+ 5 Industry Event Previews

+ 5 Industry Event Previews

The feature in this issue focuses on the role of AI, which some in the industry see as great news, while others view it far less enthusiastically and with a degree of distrust. There will always be new software or platforms to get used to, but those are just hand tools. AI is different.

AI is a master tool of sorts that some see as undermining the value of what a person does, from machine operators to plant managers, and well beyond. As the feature notes, AI’s reach can extend to just about any business department in wire and cable— such as accounting—and even to editors of trade publications.

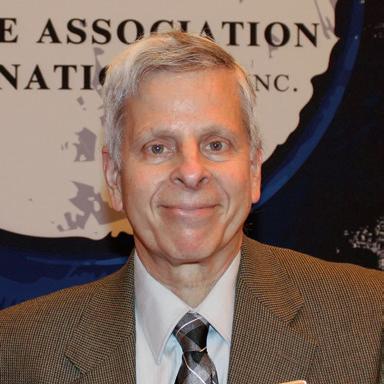

I was not a big fan of AI when it first started making serious headway. I’ve been editor here at WJI since 1994, and over the years I learned how to hone what I do. There is a sense of pride that comes with learning any craft. Long before I joined WAI, I worked in machine shops—mostly doing ID/OD surface grinding and other hands-on tasks, much of which I was introduced to during summers at my uncle’s tool & die shop. At New Britain Machine, I worked under Tom—a true master craftsman who could coax performance from equipment far beyond its OEM specs. He reveled in the art of skilled work. Not many reach that level, and I suspect he would have bristled at the arrival of AI.

At first, it was easy for me to be dismissive of AI: it was no Tom. It was far from competent at finding usable news and some of what it did was just wrong. But over time, I could see that it was getting better. I cautiously began using it more and more. It wasn’t doing my work for me, but it made it easier to complete. I also got better at working with AI. It allowed me to find stories I might never have found and, more importantly, gave me the time I needed to get to other stories. It made me a better me.

I no longer see AI as a threat or as devaluing what I do. I can understand contrary views, yet I can no more stop AI’s advance than anyone on the shop floor. It is far better to have AI as a partner than as a rival. I will continue to do what I do, and AI is helpful, especially when tackling editorial content that requires extensive research.

AI may well lead to fewer shop floor positions, although I still hear manufacturers lament they can’t find new dependable hires. Ironically, having the ability to work with AI may be the best way to secure one’s future in the industry.

Mark Marselli Editor-in-Chief, editor@wirenet.org

PUBLISHER Steven J. Fetteroll

EDITOR-IN-CHIEF Mark Marselli

DIRECTOR OF SALES Shannon Timme

DIRECTOR OF INTERNATIONAL SALES & BUSINESS DEVELOPMENT

Anna Bzowski

DIRECTOR OF MARKETING & CORPORATE COMMUNICATIONS

Janice E. Swindells

WAI PUBLICATIONS COMMITTEE

Dane Armendariz, consultant Ferruccio Bellina, TKT Group/President ACIMAF

Michael Crowle, QED Wire Lines Inc.

Tom Moran, consultant

Giulio Properzi, Continuus Properzi

Willem Sundblad, Oden Technologies Inc.

John N. Tomaz, Stolberger

Robert Wild, Niehoff Endex North America

W.T. Bigbee, Encore Wire Corp.

TECHNICAL ADVISORS

John Drummond, Scotia Group

R. M. Shemenski, RMS Consulting, Inc.

Images: Adobe Stock.

Wire Journal International (ISSN-0277-4275) published monthly by The Wire Journal, Inc., is a wholly owned subsidiary of The Wire Association International, Inc., which is located at 71 Bradley Road, Suite 9, Madison, CT 06443-2662, USA, and can be contacted at tel. 203-453-2777; fax 203-453-8384; Internet wirenet.org; e-mail editor@wirenet.org. Address all correspondence concerning advertising production, editorial and circulation to the above address. WJI is printed in the USA.

Subscription rates: $110 per year, USA; $120 per year, Canada and Mexico; other countries, $140 per year (includes air mail). Back copies: $10 WAI members, $15 non-members. Periodicals postage paid at Madison, CT 06443, USA, and at additional offices.

Wire Journal International grants photocopy permission to libraries and others registered with Copyright Clearance Center (CCC), 21 Congress St., Salem, MA 01970, USA, for a fee of $0.50 per article. Payments should be sent directly to the CCC. Requests for bulk orders or reprints should be sent to the Wire Journal International, 71 Bradley Road, Suite 9, Madison, CT 06443-2662, USA.

© 2025 by Wire Journal, Inc. All rights reserved. The Publisher of WJI assumes no responsibility for the validity of manufacturers’ claims made herein. Back issues of WJI are on microfilm and available from University Microfilm, 300 North Zeeb Road, Ann Arbor, MI 48106, USA. Phone: 313-761-4700.

POSTMASTER: Send address changes to Wire Journal International, 71 Bradley Rd., Suite 9, Madison, CT 06443, USA.

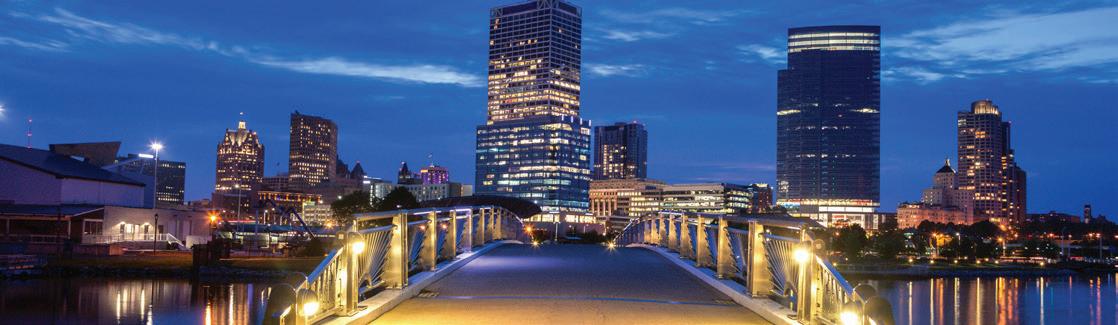

The Wire Association International will co-locate Wire Expo next year with the Electrical Wire Processing Technology Expo (EWPTE) on May 6-7, 2026, at the Baird Center in Milwaukee, Wisconsin, USA.

Bringing the Expos together under one roof creates meaningful opportunities for industry professionals to explore the entire value chain. The co-location enables manufacturers, suppliers, distributors and end-users to see and experience novel technologies, forge strategic partnerships and advance the industry.

The two events previously colocated in 2010 at the venue now known as the Baird Center. The reunion comes at a time of industry growth and technological advancement, positioning the combined event as a catalyst for discovery and collaboration.

WAI First Vice President David Fisher said that he looks forward to the co-location. “It’s a great chance for both groups to co-mingle and truly get a feel for each side of the wire and cable industry—from manufacturing to downstream end use, and all the products and equipment that go into it. The people who make this happen are key to the success of both groups.”

“The co-location of the Wire Expo and the EWPTE will create a unique opportunity for attendees to collaborate, establish valuable new contacts, and learn from industry leaders and experts,” said David Bergman, VP, international relations, Global Electronics Association, and executive director, WHMA.

The EWPTE trade show attracts nearly 200 exhibitors and over 3,000 attendees from more than 40 states and 25 countries for the electrical wire harness, wire, and cable processing industries. The WHMA, established in 1993, is the only trade association exclusively representing the cable and wire harness manufacturing industry.

The WAI Education Center has publicly released the introductory videos from its four completed courses. These videos, shared on LinkedIn, YouTube, and via email, showcase the high-quality content and end with a call to action to enroll.

Interest has grown since Interwire this past May. Notably, Prysmian enrolled 18 extrusion operators

from its Colombia plant in all three available extrusion courses, with more expected to follow.

Multiple new courses are in development, such as Extrusion – Special Process Considerations and Introduction to Wire Dies. WAI is working with instructional designers to add interactive activities and expanded quizzes to selected courses.

For more details, go to wirenet.org or contact WAI at education@wirenet.org.

The WAI will partner with Hyperion Materials & Technologies to host a two-part technical webinar series via zoom in September focused on wire die quality designed for wire die tool makers and wire producers.

Part 1: Differentiating High-Quality PCD Wire Dies will be presented at 11 am EST on Sept. 17. Presenters Hector Ferrer Ribas and Andrew Gledhill will cover the fundamentals of carbide and PCD, explaining how to separate high-quality wire dies from substandard ones. An interactive segment will include “red flags” such as EDM cutting problems and cracks. Also covered will be the causes/impact of material defects on Total Cost of Ownership (TOC). It will provide a checklist to assess product quality based on manufacturing processes, material consistency, traceability and supplier expertise as well as cover innovations in PCD materials, testing methods, certifications and quality assurance.

Part 2: Key Differentiators in Carbide Wire Dies will be presented at 11 am EST on Sept. 24. It will focus on identifying quality indicators in carbide wire dies. The presenters will outline common defects such as casing issues, breakage, cavities, pores, and scratches. Attendees will learn about the causes of these problems and how they affect TCO. A practical checklist will help evaluate wire dies based on consistency, process control, and supplier standards. The session will also address testing methods, material traceability, and recent innovations in carbide materials.

Each webinar requires separate registration. You may register for one or both. The cost is free for WAI members and $75 per session for non-members. Non-members planning to attend should consider joining WAI for $150 per year.

For more information or to register, go to wirenet.org or contact education@wirenet.org. n

The following list includes new WAI members, renewing members and those who became Platinum members through their companies.

Alban Adams Director North American Sales Microdia SA

Emma Ainsworth Process Engineer Charter Steel

Anthony Apanian Process Engineer Southwire Co

Jose Eduardo Basaca Engineer Medical Device Components LLC

Rene Erich Bourne Vice President Regional Sales Niehoff Endex North America Inc

Mark A Cairnie Process Engineering Manager Prysmian

Jason Case Director of Manufacturing Mid-South Wire Co Inc

Riley Chute Sales Coordinator Calmec Precision Limited

Andrew Collins Product Engineer Commscope

Roberto Cruz CEO Zion & Ebenezer Technologies SA de CV

Nichole J Damas Director Quality & Procurement ArcelorMittal Montreal

James A DeRosa CFO Innovative Wire Solutions

Tolga Ediz

Vice President (Technical) Sarkuysan Elektrlitik Bakir Sanayi ve Ticaret AS

Marc J Fitzner President Calmec Precision Limited

Dustin J Fox Vice President of Engineering Copperweld Bimetallics

Robert A Francis, Jr.

Senior Quality Engineer Bridgestone Metalpha USA Inc

Jody Fulbright Plant Manager Granite Falls Furnace

Michael E. Gallagher Vice President Sales - SCR Technologies Southwire Co

Gary Gordon Assistant Vice President East Penn Mfg Co Inc

David Gow Project Manager Primetals

Colton Hinkle Senior Process Improvement Engineer Direct Wire & Cable Inc

Matthew Cole Hurst Southwire Co

Nimer Ibsais Director of Engineering Matalco Inc

Tom Jackowski General Manager Nehring Electrical Works Inc

Sean Jessup Mechanical Engineer Charter Steel

Donald R Leavens

Senior Vice President and Chief Economist National Electrical Manufacturers Association

Kimars Mahmoodi Vice President/ General Manager Davis Wire Corp Kent Division

Jonathan G McSwain Maintenance Manager Prysmian

Rupert Miller

Plant Director Prysmian

Shaun Miller Process Engineering Manager Prysmian

Mitchell Norris Process Engineer Prysmian

Chintankumar Patel Process Engineer Nexans Canada Inc

Julio Z. Perez

Materials Manager Purchasing Manager Lake Cable LLC

Dominick Perrone Vice President Univertical LLC

Adam Wayne PickettMunoz Value Stream Manager Southwire Co

Lucas Richards Engineering Manager Southwire Co

Ralph M Rosenbaum President Stainless Steel Products

Jason Sheldon Process Engineer IMC Metals America

The Ohio Valley Chapter (OVC) will hold its golf tournament and target shooting event on Thursday, Aug. 21. As with its prior event, the OVC will offer a unique split activity format. Golfers will play at the Kensington Country Club (www.kensingtongolf.com), while the OVC shooting event will again be held at the Training Range (www.thetrainingrange.com) in nearby Austintown. Following both events, the Ohio Valley Chapter will hold an educational program.

Meanwhile, the New England Chapter returns to the Tunxis Country Club (www.tunxisgolf.com) on Monday, Sept. 8, for its highly anticipated 31st annual Golf Tournament, with 140 golfers expected to participate. The event will feature a DJ, raffle prizes, awards, and ample time to reconnect with colleagues and make new industry connections in a relaxed setting. If you’re not interested in golf, you can register for just the afternoon portion.

Closing out the schedule will be the WAI Southeast Chapter’s Annual Golf Outing on Thursday, Oct. 16, at the Rock Barn Country Club and Spa (www.rockbarn. com) in Conover, North Carolina. See more in the next issue.

Registration for all these events can be made through the individual chapter pages at www.wirenet.org. These events, a perfect blend of camaraderie and competition, are an excellent way to meet peers, support good causes (such as college scholarship programs), and enjoy a day on the links.

The WAI New England Chapter has rescheduled its previously planned Aug. 7 educational meeting at FENN’s plant in East Berlin, Connecticut, to October 9. The annual educational meeting will include a plant tour and a networking dinner, featuring food and drink trucks for the celebration.

The cost is $105, or $85 for WAI members. All proceeds support the WAI New England Chapter Scholarship Fund, helping invest in the next generation of industry professionals.

Midwest Chapter announced the names of its 3 scholarship winners for 2025

The WAI Midwest Chapter established this scholarship program, administered by The Wire Foundation, to improve educational opportunities for academically qualified high school seniors or college students who are children, grandchildren, or dependents of WAI Midwest Chapter members in good standing.

The Chapter made this commitment to reinforce the value of higher education in today’s society and to provide members with an opportunity to benefit from their membership in WAI and the Chapter. Below are the winners.

Mia Robillard is the daughter of Brad Robillard, owner, Elk Technologies. She is attending The Ohio State University, where she is seeking a degree in mechanical engineering.

Hailey Walker is the daughter of Robert Sears (Retired), BS Wire. She is attending the University of Illinois at Urbana-Champaign, where she is seeking a degree in English.

Amy Skolozynski is the daughter of Stephen Skolozynski, general manager, Master Spring & Wire Form Co. She is attending the University of Iowa, where she is seeking a degree in English and creative writing.

Attendees of Wire & Cable Kraków are in for a treat when the international conference is held Tuesday, Oct. 14, at the Holiday Inn Kraków City Centre in Kraków, Poland. Wire & Cable Kraków will be packed with innovation, insight and international collaboration. The conference program calls for 29 expert speakers to share their knowledge in this single-day technical blitz. The program will explore topics such as production efficiency, product development and sustainability. Ferrous and nonferrous sessions will run concurrently.

Scheduled speakers come from companies that include Tata Steel, the MFL Group, InnoVites, SAMP Group, Eder Engineering, Hyperion, TKT Group, Windak Group, Aeroel Marposs, Niehoff, WiTechs, the Pittini Group, AGH University, CRU, Metalube, Bekaert, Taymer Europe, Tokai University, Czestochowa University of Technology, University of Milano-Bicocca and Celanese.

A tabletop exhibition will be held by the conference. Space is limited to 25 companies. Contact WAI via sales@wirenet.org for more details on getting a tabletop. Go to wirecable25.com for the latest info.

The four event organizers include WAI, ACIMAF, the AGH University of Kraków and the International Wire & Machinery Association (IWMA). WAI’s Poland Chapter is graciously providing administrative services. The event is backed by media partner Expometals.net, supported by WJI, and sponsored by the International Wire and Cable Machine Exhibitors Association (IWCEA). Media support also comes from Expometals.net. The International Wire

and Cable Machine Exhibitors Association (IWCEA) is also an event sponsor. Other sponsorship opportunities are still available.

The event is designed to be more than “just a conference.” The experience includes a gala dinner on the day of the conference at the historic Stara Zajezdnia Kraków by DeSilva in the heart of Kazimierz. An optional private tour of the famed Wieliczka Salt Mine—with hotel transport— is also on the agenda.

Below is the list of scheduled presentations for the ferrous track that will follow the welcome at 9 am.

9:10 AM–9:30 AM

Analysis of the Influence of a Sigmoidal Drawing Die Geometry on the Parameters of the Drawing Process and the Properties of the Wire

Jan Walenty Pilarczyk, Professor, Czestochowa University of Technology, and also a founder/president of the WAI Poland Chapter

As part of the study, a drawing process was carried out using a sigmoidal die and a conical die in two runs, with a single crush of ~20%. The dies were made of NC 10 tool steel. The study analysed the mechanical

and technological properties of medium and high carbon wire rods, the geometric structure of the wire surfaces, the microhardness distribution and the number of fatigue cycles of the wires.

9:30–9:50 AM

Superior Strength Spring Steel Wires for New Age Two Wheeler Suspensions

Amit Agarwal, Principal Technologist, Tata Steel Limited, Global Wires

Two wheeler manufacturers constantly strive to reduce weight of motor bikes and improve fuel efficiencies. This includes designing of lighter suspensions without adversely impacting the bike’s performance. This paper illustrates the development of superior tensile spring wires with better fatigue properties as compared to normal hard drawn spring wires, for 2 wheeler suspension springs.

9:50–10:10 AM

STAR Project (stearate from steel wire drawing processes as a resource) Valorisation of Solid Lubricants for Dry Drawing in a Circular Economy Perspective

Dr. Elena Collina, Associate Professor, University of Milano-Bicocca; and Giovanni Garoli, Production Unit, TKT Group

The STAR project targets the valorization of exhaust solid lubricants from wire drawing, either as new materials or for energy recovery. This research covers characterization of stearate waste—including proximate analysis and metal content determination—followed by anaerobic digestion tests and trials incorporating stearate waste into plastics, construction materials, and metal recovery processes.

10:40–11:00 AM

Prevention of Delamination Defects in High Carbon Steel Drawn Wire by Alternate Drawing Process

Kazunari Yoshida, Professor, Tokai University

We investigated whether it is possible to manufacture drawn wires with high strength, high ductility and no delamination defects by alternate drawing of high carbon steel wire. The results indicated that the alternate wire drawing process suppressed delamination defects of drawn wire and the alternately drawn wire exhibited a higher ductility compared to conventionally drawn wire and also the tensile residual stress near the surface of the alternately drawn wire is small.

11:00 AM–11:20 AM

Low CO 2 eq Emission Wire Rod: Pittini

Applications of EAF Carbon Steel Wire Rods, and Comparison to BOF Carbon Steel Wire Rods

Gianbruno Luvarà, Laboratory Director; and Claudio Zaccomer, Wire Rod Manager, Gruppo Pittini

EAF scrap-based steelmaking CO2 emission intensity is 7 times lower than integrated BOF steelmaking. Pittini

experimented with low carbon wire rod and high carbon grades for the use of recycled steel present in cold rolling/drawing and final applications. Latest process technologies together with internal know-how brought strong improvements with EAF issues like inclusions content, uniformity of mechanical properties and differences in chemical analysis.

11:20–11:40 AM

Bezinox ® : Non-magnetic Armouring Wire

Solution with Protection against Crevice Corrosion

Peter Polakovic, Business Development Manager for the Energy Division, Bekaert

Submarine HVAC power transmission cables require armoring wires for protection during installation, operation, and decommissioning. The use of conventional ferritic steel armoring leads to power losses and local heating due to magnetic susceptibility. This presentation will discuss stainless steel wire as a non-magnetic alternative, its performance characteristics, the challenge of crevice corrosion in subsea environments, and the benefits of Bezinox® armoring wire for subsea power cable uses.

11:40 AM–12:00 PM

Influence of the Process Parameters on the Deformability of Wire-Rod for Mechanical Applications

Andrea Parimbelli, Quality and Innovation Manager; and Mirko Tenca, PhD Student, Caleotto SpA

The as-rolled deformability of wire rods has been observed to enhance following storage, exhibiting a “reverse aging” phenomenon. This study aims to investigate this recovery process through tensile tests, with a particular focus on the reduction of area (ROA) changes over the storage period. The study will also examine the impact of various hot rolling and cooling parameters on this deformability recovery, the goal being to clarify the underlying mechanisms governing this process.

2:00–2:20 PM

Pioneering Advances in Steel Cord Production: Cutting-Edge Material Innovation

Hector Ferrer Ribas, Business Development Specialist, Hyperion Materials & Technologies

This session explores the evolving technological landscape and its impact on steel cords, with a focus on material innovations and performance optimization. Attendees will gain insight into the latest advancements in ultra-fine grades and submicron thermally stable polycrystalline diamond (PCD) grades, examining their influence on performance and overall impact on production outcomes. The session will also cover improvements in performance resulting from advances in case technology, highlighting specific benefits and measurable results. It will all address the often-overlooked role of geometric imperfections— particularly miscoaxiality—in affecting the quality and efficiency of carbide blanks. Finally, the discussion will include the growing influence of finite element analysis (FEA) tools in enhancing precision and performance in steel cord manufacturing processes.

2:20–2:40 PM

Alberto Balotelli, Area Manager, MFL Group

The wire and rope industry faces two critical challenges: labor shortages and growing sustainability demands. To address labor shortages, automation plays a key role. Using our automatic rewinding and packaging line as a case study, we’ll explore how such innovations reduce labor dependence and improve efficiency. On the sustainability front, our mechanical descaling and phosphating solution demonstrates how performance and environmental responsibility can go hand-in-hand.

2:40–3:00 PM

Nontypical

Marek Burdek, Research Worker, Sie� Badawcza ŁukasiewiczGórno�l�ski Instytut Technologiczny

Sometimes it is necessary to use a small batch of thin steel wire as a welding wire or as input material in additive manufacturing for special applications. The article presents an unconventional method of manufacturing welding wire made of high-alloy steel including 12%Cr, 10%Ni, 2%Mo, that uses cold methods: hydrostatic extrusion, rotary forging and wire drawing. Finally, the wire of the assumed diameter with the required properties was obtained.

3:50–4:10 PM

Fabio Giannuzzi, Manager, Aeroel Marposs

Accurate measurement of DIE diameter is crucial in the competitive landscape of wire manufacturing, particularly during the wire drawing process. This presentation explores innovative approaches to optimize diameter measurement using advanced algorithms. We focus on sub-pixel edge detection techniques that improve measurement precision. We aim to demonstrate significant improvements in measurement accuracy and efficiency, contributing to enhanced quality control in wire production.

4:10–4:30 PM

How to Change to the Future of Steel Wire

Cleaning: Mechanical Descaling as an Alternative to Pickling

Jort Kuipers, Director, WiTechs B.V.

This presentation will highlight how mechanical descaling of wire rod offers significant operational and financial benefits across the entire production workflow. Key areas impacted include reduced wire rod purchase and handling costs, improved working and environmental conditions, lower energy consumption, easier waste disposal, streamlined workflow management, enhanced surface quality, and simpler maintenance. Mechanical descaling also minimizes required floor space and supports compliance with government regulations. The result is a cleaner, safer, and more efficient production environment with consistently higher product quality.

4:30–4:50 PM

Bringing

Andrea Meleddu, Technical and Commercial Manager, Astarte Strategies Srl

This work presents an approach for real-time prediction in steel wire drawing. Using data from validated Finite Element models, an AI model was trained to instantly estimate wire properties based on the process setup. The tool enables rapid and reliable predictions for industrial optimization. Mechanical testing confirms the model’s effectiveness, offering significant reductions in computational cost while maintaining high predictive performance for process control.

4:50–5:10 PM

Opportunities and Challenges in the Steel Industry

Chetan Soni, Analyst; and Matt Watkins, Principal Analyst, CRU

The recent economic downturn has seen the global steel industry reach a cyclical low point in both demand and prices. More recently, the shifting geopolitical landscape has exacerbated or indeed created new challenges already faced by the steel industry, including those associated with decarbonisation, competitive supply, and costs. In response, regional markets have increased their protectionist measures.

Below is the list of scheduled presentations for the nonferrous track that will follow the welcome at 9 am.

9:10–9:30 AM

Dieless Drawing Process of Ultra-thin Wires

Piotr Kustra, Assistant Professor, AGH University of Kraków

The study addresses the increase in roughness of dieless-drawn wires due to strain-induced roughness, which can cause stress concentrations and wire breakage, limiting product diameter and process efficiency. It demonstrates that combining of dieless and conventional drawing methods reduces wire roughness, improving workability compared to dieless drawing alone and enhancing product quality. Surface defects are also significantly reduced, increasing wire strength.

9:30–9:50 AM

Luis Zalamea, Application Development Leader for W&C, Celanese

Several new material developments build upon the solid base and track record of Celanese, expanding the application spaces that can be addressed. Namely, halogen-free flame retardant compounds, that comply with several of the most stringent flammability tests, and novel TPVs which significantly raise the upper temperature operating limit. Application case studies will be presented.

9:50–10:10 AM

Windak Smart Cable Packaging

Dieter Gerger, Sales Manager, Windak Group

Windak is a world-leading provider of fully automatic cable packaging machines, offering smart solutions that enhance efficiency and ensure 100% quality control. By automating the packaging process, Windak optimizes workflow, reduces scrap-length and improves productivity in cable manufacturing. This presentation will showcase the latest advancements in cable packaging automation, cost-saving benefits, and future developments that drive efficiency and sustainability in cable packing.

10:40–11:00 AM

Advancing Lubricant Sustainability Within the Copper Wire Drawing Industry

Emma Pates, Global Technical Service Management, Metalube Group

The copper multi-wire drawing industry is increasingly prioritising sustainability, driving a shift away from mineral oil and crude oil-derived lubricants. At the same time, manufacturers seek to maximise production output without compromising product quality or cleanliness. This study explores the development of sustainable lubricant solutions to meet these evolving demands.

11:00–11:20 AM

Innovative Solutions and Machine Efficiency for the Wire and Cable Industry

Enrico Conte, Product Manager, Samp Group

The main drivers for product development— renewable energies, data transmission and digital services, global competition, production efficiency, and sustainability—continue to shape the wire and cable industry. SAMP will present its latest technical advancements, designed to ensure higher product quality and reliable, efficient production while minimizing the carbon footprint.

11:20–11:40 AM

New Generation of Crane Cables - Conductor Material and Design Factors Crucial for Improving Operating Properties

Andrzej Mamala, Professor, AGH University of Kraków Crane cables for transshipment devices operate in multiple systems—including roller, drum, festoon, and chain—each of which produces distinct mechanical stresses and operational challenges. This presentation shares results from material research on copper conductors with micro-additives and conductor design, focusing on reliability in crane cable applications. The findings are part

of R&D project POIR.01.01.01-00-0716/18, which is developing a new range of flexible rubber cables with improved elastic properties.

11:40 AM–12:00 PM

Modern Service Concepts in a Digitalized World

Jürgen Krieg, Director After Sales Service, Maschinenfabrik NIEHOFF GmbH & Co.KG

This presentation will introduce NIEHOFF’s new service concepts, emphasizing opportunities enabled by advanced digital tools. Topics include: an updated service strategy integrating digitalization; myNIEHOFF, a centralized digital service portal for global customers; the NIEHOFF LIFECYCLE+ business model, offering digital support throughout the full machine life cycle; and continuous monitoring solutions, such as key performance indicator tracking and NIEHOFF Output Tune.

2:00–2:20 PM

EconoEconomical Maintenance Solutions for Strongly Growing Drawing Die Quantities in Multiple Wire Drawing Processes

Dr. Kurt Eder, Owner and CEO, EDER Engineering GmbH

The growing number of drawing dies that need to be repaired, often is presenting increasing problems for many companies, because frequently the traditionally available die-maintenance machines no longer offer the reworking potential that is currently required, or there is a lack of suitably trained personnel in the drawing die workshop. Often both come together. We have a proper solution to this problem!

2:20–2:40 PM

AI in Industry 4.0 - Quality Inspection in the Wire and Cable Industry

Piotr Wincenciak, Territory Manager, Taymer International

AI enhances quality assurance in Industry 4.0, and Taymer integrates AI-driven solutions in print verification and surface inspection for wire and cable manufacturing. The OCR-based Print Verification (PV) system ensures accurate printing, reducing false alarms and manual inspection. The Surface Inspection (SI) system uses Machine Learning to detect real defects while minimizing false positives. Taymer improves efficiency and reduces waste, with intelligent automation.

2:40–3:00 PM

Energy Efficiency Meets Peak Performance In Extrusion For High And Low Friction Materials

Robert Pinter, Area Manager, MFL Group

Our extrusion lines use two distinct thermoregulation methods to deliver unmatched performance while improving energy efficiency. For high-friction polymers like HFFR, our patented EXB system features a uniquely designed barrel, delivering top market performance while ensuring energy savings. For low-friction polymers like PEEK, we use alternative technologies that boost efficiency by +30% compared to traditional solutions, ensuring top-tier performance with reduced energy consumption.

3:00–3:20 PM Development and Implementation of a Production Technology for Biodegradable Surgical Wire from Zn-Mg Alloy

Andrij Milenin, Professor, AGH University of Kraków

This paper presents a new technology for producing biodegradable surgical wire developed at AGH. The wire’s mechanical and corrosion properties were thoroughly examined. The process combines hot drawing and final cold drawing of a hot-extruded workpiece. Hot drawing ensures the required ductility, while cold drawing improves surface quality, enhancing the wire’s biological performance. The study also describes the integration of this technology into production processes.

3:50–4:10 PM

Frederik Becker, Director Sales & Marketing, InnoVites B.V.

In today’s rapidly evolving manufacturing landscape, cable manufacturers face the challenge of balancing flexibility with scalability. Traditional MES solutions either require heavy upfront investment or offer limited growth. In this session, we explore a modular, scalable approach to MES that minimizes risk and ensures long-term adaptability. Discover key success factors, operational alignment, and lessons from realworld transformations. Leveraging low-code technology and industry case studies.

4:10–4:30 PM

Roksana Pawlicka, Senior Technologist, Tele-Fonika Kable S.A.

This article presents a comprehensive overview of metallic screens used in high-voltage cables. It discusses various screen types, including wire-based, tape-base and hybrid constructions. Key technical parameters such as thermal conductivity, flexibility, mechanical resistance, ease of application, cost and weight are analyzed. The article also explores current technological possibilities, industry trends, and how wire characteristics influence overall screen performance.

The WAI would like to single out the WAI’s Poland Chapter for its help with this conference. It is headed by Jan Pilarzyk, who is in his last year as president of the chapter, which has put on multiple educational events in Poland. Its members have presented many technical papers at WAI events, including award winners.

4:30–4:50 PM

Wires, Waves, and Shifting

What’s

Natalie Noor-Drugan, Principal Analyst, CRU

The wire and cable industry is undergoing a profound transformation driven by global electrification, data demand, supply chain disruption, and shifting trade patterns. This presentation explores the key growth areas — from renewables and grid upgrades to data centres — while also addressing the constraints: raw material costs, tariffs, and capacity bottlenecks.

The event website, www.wirecable25.com, includes the full details of the event, including the session descriptions, event registration and hotel details. The official conference hotel is listed below. n

Hotel: Holiday Inn Kraków City Centre

Address: Wielopole 4, 31-072 Kraków

Phone: +48 12 619 00 00 or +1 888-holiday

Website: www.hik.krakow.pl

Email: bc@hik.krakow.pl

Rates: Single room – 580 PLN Double room – 680 PLN

Note: schedule is subject to change. Go to www.wirecable25.com for the latest schedule.

This feature presents eclectic slices from a far-reaching topic that sparks both excitement and uncertainty. There’s a story of hard-earned 4.0 advances achieved, an amazing AI-fueled advance made by a commodity manufacturer, an AI battle of “good guys” and “bad guys,” a bolstered focus for a low-profile department, and concludes with a timely, in-depth Q&A with AI that hones in on staffing.

While there’s no single, definitive source that pinpoints exactly where the wire and cable industry stands today with Industry 4.0, many recent reports see more momentum from the growing need for automation, digitalization and advanced connectivity. They agree that this is not a short-lived trend, and that the 4.0 track is taking on an essential role. Below are takeaways from some of those reports.

Automation and digitalization are improving production efficiency and quality, with some companies reporting up to 25% cost reductions after embracing Industry 4.0 practices. (Top Wire and Cable Industry Trends for 2025)

The growing demand for smart factories and real-time data has pushed the robotics wire and cable sector to develop smart cables with embedded sensors for predictive maintenance. (Robotics Industry Wire and Cable Market, 2025)

Asia-Pacific leads in adopting Industry 4.0, driven by robust automation investment in manufacturing, while North America and Europe show steady modernization. (Industrial Automation Cable Overview, 2025)

Next-generation control cables now include real-time monitoring and AI-based diagnostics to meet the needs of smart cities and Industry 4.0 digital grids. (Power and Control Cable Market Size & Forecast, 2025)

The U.S. wire and cable industry is upgrading with resilient infrastructure and smart grid advancements, reflecting broader acceptance of Industry 4.0 principles. (US Wire and Cable Market Size, Trends, 2025)

Digital transformation in manufacturing has become a top priority, with investments in automation, IoT, and smart factory technology now standard across competitive operations. (The Future of Manufacturing Operations, 2025)

Accelerated infrastructure investment and sector demand are spurring digital innovation in wire and cable manufacturing, with a focus on enhanced data transmission and power integrity. (Wire and Cable Industry Update, 2025)

Global infrastructure investment and digital innovation are accelerating the wire and cable market in 2025, with manufacturers leveraging smart technologies to meet rising sector demand and enhance operational agility. (Wire and Cable Industry Update, Spring 2025)

Digital twin technology is becoming a cornerstone of modern manufacturing. Per a Research and Markets report, that global market will reach $96.5 billion by 2029, growing at a staggering CAR rate of 39.48% from 2025. It can be a good fit for multiple sectors. That includes wire and cable, although that use is still developing, but not so for one especially demanding need that is the focus below.

Digital twin technology is becoming a cornerstone of modern manufacturing, with the global market projected to reach $96.5 billion by 2029, growing at a staggering CAGR of 39.48% from 2025. It fits well across multiple sectors, including wire and cable where adoption is still developing, but especially for one demanding application that is the focus below. Insights drawn from multiple sources and company websites highlight how this technology is transforming wire harness design.

Designing wire harnesses can be likened to the industry’s Mt. Everest of complexity. Engineers must painstakingly route countless wires and connectors through cramped spaces, juggling tight electrical specifications, safety standards, and mechanical constraints. They face a relentless whirlwind of design changes and constantly synchronizing schematic diagrams. It’s easy for missteps—wrong wire gauges, mismatched connectors, or spatial conflicts—to slip in, triggering costly rework and production delays.

That’s where digital twin technology steps in. By creating a unified, detailed virtual replica of the wire harness that merges electrical schematics with mechanical 3D models, digital twins act as a single source of truth accessible to designers, engineers, and production teams. Early simulations verify wiring routes, spatial constraints, and electrical compliance long before a physical cable is cut. Automated design rule checks deliver real-time feedback during the design process, flagging issues before they snowball into expensive mistakes. With centralized data, digital twins break down collaboration barriers, slashing delays and miscommunications between electrical and mechanical groups.

A huge productivity boost comes from reusing and customizing existing base designs. Instead of reinventing the wheel, engineers branch off from proven digital twin templates, tailoring harnesses quickly to new requirements. This agility is vital in dynamic fields like automotive, aerospace, and industrial machinery. Plus, tight integration with mechanical CAD systems catches interference and fit issues upfront, avoiding costly on-site modifications.

One of the companies at the forefront of the digital twin revolution is Japan’s Zuken, a global leader in electrical and electronic design software. Its flagship product, E3.series, exemplifies how digital twins can rethink wire harness design and manufacturing. E3.series creates ultra-detailed digital twins by combining electrical schematics with 3D mechanical layouts, supported by modules like E3.3DTransformer, which seamlessly bridge electrical and mechanical domains. This lets designers digitally route wires, validate spatial and functional requirements, and simulate intricate assemblies with pinpoint accuracy.

Zukens’s E3.series can help cable makers scale new heights.

E3.series goes beyond design. It automatically generates production essentials—bills of materials, wire cut lists, formboard drawings, and assembly instructions— directly from the digital twin. These feed wire processing machines, harness testers, and augmented reality assembly systems, ensuring the factory floor delivers on design intent, minimizing manual errors and ramping up throughput.

One Zuken customer cited in a case study described their experience with E3.series as transformative: “It gave us unprecedented visibility and control, cutting design cycles by nearly 40% and virtually eliminating costly errors. What once took weeks now happens in days.”

Per multiple sources, it’s not just wire harness manufacturers that welcome digital twins. Cable assemblies can be less complex than full wire harnesses but still involve custom lengths, terminations, and connectors tailored for specific applications. They require precise electrical and mechanical coordination but usually with simpler configurations.

Standardized wiring products like power cables, coaxial cables, or sensor cables tend to have stable designs but benefit from digital twins in manufacturing process optimization, quality control, and predictive maintenance rather than complex design rework.

Extruded wire and cable products used in bulk (e.g., insulated wire spools) don’t require frequent redesigns but may be good candidates for digital twin applications focused on factory floor process monitoring, extrusion precision, and defect reduction. Sub-assemblies or simpler branches within larger cable systems also require coordination but with less complexity than entire wire harnesses.

As digital twins spread across the varied wire and cable segments, they could make operations more profitable and free up a lot more valuable staff time ... possibly enough to inspire someone to finally tackle a certain mountain.

Artificial Intelligence (AI), widely viewed as a long-term driver for the future of American manufacturing, has led Southwire Company on a deliberate, data-driven journey focused on tangible business outcomes. At Interwire 2025, Southwire executives Daniel Stuart (Senior Vice President and CIO) and Avidypta (Avi) Guha (Vice President of AI and Advanced Analytics) offered a look at how AI has bolstered Southwire’s Industry 4.0 journey, with Willem Sundblad, CEO of Oden Technologies, serving as the session moderator.

For Southwire, a leading wire and cable manufacturer in North America, its AI journey began with robotic process automation (RPA) tools implemented in 2021. It didn’t produce immediate, dramatic results. As Daniel Stuart explained, it was a slow start, but the company stuck with it for over a year. “Over the next couple of years, it really started to perform like an AI tool.” The arrival of generative AI technologies around 2023 sparked broader conversations at all levels of the company, including the board. “That started a lot of conversations and external conversations at the board level as well,” he noted. This led to hiring AI experts and launching proof-of-concept projects that began to show promising results.

Education and governance have been foundational to Southwire’s approach. Stuart explained that the company organized extensive training, including two-and-a-half-hour sessions for executives and leaders, followed by department-level workshops. “We saw growth when we started doing more training at the department levels to really educate them on generative AI versus machine learning,” he said. This education helped generate a rapid increase in AI use cases, growing from just a few initially to about 85 today across manufacturing, supply chain, customer experience, finance, and back-office functions.

on the KPI mean.” Projects run in disciplined 30-, 60-, and 90-day cycles with agile feedback from manufacturing and other business units.

Guha also highlighted the company’s commitment to responsible AI deployment. “We want to make sure that we are doing it responsibly, ethically, and that when it goes into production, we have the capacity to maintain it and avoid hallucinations,” he said. “It has to be genuinely useful to the end user.”

Not every project has been successful. Stuart and Guha acknowledged that some proof-of-concept initiatives failed, but these were treated as learning opportunities. “We wrapped up the POC, we learned something from those insights, and we acknowledged that this is a great learning opportunity for us to apply to future POCs,” Guha said. Stuart added, “Not everything’s a success. Everything’s a lesson learned. And I think, you know, we have friends and colleagues that are in other industries that are a little bit more advanced than us, and, you know, that they share their wounds as well. But we continue to learn every day from these use cases.”

Sundblad observed that the acceptance of failure represents a cultural shift for Southwire, a 75-year-old company accustomed to capital investments with short payback periods.

To manage this growing portfolio, Southwire established an AI and machine learning council that prioritizes projects based on business impact. “We have an executive committee made up of four or five executives that help us prioritize these use cases,” Stuart said. “You’re not going to get all 85 done, but you want the right ones to move forward.”

Guha elaborated on how these 85 use cases are not all equal, coming from every aspect of the business, but with the greatest value in manufacturing. “We are predominantly a manufacturing company. Southwire manufactures wire and cable, and that’s where most of the value is coming out of those boxes,” he said.

Guha emphasized the importance of defining clear key performance indicators (KPIs) before starting any proof of concept: “We have a laser focus on what is the right expectation, what does good look like, what is the baseline KPI, what’s the target KPI and what does each percentage move

Guha explained that their expectations for the outcome were realistic. “It’s almost like a portfolio where you know the winners are going to win really big, and they have to because they have to pay for future AI projects.” He explained, “We want to take risks, but we want to take risks in a calculated fashion where we do it 30, 60, 90 days. We don’t bet the bank. We want to make sure that the operations, the supply chain, the customer experience, people are experiencing AI in a way that is genuinely useful.”

Stuart echoed that thought. “I’ve never seen so many people accept technology so quickly. It matches the statistics I’ve read about how quickly companies can advance with it. It’s really the people who have taken this and embraced it. Getting their input and listening to them has been, I think, the winning formula.”

Scaling AI solutions beyond pilot projects presents distinct challenges. Guha noted the importance of change

management and process standardization when expanding from a few production lines to hundreds. “How do you put processes in place so you don’t have to be monitoring 24/7?” he asked. Southwire’s AI initiatives are supported by a robust data infrastructure and partnerships with technology providers. The company migrated its core SAP systems to Google Cloud, enhancing scalability and enabling advanced AI and machine learning integration.

Data quality and organization remain critical, Stuart said. “Having the right data in the right place at the right time is the key part.”

“Data is a big part of what’s below the waterline,” Guha explained, referring to the unseen complexity of data management.

Southwire’s AI projects have already delivered measurable benefits. The company invested in an AI-powered energy management platform that uses machine learning and IoT sensors to optimize energy consumption and reduce carbon emissions, supporting its sustainability goals.

Guha emphasized that AI is becoming a core competency for Southwire. “Operating on Google Cloud opens up endless digital possibilities,” he said. “When we’re ready for new initiatives, the tools are there to support our success.”

Southwire believes in the potential of AI as a useful tool for sustainability/‘green’ goals

Earlier this year, Southwire announced the company’s investment in Ndustrial.IO, which provides an AI-powered energy management platform that is designed to optimize industrial energy consumption and reduce carbon emissions.

The platform processes vast amounts of industrial data from multiple sources – over 100 million data points daily – to provide actionable insights and recommendations that optimize energy use and reduce greenhouse gas emissions.

Southwire Vice President of Operational Sustainability

Se Oh said that Ndustrial’s use of AI technology and mission supports the company’s Growing Green initiative to optimize production. “Our investment in Nudstrial reflects our commitment to advancing solutions that drive both operational efficiency and sustainability.”

Throughout the presentation, all three speakers stressed the importance of connecting AI initiatives to real business value. “That’s going to be a key differentiator,” Guha said.

Ndustrial is the first and only platform to integrate with over 60 different industrial data systems, and as part of their investment, Southwire plans to deploy the technology at several of its own manufacturing facilities. Additionally, Southwire will serve as a wire and cable solutions supplier to Ndustrial’s electric transport refrigeration unit (eTRU) power infrastructure customers.

In the wire and cable world, dies have largely been seen as just another commodity. But thanks to US Patent #12,048,957 from Paramount Die, that may well change. Below is a report created from a Q&A with Paramount Director of Research and Product Development Joao Norona, who shares what’s been achieved by pairing focused R&D with AI know-how.

About seven years ago, Joao Norona, director of research and product development at Paramount Die Co., saw a hard truth: wire manufacturers lacked the critical data to identify optimal operating speeds. As a result, they ran their lines well below capacity to avoid costly breaks. The blind spot was clear: no one had visibility inside the die system itself, the core of wire drawing.

“You could be standing at the machine, the wire’s running, everything looks fine,” Norona says. “But you’re completely in the dark about what’s happening inside the die—temperature, force, lubrication effectiveness—none of that was being measured in real time.” Yet customers had to make decisions from that incomplete picture. New dies, lubricants, coolants, or machine settings were tested and judged largely on subjective impressions. “The operator might say, ‘The wire feels better today,’ or ‘It looks shinier.’ That’s what we had to go on.”

What Norona envisioned was a system that would replace guesswork with hard numbers: a way to convert wire drawing from an art into a science. He pitched the idea to company President Rich Sarver, and he ultimately agreed to make the investment. Some six years and more than $1 million in research later, that vision became a reality: The company’s patented Smart Die System was developed entirely in-house by Paramount. In early development, select customers participated in confidential trial installations to validate the system under real production conditions. “Those initial secret tests have been invaluable,” Norona says. “They’ve confirmed the data’s accuracy and convinced cautious operators that this isn’t just theory. It’s a game-changer in everyday use.”

They are not in the front lines drawing wire hand-in-hand with their customers every day. There’s a difference. We live in this process. Our people were practically born in a wire drawing plant. They know the full manufacturing environment, and that’s what shaped this system. It was effectively designed by wire-drawers for wire-drawers.”

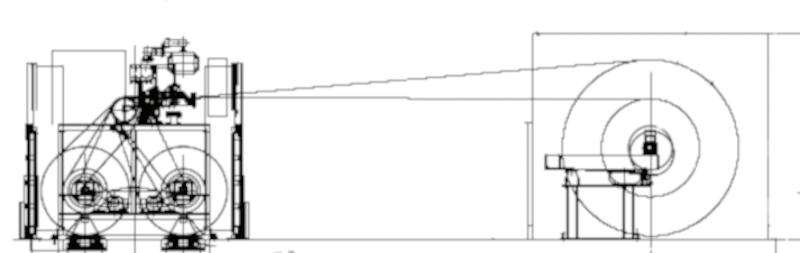

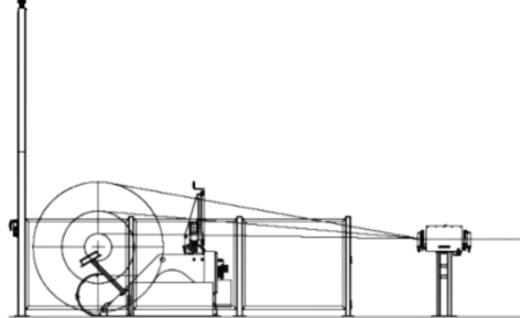

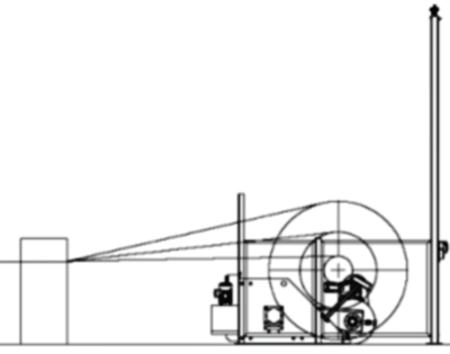

The Smart Die System doesn’t just observe the wire drawing process: it becomes part of it. The system centers on a redesigned die box fitted with sensors and electronics that measure key parameters directly at the wire-die interface. Inside this assembly, individual components work together to provide a real-time, synchronized view of what’s actually happening as the wire is shaped at each stage of the process.

The result of Paramount’s AI-driven innovation.

This was never going to be a sensor taped onto the side of a machine. From the start, Norona knew that the only way to truly measure the process was to get inside it—and that AI would have a big role in making this work.

Norona acknowledges that some OEMs do offer drawing lines equipped with gauges that provide warnings. “But they’re equipment suppliers,” he said. “They certainly design wonderful machines, but they are at an unfortunate disadvantage: they don’t actually make wire themselves.

The core of the Smart Die System is the die box integrated with Paramount’s innovative, direct water-cooled smart pressure system cassettes, which is an evolution of the company’s patented cassette Paraloc Pressure System™ design from decades prior. The die box isn’t just holding the die, it’s a nerve center packed with finely tuned sensors that measure exactly how much pulling power is required to draw the wire through each die. “That’s the best indicator of efficiency we’ve got,” Norona explains. “It tells you how well—or poorly— your system is functioning at block level, in real time.”

The temperature sensors are embedded as close as possible to the wire-die interface, capturing the actual heat generated during drawing, information that directly correlates with lubricant performance, friction, and wear. “Understanding how pressure and temperature interact tells you a lot about how your die is behaving under load.”

Water flow and cooling control units, installed beneath the machine, allow automatic adjustment of coolant delivery. Variations in flow can have a profound impact on die performance, especially as temperature ramps up. Each of these cassettes—housing sensors, dies, and cooling channels—feeds information via direct connections to a local electronics control unit, installed right on the machine. This processing unit consolidates and cleans the signal feeds before passing data through Ethernet cables to a central

communications hub—a compact but powerful edge computer that operators and engineers can visualize on a tablet or monitor in real time.

Add optional upstream signals—motor power, speed, diameter and lubricant parameters—and the system stitches together a nuanced, multi-dimensional view of what’s happening. All of this is done on site, with no reliance on cloud transfer. Once this ecosystem is running, it no longer operates like a traditional wire drawing line. The Smart Die System starts showing connections and patterns previously invisible.

Paramount’s Joao Norona is a believer in AI’s capabilities.

“You might increase the line speed and see that your force drops,” Norona says. “That’s a signal your lubricant is now in its optimal working range—it’s counterintuitive, but that happens a lot.” Or, just as easily, it might show that a speed increase causes die temperature to spike and the draw force to rise rapidly—warning signs of pushed limits. In conventional setups, draw force gets approximated based on motor load or inferred from machine behavior. But

that view is so diluted by drivetrain losses, coupling inefficiencies, and system lag that it’s virtually meaningless in fine-tuning performance or precision monitoring. “This changes that,” Norona says. “You get direct, isolated force readings—by block—with realtime feedback. You don’t wait until you’ve broken wire, overheated dies, or lost product. You see it coming.”

Another critical benefit? Seeing which block in a multi-die setup is dragging performance down. For many wire lines, that weak link sets the speed limit. “Wire drawing is like a chain, and your speed is only as good as your weakest block,” Norona says. “If block four is the one with bad cooling or poor reduction design, it’s going to fail before the others. We can now see that down to the force delta.”

With synchronized draw force, temperature, cooling data, and production trends from each block, manufacturers can now zoom in and see which one is holding the

line back. Fix that block—optimize its reduction, its die geometry, its lubrication—and then the next one becomes the bottleneck. Step by step, the entire system improves. “We’ve seen increases of 5% to 10% in line speed within the first week,” Norona says. “That’s massive. That’s not incremental. That’s gained capacity, without buying a single new machine.”

This isn’t just a monitoring tool. With the smart system in place, certain adjustments can also be made automatically as the line runs. If the temperature starts to drift outside range at Block six, for example, the control unit can adjust coolant flow dynamically to bring it back under control—without operator input. That’s part of what signals the early stages of “smart factory” functionality.

Operators can get alerts when conditions trend toward failure, rather than reacting post-incident. It’s shift-proof, experience-proof. “You don’t have to wait for your best operator to say ‘this feels wrong.’ The system tells you, in numbers,” Norona adds. All this creates the ability to start pushing limits with safety nets deployed. Manufacturers often build excessive margin into their processes for fear of failure. Now, they can reduce that buffer—and increase speed—while knowing a real-time system is watching every step.

The Smart Die System was always intended to support an AI-based process control, but Paramount knew one major obstacle had to be addressed first: data sensitivity. Manufacturers in the wire industry tend to guard plant level data closely, and cloud-based systems often raise red flags, so Paramount took a contrarian approach: all data collection and analysis happens locally, within the plant. “That gave us buy-in where we would’ve lost it otherwise,” Norona says. “Customers have full control of their data, and we built that in from the start.”

With enough data from live installations, new algorithms continue to emerge—ones that can suggest parameter changes based on conditions, forecast when certain products will start drawing outside spec, or suggest a die change

before it’s overdue. It’s a foundation built not just to support AI, but to grow smarter alongside customer processes. Initial adopters are already feeding operational outcomes—speed gains, uptime increases, lower defect rates—into the system, giving Paramount and its partners a continuous loop of learning.

Perhaps the most surprising transformation isn’t technical—it’s cultural. “We’ve had operators refuse to go back to machines without it,” Norona says. “They call the retrofitted lines the ‘walk-away machines’ because they run smoothly and let them step away confidently. There’s no guessing anymore.” Engineers, too, now have tools not just to make changes, but to prove them. “You’re not arguing opinion versus opinion anymore,” he adds. “You can say, ‘We changed the die configuration and saw a 7% drop in draw force. Here’s the chart. Here’s the data.’ ”

That turns a cost-driven procurement discussion—“Why does this die cost more?”—into a value discussion: “Your old die pulled 1,100N. This one pulls 950N. You just saved power, increased speed and reduced wear, increasing profitability by a factor of 10 to 20 compared to the increase in die cost.” Some installations have reported measurable paybacks within two to seven months—especially where mid-range or high-spec wire products are involved.

Paramount doesn’t view this as a product—it views it as a platform. More features are coming. More integrations. More layers of intelligence. But the core remains the same: deliver verified, real-time data from where the decisions matter most—from inside the die system.

Norona is pleased with the results. “This gives wire drawing teams what they’ve never had—visibility in the place that counts. Not bits. Not estimates. Not opinions. Facts. And once you have that, everything else gets better.

Further, the story of the company’s AI deployment is not complete. “As we’ve gone through this process, we’ve discovered the potential for even more ways to advance what we do,” Norona says. “This has been an amazing experience, and I don’t see any finish line.”

Experience and know-how, developed for decades, certify HENRICH Maschinenfabrik among leading suppliers of international cable and wire industry. More than 3.000 wire drawing units are well established worldwide. HENRICH product range covers entire drawing lines and single action machines for conductor cable, installation and special cable, telecommunication cable, trolley and enamelled wire. The production range is completed by cooling and cleaning devices for drawing and cooling solution, drawing tools and pay-off devices. The complete program is available at www.henrich.net

HENRICH designs, manufactures, supplies and installs custom-made and on demand.

Go, count on us!

Henrich Maschinenfabrik GmbH

Rehbergring 17, 35745 Herborn, Germany

+49 (0) 2772 506-0

+49 (0) 2772 506-196

henrich-gmbh@henrich.net net: www.henrich.net

Cyberattacks on manufacturing have surged, with nearly 5,500 ransomware incidents reported in 2024 alone. The recent breach at Nucor highlights how real this threat is. Further, AI can be a tool for both those who seek to attack or defend a company, making it increasingly difficult for any organization to fully control its critical data. Below is an overview from multiple sources.

Cyberattacks targeting manufacturing are becoming more frequent and severe. Incidents like the breach at Nucor, the largest U.S. steel producer, underscore how disruptive and costly these threats can be. Advances in AI now shape both sides: enhancing attackers’ reach and helping defenders secure infrastructure.

Understanding the types of AI tools involved is essential to understanding the threat. AI bots generally fall into two categories: general-purpose and code-generating.

General-purpose bots— like ChatGPT or Microsoft Copilot—handle tasks such as answering questions, summarizing content, and drafting messages. Codegenerating bots—such as Claude Opus 4 or Gemini 2.5 Pro—are built for software development, capable of writing functions and applications. Both use similar AI foundations but differ in focus: general-purpose bots prioritize language fluency, while code bots produce accurate, functional code for technical users.

Much of the 2025 RSA Conference focused on agentic AI’s growing cybersecurity role. Yet these advances are also used offensively. AI can generate convincing phishing emails, scan digital infrastructure for vulnerabilities, and deploy malware at scale. Some attackers even corrupt data defensive AI relies on, making it harder for defenders to trust their tools.

Could companies like Nucor have avoided such attacks? Possibly. Defensive AI systems offering real-time threat detection, automated containment, and robust segmentation reduce breach detection time and damage scope. But experts warn that when attackers use similar tools, no defense is foolproof. Cybersecurity requires advanced tech plus sound practices, training, and vigilance. Without basics like access controls and identity management, even top systems may fail.

Even novice users can misuse AI or off-the-shelf hacking tools to automate tasks like password cracking or phishing, lowering the barrier to entry. Meanwhile, advanced attackers may target firmware, manipulate source code, or hijack software update mechanisms to gain persistent access. The smarter and stealthier the attacker, the likelier they are to evade detection and cause lasting damage.

In May 2025, Nucor confirmed unauthorized access to IT systems that caused production stoppages and compromised data. It worked with cybersecurity specialists to reinforce defenses and prevent future incidents.

Preventing such attacks is complex, especially with the rise of agentic AI—autonomous systems that detect anomalies, manage security, and implement rapid mitigation without human input. These platforms isolate threats, monitor unusual activity, and automate responses, essential as attackers use increasingly advanced tactics.

Agentic AI is both a powerful ally and a significant threat, depending on its use. Its dual nature complicates oversight and deployment. As manufacturing and industrial sectors become more digitally connected, the contest between offensive and defensive AI will increasingly shape the fight to secure critical operations.

Sources:

1. Black Kite, 2024 Ransomware Threat Landscape Report.

2. SteelIndustry.News, “Nucor Cyberattack 2025 Update: Data Breach Confirmed”

3. Manufacturing.net, “Details Emerge from Hack on Largest U.S. Steelmaker”

4. Cybersecurity Dive, “Steelmaker Nucor Restores Operations After Data Breach”

5. RSA Conference 2025, Session discussions

6. IBM, X-Force Threat Intelligence Index 2024

7. Gartner, AI in Cybersecurity Market Guide, 2024

Only 14% of organizations have the necessary skilled talent to meet their cybersecurity objectives. Meanwhile, two-thirds of organizations remain vulnerable to cyberattacks and breaches due to a lack of critical skills. From the 2025 World Economic Forum report.

Pati Kelly has closely followed wire and cable hiring the last 14 years. An executive vice president and executive recruiter at Egret Consulting, she also has been a speaker at WAI conferences. Below she shares her thoughts on the role of AI on hiring and maintaining staff. She can be reached at 847-307-7128 or pk@egretconsulting.com.

While artificial intelligence dominates a lot of tech headlines, the reality in wire and cable recruiting tells a more nuanced story. Despite rapid innovation—from smarter supply chains to everyday chatbots—hiring managers in this industry still aren’t clamoring for “AI superstars” on their teams. Instead, the reach of AI is transforming recruiting and staffing in quieter, but increasingly important, ways.

In my experience, employers are not actively seeking candidates with pure AI expertise. Rather, the priority is on those comfortable adapting to new technology—especially platforms where AI is deployed behind the scenes. Across the wire and cable sector, AI’s influence is most visible in the tools and workflows used daily, and in the broader move toward tech-savvy workforces.

Within the supply chain, AI-driven improvements are ramping up inventory management, customer usage tracking, and broader market analytics. More companies are investing in ERP systems like Epicor and Infor, which now quietly integrate AI and machine learning to raise productivity and support better decision-making. Candidates who have spent time with these kinds of advanced tools increasingly have an edge.

On the distribution side, AI-enabled software is being tasked with analyzing bills of materials, sourcing components and generating part lists or quotations automatically. Professionals who are adept with these systems are able to speed up quoting, improve accuracy, and add real value to their organizations.

Manufacturing, too, is shifting. As companies grapple with labor shortages, efficiency targets, and rising

costs, they’re leaning into robotic automation—and AI is making these systems smarter, more flexible, and easier to program. That’s creating greater demand for candidates who can manage or optimize automated operations, regardless of whether “AI” appears in a job title. Adaptability and an openness to evolving technology are increasingly essential qualities.

These changes aren’t limited to large companies—even smaller manufacturers are adopting automation to boost productivity and redeploy skilled staff to roles requiring creativity and dexterity.

AI is also empowering job seekers, who are now using tools like ChatGPT to write resumes, craft cover letters, and even prepare for interviews by generating tailored questions pulled from hiring managers’ online profiles. As a result, both employers and candidates are tapping into AI, sometimes without realizing it.

Ultimately, AI isn’t erasing the human dimension from hiring, but it is influencing the mix of skills employers value and how candidates can distinguish themselves. Those willing to learn, adapt and embrace new technology will continue to find—and create—opportunity as our sector evolves.

Analytical thinking remains the most sought after core skill among employers, with seven out of 10 companies considering it as essential in 2025. This is followed by resilience, flexibility and agility, along with leadership/social influence.

From the 2025 World Economic Forum report.

Accounting may never compete with robotics or AI-driven machinery for the spotlight in a company’s Industry 4.0 transformation, but it has earned a seat at the strategic table. Per Karbon’s 2025 State of AI in Accounting Report, “AI is no longer a trend in audit and finance, but the engine of transformation.” Below are edited excerpts from the report.

It’s not hard to see accounting as being the isolated “numbers” department, detached from the pulse of the business and the front lines of innovation, but AI is rewriting that script. According to Karbon’s 2025 State of AI in Accounting Report, accounting is no longer just crunching data behind the scenes; it’s now driving strategic transformation. “If 2024 was the year of AI’s promise, 2025 is when accounting steps out of the shadows and into the boardroom, connecting financial insight directly to how businesses innovate and grow.”

Accounting teams equipped with AI now provide a comprehensive financial view of projects—far beyond the traditional ledger. While operational leaders focus on production rates, supplier deliveries, and inventory levels, accounting zooms out to analyze cost flows, contract terms, and cash impacts across the entire supply chain. AI-powered systems continuously ingest data—from invoices and purchase orders to payment schedules—and apply advanced analytics to flag cost overruns, budget deviations, and hidden risks earlier than conventional reporting allows.

This broader financial perspective often reveals surprises: rising procurement costs unnoticed on the shop floor, logistics delays inflating carrying expenses, or innovation investments failing to generate expected returns. AI also enables dynamic scenario planning, instantly simulating how supply disruptions or price swings ripple through cash flow and margins. This allows decision-makers to respond proactively— renegotiating contracts, adjusting budgets, or reallocating resources before issues escalate.

For manufacturers, this means accounting moves from simply verifying costs to shaping strategic decisions. AI-enhanced accounting solutions provide insights on cash flow timing, supplier risks, and investment returns that are vital for optimizing procurement, production scheduling, and capital expenditures. These capabilities help manufacturers not only identify inefficiencies but also anticipate the financial impacts of supply chain disruptions or technology upgrades before they occur.

Moreover, by automating routine data reconciliation and anomaly detection, AI frees accountants to act as trusted advisors who collaborate closely with plant managers and executives. This elevates accounting from a back-office function to a proactive partner that guides manufacturers on how to allocate resources, price products competitively, and plan for sustainable growth. As a result, AI makes accounting not just more efficient, but fundamentally more important to manufacturing’s ongoing innovation and resilience.

Moreover, AI automates integration of unstructured data such as contracts and delivery notes with financial records, reducing errorprone manual work and freeing accountants to interpret trends and advise strategically. Tools like NetSuite, BlackLine, and MindBridge embed AI for continuous audit monitoring, anomaly detection, and forecasting, helping firms uncover financial irregularities and run real-time “what-if” analyses faster than ever before.

Accounting’s AI upgrade not only transforms its internal operations but also significantly deepens its impact on manufacturing’s success. In an Industry 4.0 environment, where production lines are driven by robotics, IoT sensors, and AI-driven machinery, accounting becomes the critical lens through which complex operational data turns into actionable business intelligence. AI-powered accounting systems can integrate directly with manufacturing execution and inventory management platforms, enabling accountants to analyze cost structures at granular levels— such as per product line, shift, or even machine.

Yet despite growing adoption—66% of accounting professionals actively use AI—only 40% report support from management, revealing a gap between frontline innovators and leadership. Still, 85% remain optimistic about AI’s power to transform work, citing time savings of 18 hours per employee each month by automating routine tasks.

This shift is redefining accounting from a distant back-office function into a critical, AI-powered strategic partner. As Industry 4.0 technologies reshape operations, smart firms are weaving accounting insight into core business decisions—gaining clarity, agility, and a competitive edge in finance and talent alike.

Exhibiting at Wire Expo 2026 is your chance to share your products, innovations, and marketing message with valuable customers and new prospects from the Greater Milwaukee region.

Convenient travel and simple setup help you focus on what matters most. Discover shared interests. Build prized relationships. And be present when interaction leads to action. Wire Expo booth sales begin 10/2/25*

Want to set your place at Wire Expo 2026? Contact sales@wirenet.org.

*Exhibit space is assigned based on accumulated points from past participation.

Bonus: Wire Expo 2026 is co-located with: 2026

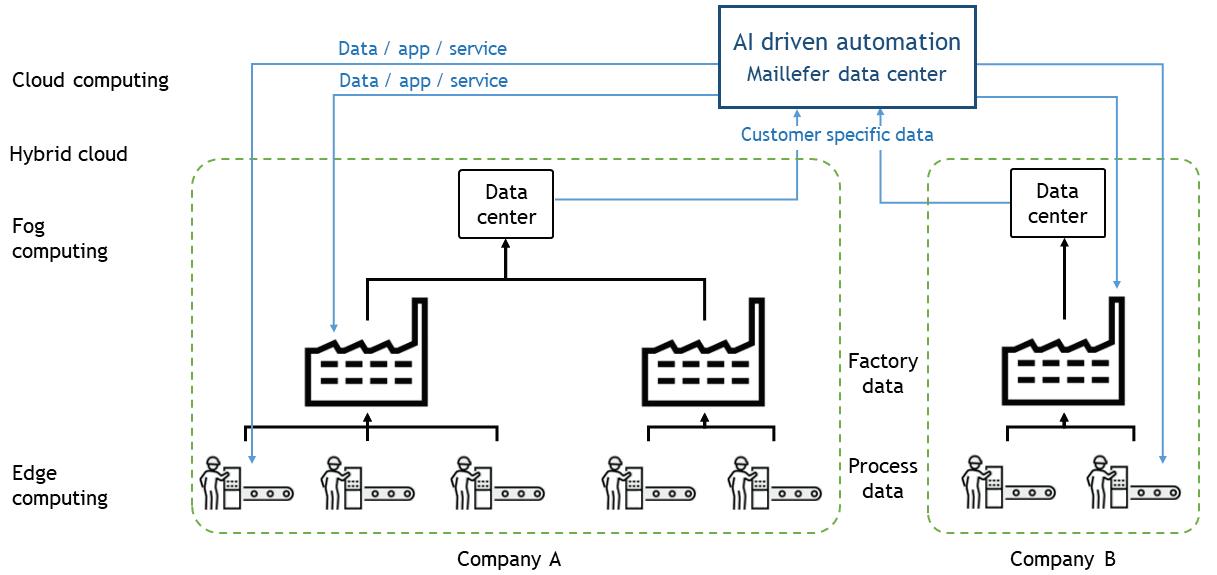

At REWIREcable 2025, Maillefer R&D Data Manager Jussi Hanhirova, who focuses on pilot projects based on AI systems, spoke about the future of cable manufacturing. His well-received presentation focused on how Artificial Intelligence (AI) can translate to maximizing the potential of Industry 4.0 deployment. Below is a summation of his talk.

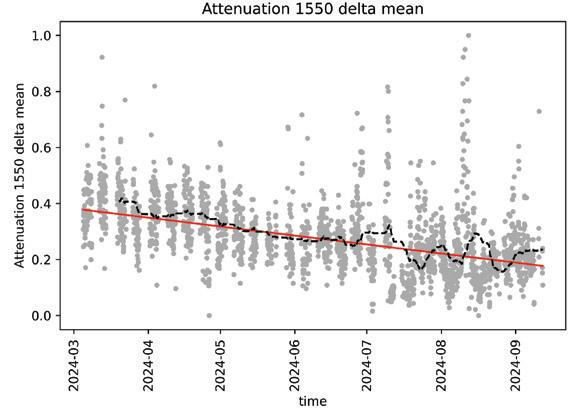

Maillefer’s Jussi Hanhirova delivered a powerful message: the future of cable manufacturing doesn’t just lie in faster machines, it lies in smarter factories. See Chart 1.

In his session, “The Industrial Transition Towards Data-Centric Manufacturing,” Hanhirova explained why Industry 4.0 is no longer a distant concept; it’s unfolding in real time on the factory floor. Through practical examples, he showed how the combination of data, AI and connected systems is reshaping how cable manufacturers think about quality, productivity, and process control.

Chart 1. Schematic of ideal layout for Industry 4.0 production.

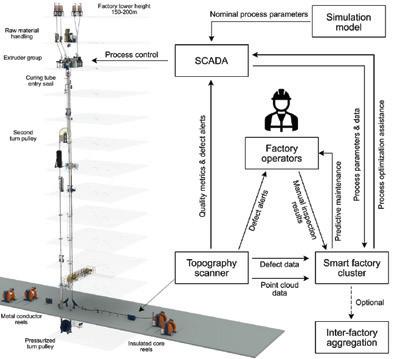

Maillefer’s Topography Scanner (see Chart 2) was a clear example of this shift. Using laser-based optical sensors, it continuously captures high-frequency 3D data on cable surfaces; identifying defects, measuring ovality and roundness, and feeding this intelligence directly into the production process. It’s not just quality control; it’s quality prediction, executed at lightning speeds and scale.

On top of that, then came Smart Buffering—Maillefer’s answer to high-speed, high-precision production in fiber

Chart 2. Some of the issues addressed by Maillefer.

optic cable manufacturing. Instead of relying on static parameters or delayed quality feedback, this system leverages end-product targets and real-time data to adjust process variables autonomously. The results? Better product quality, reduced material waste, less downtime, and even predictive maintenance recommendations based on machine behavior.

Hanhirova emphasized that data-centric thinking is at the heart of Industry 4.0. Unlike traditional factory setups, where data is siloed or reactive; Maillefer is pioneering a model where every layer, from sensors to analytics to cloud-based intelligence, is interconnected. This opens the door to digital twins, autonomous process control, and AI-driven decision-making that continuously learns and improves. See Chart 2.

But the transition isn’t without friction. Many cable manufacturers still rely on legacy systems and proven routines. Maillefer’s approach acknowledges this reality, proposing a layered transformation, where smart tools like topography scanning and buffering automation are integrated gradually without disrupting what already works.

The key takeaway? Industry 4.0 is not just about technology it’s a mindset shift. It’s about moving from reactive control to predictive intelligence. From static workflows to adaptive systems. From fragmented data to end-to-end visibility. With practical case studies (see Chart 3) and forward-looking insights, Maillefer’s session provided manufacturers with more than a vision, it offered a clear pathway to becoming future-ready, one intelligent system at a time.

Case study: Six-month operation at a customer facility

Chart 3. A snapshot of a customer’s achieved results.

ABSTRACTS DUE: OCTOBER 2, 2025

NOTICE OF ACCEPTANCE: NOVEMBER 13, 2025