Winery Wastewater

Compliance, Monitoring, Reporting and Innovation

We acknowledge the Wadandi, Saltwater people, of the Bibbulmun nation, traditional custodians of this Country we meet on today.

We recognise their continuing connection to lands, waters and communities and pay our respects to all Noongar Boodja people, their Cultures and Elders past and present.

What’s on today

• Setting the Context

• Regulatory flowchart

• Understanding your environmental licence

Morning tea @ 10:10-10:30am

• Wastewater monitoring and compliance with your licence

• Wastewater disposal and Treatment: From NIMPs to Biological Systems

• Next steps – Industry support and Code of Practice

Lunch @ 1:00pm

Strategic Plan for WA Wine Industry 2024-2034

Five Priority Areas

INDUSTRY LEADERSHIP

INDUSTRY SUSTAINABILITY

BRAND

MARKET OPPORTUNITY

REGULATION & POLICY

• Business and workforce

• Research, development and adoption

• Biosecurity

• Licence to operate

Western Australian Wine Industry Sustainability Strategy 2025-2029

To be recognised for our sustainabilityby becoming international leaders in sustainable wine production

Sustainability Priorities - Wastewater

• Research Development & Adoption

• Sustainable Wastewater Management Initiative

• Waste Management and Circular Economy Initiative

• Licence to Operate

• WA Wine Industry Governance and Compliance Program

Water Matters

• Drying Climate

• Rainfall ↓ 20% since 1970s

• River flows ↓ 70% and

• Stream flows ↓ more than 80%

• Significant impact on water harvesting capacity

• Rainfall → tanks

• Catchment → dams

Wastewater Matters

Setting the context

Winery wastewater survey results

Aim: To understand WA wine producers’ challenges in treating, disposing and managing wastewater so to guide activities that support producers and address their needs.

Survey categories

1. Respondent profile

2. Current practices

3. Challenges

4. Future support

Respondent profile

• Open throughout February to April 2025.

• Made available to 153 producers with physical winemaking facilities.

• Received 33 complete responses and 8 partial responses (41 in total).

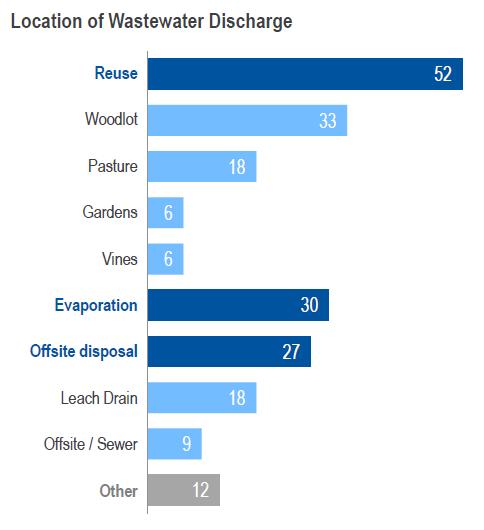

Current practices

• Majority of wineries manage their own wastewater systems

• 1 in 2 respondents spend less than 2 hours a week on WWS

• Correlation between the age of the system and the time spent on them

• 2 in 5 have additional inflows i.e. stormwater, restaurant

• Most with stormwater inflows can divert from their WWS

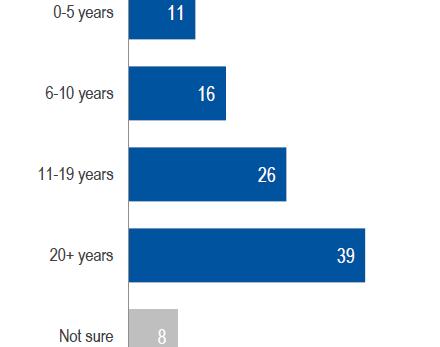

Age of infrastructure

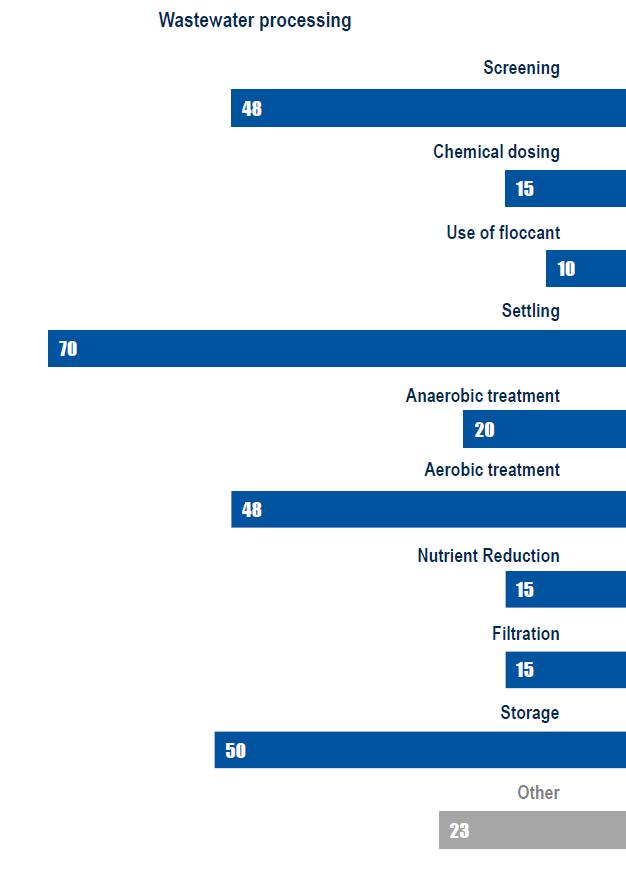

• Around half are screening their wastewater, using aerobic treatment processes and storing their wastewater

• 2 in 5 were unsure of their wastewater volume output

• 61% conduct wastewater sampling

• Most common types were volume in / out and pH

• 40% conduct soil sampling

• Most of the respondents required to conduct sampling do so

Perceptions

• Perspective of the risk WWS presents to operations was scaled by winery size.

• Around 60% felt they understood industry regulations and best practices

• Wineries with a NIMP, SWA membership and had previously engaged a wastewater consultant had the greatest confidence in understanding regulations and best practices.

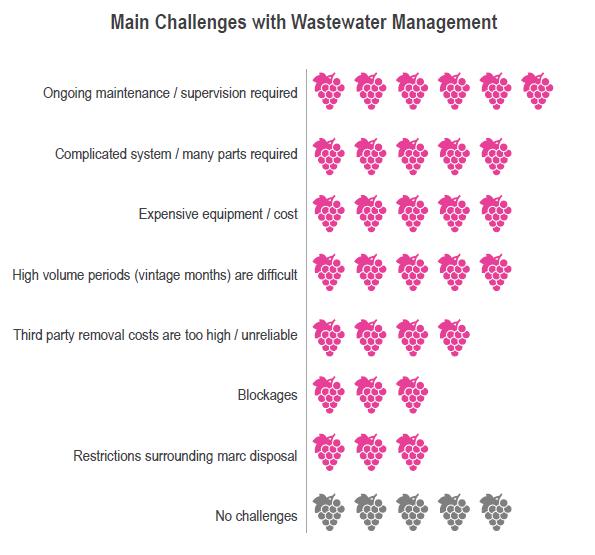

Challenges

• Common challenges:

• ongoing maintenance

• complicated systems

• cost

• managing peak volumes.

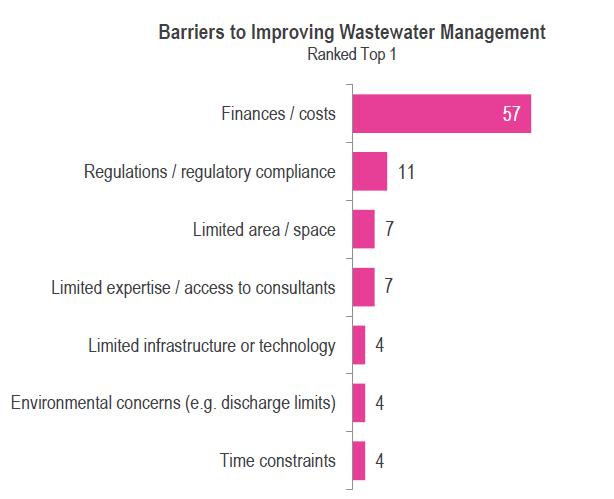

Barriers

• The biggest barrier to improving WWS by far is cost

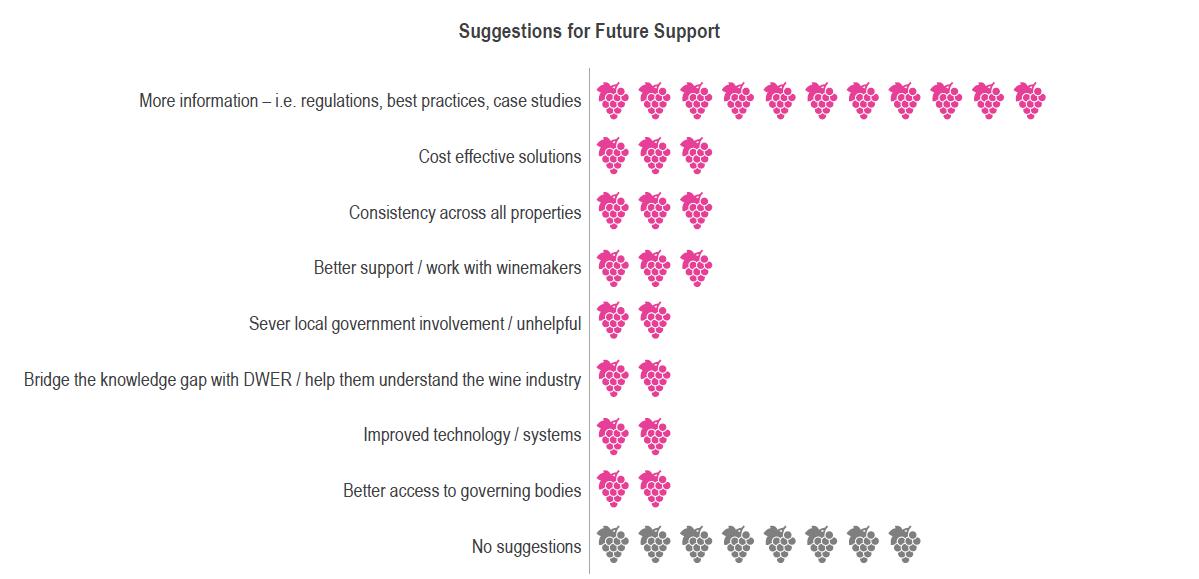

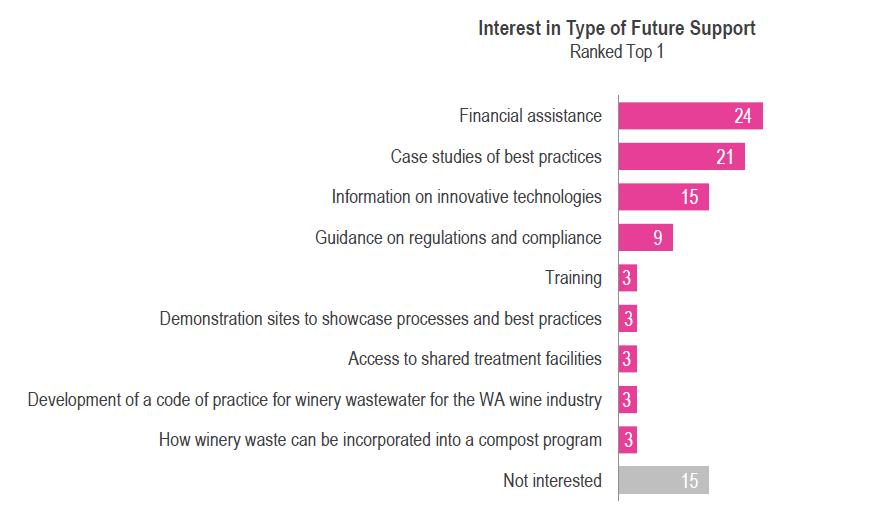

Future support

Key takeaways

- Wastewater infrastructure is aging and a potential risk

- Cost is the primary barrier to improvement

- There is a knowledge gap around best practices and regulations

- Strong appetite for innovation, benchmarking, and peer learning

Regulatory Flowchart

Approvals, licences and permits from Dept Water and Environmental Regulation, Dept of Health, and Water Corporation

Dept. Planning, Lands and Heritage

Local Government

to

to

Legislation & Regulations

Environmental Protection Act 1986

Health (Treatment of Sewage and Disposal of Effluent and Liquid Waste) Regulations 1974

Trade waste permit application lodged with Water Corporation (or other licenced service provider) Alcoholic beverage production capacity > 350 kL/yr: works approval and licence obtained from DWER

Environmental Regulation Health Regulation

<540 L/day wastewater

– lodge with local government

>540 L/day wastewater

– lodge with DoH

Must be transported by a controlled waste carrier to liquid waste facility licenced to receive food production effluent: regulated by DWER

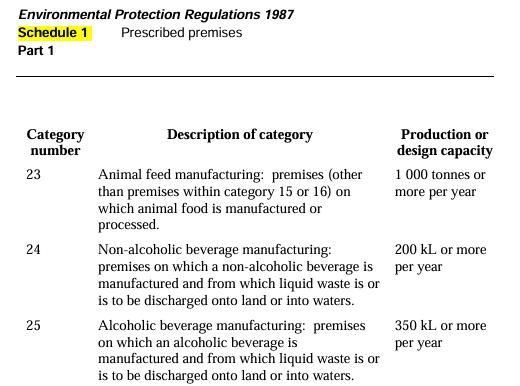

Category 25- Alcoholic beverage manufacturing: premises on which an alcoholic beverage is manufactured and from which liquid waste is, or is to be, discharged onto land or into waters – 350 kL or more per year

The production or design capacity for Category 25 generally takes into consideration the capacity of the fermentation vessels used in the manufacturing process and the duration of each fermentation cycle. It is the maximum capacity that the fermentation vessels can produce over a 12-month period.

The terms ‘production capacity’ and ‘design capacity’ are not defined in the EP Act or EP Regulations. The Guideline: Industry Regulation Guide to Licensing provides general guidance. DWER considers:

• production capacity is the rate at which a product is produced; and

• design capacity is the maximum capacity for which the facility or equipment is designed to receive, handle, process, contain or emit.

• In cases where an operator can demonstrate their operation is genuinely restricted, for example by planning approval conditions, DWER may consider the production or design capacity to be lower than its design capacity. However, factors that are temporary or readily altered such as business decisions, voluntary commitments, market demand or labour shortages are not considered genuine restrictions for the purposes of determining a wineries production or design capacity exceeds the 350kL or more per year threshold.

Regulatory trigger points

Any premises where an activity listed in Schedule 1 of the Environmental Protection Regulations 1987 (EP Regulations) is carried out at, or above, the specified production or design capacity are prescribed premises and regulated by DWER under Part V of the Environmental Protection Act 1986 (EP Act).

Prescribed premises require a works approval for construction and a licence to operate.

Licence holders require a licence amendment or works approval if they make certain changes or install or construct new equipment and infrastructure.

Environmental Protection Act 1986

53. Prescribed premises, restrictions as to changes to etc.

(1) the occupier of any prescribed premises who, if to do so may cause an emission, or alter the nature or volume of the waste, noise, odour or electromagnetic radiation emitted, from the prescribed premises —

(a) alters the method of operation of any trade, or of any process used in any trade, carried on at the prescribed premises; or

(b) constructs, installs or alters any equipment on the prescribed premises for —

(i) the storage, handling, transport or treatment of waste prior to, and for the purpose of, the discharge of waste; or

(ii) the control of noise, odour or electromagnetic radiation prior to, and for the purpose of, the emission or transmission of noise, odour or electromagnetic radiation,

• into the environment; or

(c)alters the type of materials or products used or produced in any trade carried on at the prescribed premises; or

(d) alters the industrial plant in any trade carried on at the prescribed premises; or

(e) installs, alters or replaces any industrial plant on the prescribed premises or carries out any work on the prescribed premises which is the beginning of, or any subsequent step in, that installation, alteration, replacement or carrying out, or

(d) constructs, relocates or alters any discharge or emission pipe, channel … through which waste is or may be discharged into the environment from the prescribed premises or carries out any work which is the beginning of, or any subsequent step in, any such construction, relocation or alteration, commits an offence unless he does so —

(f) in accordance with a works approval or licence

72. Duty to notify CEO of discharges of waste

(1) if a discharge of waste — (a) occurs as a result of an emergency, accident or malfunction; or (b) occurs otherwise than in accordance with a works approval or licence…; and has caused or is likely to cause pollution, material environmental harm or serious environmental harm, the occupier of the premises on or from which that discharge took place who does not, as soon as practicable after that discharge, give the CEO oral or electronic notification followed by written notification of the prescribed details of that discharge commits an offence.

Approvals for water supply or discharge of wastewater into the environment may also be required under the following legislation:

• Rights in Water and Irrigation Act 1914

• Health (Treatment of Sewage and Disposal of Effluent and Liquid Waste) Regulations 1974

QUESTIONS

Morning Tea – back at 10.30 am ☺

Understanding your licence

Wastewater monitoring and complying with your licence

What category is listed on your licence?

What is your assessed production capacity (kL)?

What is the duration of your licence?

Date of last amendment?

Amendment – changes to production, waste management, impact

Renewal – licence expires – you can no longer operate

Condition 1 Table 1- Infrastructure and equipment requirements

• Winery production and storage – indoor/outdoor areas, tank volumes

• Wastewater storage and treatment –tanks/dams/drains/sumps/pipework

• Wastewater disposal – area (size & location), distribution

• Solids management – marc, sludge, containment and leachate

Condition 1 Table 1- Infrastructure and equipment requirements

• Accurate description of infrastructure and equipment?

• Operational requirements current/correct? Are you complying?

• Integrity of hardstand, pipelines, sumps – prevent seepage and leaks – how you can demonstrate this?

• Direct all wastewater to the WWTP – if you make changes, even if it improves the environmental outcome, it may require a licence amendment

• WWTP infrastructure – can only receive winery wastewater/contaminated stormwater. No grey water or sewage. Minimise clean stormwater to WWTP.

Condition 2 Table 2 - Works

• Works – conditions are added to an existing licence via an amendment.

• No licence? Works Approval document is issued with conditions requiring you to build what you have described in your submission

• Changes to ‘works’ – can not be made without approval/update to licence or works approval – even if it is an improvement in environmental outcome.

• Delays – advise DWER as soon as possible with a plan for completion

• Completion of works –within 30 days of completion – submit compliance audit against works

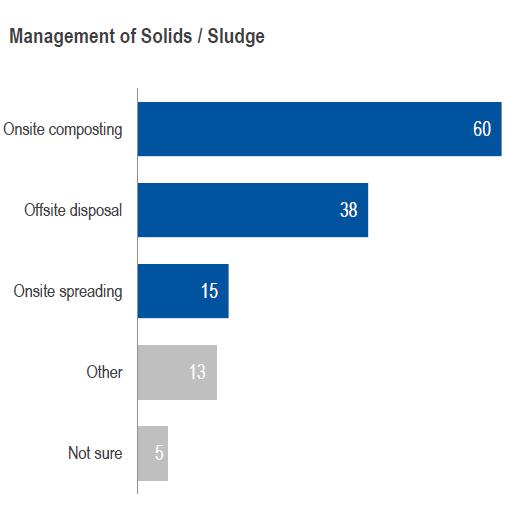

Solid waste - Marc & WWTP sludge

• ’Contained’ to prevent nutrients/juice/solids leaching to environment

• Leachate collected and treated – rainwater adds to volume

• Composting onsite or offsite for reuse

Emissions and discharges

• Emission point/area – discharge even over the area specified (eg; 5ha)

• Discharge limits

• Nitrogen, phosphorus BOD loads kg/ha/month or year or day

• pH

• Sodium absorption ratio (SAR) : electrical conductivity (EC)

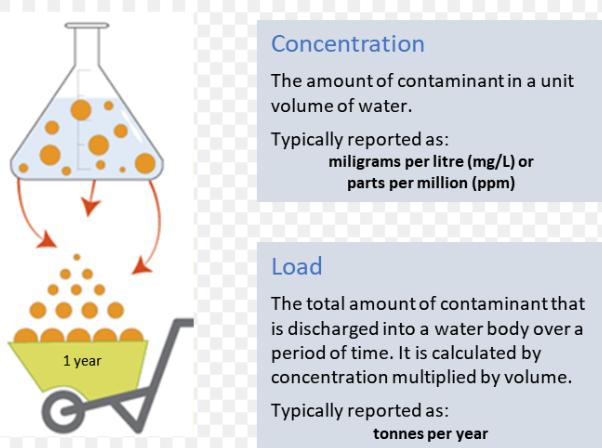

• Calculating load - Concentration x Volume = Load (kg)

• BOD 200 mg/L x 150 kL = (20/1000/1000) x (150 x 1000) (30 kg)

• BOD = 30 kg discharged over 5 ha so divide by 5 = 6 kg/ha/month

Monitoring

• Parameters – flow (meter readings), pH, EC, TN, TP, BOD, TSS, SAR (Na, Mg, Ca)

• Lab with current NATA accreditation for parameters

• “Non-NATA accredited analysis permitted” if lab is not certified for some parameter (DWER may allow)

• “In field non-NATA accredited analysis permitted for pH and electrical conductivity” – holding time is short - 6 hours

• Australian (AS) standards – AS/NZS 5667.1 sampling; 10 wastewater

• Document sampling objective in a procedure

• Sample method - representative sampling, process conditions

• Quality samples (replicates, duplicates, blanks) ‘Chain of Custody’

• Holding times and preservation

• Data review – re-sampling

Records and Annual Environmental Report (AER)

• Records - complaints, maintenance, calibration, monitoring, lab reports, incident details. Retain records for duration of licence.

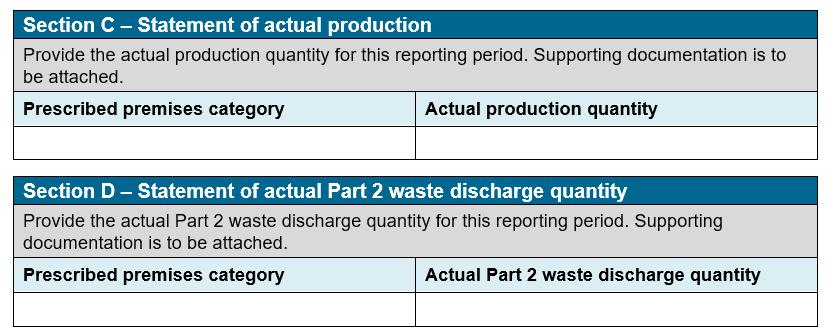

• AER – check requirements carefully to ensure compliance

• Format – tables AND graphs – check units

• Calculations need to be clearly shown (eg; hectares for loading)

• Comparison to historical results (previous 5 years)

• Interpretation – need to explain trends and anomalies

• Copies of lab reports

• Submit on time – or you will need to report a non-compliance!

Annual Audit Compliance Report (AACR)

• Audit – each condition. Document within AER or internal review

• Records – retain records and describe evidence to support compliance

• Report non-compliance when you become aware

• Non-compliance – Impact? Mitigation and prevent recurrence

• Signature page - legal authority to sign

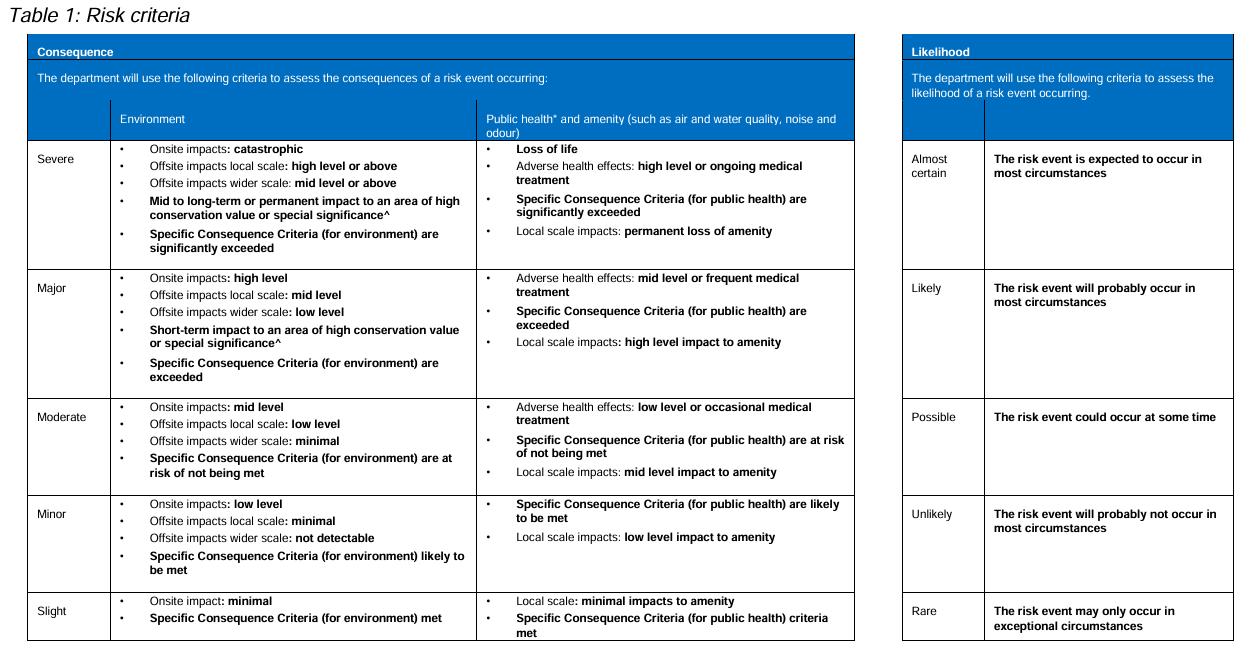

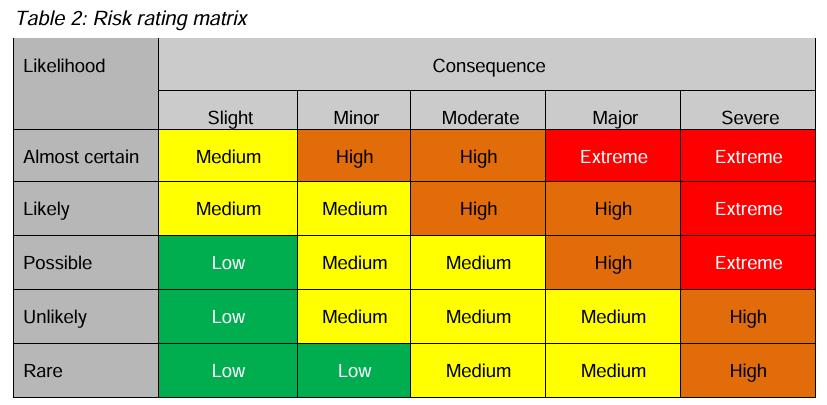

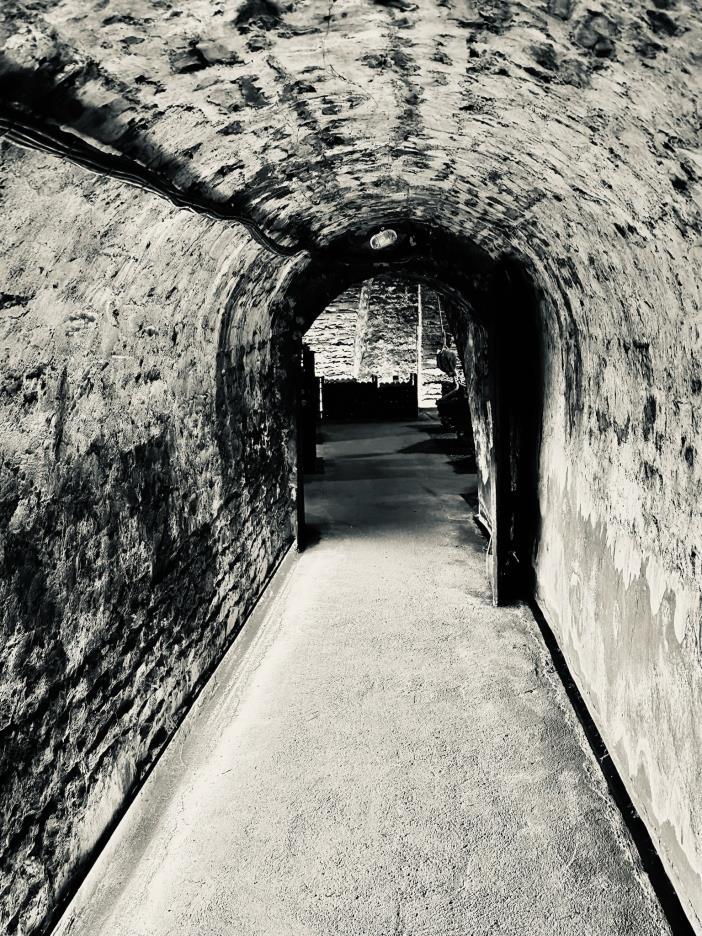

Decision Report – Environmental Risk Assessment

DWER risk-based approach – conditions are applied in proportion to the level of risk that the activity poses to public health and the environment.

Risk Rating – Consequence and Likelihood

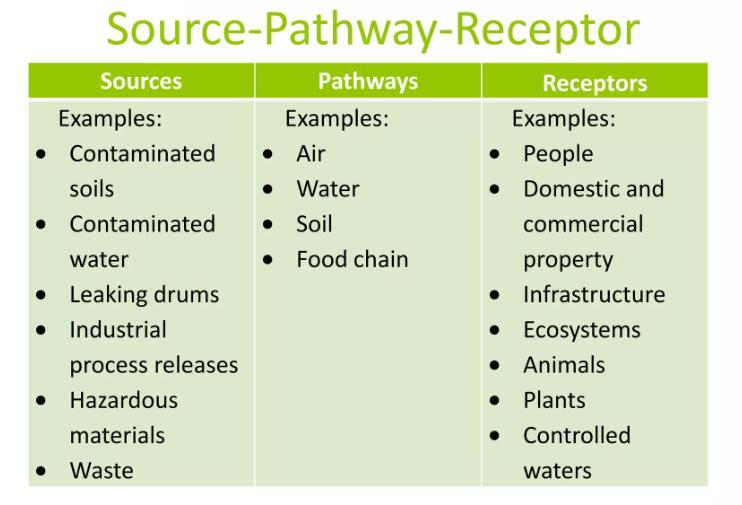

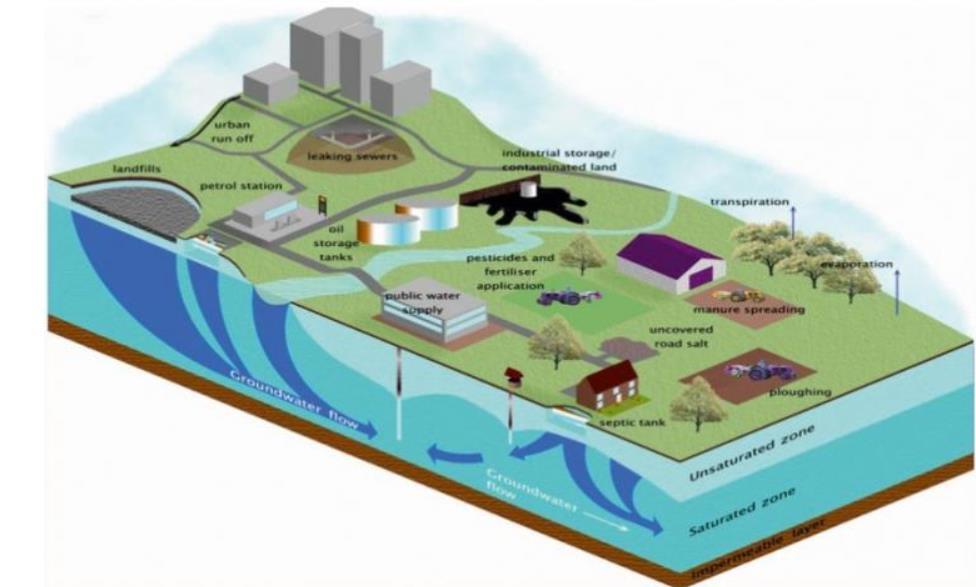

‘ Risk event’ or scenario: Nutrient rich wastewater discharge to ground

Nutrients leach through soil to groundwater which intercepts an on-site dam. In winter wastewater flows down a drain to a stream on neighbouring property.

SOURCE – winery wastewater discharge

PATHWAY – surface runoff to streams or infiltration through soil to groundwater

RECEPTOR – onsite livestock/personnel . Offsite stream ecosystem, neighbour water use

Consequence – algal bloom in onsite dam. Offsite stream becomes deoxygenated.

Likelihood – is this Likely? Possible? with and without controls

DWER will consider your controls to prevent this including hierarchy - prevent, control, abate and mitigate pollution and environmental harm.

Risk Rating – Consequence and Likelihood

Risk Rating – Consequence and Likelihood

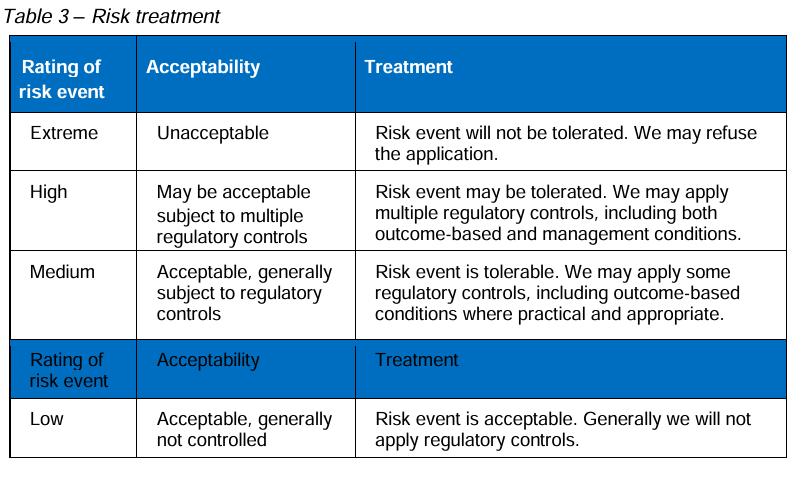

Understanding your licence

Hopefully, you can see some light (through the wine) at the end of the tunnel!

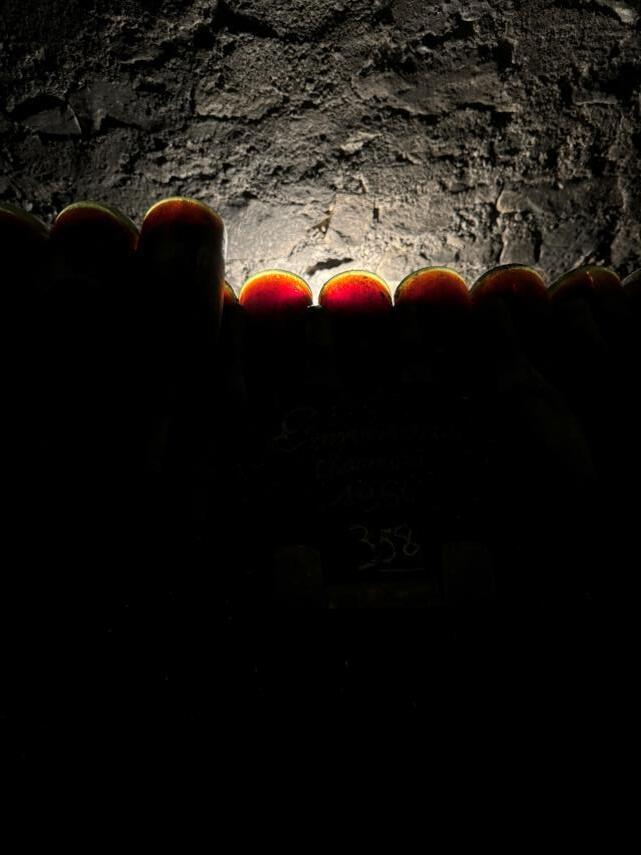

Wastewater disposal and Treatment: From NIMPs to

Biological Systems

Dept. of Primary Industries and Regional Development

Next Steps

Complete this sentence: 'Best practice wastewater management in our industry means...'

The Slido app must be installed on every computer you’re presenting from

Assistance, Tools and Resources

DPIRD

• Development of Guidelines

• Nutrient Irrigation Management Plans

• Research opportunities

• Case studies

• Innovation

DWER

• Calculators

• Loading Rates

• N P K Loading

• Organic Loading

• Land Application Area water balance

• Water Quality Protection Note

22 Irrigation with Nutrient Rich Wastewater (under review)

Assistance, Tools and Resources

Wines of WA

• Advocacy

• Roundtable discussion

• Sustainable Winegrowing Australia & AWISSP alignment

• Would templates be helpful?

• Research opportunities & collaboration

• Develop a database for water quality across catchments?

• Case studies

• Winery Wastewater Management & Recycling – Operational Guidelines (2011 GWRDC, South Australia)

• Engagement and consultation

• Working Group Industry Code of Practice

What is your immediate support priority in relation to wastewater management? Choose the top 2.

The Slido app must be installed on every computer you’re presenting from

What future workshop topics would add most value?

The Slido app must be installed on every computer you’re presenting from

Key Take Aways

Licence Fundamentals

• Assessed production capacity is legally binding

• Licence renewal – engage early, don’t wait for notification

• Accurate & current equipment descriptions

• Hardstand integrity and leak prevention non-negotiable

Triggers for review

• Prescribed premises (>350 kL/year)

• Any changes to management systems requires works approval

• Any change to alcoholic beverage production

• For everyone

• Any change that requires Planning or Dept of Health approvals

Key Take Aways

Nutrient & Irrigation Management Plans - NIMPs

• Start simple

• Nutrient neutrality

• Grow crops, harvest biomass, remove nutrients off-site

• Decision tree

• Site constraints → Waste constraints → Nutrient excess → Targeted management

Key Thresholds

• Site

• >2m groundwater separation

• >200m from wetlands

• <10% slope

• > 0.8m soil depth

• Waste

• pH 6.5-8.5, Salinity <2500 mg/L, SAR:EC <5, FOG <1500 mg/L

• Sizing

• Mass balance approach – P typically limiting factor

Acknowledge & thanks to

Richard Fennessy – DPIRD

Caron Goodbourn – DWER

Alison White – Environmental Consultant

Gerard Leddin – DPIRD

Nick Tsvetkov – DPIRD

Thank you

Please join us for lunch.