+ Wire Link Scholar Report

+ RE WIREcable wrap up

+ Century-old industry call ‘reissued’

SIKORA's next-generation X-Ray system for CCV and VCV lines

Your benefits at a glance:

• Significant cost savings with faster eccentricity measurement compared to predecessor device NXT

• Valuable material savings by reducing scrap

• Sustainable CO2 reduction

• Measurement of up to 3 material layers - begins immediately after line start-up

Save material, CO2, and costs by upgrading your line today!

+ Wire Link Scholar Report

+ RE WIREcable wrap up

+ Century-old industry call ‘reissued’

The wire and cable industry is always evolving, a story marked by highs and lows, good news and bad. The headlines in this issue’s industry news section capture that essence.

The opening spread starts with the closure of ArcelorMittal’s historic Hamilton wire plant, news that further roiled Canada’s troubled steel sector and left 153 workers facing uncertain futures. That’s followed by word of another major investment by Prysmian, this time for the massive Encore Wire campus in McKinney, Texas; a Turkish cable maker opening its first U.S. plant in South Carolina; and the launch by another company of a wire facility in Barberton, Ohio.

It’s tempting, especially in turbulent times, to believe that the current market is tougher than it ever was. Tariffs, like those doubled by the Trump administration on steel and aluminum, have certainly made life harder for North American producers, especially those in the steel wire business. The traditional growth path does not always mesh well with layers of geopolitical risk and economic uncertainty.

It’s human nature to consider the time one lives in to be unique. That goes especially for when one’s industry goes through extremely harsh periods, such as the fiber optic crash of the early 2000s. There were multiple reports in the news section back then. Some were hard to digest as they felt so implausible, so impossible, but it was the industry pulse at that time. It took years for the magnitude of that story to fade.

In my 31 years here as editor, I’ve never had a problem filling the news section. The stream of industry stories will never dry up because wire and cable is not a fad. It continues to be essential, and yes, there will continue to be more groundbreakings, closings, restructurings and tough boardroom decisions to be made, but that’s always been the rhythm of this business. The faces and technologies may change, but the industry’s resilience endures.

The news to date this year has felt uncertain, even unsettling at times. The wire and cable world has always been a place where challenge and opportunity can be likened to old friends. Sometimes one is louder than the other, but both are always there. There is a flow, and the leaders will be the companies that can best adapt and innovate. But hasn’t that always been the case?

Mark Marselli Editor-in-Chief, editor@wirenet.org

PUBLISHER Steven J. Fetteroll

EDITOR-IN-CHIEF Mark Marselli

DIRECTOR OF SALES Shannon Timme

DIRECTOR OF INTERNATIONAL SALES & BUSINESS DEVELOPMENT

Anna Bzowski

DIRECTOR OF MARKETING & CORPORATE COMMUNICATIONS

Janice E. Swindells

WAI PUBLICATIONS COMMITTEE

Dane Armendariz, consultant

Ferruccio Bellina, TKT Group/President ACIMAF

Michael Crowle, QED Wire Lines Inc.

Tom Moran, consultant

Giulio Properzi, Continuus Properzi

Willem Sundblad, Oden Technologies Inc.

John N. Tomaz, Stolberger

Robert Wild, Niehoff Endex North America

W.T. Bigbee, Encore Wire Corp.

TECHNICAL ADVISORS

John Drummond, Scotia Group

R. M. Shemenski, RMS Consulting, Inc.

Images: Adobe Stock.

Wire Journal International (ISSN-0277-4275) published monthly by The Wire Journal, Inc., is a wholly owned subsidiary of The Wire Association International, Inc., which is located at 71 Bradley Road, Suite 9, Madison, CT 06443-2662, USA, and can be contacted at tel. 203-453-2777; fax 203-453-8384; Internet wirenet.org; e-mail editor@wirenet.org. Address all correspondence concerning advertising production, editorial and circulation to the above address. WJI is printed in the USA.

Subscription rates: $110 per year, USA; $120 per year, Canada and Mexico; other countries, $140 per year (includes air mail). Back copies: $10 WAI members, $15 non-members. Periodicals postage paid at Madison, CT 06443, USA, and at additional offices.

Wire Journal International grants photocopy permission to libraries and others registered with Copyright Clearance Center (CCC), 21 Congress St., Salem, MA 01970, USA, for a fee of $0.50 per article. Payments should be sent directly to the CCC. Requests for bulk orders or reprints should be sent to the Wire Journal International, 71 Bradley Road, Suite 9, Madison, CT 06443-2662, USA.

© 2025 by Wire Journal, Inc. All rights reserved. The Publisher of WJI assumes no responsibility for the validity of manufacturers’ claims made herein. Back issues of WJI are on microfilm and available from University Microfilm, 300 North Zeeb Road, Ann Arbor, MI 48106, USA. Phone: 313-761-4700.

POSTMASTER: Send address changes to Wire Journal International, 71 Bradley Rd., Suite 9, Madison, CT 06443, USA.

This September, WAI’s Education Center, in collaboration with Hyperion Materials & Technologies, will host a two-part technical webinar series on consecutive Wednesday for wire die tool makers and wire producers. The sessions will offer in-depth guidance on evaluating PCD and carbide wire die quality, focusing on practical takeaways, red flag detection and cost-saving insights.

Part One: Differentiating High-Quality PCD Wire Dies. The first webinar, Wednesday, Sept. 17, 2025, at 11 am EST, will take place virtually via Zoom. Led by Hector Ferrer Ribas and Andrew Gledhill, the presentation will cover the fundamentals of carbide and polycrystalline diamond (PCD) dies, noting what separates premium wire dies from substandard alternatives. Attendees will learn to spot red flags such as EDM cutting problems and cracks, explore how defects affect Total Cost of Ownership and receive a die quality checklist. An interactive segment will reinforce key learning points and highlight the latest advancements in PCD materials and quality assurance practices.

Part Two: Key Differentiators in Carbide Wire Dies. The second webinar, Wednesday, Sept. 24, 2025, at 11 am EST Time, is also via Zoom. It will focus on identifying what makes a high-quality carbide wire die. Topics include common quality issues like casing problems, breakage, pores and scratches, along with their causes and consequences. Attendees will gain tools to evaluate manufacturing processes, material consistency, and traceability. The program will also cover innovations in carbide die materials and the importance of certifications and testing methods.

Each session is free for WAI members and $75 for non-members. Separate registration is required for each part. Not a member? Consider joining, as annual WAI membership is $150, and has year-round savings/benefits. Registration is now open. Don’t miss this chance to strengthen your technical expertise and make better-informed tooling decisions.

Attendees of Wire & Cable Kraków are in for a treat when the international conference is held Tuesday, Oct. 14, at the Holiday Inn Kraków City Centre in Kraków, Poland.

Wire & Cable Kraków will be packed with innovation, insight and international collaboration. The conference program calls for 29 expert speakers to share their knowledge in this single-day technical blitz. The program will explore topics such as production efficiency, product development and sustainability. Ferrous and nonferrous sessions will run concurrently, offering something for everyone in the wire and cable world.

Scheduled speakers come from companies that include Tata Steel, the MFL Group, InnoVites, SAMP Group, Eder Engineering, Hyperion, TKT Group, Windak Group, Aeroel Marposs, Niehoff, WiTechs, the Pittini Group, AGH University, CRU, Paramount Die, Metalube, Bekaert, Taymer Europe, Tokai University, Czestochowa University of Technology, University of Milano-Bicocca and Celanese.

A tabletop exhibition will be held by the conference. Space is limited to 25 companies. Contact WAI via sales@wirenet.org for more details on getting a tabletop. Go to wirecable25.com for the latest info.

The WAI is a lead organizer, joining ACIMAF, the AGH University of Kraków and the International Wire & Machinery Association (IWMA). The conference is also backed by media partner Expometals.net, supported by WJI, and sponsored by the International Wire and Cable Machine Exhibitors Association (IWCEA). Media support also comes from Expometals.net. The International Wire and Cable Machine Exhibitors Association (IWCEA) is also an event sponsor. More sponsorship opportunities are available.

The event is designed to be more than “just a conference.” The experience begins early with a welcome dinner on Monday, Oct. 13 at the historic Stara Zajezdnia Kraków by DeSilva in the heart of Kazimierz. An optional private tour of the famed Wieliczka Salt Mine—with hotel transport—is also on the agenda.

Hotel rooms can be booked now for the Holiday Inn Kraków City Centre via reservations@hik.krakow.pl or calling tel. +48-12-619-00-51. Mention the password (THE WIRE KRAKÓW) when reserving. n

The following list includes new WAI members, renewing members and those who became Platinum members through their companies.

Cornel Abratis Senior Manager Technical Marketing Copper Products Aurubis AG

Tom Allen National Account Manager Manner Polymers

Austin Arnold Process Engineer Southwire Co

Jeff Ball Maintenance Manager Southwire Co

Eduardo Barragan Zumbach Electronics Corp

Timothy Barrett Maintenance Engineering Manager Service Wire Co

Jay Baumgartner Engineering Manager Superior Essex

Fredrick Brown Value Stream Manager Southwire Co

Ruth Burdette Head of HR, North America Operations Prysmian

Dillon Christens Process Technician IMC Metals America

Alejandro Cuaron Metallurgist and Process Engineer Freeport-McMoRan Copper & Gold Inc

Keith Donahue Vice President Sales Zumbach Electronics Corporation

Joseph Edmunds Engineering Manager IMC Metals America

Leighland Fansler Maintenance Director Guardian Cable Systems

Carlton Gibbs Sr. Process Engineer OFS Fitel LLC

Devin Heckman QHSE Manager Prysmian

Joakim Larsson Research Engineer Orebro Universitetsbibliotek

Jonas Larsson Metallurgist Nexans

Rafael Lazo Principal Engineer Primetals Technologies Ltd

John McDowell Training and Instructional Design Specialist Southwire Co

Joshua Mercer Maintenance Planner Southwire Co

Petra Moioli Automotive and Elevators Operations Vice President Prysmian

Dallas Moss Value Stream Manager Southwire Co

Justin Pangburn Plant Manager Prysmian

Emma Pates Global Technical Service Manager Metalube

Sherrika Sanders Director of Product Technology Manner Polymers

Jessica Sanderson Director, Sustainability and ESG

Copper Development Association

Rajiv Sivaraman Vice President Global Alliance Management Siemens Energy

Jordan Suter Process Engineer Prysmian

Ethan Weikleenget Application Engineer Saint-Gobain Ceramics & Plastics Inc

Brian White Process Engineer Prysmian

Weifang Zhou EVP & President UL Solutions

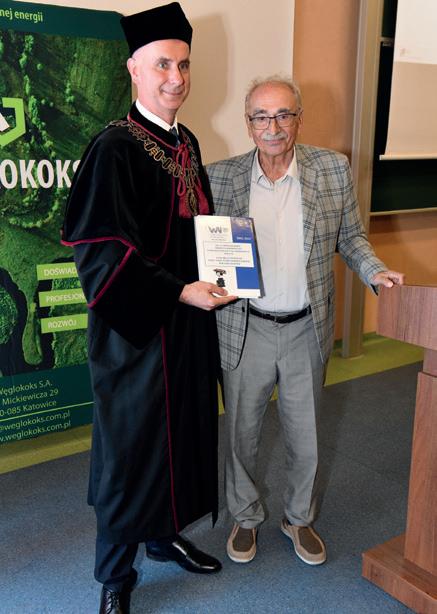

WAI’s Poland Chapter was an active part of a key 75th anniversary at Poland’s Częstochowa University of Technology (CUT) in Częstochowa, which along with the AGH University of Science and Technology in Krakow, Poland, has accounted for dozens of technical papers being presented at WAI events.

The Poland Chapter, while small in numbers, has been most productive since it was founded in the U.S. in 1999, and recognized in Poland in 2002. Three of its members from either CUT or AGH have won the Association’s Mordica Memorial Award for the excellence of their technical research and papers. It has also supported Wire & Cable Poland 2025, to be held Oct. 14, in Krakow, Poland.

CUT Dean Professor Mróz holds a book of the history of WAI’s Poland Chapter by longtime chapter President Jan Pilarczyk.

Production Engineering and Materials Technology, the chapter staged 10 international seminars and nine international conferences.

Multiple participants were cited for their efforts over the years

Those include the MSC Management Board of Agnieszka Gwiazdowicz, Piotr Milewski, Maciej Górak and Jan Pilarczyk.

“On behalf of the Faculty authorities and myself, I would like to express my heartfelt thanks to all former and current Faculty employees for their invaluable contribution to its development and achievements to date,” said Pilarczyk, who is retiring from chapter duties this year. He has presented multiple technical papers over the years and was the 2004 winner of the WAI’s Mordica Memorial Award.

The two other prior winners include the late Bogdan Golis, CUT, in 2000, and Tadeusz Knych, AGH, 2015.

The June 6th celebration of the establishment of the Faculty of Production Engineering and Materials Technology was organized by the university, helped by Jan Pilarczyk, the driving force behind the creation of the Poland Chapter. It was held under the honorary patronage of the current CUT rector, Marek Warzecha, PhD, DSc, a CUT associate professor. The Faculty, one of the oldest units of the University, dates back to 1949, when the Department of Metal Technology was established at the then Faculty of Mechanics.

The ceremony highlighted the role of the Poland Chapter. Over 20 years, in cooperation with the Institute of Plastic Processing and Automation of the Faculty of

The June 6th event marked important accomplishments, but it also featured another element that Pilarczyk explained has been important to the chapter over the years: camaraderie. He also thanked all those that have been part of the activities to date and wishes them continued success in the Poland Chapter’s mission of furthering industry education and cooperation.

Enjoying the post-event activities are Maria Rubin, a guest from the U.S., and Maciej Górak, a Poland Chapter board member and president of Gama Metal Ltd.

The Midwest Chapter will lead off the slate of WAI chapter golf tournaments on July 31 when it goes to a new location: the White Pines Golf Club in Bensenville, Illinois. Located just west of Chicago, the site has two 18-hole championship courses (east & west course), situated on over 260 acres. For more about the course, go to www.whitepinesgolf.com.

Up next will be the Ohio Valley Chapter (OVC), on Thursday, Aug. 21. As with its prior event, the OVC will offer a unique split activity format. Golfers will play at the Kensington Country Club. (www.kennsingtongolf.com). The shooting event will again be held at the Training Range (www.thetrainingrange.com) in nearby Austintown. Following both events, the Ohio Valley Chapter will hold an educational program.

The New England Chapter returns to the Tunxis Country Club (www.tunxisgolf.com) on Monday, Sept. 8, while the WAI Southeast Chapter event will be held Thursday, Oct. 16, at the Rock Barn Country Club and Spa (www.rockbarn.com) in Conover, North Carolina. Registration can be made at wirenet.org at the individual chapter pages. The events are a great time to meet with peers, support good causes (college scholarship programs) and enjoy a day on the links.

The WAI’s New England Chapter will be visiting FENN’s plant in East Berlin, Connecticut, on Thursday, August 7.

FENN offered to host the WAI’s New England Chapter for its educational meeting at the company’s site in East Berlin, Connecticut, and the chapter is looking forward to it. The annual event will include a tour of the plant as well as a networking dinner that will include food and drink trucks coming for the celebration.

Check-in is at 3:30 pm. and the tour starts at 4 pm. Registration for the event can be done at the chapter page online at www.wirenet.org. The cost for the event is $105, $85 for WAI members. All proceeds support the WAI New England Chapter Scholarship Fund, helping it invest in the next generation of industry professionals.

FENN, which this year celebrates its 125th anniversary, is a global supplier of customized metal forming machinery that includes rolling mills, wire flattening and shaping lines, Turks heads, drawbenches, swagers and spring coilers used across a wide variety of industries. Its history traces back to Jan. 15, 1900, when Wilson Lee Fenn received his first purchase order.

Aaron Heath, wire technology technician at Bridon-Bekaert’s plant in Doncaster, England, was the 2025 Wire Link Scholar. In alternate years, the program by the WAI, Wire Foundation and the Worshipful Company of Tin Plate Workers in the U.K., chooses a young professional to see how the industry works in the U.S., attend Interwire and log in some quality tourist time. Below is his report.

I manage wire technology and development projects in the steel industry at Bekaert in Doncaster, and my two-week journey as the 2025 Wire Link Scholar exploring the wire industry (ferrous and nonferrous) as well as U.S. culture/history, was unforgettable. I was told later that my visiting 19 different business unit plants in seven states over 10 days, driving 3,066 miles, is a Wire Link record. I’m not familiar with that, but I can definitely say I was very busy, but in a very good way. I got to see how different companies approach manufacturing, innovation and sustainability and taking in some of the culture and spirit of America. Along the way, I also met a lot of WAI presidents!

I was on my own that first day, and when my flight landed at New York JFK, I took the subway to my first stop, an iconic New York City experience: Times Square. I’ve seen it before in movies and videos, but physically being there, at

night, walking among the wide assortment of people in the throng was most memorable. The next day I toured the Empire State Building and the One World Trade Center before getting on an open top tour bus and taking some more sites, where I got to hear the historic background.

On Sunday, I met John Drummond, the president of the Wire Foundation and a past WAI president (1997-98), who would prove to be a great asset on my trip. He has an extensive knowledge not just of the ferrous and nonferrous industry, but also U.S. history. He was a great asset in my trip. We met up and took a boat tour around Manhattan, visiting mustsee tourist landmarks before hitting the road.

We headed towards Pennsylvania. On the way there we met for dinner with David Richards, Richards-Apex, a WAI Past President (2003). He gave me a deeper appreciation for the American countryside, sharing

personal experiences that brought the landscape to life in a way I hadn’t expected. We also caught up on mutual acquaintances—several of his colleagues at Richards-Apex whom I’d met at previous events. I would also meet him later at Interwire.

My first plant visit was to our sister-company: the Bridon-Bekaert plant in Wilkes-Barre, where we were met by Rodrigo Freitas, the regional technical and quality director for North America. One of the wire mills there draws high-carbon steel wire to feed our Exeter plant. I saw that they use the same types of machines and process lines as we do. One thing I look for in our wire mills is consistency, and it was reassuring to observe that their procedures closely mirror those in our U.K. operations. As we toured the facility, Freitas shared some of the challenges his factory faces. It gave me an insight into areas where I might be able to offer support in the future.

A short trip then took us to Bridon’s plant in Hanover, where we saw the rope-making machines. I heard about the North America market demands and more about the history of the plants. It then was a five-hour drive to our hotel that night. Back home, that would be classified as a long drive, but here, it seemed to be no big deal. We passed long miles, surrounded by fields.

Tuesday saw us visit another Bekaert site, this one in Orrville, Ohio. There, we were welcomed by Tom Efaw, a senior process engineer, who guided us through the facility. This visit stood out to me, as unlike in the U.K.—where all of our wire production is focused on round wire—the

Orrville plant specializes in shaped wire. Early in my career at Bridon-Bekaert, I had been involved in testing shaped wire, so it was particularly rewarding to finally see the manufacturing process firsthand and complete the picture for this type of product. Later that day, we drove to the Charter Steel plant in Cleveland, Ohio. There I visited both the melt shop and the rolling mill at their fully integrated mini mill. The facility specializes in producing Special Bar Quality (SBQ) steel. They use advanced electric arc furnaces and precision rolling equipment, and I got to see how the process works. I then went to the rolling mill, where Steve Allen, process metallurgist supervisor, provided similar details.

Wednesday marked my first nonferrous stop. I visited the New Haven, Indiana, plant of SDI LaFarga COPPERWORKS, a joint venture between Steel Dynamics and Spain’s La Farga Group. The facility produces copper rod and wire from recycled materials through an advanced refining process. I was met by company President Kurt Breischaft, the 2023 WAI president. With him was Process Metallurgist Matt Reinoehl, who masterfully explained how the process works. He pointed out how the incoming scrap is separated, transferred to the gas-fired furnace and goes through the complete continuous casting process. This was my first copper plant, and while the materials are different, the processes are basically the same. I would later meet up again with Reinoehl.

After the tour, I had lunch with Breischaft, Regional Sales Manager Logan Scherer and Fort Wayne Wire Die

It’s a long ways off, but employers might want to consider if their ranks include a good candidate for the next WAI Wire Link Scholar, who will be chosen for 2026. Candidates must have been employed in the industry for more than two years, be a WAI member, and be able to travel to the U.K./Germany for two weeks in April. For more details, contact John Markowski, manager, membership & social media, at tel. 203-453-2777 Ext. 121, jmarkwoski@wirenet.org.

President Eric Bieberich (the 2025 WAI president). This visit also served a dual purpose as Scherer and I discussed the possibility of how new FWWD dies might support our plant in the future. After lunch I went to the FWWD factory, and was joined by Plant Manager Brian Furlotte, Sales Manager John Downey and Vice President Brad Scherer. Furlotte led me to their lab, then down to the plant floor where I got to see dies being ground, polished and measured. This was a “wow” moment. I had never seen how dies were made. They’ve always just been something you replace as needed. Furlotte, along with Quality Manager Shelvy Newsome, helped me understand what is most important. Newsome showed me how to analyze new and used dies, and had lots of useful advice.

I then headed to Fort Wayne Metals, where I met Engineering Manager Jacob Boomershine and COO Keith Albers. The company specializes in precision wire that can be finer than human hair for use in stents and neurostimulators. Boomershine took me on a tour that included several locations where I got to see equipment

producing wire that was about as opposite as can be to what my company makes.

The next day, Drummond and I set off on a two-day trip segment that saw us leave the eastern time zone and into the central time zone. It was special because of how multiple company products “feed” into each other, and the role of the process elements that ensure it gets done properly. In this case, the focus was production of steel springs that would be used to make specific products for consumers.

The process started with Merit Steel plant in Kouts, Indiana, part of the drawn-wire division of Leggett & Platt, where I witnessed steel being made. Plant Manager Steve Tucker explained how the plant produced drawn steel wire, most of which is used in the company’s bedding and furniture components. It was similar to what I do in Doncaster but for a different market sector, so the requirements and parts of the process were slightly different. I was especially impressed by the packaging, which was both neat and very consistent.

From there, we headed to Blachford Corporation in Frankford, Indiana, where we met Plant Manager Nate Thomas. He gave us an introduction on the company and then took us to the shop floor. Blachford makes dry wire drawing lubricants for the steel wire drawing process. This visit was similar to the FWWD visit as we use wire drawing soaps daily in our machines, but I had no idea they came to be. He showed us the incoming material and how it is processed and packaged.

After Blachford, we went to Gripple in Aurora, Illinois, where I met Ross Wegman, the director of operations and finance. Gripple was very interesting for two reasons. One is that Bridon Doncaster in the U.K., where I am based, supplies wire to Gripple US, so it was good to see how the wire was used. We discussed possible ways we could improve the process to make it more streamlined and efficient. The second reason was that Gripple is a supplier to Bekaert. During the tour it was great to see how Gripple uses automation and how it set up the shop floor layout to ensure maximum efficiency throughout the plant.

Friday, we had an early start and set off for Barber Manufacturing Company in Anderson, Indiana, where I met Plant Manager Mike Moore. The five-generation family-owned business specializes in custom springs and formed wire products for the furniture and bedding industries. It also represented the third part of the puzzle, the creation of the springs. As we walked round the shop floor, there was a mix of new and old machines running. It felt like a good machine/human interaction. The volume of springs being produced was impressive. Moore gave me a good understanding of how they meet the requirements. The next stop, the final step in the process, was at the Smith Brothers of Bern Furniture plant in Bern, Indiana, which has been producing upholstered furniture since 1926. We were met by Eric Schmitz, the director of engineering, who led us through the plant. It was impressive, especially for their ability to manufacture custom furniture in a short period of time. All the furniture was hand-made,

including the creation of the wooden frames that required the placement of a lot of steel springs to complete the furniture. The attention to detail was impressive, and I could appreciate the pure scale of what they were working, the final stage. I liked how the two-day focus reflected the role of each step.

The final stop of the day was at the Prysmian Cables and Systems USA plant in Marion, Indiana. It produces a range of wire and cable products, including those for energy and telecom applications. We were met by Devin Heckman, the quality, health and safety manager, Tyler Hodson, senior quality engineer, Adam Westgate, engineer manager, and Justin Pangburn, plant manager. Heckman went into detail about their focus on health and safety. We talked about the most common accidents, which for copper and steel industry is hand safety, and you could tell that their concern went beyond just words. We then headed to the shop floor, and it felt like I was back home. The layout was very similar in terms of equipment and procedures; the main differences were the material being processed and the sheer size of their operation. I was impressed by how such a large plant could be so tidy and clean.

Saturday and Sunday saw a change of pace. Tourist cap on, I enjoyed a chilly day watching the Sonsio Grand Prix at the Indianapolis Motor Speedway. The iconic 14-turn road course combines sections of the famous oval with a technical infield layout. This was my first time watching live racing at any track. Drummond and I walked down the pit lane, soaking up the atmosphere and getting an up-close look at the cars.

Sunday saw us swap the sound of screaming engines for the solitude of nature. We first visited Mammoth Cave, which is described as the longest cave system in the world, with over 400 miles mapped so far. Needless to say, we walked through just a teeny section. From there, we went to Lookout Mountain in Tennessee, known for its dramatic views and the location of the Civil War Battle Above the Clouds, part of the Chattanooga and Chickamauga campaign.

The weekend over, we made our way to Atlanta to attend Interwire. For me, it started with going to the day-long WAI’s Fundamentals of Wire Manufacturing course. It was a full day of learning, covering a wide range of topics that are key to wire and cable manufacturing industry. I found the day-long program to be most helpful. The morning session started off with Matt Reinoehl—who I met the prior week at SDI—explaining the mechanics of wire drawing, followed by Die Quip’s Tom Maxwell, Jr., discussing dies, then Blachford’s Svet Pavlovsky talking about the chemistry behind lubricants and Dr. Horace Pops sharing wisdom about wire breaks and surface damage. I talked a lot with Dr. Pops (the 1992-93 WAI President) and was blown away by not just his knowledge, but by his ability to clearly explain how to tell the difference between different types of defects.

At lunch, I sat with other course attendees and learned more about their companies and why they were there. After lunch, the course split into two paths. I took the ferrous track, and heard from Richard Gordon, of C. Richard Gordon Consulting LLC, who that afternoon made three of the four presentations: the fundamentals of ferrous metal-

lurgy, ferrous testing and properties and ferrous heat treatment. I found his presentations particularly engaging as they closely relate to my daily work. They offered a fresh perspective as well as reinforced some of the basics I may have overlooked.

The other ferrous presentation included Zack McAfee and Chris Porada of Chemetall North America on cleaning and coating of rod and wire. I took away several ideas that I plan to apply for future projects.

Fundamentals ended with a presentation from Phillip Wyatt of Prysmian on wire and cable manufacturing problem-solving. It offered practical insights, and again, I expect the points that had been discussed will help me on the shop floor in future projects. This was not a “sit in and forget” experience. I may have eight years of experience, but the course made me reflect on some past projects and think about what I might consider doing differently in the future. I am most pleased about what I learned there.

The first official full day two of Interwire began on Tuesday, and it was packed from beginning to end. I sat in on the far-reaching industry keynote talk by Prysmian North America CEO Andea Pirondini, then spent quality time on the main exhibition floor visiting exhibitors. This was a great opportunity to see first-hand what different suppliers offer and explore ways they might help improve the systems I currently work on. Being busy day-to-day, it’s easy to overlook potential upgrades or improvements, so having direct access to various equipment and machine suppliers really helped broaden my understanding of what’s available and what could benefit our processes.

At the Welcome Reception that evening, I went on a tour of the Mercedes-Benz Stadium, which is home to the Atlanta Falcons and Atlanta United FC. I had lots of company as the venue was packed. I then went to the WAI President’s Reception, where I had the honor of meeting some prior WAI presidents and connecting with other WAI staff members. It was a great way to close out a full and valuable day.

Wednesday morning, I was part of the WAI’s Annual Awards program. It honored industry veterans who had done remarkable things over many years in advancing technology and helping the WAI further its educational mission. To get recognized there for being the Wire Link Scholar was amazing. I kept my remarks brief, and left, energized about my role.

That day I expanded my connections on the shop floor. I also spent time at the IWMA stand, where I met up with IWMA Chairman Willibert Dautzenberg and Executive Manager Jessica Bennett. I was pleased to see how the IWMA, based in the U.K., continues to play such a key role in connecting people across the global wire and cable industry by promoting innovation and supporting the next generation coming through. The night finished by attending the Niehoff reception to continue networking.

Thursday saw Drummond and I back on the road. We went to Mid-South Wire where we were met by Operations Manager David Roos. Their plant is most impressive due to its scale, which includes transport by the river as well as a sister-company truck operation that has more than a hundred rigs. I got to see their PC wire line in operation.

Back on the road, our next stop was Sumiden Wire Products Corporation EHS Manager Kevin Natterstad gave us an overview of the company, which is quite large. You could see the attention it gave to health and safety. That night, Drummond and I stopped at Lambert’s Café, which he told me was the home of “throwed rolls.” I thought he was joking until he himself got hit by a flying roll.

Friday, the “work” part of my trip ended with a visit to Alan Wire, where I met with Chris Palisch, the 2018 Wire Link Scholar who had visited our Technology Center in Doncaster. I was impressed by the speeds and automation of Alan Wire’s operation. It made me think again about processes where we could improve and possibly move to automation to make the process more efficient.

Saturday found us back at the Indianapolis Motor Speedway to watch the Indy 500 time trials. This was another unforgettable experience, with 33 cars

racing to determine grid positions through a dramatic multi-round process based on each driver’s four-lap average speed. I will just say that I have utmost respect for the courage of those drivers.

Saturday night offered a period to relax with Drummond and reflect on two incredible weeks. I met some wonderful people along the way, and I can’t thank the Worshipful Company of Tin Plate Workers alias Wire Workers of England and the Wire Association International enough for giving me this incredible opportunity.

Following my return from the U.S., I had the honor of attending the May Court Dinner at the Apothecaries’ Hall in London, where I was formally presented with my certificate. It was a special and memorable evening that recognized the importance of this scholarship and the long-standing tradition it represents. I’m deeply grateful to the Worshipful Company for the invitation and for their continued support throughout this journey.

It’s been a genuinely valuable experience, and I’m so grateful to have been a part of it. A special thank you goes to John Drummond not only for helping organize the trip, but also for being a fantastic tour guide. His knowledge of both the industry and U.S. history were second to none, and I’ve learned a great deal thanks to him. And finally, a huge thank you to my employer, Bekaert, for giving me the time and support to take part in this unforgettable journey. n

When we started planning the REWIREcable Conference 2025, we weren’t just organizing a conference, we were trying to build something meaningful for the wire and cable industry. A space that felt specific to our challenges, grounded in real-world applications, and open enough to spark honest, forward-looking conversations.

Seeing it all come together in Amsterdam was something special. This year, REWIREcable welcomed attendees from 12+ countries, bringing together manufacturers, engineers, IT leaders and digital pioneers from across the globe. The sense of shared purpose was clear from the very start: digital transformation isn’t something on the horizon anymore; it’s here, and it’s shaping how we operate, compete and grow.

One of the sessions that really captured that spirit was “The Industrial Transition Towards Data-Centric Manufacturing” by Jussi Hanhirova from Maillefer. His talk laid out how manufacturers are already applying AI, IoT, and digital twins to optimize production, reduce waste, and rethink quality control in real time. The insights were practical and refreshing, particularly for those navigating legacy systems.

Another standout came from Dr. Florian Himmler of Evosoft GmbH, who explored how AI-based digital manufacturing is key to unlocking digital product passports. As compliance and traceability move front and center in our industry, this session made a strong case for why manufacturers need to start preparing now.

We also saw strong engagement during Andrés Cartagena’s talk from MFL Group on smart manufacturing powered by GenAI and IoT. Andrés shared how manufacturers are already using real-time data and automation to reduce downtime, improve decision-making, and unlock

next-level efficiencies. His message was clear: this isn’t future thinking; it’s already underway.

Alongside these, there were many further inspiring presentations that focused on practical AI applications, the automation of cable design and quotation workflows, and unlocking hidden efficiencies within cable operations. These sessions collectively helped paint a picture of how innovation, when grounded in daily operations, can drive both resilience and growth.

But what I’m personally most proud of, were the conversations in the hallways. The quick huddles over coffee. The real talk about what’s working, what isn’t, and what might come next.

So what does come next? Well, we’ve had a lot of questions already about REWIREcable 2027. The good news: it’s happening. We’re currently deciding whether to align

Hexatronic Group’s Anna Bailey presented a real-world case study on a successful digital transformation.

InnoVites CEO Albert Groothedde welcomed attendees to the second staging of the event.

it with wire Düsseldorf or continue as a standalone event like this year’s edition. Either way, we’ll make sure it keeps the same energy; focused, useful, and led by the people doing the work.

One thing’s clear: the REWIRE community is growing. And this is just the beginning. Thanks to everyone who made it what it was. Innovites CEO Albert Groothedde

I truly enjoyed the conference, meeting, and networking with peers from other cable producers as well as with IT/ OT solution vendors and trendsetters. They inspired me with fresh ideas—and reassured me we’re on the right path. I’ll definitely be back next year. Martin Šimek, NKT Group.

The networking breaks were as valuable as the talks themselves. The quote that stuck with me most was, ‘Be brave and prepare for a bumpy start.’ We all need that reminder. Another one was, ‘It’s about people.’ Especially in tech, we forget that—but this event didn’t. Torben Wölke, Prostep AG

Microsoft’s Harold Swaanen’s presentation was “The road to autonomous ERP with Agentisc AI.”

Editor’s note. The above wrapup of the REWIREcable Conference 2025 was provided by InnoVites CEO Albert Groothedde. WJI will publish one of the InnoVites presentations in an upcoming issue.

Contact: Constantine Grapsas Tel. 813-818-8222

www.aimmachines.com sales@aimmachines.com

The show floor at Interwire had a wealth of equipment for attendees to inspect. Some of that is presented here, with a focus on one booth that partnered up quite nicely. There’s also other Interwire exhibitors presented in the Sector Update on wire surface cleaning as well as the Products section in this issue, with more to follow there in future issues.

At Interwire 2025, AIM, Inc., presented its new AFCe-3Dx line, an advanced and compact 3D wire-bending machine that was “designed to set new standards in wire-forming technology at an exceptional price point.”

Key features include: DXF, LRA, and XYZ file import; animated bending simulation with collision detection; user-friendly 19” touchscreen monitors: Microsoft Windows® operating system; a 5 hp wire payoff unit; dial-a-service remote support; and maintenance module.

Available options include: AccuCal Automatic Bend Setup; AIM Academy 24/7 online training; CMM communication; robotics integration; and STEP and IGES file import.

AFCe-3Dx specifications include: maximum wire diameter: 8 mm (10 mm also available); z-axis arm safety gates; a 5 hp payoff unit; two-plane wire straightener, one set of feeder rollers, cutters, bending pins; a tool cluster tailored to your specific wire; industrial storage drawer; unlimited z-axis rotation; proprietary SmartEditor® Software that simplifies programming and enhances user control; and Graphic Simulation with Animation that can visualize operations before production begins.

The AFCe-3Dx is designed for reliability, efficiency, and ease of use, incorporating readily available replacement parts to minimize downtime. Whether you’re upgrading from an older model or investing in your first wire-bending machine, the AFCe-3Dx offers unmatched value and performance.

Founded in 1992 by Constantine Grapsas, AIM Inc. is a premier CNC bending machine supplier serving customers worldwide.

Contact: Alessio Marin, sales area manager Tel. +39-39 3347306296 alessio.marin@betasistemi.it www.betasstemi.it

At Interwire, Italy’s Beta Sistemi Srl introduced its latest technological innovation: the M2, which it says sets a new benchmark in the copper wire drawing industry.

Designed to combine high performance with a compact footprint, the M2 redefines efficiency and quality in wire production. In just 5.5 meters, it integrates a complete system—drawing machine, annealer, and dancer—into a streamlined, space-saving solution ideal for modern manufacturing environments. Engineered for continuous operation, the M2 reaches speeds of up to 36 meters per second and a production capacity of up to 20,000 tons per year. Each drawing capstan and annealer shaft is independently motor-driven, enabling precise control.

The M2 significantly lowers energy consumption, reduces operational costs, and promotes sustainability. It extends the lifespan of drawing capstans, reduces noise emissions, and ensures outstanding final wire surface quality. These features make maintenance more cost-effective, minimize downtime, and maximize productivity.

Beta Sistemi has carefully engineered the M2 to offer the best balance between capital investment and operating expenses. Its compact, integrated design helps manufacturers optimize their production floor, making better use of available space without compromising functionality or output quality. The M2 is also versatile, perfectly suited for tandem installations with extrusion lines and tinning plants, offering seamless integration into various production configurations.

Confirming its international outlook, Beta Sistemi recently signed an agency agreement with Amaral Automation for the management of the North American and Canadian markets, ensuring direct and highly qualified sales and after-sales service.

Contact: Riley Chute

Tel: 905-677-7976, ext. 206 customerservice@calmec.com www.calmec.com

At Interwire 2025, Calmec showcased its next-generation armoring technology, machine vision systems and process automation tools, continuing its industry legacy of innovation. Calmec, a recognized leader in engineered armoring solutions, focuses on innovation and process optimization for the wire and cable sector.

Calmec designs and manufactures comprehensive solutions tailored to evolving industry demands. At the heart of Calmec’s offering is a full suite of CT1 single-strip and CT2 dual-strip armoring machines to produce armored and conduit products. These systems feature Calmec’s signature plug-and-play tooling and fixed head adjustments, enabling quicker setup times and reduced downtime for operators.

One of our Interwire 2025 highlights was Calmec’s demonstration of its 1-1/4 in. CT1 Armoring Machine (pictured). The machine features recipe-driven HMI settings, electronic strip tensioning, pneumatic chuck and a recirculating lubrication system with automatic spray regulation. This marked a significant leap in efficiency and ease of use.

Calmec also drew attention with its expanding portfolio of machine vision systems that improve quality assurance and process visibility. They support real-time dimensional measurement of cable diameters and convolution counts, along with non-contact length measurement, with configurations for single- or dual-axis measurements. Calmec’s environmental monitoring systems track reel levels during payoff and take-up operations, automatically detecting when a reel is nearing capacity or depletion. Calmec continues to invest in the development of smart wire and cable manufacturing, enhancing predictive maintenance and process control capabilities. Calmec’s booth was a success at Interwire, where its latest innovations received enthusiastic feedback.

Contact: Clifford Machines & Technology Tel: +27-33-355-3400 sales@cliffeng.com, www.cliffeng.com

U.S. AWT Machinery, Clive White Tel: 815-315-4260 sales@awtmach.com, www.awtmach.com

With the growing number of data centers in North America, wire mesh cable trays have become the preferred solution for organizing and installing cables, and South Africa’s Clifford Machines & Technology—represented by AWT Machinery in the U.S.—offers the most advanced wire mesh cable tray welding machinery.

The machinery can produce cable trays with multiple edge wire forms on a single machine: a lap-welded mesh with flush welded wire on all four edges, welded edge wires to further protect cable installation and T-welded and crimped edge wires to help installation. The edge wires are fed directly from coils to ensure high-quality, strong T-welds— even on the corners of cable trays. Off-coil edge wires are essential for producing T-welded and crimped edge wire cable trays.

Our welding port tooling enables rapid setup due to its innovative welding system and automatic positioning of tooling. Manufacturers can quickly switch between tray sizes and designs. The line has an integrated high-speed wire straightening and cutting system for preparing line wires, and a new off-coil crosswires system so there is no need to prepare them offline, store and transport them to the welder. Finally, an automated robot stacker ensures the entire cable tray is transformed from wire coils to a stacked finished cable tray. This reduces material handling, allowing the entire line to be run by a single operator. The line also has modern safety laser scanners, light curtains, and safety fencing. For over 50 years Clifford has been a leader in the resistance welding industry and won awards for innovation and engineering excellence.

Pictured is the Clifford CNC jig welder with a side-by-side jig table, assembled in Ohio, using top quality parts from around the world, that was displayed at Interwire.

Orhan Ozbaran, co-founder

Tel: +90-282-747-60-93

info@domeksmakine.com www.domeksmakine.com

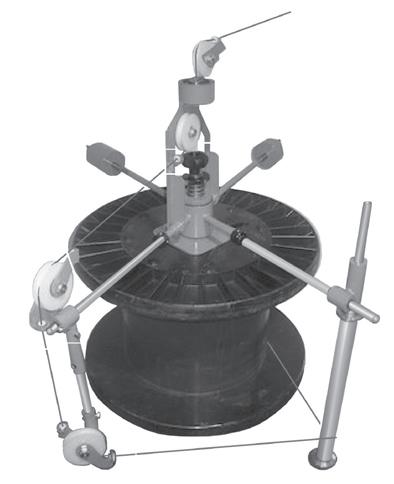

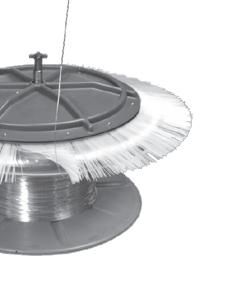

With over 23 years of experience in cable packaging machinery and a presence in more than 40 countries, Domeks Makine continues to deliver cutting-edge solutions designed to meet the evolving needs of cable manufacturers worldwide. Our latest innovation, the Reelmatik1000 (pictured), reflects this commitment to progress, offering a powerful combination of efficiency, flexibility, and ease of use.

Engineered for high-performance environments, the Reelmatik1000 supports plastic, wooden and polywood spools with flange diameters ranging from 17 in. up to 40 in., and handles round or flat cables from 0.15 in. to 1 in. With winding speeds up to 1500 ft/min and a production capacity of up to 38 spools per hour (based on 500-meter lengths), it is ideal for both offline and inline operation, seamlessly integrating into modern production lines.

What sets the Reelmatik1000 apart is its user-friendly interface, low-maintenance design, and optional automatic palletizing system, making it a perfect fit for operations prioritizing uptime and labor efficiency. Whether you’re packaging power cables, signal lines, or fiber optics, Reelmatik 1000 adapts to various production needs without sacrificing performance.

Introduced at Interwire 2025 and sold on the show floor, Reelmatik1000 has already proven its appeal to global buyers seeking ready-to-run solutions without long lead times.

At Domeks, we believe in designing machines that not only perform at the highest level but also make daily operations smoother for your team. With the Reelmatik1000, we invite the industry to rethink what cable packaging can look like: faster, simpler and smarter.

One of the most talked-about displays at Interwire 2025 wasn’t just about a single product—it was a fully functional medical extrusion line built through a strategic alliance between Joe Tools and Systematic Extrusion. WJI asked Joe Tools CEO Tim Brown how this initiative came to be at Booth 631. Below is the write-up they provided.

The idea started with Joe Tools, which approached Systematic Extrusion last year about showcasing a working line. Their medical systems were an ideal match: compact, cleanroom-capable and engineered to deliver tight tolerances. That alliance led to a setup that featured a Joe Tools precision crosshead integrated with Systematics’ extrusion equipment, a compact cooling tank and a servo puller/cutter. The line produced live medical-grade tubing throughout the event.

“Running equipment on the show floor is a bold move, but we wanted to make a statement,” said Joe Tools CEO Tim Brown. “We’re not just showing components or parts. We’re showing what’s possible when trusted partners come together with one goal: helping medical manufacturers solve problems and move faster.”

Systematic Extrusion, based in Georgia, brings a unique mix of services to the table, including Scientific Extrusion™ training, process consulting, material testing, and equipment manufacturing. Together with Joe Tools, they’re building a vertically integrated solution that’s quick to deploy, stainless steel by default, and significantly more cost-effective than traditional custom lines.

“The response from attendees was incredible,” said Systematic Extrusion CEO Braulio Polanco. “Not only were people surprised to see a full line running, they were also drawn in by how seamless it looked. It was magnetic for sure. This alliance allows us to compete at another level, offering medical device manufacturers a turnkey system built on overwhelming experience and quality.”

Also part of the mix was Zumbach, which provided its ODAC TRIO diameter and ovality measurement and control system. Zumbach’s Jorge Lage, who has long known Systematic Extrusion, said he was pleased to supply the measuring system and be available for attendees. He was located across the aisle at his company’s booth.

l-r, are: Systematic Extrusion CEO Braulio Polanco, JT Sales Engineer LATM Arsenio Baltazar, Zumbach Director of Sales Latin America Jorge Lage, JT Technical Sales Dieter Kuper, JT Medical and International Sales Michael Maduros and JT Sales Matt Lee.

Overall, the line drew a lot of attention. This wasn’t a one-off display either. The three companies have already quoted full systems for medical device OEMs in the U.S. and Latin America with strong interest in expanding into multi-line setups. With a shared vision for future-ready, modular systems that reduce downtime and accelerate production, Joe Tools and Systematic Extrusion proved that innovation doesn’t have to come from the biggest players, it comes from the most focused ones, as was seen at Interwire at Booth 631. “This partnership isn’t just about what we showed, it’s about where we’re going next,” Brown said. “Together, we’re building smarter, faster, more flexible extrusion solutions that medical manufacturers need now, not nine months from now.”

Contact: Levent Selvili, sales director Tel. 630-948-7210 lselvili@gmm-usa.com www.gmm-usa.com, www.gmm.com.tr.

GMM USA LLC (GMM) brings together its U.S.-based operations and advanced manufacturing from its modern facility in Turkey to serve the global wire and cable industry. GMM has gained recognition in Europe, America, Africa and Asia through more than 35 years of experience. From telecom to energy, we deliver tailored, high-performance machinery that meets the demands of today’s cable manufacturers.

A GMM cornerstone remains its heavy-duty take-up and payoff systems, including gantry and portal machines that handle reels up to 110 tons. They are engineered for precision and reliability, ensuring smooth winding/unwinding for the most demanding applications. We also design and build complete production lines for power cables and fiber optics. Whether for HV transmission or expanding fiber networks, these systems can improve output and product consistency. Equipment like the CA4500 caterpillar, with 70kN of pulling force, demonstrates GMM’s capability to support large-diameter cable production with ease.

What sets GMM apart is its close collaboration with clients—developing customized solutions backed by responsive support and deep industry expertise. Using the latest digitalization technologies, precision-driven facility ensures consistent quality across its product line.

We have U.S.-based engineers, and if there is a technical issue, we will connect online with their machinery within 24 hours to resolve it. If an on-site visit is needed, an engineer will come within 72 hours. We typically have two technicians on duty in the U.S. to do this.

Sustainability is also central to GMM’s mission. The company has installed solar panels on the roof of its Turkish factory and is on track to become carbon neutral in the near future—reflecting a commitment to responsible manufacturing and long-term innovation.

Contact: Dean Zhang

Tel: 908-370-3117

dzhang@hontainc.com www.hontainc.com

Honta Inc., Branchburg, New Jersey, represents equipment from China’s Jiangsu Honta Machinery Co., Ltd. (Honta). At Interwire, it displayed the Honta TMB630.02 wire drawing system.The Honta TMB630.02 provides high-efficiency and precision for processing wire materials such as copper, aluminum and alloys.

Honta’s rod breakdown drawing machine optimizes automation, energy efficiency and consistent product quality. It can draw to speeds of 25–35 m/s (varies by application); has a multi-die configuration (from 6-13) that can make significant wire reductions in a single pass; uses advanced PLC or Siemens-based control systems. In recent years, Honta has offered drawing machines and inline annealers with individual motors and drives. This offers more operational cost advantages by reducing maintenance requirements thanks to the elimination of the traditional complexities of the gears. For rod breakdown, Honta offers single or two wire designs to draw wire down to 1.0 - 4.5 mm. The direct motor design allows much higher line speeds with fewer dies to draw bigger wire sizes than conventional gear designs while saving energy by using only the needed capstans.

Honta makes multiwire drawing systems (28, 24, 16, 14, or 8 wire) that provide production flexibility for copper and aluminum conductors for output wire sizes from 0.05 mm to 1.35 mm. Honta’s new generation, multiwire drawing machine features a quick die change system that allows production of various diameters without having to change the complete die sets. Our latest high frequency annealing techniques, combined with the individual drives and motor technologies, drastically reduces the usage of electricity.

Contact: Jonas Hagstedt, president Tel: +46 122 232 00 email@lamnea.com, www.lamnea.com

Editor’s note. This section was supposed to be limited to equipment physically shown at Interwire, and while Lämneå Bruk did not haul in tons of machinery, it was hard to dispute that they had indeed brought multiple pieces ... all 3D printed! Ergo, this entry.

Lämneå Bruk is a trusted full-service supplier, offering everything from single machines to fully integrated production lines and entire factories for the manufacturing of welding, stainless steel, high-carbon, and low-carbon wire. With a legacy spanning over 200 years, the Swedish wire machinery manufacturer’s success is rooted in its dedication to providing top-tier technical and profitable machine solutions to its international customers. This commitment is lived by focusing on intelligent customization and user-friendliness, offering the highest flexibility and engineering state-of-the-art machines tailored to specific production needs.

Since bringing the complete machine line to Interwire would have been quite challenging, the innovative Swedes decided to 3D print their entire wire manufacturing line from payoff to take-up. This creative solution turned out to be a real hit with visitors. The models attracted lots of attention throughout the show, with many expo attendees stopping by to get a closer look at how the production process works. Visitors could easily see the flow from one machine to the next and understand the complete manufacturing setup, which helped them visualize what the actual production line would look like in their facility.

This hands-on approach perfectly demonstrates Lämneå Bruk’s practical thinking when it comes to solving problems, whether it’s designing custom machinery for specific production requirements or finding creative ways to showcase their capabilities at trade shows.

The same innovative mindset is reflected in how those solutions are developed from the ground up. Lämneå Bruk designs, develops and manufactures all parts and components for their machines in-house, using the most advanced systems technology available.

Contact: NENA, Robert Wild Tel: 856-467-4884 r.wild@niehoffendex.com www.niehoffendex.com

NENA’s Robert Wild (right) and Michael Dalal (beside him) at their booth with visitors.

Germany’s Maschinenfabrik Niehoff, represented in North America by its subsidiary Niehoff Endex North America Inc. (NENA), is a pioneer in nonferrous wire drawing machines. At Interwire at Booth 839, the Niehoff booth presented a range of innovations.

Pictured is the company’s heavy multiwire drawing line type MMH 121 + RM 201 (pictured). This line allows the production of AWG 30 to 20, with high productivity and a low wire break rate. The compact machine is designed to draw 32 wires on two levels simultaneously.

Via a 3D presentation, visitors gained an insight into Niehoff’s newly developed High Efficiency Annealing Technology (HEAT) which ensures an improved recrystallization process at considerably lower energy consumption. This technology is available in the new continuous resistance annealer type R 503 which is designed to be combined with the RBD machine type MSM 88. HEAT will allow the line to work continuously at an increased production speed while saving energy. This provides huge cost advantages and a short ROI.

Niehoff is also a technological leader in the manufacturing of rewinding and braiding equipment. The SMB type wire winder that was shown at the booth is a further development of the DSA-4 model and designed to re-spool wires from multiwire or fine wire drawing lines onto braiding bobbins. Four bobbins—fed automatically from a magazine—can be spooled at the same time, enabling the SMB to continuously supply around eight to ten braiding machines with bobbins. The SMB can work at a speed of up to 800 m/min, 200 m/min more than its predecessor. The SMB wire winder was specifically designed with ergonomics in mind to ensure optimal operator comfort.

Contact: Jeff Swinchatt

Tel: 315-337-3350 email@themgsgroup.com www.themgsgroup.com

Contact: Süleyman Dündar engineering@mssmachinery.de www.engineering@mssmachinery.de

At Interwire 2025, MGS Group showcased the company’s new side-loading boxing option that was in full operation. It represents the industry’s simple solution to boxing spools. It features robotic box erection, loading and sealing, all done by a single six-axis robot, making it the most efficient use of robotic technology for this application.

The FAT616 is designed for on-line or off-line packaging of various products, including THHN, NMB, category, coaxial cable, tubing, hose, and optical fiber cable. It is part of the company’s next generation of FAT systems, developed in response to customer demands. It has a smaller footprint, faster production speeds, and a more economical investment compared to previous models.

The system is flexible, capable of working with a full range of customer-designated reel sizes and formats. The model uses a state-ofthe-art integrated mechanical design and controls system for precise winding of a wide variety of products and reels, making the FAT616 easy, efficient and productive to use.

As part of the MGS Group’s automatic packaging solutions, the FAT616 contributes to labor, health and safety benefits, in addition to operational efficiency. Integration: The FAT616 can be integrated with other MGS Group technologies, such as the ReelBOT robotic systems, for a more comprehensive packaging solution. The FAT616— along with its counterpart, the FAT820—represents the MGS Group’s commitment to delivering advanced packaging solutions.

MGS also showed a Northampton SLB800M double-twist buncher for 20 to 4 AWG products. It can run up to a 36 in. reel, offering simplicity and high productivity, reduced maintenance by its no-slip-ring design, and superior performance for precision bunching.

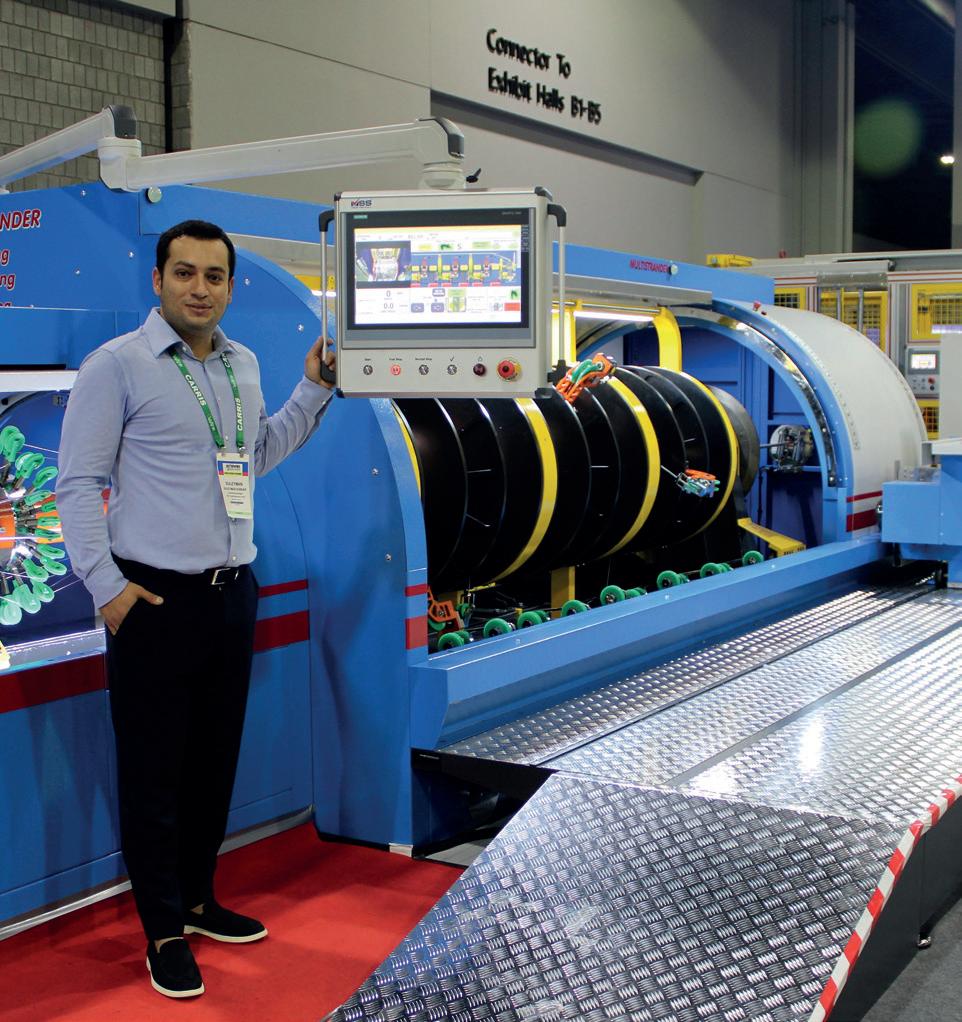

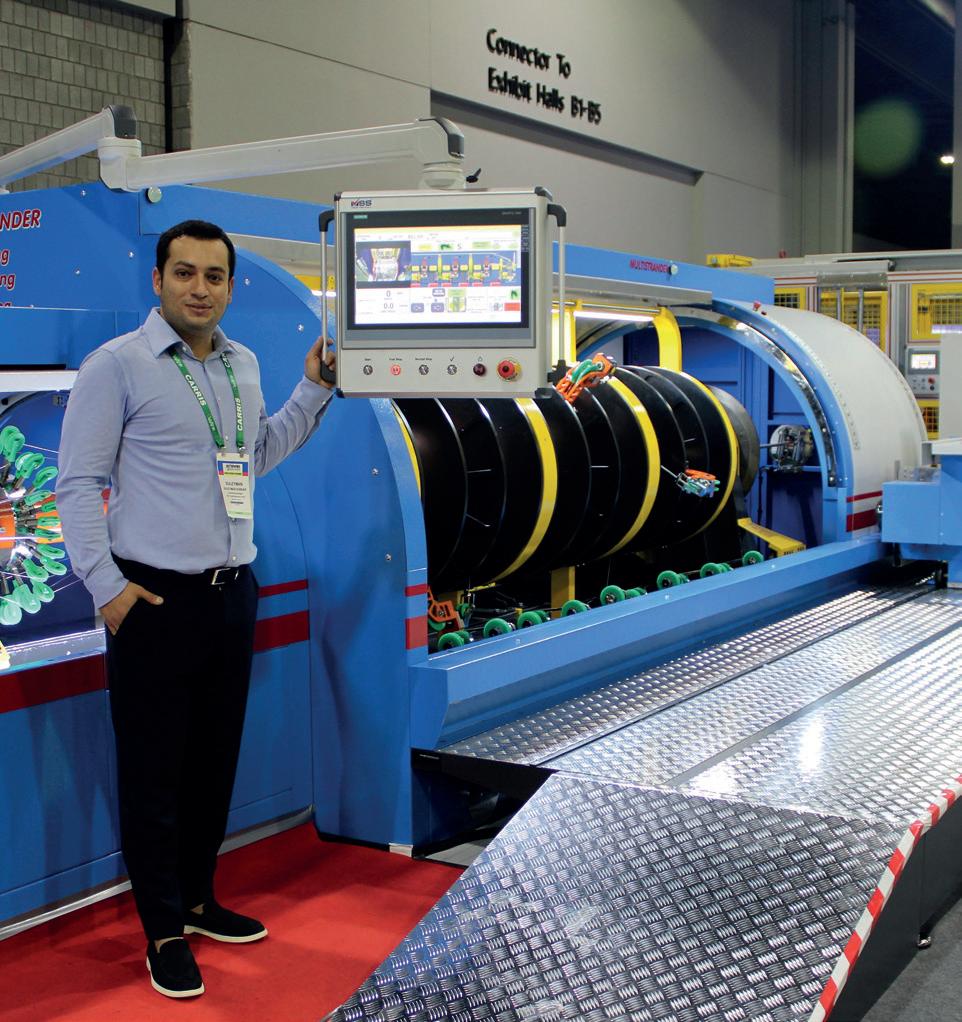

At Interwire, MSS Cable Machinery showcased its innovative Multi Strander—a high-performance central strander built for demanding cable production environments. A key is its dynamic tension control system that ensures exceptional process stability. This enables precise and repeatable stranding, screening and armoring operations, even at high speeds or during rapid emergency stops, without sacrificing product quality. The photo shows its ability to work with flat wire.

Powered by advanced Siemens-based automation and optimized motion control, the Multi Strander supports true tandem operation: stranding continues seamlessly while a new reel is loaded, maximizing uptime and minimizing manual intervention. This feature greatly enhances workflow continuity, making the system ideal for continuous or high-mix production.

The Multi Strander sets a benchmark for daily output in its class, processing sensitive materials with consistent quality and high throughput. Its energy consumption is impressively low—an important advantage for cost-conscious, sustainability-focused manufacturers. Rapid stop-and-hold functionality preserves tension in any operating state, ensuring product integrity and reducing waste. Intelligent feedback systems and real-time diagnostics provide operators with a streamlined, reliable, and efficient production experience.

Backed by over 25 years of Turkish-German engineering expertise, the Multi Strander is now in use across Europe, Asia and the Americas. Its modular, low-maintenance design makes it a future-ready solution for cable manufacturers seeking reduced downtime and improved quality, flexibility and operational control. “Engineered to strand smarter— not harder.”

Contact: Sales Tel: 405-672-0000 sales@reelpowerind.com www.reelpowerind.com

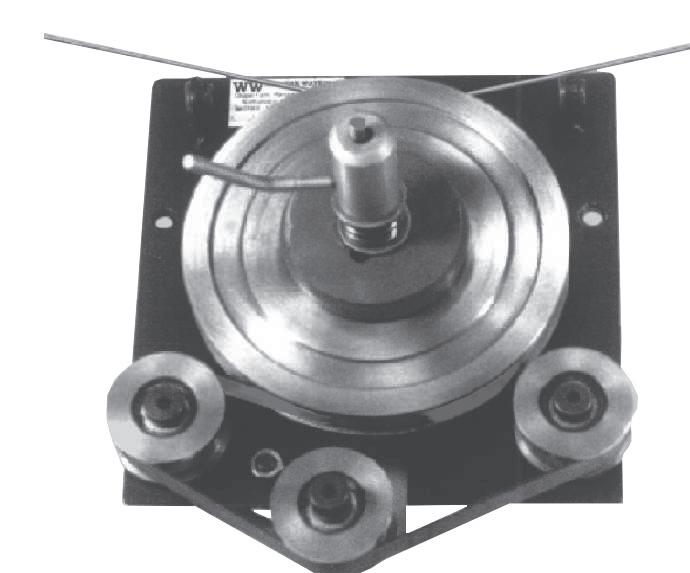

At Interwire, U.S.-based Reel Power Industrial Inc., a leading designer and builder of high-precision automated coiling, spooling, and winding equipment, displayed its new tire-driven, gantry-style shaftless take-up for reels.

The new model from Reel Power offers new innovative features and options that address industry demand. Its new equipment addition is designed for the smooth, even take-up of materials — from fiber optic cables to electrical power cables. It is perfect for heavy-duty applications and optimized for handling large reels (60 in. to 96 in., 60 in. wide, with a max weight capacity of 30,000 lb. Other capacities are available, and equipment can be customized to application requirements.

Key new model features include: advanced drive systems – main and traverse; optional AB dual 5 hp 480 V 3-phase 60 Hz AC Vector tire drive for speed, torque, or dancer-controlled operations (0-30 rpm); Allen-Bradley automatic traverse drive system ensures constant traverse speed for high-quality level-wind, digitally programmable for materials up to 3.0 in. diameter; portal ground drive system for reduced fleeting angles; improved safety by eliminating drive pins; floating pintle design for reel alignment; and both maintenance- and user-friendly.

Reel Power Industrial notes that it continues to evolve, including taking automation to the next level. The company’s automated take-up machines now leverage Al vision technology to deliver precise and consistent tension control while winding material onto spools or coils.

With over 100 years of combined manufacturing experience, Reel Power provides solutions to some of the largest companies in the transportation, communications, energy, and medical industries. Based in Oklahoma City, Oklahoma, it has a second facility in Houston, Texas.

Contact: Sales Tel. 815-624-2500 sales@rmgwire.com www.rmgwire.com

From l-r, RMG’s Bill Duenwald, Troy McCabe and Alex Kilby.

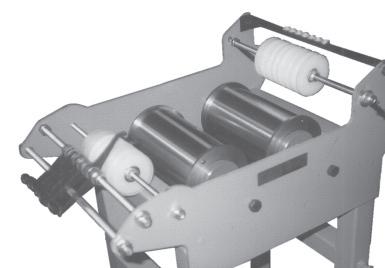

At Interwire 2025, U.S.-based RMG, a leader in the wire processing industry for almost 50 years, continues its reputation as a pioneer in the industry by introducing innovative new concepts for the company’s straighten-and-cut product lines. These include the patented clutchless cutting technology, Industry 4.0 and the Micro-Fine adjusting release. The 5SV16 model (pictured) has all the latest features including the variable frequency drive technology allowing independent control of feed, arbor and cutting systems. It can process wires from 0.062 in. to 0.315 in. and is well-suited for high-volume industrial applications.

RMG has developed new tooling for the Lewis product line that furthers the potential of its well-known Lewis Machine brand of straighten-and-cut machines. The new tooling reduces both lead time, cost, but still maximizing productivity while maintaining the longevity and consistency Lewis tooling is known for, providing a cleaner cut while accurately controlling length. The 5SV16’s five-die arbor handles sizes from 0.062 in. to .315 in. for low to medium carbon steels, stainless steels, and alloys, with a tensile strength of 90 ksi or less.

Industry 4.0 provides data collection/recipe management for up to 500 different jobs. Additional storage allows an unlimited number of recipes and monitoring (production rate, speeds, quantities) can be done in the plant or remotely with a cell phone.

RMG supplies customers with dependable service and support for all of its product lines. For payoffs, wire drawers, descalers or straightenand-cuts, we are the only OEM for RMG, Fastener Engineers, Lewis Machine and G.C. Patterson equipment and tooling. Your only source for certified tooling, spare parts and technical support.

Contact: M. Murali Das (pictured) Tel. 770-568-1230

murali.das@rosendahlnextrom.com www.rosendahlnextrom.com

ROEX extruders are the heart of every Rosendahl Nextrom extrusion line. The latest generation, combining advanced engineering, efficiency and adaptability, is ideal for wire and cable insulation and jacketing.

Equipped with a compact motor gearbox featuring innovative extruder drive technology, the machines provide uniform load transmission. Its optimized processing unit and dedicated screw and feeding section minimize the influence of counter-pressure fluctuations for high linearity across the entire operating range, ensuring consistent product dimensions and stable, high-quality results at faster production speeds.

The water-cooled compact motor gearbox and feeding section maintain precise temperature control. The plant water, separate from the coolant in the independent cooling system, prevents contamination in the water channels and reduces maintenance. Other series advantages include a quieter system, less energy use and a smaller footprint.

Rosendahl extruders are designed to last and offer high flexibility. Thanks to interchangeable feeding sections, you can easily adapt your extruder to process new materials when needed. This ensures the extruder remains adaptable to meet evolving demands in the future.

ROEX extruders can process a wide range of materials and are suitable for high-quality physical foaming and silicone extrusion. The series also includes high-temperature extruders which can withstand up to 450°C to produce heat- and extreme mechanical-resistant cables.

Rosendahl designs, develops and produces the extruder, crosshead and all extrusion tools entirely in-house. This perfect clockwork from one supplier reduces variables and minimizes potential risks for manufacturers. All Rosendahl machines are 100% tailor-made in Europe and can be customized to individual requirements.

Contact: Gustavo Astorquiza, Tel. 905-660-8800

sales@roteqmachinery.com www.roteqmachinery.com

Roteq Machinery designs and builds a comprehensive range of cable production machinery to meet the evolving needs of customers. Every machine we produce is backed by decades of industry experience, a deep commitment to innovation, and a passion for helping our customers succeed. At Interwire, we showcased our new strip armoring machine (pictured). The “new and improved” V24 model for 2 in./50 mm strip armoring offers multiple desirable features. Those include:

• A robust enclosure designed for maximum durability, security and lubricant containment, featuring structurally reinforced plate doors with pneumatic locking and sealing systems

• Fully electronic control of strip tension, strip feed, rotor rotation and line speed using AC motors and drives

• No slip rings. This eliminates associated maintenance

• Spring-actuated/pneumatic release coil chuck

• No rotary air seals, this eliminates maintenance associated with them

• A metered and controlled strip lubrication system

• Advanced oil mist extractor/separator exhausts through HEPA filter

• Rigid piping of exhaust to mist eliminator

• On-line and off-line tooling set-up jigs for fast and repeatable set-ups

• PLC process control with recipe capabilities/Ethernet connectivity

Ready to expand or upgrade? If you’re only familiar with our armoring solutions, now is the perfect time to explore how our broader product range can support your full product line. Whether you’re planning a new facility, upgrading existing lines or diversifying your product capabilities, we’re here to help.

Kinrei of America

Joshi

tel. 973-677-9500, djoshi@kinreiusa.com www.kinreiusa.com

At Interwire, Kinrei of America, which represents India’s Supermac Industries, displayed its newest innovation in physical foam extrusion technology. The state-of-the-art triple layer SkinFoam-Skin extruder setup for CAT-7 production generated a lot of interest around Supermac’s foam extrusion technology. The advantages of the technology include:

• Precision engineering for CAT-7 application. This maintains tight tolerance ranges required for high-performance copper cable insulation. It ensures consistency and reliability in demanding data transmission environments.

• High-speed data performance. This is achieved by an advanced gas dosing system delivers fine, uniform foam structure. This supports minimal signal loss and optimal high-frequency performance.

• Modular and flexible production. This allows both solid and foamed insulation to be produced on the same extrusion line. The scalable system design is tailored to varied manufacturing requirements.

• Automated gas flow regulation and integrated mass flow control unit. This adjusts the gas flow dynamically. This ensures stable operation and consistent product quality throughout.

• Support. The turnkey solution includes not just machinery but comprehensive support from installation to after-sales service.

Contact: Benjamin Roberts, sales manager Tel. 800-241-4311, cell 978-660-0599 broberts@thermoplasticseng.com wwww.thermoplasticseng.com

Since 1986, TEC has been well known in the wire and cable industry for building robust, reliable extrusion machinery. Under new ownership, the company has remained true to that legacy while pushing forward with a renewed focus on precision and efficiency. By bringing key operations in-house—including laser cutting, sheet metal bending, welding, and machining—we have strengthened our control over quality and enhanced every aspect of our manufacturing process.

At Interwire 2025, TEC showcased one of the company’s newly refined machines: a horizontal high-temperature extruder, the very type that formed the foundation of TEC’s inception. Built with motors and gearboxes known for their durability and designed to maintain consistent heat across all zones, these machines are engineered for customer-specific applications. While the displayed machine was tailored for FEP, TEC also provides equipment for polymers such as PVC, nylon, PE, and TPU.

Decades of refinement have shaped TEC’s systems to meet the rigorous requirements of high-throughput, zero-defect production environments. Each machine is engineered with reliability at its core to minimize downtime and maximize performance. From proven screw designs that ensure stable flow and uniform insulation, to modular controls that integrate seamlessly with customer operations, the equipment reflects smart, disciplined design. What sets TEC apart is its commitment to customers. We work with cable manufacturers to deliver customized solutions that align with specific materials, speeds and product goals. Whether it’s jacketing, insulation, or fiber-optic cable processing, our extrusion technology is built to adapt, ensuring consistent results without compromising efficiency.

Exhibiting at Wire Expo 2026 is your chance to share your products, innovations, and markeing message with valuble customers and new prospects from the Greater Milwaukee region.

Convenient travel and simple setup help you focus on what matters most. Discover shared interests. Build prized relationships. And be present when interaction leads to action. Wire Expo booth sales begin 10/2/25*

*Exhibit space is assigned based on accumulated points from past participation. Want to set your place at Wire Expo 2026? Contact sales@wirenet.org.

Bonus: Wire Expo 2026 is co-located with: 2026