At COPPERWORKS™, we’re proud to provide copper rod and wire that’s sustainably manufactured right here in America. No matter what happens in the international market, our innovative refining process lets us pull from the domestic “modern mine,” utilizing a steady, reliable supply of 100% recycled copper. Our ability to utilize a variety of virgin, pre- and post-consumer copper inputs makes us a dependable partner for high-performance copper that’s made in the heartland and used in all 50 states—and beyond.

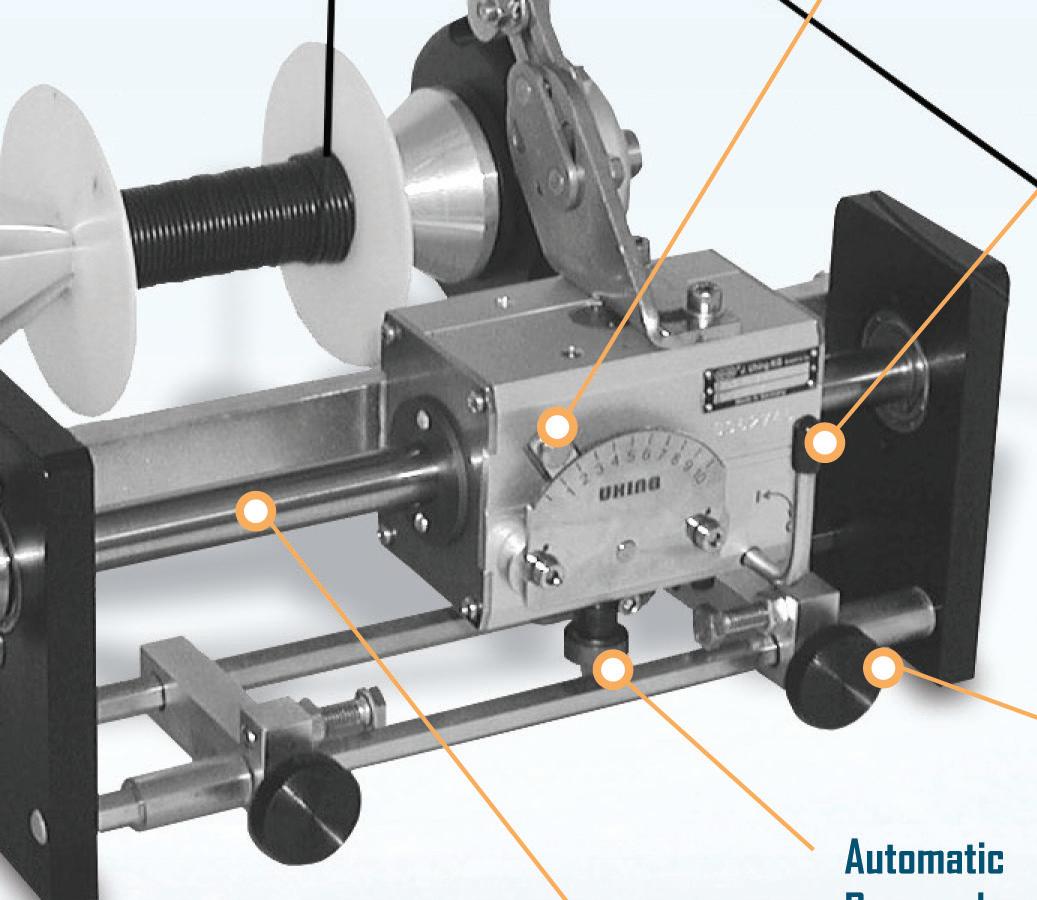

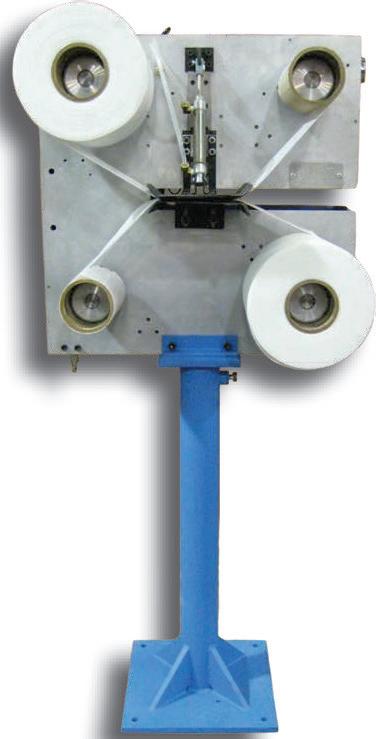

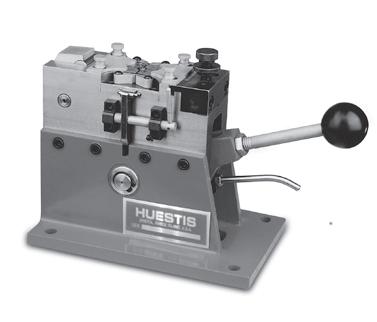

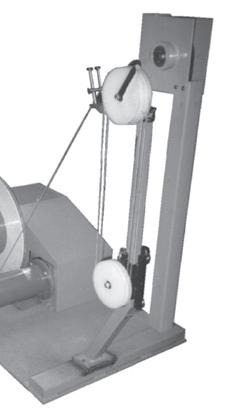

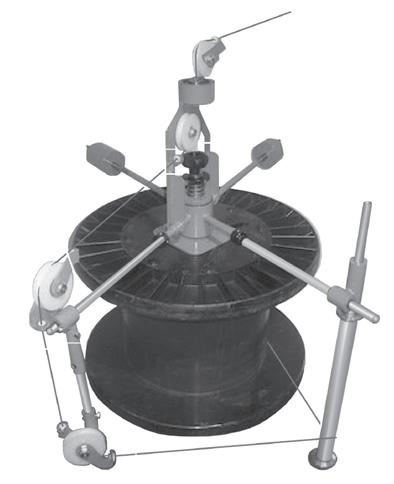

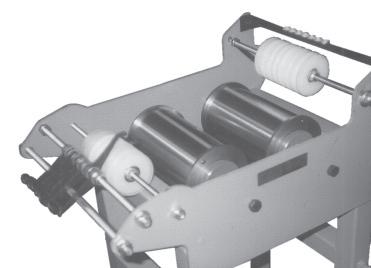

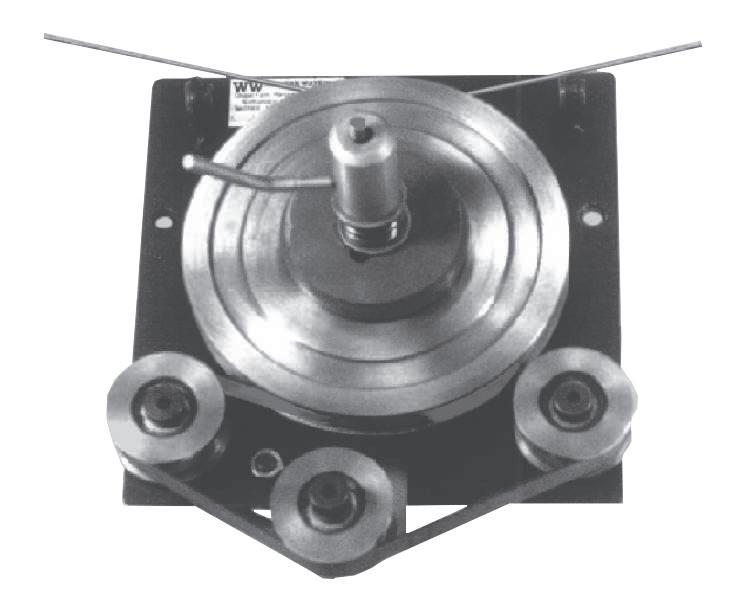

An economical way to remove copper dust, excessive oil lubricant, dirt, and dust from primary wire or strand

• Stranding & Cabling Lines

• Take-Ups / Pay-Offs / Coilers

• Fully Automatic Re-Wind Lines

• Complete Extrusion Lines

WIRE RANGE: Up to 0.098 in. (2.5 mm.) diameter

MAX. F/M: Approx. 8000 ft./m.

MATERIALS: Ferrous or nonferrous material / tinned, bare, or plated

FLOOR SPACE: 18” x 27”

• Reduce Spark Faults

• Improve Insulation Bond

• Easy to Install

• Improve Insulation Concentricity

• Increase Pre-Heater Sheave Life

• Environmentally Friendly

Single and multi-wire induction coil furnaces

Induction heating process of one wire or multiple wires in parallel, granting processing capability at various speeds, in line and offline. Maximum flexibility and efficiency thanks to Inductions M-SYS technology through the independent power regulation of each heating coil.

• Ultrasonic, Wet Blast, and Various Mechanical Cleaning Systems

• Drum Packers, Air Wipes, and Taping Lines

• Forming / Welding / Sizing Lines

• Wire Drawing and Shaving

• Semi and Auto Re-Spooling

feature returns with a range of observations and perspectives on this most vital of all industry essentials.

Masataka Tabuse, Hirotaka Koriki, Tomoaki Gonohe, Masuru Nakajima, Masamichi

Jerry Swantek, 87, who worked a remarkable 65 years at Specialty Cable Corporation, was honored by the Connecticut aerospace wire and cable manufacturer, which recently celebrated its 100th year. “Working with and mentoring great people over the years helped keep me going. ... I consider SCC my second home,” he said. From l-r are CT CMO Paul Lavoi, Swantek, SCC owner Carl Shanahan and SCC CEO Kim Bowen.

It wasn’t just the backdrop of a stunningly perfect day that made the WAI New England Chapter’s return to the Tunxis Country Club in Farmington, Connecticut, so memorable for the 143 golfers. The Lloyd & Bouvier team of Michael Tucker, Darren Tucker, Joe Yabba, and Gibson Yabba prevailed, but they weren’t the only winners: the raffle at the awards dinner raised nearly $4,000 for the scholarship fund.

EXP1538

6”, 24:1 D-S Thermatic II Extruder

TKU1796

84” Bartell Rebuilt S/L Takeup

CBR1481 – 42” WMCA Cord Twister Line, Conc Taper, AB PLC

CBR1473 – 630mm Ceeco 24W (12/12) Planetary Cabling Line

CBR1470 – 560mm Watson/Kinrei DT Buncher, Model TM-560 (11)

CBR1457.5 – Northampton 600/630 Triple Twist Twinner (6)

CBR1452 – 48” Ceeco Drum Twister, Swing Out Traverse

CBR1448 – Tensor SZ Oscillator, OSC-1500-15, 3000RPM

CBR1431 – 760 mm Watson/Kinrei DT Buncher, Model NB-760 (7)

CBR1353 – 30” Ceeco Planetary Line, 12+18, Dual Ecc Taper, 84” TU

CBR1269 – 630mm Mali 1+3 Bow Cabler Line

CBR1157 – 31” Ceeco 37W Rigid/Tubular Stranding Line

TBR230.2 – 10” Bartell Tubular Strander, 6W, Outside Model 6B64 (7)

TPR484 – Edmands 4 Head Concentric Taping Line

TBR220

6.5” Bartell 18W Tubular Strander

CBR1468

40” Watson 6W Planetary Line

EXPL504 – 1½” Davis Std.Hi Temp Extrusion Line

EXPL503 – 2½” Davis Std.Hi Temp Extrusion Line

EXPL502 – 2” Sterling Primary Line, 24” PO, 18” Auto Dual TU

EXPL501 – 6”/4.5” Battenfeld Glouster Dual Wire Primary Foam Line

EXPL499 – 2½” TEC Optical Fiber Sheathing Line, 84” PO/TU

EXPL498 – 3½” Davis Std Optical Fiber Sheathing Line, 84” TEC PO/TU

EXPL370 – 75mm Meltech/Boston Matthews Silicone Extrusion Line

EXP1488 – 4½” Davis Std, 24:1 Extruder, Therm III, 150 HP DC

EXR212 – 3½”Davis Std 15:1 Rubber Extruder, Therm III (3)

EXR205 – 4½” Davis Std 20:1 Rubber Extruder, Thermatic II, Rebuilt

WRD1169 – SAMP MS/400 Rod Breakdown Line

WRD1123 – Henrich 13 Die Rod Line, w/Annealer, Bongard Coiler

The Aug. 22 abrupt federal stop-work order on Revolution Wind—a $6 billion offshore wind project that was 80% finished—roiled the U.S. offshore wind supply chain and its companies. Nearly completed, the 704 MW Ørsted project for the New England grid had moved through years of permitting, investment and infrastructure buildout.

State and industry officials described the halt, issued for vague “national security interests,” as having the flimsiest of justifications, with no cited law violation or imminent risk. Revolution Wind had secured all required state and federal permits, passed exhaustive reviews and was months from completion. Legal challenges by Connecticut and Rhode Island described the explanation as “baseless.” Observers in The New York Times described stopping a fully permitted project at this stage as “virtually unheard of” in U.S. infrastructure history.

On Sept. 21 a federal judge lifted the order, rebuking its “arbitrary and capricious” reasoning and restoring project momentum. The episode is a gut-check, not just for Ørsted—which saw its stock price fall 16%—but for the cable industry as a whole. The drive for renewables made the subsea power cable market more desirable, spurring projects like LS GreenLink USA’s $700 million cable plant in Virginia, Nexans’ expansion in Rhode Island and investments by Hellenic Cables. Prysmian, which had selected Massachusetts for a new subsea cable plant, backed out of that plan in January, citing market uncertainty, a blow to the sector. Now, there’s uncertainty for already-placed orders for submarine cable, specialty ships and installation agreements.

Analysts at Jefferies called the move “another setback for Ørsted and the U.S. offshore wind industry.” S&P and other agencies have already downgraded credit outlooks for major project owners, with financial impacts rippling down the chain. The suspension also coincides with federal pauses on new wind leases and re-reviewing previous approvals—forcing companies to plan in an environment best described as “uncertain.”

Recent articles in Factor This and Oceantic Network warned this reversal could lead to inefficiencies, supply chain relocations and lost opportunities for standardized turbine and cable manufacturing. Even if the situation stabilizes, S&P Global observes the industry should expect “further small impairments” and more cautious capital deployment in coming years.

It looks and feels like a lose-lose situation, hard to fit into any company’s long-term plan.

Mark Marselli Editor-in-Chief, editor@wirenet.org

PUBLISHER Steven J. Fetteroll

EDITOR-IN-CHIEF Mark Marselli

GRAPHIC DESIGNER Charlotte Ashley

DIRECTOR OF SALES Shannon Timme

DIRECTOR OF INTERNATIONAL SALES & BUSINESS DEVELOPMENT

Anna Bzowski

DIRECTOR OF MARKETING & CORPORATE COMMUNICATIONS

Janice E. Swindells

WAI PUBLICATIONS COMMITTEE

Dane Armendariz, consultant

Ferruccio Bellina, TKT Group/President ACIMAF

Michael Crowle, QED Wire Lines Inc.

Tom Moran, consultant

Giulio Properzi, Continuus Properzi

Willem Sundblad, Oden Technologies Inc.

John N. Tomaz, Stolberger

Robert Wild, Niehoff Endex North America

W.T. Bigbee, Encore Wire Corp.

TECHNICAL ADVISORS

John Drummond, Scotia Group

R. M. Shemenski, RMS Consulting, Inc.

Images: Adobe Stock.

Wire Journal International (ISSN-0277-4275) published monthly by The Wire Journal, Inc., is a wholly owned subsidiary of The Wire Association International, Inc., which is located at 71 Bradley Road, Suite 9, Madison, CT 06443-2662, USA, and can be contacted at tel. 203-453-2777; fax 203-453-8384; Internet wirenet.org; e-mail editor@wirenet.org. Address all correspondence concerning advertising production, editorial and circulation to the above address. WJI is printed in the USA.

Subscription rates: $110 per year, USA; $120 per year, Canada and Mexico; other countries, $140 per year (includes air mail). Back copies: $10 WAI members, $15 non-members. Periodicals postage paid at Madison, CT 06443, USA, and at additional offices.

Wire Journal International grants photocopy permission to libraries and others registered with Copyright Clearance Center (CCC), 21 Congress St., Salem, MA 01970, USA, for a fee of $0.50 per article. Payments should be sent directly to the CCC. Requests for bulk orders or reprints should be sent to the Wire Journal International, 71 Bradley Road, Suite 9, Madison, CT 06443-2662, USA.

© 2025 by Wire Journal, Inc. All rights reserved. The Publisher of WJI assumes no responsibility for the validity of manufacturers’ claims made herein. Back issues of WJI are on microfilm and available from University Microfilm, 300 North Zeeb Road, Ann Arbor, MI 48106, USA. Phone: 313-761-4700.

POSTMASTER: Send address changes to Wire Journal International, 71 Bradley Rd., Suite 9, Madison, CT 06443, USA.

ROEX extruders are high-performance machines for cable insulation and jacketing. They are equipped with an innovative motor drive concept and can be customized to suit your specific requirements.

Choose the latest extruder technology for your next project and benefit from:

• High flexibility for different materials

• Consistent linear and high output

• Minimized energy consumption

OCT. 14, 2025: Wire & Cable Kraków 2025 Kraków, Poland. This event is organized by ACIMAF, the AGH University of Kraków, IWMA and WAI. The event website is www.wirecable25.com. See p. 38.

OCT. 27-30, 2025: 74th IWCS Cable & Connectivity Industry Forum

Pittsburgh, Pennsylvania, USA. Contact: IWCS, tel. 571-265-3657, www.iwcs.org. WAI will be exhibiting at this event, so look for us there. See p. 40.

NOV. 4-6, 2025: Cable & Wire Fair 2025

New Delhi, India. This event is to be held at the Pragati Maidan. Contact: Tulip 3P Media Pvt. Ltd.: tel. +91-01244250148, info@wirecable.in, www.cablewirefair.com. See p. 41.

APRIL 7-9, 2026: World Copper Summit Santiago, Chile. This event is organized by the CRU Group. More information and registration will be available at a later time at www.events.crugroup.com/copper/homes, and conferences@crugroup.com.

APRIL 13-17, 2026: wire Düsseldorf

Düsseldorf, Germany. To be held at the Messe Fairgrounds. Contact: Messe Düsseldorf North America, tel. 312-781-5180, info@mdna.com, www.mdna.com.

MAY 6-7, 2026: Wire Expo & 96th Annual Convention

Milwaukee, Wisconsin, USA. To be held at the Baird Center— colocated with the Electrical Wire Processing Technology Expo (EWPTE)—this WAI event includes the Fundamentals of Wire Manufacturing Course on May 5, 2026.

SEPT. 21-24, 2024: wire China Shanghai, China. This event will be held at the Shanghai New International Expo Centre (SNIEC). Contact: Messe Düsseldorf/Messe Düsseldorf (Shanghai) Co., Ltd., www.wirechina.net, www.mdna.com.

OCT. 7-9, 2026: SpringWorld Expo and Symposium Rosemont, Illinois, USA. This event, presented by the Chicago Association of Spring Manufacturers, Inc. (CASMI), and the Symposium, presented by the Spring Manufacturers Institute (SMI), will be held at Donald E. Stephens Convention Center. Contact: CASMI, tel. 414-908-4963, info@casmi-springworld.org, www.springworld.org.

OCT. 14-17, 2026: 75th IWCS Cable & Connectivity Industry Forum

Providence, Rhode Island, USA. To be held at the Rhode Island Convention Center. Contact: IWCS, tel. 717-9939500, www.iwcs.org. WAI will be exhibiting at this event, so look for us there.

NOV. 30-DEC. 2, 2026: Wire India

Mumbai, India. This event, organized by Messe Düsseldorf India Pvt. Ltd, will again be held at the Bombay Exhibition Center (BEC), also known as the Bombay Convention & Exhibition Center (NESCO). Contact: Messe Düsseldorf North America, tel. 312-781-5180, info@mdna.com, www.mdna.com.

MAY 4-6, 2027: Interwire & WAI’s 97th Annual Convention

Atlanta, Georgia, USA. To be held at the Georgia World Congress Center, this event includes the trade show, technical programs and WAI’s 97th Annual Convention.

OCT. 16, 2025: Southeast Chapter Annual Golf Outing Conover, North Carolina, USA. The Southeast Chapter’s annual tournament will return to the Rock Barn Country Club & Spa.

MAY 6-7, 2026: Wire Expo & 96th Annual Convention

Milwaukee, Wisconsin, USA To be held at the Baird Center— colocated with the Electrical Wire Processing Technology Expo (EWPTE)—this WAI event includes the Fundamentals of Wire Manufacturing Course on May 5, 2026.

MAY 4-6, 2027: Interwire & WAI’s 97th Annual Convention

Atlanta, Georgia, USA. To be held at the Georgia World Congress Center, this event includes the trade show, technical programs and WAI’s 97th Annual Convention.

For more details, go to “events” at www.wirenet.org, then choose “chapter events.”

Denmark’s NKT has signed a contract with Energinet to deliver an HVDC power cable system for the offshore interconnector linking the Bornholm Energy Island to the power grid on Zealand.

A press release said that Energinet, a Danish transmission system operator (TSO), selected NKT to provide the 525 kV high-voltage direct current (HVDC) on- and off-shore power cable systems for the Danish connection to the Bornholm Energy Island. The contract, valued at approximately $757 million, includes the design, manufacture and installation of a power cable system that includes a 200 km offshore route and a 16.8 km onshore route.

NKT will produce the power cables at its high-voltage factory in Karlskrona, Sweden, and is located close to the installation site. Bornholm Energy Island is a landmark renewable energy project located in the Baltic Sea, designed to receive up to 3.8 GW of offshore wind power from planned offshore wind farms. The energy will be transmitted to Germany and Denmark via two HVDC offshore interconnector systems.

With this award from Energinet, NKT will connect the energy island to both the Danish and German power grids. This follows the turnkey contract awarded to NKT in 2023 as part of a large framework agreement with German TSO 50Hertz to connect the island to the German grid.

“Bornholm Energy Island is a key project for Europe to enhance energy security and the exchange of renewable energy,” said NKT President and CEO Claes Westerlind “With this award, we reaffirm our strong commitment to building the sustainable and secure energy infrastructure Europe needs, and demonstrate our proven high-voltage power cable capabilities.”

Offshore installation is planned to be carried out by the new vessel, NKT Eleonora, which is currently under construction. Once operational in 2027, the vessel will be one of the most advanced and fuel-efficient cable layers in the industry.

The Rhône Group, a U.S.-based global private equity firm, has acquired Copperweld Bimetallics (Copperweld) from Kinderhook Industries for an undisclosed price.

A Sept. 9 press release from Kinderhook—which acquired Copperweld in 2019 from THL Credit Advisors— reported the sale. Copperweld, founded in 1915, was described as the sole U.S. manufacturer dedicated to copper-clad (CCS) and aluminum-clad (CCA) wire. Its products are used in building wire, utilities, infrastructure, renewable energy and mobile technology markets.

Based in Fayetteville, Tennessee, Copperweld’s business includes additional plants in Texas and the U.K., and a distribution center in Belgium, with total employment near 400. Copperweld will continue to operate under its current management.

Kinderhook noted that during its ownership, Copperweld grew into a $65 million business by scaling operations and acquisitions, which included the 2020 purchase of Seminole Wire & Cable Co. Kinderhook continues to hold two distributors of wire, Kingwire and Cameron Wire & Cable, the latter of which also provides value-added services.

The Rhône Group is a global private equity firm with about $11 billion in assets under management, specializes in middle-market and larger investments across industrials, consumer, energy, materials, and healthcare sectors. This marks its lone activity for wire and cable.

Hellenic Cables, the cables segment of Cenergy Holdings, has been awarded a turnkey contract from a Greek state-regulated entity for a new 150 kV cable interconnection between Igoumenitsa and Corfu.

A press release said that the strategic project includes the design, manufacturing, installation and commissioning of 18 km of submarine and 13 km of underground

cables to further reinforce the reliability and capacity of the national power grid. The order is from the Independent Power Transmission Operator (IPTO), which is responsible for operating, maintaining, and developing the Hellenic Electricity Transmission System. It oversees some 11,000 km of transmission lines across mainland Greece and the islands.

Igoumenitsa is a major port city in northwestern Greece, while Corfu is a Greek island just offshore in the Ionian Sea, near the Albanian border. The cable will be made at the company’s facilities in Corinth and Thiva. “We are proud to support IPTO in enhancing Greece’s energy infrastructure,” said Hellenic Cables General Manager Kostas Savvakis. “This project is another milestone in our journey of engineering excellence and innovation.”

Last November, IPTO awarded Hellenic Cables a turnkey contract for 38 km of 150 kV XLPE underground and submarine cables to enhance the electrical interconnections between Kefalonia-Zakynthos and Lefkada-Kefalonia, the Ionian islands in Greece. In

Hellenic Cables has won a repeat order from IPTO for the Greek national power grid.

2023, the company announced an €80 million investment program focused on expanding its submarine cable production capacity at the Corinth plant and upgrading land cable output at Thiva.

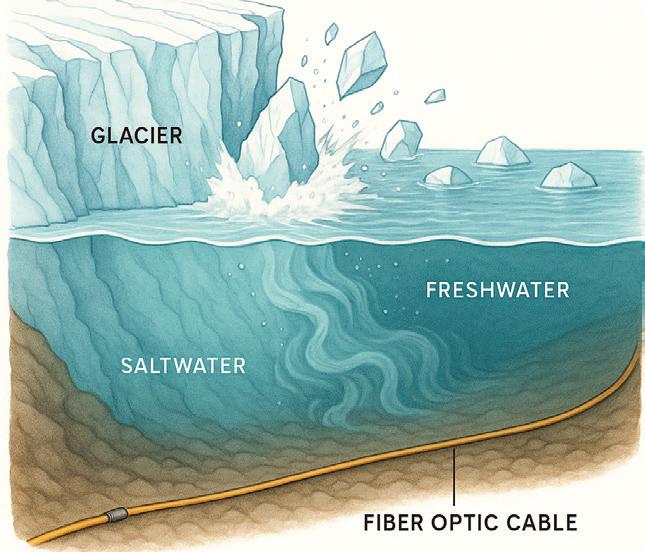

A Sept. 5 essay in Grist (www.grist.com) by Matt Simon told how an ordinary fiber optic cable became a vital research tool, one able to reveal the hidden forces driving Greenland’s rapidly retreating glaciers. Passing on satellites or dangerous fieldwork near collapsing ice, the simple cable, paired with distributed acoustic sensing technology, captured the glacier’s secret, as outlined below.

Researchers set out to understand why Greenland’s glaciers are retreating so rapidly by stringing six miles of fiber optic cable, equipped with distributed acoustic sensing (DAS), along a glacial calving front—the dramatic boundary where enormous ice slabs break away and tumble into the fjord below.

Unlike its traditional use in telecommunications, this cable’s role was to capture the subtle and violent vibrations of glacial activity, constantly translating both routine internal fractures and colossal ice falls into a continuous stream of data. Every movement along the cable yielded a unique signature, enabling scientists to tell apart small, everyday cracking from catastrophic collapses as well as the underwater waves that these events generated.

The truly revelatory insights came from below the waterline. As the days passed, the cable detected that each time a massive iceberg detached and plunged into the fjord, it stirred up immense underwater waves capable of mixing cold fresh meltwater that usually floats atop warmer, saltier water. Ordinarily, this stratification acts as a protective barrier, keep-

ing the glacier insulated from the ocean’s heat. But these underwater waves, set off by calving, disrupted that separation, heaving up deeper, warmer water and pressing it against the glacier’s front—resulting in faster and more extensive melting.

This feedback loop startled scientists: the act of calving itself—once thought to be mostly a symptom of melting—also accelerates the process, as each dramatic ice fall further churns the fjord and speeds the glacier’s retreat. By using the DAS-enabled fiber optic cable, researchers gained a safe, efficient and unbroken means of monitoring these invisible and hazardous phenomena, providing a vital new window into the hidden forces driving ice loss in Greenland’s vulnerable coastal glaciers.

LS Cable & System has won a contract valued at approximately $115 million to supply submarine cables for the Formosa 4 offshore wind project in Taiwan.

A press release said that the order from project developer Synera Renewable Energy, calls for the delivery of submarine cables by 2028, when installation will begin. The specific types of cable and how many km were not disclosed, but such projects usually call for inter-array cables to connect the wind turbines and the offshore substation, and from there export cables to connect that to onshore grid connection points, typically at a much higher voltage. Previous similar LS Cable orders for Taiwan offshore wind have included both 66 kV inter-array and 220 kV export cable packages.

The Formosa 4 wind farm will be located about 18 km off the coast of Miaoli County, in western Taiwan, and is expected to have a capacity of 495 MW once operational. The wind farm will use 35 turbines and will require both offshore and onshore substations.

The deal represents LS Cable’s 10th consecutive offshore wind cable order in Taiwan since first entering the market in 2019, continuing its involvement as a major cable supplier in the region’s energy transition initiatives. The company previously supplied cables for eight projects in Taiwan’s first phase of offshore wind development, and with this latest contract has now secured early orders in the second phase for both the Fengmiao and Formosa 4 projects.

Company representatives attribute their successful run in Taiwan to continued collaboration with leading global renewable energy developers and a strengthening track record for project execution.

To celebrate its grand opening, Southwire recently held a ribbon-cutting ceremony at the company’s new industrial plant in Bremen, Indiana, that was attended by company team members, executives and representatives from the Bremen community.

A press release said that Southwire began operating in Bremen in 2014, and that its campus now consists of four manufacturing facilities that cover a combined 1.4 million sq ft. The location primarily serves Southwire’s utility and industrial businesses, supporting some of the company’s largest customers. With the addition of the new Bremen industrial building to the campus—spanning approximately 428,000 sq ft—Southwire continues to grow and further support its markets and customers.

The state-of-the-art facility gives Southwire the opportunity to support a wide variety of growing vertical markets. These include industrial, telecom, data center, and factory automation sectors. “It’s been amazing to see the Bremen Industrial plant come to life thanks to the hard work of the Southwire team and the support of our community partners,” said Niles Voelkel, Bremen plant manager. “We’re incredibly grateful to everyone who helped make this happen.”

Southwire expects to hire around 55 team members this year to work at the facility, with plans for continued employment growth in the coming years. “Thanks to the talent, the community and the unwavering support in this area, we’re confident that Bremen will continue on a very positive trajectory,” said Clint Thompson, vice president of process technology and data optimization. “This campus is more than just a facility. It’s a testament to our commitment to innovation, modernization and, most importantly, our people. Bremen is a great place to be, and we’re excited about the continued success we’ll achieve together.”

NKT reports that the company was named the preferred bidder to provide the 525 kV high-voltage direct current (HVDC) power cable system for the interconnector Eastern Green Link 3 (EGL3).

A press release said that the joint venture project announced by SSEN Transmission and National Grid Electricity Transmission will link the power grids in Scotland and England, with a route length estimated to be about 680 km. The EGL3 project will connect Scotland and

England, and benefit Wales by reinforcing the resilience and flexibility of the wider Great Britain grid that operates across all three nations.

The long-distance subsea link will also help move clean power from areas of rich renewable generation, furthering the U.K.’s transition to a lower-carbon future. “Appointing NKT as preferred bidder ... marks a significant milestone for EGL3,” said EGL3 Deputy Project Director James Johnson. “The project will be vital in unlocking Scotland’s vast renewable energy resources, ensuring they can reach homes and businesses across Great Britain, while strengthening the resilience of the transmission network. This announcement is another important step as we work to deliver a network for net zero.”

Kris-Tech Wire has completed a multi-year upgrade of its Houston, Texas facility. The U.S.-based copper wire manufacturer began operations at the Houston site in January 2022. Since then, the company has expanded the facility by 60,000 square feet and increased its presence in the Gulf Coast and Midwest regions.

A press release said that, as part of the upgrade, KrisTech expanded its sales and customer service teams based at the Houston location, increased storm stock and

high-volume inventory and upgraded shipping capabilities. These improvements enable faster shipments, including critical materials for emergencies, with some deliveries occurring in as little as one to two days.

The warehouse carries Kris-Tech’s line of electrical utility and tracer wire products, as well as PV wire and cathodic protection cable. Custom orders continue to be produced at the company’s Rome, New York headquarters, but the Houston site can now ship key materials directly to sites within a day for certain requests.

Per the company, the Houston site’s location near Beltway 8 and I-45 allows for convenient customer pickups and rapid distribution to key regional markets. Founded in 1984, Kris-Tech manufactures wire products for the building, commercial, and utility sectors in the U.S.

JDR Cable Systems (JDR), part of the TFKable Group, has won a contract from Liverpool Bay CCS Limited to provide subsea power cables for the Liverpool Bay CO2 Transportation and Storage project.

A press release said that JDR will deliver approximately 100 km of 33 kV subsea cables to power repurposed offshore platforms in Liverpool Bay. The contract has four

cables: a primary one linking the shore to the first offshore platform, and three infield cables connecting multiple additional platforms. These platforms will be essential for the injection of CO2 into depleted offshore reservoirs, forming the backbone of the HyNet North West industrial decarbonization cluster.

The Liverpool Bay area, part of the Irish Sea between northeast Wales, Cheshire, Lancashire and Merseyside in northwest England, is a key location for offshore energy projects.

Hitachi Energy has announced a landmark investment of over $1 billion to expand its power transformer manufacturing capacity for critical electrical grid infrastructure in the U.S.

A press release said that a centerpiece of this investment plan is the construction of a new facility in South Boston, Virginia. It will be strategically located by an existing Hitachi Energy plant that makes transformers, allowing seamless integration between transformer manufacturing and cable production, both central components in the push to modernize and expand America’s electric grid.

Hitachi—through its subsidiary Proterial Cable America (formerly Hitachi Cable America)—owns and operates a cable manufacturing plant in Manchester, New Hampshire. This facility produces copper and fiber optic communication cables for the U.S. market, and it is the only large-scale communications cable manufacturing plant that Hitachi owns in the United States.

Governor JB Pritzker joined Manner Polymers, state officials and local leaders on August 28 to cut the ribbon on the company’s new $54 million, 108,000-sq-ft solar-powered manufacturing facility in Mount Vernon, Illinois.

A press release said that the new plant will expand the company’s annual production capacity by 80 million pounds. Its flexible PVC compounds are used for wire and

cable, hose and tube, profile extrusion, and sheet products. The plant has a 15-acre solar field, along with additional roof-mounted solar panels, designed to generate nearly all of the electricity the facility requires for its operations. It will provide some 60 jobs.

Manner Polymers CEO Raj Bhargava said that the company’s vision was clear when the expansion project was announced in 2023. That was to “build the lowest cost, highest quality, most environmentally sustainable flexible PVC compounding plant in the world. Not only will we incorporate the most advanced manufacturing control systems available, but we will also produce substantially all the electricity that we use.”

As part of the incentive package, the state of Illinois provided $2.5 million in infrastructure for a new rail spur, which provides direct access to Southern Illinois’ network of rail.

Bechem, Germany’s oldest specialty lubricant manufacturer with over 190 years of expertise, announced the acquisition of CLC Lubricants, a U.S.-based producer of industrial oils, metalworking fluids, and cleaners, effective Aug. 8, 2025.

A press release said that the strategic move establishes Bechem’s first wholly owned production facility in the U.S., located in Geneva, Illinois. It said that CLC Lubricants is a small, privately held company with approximately 23-35 employees and estimated annual revenue between $4.6 million and $5.7 million. The company, which operates from a 27,000-sq-ft facility in Geneva, Illinois, has been in business since 1976.

CLC Lubricants was described as having nearly 50 years of experience and a strong market position, holding ISO 9001:2015 certification, and deep technological expertise. The acquisition enhances Bechem’s global presence and furthers expansion of its footprint in North America following the establishment of Bechem Lubrication Technology in 2014 and Bechem Mexico in 2017.

The CLC Lubricants brand and product portfolio will be retained and complemented by Bechem’s offerings, ensuring continuity for customers. “We are excited to welcome CLC Lubricants into the Bechem family,” said a Bechem spokesperson. “This acquisition strengthens our ability to serve our loyal and future customers with an expanded portfolio, including cleaners and additional domestically produced oils, backed by our shared values of service and innovation.

Tele-Fonika Kable has secured a contract to supply the onshore export cable system for Poland’s BC-Wind offshore wind farm.

A press release said that the order from Ocean Winds calls for the delivery of approximately 23 km of 275 kV high-voltage cable, fiber optic cable and dedicated accessories. Based in Spain, Ocean Winds is a 50-50 joint venture owned by EDP Renewables and ENGIE that develops offshore wind farms worldwide.

Tele-Fonika Kable Board Member Piotr Mirek said that manufacturing is planned for the fourth quarter of 2026 at the company’s Bydgoszcz facility. Its responsibilities will also include comprehensive post-installation testing of the entire cable line.

The onshore section, approximately 8 km in length, will connect the landfall point in the Choczewo municipality to the new onshore substation, with construction scheduled to begin in 2026. The BC-Wind offshore wind farm will be located north of the Krokowa and Choczewo municipalities in the Pomeranian Voivodeship. Its capacity is planned to be up to 390 MW.

The project has obtained environmental permits for its onshore and offshore components as well as a Contract for Difference (CfD). The contract, while signed, is pending final approval via an obligatory final investment decision (FID).

Leggett & Platt (L&P) recently closed the sale of its Aerospace Products Group (APG), an entity outside of its wire production that makes highly engineered tube and duct assemblies for commercial and military aircraft, as part of the company’s ongoing restructuring that started in 2024.

A press release said that the sale of APG, which has seven manufacturing facilities in the U.S., U.K. and France, is expected to net $250 million. The company plans to use

most of those funds to pay down debt and strengthen the company’s balance sheet.

The sale was the latest news in a story that traces back to late 2023 when demand for both traditional innerspring bedding and wire grid components faltered. In January 2024, the company announced a sweeping plan in its annual report that called for at least 10 wire-focused plants—integral to the production of springs and mattress foundations—to be either closed or merged. A total of 20 overall plants were targeted.

Per financial media and company reports, the net result is that all wire production is now in four U.S. locations.

The latest L&P plant to be closed was the one in Plant City, Florida, where more than 80 employees were let go as operations wound down by the end of the midpoint of 2025. The L&P specialty springs plant in High Point, North Carolina, was closed in September 2024, affecting 158 workers.

Other closures include the Saltillo, Mississippi plant (130 jobs lost in 2024) and the Commerce, California facility (impacting 55 staff). In addition to those plants, four smaller spring and wire operations were consolidated into remaining regional hubs. The actions were deemed needed to improve efficiency, reduce costs and align production capacity with new realities of market demand.

L&P indicated that the final wave of restructuring will be completed by the end of 2025, with ongoing efforts to make its wire business leaner and better positioned for future growth.

Charter Steel has significantly expanded its steel wire production capacity in 2025 with a $22.8 million investment focused on its Fostoria, Ohio and Saukville, Wisconsin facilities.

A press release said that the expansion includes the installation of four new wire draw machines at Fostoria and one new draw machine at Saukville. The Fostoria facility was also expanded by about 42,000 sq ft. Three machines are already installed and in the validation phase, while two more are expected to be operational by early 2026.

The move was expected to triple Charter Steel’s wire draw output, supporting customer demand for comprehensive and reliable steel solutions. The upgrades are designed to allow customers to interact with a single, consistent team for the entire steelmaking process—from melting and rolling to processing and finishing—streamlining purchasing with “one-stop shopping” for finished products. The expansion will create about 15 new jobs at Fostoria to staff the additional wire draw machines.

Marlin Steel President Drew Greenblatt was presented the 2025 Metalworking Reshoring Award during an industry ceremony held September 11 in recognition of leadership in reshoring and domestic manufacturing. A press release said that the award, which recognizes companies that have successfully brought metalworking operations back to the U.S., was presented by the Reshoring Initiative in partnership with the Precision Metalforming Association (PMA), the Association for Manufacturing Technology (AMT), SME, the Fabricators and Manufacturers Association (FMA), and the National Tooling and Machining Association (NTMA).

Marlin Steel reshored multiple production lines from overseas, spanning industries including medical devices, food processing and aerospace. Even high-volume commodity items such as pail handles were reshored by applying advanced automation, consistent quality control, and dependable turnaround.

One cited example was that of a U.S.-based buyer who previously sourced from Mexico that moved production of 1,500 custom wire racks to Marlin’s operations in Indiana, with final powder coat painting completed in Michigan. These racks had historically been manufactured in Mexico, but were brought back to the United States to improve turnaround time, simplify logistics, and increase product consistency.

Insights from the 2025 Reshoring Initiative Reshoring Survey further underscore why Marlin’s model works. The survey found that key factors enabling reshoring include skilled workforce training, close collaboration between supply chain and customer engineering, and fast delivery. Marlin’s embodiment of all three has been

central to its reshoring success and played a direct role in winning the award.

Marlin Steel expects its reshored revenue to double or even triple in 2026, depending on the volume of upcoming projects, reflecting growing momentum behind reshoring growth fueled by favorable tariff and trade policies.

Blachford Chemical Group announced that it has acquired Baum’s Castorine (Baum’s), combining two companies with over 250 years of innovation in specialty chemical manufacturing.

A press release said that Baum’s, based in Rome, New York, provides specialty lubricants, greases, and chemical products for the wire drawing, tube and metal-working industries, as well as transportation and industrial markets. Per both companies, Baum’s Castorine will be integrated into Blachford’s global chemical group, leveraging shared resources and expertise to expand product offerings.

Baum’s specific product lines include the Dura Draw series of nonferrous wire drawing lubricants—such as Dura Draw 891 and Dura Draw 895—for copper, brass, and tin-plated copper wire applications; the Tena-Film line of industrial oils, anti-wear and extreme pressure greases (such as TenaFilm No. 300-LTH and No. 150-TH oils); specialty maintenance products for bearings and equipment operating in demanding environments; metalworking fluids; cutting oils; coolant conditioners; and stranding lubricants. It also supplies specialty fire suppression agents under the Novacool® brand, as well as industrial cleaners and surfactants for equipment maintenance.

According to Blachford, the acquisition is expected to build on longstanding reputations for technical excellence and service, with Baum’s product lines of lubricants, process oils and additives complementing Blachford’s existing portfolio of metalworking fluids, anti-tack agents, rolling oils and additives. The combination will strengthen distribution channels in North America and globally, giving customers more options and technical support.

Details of the transaction—including financial terms and transition plans—were not disclosed, but officials said that Baum’s Castorine, founded in 1879, will retain its core team and continue serving under the Blachford umbrella.

Kanthal, a global resistance materials producer, announced that it has inaugurated a new wire manufacturing facility at its Hosur campus in India that features advanced automated processes, advanced die maintenance, fully automated spooling operations and state-of-the-art quality control and material handling systems.

A press release said that with the new 1,980-sq-m facility, Kanthal will more than triple its production capacity at the

Highest measuring rate for precise diameter and ovality

• 500,000 measuring points, 10,000 high-precision measured values per second

• Precise measured values despite cable vibrations

• Robust technology and highest availability

• Slim design with swivel concept

• FFT analysis for detecting irregularities during extrusion

• First choice for fast running lines

Hosur plant. The initiative was taken to optimize production capacity globally and to offer shorter lead times across Asia.

Kanthal established the Hosur plant in 1988. Since then, the company’s activities in the country have expanded and today, with India as one of Kanthal’s key geographical areas, the Hosur manufacturing facility has grown in importance. The expansion will enable the unit to cater to local markets in India as well as Southeast Asia, including Singapore, Korea, Japan, China, and selected parts of Europe. “This strategic investment enables us to meet the growing demand for fine dimension wire with fast lead times in Asia,” said Kanthal President Robert Stål.

Case Recruiting recently took over Wire Resources, Inc., a Connecticut-based specialized wire and cable recruiting firm, owned by Peter Carino, a well-known industry recruiter.

The new owner, Ryan Case, was led by a third party to Carino, who had recently retired. Wire Resources, Inc. was founded in 1967 and Carino bought it in 1982. The two men met, and the end result was Case transitioning Carino’s business into his: Case Recruiting (www.caserecruiting.com). “I wanted to leave my personal legacy in good hands and Ryan is filling that role,” Carino said. Carino had participated in multiple WJI features over the years. Fittingly, Case is in the October feature (see p. 52) where he shares his background and his thoughts on the current hiring market.

NKT A/S, via its Czech subsidiary, NKT s.r.o., is part of an ongoing probe by the Antimonopoly Office (AMO) of the Slovak Republic.

In a formal announcement on August 27, NKT confirmed it is part of the investigation into alleged collusion among cable industry players in Slovakia, which the company denies. The AMO’s “Request Before the Issuing of a Decision” alleges possible infringements of Slovak and EU competition law involving a local cable association and 11 cable makers, including NKT s.r.o. Proposed fines are outlined but not finalized, and NKT has contested both the findings and the suggested infringement, stating it will present a reasoned defense.

A final decision from the Slovak authorities is expected within six to 12 months. If upheld, NKT plans to consider all available legal remedies, including appeals in Slovak courts. Meanwhile, NKT s.r.o. is also under investigation by Czech competition authorities, along with five other cable manufacturers, with that review still pending.

NEC, a leading Asian undersea cable manufacturer and installer, may receive hundreds of millions of dollars in subsidies from the Japanese government to acquire specialized cable-laying vessels for digital infrastructure projects.

A government statement said that Japan is considering helping cover up to half the cost—potentially $500 million—for two ships, with each vessel estimated at $300 million. It said that the action was necessary because nearly all of Japan’s communications depend on subsea cables, yet domestic firms currently lack sovereign cable-laying capacity. NEC has relied on leasing a Norwegian vessel and other short-term charters, which officials say has exposed Japan to supply chain vulnerabilities and security risks. With foreign competitors in the U.S., France and China owning dedicated fleets, Japan’s government called its lack of owned ships “very serious.”

If approved, NEC’s first ship could be operational by 2027, strengthening the country’s ability to quickly deploy and repair digital networks. The news was posted by Tech Space 2.0 and reported by the Financial Times.

The final approval for Japan’s planned subsidies to NEC for cable-laying vessels would come from the Japanese Cabinet, specifically through the Ministry of Internal Affairs and Communications (MIC), which oversees telecommunications and digital infrastructure policy.

The initiative comes after years of deliberation. In 2023, Tokyo designated subsea cables as “vital infrastructure” and required operators to report suspicious activities but stopped short of deeper support. NEC’s CEO warned earlier this year that the company was “the only one fighting with no support” as rivals benefited from direct government backing. France’s Alcatel unit was nationalized, while China provides heavy subsidies to its telecom firms.

NEC’s cable manufacturing and installation businesses operate as a unified enterprise under the NEC Group umbrella, with the entire group engaged in the submarine cable system business and no separate brand names distinguishing manufacturing from installation.

Manufacturing is conducted primarily through OCC Corporation, a subsidiary of NEC, while installation and systems integration are supported by other NEC divisions such as NEC Networks & System Integration Corporation and NEC Platforms, but all activities are marketed collectively as NEC submarine cable solutions.

The current investigation marks one of the most extensive probes into cartel activity in Slovakia’s cable sector to date, signaling heightened competition enforcement in this critical infrastructure market. n

Specialty Cable Corporation (SCC) this year traces its lineage back 100 years, marking a century-long legacy built on steady hands that have kept production moving and customers supplied. From its foundation as Lewis Engineering Company in 1925, SCC and its predecessors have adapted alongside American industry—a journey defined by its people. Here is its story.

Specialty Cable Corporation (SCC) this year traces its lineage back 100 years, marking a century-long legacy built on steady hands that have kept production moving and customers supplied. From its foundation as Lewis Engineering Company in 1925, SCC and its predecessors have adapted alongside American industry—a journey defined by its people. Here is its story.

A hundred years in manufacturing is a testament to resilience, craftsmanship, and a workforce built to last. As Specialty Cable Corporation (SCC) marks a century of industry roots, it honors the people and principles that have kept it and its predecessors at the forefront of the wire and cable field.

A hundred years in manufacturing is a testament to resilience, craftsmanship, and a workforce built to last. As Specialty Cable Corporation (SCC) marks a century of industry roots, it honors the people and principles that have kept it and its predecessors at the forefront of the wire and cable field.

SCC’s lineage began in December 1925, when Lewis Engineering Company was established in Naugatuck, Connecticut. From those early days—working with materials like paper and cotton insulation—the business has grown to manufacture some of today’s most advanced, mission-critical cables for aerospace, defense, energy, and medical markets. This transformation has been powered by steady innovation and the dedication of employees— machine operators, engineers, lab technicians, and logistics experts—who shaped the journey at every step.

SCC’s lineage began in December 1925, when Lewis Engineering Company was established in Naugatuck, Connecticut. From those early days—working with materials like paper and cotton insulation—the business has grown to manufacture some of today’s most advanced, mission-critical cables for aerospace, defense, energy, and medical markets. This transformation has been powered by steady innovation and the dedication of employees— machine operators, engineers, lab technicians, and logistics experts—who shaped the journey at every step.

Formal entry into cable manufacturing came in 1942, as the company responded to rising demand, especially for aerospace. This strategic move laid the groundwork for future growth. In the decades that followed, the company’s identity and capabilities evolved through several ownership changes, each bringing new opportunities for specialization and expansion.

In 1968, Lewis Engineering was acquired by Revere Corporation, known for engineering excellence. A decade later, in 1978, Revere’s cable operations merged with Galileo Electro-Optics Corp to form Galite Corporation, which established SCC’s current Wallingford, Connecticut, base—a modern 65,000-sq-ft facility.

Formal entry into cable manufacturing came in 1942, as the company responded to rising demand, especially for aerospace. This strategic move laid the groundwork for future growth. In the decades that followed, the company’s identity and capabilities evolved through several ownership changes, each bringing new opportunities for specialization and expansion.

In 1968, Lewis Engineering was acquired by Revere Corporation, known for engineering excellence. A decade later, in 1978, Revere’s cable operations merged with Galileo Electro-Optics Corp to form Galite Corporation, which established SCC’s current Wallingford, Connecticut, base—a modern 65,000-sq-ft facility.

A major leap followed in 1981, when Pirelli Cable Corporation acquired Galite and merged it with Cimco Wire and Cable, boosting capabilities for aerospace and defense. In 1986, Specialty Cable Corporation became an

independent entity, focused on designing and manufacturing highly specialized cables.

Today, SCC operates as a closeknit team of about 65 employees, many of them long-tenured. One, Jerry Swantek, recently retired after 65 years with the company.

A major leap followed in 1981, when Pirelli Cable Corporation acquired Galite and merged it with Cimco Wire and Cable, boosting capabilities for aerospace and defense. In 1986, Specialty Cable Corporation became an independent entity, focused on designing and manufacturing highly specialized cables.

Today, SCC operates as a close-knit team of about 65 employees, many of them long-tenured. One, Jerry Swantek, recently retired after 65 years with the company. See p. 4.

“Our employees represent the best of the best in our industry,” longtime owner Carl Shanahan said. “We offer a safe, clean and respectful environment, and our people take immense pride in what we build.”

“Our employees represent the best of the best in our industry,” longtime owner Carl Shanahan said. “We offer a safe, clean and respectful environment, and our people take immense pride in what we build.”

That pride is visible in SCC’s product quality and its unwavering commitment to excellence. The company holds industry certifications like AS 9100D and ISO 9001:2015, ensuring every product meets rigorous standards.

That pride is visible in SCC’s product quality and its unwavering commitment to excellence. The company holds industry certifications like AS 9100D and ISO 9001:2015, ensuring every product meets rigorous standards.

Across its century-spanning journey, SCC has continually evolved to meet industry needs. From high-temperature thermocouple cables to pioneering fiber optic wire, SCC has never shied away from complexity. Today, it specializes in “Light and Tight” flight-critical cables, designed to be as lightweight and durable as possible.

Across its century-spanning journey, SCC has continually evolved to meet industry needs. From high-temperature thermocouple cables to pioneering fiber optic wire, SCC has never shied away from complexity. Today, it specializes in “Light and Tight” flight-critical cables, designed to be as lightweight and durable as possible.

“Our cables are built to function under the most extreme conditions,” Shanahan said. “We’ve developed a broad range of high-performance insulation materials, including advanced fluorocarbon compounds, to meet the toughest operating environments.”

“Our cables are built to function under the most extreme conditions,” Shanahan said. “We’ve developed a broad range of high-performance insulation materials, including advanced fluorocarbon compounds, to meet the toughest operating environments.”

SCC is also known for strategically leaving markets when necessary, always bringing forward the knowledge and experience gained. This flexibility has supported the company’s resilience through decades of technological and economic change.

SCC is also known for strategically leaving markets when necessary, always bringing forward the knowledge and experience gained. This flexibility has supported the company’s resilience through decades of technological and economic change.

While honoring its past, SCC is preparing for the future— exploring 3D printing for parts and integrating artificial intelligence into operations.

While honoring its past, SCC is preparing for the future—exploring 3D printing for parts and integrating artificial intelligence into operations.

“AI is now firmly part of our world and certainly will be part of SCC’s future,” Shanahan declared. “We believe in our people’s ability to learn and adapt, and I believe the environment we’ve created here makes that possible.”

“AI is now firmly part of our world and certainly will be part of SCC’s future,” Shanahan declared. “We believe in our people’s ability to learn and adapt, and I believe the environment we’ve created here makes that possible.”

That belief in people, matched by relentless pursuit of excellence, is what Shanahan said sets SCC apart as it enters its second century. With deep roots, a clear mission, and a workforce that believes in what it builds, SCC will meet whatever challenges arise as it always has: through hard work, innovation, and the strength of its people.

That belief in people, matched by relentless pursuit of excellence, is what Shanahan said sets SCC apart as it enters its second century. With deep roots, a clear mission, and a workforce that believes in what it builds, SCC will meet whatever challenges arise as it always has: through hard work, innovation, and the strength of its people. n

Editor’s note: This occasional section is a venue where the industry can discuss topics of interest, both direct and indirect. If you would like to share your thoughts, contact WJI at editor@wirenet.org.

Editor’s note: This occasional section is a venue where the industry can discuss topics of interest, both direct and indirect. If you would like to share your thoughts, contact WJI at editor@wirenet.org.

U.S. Patent No.: 12,359,750

Patent date: July 15, 2025 Filed: Jan. 2, 2024

Assignees: Joseph Heisler, III, Michael Heesler; Christopher Lanagan, USA

Inventors: same as above

Methods and apparatus for organizing wires, each wire having a terminal connector at an end of the wire. In some embodiments, the apparatus includes: an elongated body comprising a plurality of holes, wherein at least one hole of the plurality of holes is configured to pass through and retain a terminal connector disposed at the end of a wire; and a retainer attached to the elongated body, the retainer configured to removably attach the apparatus to a structure.

U.S. Patent No.: 12,359,288

Patent date: July 15, 2025 Filed: Dec. 4, 2020

Assignee: Panasonic Intellectual Property Management Co., Ltd. Japan

Inventors: Akitoshi Kasahara, et al.

A metal wire, which is one of a tungsten wire and a tungsten alloy wire, includes alkali metal on the surface thereof. The amount of alkali metal is at most 2.0 μg per 1 g of the metal wire.

U.S. Patent No.: 12,358,751

Patent date: July 15, 2025 Filed: Dec. 15, 2022

Assignee: None listed

Inventors: Matthew PaulSmith, USA

This invention provides a system for supporting and unwinding/paying out wire from multiple spools, including a framework for supporting the plurality of wire spools. A mount is constructed and arranged to attach to mobile equipment, such as a skid steer. The framework includes forward extended beams that support a plurality of removable axles. There are axles adapted to rotatably retain a plurality of spools of wire therealong. A plurality of removable sleeves are located along each of the axles that retain the spools, respectively, against motion therealong. A levelling assembly allows the axles to tilt relative to an angle at which the equipment is disposed. The spools can

be held laterally along each respective axle by clamping sleeves/spacers.

Device and method for feeding cross wires in a wire mesh welding machine

U.S. Patent No.: 12,358,386

Patent date: July 15, 2025 Filed: July 6, 2022

Assignee: TE Connectivity Solutions GmbH, China

Inventors: Eric Chatelus, Bruno Dupont, Oliver Pamart, Stephanie Gllerand

A sealed cable feedthrough of a plug connector includes a housing having an opening receiving a cable, a cover partially covering the opening, the cover having a through hole receiving the cable along an insertion direction, and a seal member sealing an interface between the housing and the cover. The seal member has a tubular member with a through hole receiving the cable along the insertion direction. The tubular member is arranged within the through hole of the cover and extends along a direction parallel to the insertion direction. The tubular member seals an interface between the cover and the cable.

Device and method for feeding cross wires in a wire mesh welding machine

U.S. Patent No.: 12,358,040

Patent date: July 15, 2025 Filed: April 28, 2021

Assignee: EVG Entwicklungs—U. VerwertungsGesellschaft Mbh, Austria

Inventors: Johann Stindl, Georg Droschl

A device for feeding transverse wires above and below a production line for mesh mats which consist of welded transverse and longitudinal wires, said device comprising an upper transverse wire feeder, which has a guide channel and which is arranged in a first position, in which transverse wires are fed along the guide channel of the production line, and comprising a lower transverse wire feeder, by means of which transverse wires can be conveyed from below to the production line, wherein a lower transverse wire store is provided, from which transverse wires can be removed by the lower transverse wire feeder, and wherein the upper transverse wire feeder is designed as a transverse wire switch, which can be pivoted at least into a second position, wherein the lower transverse wire store can be

Normally, when you drag your feet, the consequences aren’t good. As Benjamin Franklin advised, “Never leave till tomorrow that which you can do today.” Obviously good advice.

But, when it comes to patent protection, Mark Twain gives us better advice: “Never put off till tomorrow what may be done (the) day after tomorrow just as well.”

Delay can be a huge advantage in the patent world. I’m referring to the strategy of filing continuation applications to catch competitors who design around your patents. Basically, you get a patent allowed and then re-file the application with different claims before the patent issues. It’s been done for decades and is at the heart of the Google v Sonos case.

The case involves prosecution laches, a legal term that basically means, “You waited too long in the Patent Office, and that’s unfair.” The district court decided that Sonos’s patents on multi-room “zone scene” technology were unenforceable because they introduced key claims 13 years after their initial patent application was filed.

Sonos appealed to the CAFC, which reversed the lower court’s ruling. The CAFC decision offers valuable guidance for anyone seeking patents.

The story begins with a 2006 provisional patent application. Sonos kept the patent family alive through continuation applications but didn’t include the specific “overlapping zone” claims until 2019, just as Google was launching competing smart speakers. Sonos clearly drafted claims to cover the Google system.

Judge Alsup of the Northern District of California saw this as a classic ambush. He held that Sonos unreasonably and inexcusably delayed and that this delay prejudiced Google. To him, it looked like Sonos had waited in the weeds until the market developed, then whipped out claims designed to target a competitor’s existing products, which is what they did, all but the waiting in the weeds part. In his view, this triggered prosecution laches, and he wiped out Sonos’s $32 million jury verdict. One might think that a wrong had been righted.

Fast forward to August 28, 2025. The Federal Circuit stepped in and said: not so fast.

The appellate court agreed that prosecution laches are real, but reminded us that it requires more than just delay. The challenger must show material prejudice, meaning the delay caused actual harm, such as making investments in ignorance of hidden claims.

Google couldn’t show material prejudice because Sonos’s application disclosure was made public in 2013, when its first patent was issued. (Note: Sonos chose to keep its patent application secret until the patent issued, which is allowed.) This public disclosure of the invention details occurred before Google made any investments in its product. In other words, the public already had notice of the overlapping-zone idea even though it had not been claimed.

The Court stated that “[I]t is not improper for an applicant to broaden his claims during prosecution to encompass a competitor’s products,

as long as the disclosure supports the broadened claims.”

Basically, the Court upheld the use of continuation applications to later broaden claims to catch a competitor. It isn’t material prejudice because the public is aware of everything that can be claimed in a patent application, since it is publicly available.

So, what does this courtroom drama mean for the rest of us?

First, delay alone won’t sink you. Continuation practice is alive and well. Just because you prosecute a patent application for many years doesn’t mean laches will apply. The key is whether your delay materially prejudiced someone else. Second, disclosure is your shield. Once your application publishes, competitors are on notice. If they invest anyway, it’s tough to argue surprise. The Federal Circuit leaned heavily on that in this case. Third, a non-publication request could be an issue. Sonos requested that its patent application not be published, so the first publication occurred six years later, in 2013, when that patent was issued. If Google had made investments before 2013, there may have been a different result. This suggests that non-publication practice should be carefully considered.

This case reminds us that patents are more than paperwork; they’re weapons, shields, and sometimes boomerangs. For now, continuation practice remains a safe and vital part of the patent strategist’s playbook and should be considered for all critical inventions.

-Bill Honaker

Bill Honaker has been an intellectual property attorney for more than 30 years, helping businesses—from Fortune 100 firms to individual entrepreneurs—protect their patents, trademarks and copyrights. A former Patent Office Examiner, he is a partner with Dickinson Wright, PLLC. He notes that he is especially good at keeping clients out of court. He can be contacted at whonaker@dickinson-wright.com, tel. 248-433-7381.

loaded with transverse wired by the transverse wire switch in the second position.

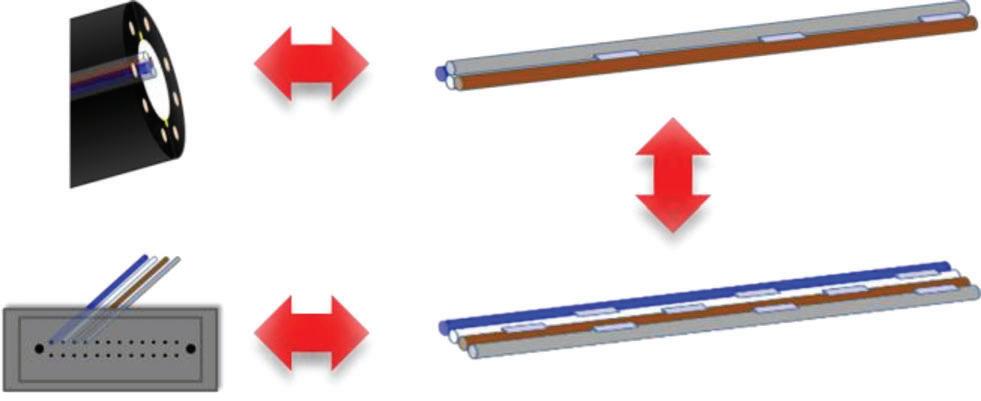

and equipment for installing a power cable in a deployment site

U.S. Patent No.: 12,355,219

Patent date: July 8, 2025 Filed: May 3, 2022

Assignee: Prysmian SpA, Italy

Inventors: Marco Bacchini, Simone Manfredi, Mario Genovesi

The present disclosure relates to a method for installing a single power cable span in a deployment site comprising a rail for supporting the single cable span by trolleys, the method comprising the steps of providing a conveyor belt outside of the deployment site, the conveyor belt having a plurality of locations set at a predetermined distance one from the other along a longitudinal movement direction of the conveyor belt and moving integrally with the latter; repeating the following steps until the single cable span reaches a predetermined position while the conveyor belt is moving, positioning a first part of a holder at one of the locations; while advancing the single cable span, laying a portion thereof on said first part of the holder positioned at the location moving with the conveyor belt; connecting a second part of the holder to the first one to lock the cable span portion in between; while the cable span portion locked by the holder is leaving the conveyor belt, removing the first part of the holder from the location moving with the conveyor belt. According to another aspect, the present disclosure relates to an equipment for the installation of a single power cable span in a deployment site.

U.S. Patent No.: 12,354,771

Patent date: July 8, 2025 Filed: Sept. 26, 2022

Assignee: Proterial, Ltd., Japan

Inventors: Hirotaka Eshima, et al.

A composite cable includes a plurality of internal cables and a covering member covering peripheries of the plurality of internal cables. At least one of the plurality of internal cables includes at least one electric wire having a conductor, a first sheath covering a periphery of the at least one electric wire, a shield covering a periphery of the first sheath, and a second sheath covering a periphery of the shield.

U.S. Patent No.: 12,354,770

Patent date: July 8, 2025 Filed: April 29, 2022

Assignee: Ying Hao Technology Co., Ltd., Taiwan

Inventor: Chih-Jung Chen

A flexible flat cable includes an upper bonding adhesive layer and a lower bonding adhesive layer bonded together, a plurality of bare wires being sandwiched, an upper metal shielding layer located on an upper side of the upper bonding adhesive layer and adhesively attached to the upper bonding adhesive layer, and a lower metal shielding layer located on a lower side of the lower bonding adhesive layer and adhesively attached to the lower side of the lower bonding adhesive layer.

U.S. Patent No.: 12,354,765

Patent date: July 8, 2025 Filed: June 22, 2021

Assignee: Komax Holding AG, China

Inventors: Cassian Straessle, Dominik Staubli, Jan Lochmatter

A method and a device twist single cables about a twisting axis. The single cables each run along a cable axis and have wires, which are twisted in a strand twisting direction to form a strand, and also each have a first cable end and a second cable end. The first cable ends are held separately by a single rotating unit in each case. The second cable ends are held by a twisting unit. The second cable ends

are rotated jointly about the twisting axis counter to the strand twisting direction to produce a twisted cable bundle. During the joint rotation, the first cable ends are rotated separately about a cable axis of the respective single cable, in the same rotation direction as the joint rotation. The single cables are each relieved of torsion thereby.

cable with SZ stranded routable fiber carrying subunits

U.S. Patent No.: 12,353,042

Patent date: July 8, 2025 Filed: March 30, 2023

Assignee: Corning Research & Development Corporation, USA

Inventor: Bradley Jerome Blazer

An optical fiber cable that includes subunits is provided. Optical fiber cables are used to transmit data over distance. The subunits are twisted and stranded within the cable to reduce degradation of stranding during use of the cable. The subunits of one or more optical fiber cables are arranged in complimentary configurations that counteract their varying asymmetrical forces to provide an improved handling performance for the optical fiber cable.

Fiber optic cassette with cable manager and system

U.S. Patent No.: 12,353,039

Patent date: July 8, 2025 Filed: Oct. 31, 2022

Assignee: Belden Canada ULC, Canada

Inventors: Moise Levy, Luc Milette, Christian Roa-Quispe, Dwayne Crawford

There is disclosed a fiber optic cassette comprising a cassette body comprising a plurality of optic fiber receptacles arranged along a front thereof and a multifiber receptacle along a back thereof opposite the first end, the front and back defining a cable assembly receiving region there between, and a plurality of optic fibers. Each of the optic fibers terminated at a first end by one of the receptacles and all of the plurality of optic fibers terminated at a second end the multifiber receptacle. In an embodiment a casing is molded over a middle portion of each of the plurality of optic fibers and received within the cable assembly receiving region. In a particular embodiment the cassette is reversible and comprises a reversible securing element which is secureable on either side of the cassette body.

Systems devices and methods

U.S. Patent No.: 12,352,827

Patent date: July 8, 2025 Filed: Oct.1, 2024

Assignee: Gistech Technologies 2023 Ltd., Israel

Inventors: Moshe Ben Basat, Eran Glikman, Zvi Biener

An electrical circuit board for testing at least one cable, which comprises one or more wires, the circuit board comprising: an input connector configured to be connected to one end of the one or more wires; an output connector configured to be connected to the other end of the one or more wires; at least one processor connected via a first signal driver to the output connector; an Analog-to-Digital Converter (ADC) and a second signal driver, an SPXT (single pole, X throw) switch configured to connect the input connector to the input circuit; an oscillator circuit coupled to the at least one processor, an energy source; and wherein the at least one processor comprises a plurality of signal generation modules, which are configured to: generate and transmit at least one test signal through the end of the one or more wires of the at least one cable; receive the at least one test signal transmitted through the other ends of the one or more wires of the at least one cable; and analyze the at least one test signal using one or more signal measurement logic methods to yield data comprising intermediate test results or final test results which relate to one or more faults in the at least one cable or characteristics of the at least one cable.

(Patent Report continued, see p. 64)

The Chemours Company (Chemours) has signed a strategic agreement with India’s SRF Limited (SRF) to expand its capacity and strengthen its presence in the region.

A press release said that the partnership will expand Chemours’ global supply chain, enhance operational flexibility and ensure greater reliability in the supply of fluoropolymers and fluoroelastomers, key materials for industries such as semiconductors, automotive, aerospace and chemical processing.

Per the website of SRF, the company’s involvement with wire and cable centers on aluminum wire, welding wires, technical textiles, and certain specialty connectors. Some listings include aluminum cables and black cable wire connectors, and SRF also manufactures a variety of specialty chemicals and fluoropolymers. U.S.-based Chemours provides several products for the wire and cable industry, most notably its Teflon™ fluoropolymer resins (including PTFE and Tefzel™), which are used for wire and cable insulation and jacketing, as well as Viton™ fluoroelastomers used for applications such as high-voltage cables and certain automotive wire coatings

While U.S.-China rivalry dominates headlines over Southeast Asia’s subsea cable infrastructure, a recent report issued earlier this year by ISEAS –Yusof Ishak Institute, spotlights a less-publicized reality: most of the region’s new undersea systems are actually supplied by Japanese companies, not Chinese or American ones.

The nuanced analysis, “The Struggle for Subsea Cable Supremacy in Southeast Asia: ASEAN Relying on Diverse Suppliers,” was authored by Research Officer Cha Hae Won and reflects the Singapore-based institute’s mission of providing policy-relevant research to support regional understanding and prudent policy choices.

Subsea cables transmit over 95% of global data traffic, underpinning everything from financial transactions and entertainment to social communication and government functions. The growing strategic value of these cables has brought them to the heart of great power competition, particularly between the U.S. and China. Tensions have escalated as both Washington and Beijing vie for influence over this critical infrastructure, each viewing it as a strategic frontier for control over digital traffic and data security.

The collaboration will enable SRF to draw on Chemours’ expertise in industrial chemicals and specialty intermediates to meet growing global demand without requiring upfront capital investment. “This ... exemplifies our Pathway to Thrive strategy as we continue to shift our product mix to higher value applications, enhancing our position as a trusted supplier paired with our commitment to responsible manufacturing practices,” said Chemours President and CEO Denise Dignam.

Prashant Yadav, president and CEO of SRF’s fluorochemicals and technical textiles businesses, said that the collaboration will benefit both companies. “We are proud to reinforce our position as a trusted manufacturer of advanced materials and believe this marks the beginning of a strong relationship with a global leader in performance chemicals and advanced fluoropolymers.”

Chemours employs approximately 6,000 people at 28 manufacturing sites worldwide, that includes 16 plants across India, Thailand, South Africa and Hungary. It exports to over 100 countries.

SRF has 16 manufacturing plants sites, including 13 in India and one each in Thailand, South Africa and Hungary, and exports to more than 100 countries worldwide.

China’s “Digital Silk Road” initiative—a component of the Belt and Road Initiative—has provided Chinese cable firms with unprecedented state support, including subsidies, technical development, and diplomatic muscle. This has allowed Chinese companies to aggressively compete on price and technology, winning key subsea projects, especially in Cambodia and Indonesia. Beijing’s assertive steps in the South China Sea, including blocking foreign cable projects, have raised alarm among competitors and regional states alike, who fear potential supply disruptions or security threats in periods of friction.

The U.S., meanwhile, has harnessed a mixture of diplomacy, sanctions, and new “minilateral” partnerships to exclude Chinese participation in high-profile cable projects and strengthen its own influence. The recent rerouting of the SeaMeWe-6 contract from China’s HMN Technologies to America’s SubCom, after diplomatic pressure and threats of sanctions, exemplifies this tug-of-war. These developments cast subsea cables not just as infrastructure assets but as highly strategic elements on the global geopolitical chessboard.

Yet, the ISEAS report strongly cautions against reducing Southeast Asia’s subsea cable landscape to a simple U.S.-China binary. Drawing from the TeleGeography Submarine Cable Map, it finds that Japanese suppliers— primarily NEC and Fujitsu—account for more than 40% of new cable projects across the region, compared to the US (20%), China (19%), and France (18%). This breakdown visually reinforces the region’s multipolar approach to critical infrastructure. France, represented by ASN, is a major player as well, especially in Indonesia and the broader area. American and Chinese suppliers trail Japan’s market share, and no single supplier or nation dominates.

This multipolar landscape is the result of deliberate strategizing by Southeast Asian countries, who are keen to avoid the risks of overreliance on any one nation. Regional governments have actively diversified their supply sources to include an array of suppliers from Europe, Japan, and beyond, often structuring contracts to encourage technology and supplier diversity within a single project. Japan’s preeminent status in subsea cables is rooted not just in market-driven competition, but in strong public-private cooperation. The Japanese government has provided direct financial support, loans, and investment incentives to bolster NEC’s regional expansion, viewing digital infrastructure as a national strategic asset.

The ISEAS report’s central message is that, while security concerns—especially regarding espionage and disruptions—should not be discounted, policymakers and industry leaders must resist being drawn into simplistic narratives to the detriment of practical supply diversity. As the U.S. and China step up efforts to nudge Southeast Asian states into mutually exclusive cable alliances, the risk of technological fragmentation and supply chain disruption grows.

Editor’s note. The report that provided the details comes from ISEAS Publishing, a unit of the ISEAS–Yusof Ishak Institute that notes that it has issued more than 2,000 books and journals, and that it is the largest scholarly publisher of research about Southeast Asia from within the region.

For more about ISEAS go to www.iseas.edu.sg.

South Korea’s Cable & Solution reports that it hit an all-time high in its order backlog, surpassing 3 trillion won. The company announced on Sept. 9 that its order backlog as of the end of last month reached a record high of 3.25 trillion won (approximately $2.34 billion).

A press release said that since its 2021 acquisition by South Korea’s Hoban Group, Taihan Cable & Solution has steadily increased its order backlog through synergy effects, more than tripling that amount, with a compound annual growth rate topping 30%.

The order backlog does not include the materials business that processes copper wire, the telecommunications cable business or sales volumes for domestic private sector clients. It primarily consists of high-profit, mid to long-term project orders, mostly ultra-high voltage power grids.

Molex has named Jim Foster as its director of operations at the company’s plant in South Grafton, Massachusetts. He has extensive experience in extrusion, braiding and custom cable manufacturing gained over more than 30 years. That includes working for nearly two decades at JSC Wire & Cable, where he served in roles such as project management, supply chain, plant operations and general management. Prior to that he also worked for Winchester Electronics, Lincoln Electric Products and Spiradrill. A global business based in Lisle, Illinois, with more than 70 plants, Molex manufactures electronic connectors, wire and cable solutions for automotive, medical, industrial and data applications.

Annelise Mackiewicz was named inside sales and marketing manager for Able Coil & Electronics. She most recently was the sales and marketing coordinator for ITEC. Prior to that, she served as marketing and sales coordinator for FENN, where she worked from 2021 to 2024. She holds a degree in communications from the University of Connecticut. Based in Bolton, Connecticut, Able Coil & Electronics supplies custom precision-wound coils, transformers, and integrated electromechanical assemblies for industrial applications.