The Dual Lock Window Lock Range. Advanced security, effortless installation, lasting durability.

Yale’s latest innovation in window security, the Dual Lock Window Lock Range, sets a new standard with its smart design, effortless installation, and exceptional versatility. Engineered to suit PVC, aluminium, and timber window systems.

Choose from two high-performance options:

• Twin Cam Espagnolette

• Shootbolt Window Lock

Both are designed for easy, single routing preparation reducing installation time while maintaining top-tier performance. The Twin Cam Espagnolette offers bi-directional locking for enhanced protection, and features Quadcoat corrosion resistance rated up to 1,000 hours (BS EN 1670 Grade 5,480hrs), ensuring long-lasting durability even in the toughest environments.

You can now receive your industry news in a range of formats: Newscast, Website, Social Media, and a magazine. So whatever your preference is for catching up with the latest innovations and news in the industry, there is a Window News format to suit everyone.

We aim to keep readers up-to-date with the latest industry news, trends, technical innovations and suppliers. Our web format means that we can be in the right place at the right time – wherever that may be.

The contents of Window News are provided for general use only and do not constitute general advice and should not be relied upon.

Publisher Gerald Batt Tel: 01255 850245

E-mail: gerald@windownews.co.uk

Editorial E-mail: edit@windownews.co.uk

Production E-mail: production@windownews.co.uk

Views/opinions, replies and specific advice expressed by external persons are not necessarily those of Window News and are not subscribed to by Window News. To see the full terms and conditions please visit: http://www.windownews.co.uk/window-news-disclaimer/ Privacy Policy: http://www.windownews.co.uk/window-news-privacy-policy/

Copyright © 2025 PO Box 13225. Frinton-on-Sea, CO13 3BT

www.windownews.co.uk

Cover picture: Hörmann Truedor launches Clima63 ‘Winter Warmer’ promotion read more on page 86

million,three-year

Quickslide have rewritten the rule book with their longawaited mech-weld machinery. Specifically designed to reduce the manufacturing time of mechanical sash windows from 15 minutes to just 90 seconds, it also delivers consistent high quality – overcoming a challenge that has long persisted across mechanical frame production. This has been achieved while eliminating human error and enabling Quickslide to deliver its Legacy Vertical Slider with mechanical joints to trade partners at market-leading lead

times, claims the company.

This new installation, three years in the making, is phase two of an overall £3 million investment in automating production at the company’s Brighouse factory. It consists of three uniquely configured machines, fully custom-designed and the first of their kind in the UK, says the company.

“The automation of window manufacturing can learn a lot from other sectors – which is why we looked outside the industry

for inspiration. This allowed us to set a high bar for commissioning a suite of machines designed to automate a notoriously labour-intensive process,” said Quickslide’s managing director Ben Weber.

“Push-button automation is crucial for repeatable, reliable results, and the £1 million we have invested in mechanical jointing is part of an overall £3 million strategy across all manual processes in our factory. Critically, we’re only just getting started.”

According to the company, this long-term operational strategy was developed with a simple premise – to increase production capacity while improving quality. Eighteen months ago, a £1.7 million Schirmer machining centre was commissioned, fully automating milling functions and incorporating auto-reinforcing across Legacy VS production.

“If we can deliver a specialised product such as our Legacy

VS in as little as five days, with guaranteed quality and competitive pricing, we know future scaling investments will take Quickslide, and its trade partners, way beyond the constraints of what the industry currently offers,” continued Ben Weber.

“Without giving too much away, we are now exploring AI-driven robotic functions and reconfiguring production layouts from cellular to line-fed systems.”

“What used to take 15 people carrying out various functions now takes just one person feeding two machines. What used to be a 15-minute process now takes just 90 seconds. As the business scales, we can redeploy that labour across other areas, using their skills and knowledge in more valuable ways – investing and automating is never about cutting back, but maximising current resources for greater returns.

“Skills shortages are a problem in this industry. Our intention is to protect those who currently work with Quickslide. At the same time, automation better protects Quickslide against a lack of skills coming into the marketplace,” added Ben Weber.

The company is driven by achieving a level of excellence that is comparable across world class manufacturing examples. Rather than competing with other window manufacturers, it prefers to compete with its own ambitions, and endeavours to bring its trade partner base along for the ride.

That means achieving fundamental market focused guarantees such as product quality, delivered on time, at the right price. It’s not rocket science, but it is foundational. This latest installation puts us well on the road to achieving it, but there is still more work to be done!” concluded Ben Weber.

The latest Insolvency Report from leading UK marketing data firm Insight Data reveals a sharp rise in company closures across construction, glazing and building product sectors in October, reversing the improvement seen the previous month.

Small builders were hit hardest, with 138 firms going out of business – a 60 per cent increase from September’s 86. Main contractors with turnovers above £5 million saw insolvencies double from three to six, while 124 fenestration companies ceased trading, up 36 per cent. Builders’ merchants also suffered, with 16 closures compared to 12 the previous month. The only sector to show improvement was architecture, where insolvencies fell by nine per cent.

Insight Data’s commercial director, Alex Tremlett, commented: “These figures reflect the financial pressure many businesses are under,

especially with the upcoming Budget likely to bring more uncertainty. It’s a reminder that companies need to stay agile, diversify and make decisions based on live market intelligence rather than instinct or outdated information.”

Insight Data says businesses investing in renewables, energy-efficient products and new market segments are weathering the storm more effectively. The company advises that focusing on reputation, communication and customer loyalty will be key to long-term survival and growth.

Insight Data provides B2B marketing data and CRM tools specifically for the construction, glazing and building products sectors in the UK. It offers live prospect data, market intelligence and lead generation services through its online platform, Salestracker.

To access the full Insolvency Report, visit https://bit.ly/4i97sW5

The economic outlook for UK construction may be subdued, but there are reasons for cautious optimism – that was the key takeaway from Noble Francis, Economics Director at the Construction Products Association (CPA), speaking at the Council for Aluminium in Building’s (CAB) 31st Annual General Meeting, held at Stratford’s Crowne Plaza on 23rd October.

As one of the most respected voices in UK construction

economics, Noble delivered a detailed and data-rich assessment of the market, offering CAB members a grounded but forward-looking view of what lies ahead for 2026 and beyond.

Economic overview: Slow but steady growth

According to Noble, the UK economy continues to “bumble along”, with GDP forecast to rise by 1.3% in 2025 and 1.5% in 2026 – below the long-term trend

of 2% growth.

“We’re seeing some recovery, but it’s hesitant,” he noted, citing the upcoming Autumn Budget and uncertainty around who will shoulder forthcoming tax rises as a major drag on confidence.

“Whether those costs fall on businesses or households, they will have a ripple effect,” he said.

“If it’s businesses, we’ll see lower investment; if it’s households, that will hit consumption, and consumption drives our economy.”

He also highlighted rising unemployment, partly the result of the April increases in the National Living Wage and employers’ NICs, which have prompted many companies to freeze non-essential

recruitment.

CPA forecasts show total construction output up 4% in 2025, followed by 2.8% in 2026, suggesting moderate but broadbased growth. However, Noble cautioned that this growth will not be evenly distributed.

• Private housing remains the sector’s biggest challenge. Completions fell by around 20% between 2022 and 2024, and while a modest uptick is expected in 2026, affordability issues and building safety regulation delays are slowing recovery. Developers are finding it increasingly hard to justify new high-rise projects, particularly in London.

• Commercial refurbishment and fit-out offer a contrasting picture of strength. “If you’re working with the Overburys of this world, there’s good margin work in high-quality office refurbs,” Noble said. “But large-scale new builds remain difficult to finance, especially with 70% of existing office space below the minimum EPC ‘B’ threshold required for letting after 2030.”

• Public non-housing activity, particularly in schools, defence, and prisons, is poised for gradual expansion, underpinned by longterm government programmes such as the School Rebuilding Programme and the New Hospital Programme.

• Infrastructure, driven by energy generation and distribution, is a major bright spot. “The National Grid’s capacity upgrades and the growth of renewable energy projects will keep this area buoyant,” Noble said. “Water investment under AMP8 is also expected to pick up significantly in 2026.”

Despite the subdued overall forecast, Noble emphasised that “there are real opportunities for those positioned in the right markets.”

He pointed to data centres, biotech and private healthcare, and energy infrastructure as sectors with multi-year growth potential.

“These are long-term trends driven by technology, sustainability and population change, not short-term economic cycles,” he explained.

However, he warned that the Building Safety Regulator’s 6–9 month project delays and rising compliance costs, from the Future Homes Standard to the Building Safety Levy, will continue to challenge developers and

suppliers alike.

Long-term, Noble identified the industry’s skills shortage as a major constraint. “Even if we achieve only half of the Government’s targets for 1.5 million new homes and £725 billion of infrastructure, we simply don’t have the workforce to deliver it,” he said.

The ageing profile of skilled trades and insufficient recruitment remain structural risks to sustainable growth.

Summing up, Noble described 2026 as a “year of stability and transition,” with modest gains across most major sectors.

“Next year won’t bring dramatic recovery,” he said, “but it will bring momentum. For those in refurbishment, retrofit, or energyrelated work, the prospects are particularly strong.”

His insight set the tone for the evening, providing valuable context for the discussions that followed, from competency frameworks with Wates Construction’s Claire Fenton to CAB’s ongoing leadership on training, sustainability, and regulatory advocacy.

As CAB chief executive Nigel Headford noted in closing, the forecast underscores why collaboration across the aluminium and construction sectors is more critical than ever.

“In a market defined by uncertainty, knowledge and adaptability are everything,” he said. “Noble’s analysis gives our members the clarity they need to plan ahead and identify where the real growth opportunities lie.”

www.c-a-b.org.uk

Window and door steel reinforcement specialist, Anglo, is helping fabricators cut their reinforcement costs by up to 30% – guaranteed, says the company.

Anglo has announced a new 12-month price guarantee, pledging to beat fabricators’ current ancillary aluminium and steel reinforcement prices on any like-for-like product.

The guarantee forms part of managing director Paul Sullivan’s ongoing commitment to help fabricators take control of their costs and maximise margins at a time when the industry continues to face significant financial pressures.

“Margins are tighter than ever,” said Paul. “We know that steel and aluminium prices have been a constant challenge for fabricators, and we’re changing that.

“If you’re paying more elsewhere,

you’re paying too much. We’ll beat your current price, and we’ll keep it for 12 months.”

Now part of the Amari Metals Engineering Group, Anglo has secured its material pricing well into 2026, giving customers longterm confidence and cost stability.

“We’ve locked in our steel supply and pricing for the next 12 months,” Paul added. “That allows us to guarantee our prices while others are still facing uncertainty.

“We’ve streamlined our operation, cut overheads, and invested in more efficient production, and those savings go straight back to our customers.”

Available for all leading PVC-U systems, Anglo’s reinforcement is supplied in full bar length or precision cut-to-size, with national delivery in as little as three days from order.

Anglo says its cut-to-size service continues to help fabricators reduce labour, stockholding, and waste, delivering average savings of 30–40% compared to system company prices.

Having achieved ISO 9001 accreditation in 2024 and launched its AngloGalv brand of BS EN 10346-accredited galvanised steel, Anglo has reinforced its reputation for quality and reliability.

Paul continued: “This is about giving fabricators certainty in an uncertain market. With guaranteed supply, guaranteed prices, and guaranteed savings for 12 months, we’re putting our customers back in control.

“It’s not a one-off offer, it’s a commitment.”

www.anglometal.co.uk

With growing concern over the rise of indemnity policies being used in place of proper certification, Fensa is warning that installers must take the lead in safeguarding standards by ensuring every installation is correctly certified.

In the world of window and door installations, few documents carry as much importance as a Fensa certificate. It’s the homeowner’s proof that the installation meets Building Regulations, that it’s safe, energy

efficient, and properly registered with the local authority.

Yet, all too often, when a certificate is missing, the solution offered is not compliance but convenience: an

indemnity policy. And that, warns Fensa, is a growing problem that puts both homeowners and the wider industry at risk.

Indemnity policies are often presented as a quick fix when a property is sold without the right certification. They can seem reassuring – a neat piece of paperwork that allows the sale to proceed. But while they may

satisfy a solicitor’s checklist, they do nothing to verify that the installation is compliant, safe, or efficient. In effect, they conceal the issue rather than solve it.

“An indemnity policy gives a false sense of reassurance,” says Sam Davies, Fensa technical manager. “It doesn’t check the installation, it doesn’t verify compliance, and it doesn’t protect the homeowner. The real risk remains, buried in the fabric of the property.”

When an installer is not registered with a competent person scheme like Fensa, the responsibility for compliance falls on the homeowner. Many don’t realise that replacing windows and doors is classed as notifiable work, meaning it must be legally reported to building control.

Without that notification –

through a Fensa certificate or a local authority inspection – the work is technically illegal.

“If an installation isn’t notified, it’s unregulated,” Sam explains. “That means it hasn’t been checked for compliance with building safety or energy efficiency standards. A homeowner could be sitting on unsafe non-compliant work without even knowing it, which is obviously a huge safety risk.”

The consequences often only surface years later, when the property is attempted to be sold. Missing certification can delay transactions, reduce property value, or result in costly remedial work to prove compliance retrospectively.

Indemnity insurance won’t help in those cases. It doesn’t fund repairs or upgrades; it simply offers financial cover if a local authority acts – something that rarely happens but leaves the homeowner with an uncertified, potentially substandard installation.

For installers, the message from Fensa is clear: offering a certificate isn’t just a regulatory box to tick, it’s a vital part of building trust and professionalism.

Being Fensa-approved means being able to self-certify that every installation meets current regulations, sparing customers the cost and complexity of dealing with building control. It also provides the legal proof that homeowners, conveyancers, and lenders increasingly expect.

“A Fensa certificate is the difference between reassurance and risk,” says Sam. “It tells a homeowner that you care about doing things properly, that your work stands up to scrutiny, and that you take compliance seriously.”

The wider implications extend far beyond individual properties. Fensa believes that as the industry faces growing pressure to meet sustainability goals and higher energy standards, the absence of proper certification undermines confidence in the entire sector.

Homeowners are becoming more discerning, and they want evidence of compliance. For installers, being part of Fensa is both a mark of professionalism and a competitive advantage. It signals that their work contributes to a regulated, accountable, and energyconscious industry, says Fensa.

But according to Sam, the glazing sector must also confront a cultural issue – a lingering belief that certification is an administrative burden rather than a core part of quality assurance.

“We have to move beyond the idea that compliance is just paperwork,” he says. “It’s about safety, efficiency, and long-term assurance. Indemnity policies can’t deliver that. Only certification can.”

Ultimately, offering a Fensa certificate is not only the right thing to do, it’s essential to maintaining the integrity of the profession. Fensa says that installers who provide certificates protect their customers, their reputation, and the market itself. And that those who don’t may leave behind a legacy of uncertainty and risk that will surface long after the job is done.

Because in the end, a Fensa certificate isn’t just proof of compliance. It’s proof of competence. And that’s something no indemnity policy can ever replace.

For more information visit www.fensa.org.uk

In response to growing market demand for contemporary, designled colour options, Liniar has announced the addition of three new foiled finishes to its everevolving colour range: VLF Black, 7030 Grey and 7044 Grey. The latest additions strengthen Liniar’s already extensive palette, giving fabricators and installers even greater flexibility to meet customer expectations.

“We’ve seen a clear shift in market trends towards darker, more architectural tones,” explains Colin Sharpe, Liniar commercial director. “Black and grey shades continue to increase in popularity for both new-build and refurbishment projects, offering a sleek, modern aesthetic that works beautifully across a range of property styles. Our new foils reflect that trend – and as always, they’ve been introduced with our customers’ needs front of mind.”

Liniar’s decision to introduce these colours follows sustained demand from its network of fabricators and installers, many of whom report that homeowners are looking for a more refined, minimalist appearance in their window and door choices. By expanding the colour offering, Liniar ensures its customers can stay ahead of design trends while maintaining the exceptional quality and consistency for which the brand is known.

All three new finishes are foiled in-house at Liniar’s advanced lamination facility, where every profile undergoes meticulous quality control. Liniar says the Lamination Hall features a humidity and temperature-controlled environment, which not only guarantees a flawless, longlasting bonded surface but also ensures perfect colour-matching across Liniar’s PVCu systems and

its Alumina aluminium range – a unique advantage for fabricators working on mixed-material installations.

“Because we handle every stage of the foiling process ourselves, we’re able to maintain full control over quality and colour consistency,” adds Colin. “That’s something we’re extremely proud of, and it gives our customers total confidence in the end product.”

The expansion of Liniar’s colour range also underscores the

Continued on page 14

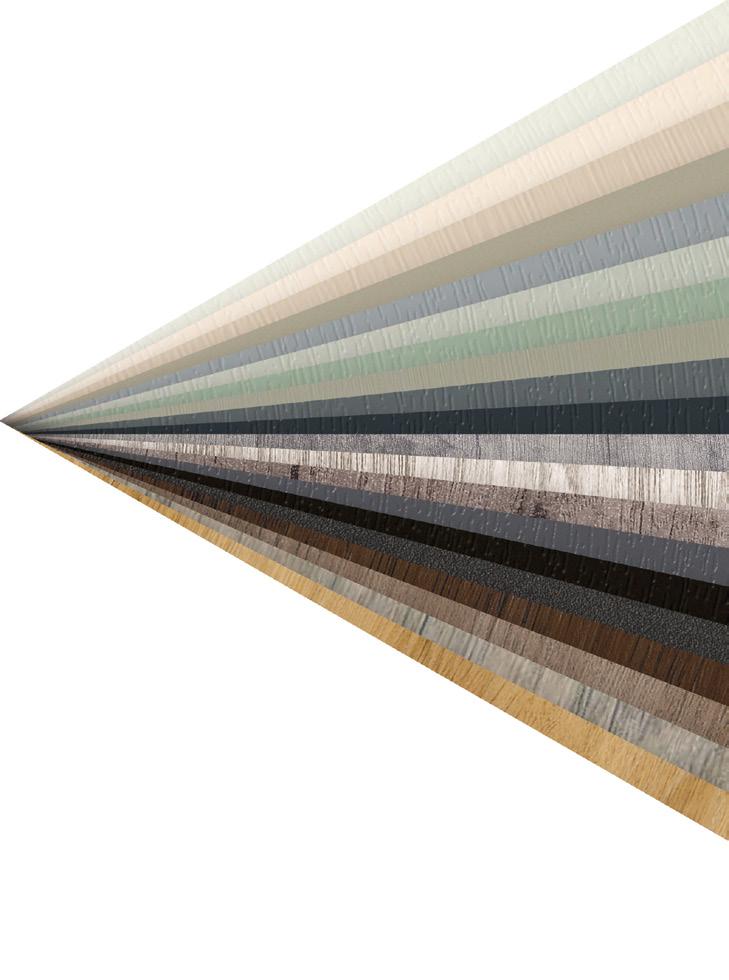

36 colours with a staggering 3330 possible combinations. Delivered from our in-house lamination hall featuring cutting-edge wrapping technology. A PARTNER IN YOUR SUCCESS FUTURE-READY PERFORMANCE SMARTER FABRICATION, BETTER MARGINS SINGLE-SOURCE BUILDING PRODUCT SOLUTIONS SCALABLE, RELIABLE SUPPLY

Continued from page 12

company’s ongoing commitment to innovation, sustainability and customer choice. With advanced foiling technologies designed to minimise waste and enhance efficiency, Liniar believes it continues to lead the way in sustainable UK manufacturing –without compromising on design flexibility or performance.

As aesthetics and personalisation become increasingly important in the home improvement market, Liniar’s three new shades offer

Keystone Market Research has announced the publication of its Autumn 2025 Consumer Fenestration Trends Report, marking two years of continuous insight into UK homeowner attitudes, preferences and spending behaviour across the fenestration market.

Drawing on feedback from more than 5,300 homeowners throughout 2025, this report consolidates findings from all four quarterly surveys, providing the most complete view yet of how consumer choices around materials, glazing types and investment intentions have evolved over the past year – and how they compare to trends first identified in 2024.

This edition was made possible through the continued support of our sponsors: Endurance Doors, Epwin Window Systems, the GGF, Liniar and Veka; whose backing has helped Keystone deliver independent, high-quality consumer research to the fenestration industry.

Charlotte Hawkes, director of Keystone Market Research, commented: “We’re proud

to celebrate two full years of publishing the Consumer Fenestration Trends Report and thanks to the support of our sponsors, we’re able to share this report for free, allowing more fabricators, installers and system companies than ever to access this important resource.”

Charlotte also joined an expert panel at this year’s Glazing Summit, where she shared highlights from the Autumn report – including key insights into shifting material preferences, consumer priorities and longterm spending confidence. The discussion drew attention to how young homeowners are set to be the largest market for home improvement projects next year and they are setting aside higher budgets to meet their requirements for superior quality, aesthetics and efficiency.

Now in its second year, the Consumer Fenestration Trends series has established itself as a trusted benchmark for the industry, helping businesses anticipate demand and tailor their strategies accordingly.

Keystone also announced that

fabricators and installers the opportunity to deliver even more tailored solutions.

“It’s all about giving customers the freedom to choose,” concludes Colin. “Whether it’s the timeless elegance of greys or the bold sophistication of black, these new finishes help create the perfect look – every time.”

You can take a video tour of Liniar’s world-class facilities at: liniar.co.uk/about/our-facilities

sponsorship opportunities for the 2026 series are now open. Sponsors receive early access to each quarterly edition and the ability to share the content directly with their customers, ensuring that their networks are armed with the latest consumer insights.

Companies can also subscribe to receive all 2026 reports annually, providing an ongoing source of market intelligence throughout the year.

You can register to receive your free copy of the Autumn edition until 19th December at: www. keystonemr.co.uk/sign-up.

For more information about the Autumn 2025 Consumer Fenestration Trends Report, sponsorship opportunities, or annual subscriptions, visit www.keystonemr.co.uk.

Emplas has launched a new £10,000 home security guarantee – which it says is proven to increase average order values by almost 40%.

The unique Emplas Total Home Security Guarantee gives qualifying Emplas customers the facility to offer a £10,000 guarantee to homeowners who sign-up to a full house window and door replacement.

Developed in partnership with Kubu, Avantis, Cotswold, and Avocet, the scheme was trialled for a year within Emplas’ dedicated retail business, T&K

It delivered a 39% uptick in average order values; a 14% increase in leads; a 46% increase in appointment booking rates; and a 27% increase in year-onyear sales.

Jody Vincent, sales director at the company, said: “The big difference is that whereas traditional security guarantees have historically focussed on door cylinders, the Emplas Total Home Security Guarantee will pay out on forced entry through any point in the home, as long as the installation meets set criteria

and doors and windows are deadlocked at the time.

“We’ve seen it generate a big increase in order values in our own retail business T&K Home Improvements by encouraging more homeowners to opt for full replacements, and just as importantly, drive an increase in leads.”

Available to qualifying Emplas customers only, the Emplas Total Home Guarantee, applies to any installation where all doors and windows are replaced by an Emplas approved registered installer.

As part of the scheme all windows and doors supplied feature Kubu Smart Security which must be activated within 48hrs of installation. The homeowner must also commit to a continuous Kubu subscription. Products also have to be specified to an enhanced security Secured by Design specification.

As long as they meet the requirements, homeowners who buy in to the scheme get access to £2,000 towards locksmith services; £3,500 for the replacement of damaged windows and doors; £2,500 to cover home insurance excess; and £2,000 towards any uninsured losses.

Emplas is also underpinning the scheme with marketing support for participating installers.

“Lead generation has never been more important”, Jody continued. “Homeowners are more discerning and the market remains highly competitive.

“By collaborating with Avocet, Avantis, Cotswold and Kubu, we’re providing our participating installers with the only £10k guarantee in the market to help them secure new retail business.”

In a market regularly described as a ‘race to the bottom’– Silka is showing installers that confidence in premium products still pays off. The aluminium brand has launched a new homeowner offer that rewards higher-value sales with up to £5,000 worth of free integral blinds, designed to help installers convert more customers while protecting the value of their sale.

Running until the end of the year, the promotion applies across Silka Aluminium Windows, Tilt & Turn Windows, Bifold Doors and French Doors. The value is calculated from the installer’s purchase price with Silka – not the resale price – giving trade partners complete control over their own margins and positioning.

Asa McGillian, managing director at Silka, says the promotion reflects a growing demand

for support that goes beyond product supply. “We know that homeowners are more informed than ever. They recognise quality but still want a reason to justify the investment. This offer helps our partners have that conversation with confidence – it’s about adding genuine value, not reducing price.”

The promotion is part of the Silkaselect trade partner programme, built to help installers succeed in the premium market. Silkaselect trade partners gain access to free homeowner leads, marketing content, showroom materials and sales support – all designed to make selling Silka’s high-end aluminium products easier, more credible and more profitable.

“As a business we’re focused on helping installers build sustainable growth, not short-term sales,” Asa

adds. “Silkaselect gives them the right tools, and the right story. Our luxury integral blinds promotion adds another layer to that – a tangible incentive that turns interest into action.”

Silka Integral Blinds are fully enclosed within the sealed unit and finished with a ceramicprinted edge – a baked-on enamel border fused to the glass during toughening. The ceramic edge hides the perimeter hardware and spacer sightlines, giving a clean, uniform finish that won’t scratch, fade or peel over time, says the company.

For installers, that means a clear visual advantage homeowners can see the moment they compare it with a standard unit – a premium, maintenance-free upgrade that’s easy to explain, simple to fit, and built to last. Every blind is also backed by a two-year warranty, reinforcing the quality homeowners expect from Silka.

Available until 31st December 2025, Silka’s free integral blinds promotion gives trade partners a powerful way to demonstrate a quick, quality, call-to-action.

National

Processing,

Quality

In-house technical team

Partner

CAB and GGF memberships

Full accreditation

Sustainability

Continuing delays at Gateway 2 are increasing pressure on cashflow and putting the construction supply chain at risk, according to the Glass and Glazing Federation (GGF).

The warning was made by Mike Butterick, President of the GGF at the launch of The Glass & Glazing Collective at the Houses of Parliament on October 28th.

Speaking to an audience of politicians, including keynote speaker Chris McDonald, Minister for Industry in the Department of Energy Security and Net Zero (DESNZ), and industry drawn from glass manufacturing, processing, recyclers and the

wider construction sector, Mike warned that companies were going out of business despite having healthy order books.

He said while the GGF and its members were fully supportive of the regulatory and legislative framework regarding Gateway 2 and were committed to improving safety and compliance in buildings, it was also important that the Government held up its side of the bargain, by making sure that regulators were properly resourced.

According to an update from the Building Safety Regultor in October, it still has 91 historic new build applications waiting for

Gateway 2 approval.

“The frameworks were put in place to improve safety and quality of buildings. They were not put in place to reduce economic activity at a time when we all want economic growth”, Mike said.

He also set out the GGF’s position on VAT on windows and doors arguing it should be rated at the same level as other insulating building products and renewables.

He said that against the backdrop of the move to renewables improving the thermal performance of UK homes “just made sense”

He argued that homeowners needed to be incentivised to replace many older doubleglazed windows and doors which might look good, but which fell significantly short of today’s high performing windows and doors.

“We provide great insulators. They save energy, and that’s still the number one reason why people replace their old windows and doors.

“But there are 80,000,000 first generation double glazed windows in the housing stock that don’t perform very well –those 80 million windows need replacing”, he said.

Mike built on this in a subsequent point on sustainability and circularity. He said: “If you remember those 80 million windows, well the good news is our industry recovers the materials in those old windows and recycles them, including the glass which is infinitely recyclable ,without any detriment to the performance of the product and to the quality of the product.

“It makes replacing those 80 million plus windows is the right thing to do, because we’ve got the circularity, the economic circularity system, in place.”

He also highlighted the economic and social value of the glass and glazing industry which he said turned over in excess of £5bn annually, while providing skilled employment for more than 100,000 people, with 80% of fenestration products manufactured in the UK.

This extened to a societal value, with windows and doors not only saving energy but also contributing to home security. He flagged the expected consultation on a revision of Document Q, which he stated included proposals to extend new build window security standards to the replacement and home improvement sectors.

“If we did that, it would mean, as a standard, our industry would provide the highest security performing windows and doors, and that takes pressure off the

police and off our legal systems, because it’s proven that high security products reduce domestic break in and burglary”, he said.

The Glass & Glazing Collective is a broad-church collaboration between the GGF, British Glass, Glass Futures and the Worshipful Company of Glass Sellers of London. It aims to unite the UK’s leading glass and glazing organisations and industry to champion the role that the sector plays in Britain’s industrial strength and net zero ambitions.

Other speakers included David Baines, MP for St Helens North and Sarah Champion MP for Rotheram, who highlighted the vital role the glass sector played in the UK economy and security. The event was also attended by Neil Coyle MP for Southwark and Bermondsey.

“The glass and glazing Federation is the only organization that represents all parts of our industry. So window systems, manufacturers, fabricators, installers, hardware suppliers, glass processors, flat glass manufacturers, and more besides”, Mike continued.

“We’ve got huge knowledge and experience. In recent years, we’ve been providing expert technical advice to support government.

“It’s really important that we nurture that and we do more across more government departments so that together, we can navigate the complexities and the challenges that we all face . . . to accelerate the economic and social value of what we do as an industry, because we do it so well”, he concluded.

For more information about the GGF and how it can support your business’ growth, please visit www.ggf.org.uk

Trade fabricator Modplan has announced the purchase of a new Supercut 6 Machining Centre from Avantek Machinery, marking the latest in a series of strategic investments designed to support the company’s continued growth and expand its production capacity.

The new Supercut 6 provides fully automated, high-precision cutting and machining, enabling Modplan to increase efficiency, consistency and output across its fabrication plants. This latest investment underpins Modplan’s long-term strategy of combining advanced manufacturing technology with its strong partnership ethos.

Heidi Sachs, managing director at Modplan, said: “Investment in the latest manufacturing technology is central to maintaining the high standards our customers expect from us. The Supercut 6 will further streamline our production processes, helping us to deliver volume premium-quality products more efficiently and with even greater precision. It’s another example of our ongoing commitment to future-proofing our business and supporting our growing network of trade partners.”

www.modplan.co.uk

In a world of rising costs and shrinking margins, window and door installers need a supply partner they can rely on. Renowned for its customer-first approach, Universal Trade Frames is putting its money where its mouth is, with a bold new initiative.

From the skills shortage to tightening regulations and increased labour costs, installation companies are arguably under more pressure than ever before. And with consumer expectations on the rise, one false move can severely impact a company’s reputation.

Against this backdrop, a trusted and reliable supply partner is key for any reputable window and door installer, as Richard Hammond, sales director at Universal Trade Frames, explains:

“Confidence in the supply chain has always been key, but especially so in the current climate,” he says.

“Today’s homeowners expect perfection, and installers often find themselves in the firing line if something goes wrong. We’re keen to demonstrate that Universal Trade Frames is a partner that won’t let you down.”

With this in mind, the Shrewsburybased fabricator has introduced ‘If It’s Faulty, It’s Free’, a marketleading guarantee scheme applicable across its full range of PVC-U windows and doors, including the Residence Collection.

The no-nonsense initiative offers a direct product replacement on any item with a confirmed manufacturing fault, reported prior to installation.

Covering issues such as irreparable surface finish defects, dimensional inaccuracies and other problems that prevent installation, all claims will be assessed by Universal’s quality control team. Faults must be reported within two working days of delivery and identified before installation begins to qualify for a replacement as part of the guarantee, but it doesn’t stop there.

Recognising the inconvenience caused by a faulty product, Universal has also pledged to reimburse the customer, in full, for the faulty item on their next order.

“Faulty products can be a major headache for installers,” explains Richard. “For a start, they cause disruption and waste time, and we all know time is money. Additionally, installers face added risk to their reputation, which can be very damaging, especially in the age of social media and online reviews.

“This guarantee shows that we are extremely confident in the high quality of our products. So much so, that on the rare occasion an item falls short of our impeccable standards, we will replace it and refund you the cost of the item, no quibbles.”

Raising the bar for customer support

This straightforward approach to fault resolution is part of Universal’s wider effort to make life easier for its customers, with a simplified, single-source supply model that boosts reliability and minimises site disruption.

Backed by an impressive On Time in Full (OTIF) delivery score of 98%+ and a dedicated quality control process, including hand finishing on premium products, the fabricator sees customer support as a problem solver, not a problem creator.

“We don’t just talk the talk when it comes to good customer service, we walk the walk,” adds Richard. “‘If It’s Faulty, It’s Free’ aims to reinforce our culture of confidence and trust and reduce risk for installers battling the everyday challenges of the modern window and door market.

“We hope it will give them peace of mind that we’ve got their back, especially when things go wrong.”

https://bit.ly/447cXio

THE WIDTH OF DOUBLE. THE POWER OF TRIPLE.

An ultra-thin centre pane is placed with sub-millimetre accuracy, using our leading flexible warm-edge spacer, allowing for the production of high-performance triple-glazed IGUs that are compatible with 70mm systems and require just one outer seal.

Thin triples, powered by Super

deliver exceptional energy efficiency in a smarter, lighter package

U-VALUES AS LOW AS 0.7-0.9 W/(M 2 K)

DESIGNED TO FIT STANDARD 70MM FRAMES

MORE THAN 40% LIGHTER THAN TYPICAL TRIPLE GLAZING

as

The latest Builders Merchant Building Index (BMBI) report, published in October, shows builders’ merchants’ total value sales in August 2025 were down -5.0% compared to the same month a year before. Year-onyear volume decreased -4.1% while prices were also down -1.0%. With one less trading day in 2025, like-for-like value sales for August (which take trading days into account) were -0.3% lower.

Only one of the twelve

categories sold more in terms of value compared to August 2024 – Workwear & Safetywear –which was up +2.7%. The worst performing categories were Ironmongery (-6.4%), Heavy Building Materials (-6.6%) and Decorating (-7.8%), but Timber & Joinery Products (-3.0%) performed better than Total Builders Merchants.

Looking month-on-month, value sales in August were -12.7% lower than in July. Volume sales were down -13.4% and prices

increased +0.8%. All categories sold less, but Ironmongery (-14.5%) and Miscellaneous (-15.0%) declined more than the rest. With three less trading days in August, like-for-like value sales were +0.3% higher.

Total value sales in the 12 months from September 2024 – August 2025 were up +0.1% compared to the previous 12-month period (September 2023 – August 2024). Volume sales were up +1.9% but prices decreased -1.8%. Five categories sold more by value, with Services (+3.1%), Tools (+2.9%) and Landscaping (+2.3%) performing best. Timber & Joinery Products, one of the two largest categories, fell -0.6%. Decorating (-2.7%) was the weakest category. With one less trading day in the most recent period, like-for-like value sales increased +0.5%.

Total value sales year-to-date (January to August 2025) were up +0.8% compared to the first eight months of 2024.

Mike Rigby, managing director of MRA Research which produces the BMBI report says: “August was an extra quiet month for Britain’s builders’ merchants and their builder and trade customers, with volumes down year-onyear and month-on-month. How much of the drop can be blamed on the weather and how much on hesitancy among consumers and businesses as the economic landscape looks uncertain is anyone’s guess. But 2025 has pushed the famous summer of 1976 out of the UK top five hottest summers on record. An August heatwave brought temperatures of 33.4C in parts of England

with 31.6C the highest in Scotland. The weather was also variable and varied by region with hosepipe bans across large parts of England, while Storm Floris brought gusts of over 80mph to parts of the UK and widespread disruption in Scotland. Not ideal for external work!

“But confidence in the economy and in the Government’s handling of it is undoubtedly playing a part, with almost daily references in the news to the Chancellor’s delayed Autumn budget and the bad news it may bring. The Institute of Directors announced in October that business confidence was at a record low according to its Economic Confidence Index, while consumer confidence dropped two points to -19 in September according to the

long-running GfK Consumer Confidence Index. With grocery inflation rising to +5.2% in October, and official UK inflation data expected to follow, there is no let-up in the squeeze on already stretched budgets.

“That said, there is good news for merchants, in the chancellor’s pre-budget announcement with Rachel Reeves expected to unveil a new raft of planning changes to make it easier for developers to press ahead with housebuilding and infrastructure projects. This could be the shot in the arm the construction industry needs to get building again, but the government may need to do more to revive consumer and business confidence.”

www.bmbi.co.uk

Conservatory Outlet is marking its 20th birthday in style by setting out a four-year growth plan to achieve £100m in sales.

The company, which is headed up by CEO Greg Kane and managing director Mick Giscombe, has unveiled a strategy that will see it invest heavily in diversifying its manufacturing operations and further expansion of its home improvement offering.

The Wakefield-based company is also marking the major anniversary by introducing a new corporate structure that will involve the introduction of Conservatory Outlet

Group as the holding business, with CO Manufacturing and CO Home Improvements reflecting its two main areas of operation.

New websites and branding have been introduced to support the name change, kickstarting a £1m investment drive that will involve the installation of state-of-theart CNC machining at its Cutting Room facility, a fleet of commercial vehicles, new IT infrastructure and the creation of 20 new apprenticeships.

“We’ve had a fantastic two decades in business, enjoying significant growth across both

our manufacturing and retail arms – so much so that we are now generating £62m of annual revenues and employing more than 400 people,” explained Greg Kane, CEO of Conservatory Outlet Group.

“This is just the start. You can’t stand still in our world, and we want to continue to meet customer expectations when it comes to new home improvement products and improving their experience.”

He continued: “That’s why we’ve outlined a new four-year growth plan that will look to accelerate us towards £100m and, to do this, we required a clear business structure that clearly celebrated our history but also paved the way for the future.

“Our group will now comprise CO Home Improvements (covering

the six retail businesses we own – Clearview, Orion, Planet, Trent Valley Windows, West Yorkshire Windows and Yorkshire Windows) and CO Manufacturing.

“The latter reflects our commitment to delivering the highest quality windows, doors and living spaces to our vitally important Premium retailers, but also the growth opportunities we see in other markets.”

CO Manufacturing has identified strong expansion possibilities in its fledgling trade products business in the North West and Yorkshire, as well as with housing companies through its dedicated new build offer.

The firm has developed a specialist collection of windows and doors for both areas and is investing £1m in 4-axis CNC machines to give it greater capacity and repeatable quality across its production facility.

Similar levels of investment are being channelled into boosting the skills of its workforce, with 10 apprentices currently being recruited and the launch of its tailored Manufacturing Degree pathway that aims to create the production leaders of the future.

Greg went on to add: “We’re currently generating over £30m of revenues across manufacturing and we believe, with the right backing and diversification, we can take this figure up to £50m.

“The market is changing and we’re helping push the boundaries of innovation when it comes to thermally efficient products and utilising new materials for achieving different aesthetics.”

CO Home Improvements will work closely with the company’s network of 22 independently owned retailers, which span all of England and Scotland.

These firms have worked with the business for many years and share its values of excellent customer service and trust, with an appetite to embrace the latest technology to improve the client journey.

The network complements the firm’s six retail brands that operate predominantly in the East Midlands, North West and Yorkshire.

Greg concluded: “We are expecting similar growth in retail as we are in manufacturing and, together, we’ll hopefully hit the £100m target by 2029.

“Our aim is to enhance the support we give to our network even further so they can collectively achieve great things, as well as looking at the opening of four new showrooms in Derbyshire, South Yorkshire, the Lakes and one in either Liverpool or Manchester.”

comanufacturing.co.uk

Reynaers Group has published its new annual sustainability report – Our Sustainable Road Ahead 2024–2030 – which highlights an 8.5% reduction in operational carbon, as well as a 13.6% reduction in embodied carbon, crediting its comprehensive approach as the key driver in its sustainability gains.

With its initial sustainability benchmarks set in 2019, this new report denotes the halfway point towards Reynaers achieving its ambitious Science Based Target initiative (SBTi) goals of a 46.2% absolute reduction in emissions and 55% relative reduction in emissions by 2030.¹

Looking beyond embodied carbon, Reynaers takes a broad approach to sustainability, the focal point of its new campaign ‘Sustainability. From Every Angle’ which calls for a wider focus on sustainability, challenging the established view in the construction sector that embodied carbon is central to achieving long-term sustainability.

Having said this, Reynaers is achieving a consistent decline in emissions through further decarbonisation of its aluminium systems, according to the company. In 2019 for each kilogram of sourced aluminium the average footprint was 5.16kg Co2 eq. The report highlights that by pursuing low-carbon aluminium Reynaers was able to reduce this by 20% to 4.13 Co2 eq./kg by 2024. The aim is to reach 2.81kg Co2 eq./kg by 2030.

Reynaers approach calls for much more than a focus on embodied carbon. Its latest

112-page report cites a variety of factors contributing towards an improved carbon footprint, including its investment in infrastructure incorporating new low-energy campuses in Poland and Switzerland, electric car fleets and developments in ecodesign for product circularity.

Reynaers Aluminium now boasts 15 Cradle to cradle systems including over 50 variants – MasterLine windows and doors, ConceptSystem 77 windows and doors, SlimLine 38 windows and doors, MasterPatio, HiFinity as well as its curtain wall ranges including ConceptWall, ElementFacade 7 and SlimWall 35 products.

John McComb, technical director and sustainability

champion at Reynaers Aluminium UK, said: “Sustainability is at the core of what we do at Reynaers, and this new report highlights the significant gains we have made in our journey to a sustainable future.

“In order to lower our environmental impact, we have implemented a comprehensive sustainability strategy that looks beyond the focus on embodied carbon in the industry, to cover all aspects of our products and operations.

“It is essential to understand that sustainability is constantly evolving, and to adequately reduce our environmental impact we must be adaptable and foster a culture of continuous education and change within the industry as a whole. The sustainability gains highlighted in the latest Reynaers annual report demonstrates why it is vital to look at our environmental impact from every angle, and that we all take ownership of our impact to ensure true sustainability for our built environment, and those who reside within it, long-term.

“We recently held a webinar outlining our journey to a more sustainable future and our approach to sustainability from every angle. In 2026, we aim to host further webinars centring on various angles and what impact we can make in helping to carve out a future of sustainable construction.”

Reynaers ambitious sustainability goals are guided by The Science-Based Targets Initiative (SBTi).

Find out more about Reynaers commitment to a sustainable future and download its latest report ‘Our Sustainable Road Ahead: 2024-2030’ here: reynaers.co.uk/sustainability

Coral Windows has built a 35year legacy as one of Yorkshire’s most established home improvement firms, and its 20year partnership with systems company Deceuninck has been central to that success, according to the company.

Founded in 1990, managing director, John Valente, came into the industry through joinery, later gaining experience in sales, finance and manufacturing. “I’ve worked across trade and retail, in timber and uPVC,” he says. “It gives you perspective on what matters to installers and to

homeowners.”

Today, Coral focuses primarily on the retail market, while also taking on contracts for schools, colleges and commercial premises.

Coral began working with Deceuninck in 2004. “What stood out was how forward-thinking the business was, and still is,” John explains. “They had big plans and have always backed them up.”

Over the past 20 years, Deceuninck has supported

Coral across tooling, marketing, product development and more.

“They’ve helped us in so many ways it’s hard to quantify,” John says. “What’s always been consistent is their honesty, and how easy they are to deal with.”

The partnership is underpinned by shared values, particularly around sustainability.

“Deceuninck’s environmental targets, like reducing CO₂ by 60% by 2030, give us real talking points with customers,” says John. “People want better performance, but they’re also thinking about the bigger picture. That alignment is important.”

Innovation remains a key part of Coral’s growth strategy. The company’s exclusive SmartFrame technology, for example, integrates with ERA’s Smart Hub to offer live monitoring, tamper alerts and instant notifications through a dedicated app.

“SmartFrame’s been a great success for us,” says John. “It

gives us something different in the market. And Deceuninck’s profiles gave us the flexibility and strength to bring it to life.”

Deceuninck’s broad colour offer, which includes 30+ options from stock and more available to order, has also played a part in Coral’s retail performance. “Coloured frames and Flush Sash are only going one way –up,” John continues.

“People want choice and design freedom. Colour lets them personalise their homes, and the demand’s there.”

Coral’s customer-first ethos is also reflected in its long-standing no-deposit, no-stage-payment policy. “It’s about trust. We do the work, then take payment,” John says. “Simple as that.”

“We’re ahead of this point last year, and that’s encouraging,” says John. “It’s not a boom market, but we’ve got strong repeat business and we’ve stayed focused.”

With the second half of the year now well underway, Coral is focused on building momentum. “We’re always looking for new products and innovations to expand our portfolio,” John explains. “Our latest addition is the Triple Track sliding patio; it’s where the market is heading, and Deceuninck’s support helps us stay ahead of the competition.”

With 35 years of experience and a trusted supply chain in place, Coral is approaching the future with confidence.

“We’ve always backed our service, backed our people, and partnered with suppliers who do the same,” John concludes. “That’s how you keep moving forward, and we’ve no intention of slowing down.”

www.deceuninck.co.uk

RegaLead has teamed up with window and door design software specialist WindowCAD, to bring Engineered Door Components directly to installers.

The entire range of Engineered Door Components is now available as design options in WindowCAD 7. It gives installers the ability to design and upsell high-end PVCu doors to homeowners, using WindowCAD’s software which creates rotatable, 3D images of door styles in real-time during the design process.

“WindowCAD software really delivers the wow-factor,” says Guy Hubble, joint managing director at RegaLead. “The detailing on the 3D images is second-to-none and you can zoom in and rotate the images so you can see the finer details during the design process. It’s such an impressive tool to help installers sell.”

Engineered Doors are a growing market opportunity and RegaLead has designed a PVCu – based system of decorative door panels and plant-on mouldings to make Engineered Doors an easy addition to any

fabricator or installer’s product range. The collection includes flat, tongue and grooved, and raised and fielded panels in more than 70 standard and 100 special order colour foil finishes to suit most PVCu systems.

Guy adds: “We’ve seen phenomenal growth in timberlook PVCu windows, showing there is a real appetite for high-end, premium products that mimic the traditional craftsmanship of timber whilst offering all the benefits of PVCu.

“All that was missing was a PVCu door system that could offer an equally high-end timberstyle design with the right colour options and aesthetic components – that’s what our Engineered Door Components range delivers.”

Leigh Walker, managing director at WindowCAD, adds: “Accurate 3D visuals are one of the strongest tools that installers can have in their pocket when selling premium products.

“Having all of the door panel styles, decorative and bolection mouldings, in the full range of colours and finishes in WindowCAD, makes it easy for installers to show all of the options. Plus, they can show decorative glass styles and additions such as astragal bars, so homeowners don’t have to imagine their new door – they can see exactly how it will look on screen, right down to the finest detail.”

www.regalead.com

www.windowsoftware.co.uk

Jeld-Wen, manufacturer of timber fire doorsets, has reported a 10% reduction in Scope 1 and 2 greenhouse gas emissions since 2021 across its global footprint, as it continues to target net zero in its operations, says the company.

The results published in the company’s 2024 Sustainability Report reflect the progress JeldWen has made in embedding sustainability into its operations, from energy efficiency upgrades to smarter resource management and renewable energy use.

At its flagship sustainability facility in Penrith, Jeld-Wen has already achieved zero waste to landfill and transitioned to 100% renewable energy, supported by biomass boilers powered by timber byproducts.,claims the company.

The site’s ongoing investment in low-carbon technology, including

electric forklift fleets and smart energy monitoring, has played a key role in reducing emissions, improving operational efficiency and securing Cradle to Cradle Certified Bronze status for selected door ranges, according to the company.

Building on this progress, Jeld-Wen has also announced the relocation of its Sheffield operations to a new, purposebuilt facility at Bessemer Park, designed to support sustainable manufacturing. The modern site is being developed to improve operational efficiency, reduce environmental impact and provide an enhanced working environment for employees.

“Sustainability is at the heart of how we operate,” said Hamish White, director of operations at Jeld-Wen UK. “We’re investing in efficient technology, renewable

Jeld-Wen has reported a 10% reduction in Scope 1 and 2 greenhouse gas emissions since 2021 across its global footprint, as it continues to target net zero in its operations.

energy and responsible processes that make a measurable difference to our carbon footprint, all while ensuring we continue to deliver the quality and reliability our customers expect.

“Tackling operational emissions has been a key priority for the UK, and we have made substantial progress in supporting the company’s global reduction of 10 per cent,” Hamish continued. “We are continuing to make improvements to operate more sustainably, as well as look at effective ways to bring down scope 3 emissions.’’

Across its UK operations, JeldWen continues to make progress against its long-term ESG commitments, which include achieving net zero Scope 1 and 2 greenhouse gas emissions and eliminating manufacturing waste to landfill by 2050, claims the company

To view the full 2024 Sustainability report, visit: https://bit.ly/481fSvq

With a shared passion for quality products and customer care, Sternfenster and CWD Improvements make a dynamic fabricator-installer team. We report.

Local to Camberley and serving Berkshire, Hampshire and Surrey, CWD Improvements specialises in the supply and installation of windows, doors and conservatories, as well as roofline accessories.

Established eight years ago, the Sternfenster installer offers highquality fenestration in PVC-U, aluminium and timber, as well as composite products, working across both residential and commercial markets.

Run by a team of formally trained carpenters with extensive experience of designing, producing and fitting windows and doors, CWD is defined by its passion for precision, quality, and craftsmanship.

“We’ve been working with Sternfenster for the past four years now,” says Joanne Campbell, director at CWD Improvements.

“Professionalism and service are key priorities for us, and we felt

that Sternfenster were a great fit because they strongly reflect our values.

“The quality of manufacture is outstanding, the lead times are very good, and the customer care is second to none. They tick all the boxes,” she adds.

When it comes to products, Sternfenster’s PVC-U flush casement windows are a particular favourite of CWD.

“We’re a big fan of the PVC-U flush casement,” says Joanne. “It’s a really well-made product that looks great, with numerous energy efficiency and performance benefits.

“The aesthetics are quite sleek and similar to aluminium, but being PVC-U, the price point is much more competitive, and that’s a big plus for our customers.

“The colour choice is great too, with single colours kept in stock and available on a quick turnaround, which really helps us out.”

With standard and premium options available, Sternfenster offers cutting-edge in-house spraying facilities, with the ability to match virtually any RAL colour.

Offering a u-value of 1.4 W/m2K and a WER of ‘A’ for superior thermal efficiency,

Sternfenster says its flush casement windows won’t rot, warp, rust, bow, crack or discolour over time.

And for those looking for the ultimate flush finish, the fabricator’s exclusive StyleLine windows and doors utilise a unique cornerwelding process to achieve just that.

Available as a flush sash or chamfered profile with authentic styling, StyleLine windows are manufactured with state-of-the-art

Seamless Quad Welder technology from Graf Synergy, to create their trademark look.

With the grooving stage entirely removed from the process, there is no loss of vinyl at the corner joint, meaning the excess plastic is pushed inside the chambers for a tidier, more appealing finish.

Sternfenster’s innovative product offering is backed by its unique online customer portal, SF+, and EasyAdmin+, a cloud-based

quoting and delivery processing tool.

Window installers are able to design professional quotes and track and manage leads, with full control over the production and delivery process, creating new business, reducing errors, and maximising profits.

“SF+ is a great source of technical information, and it also gives us delivery dates within 24 hours of ordering, which is really helpful,”

Barnsley based Euroglaze already boasts a wider range of options in Rehau than almost any other trade fabricator in the UK, and now it has gone one step further – leading the way with the launch of frames in the new Rehau Alux finish.

Alux is a gunmetal colour with a metallic finish, which gives the

sleek appearance of aluminium, while retaining all the inherent performance benefits of PVC-U.

Euroglaze is offering Alux as an option on all its Rehau frames in the Total 70, Rio and Slinova systems, giving trade customers plenty of new sales opportunities.

Nicky Park from Euroglaze’s

adds Joanne.

“Sternfenster manufacture to a very high standard, with no delays or quality issues. On the rare occasion that there is a problem, it is dealt with promptly and efficiently.

“The quoting team are knowledgeable and helpful – we couldn’t ask for a better supply partner,” Joanne concludes.

www.sternfenster.com

sales and new business development department commented: “We expect Alux to sell particularly well on our Rio Flush casements because it creates a modern, contemporary window which is almost indistinguishable from aluminium – at a much more affordable price.

“Flush casements are already almost twice as likely to be foiled as traditional PVC-U casements, and we are seeing that trend increasing. According to the latest figures from software specialists Tommy Trinder using data from their 700+ installer base, 34% of flush casements are already finished in grey – whether that is agate, anthracite or another shade, and I think this Alux metallic grey option will only add to that.

“It gives our installers a new and exciting alternative to anthracite and is a great way to differentiate themselves from their competition. It means they can potentially win business in new builds and contemporary refurbishments which might previously have automatically gone to aluminium, as well as increasing their margins in PVC-U with a product which looks and feels very premium.”

https://www.euroglaze.co.uk/

As ESG performance becomes a defining factor in specification and tendering, Glass Express Midlands’ partnership with Guardian Glass reflects a commitment to responsible supply practices.

Demonstrating environmental responsibility is fast becoming a prerequisite for success for commercial projects, with

ESG (Environmental, Social and Governance) credentials and sustainable supply chains increasingly influencing tender outcomes.

For Glass Express Midlands, its partnership with Guardian Glass on the manufacturer’s innovative cullet return scheme reflects a genuine commitment to closing

the loop on glass production – and to helping its customers strengthen their own sustainability story, says the company.

The initiative allows waste glass from Glass Express Midlands’ manufacturing process to be collected, returned, and recycled directly into Guardian’s float glass production. It’s a simple yet powerful system that turns what was once waste into a valuable resource.

“Every offcut that leaves our factory now has a second life,” explains Fraser Caithness, sales director at Glass Express Midlands. “We collect all our cullet in dedicated bins that Guardian collects and feeds back into their production line.

“That glass is then remade into new float glass, so the circle continues. It’s proof that sustainability doesn’t have to be complicated – it just needs commitment.”

The environmental impact is

considerable. By reintroducing cullet into the manufacturing process, Guardian reduces its reliance on virgin raw materials like sand and stone, while also cutting the energy required to melt them. The result is a lower-carbon product with far less waste to landfill, according to the company.

“Recycling glass through the cullet scheme doesn’t just make environmental sense, it makes business sense,” Fraser continues. “It reduces waste disposal costs, conserves natural resources, and helps lower emissions right across the supply chain. It’s a win for us, for Guardian, and for the end customer.”

For Glass Express Midlands, initiatives like this are also a key part of its customers’ commercial success. Many of the company’s clients work on public or government-funded projects,

where sustainability is now a key evaluation criteria.

“Tender documents now ask directly how you manage your environmental responsibilities and how your supply chain supports that,” Fraser says. “Installers can’t just say they care about the environment – they have to show it. Working with a manufacturer like us, who’s embedded sustainability into our processes, helps them prove it on paper and in practice.”

Glass Express Midlands’ approach to environmental responsibility extends beyond recycling. The company prioritises local sourcing to reduce transport emissions and partners exclusively with suppliers who share its sustainability principles.

“We’ve always believed that doing the right thing environmentally is also the right thing commercially,”

Discover service that goes beyond hardware supply. Our team of experts are on hand to advise, source and deliver the hardware you need, when you need it.

Fraser adds. “By buying locally, optimising production, and collaborating with partners like Guardian, we’re creating a genuinely sustainable model that benefits everyone involved.”

As sustainability continues to shape procurement standards and customer expectations, Glass Express Midlands’ partnership with Guardian Glass shows how meaningful collaboration can create both environmental and competitive advantages.

“As a supplier, our role isn’t just to deliver glass, it’s to add value,” concludes Fraser. “By reducing waste and helping our customers demonstrate real environmental action, we’re not just improving our footprint – we’re helping theirs look better too.”

glassexpressmidlands.co.uk

‘what you see is what you spec’ with

Following on from the publication of its new Environmental Product Declaration (EPD) for its SF52 aluminium curtain wall system, Senior Architectural Systems is encouraging contractors to challenge manufacturers to provide the proof behind their sustainability claims.

Overseen by Senior’s dedicated UK sustainability lead Luke Osborne, the development of the company’s new EPD

document has been done in a deliberately different way and, according to Senior, sets a new benchmark for transparency in the fenestration industry. Unlike many EPDs that include insulated glass units, which are typically not supplied by system houses, Senior has chosen to omit glazing from its calculations on the environmental credentials of its SF52 aluminium system. This is because the heavy weight of glass, combined with

Luke Osborne, Senior’s UK sustainability lead

its relatively low carbon per kg, can make the overall figures for the aluminium system look lower than they really are after conversion. By omitting the glazing from its EPD, Senior ensures that the carbon figure per square metre reflects only the aluminium system itself,

giving a more accurate and honest assessment, says the company.

The SF52 EPD also introduces non-linear scaling, which is a first for the sector. Instead of relying on a single reference size, Senior has verified three different system sizes and consolidated them into one publication. This is said to allow for more precise calculations across a range of project configurations and removes the guesswork from environmental assessments.

Senior’s approach goes further still by including the environmental impacts of profile extrusion and non-aluminium components such as thermal breaks, gaskets, and fixings. These elements are often overlooked but can significantly affect the overall footprint of a system. By accounting for them, Senior says it provides a more complete picture of what specifiers are actually choosing.

Senior’s UK sustainability lead Luke Osborne explains:

“Our new EPD offers a holistic overview that spans from manufacture to delivery and fabrication. It reflects the realworld journey of the SF52 system through our UK-wide fabricator network, but most importantly, it includes the depth of relevant detail that is needed for a more accurate assessment of a product’s performance. We are proud to be setting a new standard for how environmental data should be presented in the fenestration industry and we are set to build on this with the development of further EPDs across our product range, including our patented PURe aluminium system.”

Download the SF52 EPD via Senior’s NBS Source profile or request a copy from UK sustainability lead Luke Osborne at lukeo@sasmail.co.uk seniorarchitecturalsystems.co.uk

Eurocell has launched two CPD courses designed to help fenestration and construction professionals stay ahead of evolving building regulations and overcome common compliance conflicts.

The manufacturer, distributor, and recycler of PVC-U building products has released Compliance with Design: Part L vs Part O and Elevating Design: Fenestration Solutions for Regulatory Compliance. The courses offer architects, specifiers, fabricators and builders, practical solutions for meeting the latest requirements in energy efficiency, overheating prevention, and fenestration design.

Compliance with Design: Part L vs Part O focuses on the balance between energy efficiency and preventing overheating. It explains how professionals can meet the requirements of both Approved Documents L and O by managing heat loss, reducing energy demand, and selecting the right glazing solutions for optimal comfort.

Elevating Design: Fenestration Solutions for Regulatory Compliance offers a comprehensive guide to overcoming the challenges of

energy performance, solar gain control, and safety standards. This CPD explores how to select the best materials, glazing, and window configurations to meet regulatory demands while balancing solar gain control, ventilation, and design goals.

“We’re committed to helping fenestration professionals navigate the increasingly complex world of building regulations,” said Arron Crisp, technical specification manager at Eurocell.

“For example, the conflict between Approved Document L’s energy efficiency targets and the overheating concerns in Document O is a common challenge. Maximising window size for daylight can often increase solar gain, undermining the thermal performance required by Document L. It’s a delicate balance and that’s where our CPDs come in.

“We’ve designed these CPDs to tackle challenges like this headon, providing professionals with practical, actionable solutions to meet the toughest regulatory standards. Our goal is to help the industry create highperformance, energy-efficient designs that don’t compromise on comfort or sustainability.”

Eurocell’s courses can be taken online, in-person or on demand and provide forward thinking solutions for some of the industry’s most common challenges with building regulations.

www.eurocell.co.uk/cpd

The Haffner team has returned from a week-long series of open days for customers and partners at Graf Synergy’s headquarters in Nonantola, Italy, with a host of new orders to fulfil.

Matt Thomas, managing director at Haffner Ltd, said: “The open days were attended by more than 950 customers and industry operators from around the world. As Graf Synergy’s exclusive UK partner, we were delighted to have hosted so many UK businesses. The value we were able to demonstrate led to most attendees placing orders for Graf machinery.”

The open days were an opportunity to showcase the advanced technological solutions developed by Graf Synergy to improve quality, aesthetics and production efficiency.

Matt commented: “The open days allowed us to show how Graf

machinery transforms production processes and creates value for customers, not least through its patented V-Perfect seamless weld technology.”

During the open days, visitors were able to see a fully automated production line layout, from the renowned welders with the V-Perfect technology to the latest generation cutting centres and the integrated Fast Forward Plant logistics system.

The machinery on display showcased the latest in precision and efficiency, including V-Perfect welding machines with 2-4-6 and 8-head configurations. These offered welding without the need for post-corner cleaning, as well as crossbar welding with or without aluminium covers, and threshold welding. Also featured were systems designed for V-cut crossbar welding and inverted frame welding for both internal

and external openings, along with high-speed welders capable of completing one or two frames in under 50 seconds. Completing the display was a traditional production line, incorporating double-head cutting machines, controlled-axis cleaning systems and an automated centre for glazing beads.

The open days also featured live demonstrations of innovations and systems designed to speed up production and increase the quality of the final product, as well as presentations from Graf Synergy technicians.

Alongside the learning, attendees were able to network with fellow professionals and make valuable industry connections.

Matt concluded: “Graf Synergy seamless technology is a powerful differentiator for fabricators, and these open days demonstrated the strength of the innovations. We’re looking forward to supporting our customers to realise all the benefits and opportunities they bring.”

www.haffnerltd.com

Six months after its debut, Alunet Systems’ Aluna+ window system is steadily gaining momentum within the aluminium fenestration sector. Launched at RAF Cosford in April this year, the system arrived at a time when Alunet says the market had grown increasingly saturated with complex, over-engineered options that often-added friction for both fabricators and installers. Aluna+ was designed to take a different approach. According to

Alunet, where much of the industry has chased innovation through complexity, the company took the opportunity to re-evaluate what efficiency could look like in practice. The result, says Alunet, is a system that aims not only to meet current performance and compliance standards but to do so with fewer moving parts and clearer fabrication logic, attributes that have become increasingly valuable in today’s demanding

commercial and residential project landscape.

At the centre of the Aluna+ design is a patent-pending universal sash and transom profile, developed to simplify stockholding and manufacturing while reducing overall system part count by more than 30%. The intention is to free up bench space, streamline assembly, and help fabricators retain cashflow, without compromising on technical integrity or visual impact. “The traditional mindset in aluminium system design often sees complexity equated with innovation,” says Chris Armes, technical and new product development director at Alunet Systems. “But for fabricators, complexity can slow production, inflate overheads, and introduce

more room for error. With Aluna+, we wanted to deliver a system that does the opposite – one that makes aluminium fabrication feel as straightforward as it should be.”