Carbon Smart Winemaking

Low-cost Solutions for Sustainable Production

We acknowledge the Whadjuk people of the Bibbulmun nation, traditional custodians of this Country we meet on today. We recognise their continuing connection to lands, waters and communities and pay our respects to all Noongar Boodja people, their cultures and Elders past and present

• Carbon Footprint in Wine Production

• Energy Audits and Efficiency

Morning tea @ 10:00am

• Digital Solutions for Sustainability

• Packaging – Lightweight Glass

• Throughout → Tools & Resources

Lunch @ 1:00pm

Source: Wine Australia An Emissions Reduction Roadmap

Source: https://www.awri.com.au/wp-content/uploads/2023/03/s2341.pdf

• Vineyard

• Mechanisation

Nutrient and soil management

Pest & disease management

Pruning, canopy management, harvest

• Transportation

• Fuel

• Renewable Energy

Solar-power

Energy recovery - biomass

• Winery

• Equipment

Air Compressors | Refrigeration Chillers

• Thermal management

Insulation – tanks & buildings

Heating ventilation air-con systems

• Operational Practices

Production scheduling

Maintenance programs

• Process-specific

• Refrigeration & Tank storage 5070% energy consumed

• Distribution across two areas

• Processing, fermentation, & stabilisation ~45-90%

• Bottling & storage ~18%

• Technology

• High efficiency equipment

• Variable speed drives ↓ 20%

• Temperature optimisation

• Set points

• Smart thermostat integration

• Renewable energy integration

100% efficient system kW = kVA

• Scale & Design

• Economies of scale

Energy consumption range 0.75 – 2.0

kWh/L of wine produced

• Building design

Thermal performance of buildings

Natural ventilation

Integrated renewable energy systems

• Monitoring

• Identifies areas for improvement

• Allows performance benchmarking

• Real-time monitoring allows optimisation and maintenance scheduling

• Business Benefits

• Cost savings

• Reduced costs associated with water, materials and waste consumption

• Reduced maintenance and downtime costs

• Improved productivity

• Enhance brand

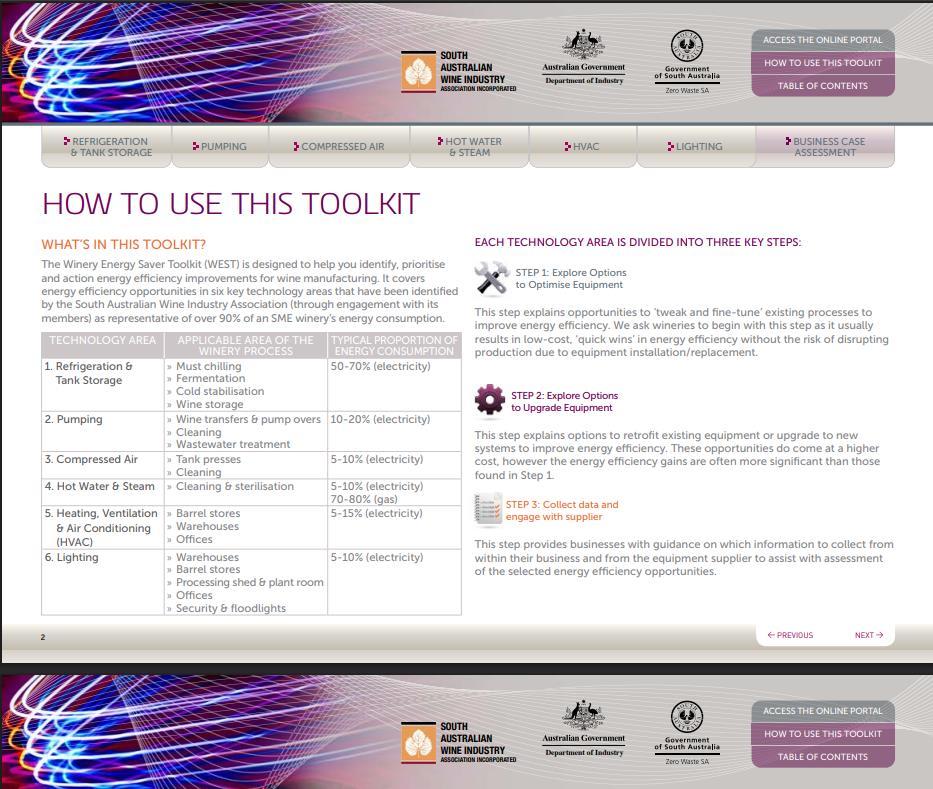

• Assesses

• How a facility uses energy

• Opportunities to improve efficiency

• Behavioural practices

• Operational practices

• Technical

• Energy costs

• Examines

• Equipment

• Vineyard

• Winery

• Operations scheduling

• Temperature controls

• Refrigeration & compressor units

• Lighting systems

• Heating, Ventilation, Air

Conditioning (HVAC) systems

Have you conducted an energy audit in the past 2 years?

The Slido app must be installed on every computer you’re presenting from

• Level 1 – Walk through

• Scope: Basic visual inspection and review of utility bills

• Duration: 2-3 hours to collect basic information

• Cost:

• Small (<5000m2) $2000 – $5000

• Medium: $5000 – $10000

• Savings Potential: 10-15%

• Best For: Small wineries, initial assessments, limited budgets

• Includes: Identifies obvious energy waste, no capital investment

• Level 2 - Energy Saving & Analysis

• Scope: Detailed analysis of all major energy systems

• Duration: Multiple site visits for extended periods

• Cost:

• Small-medium wineries: $10,000-$25,000

• Large wineries: $25,000-$50,000

• Savings Potential: 15-25%

• Best For: Medium-sized wineries, when business case development is needed

• Includes:

• Financial return analysis, examining payback periods and ROI calculations

• Detailed descriptions of how each opportunity will affect your facility

• Capex budgets, potential utility incentive (rebate) opportunities, operational implications, and estimated energy savings

• Life cycle analysis

• Level 3 – Investment Grade

• Scope: Comprehensive computer modeling and financial analysis

• Duration: Extensive multi-week process

• Cost:

• Complex facilities: $50,000 +

• Savings Potential: 20-30%

• Best For: Large wineries, complex facilities, major capital investments

• Includes:

• Fully calibrated energy model (computer simulation) of the facility that predicts energy use and cost down to time increments of an hour or lower

• Risk assessment and detailed uncertainty analysis

• Precise vendor quotes and lifecycle cost analysis

Feasibility study increases production capacity Project

• Identified power supply issue

• Funded by

• DPIRD Agrifood and Beverage Voucher Program (feasibility study)

• SWDC Regional Economic Development (RED) Grant (Power upgrade) 50:50 contribution

• Timeline: Feasibility study → Power upgrade → Equipment installation → Vintage 2025 commissioning

Feasibility study increases production capacity Infrastructure improvements

• Power supply upgrade to meet future winery capacity requirements

• Inverter system installation for energy efficiency

• Upgraded refrigeration system for quality control

• New crushing and pressing equipment commissioned for Vintage 2025

• Production efficiency: More efficient grape processing with best practice standards

• Domestic growth: Increased wine production and domestic sales

• Export expansion: New markets in Singapore and Malaysia

• Service diversification: Contract crushing services for equipmentless wineries

• Employment: Additional staffing opportunities created

• Production efficiency: More efficient grape processing with best practice standards

• Domestic growth: Increased wine production and domestic sales

• Export expansion: New markets in Singapore and Malaysia

• Service diversification: Contract crushing services for equipmentless wineries

• Employment: Additional staffing opportunities created

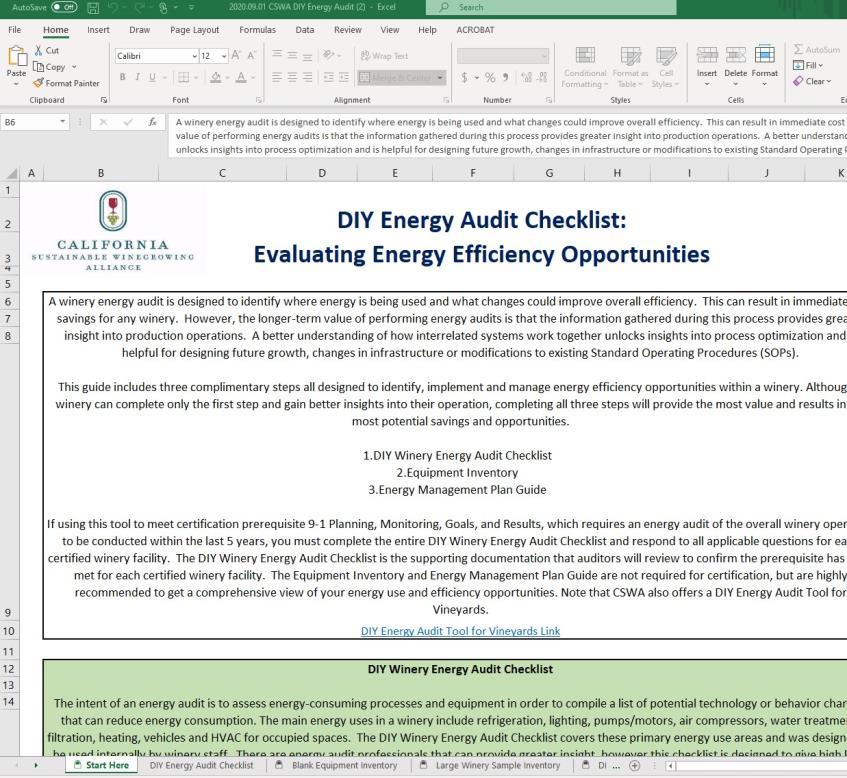

• Before

• Energy bills & usage data

Minimum 12 months

• Equipment list & specifications

• Document operational schedules & production patterns

• Identify upgrades implemented

• Establish goals and budget constraints

Would this be a useful tool for your business?

The Slido app must be installed on every computer you’re presenting from

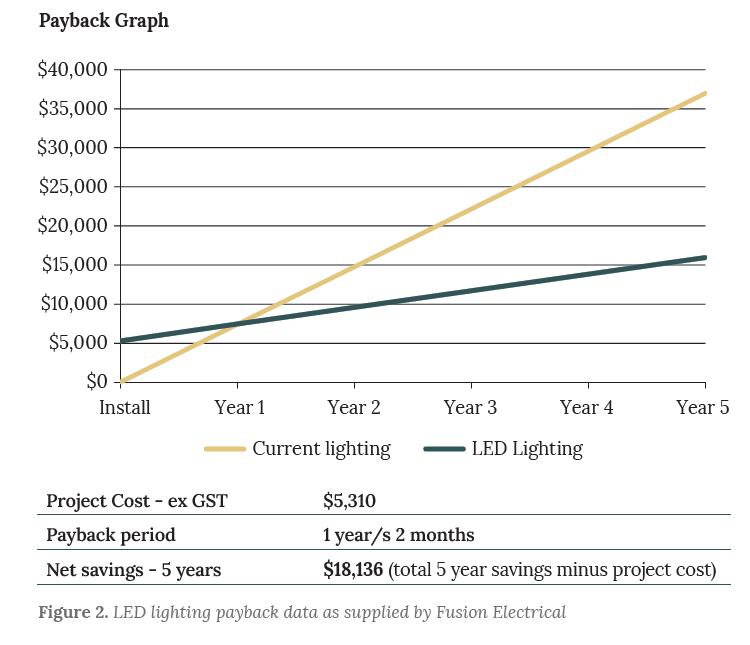

Low Cost, Short Payback

• LED lighting upgrades

• Programmable thermostats

• Pipe and tank insulation

• Basic maintenance of existing equipment

• Operational changes (scheduling, setpoint optimisation)

Higher Cost, Longer Payback

• High-efficiency chillers and refrigeration systems

• Air compressors and solar electricity generation

• Building envelope improvements

• Renewable energy systems (solar PV, heat pumps)

• Cogeneration: solar electricity

• Net energy savings over 5 years was $18136

• Upgraded lighting from halogen to LED lighting.

• Made use of flotation technology for juice clarification.

• Energy savings of 66%

• Payback period 1 yr 2 months

Source: Margaret River Wine Association Case Study – Energy savings in Xanadu’s Winery

• Chiller replacement

Replace with more efficient ones

• Variable Speed Drives Compressors and pumps

• Building Management Systems

Centralised controls for cooling, heating and ventilation

• Energy Monitoring Identify energy consumption

• Swan Valley – Perth Hills Wine Industry

Co-design opportunity

Small scale – 80 m2

10 kW System integrated with existing trellis

• Compatible with current operations

No bird netting

• Measuring

Climate impacts

Vine Performance

Energy generation

Economic modelling

• Energy Monitoring

Identify energy consumption

Glass Bottle Weight Reduction Savings Analysis

Question – what would be the savings switching from a 750 g EU-imported glass bottle to an Australian produced bottle weighing:

500 g

420 g 330 g

Glass Bottle Weight Reduction Savings Analysis – 100,000 bottles

750 g EU-imported

500g

• Weight 33.3%

• Cost saving (Glass + Freight) 42%

• Annual Potential Savings $87,500

• CO2 reduction 569 tonnes = 123 cars off road

420 g

• Weight 44%

• Cost saving (Glass + Freight) 50%

• Annual Potential Savings $117,500

• CO2 reduction 751 tonnes = 163 cars off road

330 g

• Weight 56%

• Cost saving (Glass + Freight) 57.1%

• Annual Potential Savings $150,000

• CO2 reduction 956 tonnes = 207 cars off road

Western Australian Wine Producer – ~125 Tonnes

Glass Bottle Weight Reduction Savings Analysis – 100,000 bottles

• Benefits

• Cash flow improvement

• Reduced freight costs

• Supply chain security

• Strategic Advantages

• Sustainability credentials

• Market positioning

• Risk reduction

• Local partnerships

Fastest way to reduce CO2 emissions

Sustainable Wine

Roundtable launched Bottle

Weight Accord 2023

Sustainable Winegrowing

Australia does not capture packaging emissions reduction

Launched in 2024

• Option 1 – Full Signatory

• We are committed to reducing greenhouse gas emissions.

• We have successfully reduced our average 750ml bottle weight to below 420 grams.

• Option 2 – Statement of Intent

• We will reduce the average weight of our 750ml still wine bottle to less than 420 grams by the end of financial year 2025-2026.

Creation of web page and a list of SKUs in Lightweight Glass (over 100+ wines) and growing daily

Creation of the Average Bottle

Weight Calculator

Inclusion in the 2024 Sustainability

Report

UK Press Drop and Media Release to 12 media celebrating Margaret River wines in Lightweight Glass

Average Bottle Weight Calculator

What other measurements would be helpful on the lightweight glass packaging calculator?

The Slido app must be installed on every computer you’re presenting from

PRESENTATION FRIDAY 23 MAY @

2025 MRWA Coastal Community

Revegetation Day

“Over 7,500 kg on annual reduction in glass weight projected”

“Estimated 28% reduction in glass costs in 2025”

From today's workshop which solution/tool interests you most?

The Slido app must be installed on every computer you’re presenting from

The Slido app must be installed on every computer you’re presenting from

One word to describe today's workshop.

The Slido app must be installed on every computer you’re presenting from

Please join us for lunch.