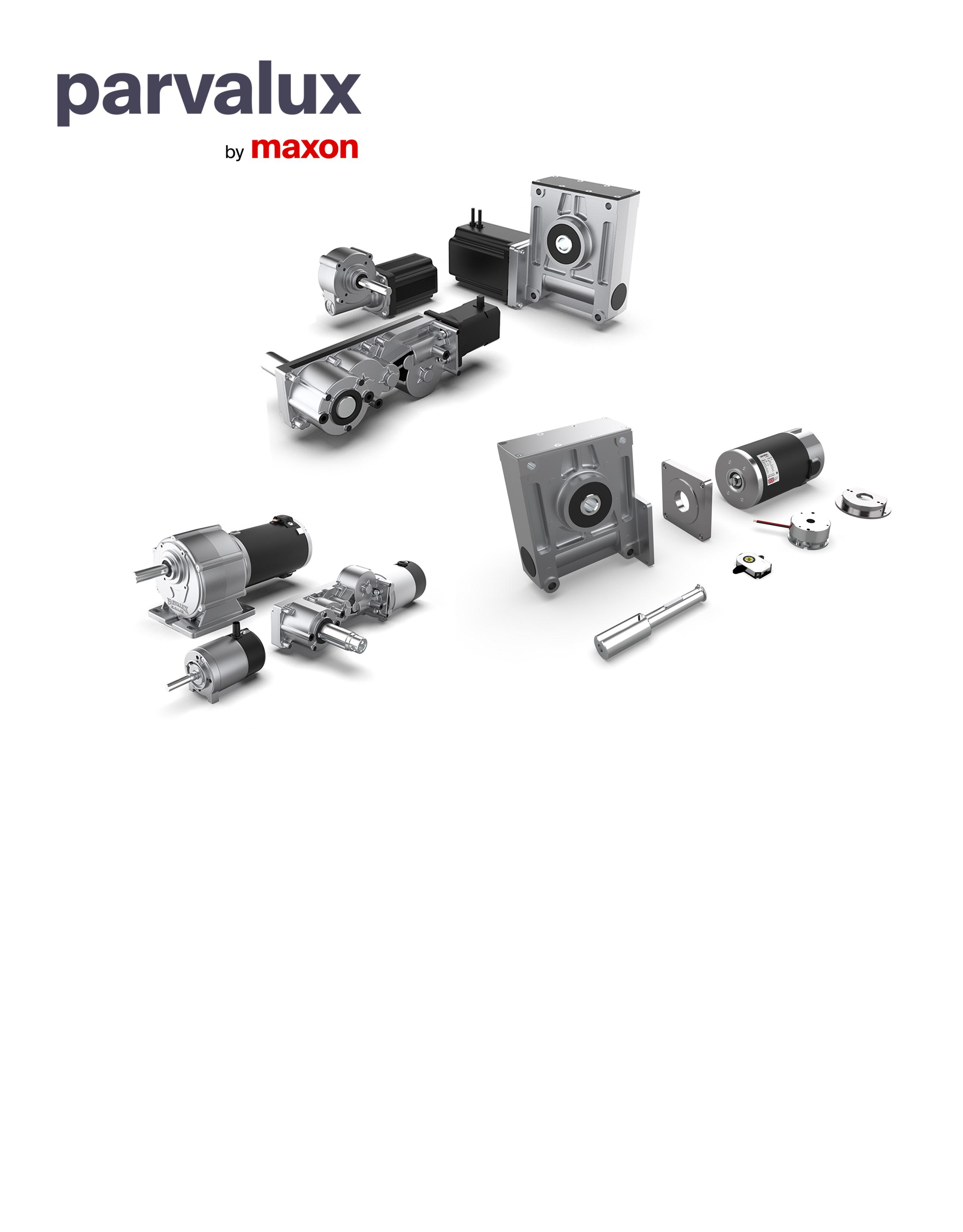

by

by

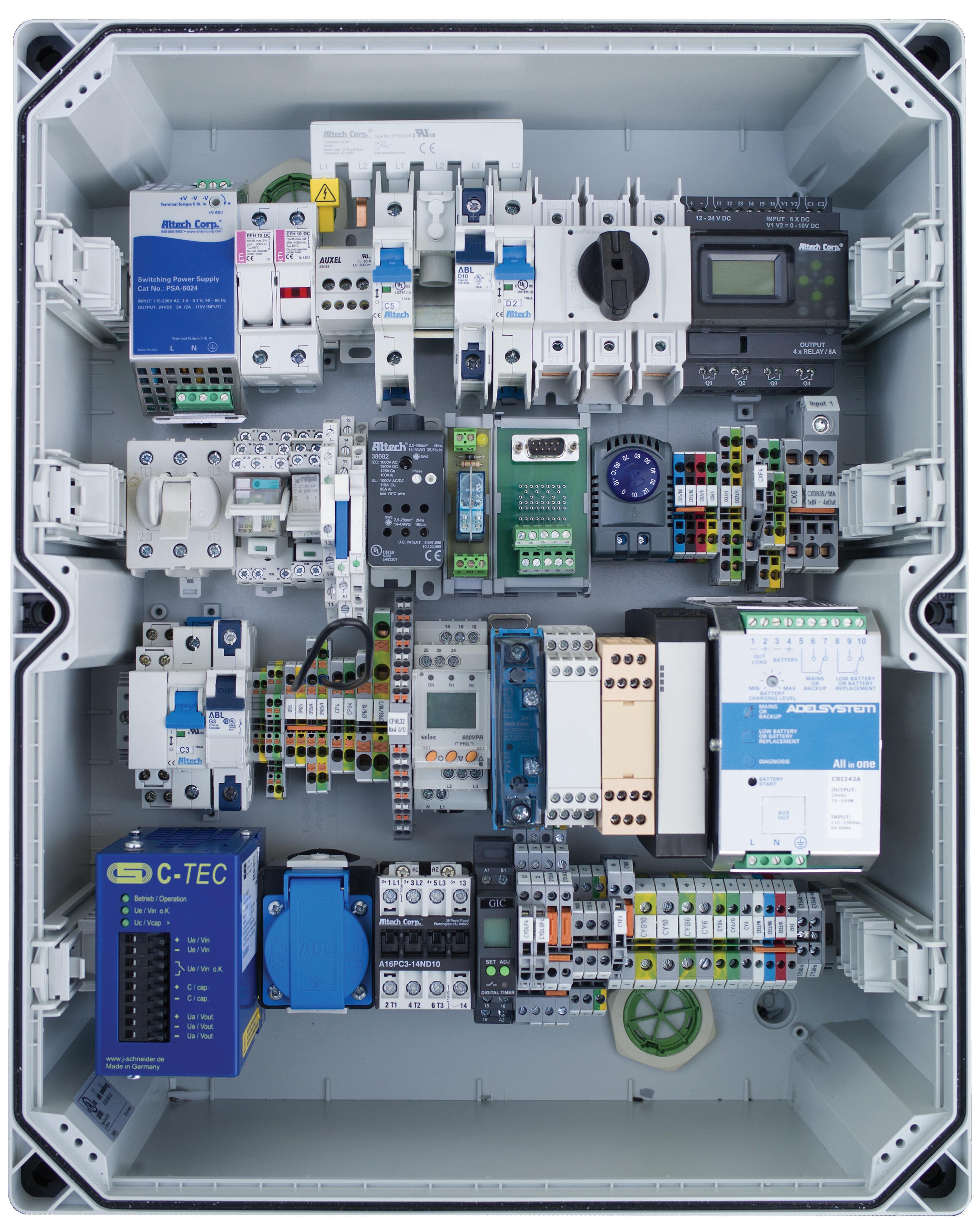

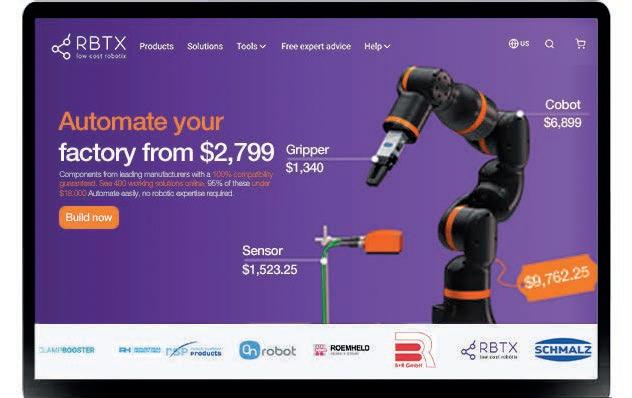

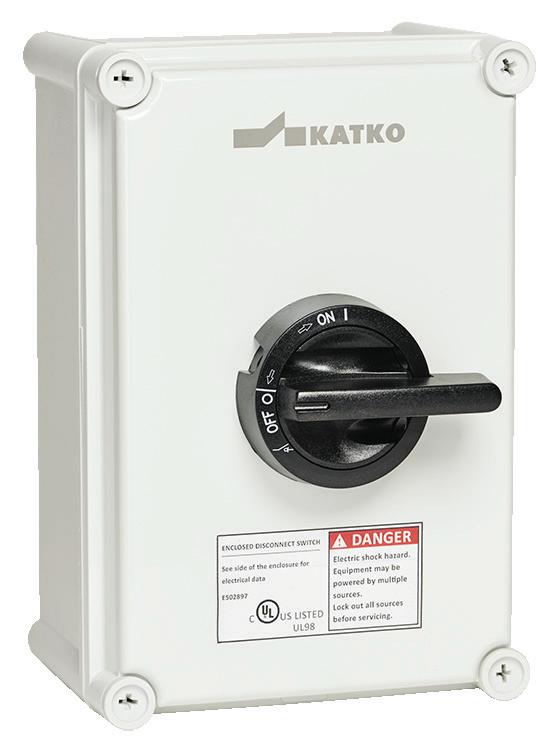

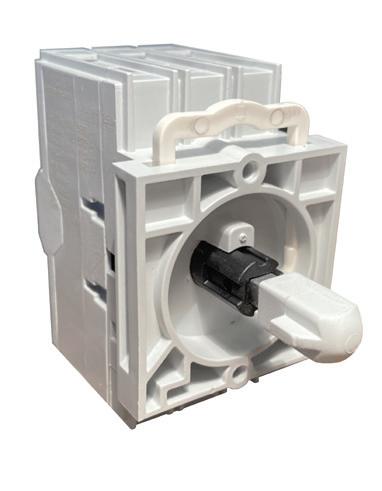

Over 6,000 top brand enclosures starting at only $7.00

Newest Addition:

AutomationDirect is continually expanding our offering of quality enclosures from the best manufacturers in the world.

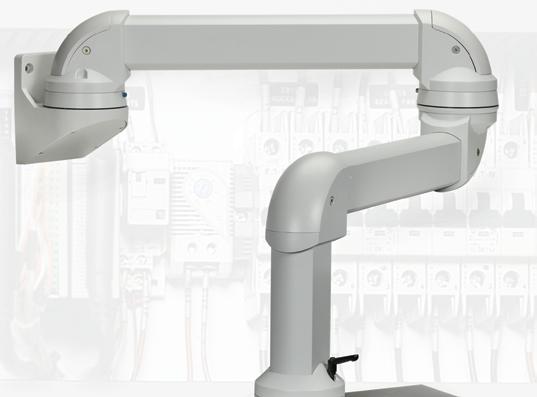

Saginaw HMI Enclosures and Suspension Arm Systems HMI enclosures starting at $505.00

Quality-built Saginaw HMI enclosures provide supreme protection for HMI panels.

Modular HMI enclosure suspension arm systems enhance your HMI installation by allowing operators to easily adjust the HMI enclosure’s position for utmost comfort and accessibility.

• Carbon and stainless steel HMI enclosures in various sizes, in NEMA 3R/4/4X/12/13 ratings, and with removable covers for easy HMI installation and access

• Modular suspension arm systems include tubes and couplings to provide the perfect configuration or your needs

• HMI enclosure accessories such as handles and keyboard trays also available

the #1 value in automation Order Today, Ships Fast! * See our Web site for details and restrictions. © Copyright 2022 AutomationDirect, Cumming, GA USA. All rights reserved. 1-800-633-0405

low-cost

wiring

for those all-important

touches! Research, price, buy at: www.automationdirect.com/enclosures

n

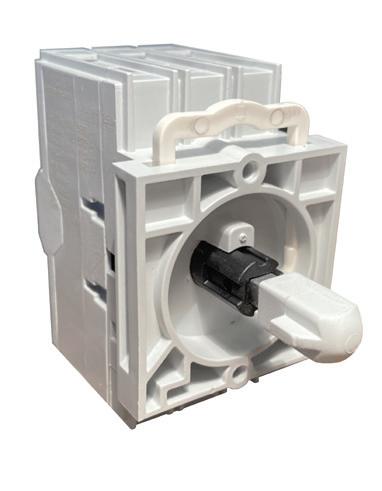

Sanitary E nclosures Pus hbuttonEnclosur e s M-roolF uo n t E nclosures Freestand i n g serusolcnE M odularEnclos u r es Dis c onnectEnclosur e s

En closures Miniature C a ses

Wire w ays , Troughs

Plus over 5,800

accessories and

solutions

nishing

Wall-Mount Enclosures Junctio

Boxes

Console s/Consolets HMI

R s,

HMI not included

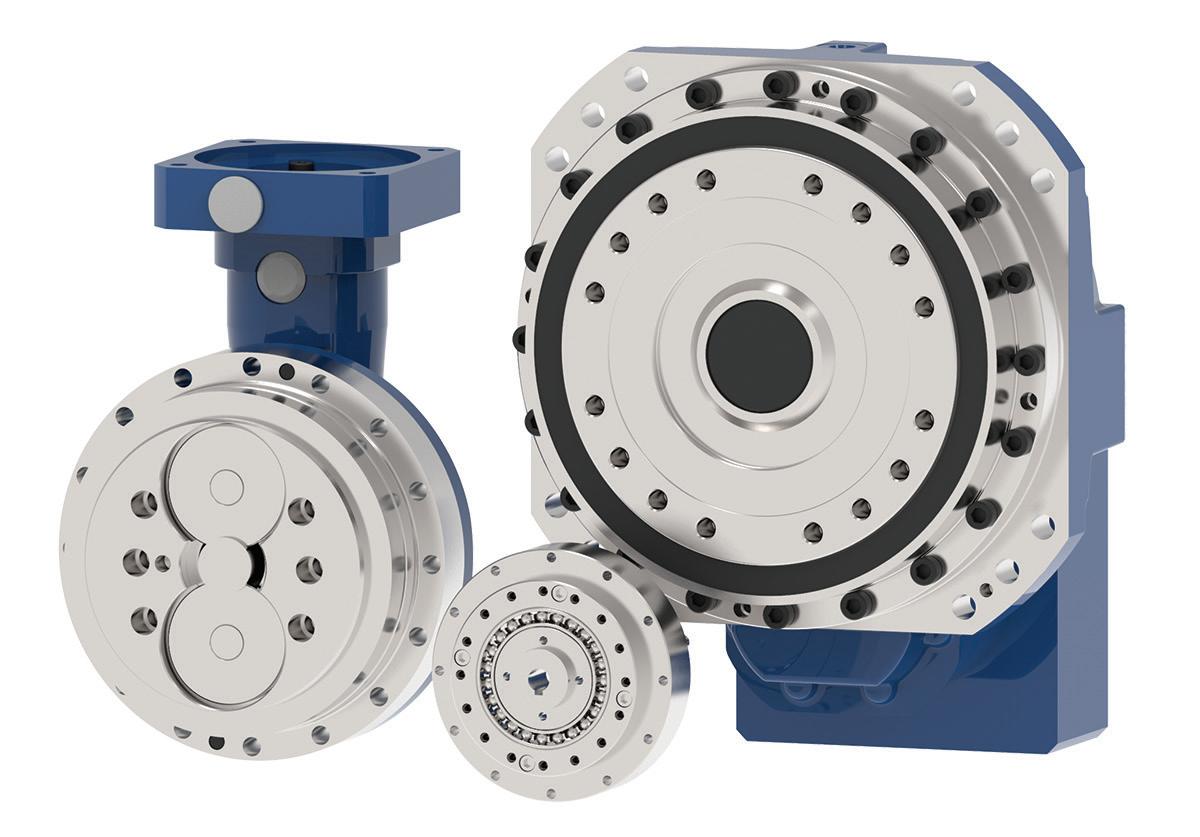

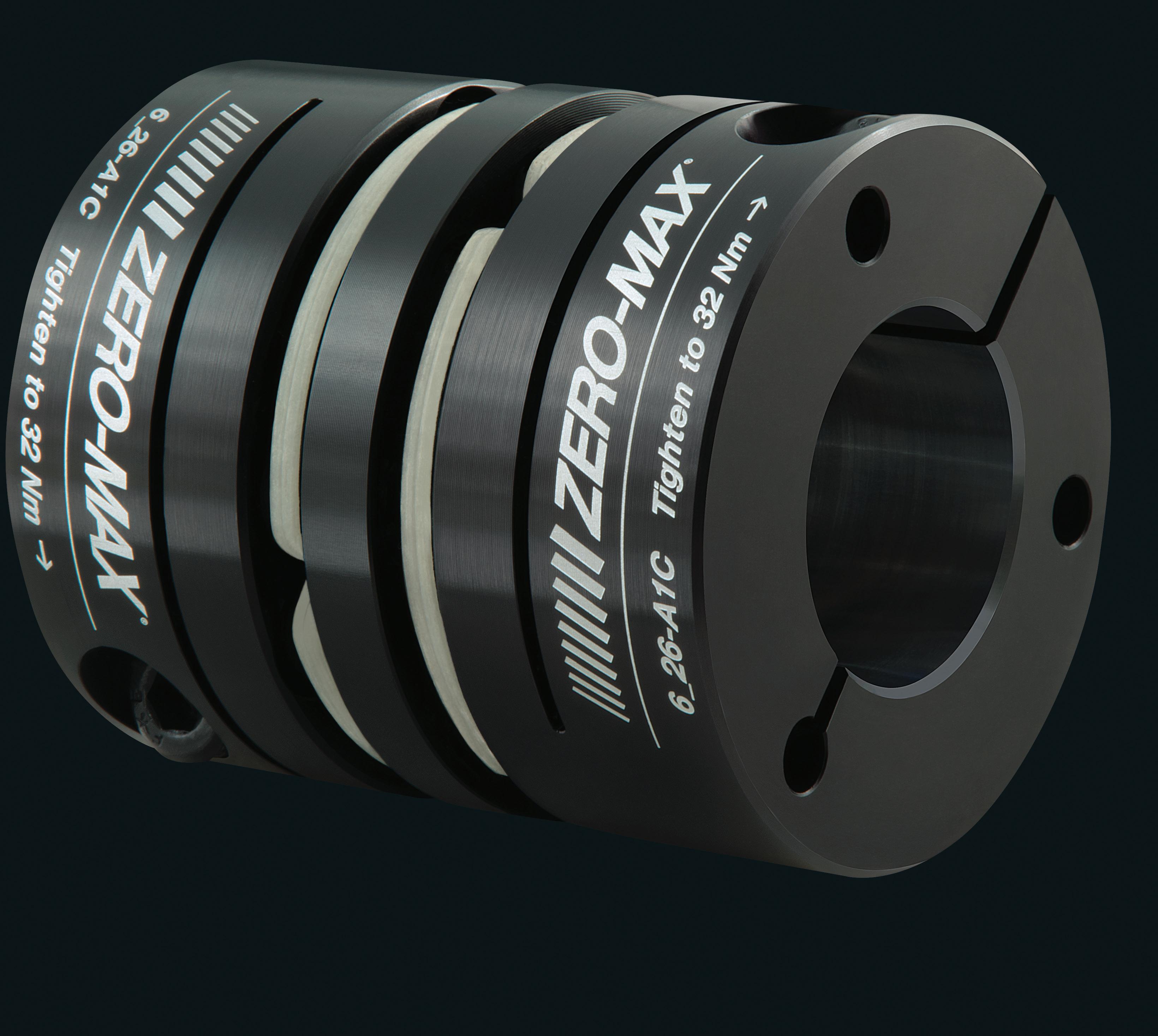

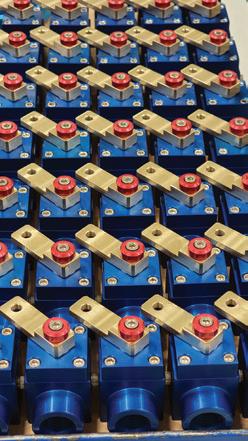

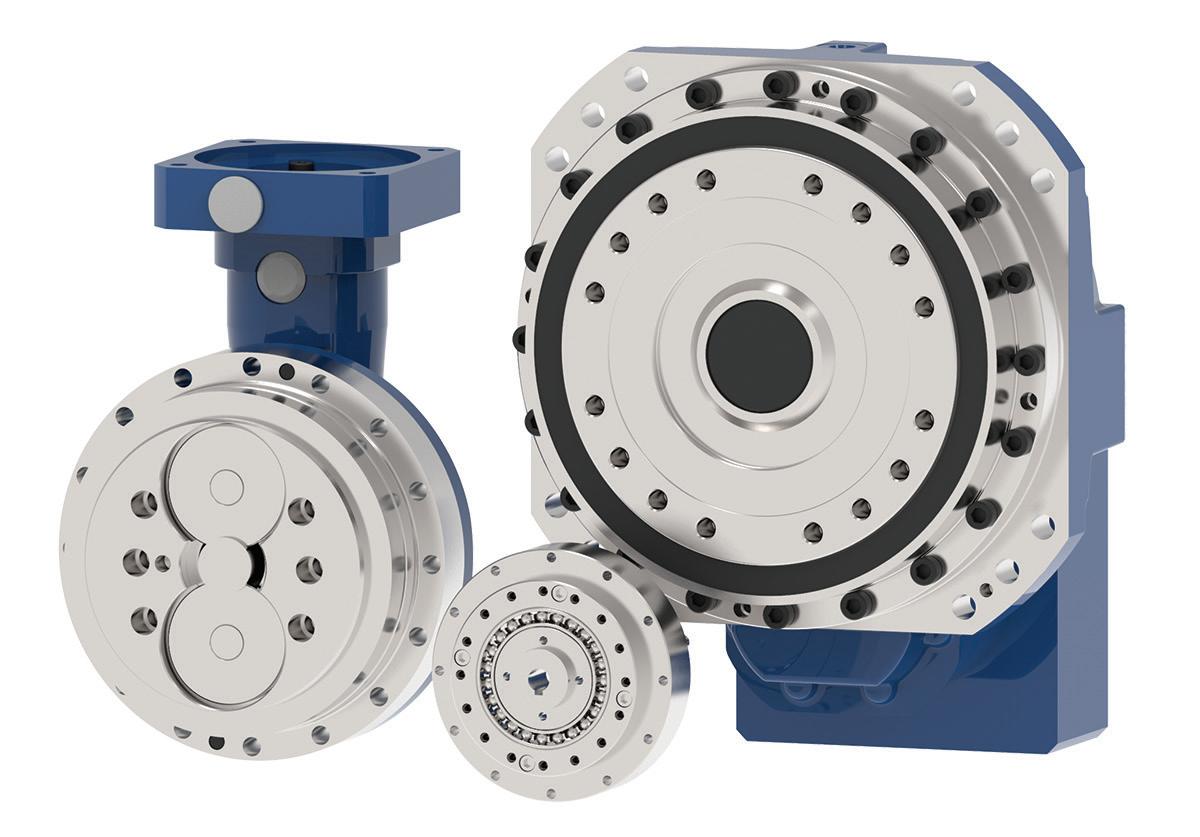

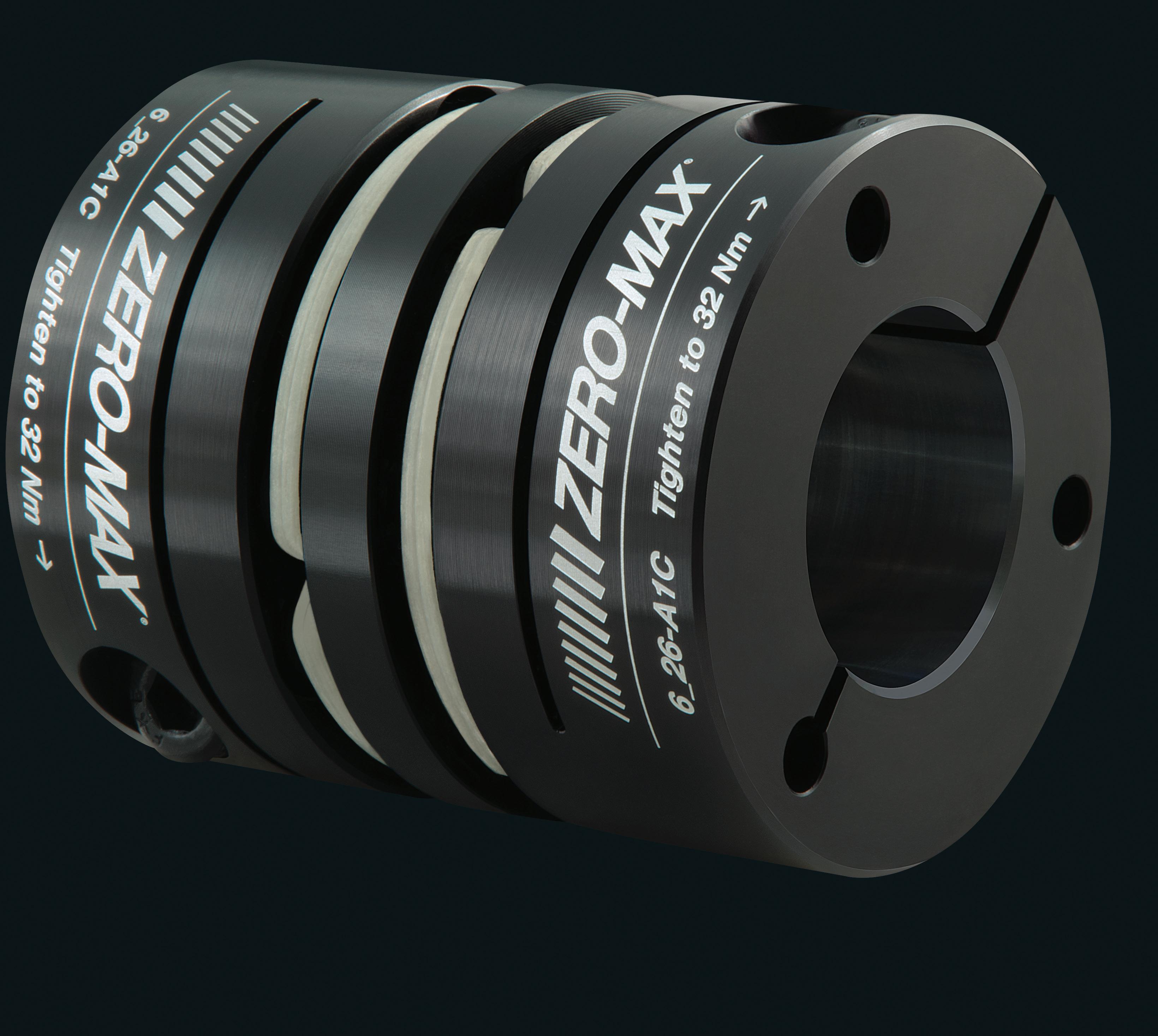

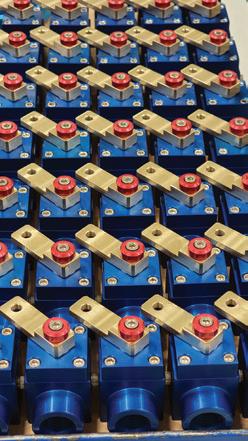

CD® Couplings

• Zero-Backlash & High Torsional Stiffness

• Engineered Performance for Reliable 24/7 Operation

• Servo-Rated for Reversing, Positioning & Precision

• Single-Flex, Double-Flex, Floating-Shaft Solutions

• Standard Models / Fully Customizable

• Engineering Assistance / Fast Delivery

www.zero-max.com 800.533.1731

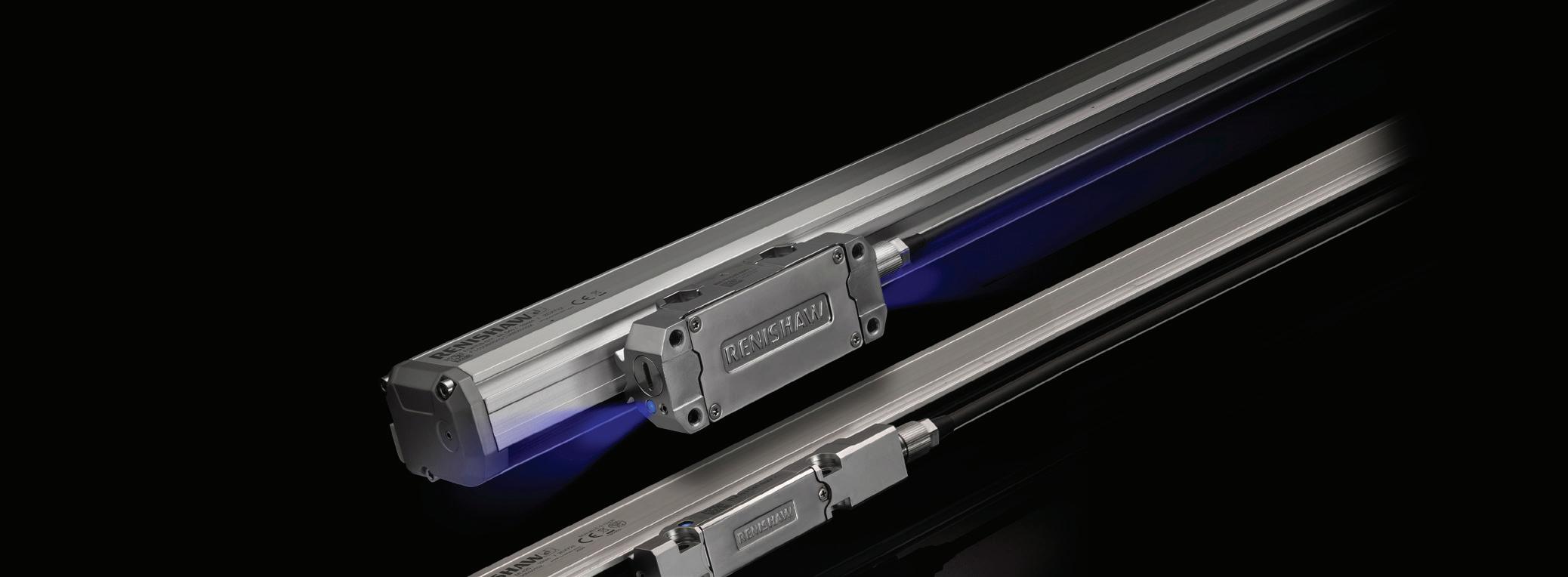

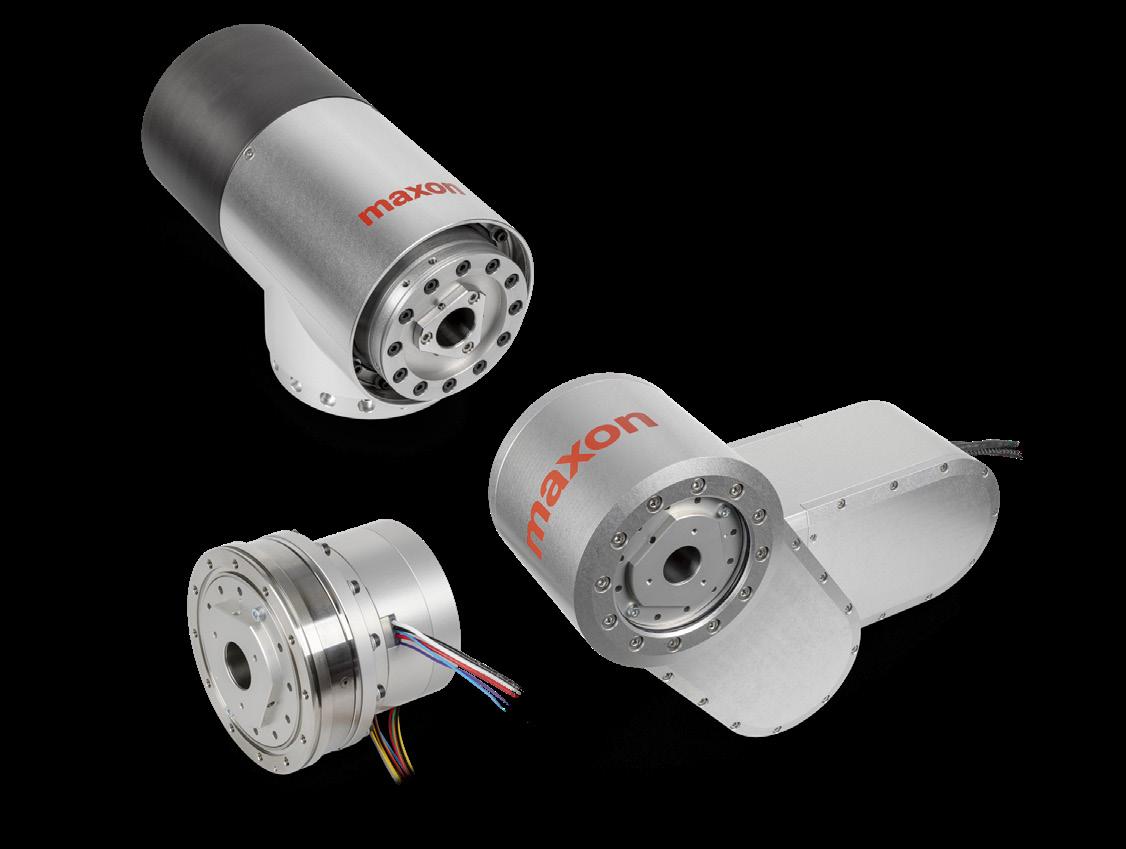

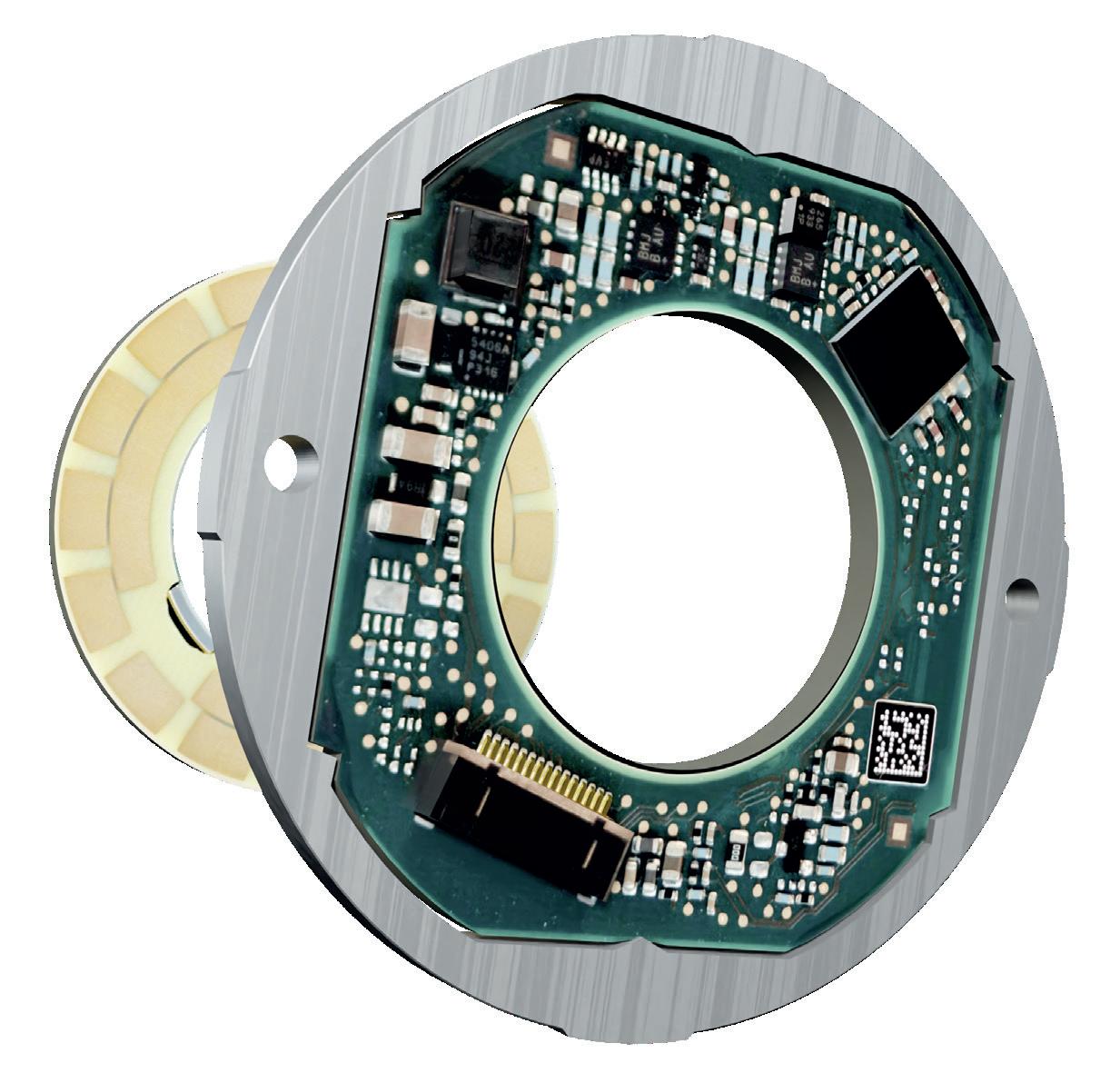

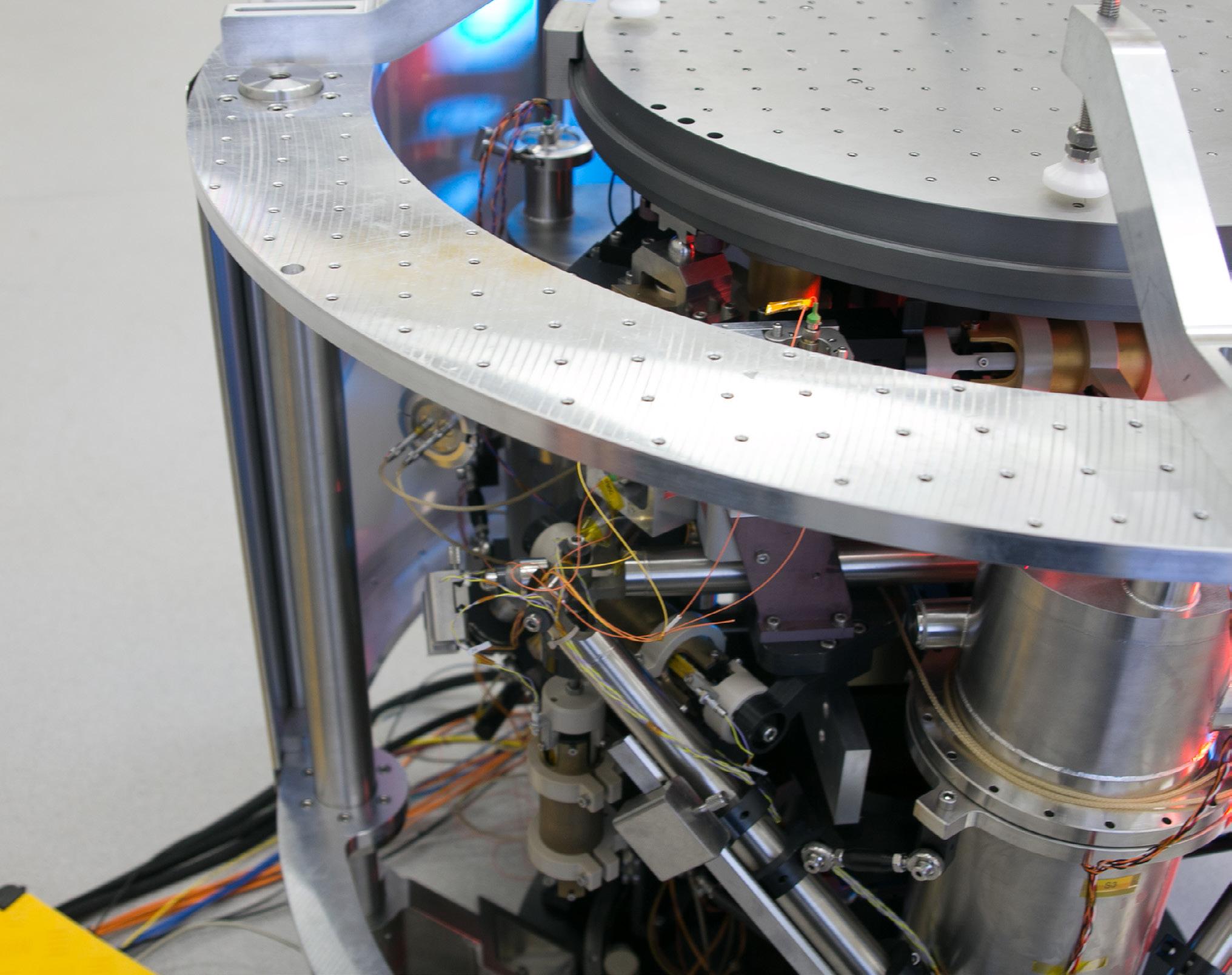

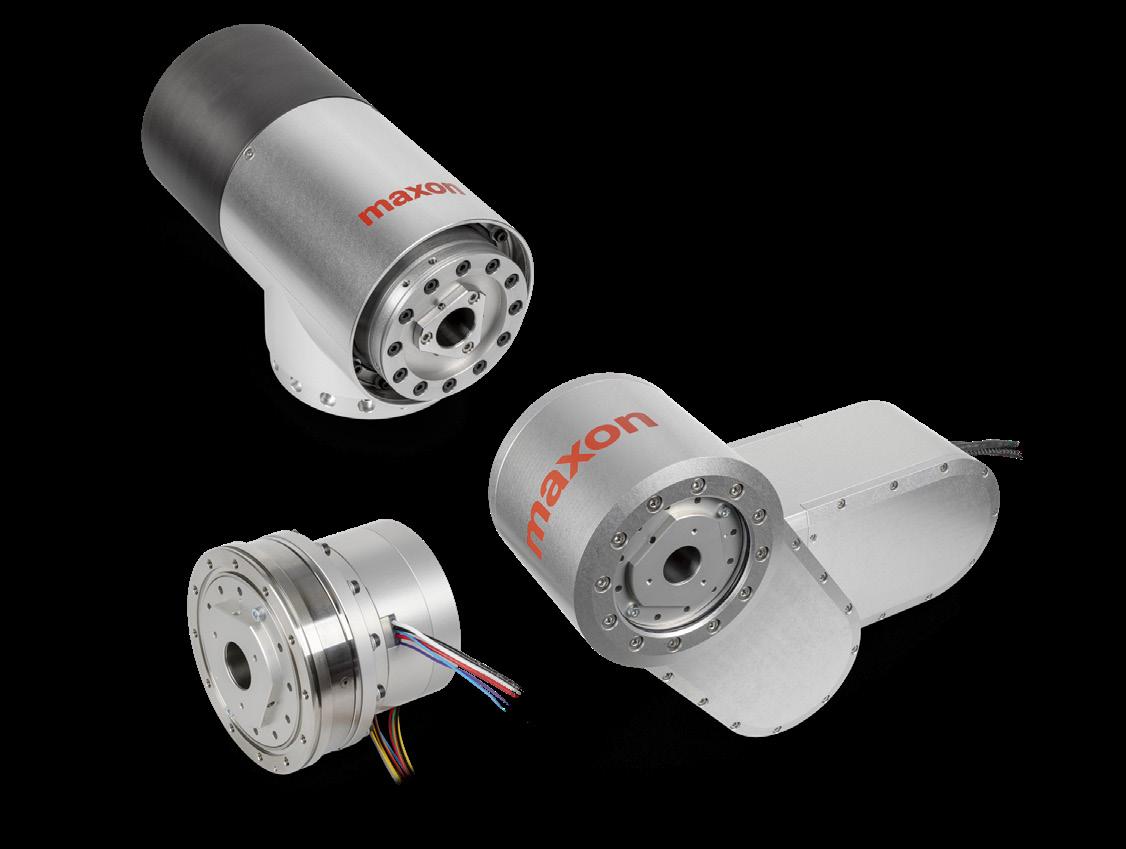

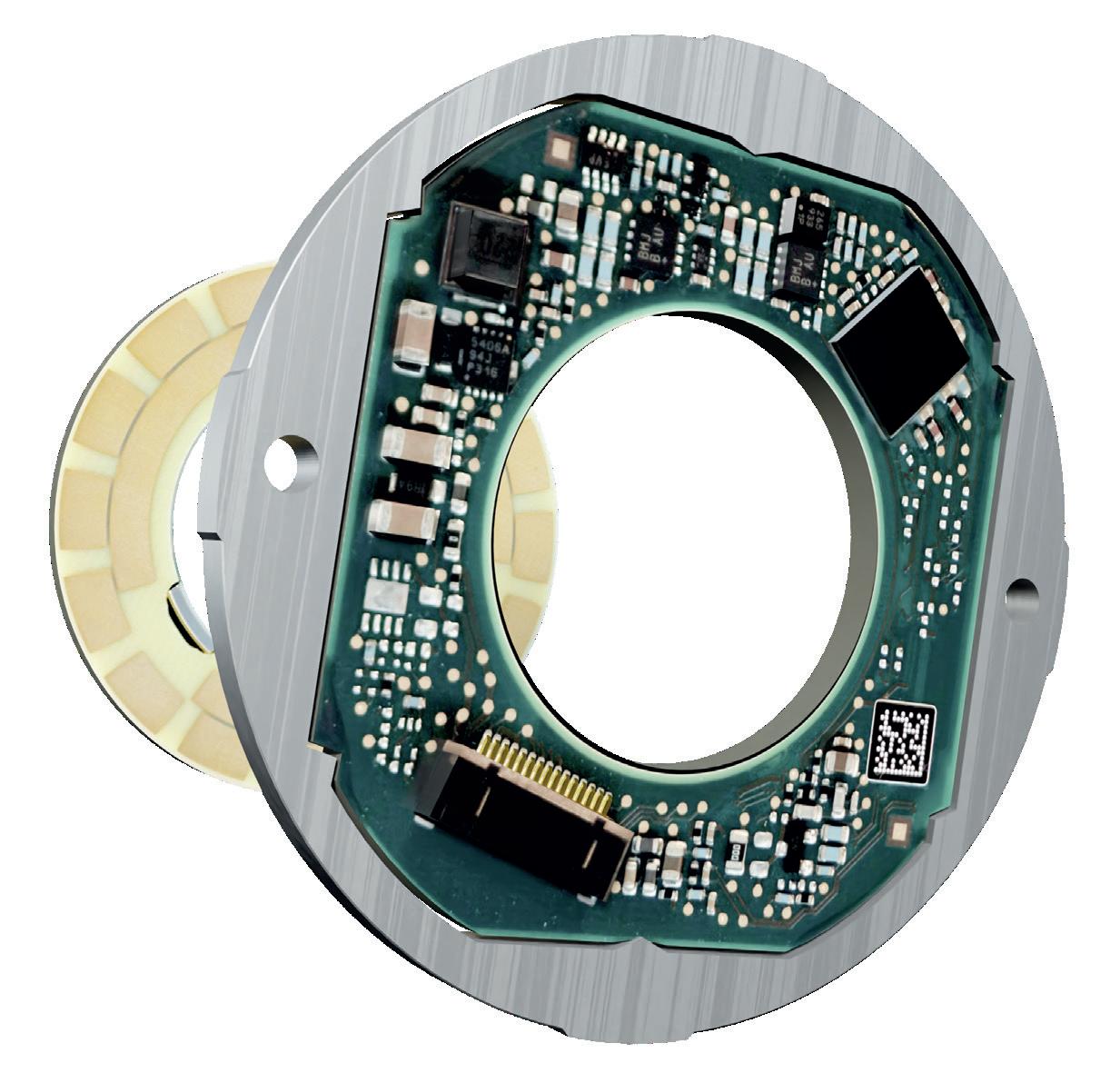

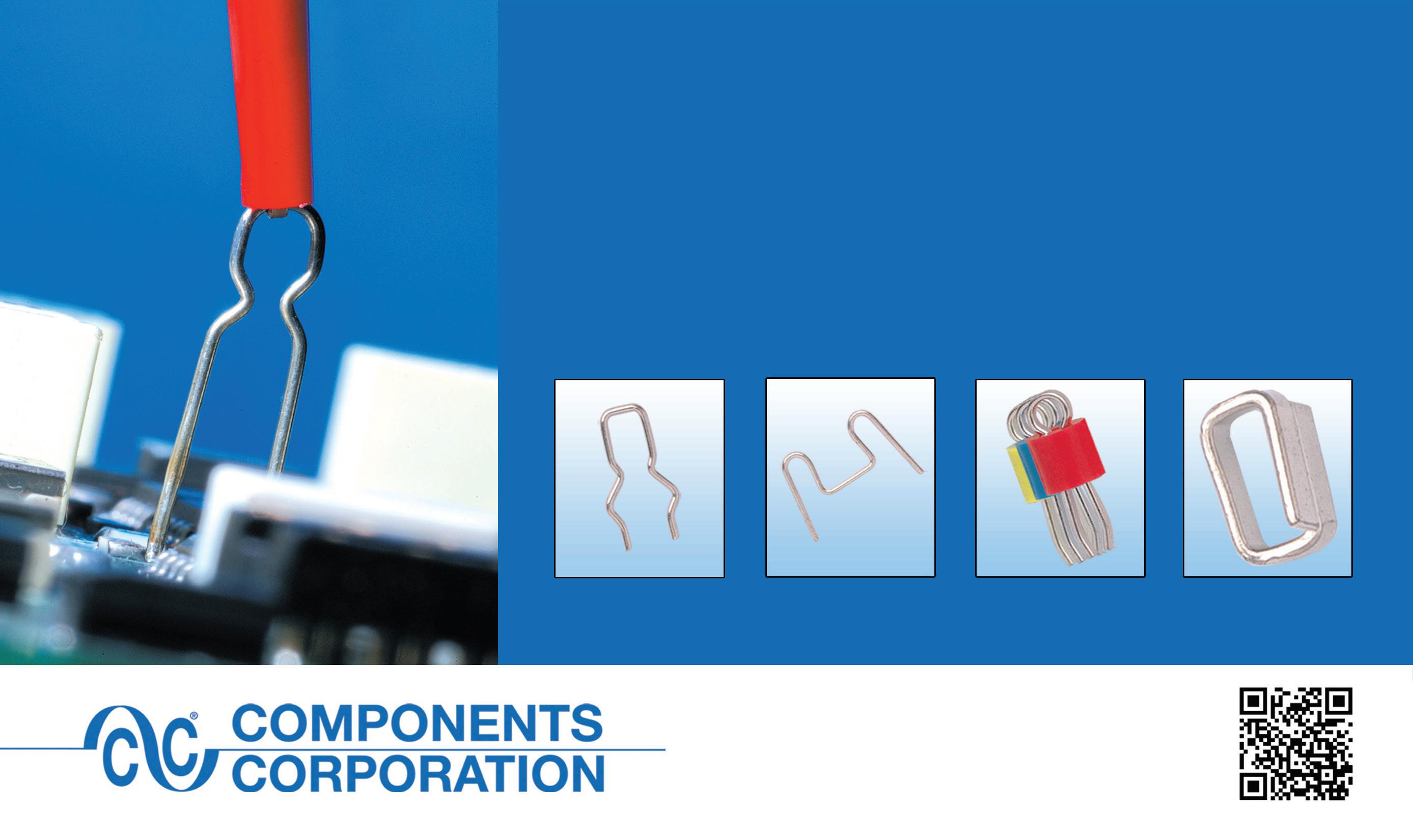

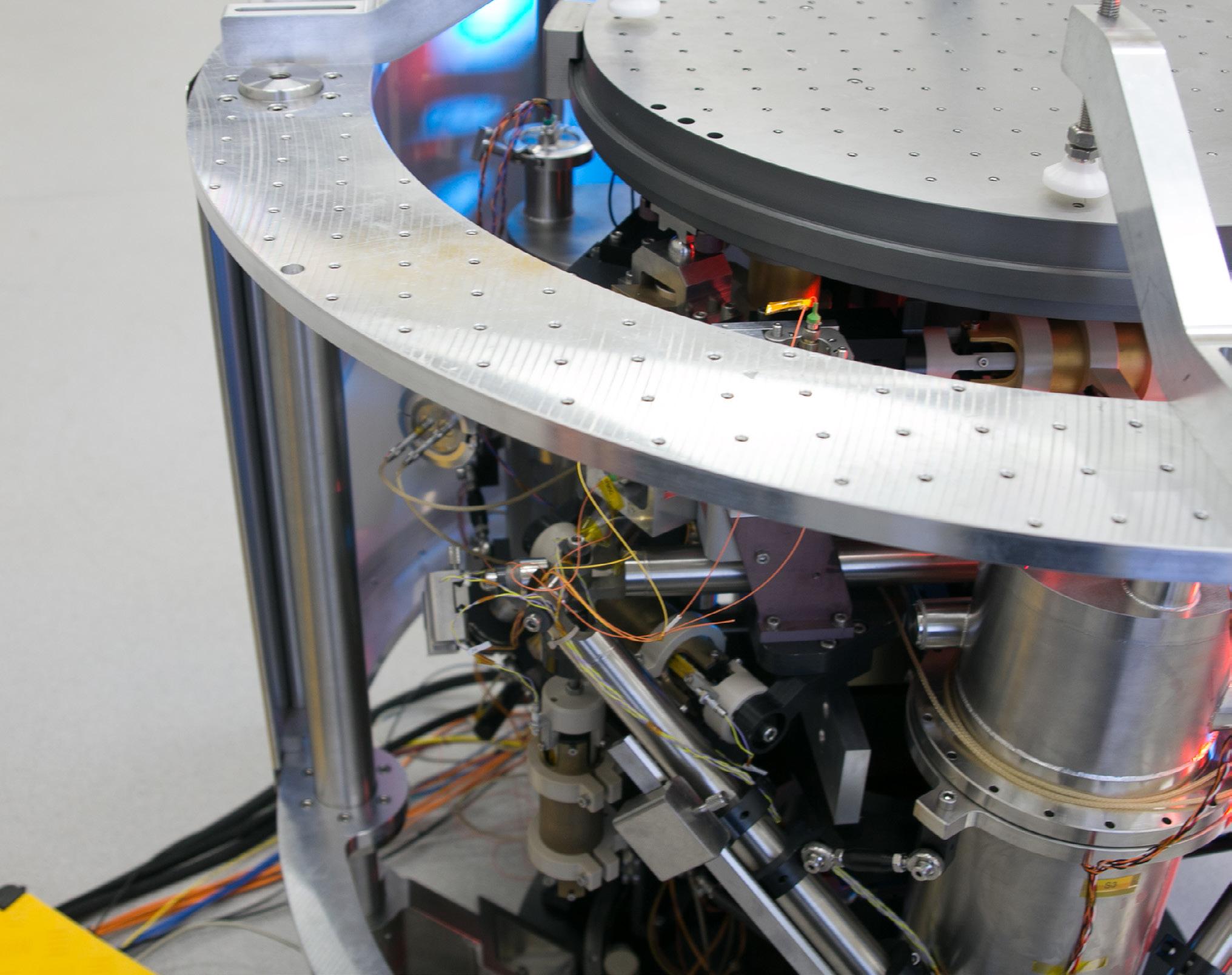

KCI 1319 and KBI 1335 Motor Encoders

Small and light for compact Servomotors

These encoders were created for the rigors of compact motor feedback in robotics applications. Meet the singleturn KCI 1319 and multiturn KBI 1335 inductive rotary encoders from HEIDENHAIN. Their simple design of a scanning unit plus circular scale gives you the benefits of low mass and a flat profile. Inductive scanning ensures

high resistance to contamination and magnetic fields. Installation is easy and secure thanks to wide mounting tolerances and mechanical fault exclusion. Simply perform a press-fit, or fasten the encoder to the motor shaft via screws. And when safety is called for, leverage the functionally safe EnDat 2.2 data interface.

robotics.heidenhain.com

CORPORATION www.heidenhain.us

HEIDENHAIN

Visit us at AUTOMATE Booth #1472

Looking at digital transformation

If you follow the publication online, you’ve surely seen some of the insightful stories from our new Executive Editor, Stephanie Neil, who’s a well-known and respected journalist in the world of packaging technology. Her recent article on how packaging machinery incorporates safety in different areas is a necessary read for anyone in that segment of the industry.

But she’s also been leading us in the development of an all-new in-person event in Boston this Spring focused on digital transformation. This buzz phrase is all about the exciting times for manufacturing that we find ourselves in — the confluence of 3D printing, CAD and simulation software, and more. That said, it can be hard to find the right answers for a manufacturer looking to evolve their businesses over the coming years.

Our new Digital Transformation Forum will take place on May 1-2 and will educate manufacturers as they move into the increasingly digital future, to maximize production and strengthen supply chains. Among the topics that will be covered are:

• Analytics and artificial intelligence

• The Industrial Internet of Things

• Our future workforce

Viability of current supply chains

Infrastructure for Industry 5.0, and Engineering and the digital thread

I hope to see you in Boston next month; please visit

digitaltransformationforum.com for more information and the exciting lineup that Stephanie and our team have put together for you. There will be talks by Walker Reynolds of Intellic Integration, Richard Braatz and John Carrier of MIT, and John McEleney of PTC. There will also be speakers from Collaborative Systems Integration, Lockheed Martin, Siemens Digital Industries Software, Deloitte, and Harting.

I’d also like to call your attention to a new change here at Design World. Starting with the May issue, our Senior Editor, Rachael Pasini, will be jumping into this Insights column every other month. Rachael and I will alternate authoring this introductory opinion piece in the magazine. You’ve probably seen some of her excellent contributions to the Technology Forward column over the past year and a half, and this feels like a natural progression for us.

Lastly, I’m pleased to announce that our special Engineering Diversity + Inclusion issue from last Fall has been named a finalist for both an ASBPE Award and a Neal Award, two of the most prominent honors in the trade publication space. Kudos to our amazing editorial and design team for putting together this incredible and much-needed issue. If you know of an engineer who’s making a difference in their industry who you feel should be recognized in this year’s EDI issue, please drop a note to me at the email address below. DW

Paul J. Heney - VP, Editorial Director pheney@wtwhmedia.com

On X (formerly Twitter) @wtwh_paulheney

www.designworldonline.com DESIGN WORLD April 2024

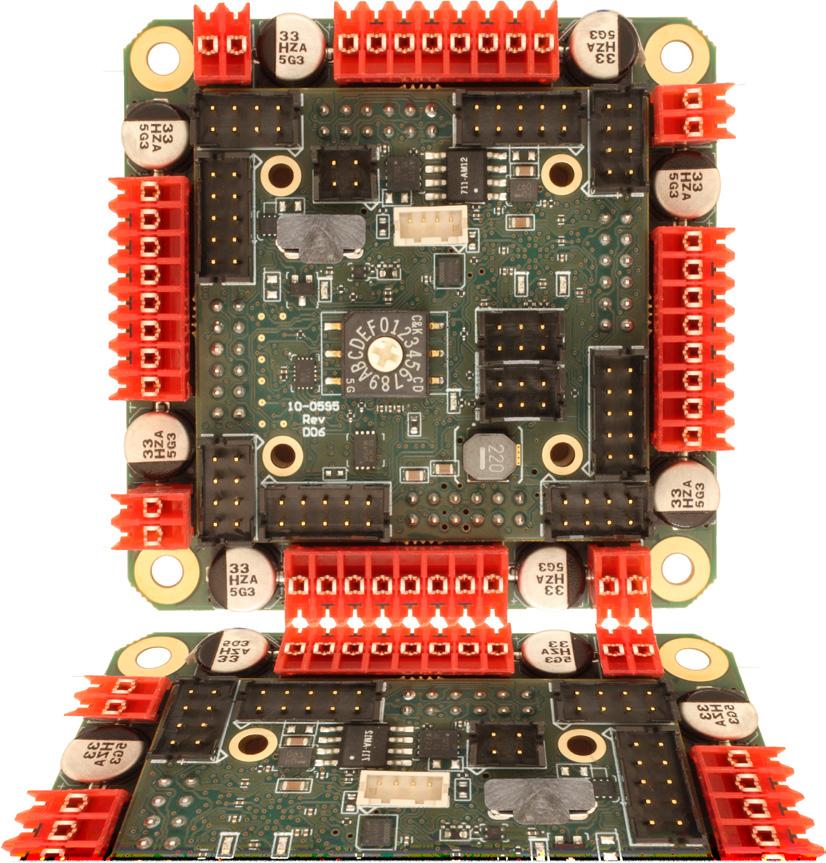

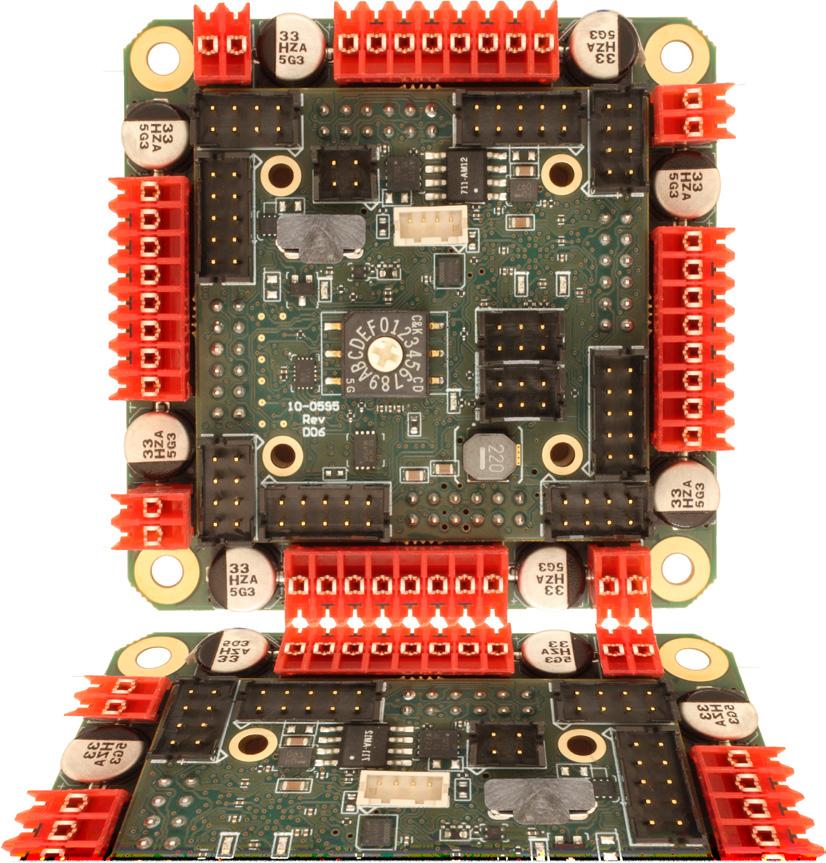

- brushed or bldc motors - 5 amps per axis - 16 analog inputs

16 on/off drivers - home and limit in - live tech support - made in the USA WWW.ALLMOTION.COM (510) 471-4000 30097 Ahern Avenue Union City, CA 94587 Technical Support (408) 460-1345 See the EZQUAD SERVO in action! 2.25” 4 AXIS SERVO from NEW! Insights

-

Stronger, quiet, reliable.

Sensitive electronics need a reliable cooling system. Our AxiForce compact fans are highly efficient, powerful, and extremely robust – in data centers, 5G power modules, electric charging stations, and many more. More

info at: www.ebmpapst.com/axiforce

LEE Linear

Bearings & Shafting Created for Demanding Environments Request a FREE Sample at 6402 E. Rockton Rd. Roscoe, Illinois USA +1.800.221.0811 sales@leelinear.com leelinear.com

Roller Pillow Block

By: Rachael Pasini • Senior Editor

By: Rachael Pasini • Senior Editor

Wind turbine blades make artful park furniture in US communities

According to the U.S. Department of Energy (DOE), more than 72,130 wind turbines and 210,000 blades were deployed as of July 2022. The DOE expects up to 9,000 blades to be retired annually through 2026, and up to 20,000 will be retired annually by 2040. Blade waste could reach up to 370,000 tons per year by 2050, with landfilling

remaining the most cost-effective option. However, one innovative manufacturer has an alternative solution that reduces landfill waste and bridges corporations and communities.

Canvus, located in Avon, Ohio, turns decommissioned wind turbine blades into artfully designed park benches, picnic tables, and other creative furniture

for public spaces. The unique structures come from different cross-sections of the fiberglass blade, and the seating and tabletop materials are from various sources, including composite lumber made of recycled plastics, rubber made from recycled tires and shoes, and mixed plastics from carpet and plastic waste.

When communities request a bench or table, corporate donors provide funding to fulfill the request. Canvus also includes a small plaque on the product with the company’s name, a custom message, and a QR code for the company’s preferred website. Corporations connected to the renewable energy industry, such as PPG, Grainger, Chevrolet, Lincoln Electric, and Siemens Gamesa, have already participated in the request program to support communities around the U.S.

“But they’re not out there enough yet for people to drive 10 minutes and see them,” said Brian Donahue, managing partner at Canvus. “So, we built a gallery that lets people see what they look like in the wild.”

The gallery is full of tables, benches, and beautiful artwork from local artists. They went further and created everything from the chandelier, entertainment center, and bookshelves out of wind turbine blades, leveraging the original blade designs for shelving or interesting features instead of destroying and conforming them. The gallery feels like a Zen garden and encapsulates everything the company stands for and wishes to contribute to the world.

Canvus’ designs also deter vandalizers and theft — a common problem for public spaces. At an average park, mounting brackets are no match for rebellious kids with a hankering for stacking picnic tables and relocating benches. But park furniture made from wind turbine blades weighs hundreds of

Sustainable Engineering

www.designworldonline.com 8 DESIGN WORLD April 2024

This upcycled wind turbine blade bench will last for decades at the Every Child’s Playground in Avon, Ohio. | Canvus

Canvus invites customers and partners to the gallery to experience its products and get inspired.

pounds and takes heavy machinery to transport and install. If kids can lift and move a Canvus bench, Donahue recommends signing them up for the football team.

“Plus, everything we build is ADA-compliant, and the tables are wheelchair accessible from both sides. So, everybody can be included,” said Donahue. “And it’s all low maintenance. You can power wash the composite lumber, and we use all stainless steel fasteners.”

Canvus also cut the blades to create a decorative wall in its gallery, which a University of Houston team thinks could replace sound barrier walls along highways.

“If you want to upcycle 15,000 blades, that’s how you do it,” said Donahue.

The benches and tables have a smooth stone finish or can be primed and painted. The company invites Cleveland-based artists to paint custom designs as yet another way to get community members involved.

“Every city has 4.6 parks, so that gives us 100,000 parks out there to work with,” said Donahue. “The average bench lasts six to eight years. Ours will be out there for 20 to 30 years.”

With product names such as the Mimi Bench, Deborah Grand Swing, and Rose Sanctuary, the company instills a personal vibe in public spaces. It also creates a Legacy Bench to serve as a memorial or to honor notable community members.

“Tehachapi, California, received an order of benches, and one is outside their VFW (Veterans of Foreign Wars). A man from that community went missing in Vietnam and never came home. Every time somebody scans that QR code, they learn about him, his story, his family, and the community. It’s so magical,” said Donahue. DW

Canvus • gocanvus.com

9 DESIGN WORLD April 2024 WHITTET-HIGGINS manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly. Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor. 33 Higginson Avenue, Central Falls, Rhode Island 02863 Telephone: (401) 728-0700 • FAX: (401) 728-0703 E-mail: info@whittet-higgins.com Web: www.whittet-higgins.com POWER TRANSMISSION RETAINING DEVICES & maintenance & assembly tools WHITTET-HIGGINS USA BEARLOK SHOELOK BEARLOK Shrink Disc BEARHUG CLAMPNUT TANGENTLOK PRECISION NUTS & WASHERS ADAPTER SLEEVE ASSEMBLIES NUTS & WASHERS HARDENED TONGUE WASHERS SPLIT COLLAR RETHREADING DIES ADJUSTABLE SPANNER WRENCH BEARING ASSEMBLY SOCKET INCH and METRIC THREADS LEFT HANDED as well as RIGHT -HANDED Materials of: CARBON, ALLOY and HARDENED ALLOY STEELS Materials of: ALLUMINUM and CORROSION RESISTANT STEEL

| Canvus

Contents DEPARTMENTS SUPPLEMENTS FEATURES MOTION CONTROL PAGES 39-52 PAGES 53-60 PAGES 61-86 Microdrives bring dynamics into handling Small dc micro drives bring dynamics into handling applications, such as swiveling-rotary modules www.designworldonline.com 10 DESIGN WORLD April 2024 4 • 2024 • VOL 19 NO 4 • DESIGNWORLDONLINE.COM Insights Sustainable Engineering Design For Industry Design Notes Digital Manufacturing Machine Tool Fluid Power Automate Show Preview Ad Index Technical Thinking 04 08 16 20 26 31 32 34 87 88 36 36 asbpe rg SILVER REGIONAL AWARD 2023 asbpe.org asbpe rg SILVER NATIONAL AWARD 2023 asbpe.org asbpe rg BRONZE REGIONAL AWARD 2023 asbpe.org RBR INNOVATION AWARDS 50 20 ON THE COVER Why bearings will be essential to Agriculture 4.0

Help us honor the companies that have provided the most leadership in engineering

It has been a fascinating decade for all businesses, including manufacturers. We’ve seen the difficult supply chain issues brought on by the worldwide pandemic, along with a shortage of qualified workers and the strong reshoring trends in many industries. If nothing else, this helps to show how resilient manufacturers can be.

These companies represent the best and brightest, and they reflect the continued vision, integrity, and creativity of their design (and manufacturing) engineers.

We think they deserve recognition from you, too. Vote online for one or more of the companies listed through October. leadership.designworldonline.com

Director, Audience Development

Bruce Sprague bsprague@wtwhmedia.com

Web Development Manager

B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

Senior Digital Media Manager

Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer

Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

DIGITAL MARKETING

VP, Digital Marketing

Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager

Taylor Meade tmeade@wtwhmedia.com @WTWH_Taylor

Digital Marketing Coordinator

Meagan Konvalin mkonvalin@wtwhmedia.com

Webinar Coordinator

Emira Wininger ewininger@wtwhmedia.com

Webinar Coordinator

Dan Santarelli dsantarelli@wtwhmedia.com

EVENTS

Events Manager

Jen Osborne josborne@wtwhmedia.com @wtwh_jen

Events Manager

Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist

Olivia Zemanek ozemanek@wtwhmedia.com

FINANCE Controller

Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist

Jamila Milton jmilton@wtwhmedia.com

VIDEO SERVICES

Videographer

Kara Singleton ksingleton@wtwhmedia.com

Videographer

Cole Kistler cole@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager

Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative

Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative

JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative

Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative

Trinidy Longgood tlonggood@wtwhmedia.com

Digital Production Manager

Reggie Hall rhall@wtwhmedia.com

888.543.2447

TOP WORK PLACES 2022

FOLLOW THE WHOLE TEAM @DESIGNWORLD Medical Design & OUTSOURCING EDITORIAL VP, Editorial Director Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney Managing Editor Mike Santora msantora@wtwhmedia.com @dw_mikesantora Executive Editor Lisa Eitel leitel@wtwhmedia.com @dw_lisaeitel Senior Editor Miles Budimir mbudimir@wtwhmedia.com @dw_motion Senior Editor Mary Gannon mgannon@wtwhmedia.com @dw_marygannon Senior Editor Rachael Pasini rpasini@wtwhmedia.com @WTWH_Rachael Associate Editor Heather Hall hhall@wtwhmedia.com @wtwh_heathhall CREATIVE SERVICES VP, Creative Director Matthew Claney mclaney@wtwhmedia.com

Art Director Allison Washko

Senior Graphic Designer Mariel Evans

Graphic Designer Shannon Pipik spipik@wtwhmedia.com

WTWH Media, LLC 1111 Superior Ave. 26th Floor Cleveland, OH 44114 Ph:

2011 - 2020 2013 - 2017, 2021 2014 - 2016 WEB DEV / DIGITAL OPERATIONS

DESIGN WORLD

@wtwh_designer

awashko@wtwhmedia.com

mevans@wtwhmedia.com @wtwh_mariel

@wtwh_shannon

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com Digital Design Manager Samantha King sking@wtwhmedia.com Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com Digital Production Specialist Elise Ondak eondak@wtwhmedia.com HUMAN RESOURCES Vice President of Human Resources Edith Tarter etarter@wtwhmedia.com asbpe SILVER REGIONAL AWARD 2023 asbpe. asbpe SILVER NATIONAL AWARD 2023 asbpe. asbpe BRONZE REGIONAL AWARD 2023 asbpe. www.designworldonline.com 12 DESIGN WORLD April 2024

NOW ONLINE!

VOTE ONLINE

ELECTRIC MOTORS GEAR PUMPS HPUs

The US has many separate electric grids and there are differences in maximum and minimum voltages, but the small differences are enough to cause problems for a company. Gaudent Technology can design an AC electric motor with winding that covers the full range of the US electric grid thus minimizing problems.

CALL TODAY FOR YOUR CUSTOM SOLUTIONS: (219) 706-8521

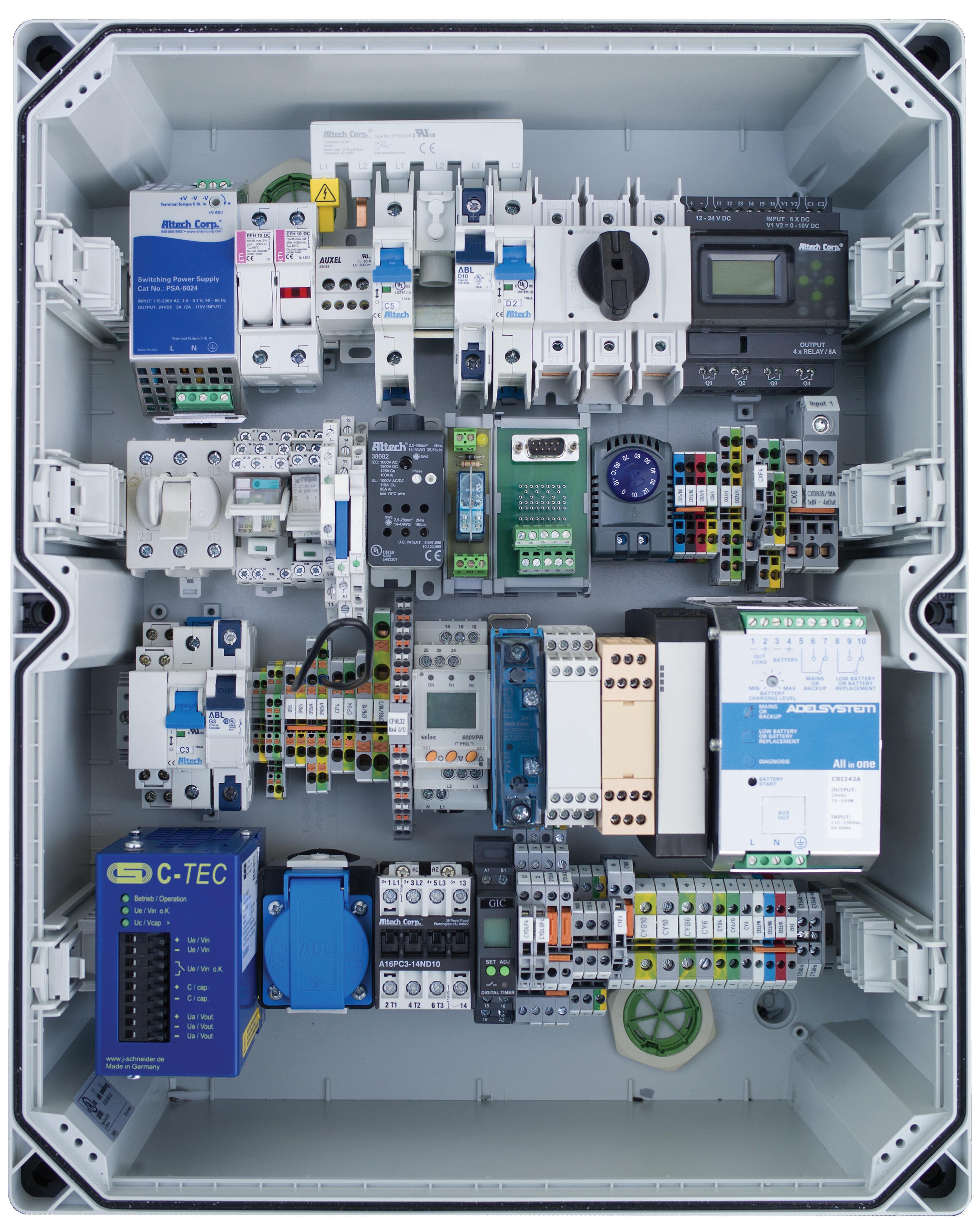

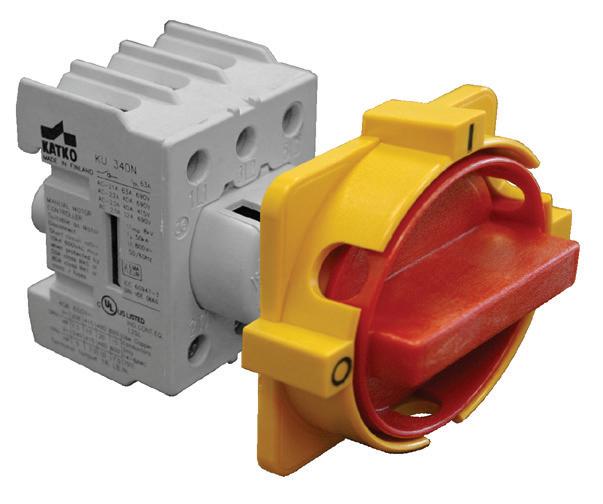

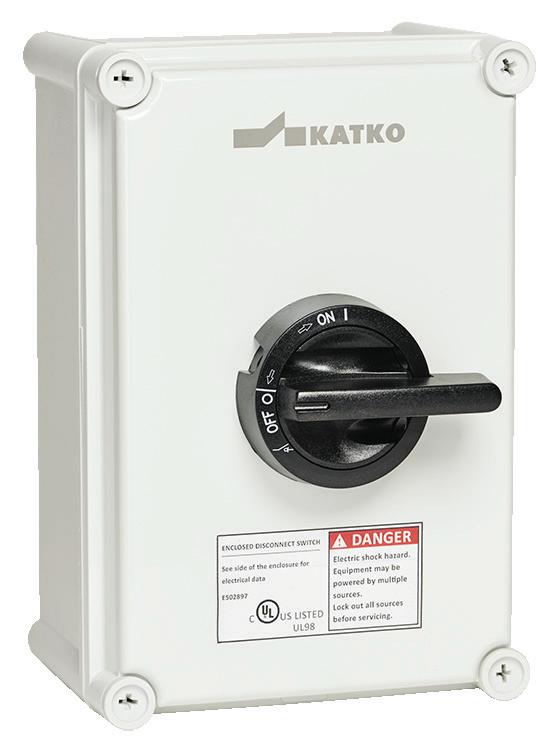

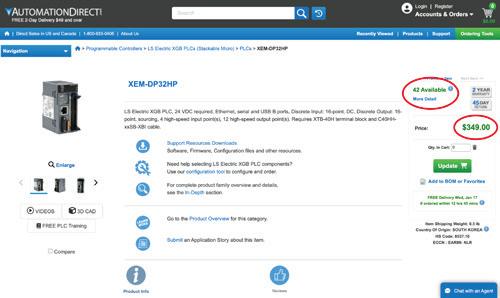

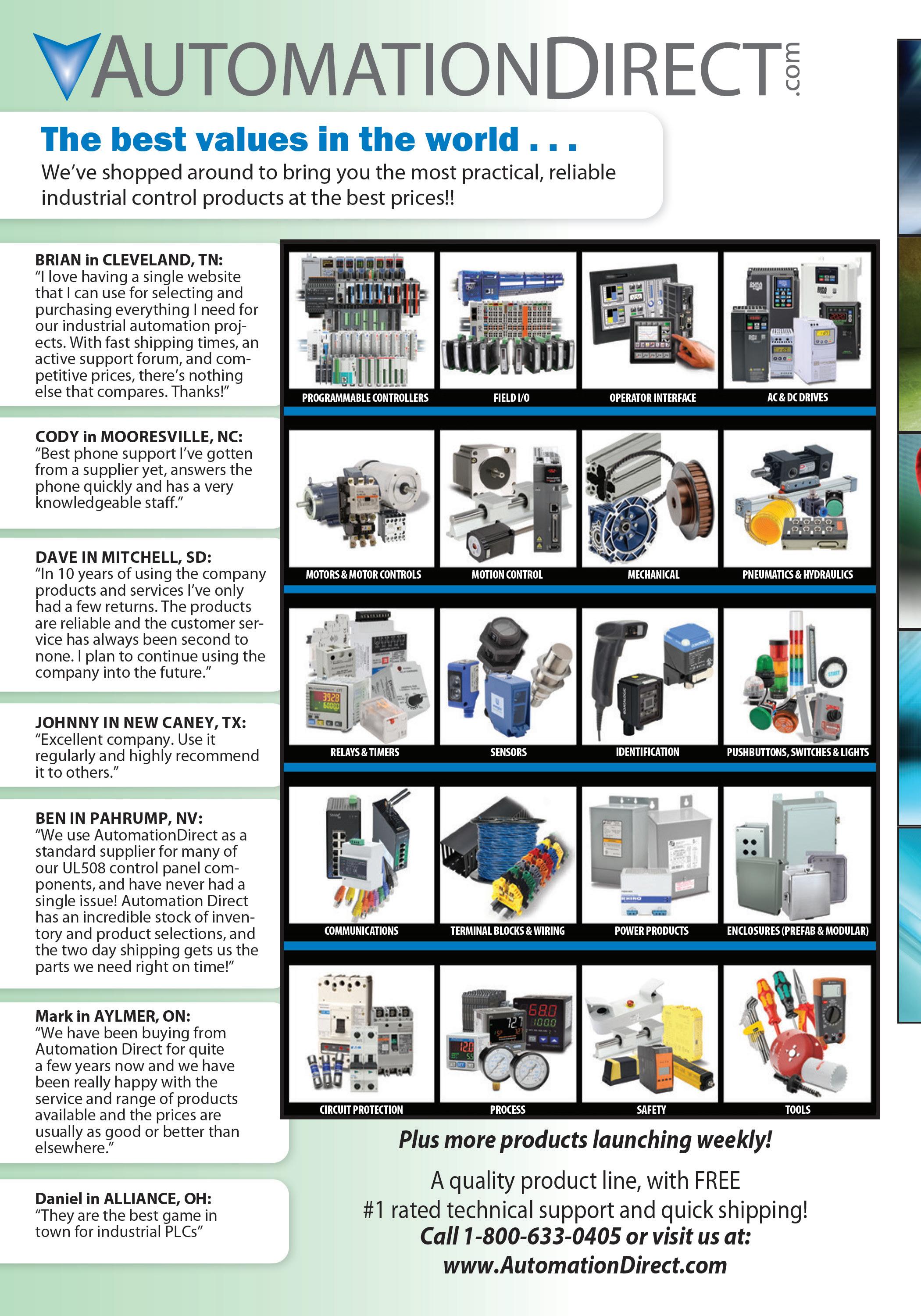

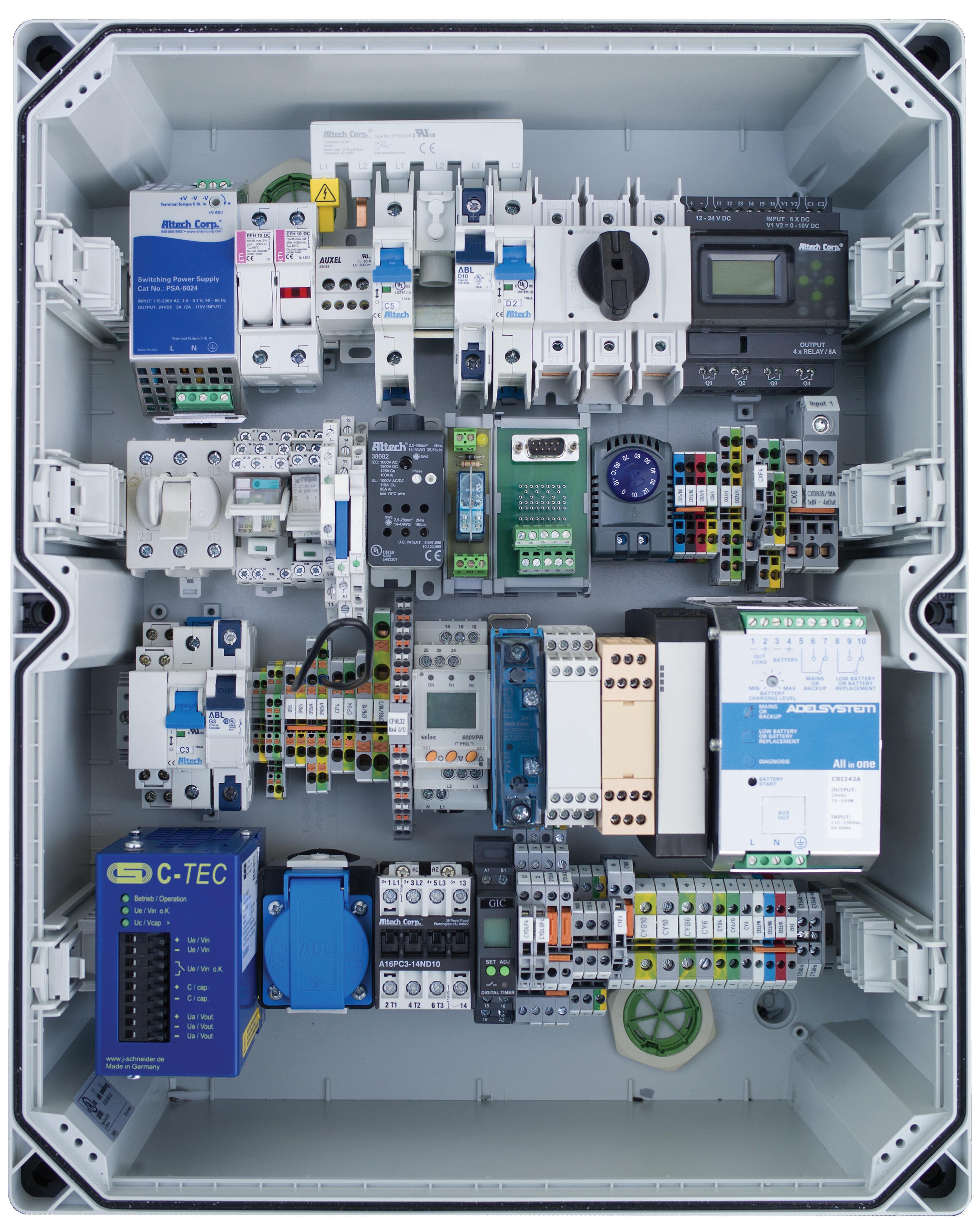

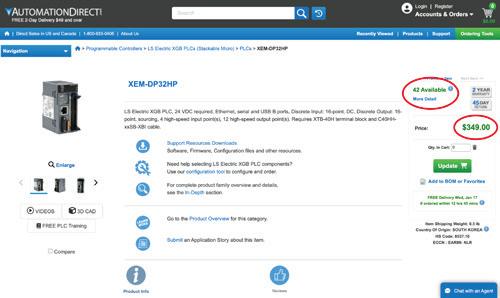

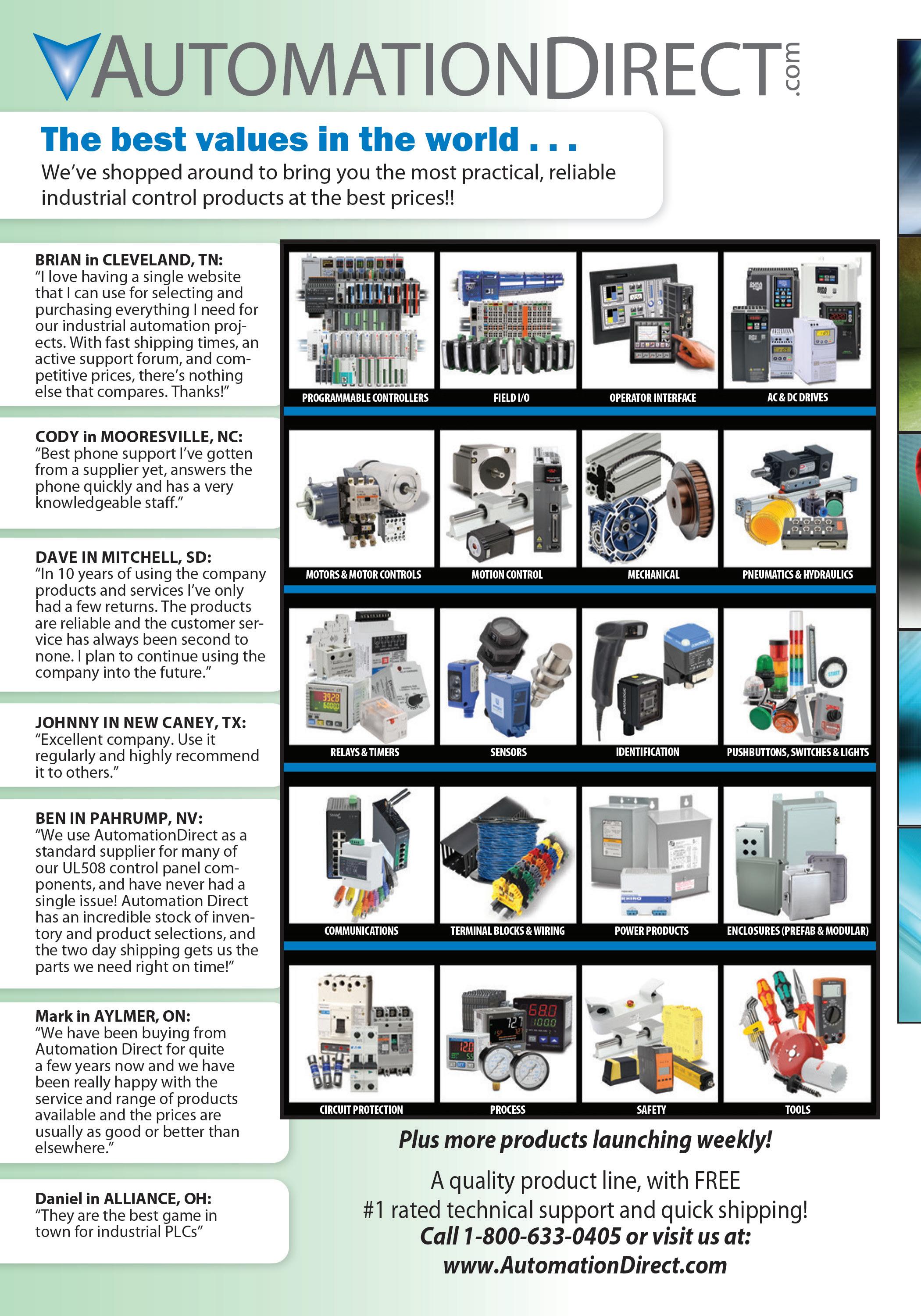

Over 35,000 quality industrial control products at great everyday prices are available on our webstore 24/7/365, and each one comes with the customer service you deserve.

www.AutomationDirect.com 1-800-633-0405 The #1 Value in Automation F R E EShipping- Ordersove r $94 FREETechnicalSupport Located in USA F a s t Shippingof In-stockProd u c st 45 4 5dayMoney-BackGuarant e e F R EEDownloadableSof t w a r e seewebsite for details for many products When every dollar counts . . . . . . count on AutomationDirect!

AutomationDirect:

much more than just a “.com”

You want complete product information to make the right purchase decision.

Whether you’re deciding on purchasing our products or learning our products after you buy, why jump through hoops or even pay for the information you need?

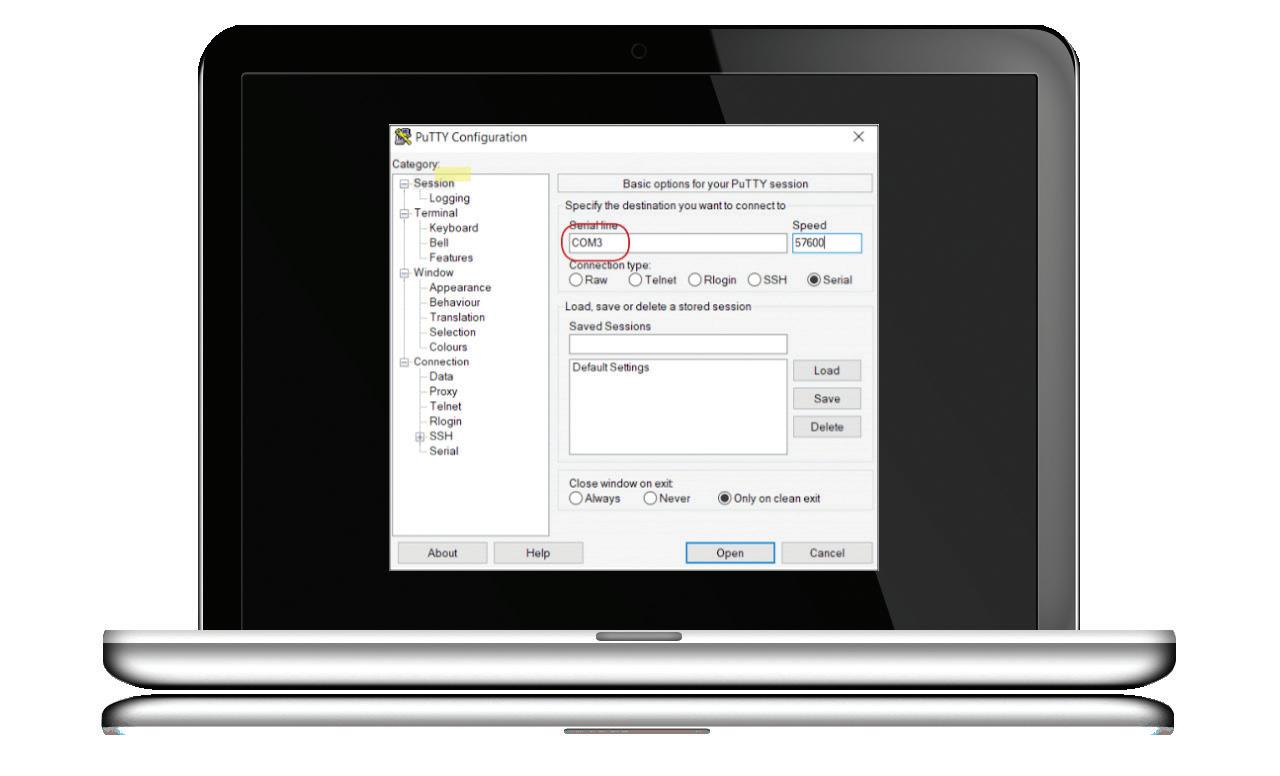

We have exhaustive documentation all freely available online, including overviews, technical specifications, manuals and 2D and 3D CAD drawings.

We have over 1,500 videos online to get you up to speed quickly. We even provide FREE online PLC training to anyone interested in learning about industrial controls.

http://go2adc.com/videos

http://go2adc.com/training

You need quality products at great

For over 25 years, we’ve been offering a better by running our direct business efficiently and you. No complex pricing structures or penalty everyday prices on everything from fuses to Programming software for controller products can be costly, so we help you out by offering FREE downloadable software for all our latest PLC families and C-more HMIs. No license or upgrade fees to deal with!

http://go2adc.com/why

You don’t want to wait for your We have fast shipping, and it’s FREE if your order is over $49.*

At AutomationDirect, we strive to have what you it. We’ve invested heavily into infrastructure, inventory, automation so that we can continue to provide you products, at great prices, extremely fast!

*Order over $49, and get free shipping with delivery in 2 business the U.S. (Certain delivery time or shipping cost exceptions may Conditions online for complete details.

You insist on getting better service and you want it FREE.

AutomationDirect is a non-traditional industrial controls ideas from the consumer world to serve your automation quality products fast for much less than traditional suppliers, every step of the way. See below . . . FREET

http://go2adc.com/terms

Our technical support team provides superior assistance and has consistently received high ratings from satisfied customers. And it won’t cost you a cent!

Before, during, and after any sale, contact us with questions and we’re glad to help,

http://go2adc.com/support-ss

F R E EShipping- Ordersove r $94

AutomationDirect.com Product Engineering and Development AutomationDirect.com Content and Web Store Development

Our campus is located about 45 minutes north of Atlanta, GA, USA. We’re all here - our sales and technical support teams, purchasing, accounting, and of course our huge warehouses and speedy logistics team.

“.com”

company using the best automation needs. We deliver suppliers, and support you

value on industrial controls and passing the savings on to

for small orders, just low motors.

Our primary focus has always been customer service — practical products, great prices, fast delivery, and helpful assistance. But the intangible value of customer service is something that cannot be faked, automated or glossed over.

Our team members here at AutomationDirect approach every day with one goal in mind - serve the customer. If the answer to any decision is “Yes, this is good for our customers”, then we do it, whether personally or via self-serve features on our site.

We want you to be pleased with every order. That’s why we offer a 45-day money-back guarantee on almost every stock product we sell. (See Terms and Conditions online for exclusions.) great prices.

need, when you need inventory, and warehouse you with quality business days (or less) within may apply; see Terms and http://go2adc.com/terms) your order.

You want to be confident in our products and our commitment to you.

We stand behind our products and guarantee your satisfaction.

Located in USA

TechnicalSupport

products latest

better

penalty

45 4 5dayMoney-BackGuarant e e F R EEDownloadableSof t w a r e seewebsite for details for many products Check us out at: www.automationdirect.com Upfront pricing and realtime stock availability

access to

and

history, online returns

This “.com” is powered by “.awesomepeople”!

Easy

account

order

How cold can you go?

Extreme temperatures can degrade or compromise the integrity of seals not designed for harsh environments. Metal spring energized (MSE) seals can improve reliability, durability, and performance in demanding applications compared to elastomer- or polymerbased seals.

Greene Tweed recently introduced a new Canted Coil MSE sealing solution to reduce power loss and improve precision movement while maintaining leakage control and durability. The seals have broad chemical compatibility and resistance to extreme temperatures, pressure, and wear.

The company devoted two years of design, development, and in-

house testing to reduce friction and take on challenging low-temperature applications. Benchmark testing against other spring-energized seals highlighted the usual compromise in performance at extreme temperatures. Low friction at higher temperatures resulted in high leakage at low temperatures. Prioritizing leakage control at low temperatures resulted in higher friction. Greene Tweed’s new canted coil demonstrated a friction improvement across a wide temperature range while improving leakage control.

The new seal exhibits broad temperature resistance — from cryogenic to 550° F (288° C). Plus,

as the sealing material wears away, the sealing and friction performance remains consistent. It is also suitable for various smaller-diameter applications, including precise robotic movement, precise valve controls, hydraulic actuation, medical dispensing, and semiconductor production. DW

Greene Tweed • www.gtweed.com

HARSH ENVIRONMENTS

www.designworldonline.com 16 DESIGN WORLD April 2024

Design For Industry

Design For Industry

3D technology creates custom TMJ implants

The human temporomandibular joint (TMJ) connects the jawbone (mandible) to the skull, allowing the jaw to open and close, enabling actions such as chewing, speaking, and yawning. TMJ arthroplasty involves the reconstruction or replacement of the joint to improve function and alleviate symptoms associated with TMJ disorders.

Materialise’s Personalized TMJ

Total Arthroplasty System combines implants, guides, and digital planning to streamline patient-specific TMJ treatments. This new solution gives personalized treatment for patients facing severe TMJ complications that require a joint replacement.

A clinical study with patients who have already received the TMJ prosthesis showed improved quality of life, pain levels, satisfaction, and eating ability compared to pre-surgery, with accurate implant placement reported in 97% of cases. Within the same clinical

study, clinicians reported a 100% success rate for the TMJ system one year after surgery.

The TMJ system is based on a fully digital process based on the patient’s anatomy. Clinicians work with Materialise’s clinical engineers, who perform the digital planning process in close collaboration with the surgeon. The digitalized workflow starts with a patient’s CT scan and dental information. During an interactive online session, a Materialise clinical engineer supports the treating physician in surgical planning and device design. Once finalized, Materialise manufactures the personalized TMJ implant for the surgeon.

The TMJ Total Arthroplasty System is currently available to surgeons in Europe, the U.K., and Brazil.

Materialise • www.materialise.com

1 APS Powers

12 Devices? In 1 Week or Less?

Accessory Power Strips (APS) and IEC 60320 jumper cords make designing electrical systems worldwide EASY. The APS offers 4-12 IEC 60320 Sheet F or J outlets and one IEC 60320 C14 or C20 inlet, options on circuit protection and on/off switches, and come in white, beige, and black.

The APS plugs into the wall outlet, and the outlets on the APS are used to plug in IEC 60320 jumper cords to power multiple equipment—power up to 12 devices using only one country-specific plug! Export power cords, cord sets, and components globally using this and other accessory power systems.

Toll-Free Phone: (800) 662-2290

E-mail: info@interpower.com

Business Hours: 7 a.m.–5 p.m. CST

Order Online! www.interpower.com ® ® Interpower® Accessory Power—

17 DESIGN WORLD April 2024 www.designworldonline.com

MEDICAL

800-877-8351 sales@jwwinco.com

Explore our full product range online.

« Super Strong Joints are virtually unbreakable.

« Low cost, highly efficient, elastic flat belts.

Say “ahoy” to additive’s new copper alloy

Carbon nickel alloys, CuNi30, are commonly used in offshore applications because of their corrosion resistance, mechanical properties, and ease of fabrication. CuNi30, specifically, is suitable for use in naval vessels, offshore platforms, submarine components, and other marine infrastructure.

EOS recently announced the commercial availability of its new CopperAlloy CuNi30 for laser powder bed fusion (LPBF) additive manufacturing. The material delivers high strength, around 510 MPa UTS, and more than 20% elongation. It also achieves corrosion resistance in salt water and sustained performance in low temperatures. These mechanical properties meet UNS C96400 specifications mentioned in ASTM B369-09 for mechanical performance.

In partnership with Phillips Federal and Austal USA for the submarine industrial base (SIB), EOS CopperAlloy CuNi30 was developed and tested to alleviate the supply pressure of traditional castings and meet the goal of “2+1 Columbia and Virginia Class submarine platforms” for the U.S. Navy. The material’s performance and competitive cost-per-part create a strong business case for production.

Traditionally, the manufacturing of CuNi alloy applications is done by casting, which can be costly due to testing and quality requirements. Now, parts can be produced regionally, locally, and on demand. EOS CopperAlloy CuNi30 is now commercially available for the mid-frame EOS M 290 and the large-frame EOS M 400, followed by the four laser EOS M 400-4 later in 2024. DW EOS

18 DESIGN WORLD April 2024

Industry OFFSHORE

Design For

Steel

Parts. Winco.

durable, robust

• www.eos.info Stainless

Standard

corrosion-resistant,

www.jwwinco.com

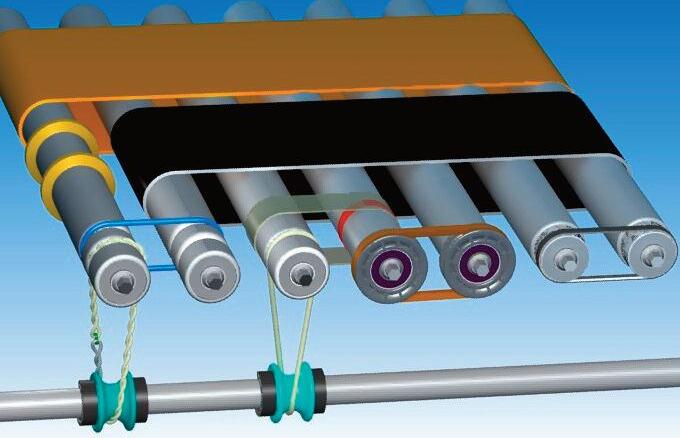

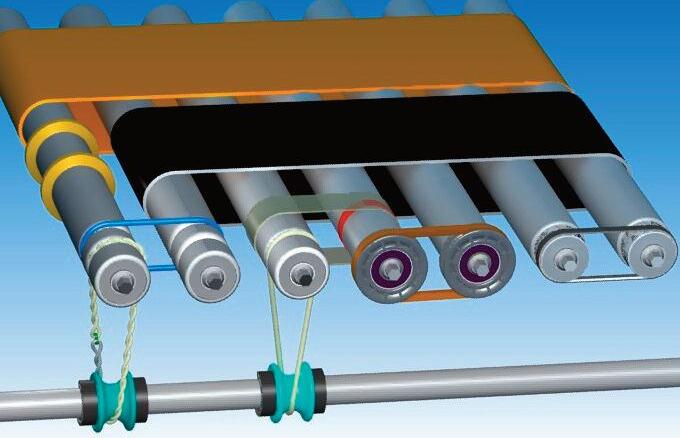

« Ultra-Drive belts on standard rollers move 350+ lb boxes.

« High Tension Belts move heavier loads

Dura-Belt 800-770-2358 614-777-0295 Fax: 614-777-9448 www.durabelt.com Better than Lifetime Warranty

Line-shaft Spools

« HEHT black belts double capacity

Split

Zero

use 100% virgin urethane (no regrind waste) Makes stronger, longer lasting belts.

Flat, Vee and Poly-V belts and pulleys new format Longer lasting new rormat Belts, HEHT Split Spools_Layout 1 12/5/2

l High precision. Reasonable price. l Easy to install.

downtime. We

Longer Lasting Belts & Pulleys Round,

Design For Industry

Clearing the air for mobile machines

Lubricants and hydraulic oils must be protected from unwanted particles to ensure the safe operation of hydraulic systems. Additionally, as hydraulic oil degasses inside the reservoir, it releases oil particles into the air, posing a health and safety risk. Filters help mitigate these problems, protect machinery, and maximize operations.

Eaton recently complemented its tank-mounted filtration solutions with the BR210 Dirt-Gate and BR110 H2O-Gate vent breathers to remove abrasive particles from the air before they can enter the hydraulic tank. This protects the hydraulic system from external contamination and significantly extends the fluid life. The vent breather ensures no moisture enters the tank, minimizing condensation and optimizing hydraulic oil performance through continuous air exchange. The filter also inhibits oil particles from escaping into the environment.

The BR series of vent breathers feature a durable plastic housing that protects the filter media from external influences. The filters are temperature resistant up to 250° F (121° C) and with a nominal output of up to 25 cfm (708 lpm). A visual-mechanical indicator actuates when the filter capacity is exhausted or the media is clogged. The new filters are suitable for heavy commercial vehicles, agriculture, and various mobile applications in industries such as chemicals and oil and gas. DW

Eaton www.eaton.com

Interpower®

Accessory Power—

1 APS Powers

12 Devices? In 1 Week or Less?

Accessory Power Strips (APS) and IEC 60320 jumper cords make designing electrical systems worldwide EASY. The APS offers 4-12 IEC 60320 Sheet F or J outlets and one IEC 60320 C14 or C20 inlet, options on circuit protection and on/off switches, and come in white, beige, and black.

The APS plugs into the wall outlet, and the outlets on the APS are used to plug in IEC 60320 jumper cords to power multiple equipment—power up to 12 devices using only one country-specific plug! Export power cords, cord sets, and components globally using this and other accessory power systems.

®

®

Toll-Free Phone: (800) 662-2290

E-mail: info@interpower.com

Business Hours: 7 a.m.–5 p.m. CST

Order Online!

www.interpower.com

19 DESIGN WORLD April 2024 www.designworldonline.com

OFF-HIGHWAY

EDITED BY MIKE SANTORA

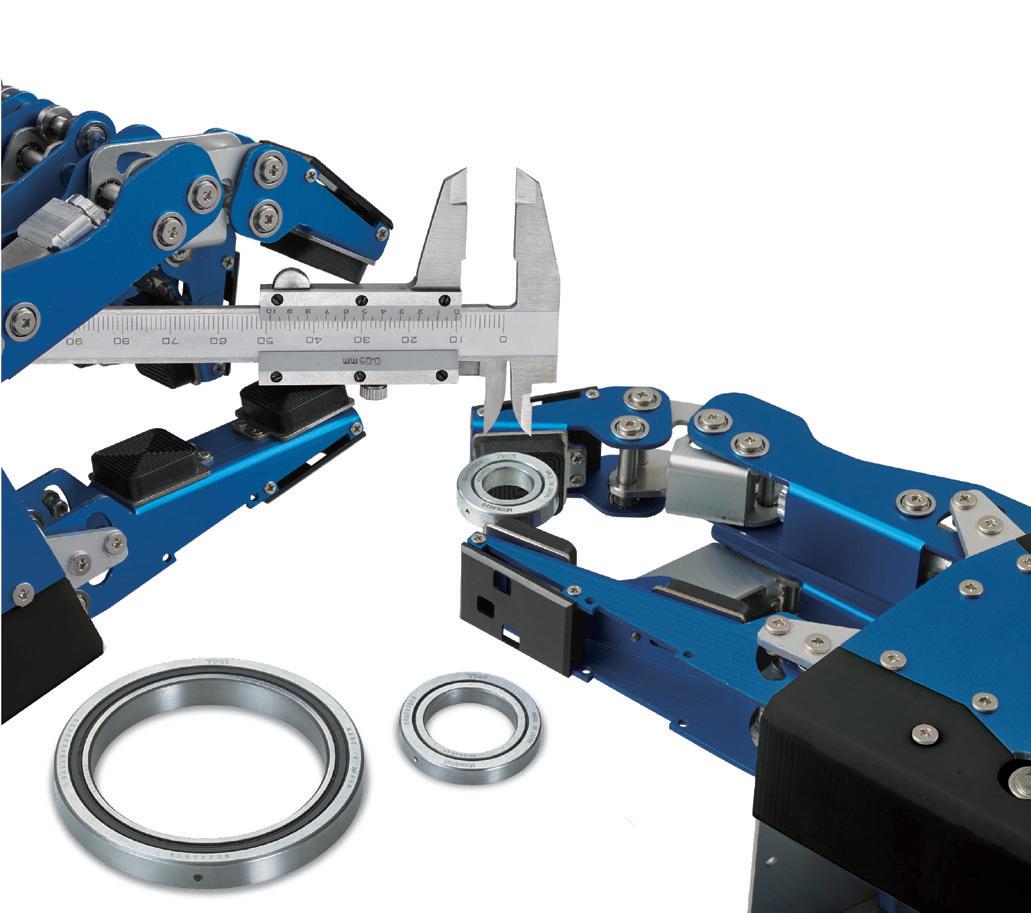

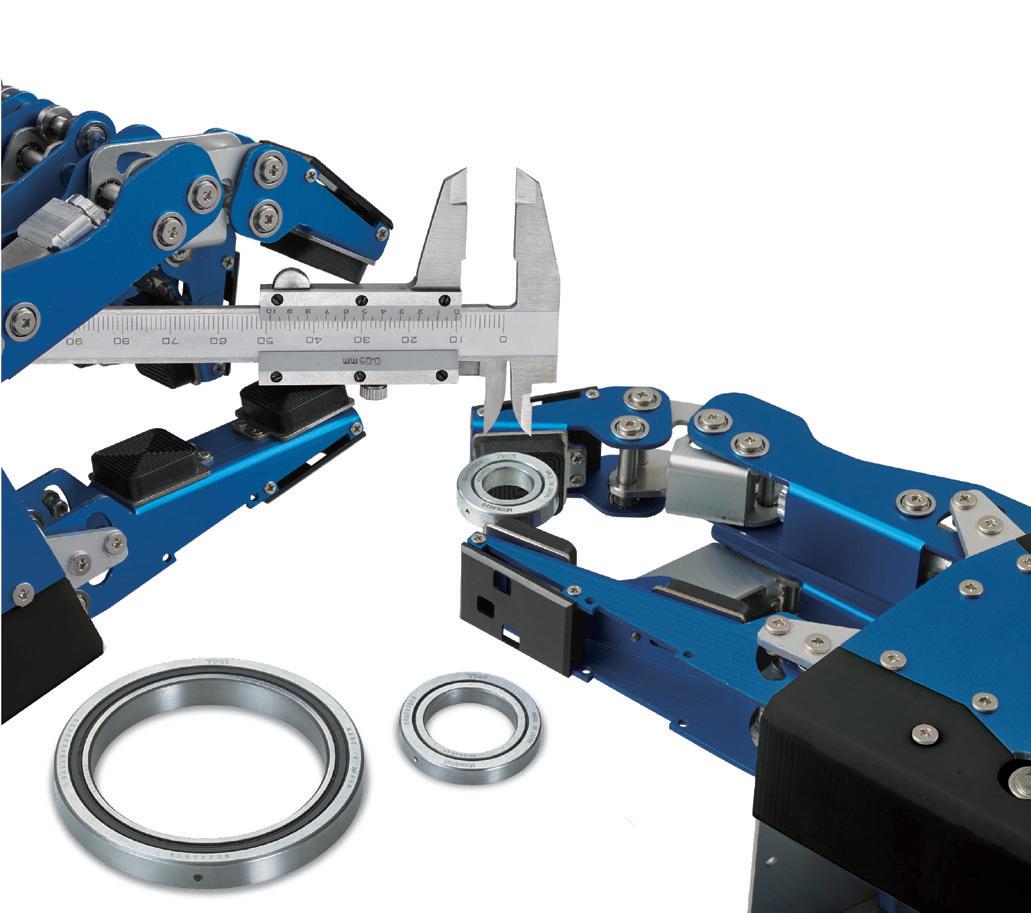

Why bearings will be essential to Agriculture 4.0

According to the European Commission (EC), “The digitalization of the European agricultural sector has the potential to revolutionize the industry, promoting efficiency, sustainability, and competitiveness.” New technologies, including smart actuators and intelligent sensors, will be vital to Agriculture 4.0 and ‘precision agriculture.’ But a vital component in these technologies mustn’t be overlooked: bearings. Here, Chris Johnson, managing director at SMB Bearings, explains how specialty bearings support smoother movement, reduced friction, and great precision on Agriculture 4.0 farms.

The EC predicts that everything from artificial intelligence (AI) and robotics to the Internet of Things (IoT) and 5G will all “offer invaluable support for farmers and agribusinesses.” This is reflected by changes in the markets, as reported by Forbes: “The autonomous-farming industry is beginning to boom, with approximately 200 AI-based agricultural startups in the US alone.”

The Forbes report cites “self-driving tractors and combine harvesters, robot swarms for crop inspection, and autonomous sprayers” as key Industry 4.0 technologies that will revolutionize farming — or ‘Agriculture 4.0.’ These technologies can converge with smart actuators, intelligent sensors, electric motors, and alternative drive systems.

For instance, AI can help optimize crop management thanks to real-time data analysis from intelligent sensors. This data can then guide smart actuators, which produce a motion by converting energy and signals going into a system like an autonomous sprayer. The actuators can control the

height or angle of the crop sprayer, positioning the nozzle to work more effectively. Another example would be an electric motor controlled by a variable speed drive (VSD). The motor’s performance can be guided by AI algorithms to optimize its performance and energy consumption, again based on real-time data.

These processes are called ‘precision agriculture,’ where automated Agriculture 4.0 devices operate more effectively and accurately based on a hotbed of real-time data. Essential variables like soil conditions, crop health, and other environmental factors can be monitored to optimize yield, resource efficiency, and sustainability. Moreover, this data management and remote control of equipment can be accelerated by high-speed 5G connections so farmers can make faster and more valuable decisions.

However, precision agriculture is also putting farmers under pressure. Higher

demands are also being placed on equipment; while self-driving tractors may seem like a magic solution, they are still machines that require ongoing maintenance. The onus is on maintenance engineers to guarantee high-quality equipment so modern farmers can stay competitive and get the most from Agriculture 4.0.

Precise movement

This brings us to an essential component in Agriculture 4.0, which the latest technologies like smart actuators, intelligent sensors, and alternative drive systems all rely upon: specialty bearings.

For instance, bearings are essential for providing smooth and precise linear motion in smart actuators. They support

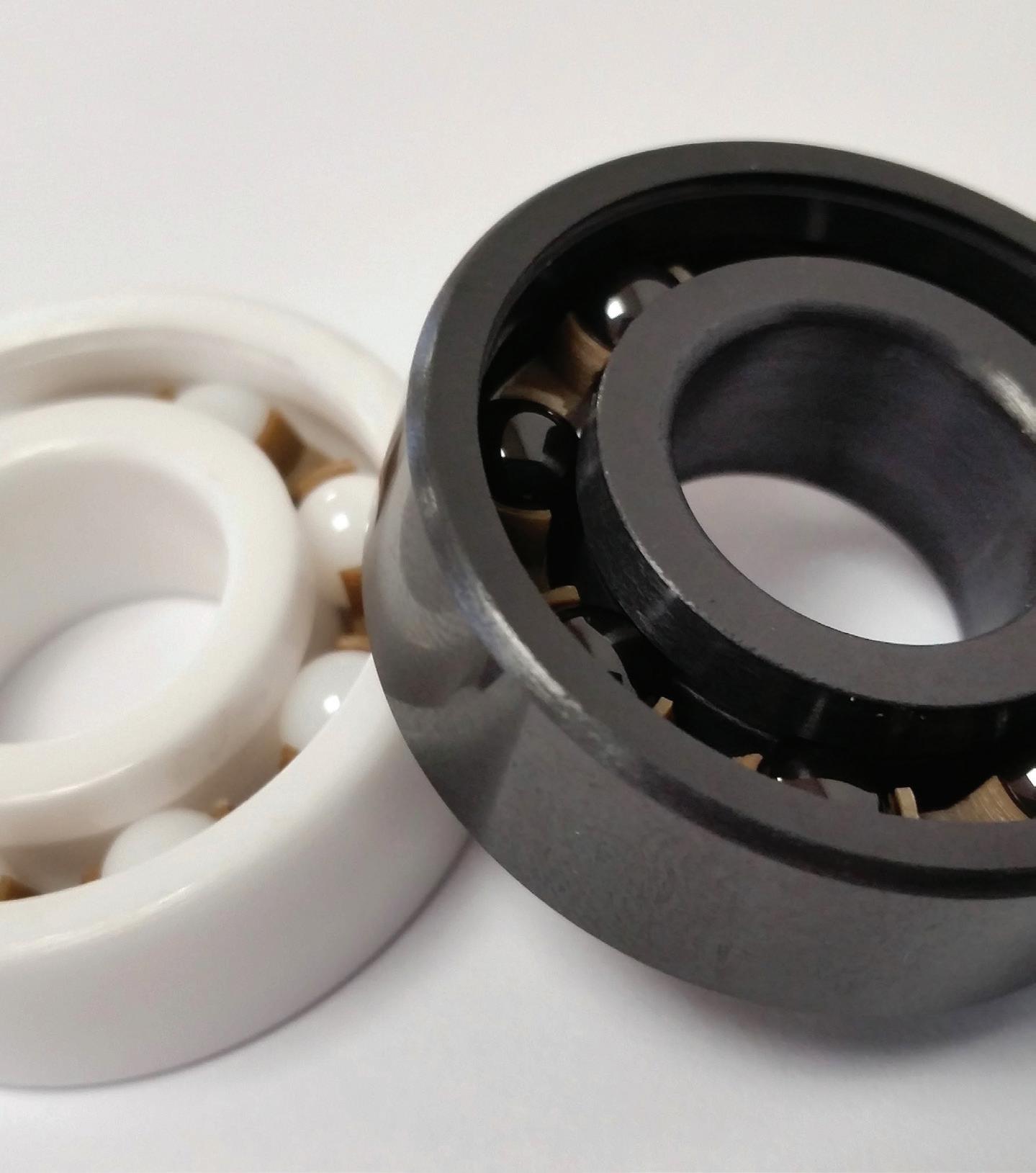

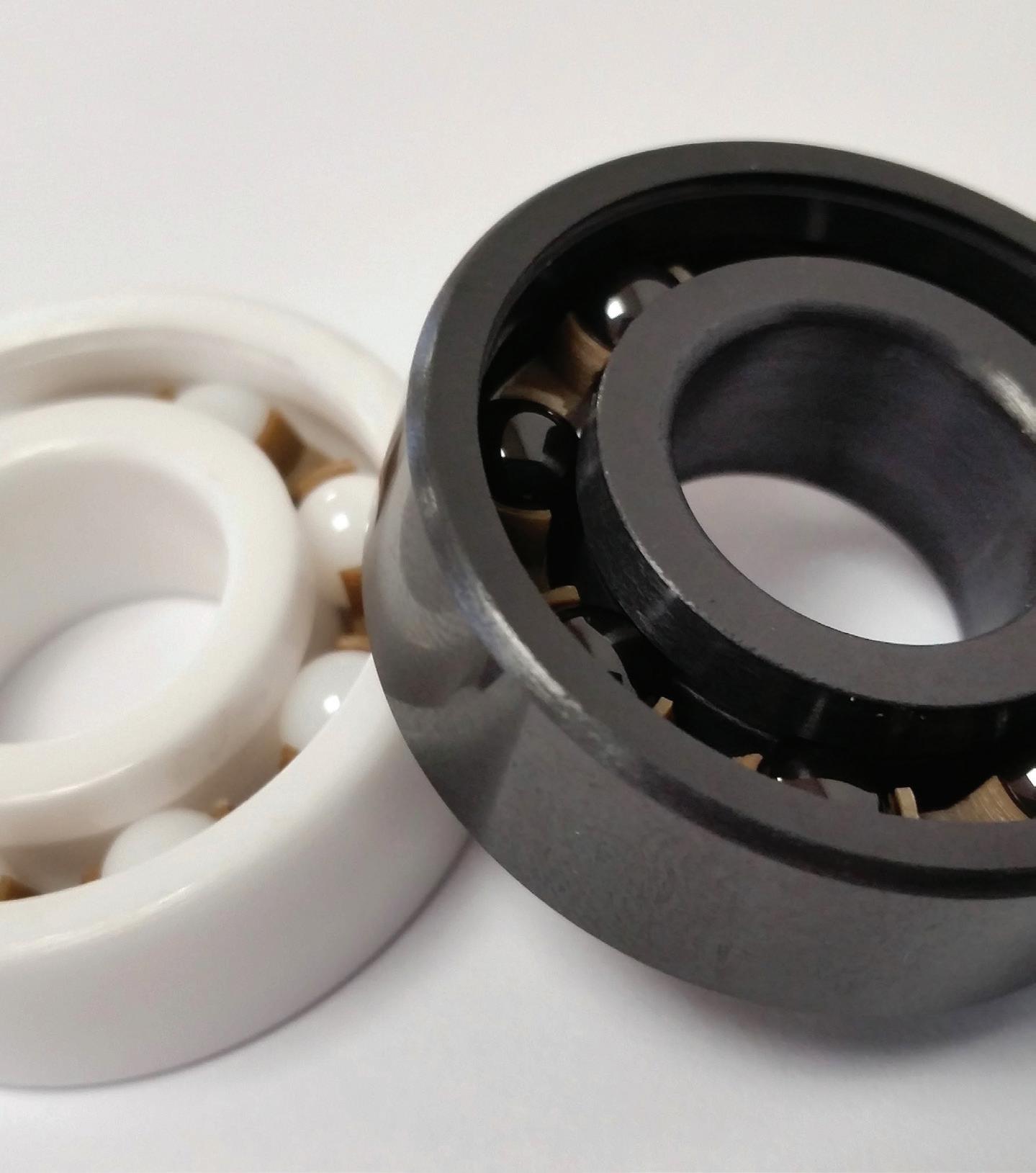

Various types of ceramic bearings are worth considering for Agriculture 4.0 applications as they facilitate smooth movement and precise functionality.

www.designworldonline.com 20 DESIGN WORLD April 2024

Notes

Design

The European Commission says Artificial intelligence (AI), robotics, and the Internet of Things (IoT) will “offer invaluable support” for farmers.

the movement of the actuator shaft or rod, ensuring minimal friction and efficient operation. Bearings distribute the loads applied to the actuator evenly, which prevents excessive wear and facilitates consistent performance. This is especially important in applications where precise force and positioning are required.

In electric motors, bearings support the rotor and shaft, allowing them to rotate with minimal friction. This is crucial for the efficient and reliable operation of the motor. Bearings handle both axial and radial loads in electric motors, ensuring stability and smooth rotation. This is particularly important in high-speed Agriculture 4.0 applications where precise control is necessary.

Specialty bearings can help maintain the alignment of Industry 4.0 sensor components for more accurate data collection. This information is especially useful to modern farmers. Forbes reports, “To survive today, farmers need to be experts in fertilizers and soil, insecticides specific to different crops, planting and irrigation cycles, and weather impacts, among other things.”

Elsewhere, smart bearings with builtin sensors — which gained popularity in automotive anti-lock braking systems (ABS) — are now increasingly being adopted by the industry. Smart bearings can be affixed to Agriculture 4.0 technologies to gather various data, including measuring force and torque measurements or external factors like weather conditions, crop characteristics, and more.

But which specialty bearings should engineers choose for faster, more precise Agriculture 4.0 tasks?

Equipment longevity

First, engineers should consider nonconductive bearings that resist corrosion and withstand damp outdoor farming conditions. Second, the bearings should have an extended lifespan to cut down on the maintenance of precision agriculture equipment.

Plastic bearings are less suited to this environment, as this type of bearing tends to wear down quickly. Instead, ceramic bearings are a more durable option due to their non-conductive properties and the material’s stiffness. Both the rings and balls are entirely made from ceramic and are not to be confused with hybrid bearings, which have steel rings and ceramic balls.

Various types of ceramics are worth considering for precision farming applications. Zirconia is popular because of its high density and wide temperature range. Moreover, full ceramic bearings in zirconium oxide (ZrO2) typically handle 65 to 75% of the load of a steel bearing, which is crucial for heavyweight farming machinery. Unlike plastic bearings, full ceramic ones need minimal upkeep, resulting in much longer intervals between replacements.

Specialty bearings are vital in facilitating smooth movement, reducing friction, and ensuring precise functionality in smart actuators, intelligent sensors, and electric motors. Their proper selection and integration contribute significantly to the overall performance, efficiency, and longevity of these electromechanical systems and will be integral to Agriculture 4.0. DW

SMB Bearings • smbbearings.com

21 DESIGN WORLD April 2024 www.designworldonline.com

EDITED BY MIKE SANTORA

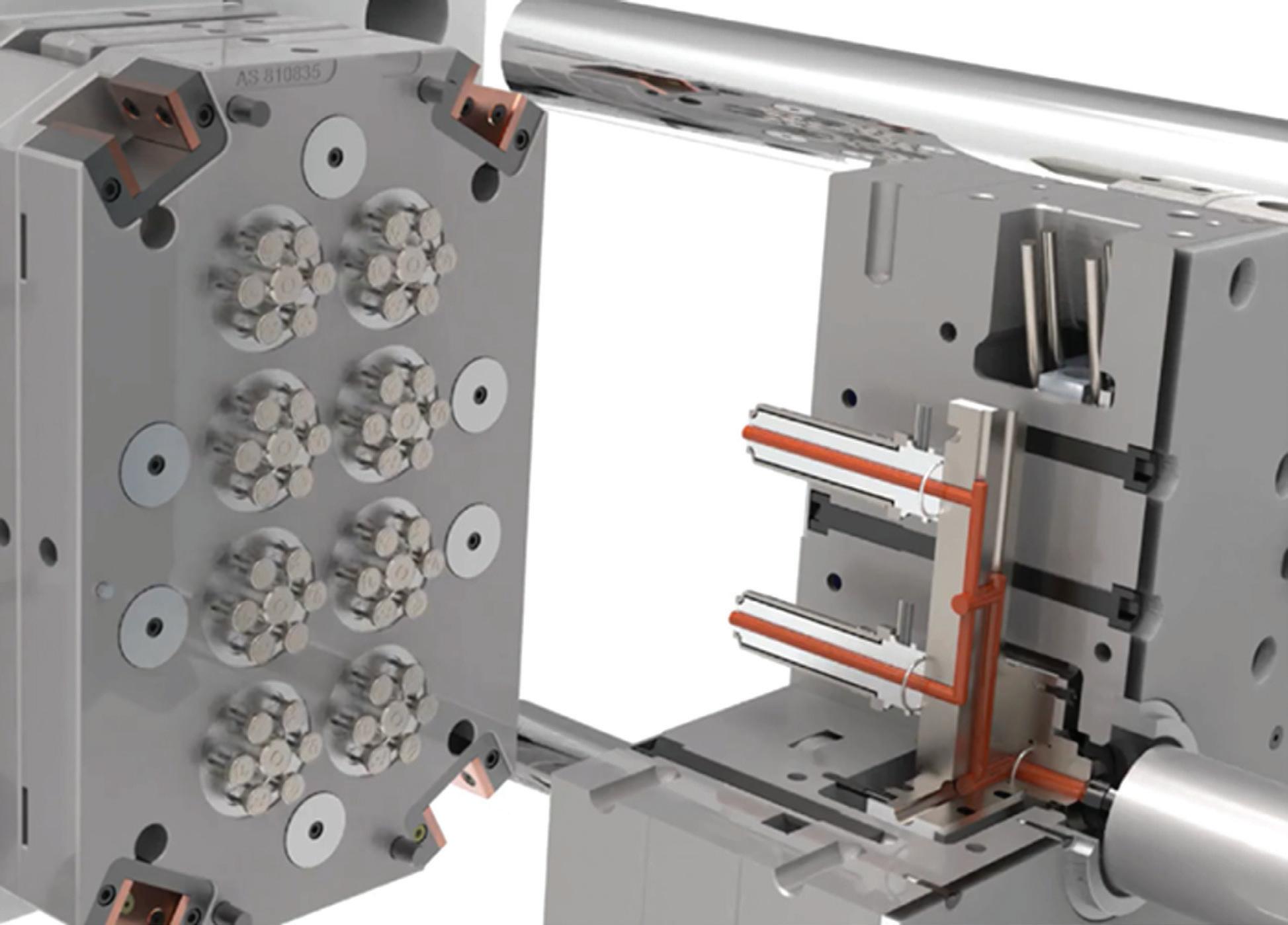

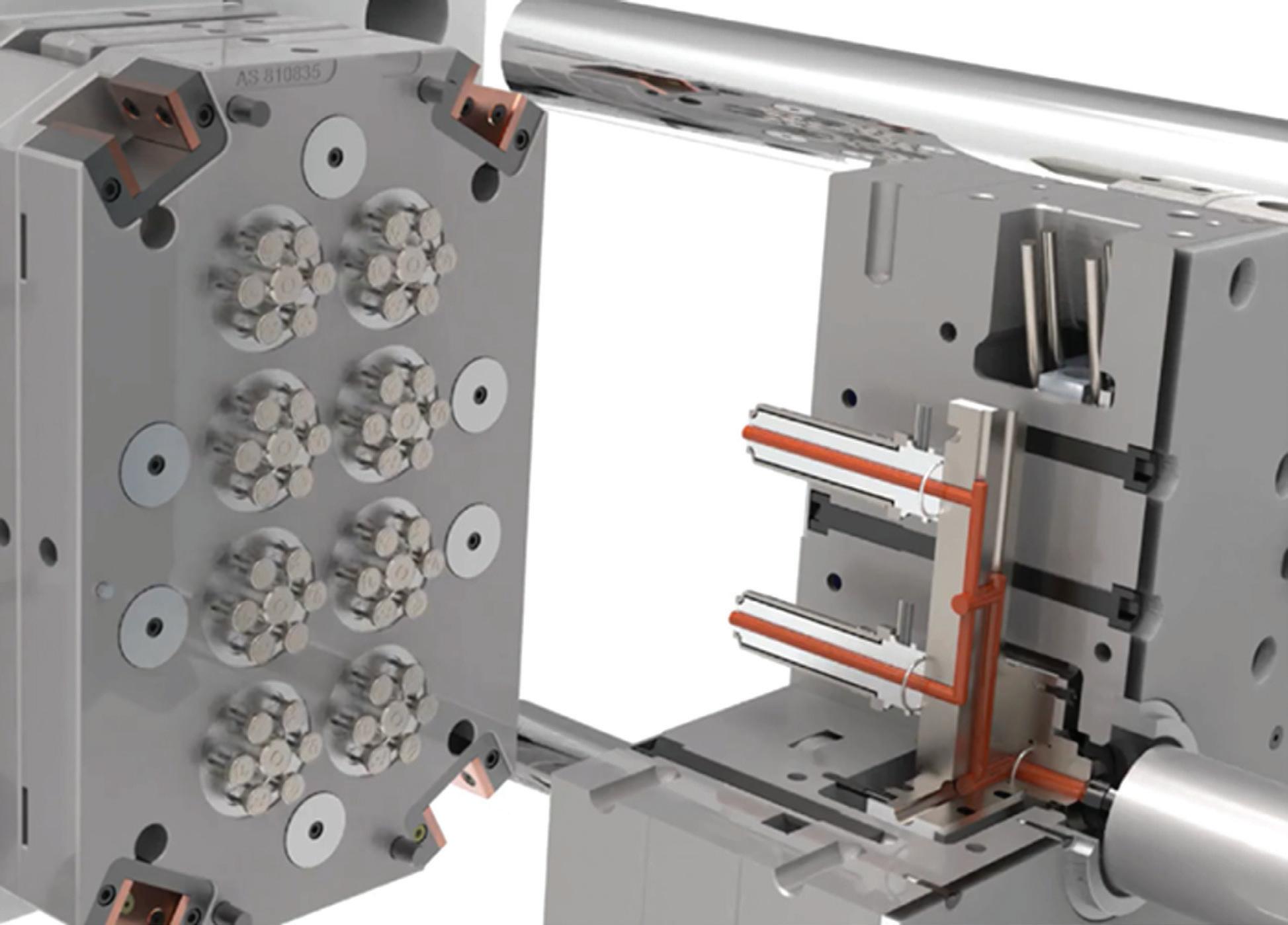

Hot runner systems for zinc die casting?

Hot runners have been a common manufacturing tool in the plastic injection molding industry for over 30 years. With this technology came improved efficiencies and benefits. Although hot runners for zinc die casting have surfaced occasionally, die casting with molten metal has proved to be much more challenging for this technology compared to plastics — until now.

In 2016, the German company Ferrofacta solved the challenges that hot runners faced when die casting in zinc. With new materials and a new design concept, hot runners can now be incorporated into most conventional die casting machines, regardless of manufacturer.

This technology improves zinc die casting efficiencies by significantly lowering scrap rates, decreasing cycle times, increasing die usage, improving casting quality, and lowering overall carbon footprint.

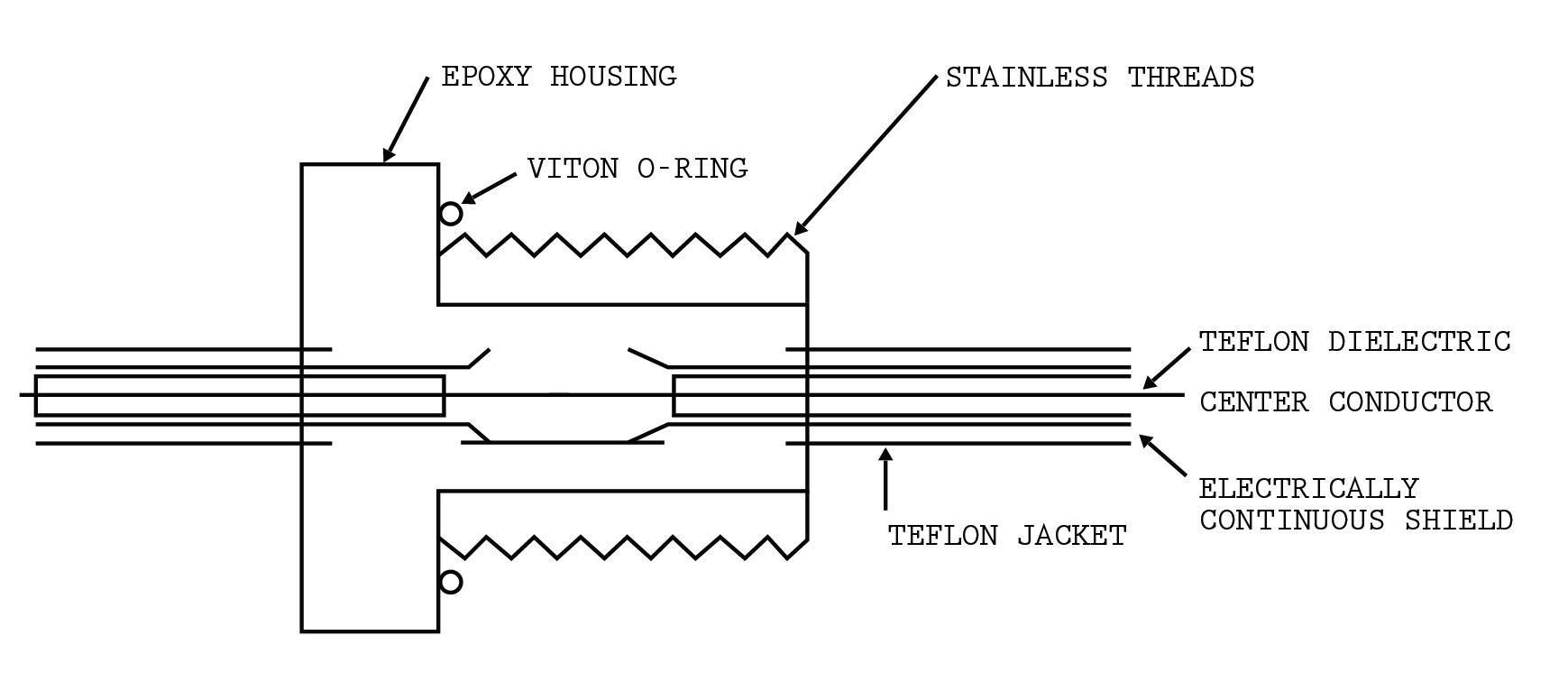

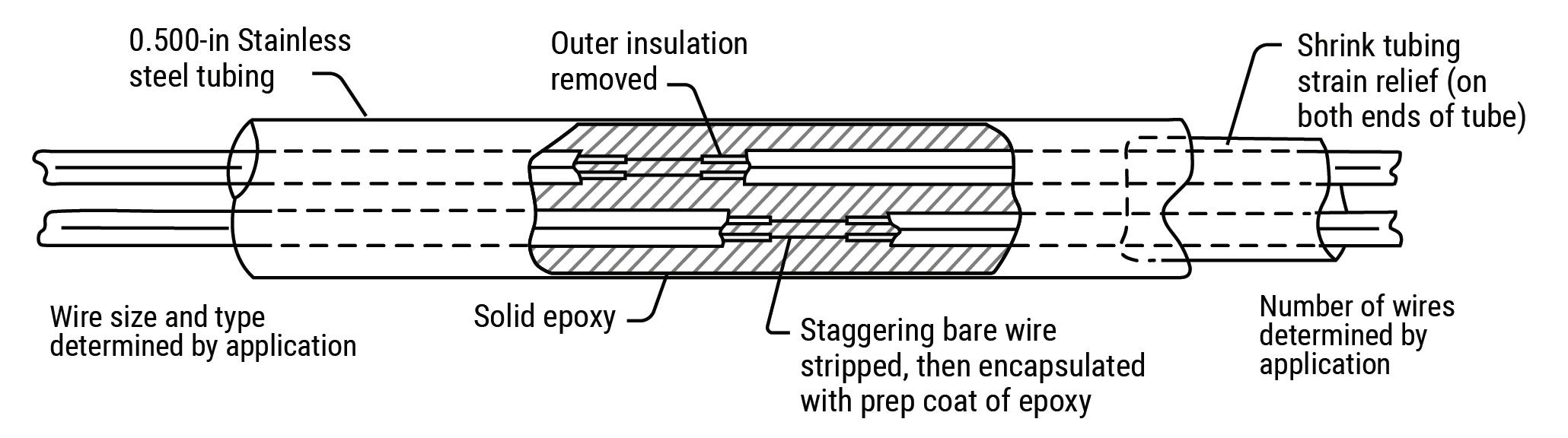

In conventional zinc die casting, a sprue bushing is incorporated into a die to direct the molten zinc from the machine through a runner and gating system and finally into the die cavities. This full “runner system” is then ejected, and the parts are separated. The remaining scrap runner system is then either remelted or sold.

The sprue and main runner system are eliminated when using a hot runner system. Depending on the size and shape of the components being cast, molten zinc can be either directly injected into a casting or indirectly into a small sub-runner that feeds molten zinc into a single or multiple cavities.

Cycle times in die casting depend on how long it takes to solidify the largest section of the entire shot. Typically, this is the sprue and runner system. With a hot runner system, the sprue and runner have been eliminated or significantly reduced, resulting in much shorter cycle times and additional cost savings.

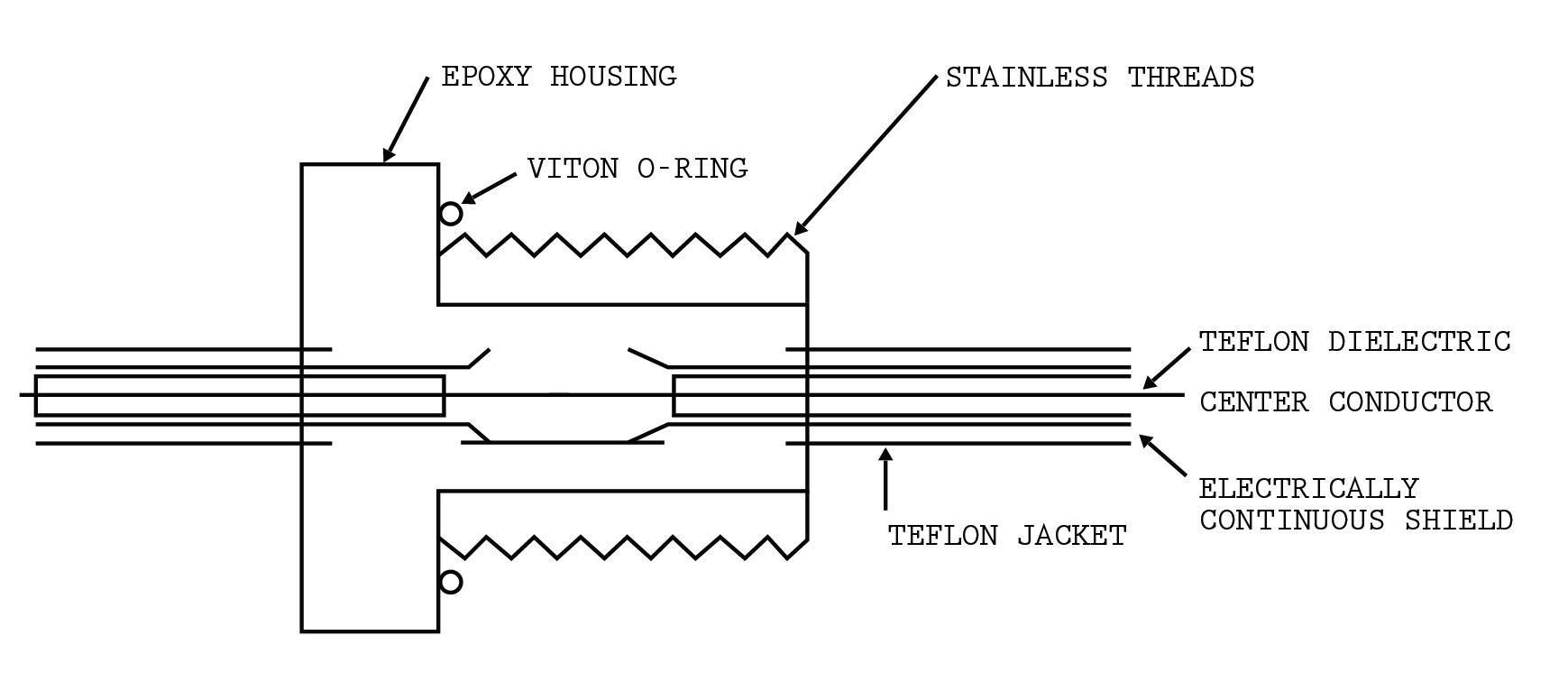

Shown here

the hot runner system with an indirect runner eliminating the conventional sprue and runner system.

quality can also be improved, leading to higher yield levels and lower scrap rates due to quality issues.

Zinc die casting alloys are extremely fluid. Casting thickness as low as 0.2 mm (.008-in.) has been achieved, but it can be difficult to cast in normal operating conditions. Using hot runner systems can provide more control over the critical process variables that affect casting quality, such as die temperature, which is crucial for casting thin wall applications.

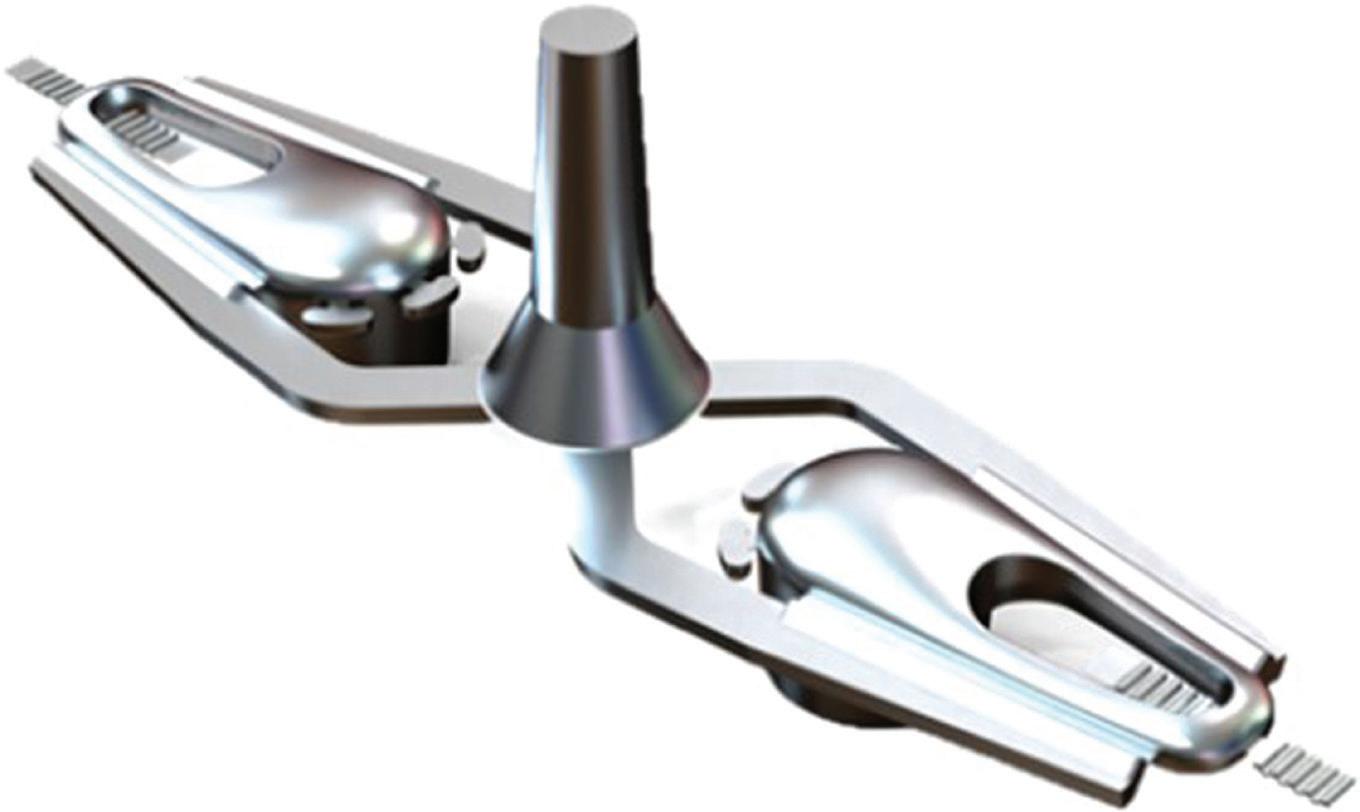

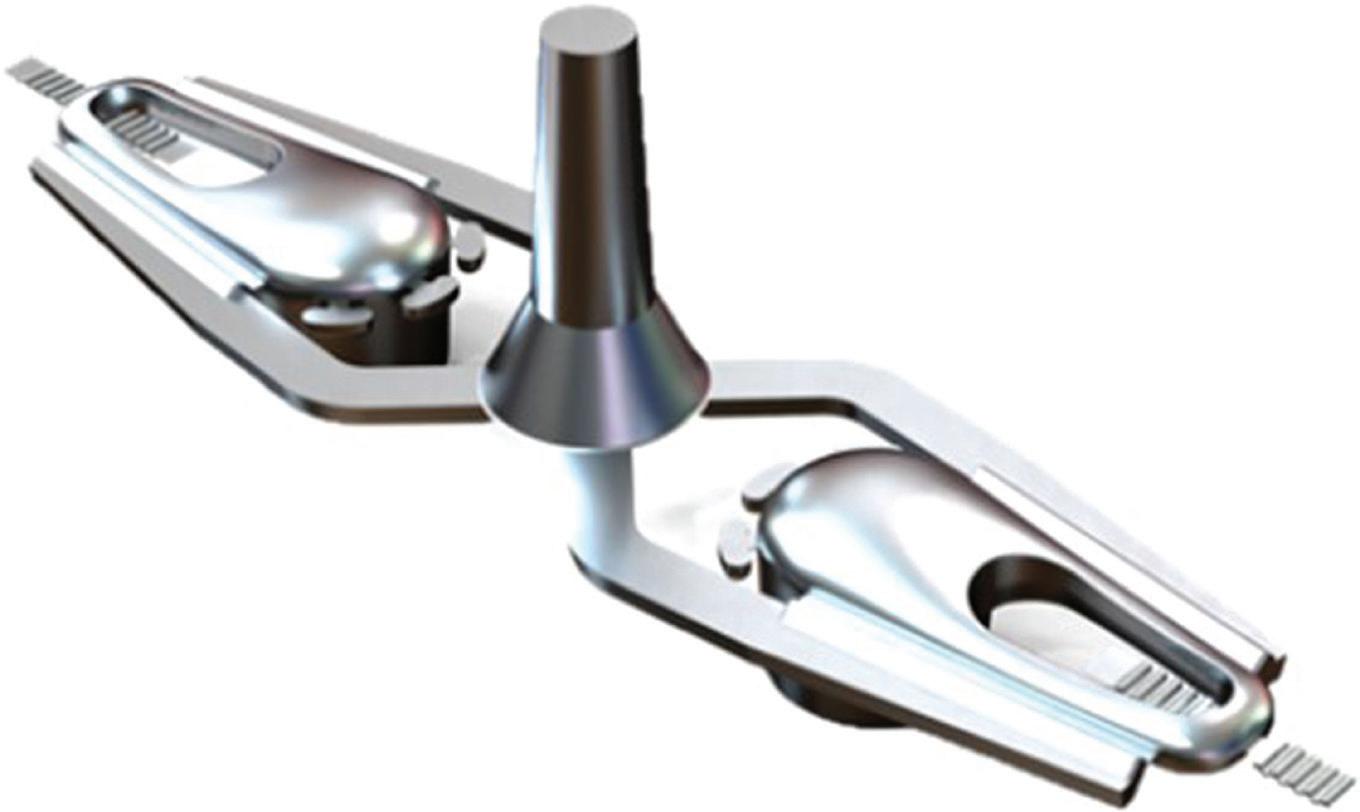

Case study: Ferrofacta knife

This is an example of a sprue and runner in a conventional runner system. The hot runner system will eliminate most of this processing scrap.

By keeping zinc liquid throughout the die casting process, air is almost eliminated. This means less porosity in the casting. In addition, by controlling temperatures more effectively, surface

The Ferrofacta knife is a sample piece given away at tradeshows. The tooling and hot runner system was designed to showcase the different methods of gating — direct or indirect gating — and their advantages.

The direct gating option involves feeding liquid zinc directly onto the surface of a part, resulting in the

www.designworldonline.com 22 DESIGN WORLD April 2024 Design Notes

is

complete elimination of a scrap runner system. There are also no residual traces of gate marks or overflows on the split line. However, a remnant of the gate remains on the casting surface, which may be acceptable for functional castings, or can be covered by a cap or secondary process. This gating option is used more often for medium to larger casting sizes.

The indirect gating option is where liquid zinc is fed into a small sub-runner before filling cavities. This option’s main advantage is allowing multiple cavities per nozzle, and is far more economical, especially for smaller castings.

The following theoretical scenario compares casting the Ferrofacta knife in a conventional die casting process compared to an indirect hot runner system. In each case, a total of five million sets (left- and right-hand parts) or a total of 10 million castings are made in one year. The same machine is used with an operating cost of $100/hr.

In this scenario, when using a conventional runner system, four sets of knives (eight cavities) are cast, whereas when incorporating the hot runner system, six sets of knives (12 castings) can be cast with the same size tool and die casting machine.

Conventional Runner System Indirect Hot Runner Parts per Year 10 million (five millions ets) Casting Weight 45g (0.1lb) Machine Rate (USD/hr) $100 # Cavities per shot 8 12 Runner System Scrap (lb) 1 0.34 Cycle Time (s) 16 10 Hours required to cast 10 million parts 5556 2315 Amount of scrap (lb) 1,250,000 283,333 Amount of scrap saved (lb) 967,000 Cost to operate die casting machine (USD) $555,600 $231,500 Operational Savings (USD) $342,100/year Amount of CO2 to recycle emitted (tons) 94 21 CO2 emissions saved (tons) 73

Table 1 conventional runner vs indirect hot runner

Because of the shorter cycle time and a higher number of cavities, it takes far less time to cast five million sets with the hot runner than the conventional system. The yearly savings in operating the machine are $324,100.

Additionally, scrap is reduced by 967,000 lb. This translates to lower energy costs (remelting less scrap) and lower WIP inventory costs. Eliminating the need to remelt scrap also decreases carbon emissions by 73 tons.

Incorporating hot runner systems into the zinc die casting process can improve casting efficiency, cost savings, lower WIP inventory costs, and a lower carbon footprint. This can be achieved by an OEM looking to receive these benefits directly, or a die casting manufacturer wanting to increase profit margins.

Hot runners can be used in conventional machines casting small components indirectly using a subrunner to feed multiple cavities or casting medium to large components feeding directly onto the casting surface, potentially eliminating up to 100% processing scrap.

This new technology is in the process of changing zinc die casting, with higher efficiencies, lower scrap rates, better quality, and more. DW

24 DESIGN WORLD April 2024

Design Notes

Ferrofacta • ferrofacta.com SHOCK & VIBRATION SOLUTIONS NEED A STANDARD VIBRATION ISOLATOR? We Have A Solution for That! MADE IN THE U.S.A. 800.838.3906 | sorbothane.com Sorbothane_DesignWorld_Ad_D.indd 1 1/8/24 10:48 AM

Shown here is the Ferrofacta Knife sample.

BY IAN WRIGHT

SENIOR EDITOR

ENGINEERING.COM

BY IAN WRIGHT

SENIOR EDITOR

ENGINEERING.COM

Top five misconceptions about 3D printing in 2024

The rapid pace of advances in 3D printing hardware, software, and materials means that many engineers still have obsolete ideas about the capabilities and benefits of additive manufacturing (AM). Those behind on 3D printing knowledge likely sacrifice innumerable opportunities for greater efficiency, product innovation, and responsiveness to customer demands.

To gain an AM edge, let’s bust five of the most common 3D printing myths.

Myth #1: 3D printing is only costeffective for prototypes and limited runs

While the flexibility and relative speed of 3D printing make it particularly

valuable for prototyping, it can be costeffective in other applications, including volume production. For example, Airbus and Boeing have been 3D-printing interior aircraft components for years. In the dental space, millions of customized aligners are produced each year using additive manufacturing.

Myth #2: 3D-printed parts are weak

As with any process, the strength of a 3D-printed part depends on its design, material selection, and post-processing. In general, a plastic part made with 3D printing will be weaker than an equivalent part made with injection molding. However, metal 3D-printed parts can perform comparably to their

machined equivalents, though typically only with additional post-processing, such as hot isostatic pressing (HIP). Adjusting printing parameters, such as layer height and infill density, can also improve 3D-printed part strength.

Myth #3: Material selection for 3D printing is limited

After decades of development, the materials industry for 3D printing has grown from a few filaments and resins to hundreds of options, including ceramics, composites, and biomaterials — not just plastics and metals. Of course, the material options for a given 3D-printing application will vary depending on the process. But even 3D-printed dentures are increasingly common and highly customizable to each patient’s needs. | 3D Systems

www.designworldonline.com 26 DESIGN WORLD April 2024 Digital Manufacturing

•

•

JUNE 25-27, 2024 Los Angeles Convention Center | Los Angeles EXPLORE THE ADVANTAGES OF ADDITIVE From shortening supply chains to enhancing productivity, industrial 3D printing can augment traditional manufacturing methods to create faster, smarter processes. That means more ways to innovate — and better results for your company. SAVE $125 Claim Your Free Expo Pass & Save 25% on Conference Passes Register by May 15 With Code: RPMS REGISTRATION IS OPEN rapid3devent.com NORTH AMERICA’S LARGEST ADDITIVE MANUFACTURING AND INDUSTRIAL 3D PRINTING EVENT.

Digital Manufacturing

You also have a choice for hydraulic cylinder

Inside the cylinder?

Compact, robust design

Our Hall E ect Transducers Give You A Choice COFFEE

Maintains ASAE pin dimensions

20g RMS Vibration Rating

UN ECE R10 Automotive Approval

the cylinder? Or

within a single category, such as binder jetting, there is a wide array of substrates to choose from, including fullcolor and elastomeric 3D printing materials.

Myth #4: 3D printers are difficult to operate

While desktop 3D printers have become increasingly user-friendly over the years, industrial 3D printers typically require some training to operate. There are similarities between operating a CNC machine and an industrial 3D printer — both require setup, calibration, and a software interface — but there are also important differences. For example, 3D printers typically have more calibration parameters, such as the atmosphere inside the build chamber. Prior knowledge of CNC operation will put one ahead of the curve in learning to operate an industrial 3D printer, but a deeper understanding of materials, process parameters, and quality control might still be useful.

Myth #5: 3D printing will replace other manufacturing processes

3D printing technology will continue to advance, and the adoption of industrial-scale additive manufacturing will grow along with it. Nevertheless, AM will not replace conventional manufacturing processes but rather augment them. For example, 3D-printed jigs and fixtures can reduce cycle times and improve product quality in many traditional manufacturing applications. In any case, the relative costs, production speeds, and size constraints of 3D printing make it unlikely to replace other manufacturing processes completely in the foreseeable future. DW

Independantly Mounted Transducers

Advanced 3D-printing materials provide strength, weight reduction, and cost savings for industries such as aerospace. | Markforged

28 DESIGN WORLD April 2024

Tank Level Transducers On Site Replaceable Magnet Works Through Carbon Steel

TEA? or

No Deep Drilling Costs Miniature Mounting Non Contact Operation Short Length Maintains Pin to Pin Dimensions

Float

Velocity Temperature

to 6 metres High

Rota Limited www.rota-ltd.com info@rota-ltd.com

Also from Rota

Light Duty Mounts with cylinder Ideal for high volume, low cost OEM applications Outside 3 in 1 - Capable of Position

Up

Accuracy

Easily eld replaceable for maximum machine uptime

Ideal for steering cylinders

Ideal for long cylinders

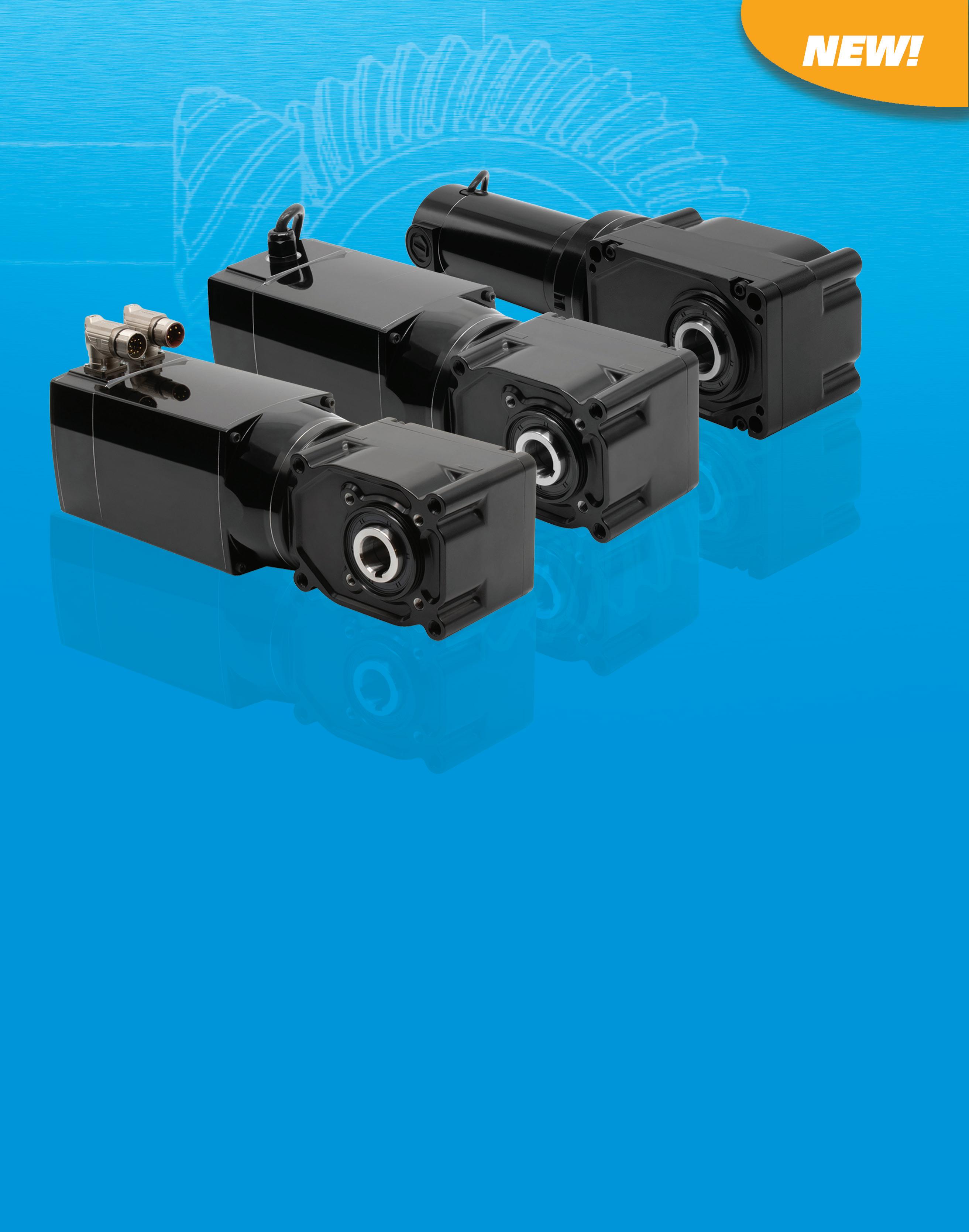

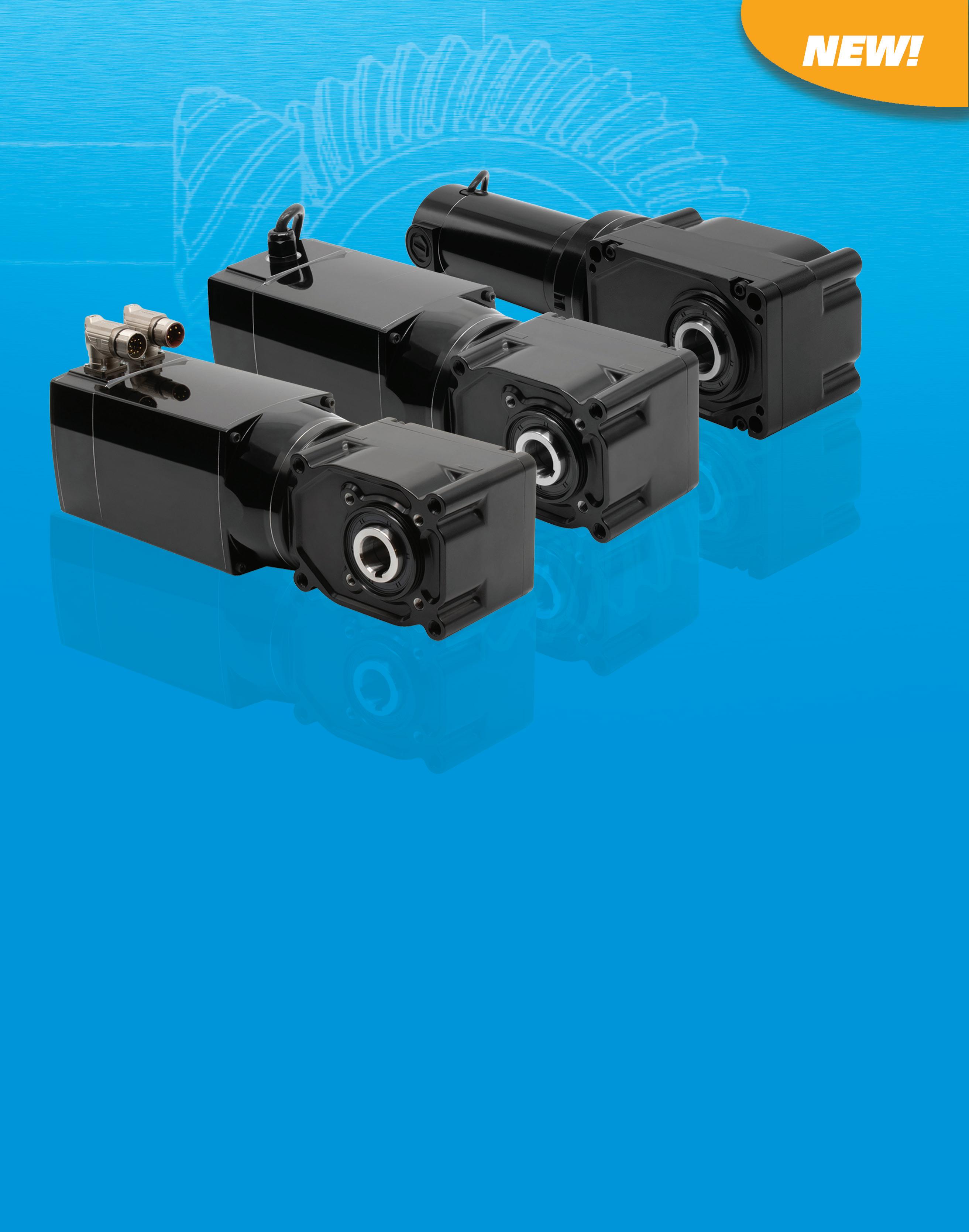

bodine-electric.com | info@bodine-electric.com | 773.478.3515 (USA) Efficient. Powerful. Dependable. Bodine’s New Hypoid Gearmotors Get high efficiency, increased torque and quiet operation. Compact and versatile hollow shaft designs deliver up to 2,370 lb-in (268 Nm). AC inverter-duty, permanent magnet DC, and brushless DC models available now. Visit Bodine-electric.com for complete specs. TYPE SPEED (rpm) TORQUE (lb-in) GEAR RATIO VOLTAGES Inverter -Duty AC 7 - 340 53 - 2,328 5:1 to 240:1 230/460 VAC, 3 - Phase Permanent Magnet DC 10 - 500 35 - 1,535 5:1 to 240:1 12 & 24, 90, 130, 180 VDC Brushless DC (EC) 8 - 400 66 - 2,370 5:1 to 240:1 130 VDC

PMDC

BLDC AC

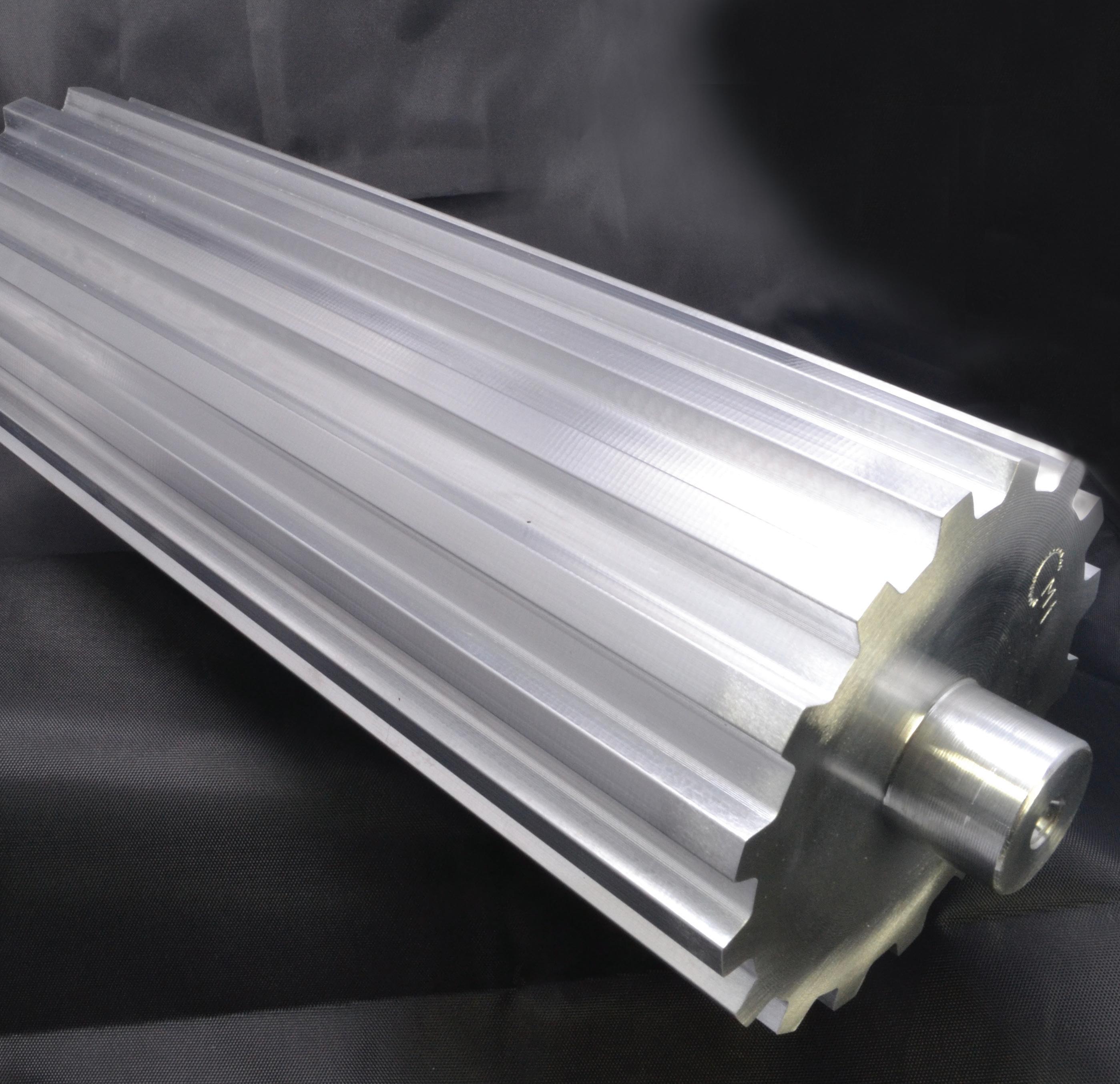

We guarantee your pulley stock order* ships within 72 hours or we pay the UPS ground freight charges. *Exclusions apply Email or call to get your Pulley Stock 72-Hour Shipping Program Catalog.

Custom Machine & Tool Co., Inc. 800-355-5949 sales@cmtco.com www.cmtco.com Precise. Reliable. Trusted. American Engineering | American Made © Custom Machine & Tool Co., Inc. Manufacturer of Power Transmission and Motion Control Components Timing

CMT 3-21_PULLEYSTOCK_Vs7.indd 55 12/13/23 11:12 AM

Pulley Stock

EDITED BY MIKE SANTORA

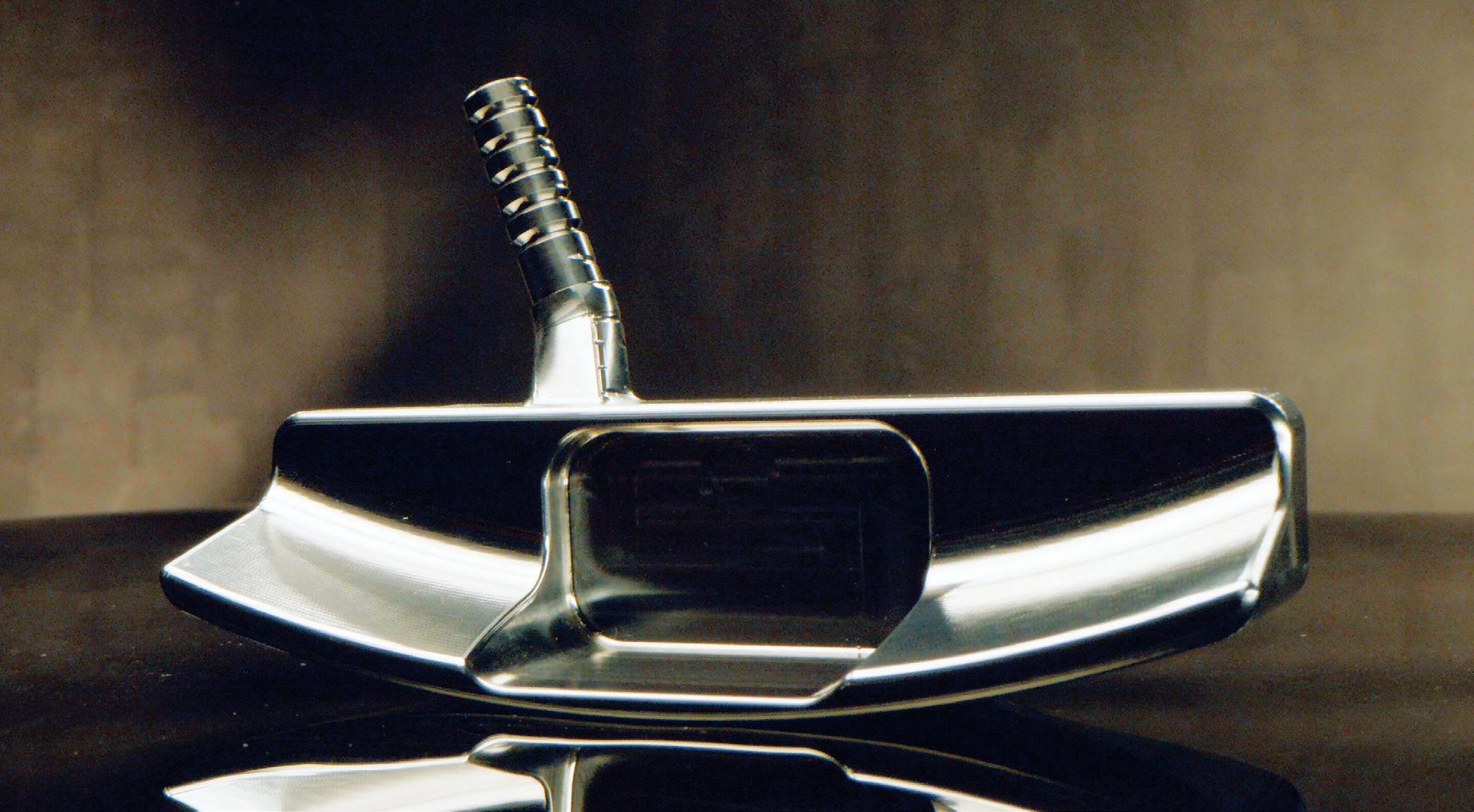

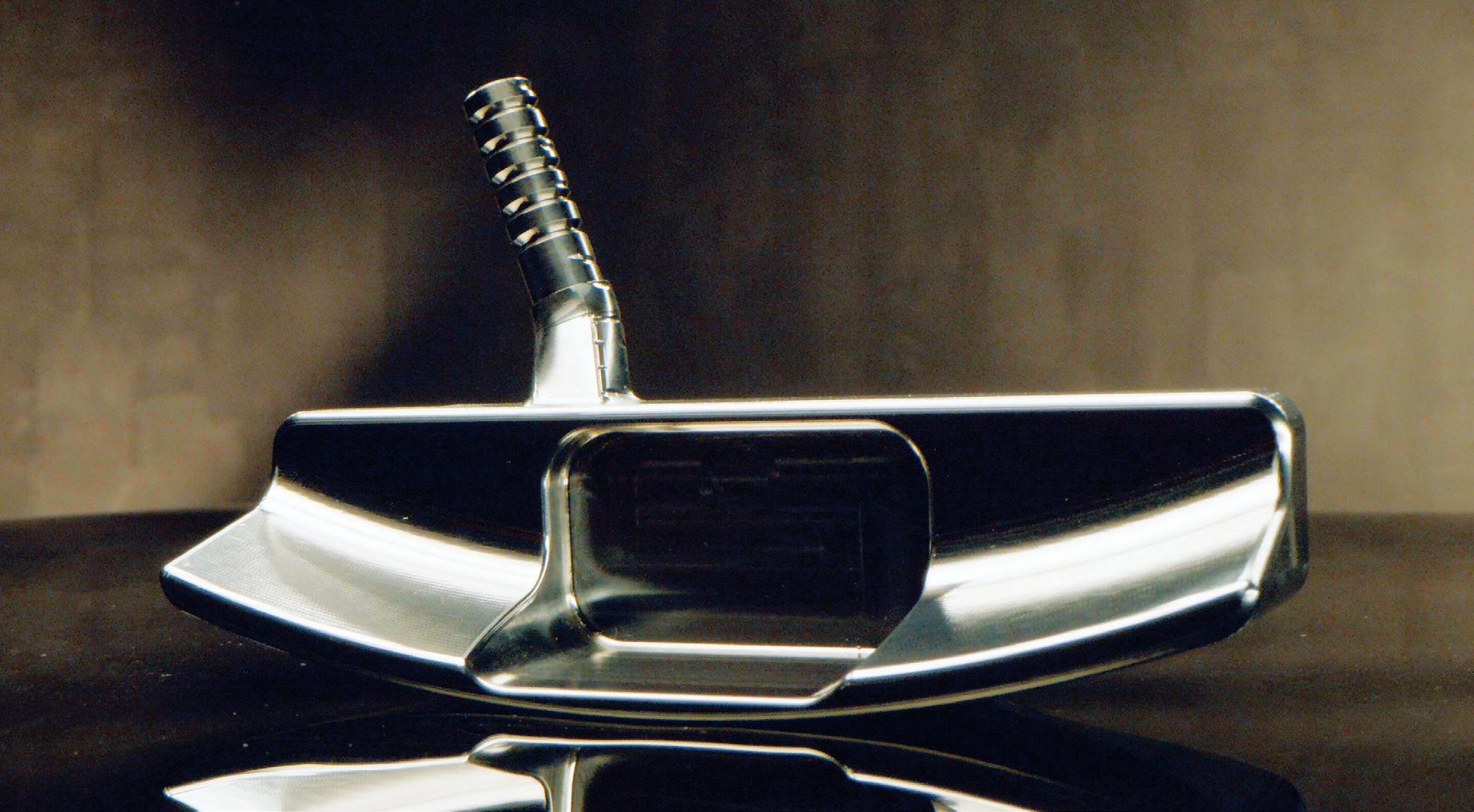

Acing a custom manufacturing job

If you golf, or even attempt mini-golf, you know it all comes down to putting. Whether you are trying to lower your handicap, make the tour, or simply putt your way through the laughing clown obstacle while on a family vacation, the entire game comes down to putting.

Bruce Rearick from Burnt Edges

Consulting in Indianapolis, Indiana, is the guru of putting and is known nationally for “a better understanding of the science and art of putting.”

Bruce cut his teeth for 15 years with the Palmer organization (Yes, that one. Think lemonade and iced tea). While Bruce has many putter design ideas and concepts, such as moving the putter head, hosel placement, and customizing for each golfer (Note, every other club in the bag gets customized except the putter), the large golf club companies would not take the manufacturing risk. Enter Brian Olson, and Olson Custom Designs, also of Indianapolis, a custom manufacturer with expertise in CNC milling, turning, and fabrication. “Unlike the behemoth golf manufacturers, Brian took the time to listen. He entertained my

The Olson Custom Designs putter.

ideas, my challenges, and even made manufacturability suggestions,” said Bruce Rearick.

The Challenge

Aligning the proper manufacturing process to support the ideas Bruce had developed was of primary importance. Just getting someone to listen was a big challenge. Bruce now knows he has a responsive, engaged partner in OCD.

The Solution

Once Bruce engaged with Olson Custom Designs, everything changed. The clean shop, coupled with personal, responsive engineers, and the knowhow to run the 5-Axis CNC led to 6 different versions.

The Results

Making inroads with famous golfers and business professionals such as Joel Stalter, the BP world tour, Bo Van Pelt, and Aaron Bradley with the Korn Ferry tour, has been invaluable for the company. “One of my favorite moments was providing Charles Schwab a private lesson in his home,” said Rearick. DW

31 DESIGN WORLD April 2024 www.designworldonline.com

Machine Tool

Fluid Power

BY JOSH COSFORD

How long should hydraulic fluid last?

Forever. It should last forever. Thanks for reading, and come back next week for more YouTube Shorts. I kid, of course, although there is always truth in comedy because you should treat your oil as your forever fluid. Of course, simply showering your hydraulic fluid with love will not guarantee a lifelong relationship. However, when all the proper maintenance and care are offered to your hydraulic system as a whole, you can expect your hydraulic fluid to last the life of the machine.

Of course, I’m not so extreme an optimist as to believe all oil in all conditions will age like an Okinawan. Like any Blue Zone centenarian, aging healthfully requires conscious thought and effort. Hydraulic fluid must be kept clean, cool, and dry to prevent potential side effects, and regular testing elucidates any potentially unmanageable concerns.

Clean oil, at first, may seem to benefit only the pumps, valves, and actuators that constitute most of your hydraulic system. But consider the future state of any hydraulic system making do with poor filtration — it’s a place where sludge, oxidation, and erosion lead even more self-generated contamination. Picture excessive particles acting like a honing fluid that

erodes metal, increasing clearances, and gaps, and reducing machine efficiency while increasing heat.

We’ve established that clean oil is good, so how clean is clean? Let’s just say that there is no such thing as oil that’s too clean. Always use the finest and largest filtration system you can afford and have the space to install. It's been proven that clean oil is a self-reinforcing concept that reduces the particle generation rate, thereby extending your oil's life.

You also want to ensure that your oil remains cool, and by "cool," I mean optimal operating range. What is optimal depends on the oil type, quality, and application. What's essential is preventing overheating. The rate of oil oxidation increases exponentially as the temperature rises, and the useful life of oxidized oil is precisely zero, as its actual structure is adulterated into ketones, acids, and aldehydes. Should oxidation veer out of control, conditions as bad as sludge and varnish may require replacing significant components in addition to the fluid itself.

Oxidization is natural and unpreventable, but the oxidation rate is slowed down through additives that can be monitored with regular

oil testing or even sophisticated TAN (Total Acid Number) sensors. Should the antioxidant additives degrade over time, they can be replaced, helping to ensure that your fluid life is extended indefinitely.

Keeping your oil dry also prevents hydraulic fluid morbidity, as water increases oxidation, hydrolysis, and microbial growth. We’ve discussed oxidation but hydrolysis creates similar effects and the creation of alcohols, acids, and other forms of degradation. With excessive water and a warm, cozy environment, bacteria, yeast, and fungi can sometimes proliferate, accelerating oil death while often creating unpleasant odors.

Sometimes, hydraulic fluid may be reconditioned back to life, but the process is often expensive and justified only for high reservoir volume or expensive fluids. Even if you follow my recommendations, there's still no guarantee of everlasting life. However, when you are thoughtful about fluid maintenance by keeping your oil clean, cool, and dry, you can expect a long, reliable life of not only the fluid but also the rest of the system in general. DW

www.designworldonline.com 32 DESIGN WORLD April 2024

VXNAGHIYEV | ADOBE STOCK GENERATED WITH AI

Industries Served: • Oil & Gas • Industrial Hydraulics • Mining • Forestry • Chemical & General Processing Plants • Medical • Aerospace • Factories • Mobile Equipment • Defense • Machine Tool • Testing Equipment • Ocean Depth Technology • Automotive • Food Processing • Agriculture • Industrial • Aviation • Petrochemical • Marine • Subsea DELAWARE MANUFACTURING INDUSTRIES CORPORATION Solutions Under Pressure ISO 9001 Certified Medium - High Pressure Valves Low Pressure Suction Valves Subsea & Gas Valves Specialty Valves 800.248.DMIC (3642) • WWW.DMIC.COM • SALES@DMIC.COM Made In America Manifold Mounted Valves Manifolds Ball Valves Check Valves Flow Control Valves Needle Valves Flanges & Adapters Bar & Custom Manifolds Pressure Gauges & Snubbers SSW Power Unit Systems Transfer Pumps

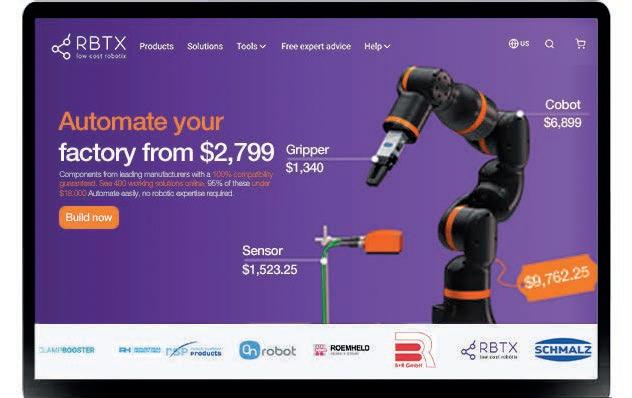

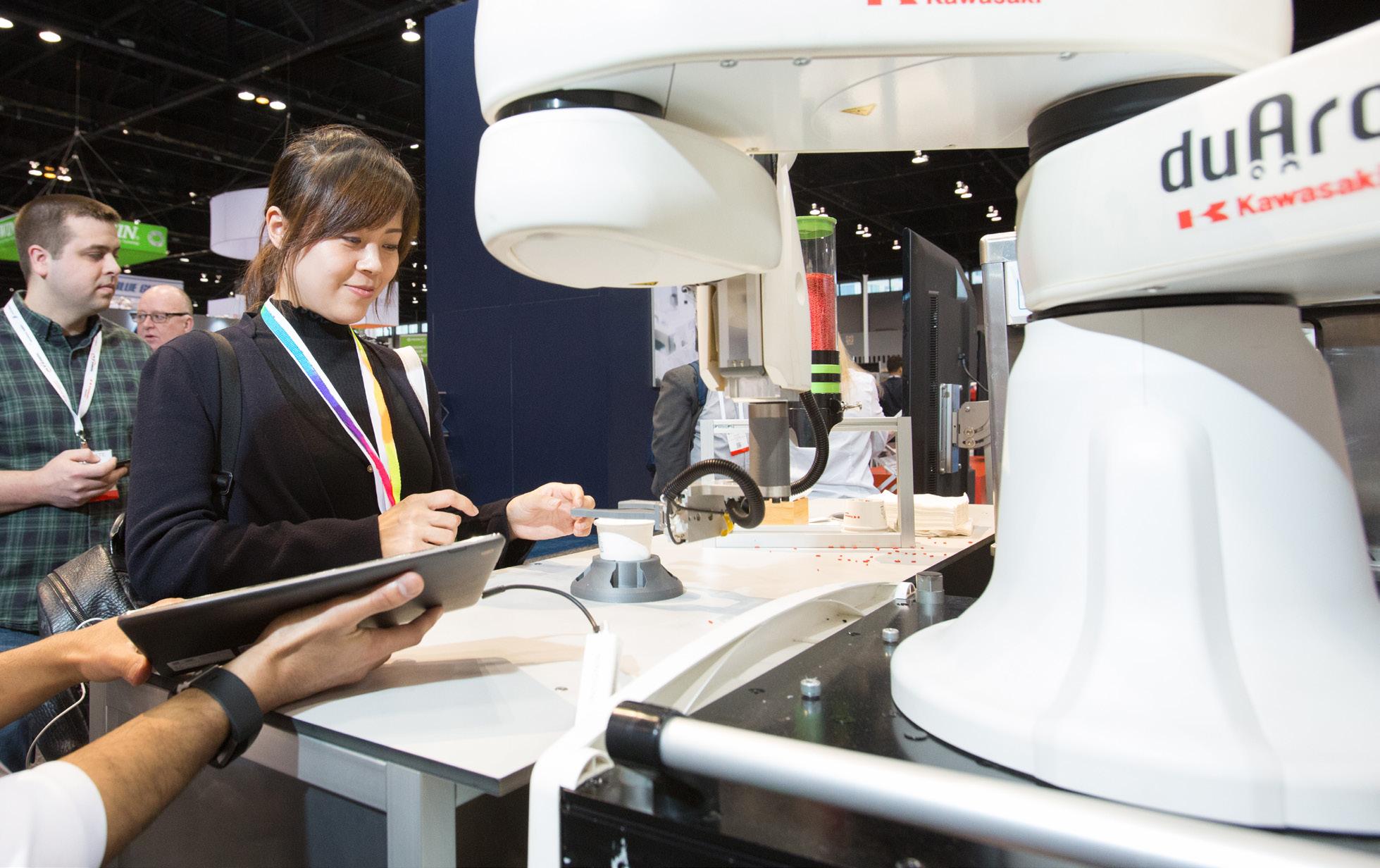

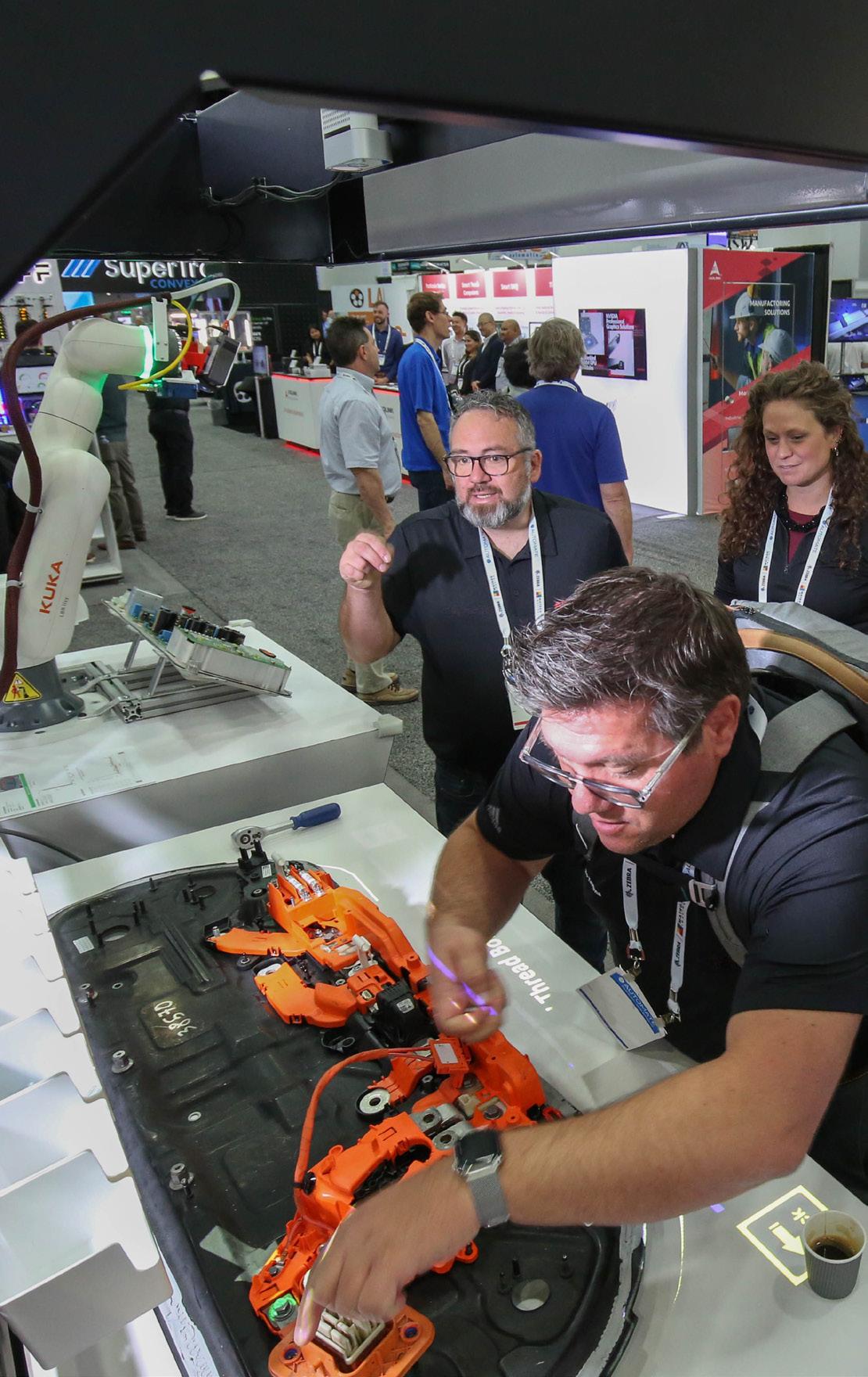

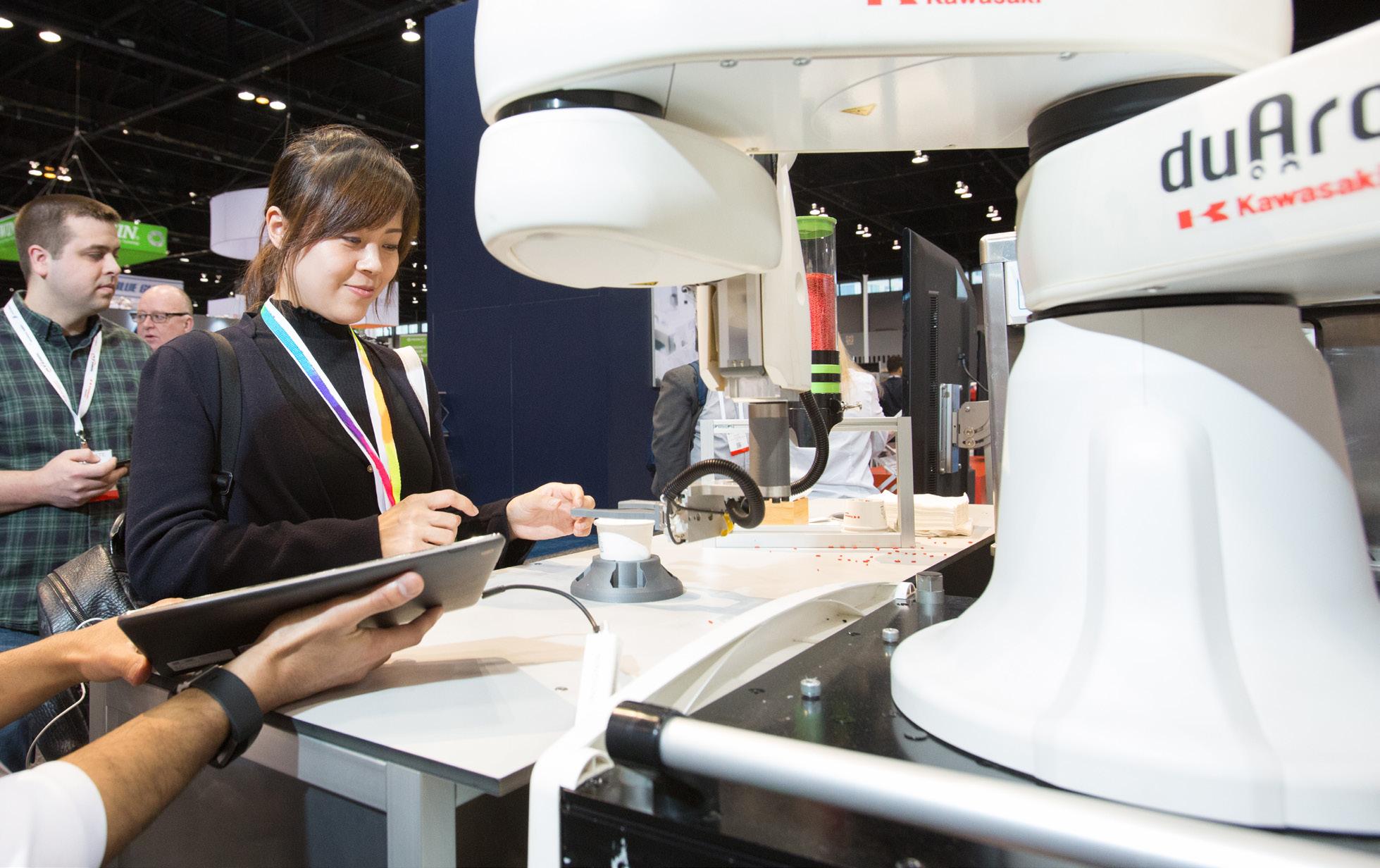

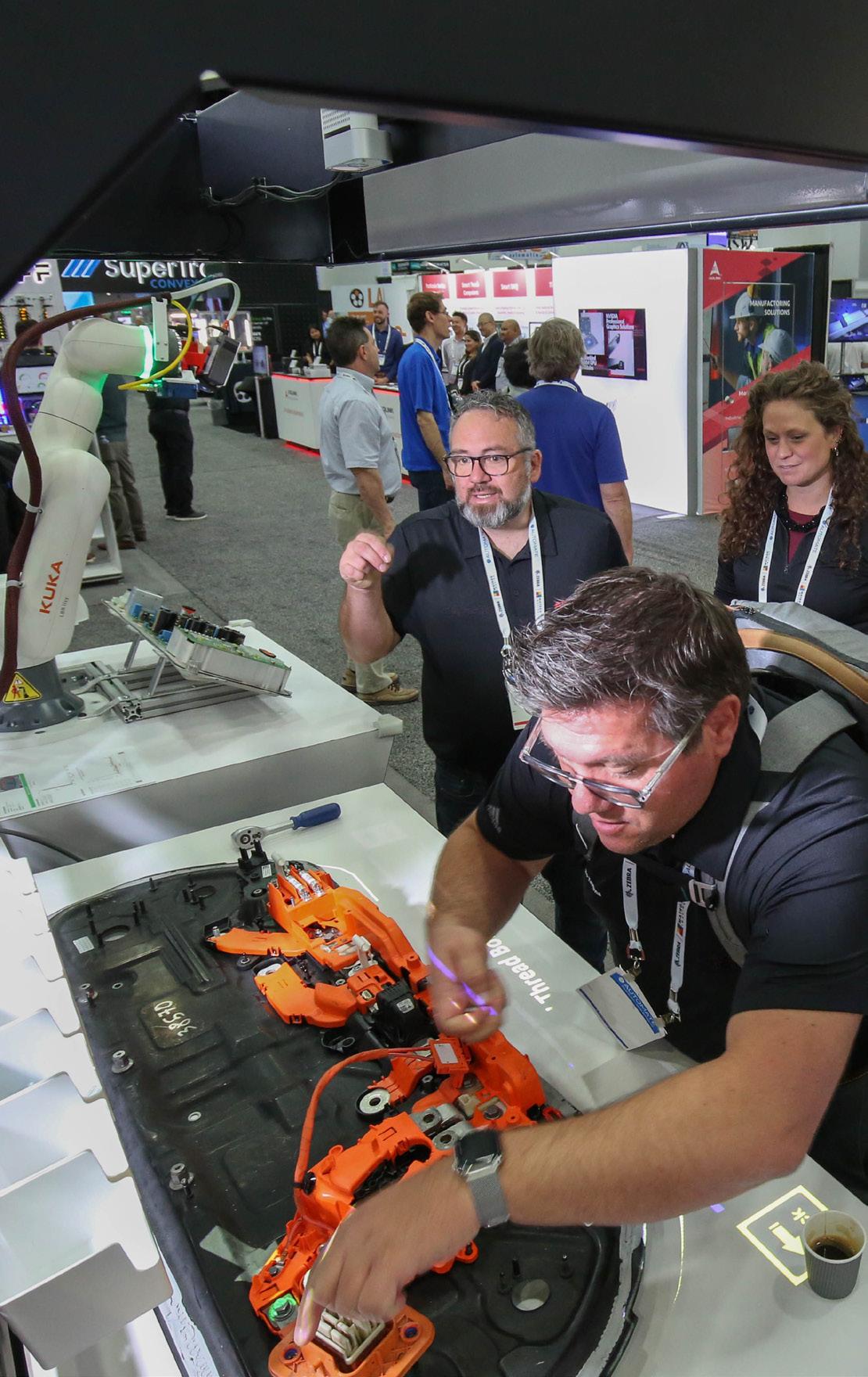

Women to lead the way at AUTOMATE 2024

Automate — the largest robotics and automation trade show in North America — is back and has big plans for this year’s upcoming event. Show organizers plan on “redefining the tech industry narrative by celebrating and empowering women in automation.” The annual trade show and conference, running May 6-9 in Chicago and hosted by the Association for Advancing Automation (A3), will open its third day with an inaugural Women’s Empowerment Forum and a muchanticipated keynote address by MIT Professor Daniela Rus.

The Women’s Empowerment Forum, free for show registrants, will feature a panel of female executives in automation, including Marina Bill of ABB Robotics, Adi Leviatan of 3M, and Rashmi Misra of Microsoft. The panel will discuss breaking barriers and staying motivated to make a mark in this male-dominated industry. Following the Empowerment Forum, Professor Rus will delve into the future of automation and robotics, exploring the transformative potential of the next

60 years in the industry. The show will wrap up its final day with Wendy Tan White, CEO of Intrinsic, discussing advances at the intersection of robotics and AI to solve real problems in industrial automation.

“Automate has always been at the forefront of innovation. Yet, as technology continues to evolve and its economic impact grows at an unprecedented rate, the need for diverse voices in the conversation has never been more critical,” said Deb Kling, vice president of marketing for A3. “The Women’s Empowerment Forum, combined with our featured keynotes, not only recognizes these incredible female leaders who are driving change but also helps to strengthen awareness of the critical need for women in the industry.”

The Automate Show is free for anyone who works with, or is interested in, automation. The Chicago event will be the largest Automate Show yet, with more than 30,000 registrants from across the globe, 200 speakers, and more than 800 exhibitors occupying

over 365,000 square feet of exhibit space. Attendees will see the latest solutions in cutting-edge robotics, vision, artificial intelligence, motion control, and related automation technologies.

In conjunction with the free show, the paid Automate Conference will feature 200+ accomplished industry professionals leading classroom-style sessions. Those looking to sharpen their skills or deepen their automation knowledge should sign up for these educational conference sessions to get practical solutions, discover the latest innovations, or learn from real-world case studies. Conference attendees can also take advantage of Certified Vision Professional courses in basic and advanced tracks and Certified Motion Control Professional — Basic courses culminating in an exam to secure professional certification (exam fees are separate). DW

www.designworldonline.com 34 DESIGN WORLD April 2024

Automate 2024 • automateshow.com

Don’t miss North America’s leading automation event.

With more than 800 exhibiting companies from around the world, Automate 2024 provides unparalleled access to cutting-edge robotics, AI, technology and industrial automation solutions. Experience what’s possible—only at Automate.

SEE THE FUTURE OF AUTOMATION.

REGISTER FREE automateshow.com

MAY 6–9, 2024 • CHICAGO, IL • MCCORMICK PLACE IS BROUGHT TO YOU BY

MICRO DRIVES BRING DYNAMICS into handling

EDITED BY MILES BUDIMIR • SENIOR EDITOR

Small dc micro drives bring dynamics into handling applications, such as swiveling-rotary modules

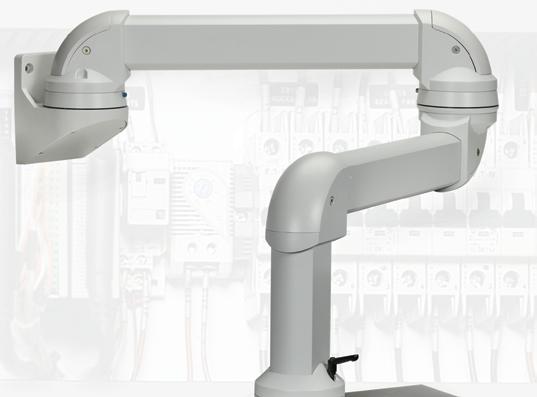

Miniature drives and microdrives are used in virtually all areas of automation technology and have a correspondingly wide variety of applications. These range from medical technology and laboratory automation as well as general machine construction and intralogistics through to aerospace applications. In all areas, the small drive systems play a role in ensuring that the associated automation systems function with optimum process safety, reliability and cost-effectiveness. This also applies to handling applications. In slimline, yet high-torque swiveling-rotary modules, these drives ensure that even large workpieces are moved precisely, both in the case of fast screwdrivers and also in automatic rotary handling, assembly and testing systems.

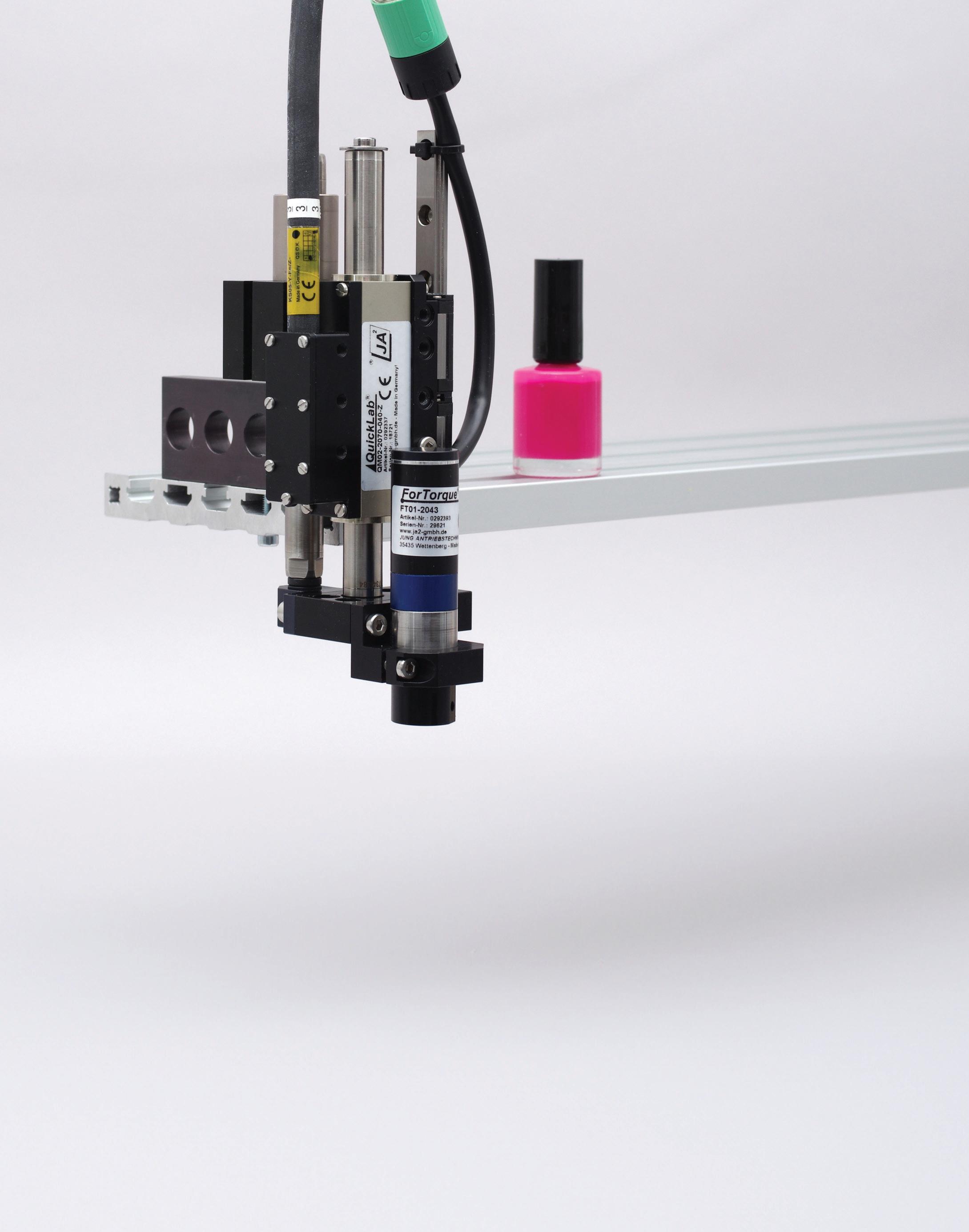

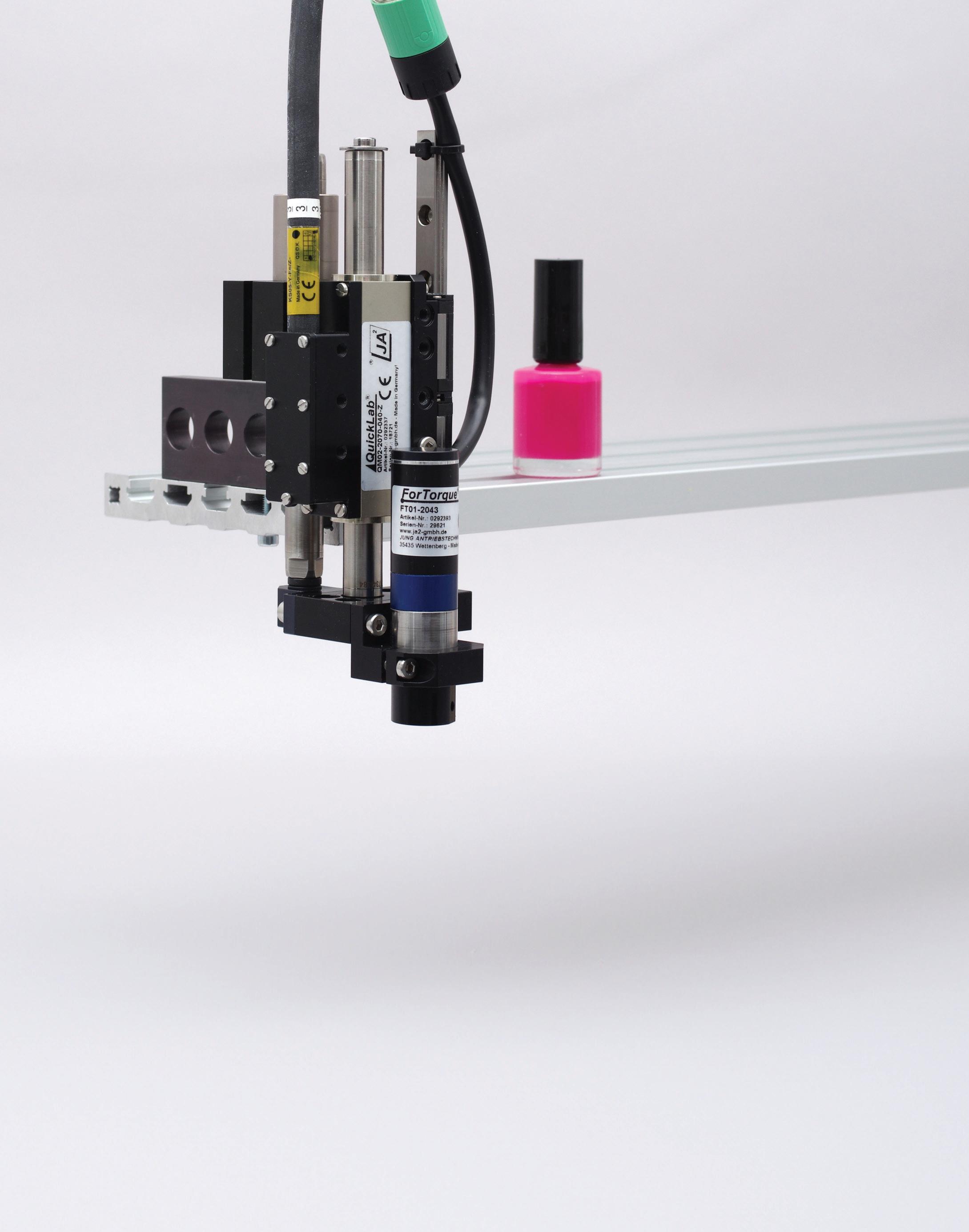

For typical movement sequences in handling and assembly technology, such

as turning, swiveling, screwing, rolling or coiling, swiveling-rotary modules answer the call. One such example comes from Jung Antriebstechnik u. Automation (JA2) based in Wettenberg, Germany. The company’s ForTorque is a kit consisting of servo-electric swivellingrotary modules compatible with the company’s linear motor actuator series and are equipped with an ac servo drive, a gearbox and backlash-free bearings. The modules are especially suitable for the highly dynamic rotation of large, high-inertia workpieces and eccentric grippers as well as for use in screwing and coiling technology.

Turning, swiveling, screwing, coiling

A typical application case for the miniature swiveling-rotary modules is, for example, screwing the caps on small cosmetics or pharmaceutics containers in constrained spaces on fully automated

packaging lines. The modules are also suitable in cases where grippers or workpieces need to be swiveled; that is, when assembling or separating products. Designed as a modular system, six sizes with diameters of 16, 20, 25, 35, 40, and 45 mm are available. This covers peak and continuous torques of 0.3 and 0.14 Nm to 4.0 and 2.6 Nm respectively. The inertias of the load may be between 2.0 and 200 kgcm2. This provides the most suitable solution for accurately angled movement and positioning for a range of different handling and assembly tasks.

To reduce the load on the output shaft of gearheads in the case of high external moments of inertia, the output plate of the four larger module has an extremely rigid bearing consisting of two thin-section bearings. Plus, the swiveling-rotary module with 40-mm diameter can be equipped with a fluidic

Motion Control www.designworldonline.com 36 DESIGN WORLD April 2024 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

rotary joint for pneumatics or vacuum applications, for instance, to supply a pneumatic gripper with compressed air. This modular concept can be pushed even further. For instance, an interesting possibility is to combine the fast rotary units with linear axes, such as that of the QuickLab series, with matching adapter plates available as accessories. The result is a compact lift-rotary or lift-swiveling system through to five-axis handling systems.

High dynamics and precision

"The drives are the heart of our modular automation system and the requirements placed on them are very high," explained Wilhelm Jung, Managing Director at JA2. "The motors must operate highly dynamically, be precisely controllable

and have suitable dimensions." In the case of the ForTorque modules, for example, brushless dc motors of the B and BX4 series from FAULHABER are used. The motors, with their two-pole and four-pole technology, are extremely compact. The ForTorque modules use motor variants of the B series with diameters of 16, 20, and 35 mm and are just 28, 36 and 68 mm long respectively, but deliver continuous torques of up to 168 mNm in the case of the largest variant. In the case of the BX4 series, "here we use motors with 22 mm or 32 mm diameter and continuous torques of 18 and 53 mNm respectively," reported Jung.

The motors are used in the ForTorque modules at speeds of up to 8,000 rpm. Different gearheads,

The swiveling-rotary module with 40 mm diameter can be equipped with a fluidic rotary joint for pneumatics or vacuum to supply a pneumatic gripper with compressed air.

including zero backlash planetary gearheads from FAULHABER, provide gear reduction. Ultimately, the gearhead technology with the respective maximum input speed determines the limit for the maximum motor speed. "We then select the reduction ratio according to the application," continued Jung. This lets them influence the extent to which the external moment of inertia is reduced by the square of the reduction. The motor can then be precisely regulated unaffected by the lever. “When selecting the gearheads, we paid particular attention to the efficiency of the gearheads,” added Jung. “Because the better the efficiency is, the more precisely the torque applied at the gearhead output can be determined from the motor current. This is a key feature particularly in the case of screwing applications where delicate (plastic) parts need to be screwed on with a defined torque.”

Single-cable technology for fault-free control

All swiveling-rotary modules are connected and controlled using a standardized bayonet connector, single-cable technology, and a motion

37 DESIGN WORLD April 2024 www.designworldonline.com • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Motion Control

The slimline infinite rotary units are suitable for the highly dynamic rotation of large workpieces and eccentric grippers as well as for use in screwing and coiling technology.

MILLIONS of Springs

IN STOCK AND READY TO SHIP!

controller. In automation systems, however, the switch cabinet is usually some distance from the actual drive. "Between the motor and the controller in the separate switch cabinet, there can then be 10, 20, or more meters," said Jung. There is therefore a special, multi-shielded cable that transfers the motor power and the position sensor signal between the motor and controller up to 30 m without interference. The cable is fastened with strain relief, can be plugged in and is also designed for use with cable chains. Moreover, thanks to the available preassembled cable sets, the single- cable technology simplifies installation.

With the motion controllers, the user has the choice because the motors are compatible with different controllers. "We also offer motion controllers from FAULHABER," said Jung. For example, the QuickLab linear axes use the LM2070 and LM1247 dc linear drives. They are not designed as classic "surface rotors" with carriages and guides. Instead, the forcer rod is guided within a 3-phase self-supporting coil. "This design produces an exceptionally good relationship between linear force and current and high dynamics. In addition, there are no cogging torques, thereby making the linear motors ideal for use in our modular QuickLab system," added Jung. DW

Jung Antriebstechnik u. Automation (JA2)

www.faulhaber.com/en/

www.ja2-gmbh.de/home-en

DESIGN WORLD April 2024 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Vibe check: testing components for satellite-environment readiness

SPACE RACE(S): ceramic bearings are ready for takeoff Page 40

2024

ALSO INSIDE: Page 44 APRIL

www.designworldonline.com 40 DESIGN WORLD April 2024

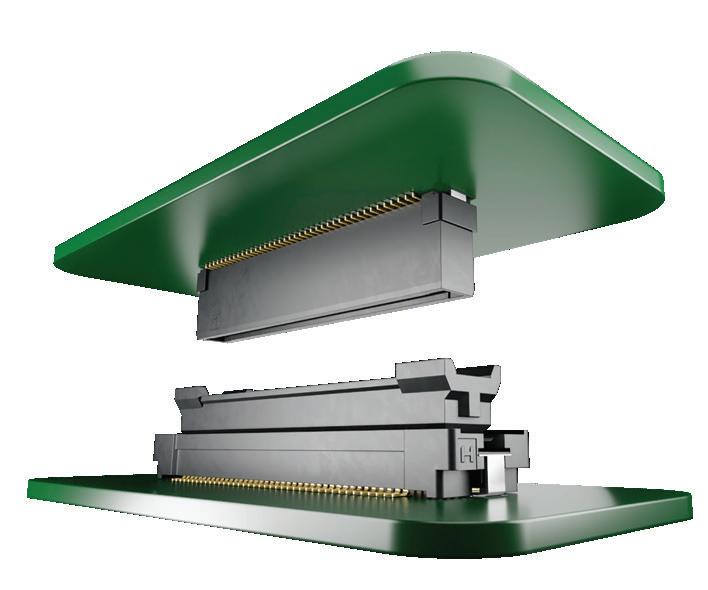

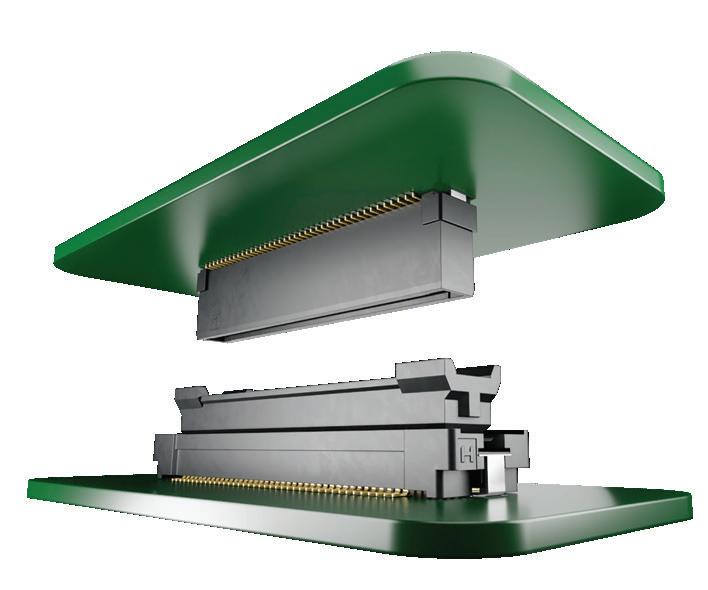

Harwin Flecto connectors are fine-pitch, high-pin-count board-to-board connectors offering perfect alignment, high-speed data transmission, mixed signal and power options, and multiple mating heights.

CONNECT TECHNOLOGY WITH CONFIDENCE.

WWW.HARWIN. COM /FLECTO ALWAYS ALIGNED Introducing DESIGN WORLD www.designworldonline.com 41 April 2024

//

: Specialist bearings must withstand the harsh conditions of space, including absolute vacuum and fluctuating temperatures.

Brushless Motors

Solid or hollow shaft, high performance, housed and frameless, brushless motors and matching drives for demanding applications.

Hall or sensorless motors and drives for surgical tools, aerospace, military, and scientific instrument applications. Custom drive programing and designs available. Motors up to 95% efficient, power up to 1,500 watts. Highest power density in the industry.

Operating temperatures from -73C to 150C

Slotless and slotted designs. Available with encoders and gearheads and separate or integral electronics.

Quantities 1 to 5,000.

www.koford.com

Contact us at mail@koford.com

Because they are lightweight and vacuum-compatible, ceramic bearings will be greatly relied upon in space exploration.

are most commonly used in applications where excellent corrosion resistant is required, along with exposure to extremely low or high temperatures. In other words, ceramic beings are ideal for use in space.

One of the key advantages of full ceramic bearings is that they can run constantly at speed without lubrication, which is why Si3N4 is often used in vacuum environments.

ZrO2 bearings can be used up to 400° Celsius, and Si3N4 bearings up to 800° Celsius. Also, for these temperatures, it is recommended that the bearings should be full complement. This means the bearing doesn’t have a ball retainer; instead, the free space allows additional balls to be fitted. This increase in ball complement allows for significant increases in radial bearing capacity, although maximum speed is significantly reduced. Down to approximately minus 200° Celsius, ceramics also have excellent low-temperature performance provided a suitable cage is used.

With their lightweight and vacuum-compatible properties, silicon nitride bearings will be greatly relied upon in space-exploration applications. They will particularly benefit satellites and spacecraft, which need optimal weight capacities to perform enhanced flight dynamics and acceleration. These specialist bearings, along with their stainless-steel counterparts, will be vital to ensuring that the next giant leap for humankind is a farfrom-risky business. AD

SMB Bearings

• smbbearings.com

42 DESIGN WORLD April 2024 Aerospace/Defense

• • • • • • • • Timing Belt & Pulley Drive Components • Precision Gears & Gearheads • Mechanical Components • Prototypes • Production Runs Engineering Development & Precision CNC Machining CNC Swiss Turning • CNC Milling & Turning 4 & 5 Axis CNC Milling & Machining • Gear Cutting Bevel Gear Cutting • Rapid Tooth Cutting Only Capability

are here to help, contact us today! www.sdp-si.com • (516) 328-3300

Built to Print

Assembly

Long Term Agreements

Engineering Support ISO 9001:2015 | AS9100D ITAR Compliant - DDTC Registered DFARS Compliant

We

•

•

•

•

Edited by Mike Santora

Edited by Mike Santora

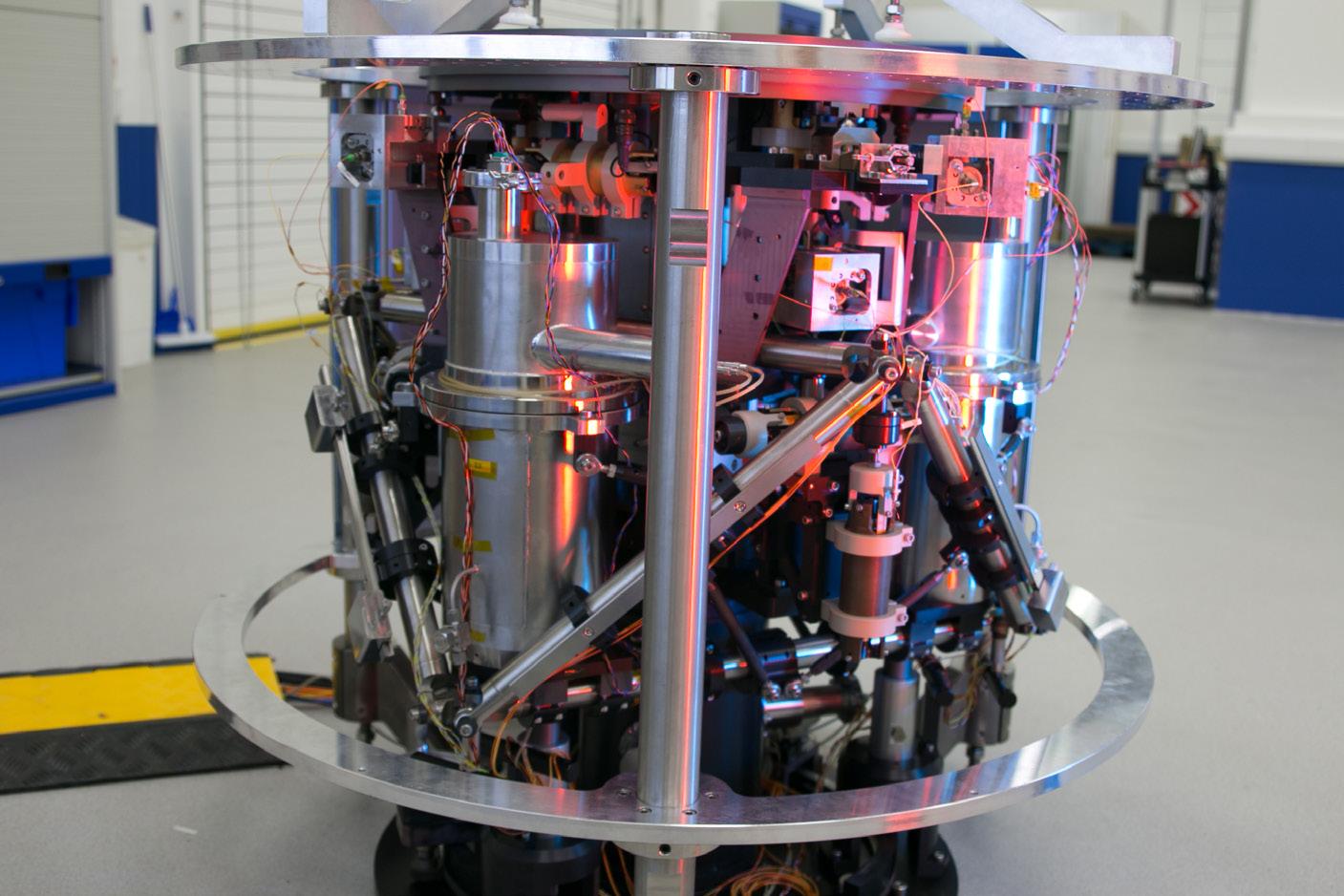

Vibe check: testing components for satellite-environment readiness

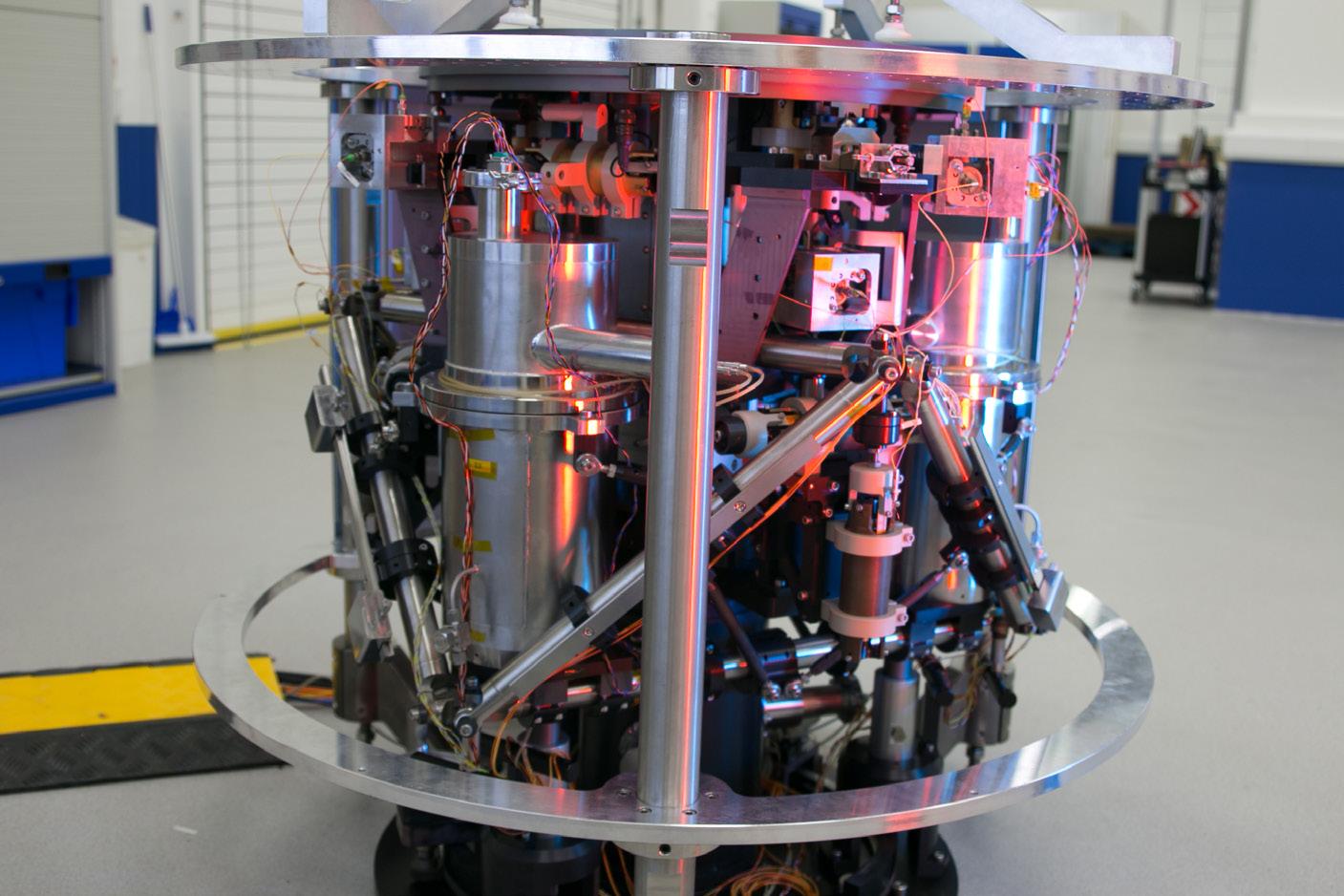

The European Space Agency (ESA) has added a microvibration test instrument, developed by the National Physical Laboratory (NPL), to its satellite testing facilities. NPL is the UK’s National Measurement Institute, developing and maintaining the national primary measurement standards. The instrument measures vibrations generated by satellite subsystems to quantify their effects on images and measurements made from space. This facility is the result of five years of collaboration between NPL and ESA.

Vibrations onboard a satellite can be caused by common instruments and mechanisms, such as spinning reaction wheels, solar array drives, and rotating cryocoolers. ESA needed to be able to measure and correct for these jitters and vibrations to improve the accuracy of its Earth observations. This required the simulation of satellite components under a range of controlled vibration conditions.

“The NPL won a tender to design a system for the European Space Agency, which required a very high level of performance,” said Dan Veal, Senior

Research Scientist with the National Physical Laboratory in the United Kingdom. “The system was required to measure very low frequency related to very low force. ESA needed a better way to check satellite components for these micro-vibrations, and to what effect they might disrupt a spacecraft.”

Measurement Platform Supported by a Vibration Isolation Platform

“NPL developed a platform which can characterize any force produced by a satellite component weighing up to 150 pounds,” added Veal.

www.designworldonline.com 44 DESIGN WORLD April 2024

European Space Agency’s micro-vibration test platform. | National Physical Laboratory

The micro-vibration platform can measure vibrations to an unprecedented degree of accuracy. It is so sensitive it can measure the force of a single dropped feather. Sometimes housed in a vacuum chamber to simulate space conditions, when used in air, the system is enclosed in a tent to limit perturbations caused by airflow.

The platform is built as a structure of two main levels: 1) a lower vibration isolation platform to cancel disturbances coming from the ground, and 2) an upper measurement platform.

Lower Vibration Isolation Platform

The lower vibration isolation platform uses a passive Negative-Stiffness vibration isolator, coupled with three highly sensitive active seismometers that control actuators, to sense ground vibrations coming into the system. The seismometers are designed to measure up to 0.3 hertz. Coupled with the Negative-Stiffness isolators, the passive/active system enables vibration isolation down to 0.1 Hz.

This system significantly reduces the effects of the vibration coming from sources, such as footsteps and

even waves from the nearby North Sea, ensuring a quiet environment for the measurement platform that is mated on top.

“We developed the lower vibration isolation platform around Minus K’s Negative-Stiffness isolators because they are capable of passively isolating vibrations down to 0.5 Hz,” explained Veal. “This was very important for our low-frequency application. But we also selected Negative-Stiffness because it is vacuum compatible.”

“Essentially, we stripped the Negative-Stiffness isolators down to their core systems, then augmented them with active seismometers connected with a custom interface,” explained Veal. “This enabled us to get down to 0.1 Hz isolation.”

Negative-Stiffness vibration isolation was developed by Minus K Technology, an OEM supplier to manufacturers of scanning probe microscopes, micro-hardness testers, and other vibration-sensitive instruments and equipment, such as for testing zero-g simulation of spacecraft.

These vibration isolators are compact and do not require electricity

• High Temp. Adhesive Tapes

• Engineering Grade Polymer Films

• PTFE Coated & Silicone Coated Fabrics

• Silicone Rubber Sheeting

Converting Capabilities

• Roll Width Slitting

• Adhesive Lamination

• Automated Sheeting

• Die Cutting

• Rapid Prototyping

45 DESIGN WORLD April 2024 www.designworldonline.com Aerospace Insulation, Assembly, Masking, Materials

Performance Products

800-461-4161 www.cshyde.com

Schematic of Negative-Stiffness Isolator

Schematic of a Negative-Stiffness isolator. | Minus K Technology

or compressed air, enabling sensitive instruments to be located wherever a production facility or laboratory needs to be. There are no motors, pumps, or chambers, and no maintenance because there is nothing to wear out. They operate purely in a passive mechanical mode.

What is very advantageous about Negative-Stiffness isolators is that they achieve a high level of isolation in multiple directions. These isolators have the flexibility of custom tailoring resonant frequencies to 0.5 Hz* vertically and horizontally (with some versions at 1.5 Hz horizontally).

(*Note that for an isolation system with a 0.5 Hz natural frequency, isolation begins at 0.7 Hz and improves with increased vibration frequency. The natural frequency is more commonly used to describe the system performance.)

“Vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a Negative-Stiffness mechanism,” said Erik Runge, Vice President of Engineering at Minus K Technology. “The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam columns connected in series with the vertical-motion isolator provide horizontal-motion isolation. A beam column behaves as a spring combined with a negative-stiffness mechanism. The result is a compact passive isolator capable of low vertical and horizontal natural frequencies and high internal structural frequencies.”