Speciality Marine Lubricants

At Wilhelmsen, we understand the challenges you face operating in a demanding marine environment, and the need to protect your people, assets, cargoes, and the environment from potential harm.

That’s why we have chosen to form an exclusive partnership with Klüber Lubrication in the field of high-performance speciality marine lubricants.

Klüber Lubrication, in close cooperation with leading OEMs, has pioneered the creation of high-performance speciality marine lubricants, including the environmentally friendly range of EALs that safeguard maritime equipment, prolong the lifespan of its components, improve reliability, reduce downtime and operational costs, and extend maintenance intervals.

This exclusive partnership brings you Wilhelmsen Ships Service’s reputation for servicing the maritime industry through our unparalleled worldwide distribution network, our global team of committed technical lubrication experts, and dedicated 24/7 customer service, combined with Klüber Lubrication expertise in precision engineering and high-performance speciality lubricants.

We have a global footprint and the largest delivery network in maritime industry.

Klüber Lubrication has been cooperating with all major OEMs from the maritime industry and has received multiple OEM approvals.

We always test the products that we include in our portfolio. Thus, our product range only includes highly performing and highly reliable solutions.

We have global delivery capabilities and can supply our complete range of solutions in more than 1,800 ports.

We have a team of specialised Technical Specialists & Business Development Managers that can support and provide technical consultancy to our customers about Speciality Marine Lubricants.

We are always compliant with local and international regulations, and we choose partners and products that are also compliant.

Klüber Lubrication high-performance speciality lubricants are designed for a variety of vessel applications. They provide protection against wear and corrosion, which allows longer intervals between maintenance and greater lifespan of ship components. The range also includes Environmentally Acceptable Lubricants (EALs) that comply with the requirements of the Vessel General Permit (VGP).

• High resistance to water spray-off

• Increase re-greasing intervals to 4 times as long as before or even longer

• Reduced types of different greases required on board

• Crew can easily manage the reduced inventory

• Multipurpose greases can be used across multiple applications

Grease loss due to rain, waves, and spray on steel wire rope and other deck equipment contributes to increased lubricant usage and higher operating costs. Klüberplex AG 11-462 with its excellent water resistance and adhesion offers:

• Extended re-lubrication intervals

• Lower grease consumption

• Better corrosion and wear protection

This helps lower your operating costs and increase your profits.

Test procedure ASDM D-4049

1. Application of approx. 3 g of grease onto steel plate and weigh

2. Spray water (38 °C, 2.8 bar) for 5 minutes

3. Clear all grease that was pushed off of the top surface of the plate

4. Dry at 66 °C for 1 hour, then reweigh

5. Calculate % of grease sprayed off of the plate

Standard EP2 grease after test: 88% spray-off

Adhesion is important for open gear and steel wire rope lubricants to prevent dripping down, especially in tropical temperatures or on sun heated surfaces. Due to its unique composition, Klüberplex AG 11-462 shows excellent adhesion to metal. Customers benefit from reduced wear of machine elements and better corrosion protection.

In-house adhesion test

NLGI 2 open gear grease

Pictures show 2.5 mm thick grease layer after 48 h at 70 °C on a vertically positioned sheet metal.

AG 11-462: 1% spray-off

In addition operators benefit from:

• Lower work load and grease consumption

• Cleaner decks – increasing worker safety

• Extended life of equipment operating in harsh environmental conditions.

Open slewing gear lubricated

Result: Klüberplex AG 11-462 achieves better adhesion on metal surfaces at higher temperatures than other open gear lubricants.

• Compliant with 2013 Vessel General Permit (VGP)

• Biodegradable, non-toxic to aquatic life and non-bioaccumulated

• Excellent corrosion protection and water resistance

• Lower maintenance costs and extended equipment life

• Cost-Effective Over Time

Klüberbio AM 92-142 was developed in response to Redaelli’s request (Italian OEM for offshore steel wires) for a grease that meets several important requirements such as:

• Excellent compatibility with zinc coating

• High dropping point above 150°C when used in dynamic wire rope operations

• Good adhesion and water wash off stability

• Good wear and corrosion protection

• Low temperature behavior - retains its functionality down to -60°C.

1. A thin metal plate with a film thickness layer of 1 mm was used 2. This was cooled down to desired low temperature for 24 hour 3. The test sample was wrapped around a cylinder

The lubricating film of Klüberbio AM 92-142 retains its functionality down to the tested temperature (-60°C), if the grease does not get disrupted of peeled off.

Klüberbio AG 39-602 N is applied in several different applications on vessels such as steel wire ropes, open gears, sliding bars, slewing gears, slow turning plain and roller bearings. Main advantages are:

• Strong adhesion with no dripping

• High stability against water washout

• Good wear protection

• Strong protection against corrosion

• Suitable for automatic lubrication systems

• EU Ecolabel

The test determines the grease’s ability to protect gears from wear under slow-speed conditions, which is crucial for applications such as open gears, slewing bearings and slow-turning plain and roller bearings.

Klüberbio AG 39-602 N demonstrates 10 times lower levels of wear compared to competing products and better protection for gears due to its special composition and higher water resistance.

• Specifically designed for thruster, stern tube or gearbox applications

• Less frequent top-up required with emulsifying oils

• Maximum protection against wear and corrosion, high efficiency and extended life performance at increasingly numerous lubrication points

• Largest number of OEM approvals offering the right lubricants for your vessel needs

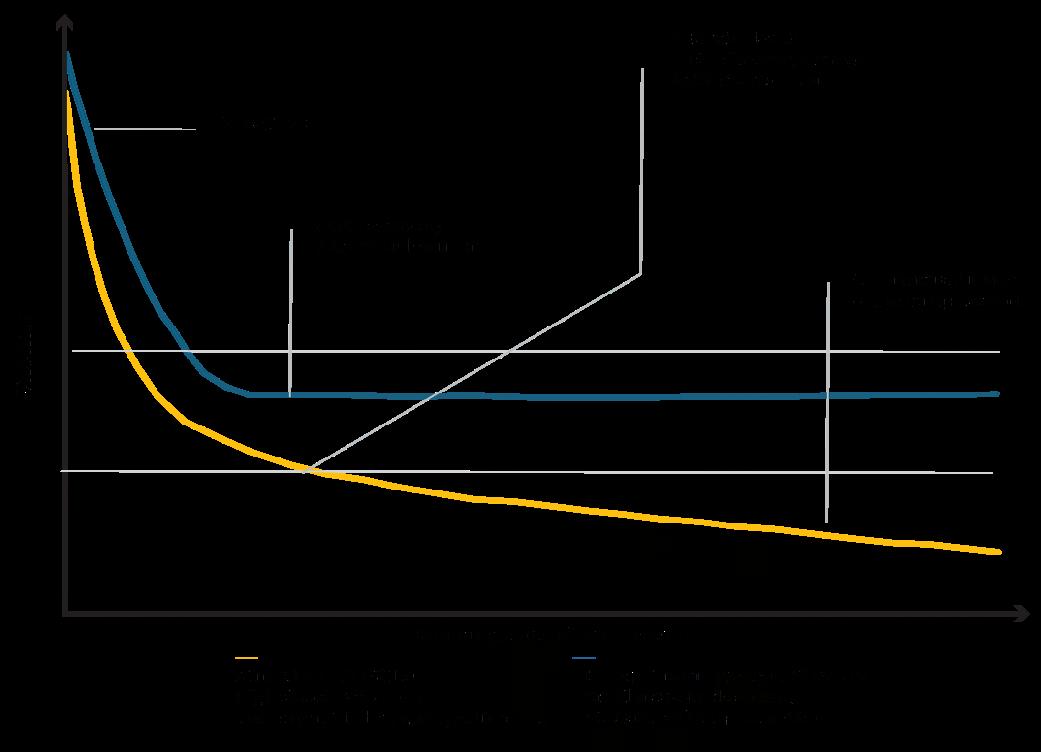

High shear stability of Klüberbio EG 2 gear oils ensure long service of equipment and lubricant

One measure of a lubricant’s protective value is how well it withstands shearing under pressure. “Shear Stability” describes a lubricant’s ability to resist a decrease in viscosity due to exposure to mechanical loads. Maintaining the appropriate viscosity is critically important to both protect the equipment with a proper lubrication film and to extend the time between oil change intervals.

Viscosity Shear Stability Test CEC L-45-A-99

Decrease of kin. Viscosity @ 40 °C

Viscosity change after exposure to shear stress for 20 and 100 h

Klüberbio EG 2–100

Competitor product EAL 1

Competitor product EAL 2

Competitor product EAL 3

Result: The EAL 1) for thrusters – Klüberbio EG 2-100 exhibits minimal loss of viscosity under shear stress. Other EAL gear oils lose up to 61 % of their initial viscosity level.

1) EAL – lubricant complies with requirements of Environmentally Acceptable Lubricants as defined in Appendix A of the 2013 Vessel General Permit

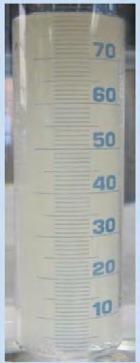

Klüberbio RM 2-100, non-emulsifying EAL stern tube oil

After intensive mixing with 50% water:

Klüber Non-Emulsifying Oil

Due to separation of oil and water, you can easily remove the water and just spend on top-up volume.

Other Emulsifying Oils

A stable emulsion forms so you are unable to drain the water. You will require a costly full oil replacement.

• Maintain the efficiency and longevity of the vessel’s compressors

• Reduce maintenance costs

• Increase number of running hours up to 10.000

• Cover a wide range of complex applications

• Keep stable viscosity levels in the oil

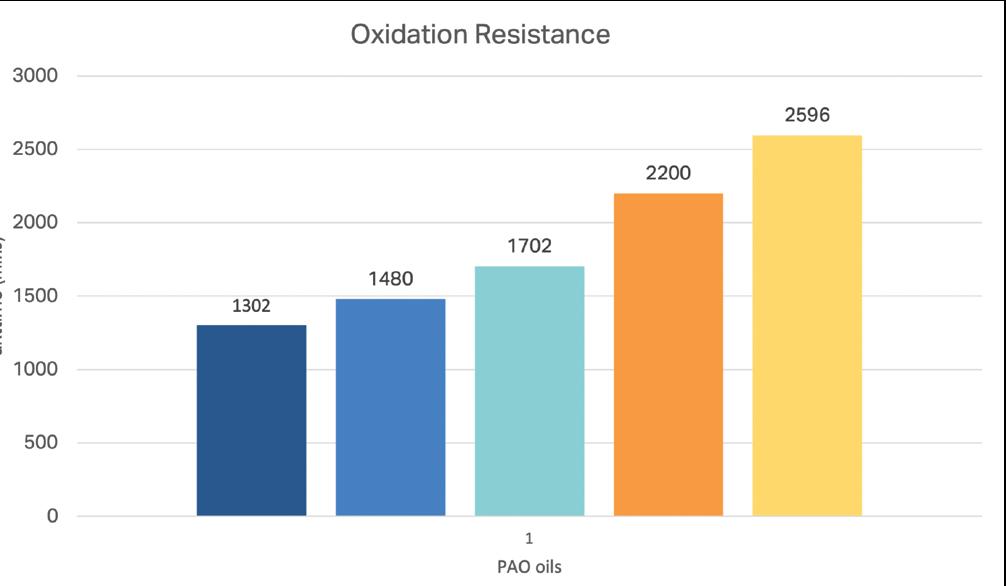

Klüber Summit SH Series, Air compressor oils

Klüber Summit SH compressor oils have excellent oxidation stability due to the synthetic base oil, thus minimizing oxidation residues in the compressors and extending oil change intervals and the service life of oil filters and separators. Special inhibitors contained in the oils keep the inside of compressors clean. High RPVOT (rotating pressure vessel oxidation test) number correlates to high oxidation resistance and long oil life.

Key Benefits

• Low maintenance and operating costs

• High evaporation stability of the base oils

• Reduced oil consumption

• Efficiency improvement from 3% to 5%

• Easy compressor oil conversion

• Longer service life of the oil filters

• Low formation of oxidation residues in the oil circuit

• Reduced energy costs

Klüber Summit SH 46 surpasses competition in RPVOT results

Klüber Summit PGS compressor oils are based on polyalkylene glycols and special additives. In high-pressure piston compressors for natural gas or hydrocarbon process gas, mineral oils are easily absorbed into, and diluted by, the gas stream. Klüber Summit PGS compressor oils are extremely resistant to such effects. The extremely high viscosity index of Klüber Summit PGS compressor oils ensures good lubrication in a wide range of temperatures.

Key Benefits

• Highly resistant to hydrocarbon dilution

• Excellent protection against corrosive attack from wet CO2

• Free from compounding agents

• Low tendency to evaporation

• Reduces the frequency of oil changes and saves oil over time

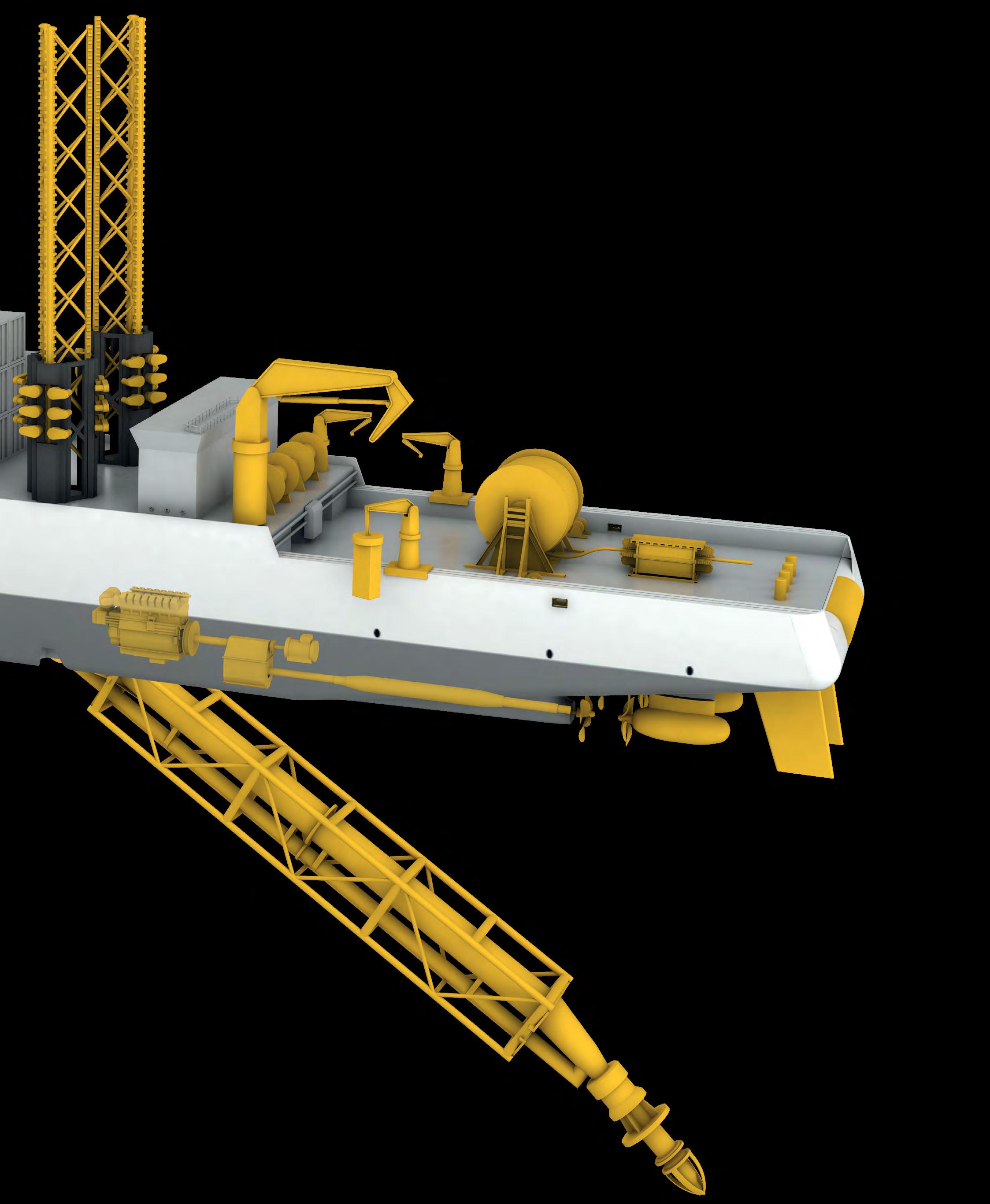

Optimally Equipped with Our Speciality Lubricants

This illustration shows the various applications of our marine lubricants. To show as many applications as possible in one illustration, we included components of the following ship types in this synthetic ship: Ro-ro ferry, cruise ship, cargo ship, wind turbine installation vessel, anchor handling tug supply vessel, pipe layer, cutter suction dredger, ATB tug boat.

1 Ro-Ro ramp, hatch

Hydraulic oil according to HEES, ISO 15380

Gear oil according to CLP, DIN 51517-3

Grease, NLGI class Wear protection and load carrying capacity

Corrosion protection

Adhesion Resistance to water spray-off and washout Low temperature performance Compatibility with elastomers

Demulsifying oil

Biodegradation

Component / lubrication point

Anchor handling winch

Enclosed gear box

Bearing – rolling bearing

Anchor winch spooling device

Speciality lubricant from Klüber Lubrication Base oil

Klübersynth GEM 4-220 N 220

Klübersynth GEM 4-320 N LWC 320

Klübersynth GEM 4-460 N 460

Klüberbio EG 2-320 320

Klüberplex AG 11-462 460

Klüberbio BM 32-142 140

KLÜBERLUB BE 41-1501 1500

Klüberplex AG 11-462 460

Klüberbio AG 39-602 N 600

Offshore crane Klüberbio LM 2-32 32

Rail crane Klüberbio LM 2-46 46

LARS system

Sheave bearing / slewing bearing

Klüberbio BM 32-142 140 Hinge

Open gear on hoisting winch

Open gear at slewing bearing and drive pinion tooth rack & pinion

Umbilical cable

Klüberplex AG 11-462 460

Klüberbio AG 39-602 N 600

Klüberplex AG 11-462 460

Klüberplex AG 11-462 460

AG 11-462

AG 11-462

AG 39-602 N

BM 32-142

11 Towing pin Bushing, bronze plain bearing Klüberplex AG 11-462 460

Stern roller Bearing – plain bearing

Rudder Bearing and seal

Azimuthing thruster Gear and bearing

Steering shaft seal

Azipod V

Azipod V and X – slewing bearing with gear teeth

Klüberbio AG 39-602 N 600

Klüberbio AG 39-700 N 680

Klüberbio LG 39-701 N 680

Klüberbio AG 39-602 N 600

Klüberbio BM 32-142 140

Klüberbio EG 2-68 68

Klüberbio EG 2-100 100

Klüberbio EG 2-150 150

Klüberbio AG 39-602 N 600

Klübersynth GEM 4-320 N LWC 320

Klüberbio EG 2-320 320

Azipod X Klüberfluid C-F 3 ULTRA 16500

Azipod V and X – sealing grease for turning shaft seal

Klüberbio AG 39-602 N 600 Empty field = not relevant; + = good; ++ = excellent; = applicable, fulfilled

Hydraulic oil according to HEES, ISO 15380 Gear oil according to CLP, DIN 51517-3

Grease, NLGI class Wear protection and load carrying capacity

Corrosion protection Adhesion

and washout

Module Component / lubrication point

Speciality lubricant from Klüber Lubrication Speciality lubricant from Klüber Lubrication

Azipod V

Azipod X

Azipod C and D

Azipod VI – seal and support bearing (ice operation) Klüberbio LG 39-701 N

Azipod V – thrust bearing Klübersynth GEM 4-320 N LWC

Azipod X – thrust bearing (hybrid bearing)

Azipod V and X – propeller shaft bearing

Azipod X – propeller shaft seal

Azipod C and D – slewing bearing

Azipod C and D – propeller shaft bearing and seal

Azipod C and D – gear teeth on slewing bearing

Azipod C and D – thrust bearing

GEM 4-150 N LWC

GEM 4-320 N LWC

RM 2-150

GL 262

GL 262

C-SG 0 ULTRA

GEM 4-320 N LWC

Curved tooth gear coupling –oil lubrication

Curved tooth gear coupling –grease lubrication

GEM 1-320 N

Klübersynth GEM 4-100 N

Klübersynth GEM 4-150 N LWC

GEM 4-460 N

Klüberoil GEM 1-460 N

Hydraulic oil according to HEES, ISO 15380

Gear oil according to CLP, DIN 51517-3

Grease, NLGI class Wear protection and load carrying capacity

Corrosion protection Adhesion Resistance to water spray-off and washout Low temperature performance Compatibility with elastomers Demulsifying

Module

20 Electric motor Alternator/generator

21

Electric motor bearing Alternator bearing (grease lubricated)

Generator bearing (oil lubricated)

Jacking system Tooth rack and pinion – manual lubrication

Tooth rack and pinion – automatic lubrication

AG 39-602 N

LG 39-700 N

LG 39-701 N

22 Fin stabiliser

Hydraulic oil according to HEES, ISO 15380

Gear oil according to CLP, DIN 51517-3

Grease, NLGI class Wear protection and load carrying capacity

Corrosion protection

Adhesion Resistance to water spray-off and washout Low temperature performance

Compatibility with elastomers

Environmentally Acceptable Lubricant

Many lubrication points are difficult to access or a special challenge from a health and safety perspective. To increase safety, reliability and machine availability, Klüber Lubrication supplies high-performance oils and greases in “intelligent packages” for automatic lubrication of your machines and components.

Engine room applications:

• Fan bearings

• Electric motor bearings

• Pump bearings

Lubrication system:

Klübermatic FLEX 30 cm³

Klübermatic FLEX 60 cm³

Klübermatic FLEX 125 cm³

Selected lubricants are available in automatic lubricant dispensers for single-point lubrication. These tried-andtested electromechanical or electrochemical devices are available with various speciality lubricants.

Klübermatic FLEX is a compact, ready-to-use lubricator. It can be used for diverse applications at temperatures between −20°C and +60 °C. The lubrication interval can be selected in monthly increments between 1 and 12 months. An electronically controlled chemical reaction generates the pressure to ensure continuous fresh lubricant supply to the lubrication point at set intervals. Klübermatic FLEX is available in volumes of 30cm³, 60 cm and 125 cm³.

Klübermatic FLEX is particularly suitable for single-point lubrication in rolling and plain bearings, slideways, open gears, toothed racks, shaft seals and chains. The lubrication system is dust-tight and protected against splash water (according to IP 68).

Life raft davit applications:

• Rolling bearings

• Cable pulley

Lubrication system:

Klübermatic FLEX 60 cm³

Klübermatic FLEX 30 cm³

Klübermatic FLEX 125 cm³

Example:

Klübermatic FLEX filled with Klüberplex BEM 34-132 for on-deck applications

Klüberplex BEM 34-132

210000 Klüberbio EG 2-68 200 LTR

210004 Klüberbio EG 2-100 200 LTR

210008 Klüberbio EG 2-150 200 LTR

210062 Klüberbio EG 2-320 200 LTR

210012 Klüberbio RM 2-100 200 LTR

210056 Klüberbio RM 2-150 200 LTR

210069 Klüberbio RM 8-100 200 LTR

210095 Klüberbio RB 2-100 200 LTR

210073 Klüberbio LM 2-22 200 LTR

210050 Klüberbio LM 2-32 25 LTR

210074 Klüberbio LM 2-32 200 LTR

210075 Klüberbio LM 2-46 200 LTR

210016

210028

210072

Klüberbio BM 32-142 25 KG

Klüberbio LG 39-701 N 18 KG

Klüberbio LG 39-701 N 180 KG

210071 Klüberbio LG 39-700 N 180 KG

210037 Klüberbio LG 39-700 N 25 KG

210068

210021

Klüberbio AM 92-142 25 KG

Klüberbio AM 92-142 180 KG

210077 Klüberbio AG 39-602 N 25 KG

210078 Klüberbio AG 39-602 N 180 KG

210094

210098

Klüberbio GE 32-681 180 KG

Klüberbio GE 32-681 25 KG

210048 Klübersynth GEM 4-150 N LWC 200 LTR

210052 Klübersynth GEM 4-320 N LWC 200 LTR

210058 Klübersynth GEM 4-460 N 200 LTR

210055 Klüber Summit PGI 68 200 LTR

210006 Klüber Summit PGI 100 200 LTR

210057 Klüber Summit PGS 68 200 LTR

210070 Klüber Summit PGS 100 200 LTR

210059 Klüber Summit PGS 150 200 LTR

210067 Klüber Summit HYSYN FG 46 200 LTR

210088 Klüber Summit SH 32 200 LTR DRUM

210089 Klüber Summit SH 32 20 LTR CANISTER

210079 Klüber Summit SH 46 200 LTR DRUM

210080 Klüber Summit SH 46 20 LTR CANISTER

210090 Klüber Summit SH 68 200 LTR DRUM

210091 Klüber Summit SH 68 20 LTR CANISTER

210092 Klüber Summit NGL 444 200 LTR DRUM

210093 Klüber Summit NGL 444 20 LTR CANISTER

210065 Klüberoil GEM 1-46 N 200 LTR

210066 Klüberoil GEM 1-68 N 20 LTR

210032 Klüberoil GEM 1-68 N 200 LTR

210036 Klüberoil GEM 1-100 N 200 LTR

210040 Klüberoil GEM 1-150 N 200 LTR

210044 Klüberfluid C-F 3 ULTRA 25 KG

Mineral Greases

210024 Klüberplex AG 11-462 25 KG

210064 Klüberplex BEM 41-132 25 KG

210063 Klüberplex GE 11-680 25 KG

210081 Klüberlub BE 41-1501 25 KG

210082 Klüberlub BE 41-1501 180 KG

210060 GRAFLOSCON C-SG 0 ULTRA

210061 MICROLUBE GL 262 25 KG

Klübermatic Flex

210084 Klüberplex BEM 34-132 – (10x30ML)

210085 Klüberplex BEM 34-132 – (10x60ML)

210086 Klüberplex BEM 34-132 – (10x125ML)

With the largest maritime network in the world, Wilhelmsen Ships Service is active in 2,200 ports, in 125 countries worldwide.

Supplying marine solutions including the UnitorTM brand of products, TimmTM ropes, UnicoolTM refrigerants, and UnitorTM and NalfleetTM marine chemicals, along with a complete portfolio of ships agency services and maritime logistics, last year we made product deliveries to 27,500 vessels and handled 75,000 port calls. The maritime industry’s trusted partner in port, on board and offshore, our wide portfolio of products and services are available in every market and region, to every conceivable vessel type.

Wilhelmsen Ships Service is part of the Wilhelmsen Group.

For more information, see https://www.wilhelmsen.com/shipsservice/speciality-marine-lubricants/

Klüber Lubrication is one of the world’s leading manufacturers of speciality lubricants, offering high-end tribological solutions to virtually all industries and markets worldwide. Most products are developed and made to specific customer requirements. During its more than 90 years of existence, Klüber Lubrication has provided high-quality lubricants, thorough consultation and extensive services, which has earned it an excellent reputation in the market. The company holds all common industrial certifications and operates a testing section hardly rivalled in the lubricants industry.

Klüber Lubrication, set up as a retail company for mineral oil products in Munich in 1929, is today part of Freudenberg Chemical Specialties GmbH, a Business Group of the Freudenberg Group, Weinheim. Klüber Lubrication has about 2,400 employees in more than 30 countries.

Wilhelmsen Ships Service

Phone: (+47) 67 58 40 00

Fax: (+47) 67 58 40 80

Postal Address:

PO Box 33, NO-1324

Lysaker, Norway

wilhelmsen.com

V2.1-012025

Contact your local WSS customer service for prices and availability.

For technical support for your vessels, consult our Technical Sales and Business Development Managers.