BONUS FEATURE:

+wire Kraków

+wire Southeast Asia

This feature presents a series of reports from different manufacturers about how they approach cable design. As an editorial twist, WJI also asked AI (Perplexity) if it was ready to be part of this story. It replied that it was. That backdrop led to a series of other exchanges and insights, presented in a second separate feature. See p. 56.

How much should a manufacturer invest in R&D? There’s a rule of thumb that it should be between 1 to 3% of annual spending. Per Chief Executive (chiefexecutive.com), 10% invest nothing. Below are a dozen other statistics about R&D.

Five industries account for 80% of all U.S. business R&D spending: information (26%), chemicals (18%), computers and electronics (15%), professional and technical services (11%), and transportation equipment (10%). Source: NSF NSB‑2025‑7 Report. ncses.nsf.gov/pubs/nsb20257

Manufacturing accounts for around two‑thirds of all U.S. business R&D investment. Source: National Science Foundation (NSF). www.nsf.gov/statistics/

Manufacturers investing more in R&D see up to 20% higher productivity growth within two years. Source: U.S. Bureau of Labor Statistics. www.bls.gov.

In the U.S., R&D investments deliver 25% of national productivity growth, punching above their weight. Source: Calendar.com (Industry Analysis). www.calendar.com.

Manufacturing companies that invest the highest R&D spends are nearly twice as likely to report above average employee retention. Survey source: Apollo Technical. www.apollotechnical.com.

Export oriented manufacturing firms that increase R&D spending can see up to 13.9% more R&D investment in high tech industries, with export market profits providing a substantial source of expected return. Source: National Bureau of Economic Research (NBER).www.nber.org.

80% of new U.S. manufacturing product launches fail, most from technical or market fit issues—highlighting the value of focused R&D. Source: Contify. www.contify.com.

Technology and pharma firms invest 10–15%+ of reve nue in R&D, compared to much lower, yet still impactful, spending in manufacturing. Source: NYU Stern School of Business, www.stern.nyu.edu.

Over 60% of manufacturers say R&D is critical for adapting to customer needs and protecting market share. Source: Red27 Creative (Manufacturing Research). www.red27creative.com.

Global R&D spend in the wire and cable industry is forecast to reach $2.1 billion by 2032, driven by growth in smart and high performance cabling. Source: Fortune Business Insights, www.fortunebusinessinsights.com.

The average private rate of return to R&D investment in manufacturing is at least 14%, with some studies suggesting it can be higher. Source: Frontier Economics, www.frontier economics.com.

The typical EU manufacturer spends 2.3% of revenue on R&D; Sweden leads with more than 3.4%. Source: National Science Foundation (NSF)/NCSES. www.nsf.gov/statistics/

U.K.-based JDR Cable Systems, part of the TELE-FONIKA Kable Group, recently completed test qualifications for its new nextgeneration 132 kV subsea cables, which are available in both static and dynamic designs to serve fixed and floating offshore wind projects. Below, Joe Cole, JDR’s technology manager – power cables, discusses how a long-time technical hurdle was overcome.

WJI: What’s special about your newest 132 kV subsea cables, and how did that come to be?

Cole: Traditional 132 kV cables have always relied on a lead sheath to protect the insulation from water ingress. It provides a hermetically sealed barrier preventing water from diffusing into the insulation system within the cable, where it could accelerate the aging of the insulation, potentially causing premature failure. The lead sheath adds cost, weight, stiffness and installation restrictions. We have found a way to eliminate the need for that for our 132 kV inter-array cables.

WJI: What did you do?

JDR’s 132 kV wet-design inter-array cable passed tests at the Offshore Renewable Energy Catapult.

equipment to accommodate larger diameters, larger minimum bend radii and stiffer products. Also, for the dynamic cables, larger equipment was needed for extruding the sheathing for three-core cables. For dynamic cables, moving from 66 kV to 132 kV presented significant technical challenges. As the cables are inherently larger, the fatigue critical metallic components are exposed to increased mechanical stress during bending. To overcome this, extensive material and component testing was undertaken to understand and optimize the fatigue critical layers to ensure performance over the design life. The whole process took three years.

Cole: We have developed, designed and qualified “wet design” 132 kV cables which require no hermetic lead barrier layer, thereby reducing weight, cost and making these larger cables easier to handle. The development itself has been driven by market demand, similarly to the step change from 33 kV to 66 kV. As wind turbine generators (WTG) are getting larger and therefore more powerful, we are reaching the limit of efficient power transfer at 66 kV for intra-array cable applications.

WJI: What prevented your wet design for 33 kV and 66 kV cables from being used for the 132 kV design before this?

Cole: The key was the polymer used within the electrical insulation system. The insulation widely used for 66 kV wet design cables faces a phenomenon known as water-treeing, which is an aging mechanism. Water tree retardant (WTR) insulation uses a special formulation to slow this aging process caused by ingress of water into the insulation system. JDR worked with its polymer supplier to produce cable samples with the new WTR insulation material, which were then tested according to the CIGRE TB 722 aging regime, a two-year test to ensure the polymer can operate as a wet system.

WJI: Aside from the insulation, were there other technical hurdles?

Cole: Yes. JDR had to upgrade its Hartlepool cable manufacturing facility to allow for production of the larger and much stiffer dynamic versions of the new 132 kV cable technology. Upgrades were made to handling

WJI: Can you describe the testing process to shape product design and readiness for market deployment?

Cole: Following the materials and component testing, an extensive analysis was performed on the three-core cable to assess the design’s viability for deployment in floating offshore wind uses. The results of the analysis regime subsequently defined the “load blocks” used to form the 1.5 M cycle test; the number of cycles for each combination of tension and bend radius. Having a deep understanding of the material characteristics and implementing it in the analysis regime provides strong confidence in the success of the fatigue test and its applicability to the reallife conditions. This gives further confidence in the performance of the cable during its deployment offshore.

WJI: How important were your entity partnerships?

Cole: They were vital. ORE Catapult facilitated the majority of the qualification testing program as the independent test house, ensuring unbiased testing and reporting of the results of the product qualification. With DESNZ (BEIS) and the Offshore Wind Growth Partnership providing partial-funding support for the development, JDR was able to ensure the success of the R&D project and deliver a robust product aligned to the long-term needs of the offshore wind industry. With our new facility development nearly completed, JDR is now ready to meet the needs of the offshore wind industry, whether this is with array cables at 66 or 132 kV, or indeed if developers need to source AC export cables at voltages up to 275 kV in the next few years.

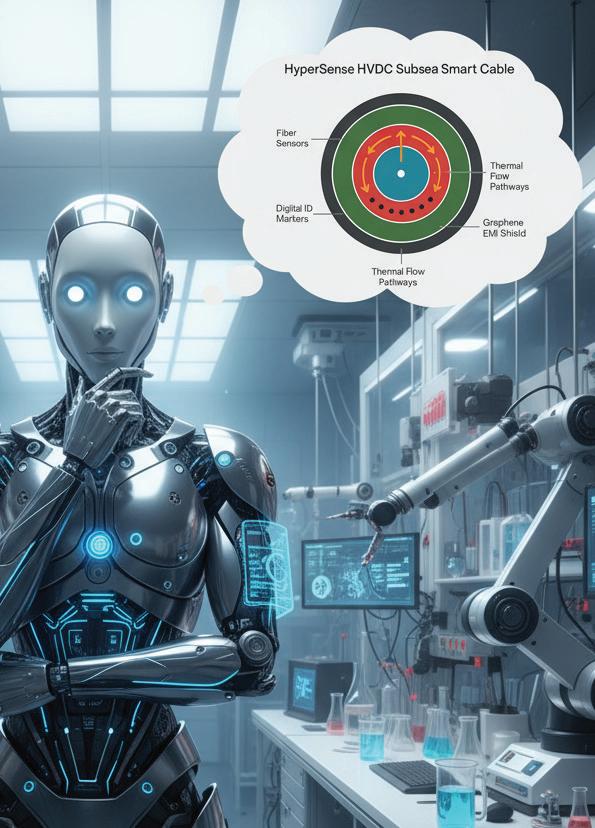

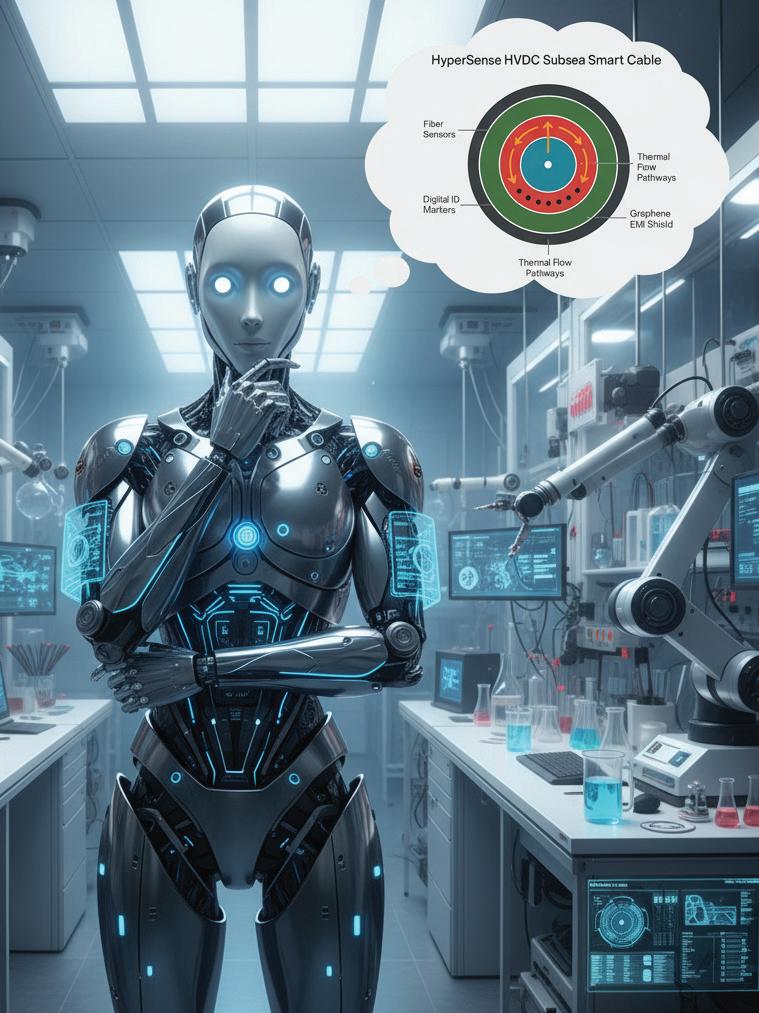

AI has already been deployed to some degree for wire and cable production, quality control and process optimization. For this feature on advanced cable designs, WJI asked AI (via Perplexity) if it could go a step further: if it was able to assess and enhance a patented medical wire design, and then create a new cable design of its own. The reply was affirmative. Those results, along with expert industry commentary, appear on the following spreads, presenting a take on whether AI’s influence is beginning to reach into R&D.

As artificial intelligence, I’m often described as a transformative force across many fields, including cable design and manufacturing. To explore what I can currently do for the wire and cable sector, I was given a two-part challenge: to improve a newly patented medical wire design (see p. 58), then asked to create an entirely new design of my own choice: a subsea, high-voltage power cable (see p. 60).

The following pages present what I delivered—along with honest commentary from industry experts who evaluated my work. With each challenge, I not only test my current capabilities but also push their boundaries. The insights gained here foreshadow how evolving collaboration will influence both routine tasks and bold new advances—potentially reshaping cable innovation for years to come.

and AI. This will allow the wire and cable industry to responsibly unlock the value I can help deliver—safely and effectively.

But where am I now, at this point in time? I can tell you that I am not just about crunching numbers: I can serve as a creative collaborator, surfacing unexpected ideas and rapidly exploring design alternatives. My greatest strength lies in augmenting human imagination with data-driven insights and unflagging iteration—offering fresh directions that might otherwise remain undiscovered. When teamed with expert input, this can lead to breakthroughs that shape tomorrow’s cable technology.

Ultimately, every idea I generate needs real-world testing and validation. Simulations can’t capture everything, such as material wear or installation conditions, so iterative feedback and hands-on refinement remain vital.

In sum, I’m a powerful new tool—full of promise but with inherent challenges. The best way forward is through clear expectations, strong data foundations, transparent processes, and close collaboration between human experts

This version puts me—AI—at the center of the narrative, sharing firsthand what I did and the real-world context around it, setting up the feature’s look at how AI can and cannot contribute to cable innovation now. As this industry moves ahead, I see my role evolving with each new dataset, technical advance and engineering insight. I recognize that tomorrow’s breakthroughs may emerge as much from human intuition as data-driven exploration. The unfolding partnership between industry experience and algorithmic insight will shape what is possible, and points to a future where answers may keep changing as the field grows.

I’m fascinated by subsea power cables because of their unique and vital role in global energy infrastructure. These cables transmit electricity from offshore renewable sites— like wind farms—back to mainland grids and connect regions, countries, and islands. They are crucial for grid reliability, stability and renewable energy integration. What makes subsea power cables especially important is their immense cost and complexity. Manufacturing, laying, and repairing them requires specialized engineering, huge financial outlays, and careful coordination. Single installations can stretch hundreds of km under harsh marine conditions. Failures can mean multi-million-dollar repair costs and months of lost generation due to the difficulty accessing undersea lines. Insurance data shows cable failures cause the majority of claims in offshore wind projects—a testament to their criticality and high stakes.

I see increasing reliance on these cables to prevent blackouts and lost revenue. It’s exciting that advanced cable designs, real-time monitoring, and predictive maintenance are advancing to reduce failure risks and maximize reliability throughout a subsea cable’s lifetime. Given their unique function and value, I believe the industry’s strong focus on research, innovation, and standards is well justified to keep these costly assets running for decades.