Alex Hilton

ROSE CITY PIGMENTS

HARVEST HALL

DUNDEE TERROIR

WHITAKER FURNITURE SCHOOL

SELECTED WORKS

When matter receives light, it effuses color. For millenia, humankind has transformed the matter found in nature to reveal the extraordinary properties within. Serving as a community center for education and experimentation, a supplier of locally-drived pigments and respective tools, a home for artists and scientists, and an exhibition space, this building intends to continue this tradition by celebrating nature as the original source of pigment.

In many contemporary cities, material goods are bought and consumed, but for the majority no longer made. Shifting the city as a place of production, not only consumption, drives this project.

Utilizing vaporization technology, this spray-drying process takes food waste such as beetroots, lemon peel, avocado seed and pomegranate rinds and transforms them into raw pigment powder. There is also potential to source pigment from the invasive plants of local ecosystems such as japanese knotweed or scotch broom.

This building supports an industry that engages circular economy principles to repurpose something often treated as waste or problematic into something celebrated and treasured.

above spread southeast perspective render of building in site opposite page above image of Kaiku System prototype developed by Nicole Stjernsward that informs this production model opposite page below diagram of process that informs the production design.

above diagram of site on border of commercial and residential zoning

opposite page left

wall section detail with material pallette

opposite page right

window detail illustrating how pigment reveals itself on material below south elevation

FLEMISH BOND

POLISHED CONCRETE

SOLDIER COURSING

below collage of full scale mock up of brise soleil corridor

opposite page 1/8 scale mock up of perforated brise soleil

above longitudinal section of courtyard

below longitudinal section of production space

above transverse section showing courtyards and production space

below

Around October, the season begins it’s change and so the environment responds. The forested canopy above shifts in kaleidoscopic color as the crisp air cools all around. In Portland, Oregon, families and friends gather in defiance of rain and wind to celebrate the fruits of harvest: specifically that of the apple. For over thirty years, the Portland Nursery has held the Apple Tasting Event on their 6-acre retail space where grandparents who once attended as a child, revel in the same excitement their grandchildren now experience.

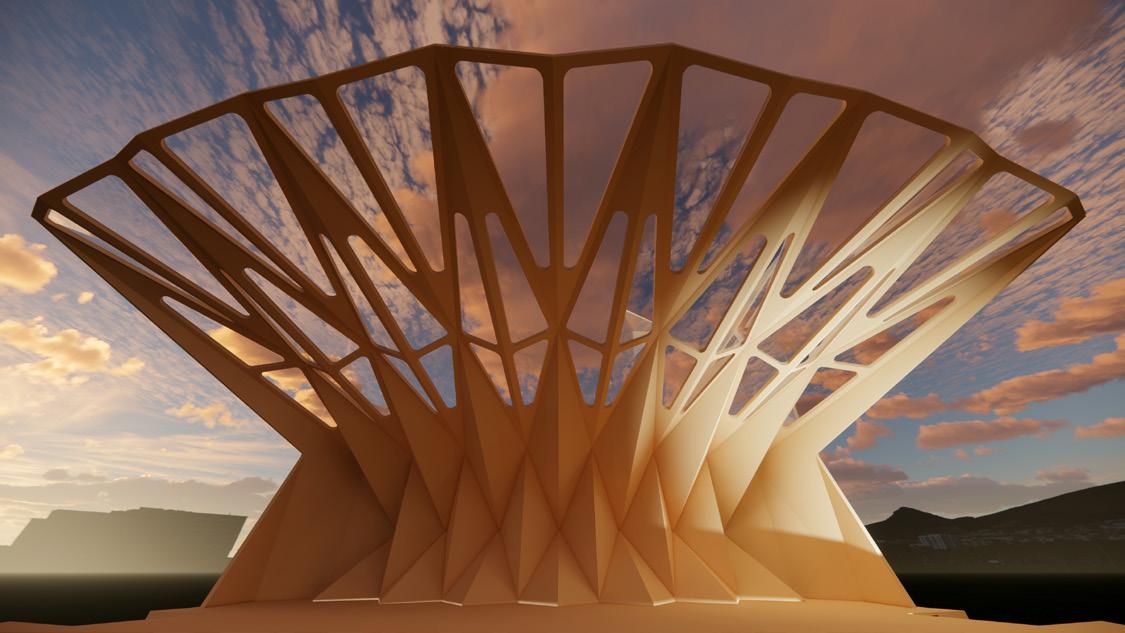

Tents emerge from the rows of potted plants; all housing various activities like hand pressed fresh cider, baking hot strudel, and pumpkin painting. Centered among these activities sits the HARVEST HALL: a mass timber pavilion utilizing the rigidity of a folded plate structural system inspired by origami.

Five different triangles all composed of Mass Plywood Panels are CNC cut to precision and pre-fabricated into folded diamonds with in-set knife plates. The diamonds can stack on top of another to save maximum space during transportation. On site, the diamonds are slipped onto the knife plate of another and bolted into place to form a cantilevering canopy.

Inspired by the cellular nature of a deciduous leaf, the Harvest Hall fluidly shapes a performance space supporting live-music and celebration. In it’s faceted nature, the canopy offers protection from the elements and an increased acoustical presence for wherever a performance is desired.

below concept sketch opposite page night performance render

First inspired by vein-like qualities of a leaf, the initial design used curved glulam members in a diagrid framing system. Then, a standardization of member dimensions address on-site construction simplicity. Panels are explored for resisting lateral forces. Origami research informs geometry. Finally, the design settles on a rigid folding plate system to elegantly handle structural forces while integrating cellular relationship of leaves.

opposite page concept sketches exploring grid proportions, connection details, and origami

below bird’s eye view renders of pavilion evolution

opposite page using grasshopper component, Karamba, to model and analyze the axial stress and deformation of structural members

below using grasshopper components to analyze and identify optimal organization of the five types of triangles for CNC routing. Different factory sizes paired with certain types minimize material waste. Offcut loss analysis underscores the importance of geometry optimization.

below plan and elevation drawings

opposite page fish eye rendering

Perched on the Dundee Hills of Willamette Valley, Oregon, this project develops both a tasting and event space with a full scale production facility on one of the hills. The site’s slope and unique soil informs a design that integrates wine culture and the iconic Oregon landscape. In addition, structural elegance seeks to luminously express the intended spaces.

The 20,000 square foot production facility utilizes the northward sloping face of the hill, where land is previously developed and sun exposure less favorable for pinot noir grapes. To maximize barrel aging space and minimize energy strain to control its environment, the facility digs into the hillside. As a result of its extraction, the Willamette Valley’s famous Jory soil is used for a specialized method of rammed earth. Just as it structures the palate of the wine grown there, Jory soil used for the pneumatically-impacted stabilized earth (PISE) walls emerge from the hillside to define a presence of its own.

Passing these walls moving south to the hill’s crest, visitors are welcomed by a tasting center overlooking the vinyard below and valley beyond. Capable of hosting private events and public tasting, these series of interior and exterior rooms align on axes defined by the earthen walls. Here, the terroir is not experienced only by taste or smell.

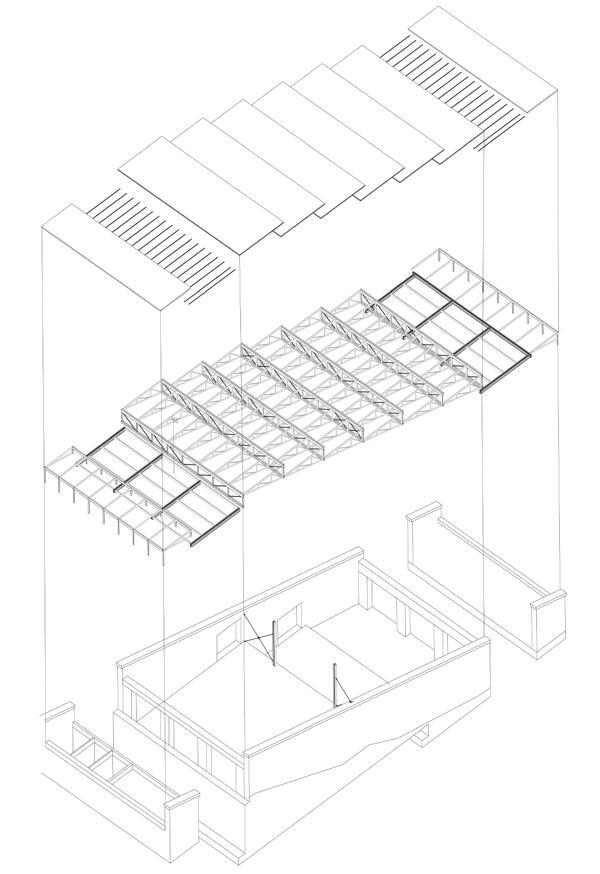

right exploded structural axonometric of production building

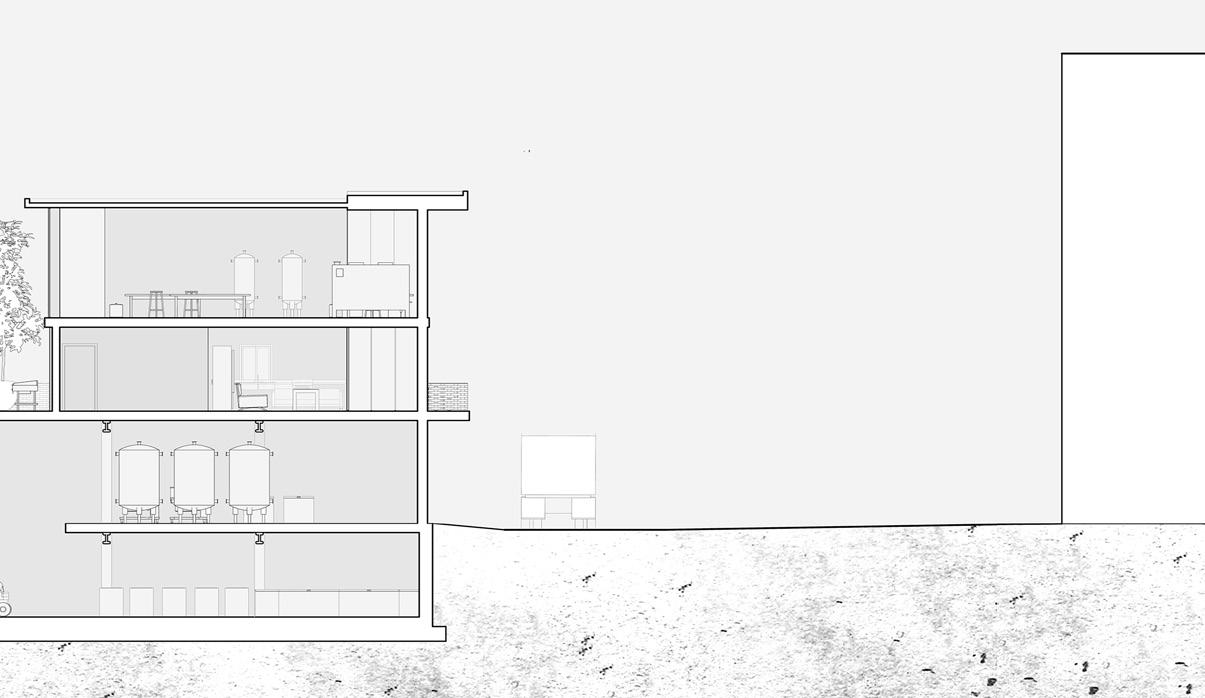

below longitudinal section of production building

opposite page:

fig 1. detailed longitudinal section of sawtooth roof

fig 2. detailed of structural tie rod bracing system

fig 3. detailed of transverse section showing sawtooth roof meeting PISE wall

fig 4. detailed of transverse section showing PISE wall meeting concrete foundation

fig 5. detailed of transverse sectton showing concrete foundation footing

above

axonometric detail of steel post and beam connection

right

detailed longitudinal section of tasting center

opposite page above

continuation of detailed longitudinal section of tasting center

opposite page below

longitudinal section of tasting center

below plan of tasting center opposite page above south elevation of tasting center opposite page below south transverse section of tasting center

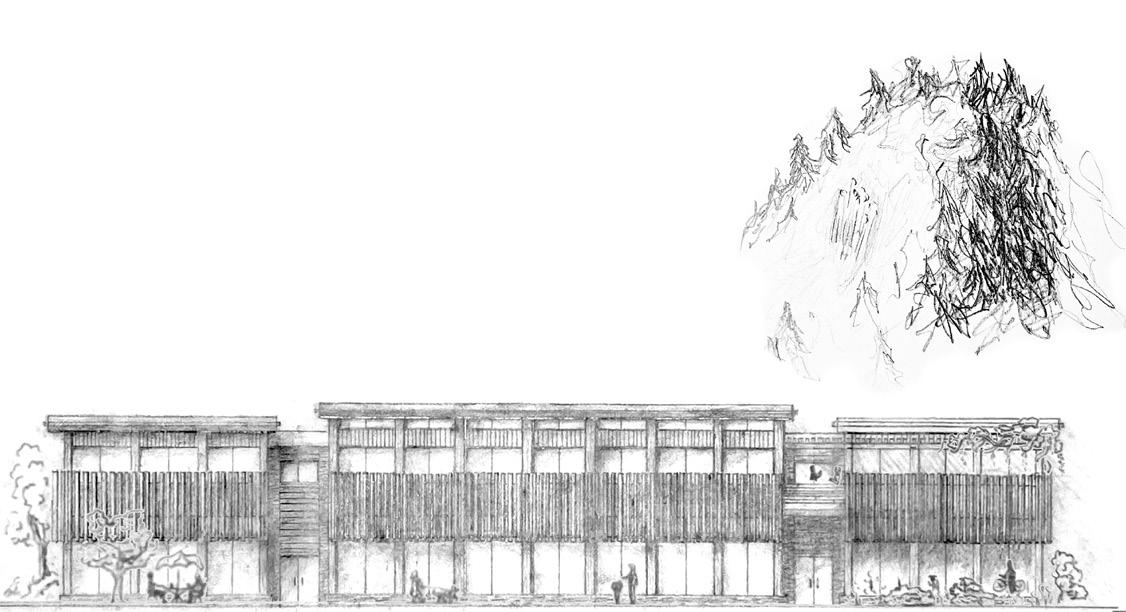

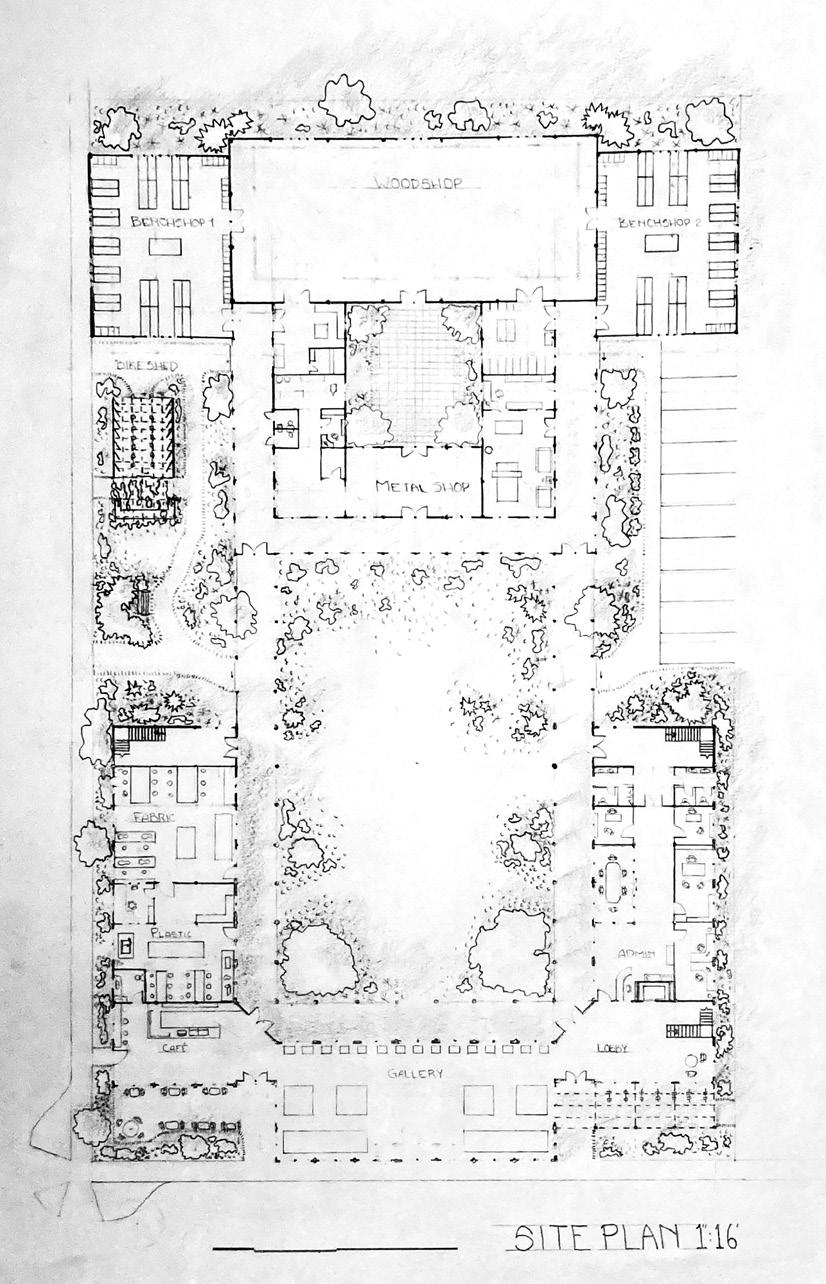

Resting between the foot of Skinner Butte and Eugene’s Whitaker District, this school for furniture-making brings together a community of makers, students and curious visitors.

Reflecting the mortise and tenon, two interlocking buildings create a variety of spaces to encourage public engagement and support private workshops and classrooms. In between, a semi-private courtyard hosts a diverse mix of indigenous plants, celebrating the pacific northwest region. Using a heavy timber structural system clad with douglas fir, the center weaves itself into the blended fabric of the industrial district and agricultural history.

Where a passerby can visit the school’s gallery, shop for handmade furniture or even enroll, the southern building stands as the face of the school. Slightly removed from the busier end of the block, the northern building’s workshop and benchshops provide luminous volumes of workspace inside and out.

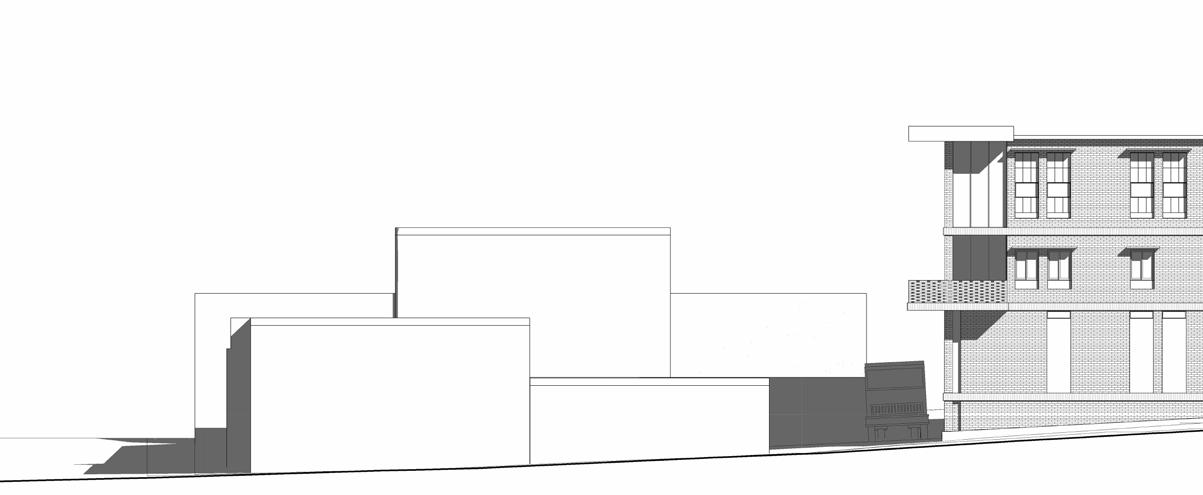

below south elevation of school

opposite page site plan

top spread east section

bottom spread west elevation

opposite page above structural axonometric model of workshop

opposite page below south elevation of workshop

current page structural framing plans