation. Low-carbon heating systems like Networked Ground Source Heat Pumps and Community Heat Hubs, when coupled with smart technologies like a Passiv Smart Thermostat, create sophisticated ecosystems where data is used to optimise energy use, enhance comfort, and support grid stability. Through this digital integration, homes can achieve high efficiency without placing undue strain on the grid, making electrification sustainable at scale.

Networked Ground Source Heat Pumps, when installed as part of a smart bundled solution, can meet the demands of modern, digitalised homes. Networked Ground Source Heat Pumps work by extracting thermal energy stored in the ground, which is then amplified by a heat pump to provide consistent, efficient heating. As an electrically-driven system, Networked Ground Source Heat Pumps represent an essential component of electrification efforts, but their digital capabilities are what truly enhance their value. When integrated with smart thermostat technology, Networked Ground Source Heat Pumps enable residents to set their comfort levels. The device then optimises the home's

Tom Brough, GTC Sales and Marketing Director.

energy use in real-time, making informed adjustments. This removes the need for manual adjustment, creating a seamless, easyto-use home energy management system.

This smart technology also contributes to grid stability by allowing homes to respond to demand-side incentives. For example, users can be incentivised to reduce their heating demand during peak times, reducing pressure on the grid and lowering overall energy costs. This level of digital flexibility makes homes future-proofed, supporting not only today’s energy needs but also those of a rapidly evolving, decarbonised energy landscape.

Community Heat Hubs bring low-carbon heating to multi-unit developments and urban communities, where individual heat pumps may not be feasible. Community Heat Hubs use a shared heat network to distribute renewable heat to multiple homes, centralising energy use and creating efficiencies that align well with grid demands. Through digitalisation, Community Heat Hubs offer even greater benefits, with smart systems that allow for heat demand to be controlled, monitored, and balanced across the development.

By integrating Community Heat Hubs with Passiv’s digital energy management platform, a cohesive, adaptable system is created that operates efficiently at scale. The digital energy management platform provides real-time data on energy consumption across the Hub, enabling responsive heat distribution that matches both user demand and grid capacity. This digital integration also offers housebuilders a scalable, future-ready solution that supports both cost efficiency and compliance with sustainability standards, making it easier to create smart, low-carbon communities.

Combining Networked Ground Source Heat Pumps and Community Heat Hubs with smart thermostat technology creates a digital ecosystem that benefits housebuilders, residents, and the grid alike: