Published 2019 Swan Housing Association Text © Waugh Thistleton Architects, NU living and Ramboll Photographs and illustrations © Waugh Thistleton Architects Cover design by Fuel All rights reserved No part of this publication may be reproduced without the written permission of the publisher or the copyright owner. Printed in the UK

REPEATABLE PROCESS, NOT REPEATABLE PRODUCTS

CONTENTS 1 INTRODUCTION 7 1.1 How to use this guide 9 1.2 Swan and NU living 10 1.3 Modular benefits 12 1.4 Sustainability 14 2 MODULAR PROCESSES 19 2.1 Factory process 20 2.2 Design and assembly process 22 3 MODULAR PRINCIPLES 35 3.1 Transportation 36 3.2 Site considerations 42 3.3 CLT panels 48 3.4 Structural principles 52 3.5 Ground floor construction 58 3.6 Waterproofing 64 3.7 On site finishes 68

3.8 Roofs 72 3.9 Communal stair cores 76 3.10 Fire design principles 80 3.11 Thermal principles 84 3.12 Acoustic principles 88 4 INTERNAL PRINCIPLES 93 4.1 Internal layout of modules 94 4.2 Servicing principles 100 5 INFORMATION FOR MANUFACTURE 107 5.1 Using BIM and 4D 108 5.2 Drawing for manufacture 112 5.3 Room data sheets 116 5.4 Module types 120 6 APPENDIX 125 6.1 Checklist 126 6.2 Glossary 136

1

INTRODUCTION

1.1 HOW TO USE THIS GUIDE

This guide sets out considerations for designing modular housing, based on NU living’s ‘NU build’ modular system.

It aims to give the design team an understanding of the interrelationship between the consultants, the client and the factory.

Designing for modular means thinking about how each module is made, transported and assembled at every stage of the design development. It does not mean standardising homes, but considering the standard process of manufacture.

This guide is not intended as a pattern book, but instead presents topics for the reader to consider during the design process, offering guidance notes to aid the designer in finding solutions. The guide should be used alongside all relevant regulations and legislation.

9

1.2 SWAN AND NU LIVING

Swan’s mission is to deliver effective services, enterprising solutions and exemplary homes and communities in Essex and East London, delivering neighbourhoods that are healthy, vibrant and sustainable.

The Swan Group includes Swan Housing Association and NU living.

1.2.1 Swan

Swan Housing Association was first formed in 1994 and provides high quality and affordable homes to rent and buy.

Today, Swan operates in Essex and East London and manages over 11,000 homes. With a secured development pipeline of 8,000 homes, it is on track to meet its ambitious plan to deliver 10,000 homes by 2027.

Swan is committed to growth and innovation in delivering excellent services. They are one of the UK’s leading regenerating housing associations and boast a host of award winning schemes. Efficient and enterprising, they deliver new, high quality housing across all tenures.

Swan Housing Association Limited is registered as an exempt charity under the Cooperative and Community Benefit Societies Act 2014 (Registered Number: 28496R) and with the Homes and Communities Agency (Registered Number: L4145).

1.2.2 NU living

Swan Housing Association was one of the first housing associations to have its own in-house developer, NU living. NU living is building homes that are environmentally, socially and economically sustainable. This commercial acumen means that generated income produces gift aid to make a real difference to local communities by funding the provision of affordable homes, care and support. All profits made by NU living through its commercial activities, including the sale of homes, are reinvested in delivering Swan’s social purpose – that is providing homes and services to those who need them.

1.2.3 NU build system

Swan has created an offsite modular manufacturing approach known as the ‘NU build system’.

The NU build system, operated by NU living, will deliver stylish, high quality modular homes to meet housing need. Going forward, NU living will complete many of Swan’s exemplary regeneration projects using modular homes built by NU living in their state of the art, high-tech factory in Basildon, Essex, using the NU build system.

10

At full capacity they will deliver up to 500 homes a year, employing over 60 staff and supporting the growing local economy in Basildon and investing in UK manufacturing.

1.2.4 What makes Swan unique?

Swan are leading the way by deliberately focussing on supporting the growing UK modular construction industry rather than looking to overseas expertise.

There are many types of modular homes being built across the UK. Swan’s are unique for a number of reasons:

– The homes are mortgageable.

– They are built to current building regulations.

– They are insurable and warrantable.

– They are sustainably funded.

– The homes are built for their own marketing and sale.

– The homes are designed to be fully customisable by the buyer.

Unlike other private developers, all profits from the sales of homes are reinvested within the Swan Group to fund their regeneration and housing activities providing thousands of high quality affordable homes in Essex

and East London. Critically, these homes are part of wider regeneration projects which will see Swan build new sustainable communities with much needed health, education and infrastructure services, as well as retail and commercial spaces and high quality public realm. All are maintained by Swan for the long term.

Every home sold means that the buyer is contributing to the regeneration of homes and communities for others.

11 Swan and NU living

somewhere to feel at home

Figure 1 The NU build factory in Basildon, Essex

1.3 MODULAR BENEFITS

The UK is suffering from both a housing and a labour crisis. Fewer homes are being built each year and fewer people want to work in the construction industry yet demand for homes continues to outstrip supply. Drawing on the efficient production methods and product quality developed by ship, aircraft and car production, offsite manufacture addresses some of the failings of traditional methods of construction.

1.3.1 Fast

Time on site is significantly reduced as whole finished homes can be assembled within a day, reducing the lengthy disruption associated with a traditional building site. The manufacturing times of elements in the factory are also reduced compared to a traditional on site build. Information generated by Building Information Modelling (BIM) allows the factory to order products ‘just in time’ with the benefit of a consistent material and labour supply chain.

The controlled factory environment means that short days and bad weather do not interfere with production.

1.3.2 Quality control

Each module can be constructed in a clean and controlled environment with the necessary tools and materials close at hand. The construction process under factory conditions can offer a level of quality and consistency that traditional construction cannot compete with.

12

JUST IN TIME Improved cash flow Stock forecasting Reduced lead times Stock management Make and hold stock Secure and competitive pricing

Figure 3 Modular design with BIM allows products to be ordered ‘just in time’ which offers a number of benefits

Figure 2 Fiat’s production line

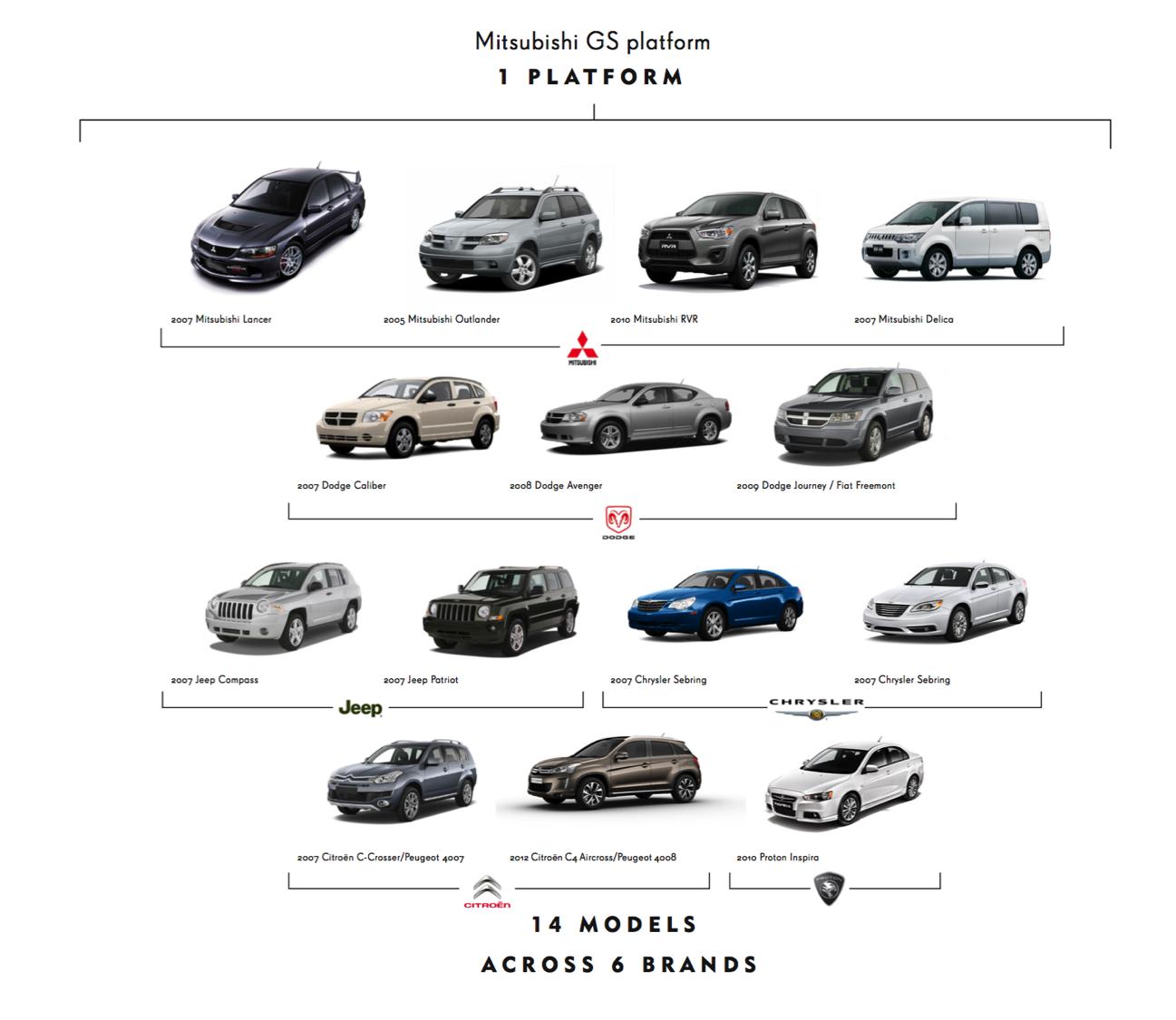

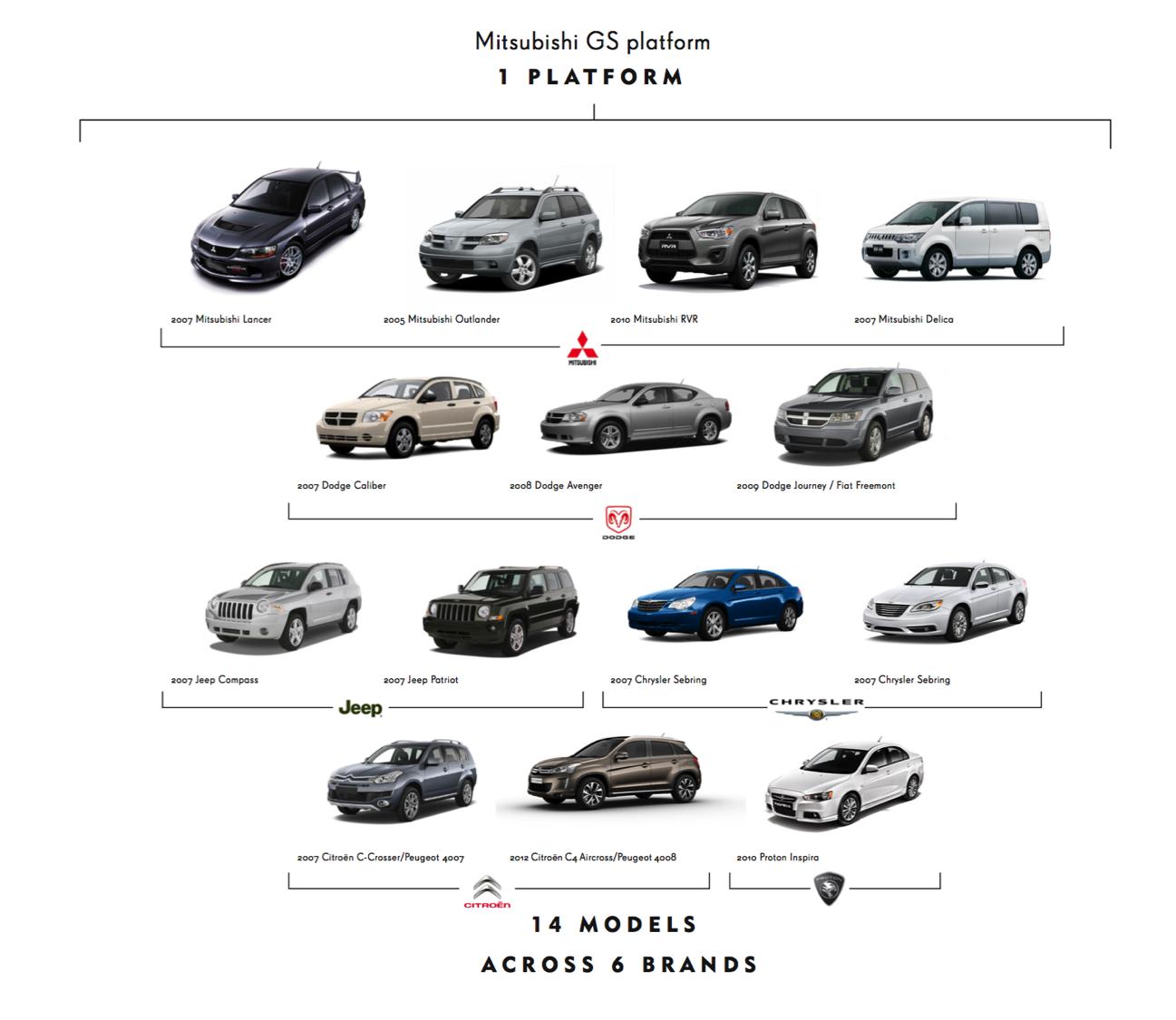

Mitsubishi GS platform

1 PLATFORM

1.3.3 Weather tight to site

Modular construction provides the significant benefit of being able to deliver a fully weather tight unit to site.

1.3.4 Reduced waste

The direct link between the BIM model and ordering materials minimises over supply. Efficiencies in the use of CLT and other products can be incorporated into the design so that off cuts do not go to waste - refer to Chapter 3.3 : CLT panels for more information.

1.3.5 Repeatable process not repeatable product

The Mitsubishi GS Platform uses the same compact car platform for numerous models across many brands. Similarly the NU build modular system can form the base of a wide range of module types and buildings.

The modular process is a way to enable the designer to create a variety of products that can be linked together to create different

MITSUBISHI

DODGE

JEEP CHRYSLER

CITROËN PROTON

14 MODELS

ACROSS 6 BRANDS

building types, rather than a limited number of modules that create repetitive buildings.

1.3.6 More attractive jobs

Factories offer workers regular hours along with a safe and clean working environment. Improved conditions attract more diverse workers to the construction industry.

13 Modular Benefits

Figure 4 CLT modular construction process

Figure 5 The Mitsubishi GS Platform - numerous models across many brands

1.4 SUSTAINABILITY

The world is in the midst of a housing crisis with unprecedented global mass migration to cities. In order to deal with this flow of people, more high density buildings are required. The production and installation of concrete and steel are currently responsible for more than 10% of the world’s carbon dioxide emissions, a figure that will increase if current trends within the construction industry continue. Alternative building materials need to be used to address this. (Source: PBL Netherlands Environmental Assessment Agency; European Commission Joint Research Centre; MIT)

Concrete Steel Shipping Airlines

Everything else

Concrete and steel production is responsible for 10% of all carbon emissions

(IPCC)

Cement/clay

Cement and clay make up

64% of the CO2 emissions for manufacture of construction materials

(gov.uk)

One million new homes are required between 2015-2020

18 million tonnes of carbon emitted, if constructed from concrete

14

Plastics Wood Glass Rubber Paint

=

Figure 6 Carbon emissions to build one million homes

1.4.1 Context

The operational energy consumption in modern buildings is low. Therefore reducing the energy embodied in the construction process is now the major challenge facing the industry.

Embodied carbon accounts for almost 70% of the carbon emissions for a residential project’s 60 year lifespan. It receives less attention than the carbon emitted in the operation of a building, but it is essential that we address embodied carbon if we are to transition towards a net zero carbon economy and meet the targets set out in the Climate Change Act and Paris Climate Agreement.

Forests can be replenished as needed and harvested timber absorbs carbon dioxide as it grows becoming a carbon store. Using timber for structure, cladding, and fittings can significantly lower a building’s embodied carbon profile.

1.4.2 What is CLT?

Cross-laminated timber (CLT) is made from multiple layers of solid wood. By bonding the longitudinal and transverse layers together using environmentally friendly glue, any warping of the wood - swelling or shrinkage - is reduced to a negligible level and considerably increases the load bearing capacity of the material.

15 Sustainability

Figure 7 CO2 emissions caused by the building’s operation and use compared with embodied CO2 from construction (Source: EIA/Richard Stein, 2011)

2035 2018 100% 80% 60% 40% 20% 0% 2078 2050 Operations 54% 46% Products Products 68% 32% Operations

Wood can be burned for clean energy

Wood products can be reused or recycled to create new products

Forests absorb CO2 from the atmosphere through photosynthesis

Timber buildings store carbon in their structures for the period of their maintained life

Engineered timber products require fewer deliveries to site

Trees are a renewable resource and store carbon

Manufacturing processes typically use all parts of the log, producing no waste and little pollution

16

Sustainability

Figure 8 CLT carbon cycle (Illustration: Yugon Kim)

After extensive research, NU living selected CLT as their material because it is:

– Incredibly rigid.

– Capable of being manufactured to a fine tolerance.

– Structurally stable.

– More environmentally sustainable than alternative modular systems, such as steel frame.

– Able to achieve high levels of air tightness with relative ease.

As CLT is a solid timber panel it has advantages in terms of sound, airtightness and thermal insulation as well as being easy to fix to.

1.4.3

CLT acoustic and thermal properties

The solid panel construction and air tightness of CLT construction enhances the acoustic and thermal properties of the building fabric: the typical U-value of CLT in accordance with EN ISO 10456 is lamda r of 0.12W/mK. Refer to Chapter 3.11 : Thermal principles and Chapter 3.12 : Acoustic principles for further information.

1.4.4

CLT can be easily machined

CLT is processed using automatic profiling and CNCcontrolled joinery machines. The panels arrive in the factory and data from the BIM model is fed into the CNC machine to cut out penetrations such as doors, windows and service holes.

Digital technology can be used to ensure that the maximum number of usable panels are cut out of a single CLT panel - refer to Chapter 3.3 : CLT panels for further information.

Bark + wood chips

Biomass power

Biomass fuel + animal bedding

17 Sustainability

Kiln drying Cutting + planing CLT panels for distribution

Figure 9 The waste products from CLT manufacture can be reused as a fuel source

2

MODULAR PROCESSES

2.1 FACTORY PROCESS

In order to successfully design for modular construction, the designer should have an understanding of the way in which the NU living factory operates This will allow elements of the design to be adapted to compliment the manufacturing process, creating an efficient and easily assembled modular design.

2.1.1 Geographic region

NU living’s state of the art factory is located in Prologis Park, Basildon and comprises a 7000 sq m facility which includes the manufacturing plant, staff and office areas and an Innovation Centre that is used to host events and as a creative space for the Swan Group. The building is sustainably designed, with performance measured through environmental certification, reduced operational carbon emissions and mitigated embodied carbon emissions. Waste from CLT panels is used to make wood chips that are used to heat the factory.

Swan’s modular developments are situated within a limited geographic region. The factory’s location in Basildon allows for good connections to the M25, providing easy access to Essex and east London, reducing the distances between the factory and site.

The factory employs over 50 staff, and contributes to local economic growth, providing jobs in Basildon and helping to build upon local expertise in manufacturing.

The NU build system uses a continuous flow production model. This is where modules move through a series of stages around the factory. Jigs and fixtures can be utilised to aid tasks and workers are trained to focus on specific tasks which improves speed and consistency. Processes and methods that compliment this model should be considered throughout the design process.

20

2.1.2

Factory operation style

Figure 10

20 km NU

Modular sites 0

Current geographic region of the NU build factory

build factory

START FINISH

2.1.3 Processes and time

In order to produce the optimal number of modules, the factory aims for each process to take as little time as possible, and each process should be balanced so that they all take a similar amount of time. This allows the modules to progress through the factory at an even pace.

This should be considered when specifying any finishes that have a lengthy drying time as this can reduce the number of modules that are produced each day or require additional space in the factory to store drying modules.

2.1.4 Storage programming and design

The manufacturing process can be improved if common sizes and shapes of CLT panels are used. These can be easily stacked, taking up less room for storage, and will not require a complicated system to coordinate the different panel types.

If the design requires every panel to be a different size and shape, consideration should be given to the time and space needed to store the panels before use. Additional time will be needed to coordinate panel locations in order to select the correct panel for each part of the design.

2.1.5 CNC programming

The CNC machine is a five axis machining centre which allows high speed cutting of CLT. It has two working beds each capable of taking a full sized CLT panel. This allows one panel to be machined on one bed while the next panel is being loaded onto the adjacent bed. The versatility of the five axes means complex angles can be easily machined with high accuracy and consistency.

Using data from the BIM model, the CNC machine is programmed offline using specialist software that can simulate the machining to maximise efficient usage of the CLT panels reducing errors and waste.

Unifying the size of openings, such as those for services, windows and doors, makes tooling and programming requirements less complex.

21 Factory Process

Pr o c e s s 2 Pr o c e s s 3 Pr o c e s s 4 Pr o c e s s 1

Figure 11 For a continuous flow model, each factory process should take an equal amount of time, this is known as line balancing

2.2 DESIGN AND ASSEMBLY PROCESS

There are two main benefits of offsite manufacturing: to speed up delivery and to increase quality. However, to fully realise its potential, it is essential that the design team understands that designing for manufacture and assembly is fundamentally different to designing for traditional construction, requiring a different mindset and a different approach from the outset.

2.2.1 A different way of building

Information for manufacture needs to be fully coordinated at the point at which production begins. This means that the quality of information produced by the consultant team far exceeds that produced for a typical design and build contract - it cannot just be design intent and instead requires a fully coordinated and detailed design.

A design and build contract allows the contractor to complete the design, resulting in changes and cost savings during the construction phase. When designing for manufacture, consultants must understand that changes to the design or specification during the manufacturing process has huge

cost and time implications. If the production line stops this results in significant financial and programme loses. Figure 13 compares the relationship between the design changes and cost for a typical design and build contract with a modular project.

2.2.2 RIBA workstages when designing for manufacture

To understand how to design for the NU build manufacturing process consultants need to fundamentally change their approach to the design process. Figure 12 shows a high level comparison of the work required for a typical design and build contract compared to designing for manufacture. During RIBA workstages 0-5 the consultants’ work is compressed into the pre-manufacture stage and minimal stage 5 work is done once manufacture starts.

22

TRADITIONAL SITE BUILT CONSTRUCTION - SEQUENTIAL PROCESS Design, Permitting, Engineering, Approval Process Site Preparation, Civil Engineering, Infrastructure Site Construction, Mechanical Installation, Finish Work OFF-SITE CONSTRUCTION - CONCURRENT PROCESS Design, Permitting, Engineering, Approval Process Site Preparation Assembly FINISH FINISH Manufacturing

Figure 12 Comparison of the work required for a traditional construction and manufacture and assembly

The RIBA have produced an overlay to the 2013 Plan of Work where they describe the ways in which designing for manufacture and assembly (DfMA) should be considered at each of the RIBA workstages. In addition to this, Swan have a suite of documents that outline the DfMA services to be provided from each consultant.

When starting a project, consultants should refer to the RIBA workstages, the DfMA overlay and Swan’s suite of documents,

to set out their fees and scope of services. To assist designers in understanding their modular design process, NU build have devised their own stages.

2.2.3 NU build modular process

Figure 14 gives a breakdown of the stages of work for a NU build modular project, leading up to and including assembly on site. All the stages are interrelated and need to be continually evaluated as the design evolves. The NU stages are: – Brief –

Figure 13 The relationship between the design changes and cost for design and build and modular

Each NU stage is a gateway to the next and must be reviewed before the design can progress. The first five NU stages should be signed off as a whole by both the client and the factory before final information is produced and the modules are manufactured. The last three NU stages are separated from the earlier stages to illustrate that the information required by consultants should be minimal to avoid the large cost and time implications of changes once manufacture has begun.

23 Design and assembly process

T I M E DESIGN TENDER CONSTRUCTION C O S T I M P A C T O F D E S I G N C H A N G E S A B I L I T Y T O I N F L U E N C E D E S I G N MANUFACTURE + ASSEMBLY C O S T I M P A C T O F D E S I G N C H A N G E S A B I L I T Y T O I N F L U E N C E D E S I G N T I M E DESIGN MANUFACTURE ASSEMBLY

DESIGN + BUILD

Logistics – Strategy – Performance – Detail – Information

– Manufacture and Transportation – Assembly

- Check that site is viable for modular

- Employer’s Requirements

- Educate design team on modular

- Incorporate lessons from previous projects

LOGISTIC

- Access to site

- Ground conditions

- Site assembly

- Transport

- CLT panel sizes

- Assembly and installation sequence agreed

STRATEGY

- Structural principles

- Servicing principles

- Accessible units

- Lifting principles

- Fire principles

- Ground floor detail principles

- Waterproofing principles

PERFORMANCE

- Fire performance

- Acoustic performance

- Materials

- Finishes

- Roof type

0

BRIEF

C L I E N T + F A C T O R Y R E V I E W 1

C L I E N T + F A C T O R Y R E V I E W 2

C L I E N T + F A C T O R Y R E V I E W 3

- Thermal performance

C L I E N T + F A C T O R Y R E V I E W R EADDRES S A S NEEDE D R EADDRES S A S NEEDE D R EADDRES S A S NEEDE D R EADDRES S RIBA WORKSTAGES

Figure 14

The NU build Modular Design Stages

DETAIL

- Kitchens

Bathrooms - Doors - Windows

- Internal finishes

- Details of walls, floors, roof and foundations

INFORMATION

- 1:20 drawings of each module

- 1:10/1:5 details

- Room data sheets

- Specification information such as NBS

- Full plans, sections and elevations

- Schedules

OFF

- Protect modules from water during transit

- Timings

- Just in time delivery

- Storage

ASSEMBLY

- Site preparation

- Accuracy of landing the modules on the foundations

- Underground services alignment and fixing details

- Scaffolding plan

- On site water management and fire strategy

CLIENT + FACTORY SIGN

5

C L I E N T + F A C T O R Y R E V I E W 4

MANUFACTURE & TRANSPORTATION

C L I E N T + F A C T O R Y R E V I E W 4

-

C L I E N T + F A C T O R Y R E V I E W 5

C L I E N T + F A C T O R Y R E V I E W PROGRES S I ON ONLY PROGRES S I ON ONLY A S NEEDE D RIBA WORKSTAGES

Design and assembly process

The Brief

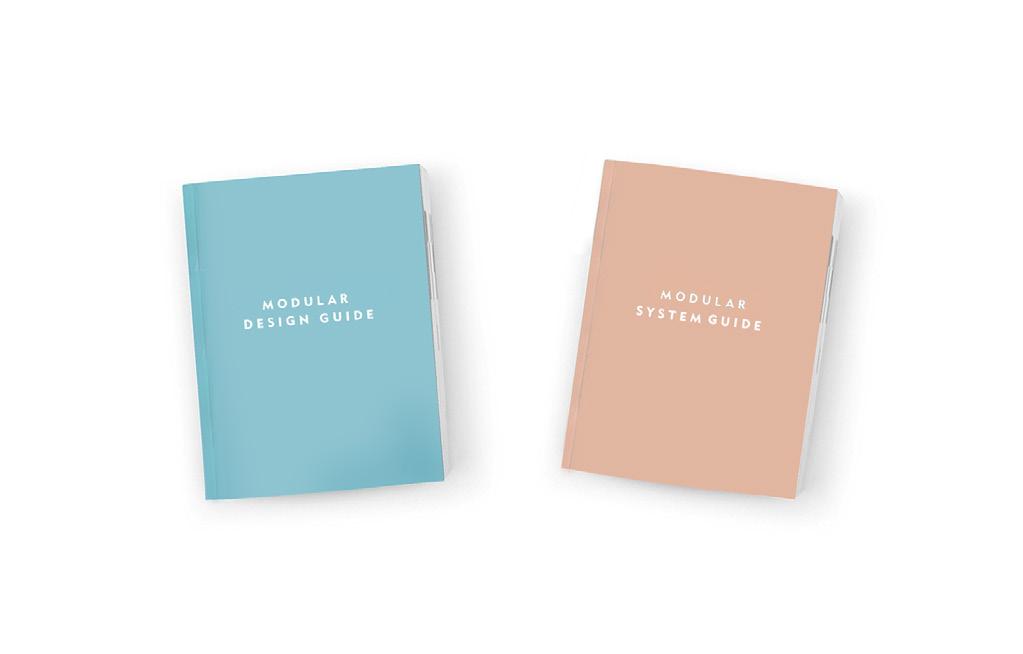

– The client’s employer’s requirements, the NU build Modular Design Guide and the NU build Modular System Guide are be used to help understand the brief.

– The viability of the site location for modular construction should be determined at the earliest opportunity, as not all sites will be accessible for modular transportation.

(Refer to Chapter 2.1 : Factory process;

Chapter 2.2 : Design and assembly process;

Chapter 3.1 : Transportation; Chapter 3.2 : Site considerations)

Logistics

– Understanding site access, ground conditions, method of site assembly and how the modules will be delivered to site are key to setting out the parameters for designing the modules.

– A knowledge of the size of standard CLT panels also sets dimensional parameters.

– These constraints, which are conventionally discussed later in the design development, form the basic building block when designing a modular scheme and set out the three dimensional size constraints of the modules.

– Understand the installation and assembly sequence.

(Refer to Chapter 3.1 : Transportation; Chapter 3.2 : Site considerations; Chapter 3.3 : CLT panels)

26

modular - Incorporate lessons from previous projects - Site assembly - Transport - Accessible units - Lifting principles - Fire principles - GF detail principles - Acoustic performance - Materials - Finishes R E A D D R E S S A S N E E D E D R E A D D R E S S A S N E E D E D R E A D D R E S S A S N E E D E D A S N E E D E D C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W - Educate design team on modular - Incorporate lessons from previous projects - Ground conditions - Site assembly - Transport - Servicing principles - Accessible units - Lifting principles - Fire principles - GF detail principles R E A D D R E S S A S N E E D E D R E A D D R E S S A S N E E D E D S N E E D E D C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W

Strategy

– Establish the layout of the scheme, taking into account the structural, acoustic and services constraints as well as planning and regulatory considerations.

– Consider the sequence of construction, including the assembly, lifting and connection strategy, to understand how the modules will be set out on site. The tolerance gap between modules and the dimension of the structural walls will inform how many modules can fit on the site. Consider if any non modular elements are needed in addition to the modules.

– The location and layout of accessible units is a crucial decision to make at this stage. Modular construction is most efficient when it is stacked. Accessible modules are usually larger than others and may result in non typical structural design.

(Refer to Chapter 3.4 : Structural principles; Chapter 3.5 : Ground floor construction;

Chapter 3.11 : Thermal principles; Chapter 4.1 : Internal layout of modules)

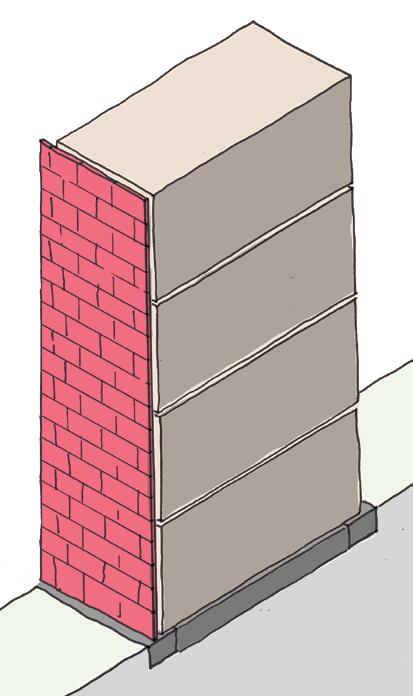

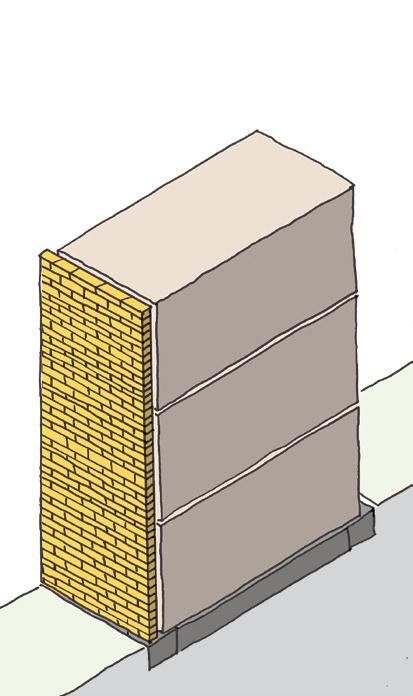

Performance

– The thermal, fire and acoustic performance of the building and the services strategy all need to be agreed.

– Consider services strategy. ‘Plug and play’ systems for services connections should generally be utilised over conventional systems.

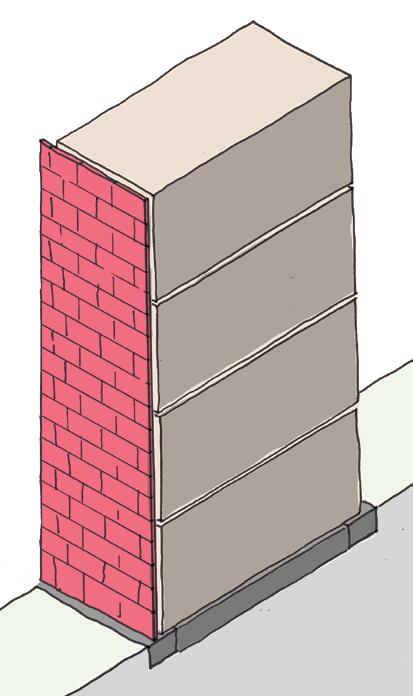

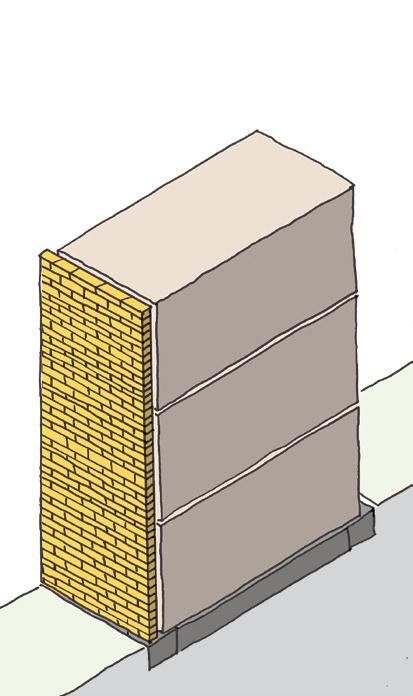

– The type of cladding, secondary structure and insulation should be considered, deciding if these will be applied in the factory or on site. The implications of site access for installation of any on site external finishes should be considered.

– When the performance criteria are set, these must be reviewed in terms of the strategic and logistical considerations. For example, if the cladding and insulation is applied in the factory, the impact on the dimension of the module during transport should be reviewed to ascertain if it fits within the transport constraints.

(Refer to Chapter 3.7 : On site finishes; Chapter 3.10 : Fire design principles; Chapter 3.11 : Thermal principles; Chapter 3.12 : Acoustic principles)

27 Design and assembly process

Ground conditions Site assembly Transport - Servicing principles - Accessible units - Lifting principles - Fire principles - GF detail principles - Fire performance - Acoustic performance - Materials - Finishes - Bathrooms - Doors - Windows - Internal finishes - Interfaces - Membranes R E A D D R E S S A S N E E D E D R E A D R E A D D R E S S A S N E E D E D R E A D D R E S S A S N E E D E D NO L Y CLIENT + FACTORY SIGN OFF C L E N T + F A C T O R Y R E V E W C L E N T + F A C T O R Y R E V E W C L E N T + F A C T O R Y R E V E W C L E N T + F A C T O R Y R E V E W C L E N T + F A C T O R Y R E V E Wmodular - Incorporate lessons from previous projects - Site assembly - Transport- Accessible units - Lifting principles - Fire principles - GF detail principles- Acoustic performance - Materials - Finishes - Doors - Windows - Internal finishes R E A D D R E S S A S N E E D E D R E A D D R E S S A S N E E D E D R E A D D R E S S A S N E E D E D R E A D D R E S S A S N E E D E D C L E N T + F A C T O R Y R E V E W C L E N T + F A C T O R Y R E V E W C L E N T + F A C T O R Y R E V E W C L E N T + F A C T O R Y R E V E W C L E N T + F A C T O R Y R E V E W

Detail

– Many of the detail design criteria are set out in the employer’s requirements, NU build Modular System Guide and planning conditions.

– The fit out of accessible units for future tenants will need to be considered.

– Coordination of information between all consultants is required at this stage. The BIM model needs to be fully coordinated.

– The setting out of the modules will need to be considered and agreed by all consultants and the factory.

– Following this stage, the client and factory need to sign the design off. A thorough assessment of costs must be carried out.

(Refer to Chapter 3.5 : Ground floor construction; Chapter 3.6 : Waterproofing; Chapter 3.8 : Roofs; Chapter 3.10 : Fire design principles; Chapter 3.11 : Thermal principles; Chapter 3.12 : Acoustic principles)

Information

–

The information produced for manufacture must include everything the operatives in the factory need to build each module.

– The 1:20 layouts and the room data sheets of each module type are key to informing the factory process. This will require input from all consultants.

(Refer to Chapter 5.2 : Drawing for manufacture

Chapter 5.3 : Room data sheets)

28 Design and assembly process

performance - Doors - Windows - Internal finishes - Membranes R E A D D R E S S A S N E E D E D P R GO R E S S I O N NO L Y P R GO R E S S I O N NO L Y CLIENT + FACTORY SIGN OFF C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W Accessible units Lifting principles principles detail principles - Acoustic performance - Materials - Finishes - Doors - Windows - Internal finishes - Membranes R E R E A D D R E S S A S N E E D E D R E A D D R E S S A S N E E D E D P R GO R E S S I O N NO L Y N NO L Y CLIENT + FACTORY SIGN OFF C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W

Manufacture & transportation

Assembly

– Modules will be fully wrapped before transportation to prevent water damage.

– The factory will coordinate the delivery of the modules to site. They will determine if the modules will be delivered ‘just in time’ or stored on site/elsewhere prior to assembly.

– Delivery strategy to be in line with assembly and installation sequence.

(Refer to Chapter 2.1 : Factory process; Chapter 3.1 : Transportation; Chapter 3.6 : Waterproofing)

– If large openings are required, temporary support may need to be installed during transportation. Consideration of how this will be removed needs to be addressed early in the design phase.

– The sequence of construction is determined by factors including site constraints, crane size and the structural stability of the modules during assembly. If non modular components form part of the build, then how the connection details between these and modules impact stability also needs to be considered. These decisions will have been made during the earlier stages in the design process.

– Access for operatives to make services and structural connections needs to be considered during the earlier stages. Prototyping of typical connections can assist in understanding the access requirements for these connections.

(Refer to Chapter 3.7 : On site finishes)

29 Design and assembly process

- 1:20 drawings - Interfaces - Membranes P R GO R E S S I O N NO L Y P R GO R E S S I O N NO L Y CLIENT FACTORY OFF C L I E N T + F A C T O R Y R E V E W C L I E N T + F A C T O R Y R E V E W C L I E N T + F A C T O R Y R E V E W - Kitchens - Bathrooms - Doors - Windows - Internal finishes - 1:20 drawings - Interfaces - Membranes R E A D D R E S S A S N E E P R GO R E S S I O N NO L Y P R GO R E S S I O N NO L Y CLIENT + FACTORY SIGN OFF C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W C L I E N T + F A C T O R Y R E V I E W

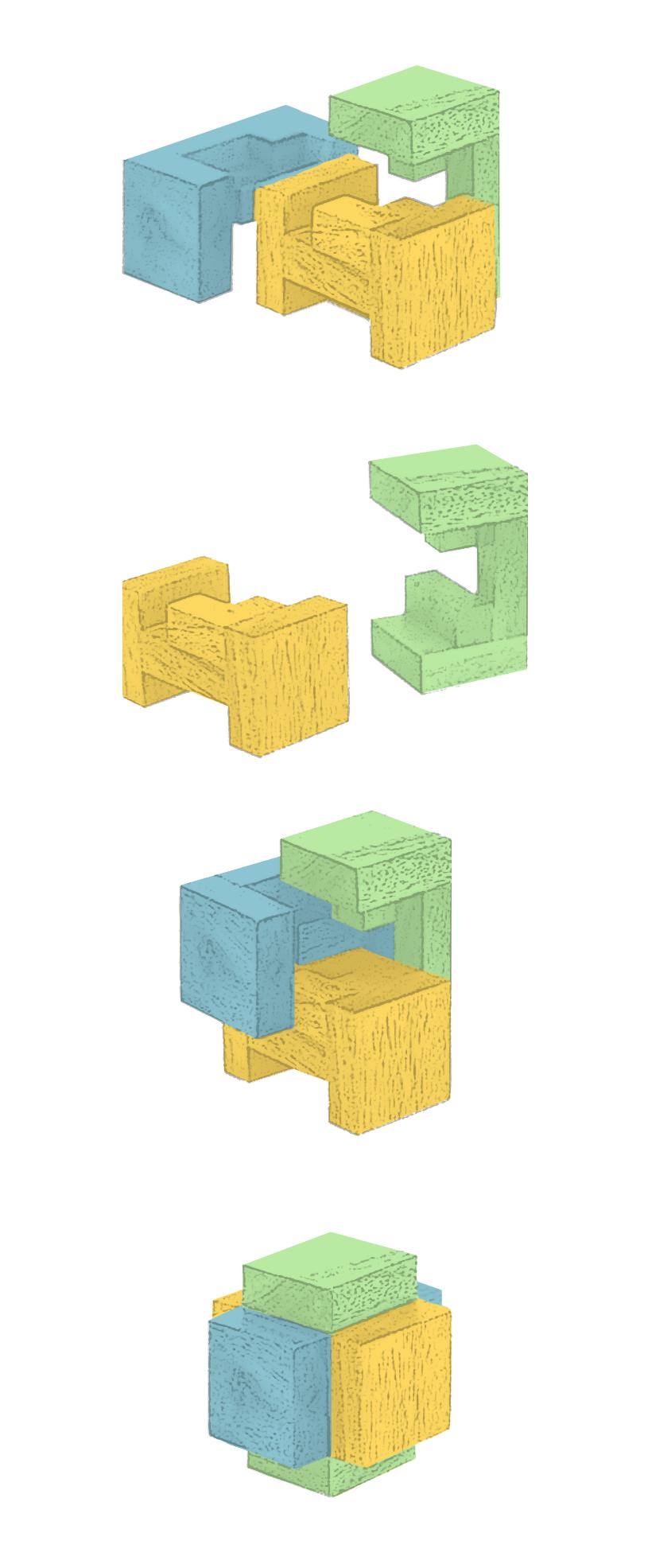

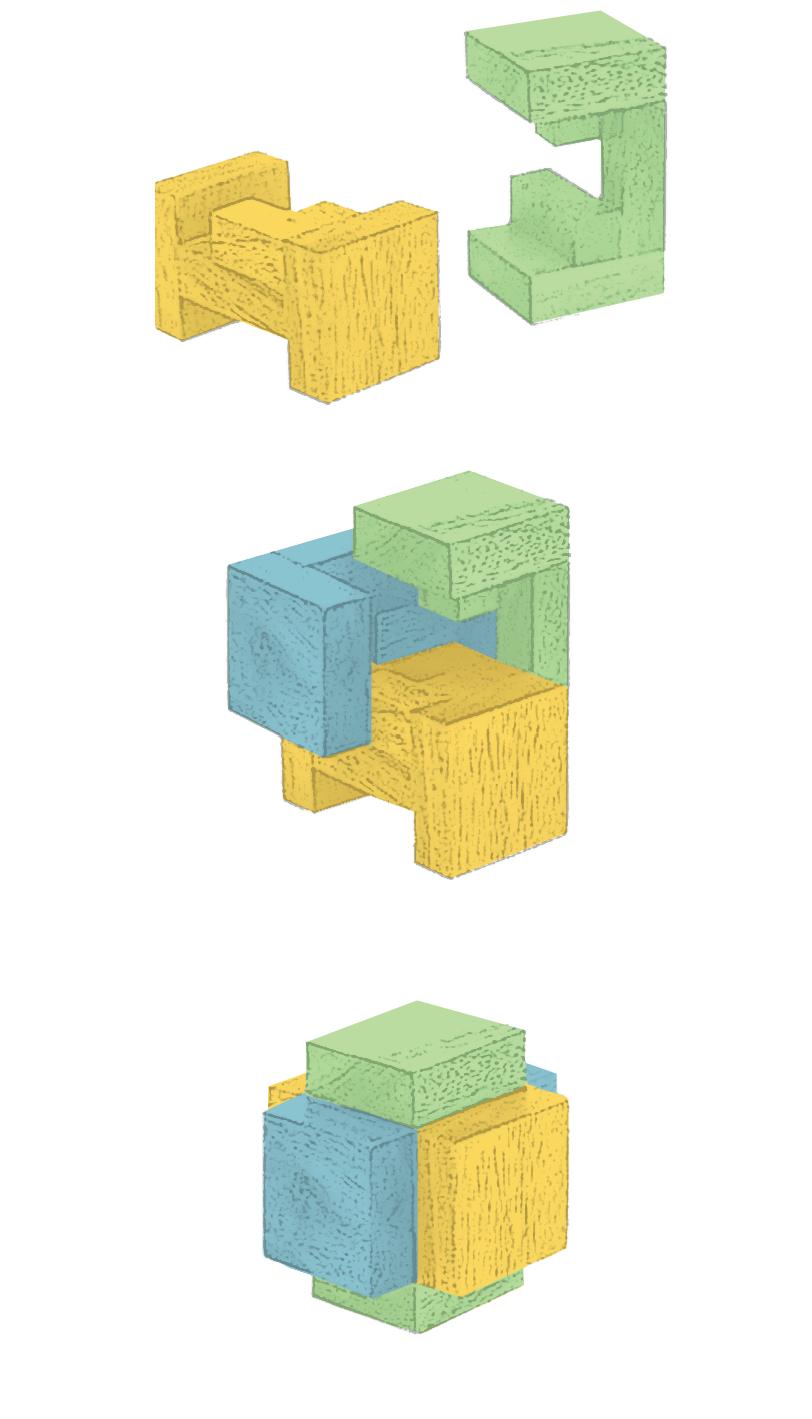

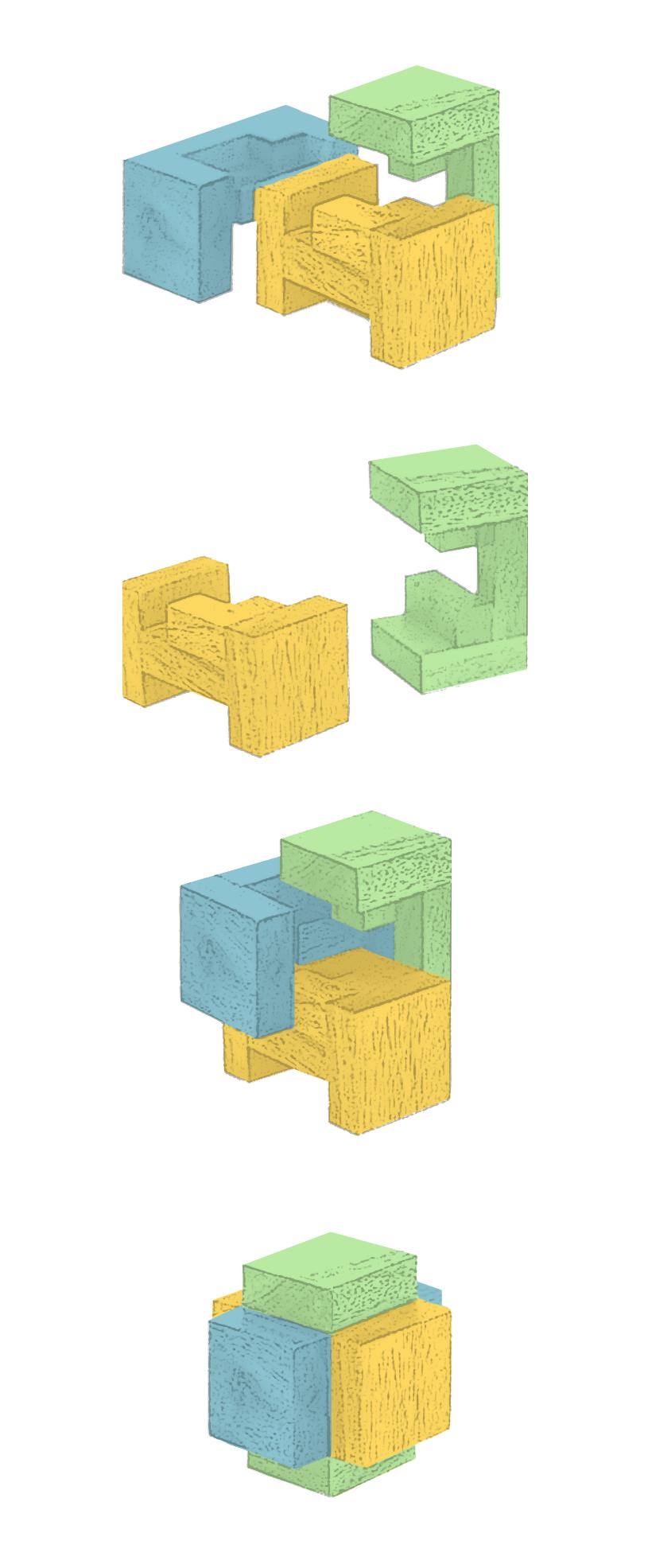

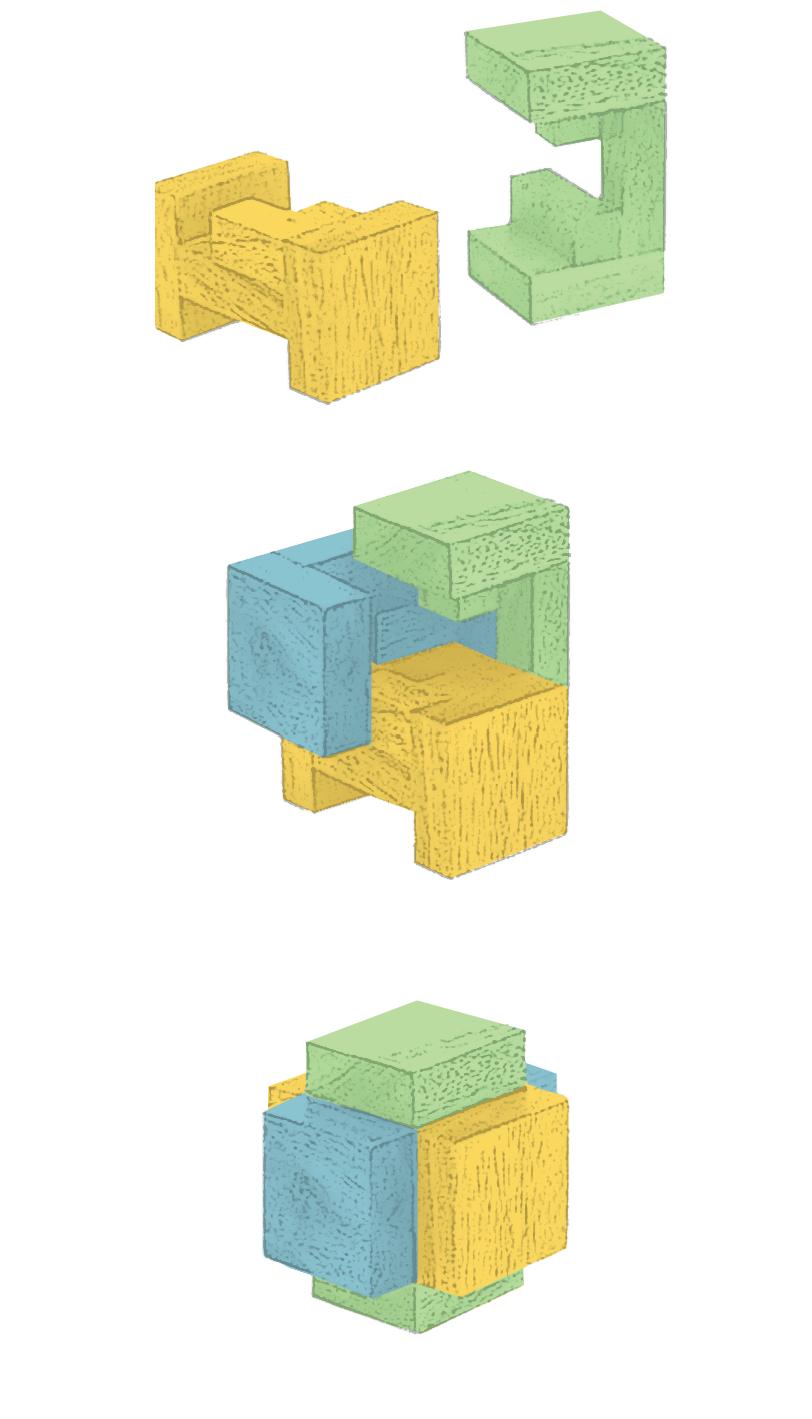

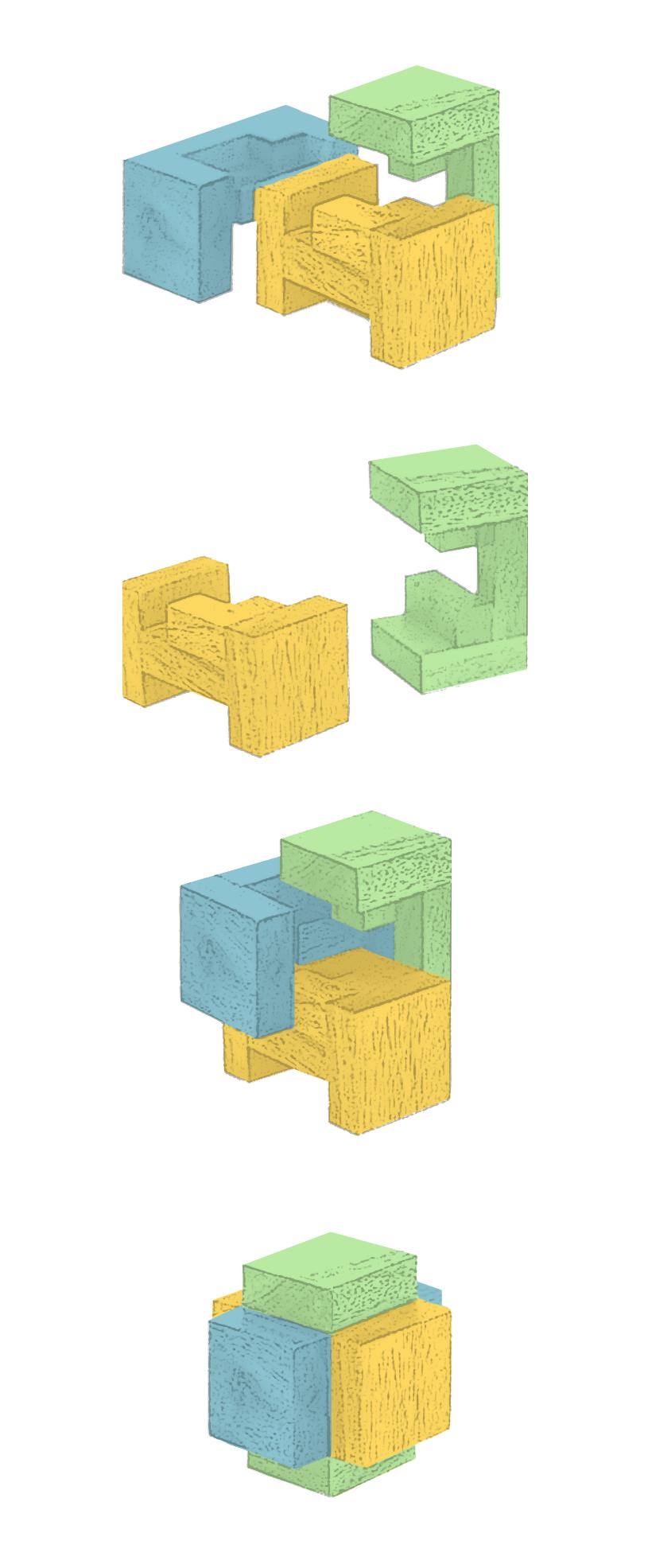

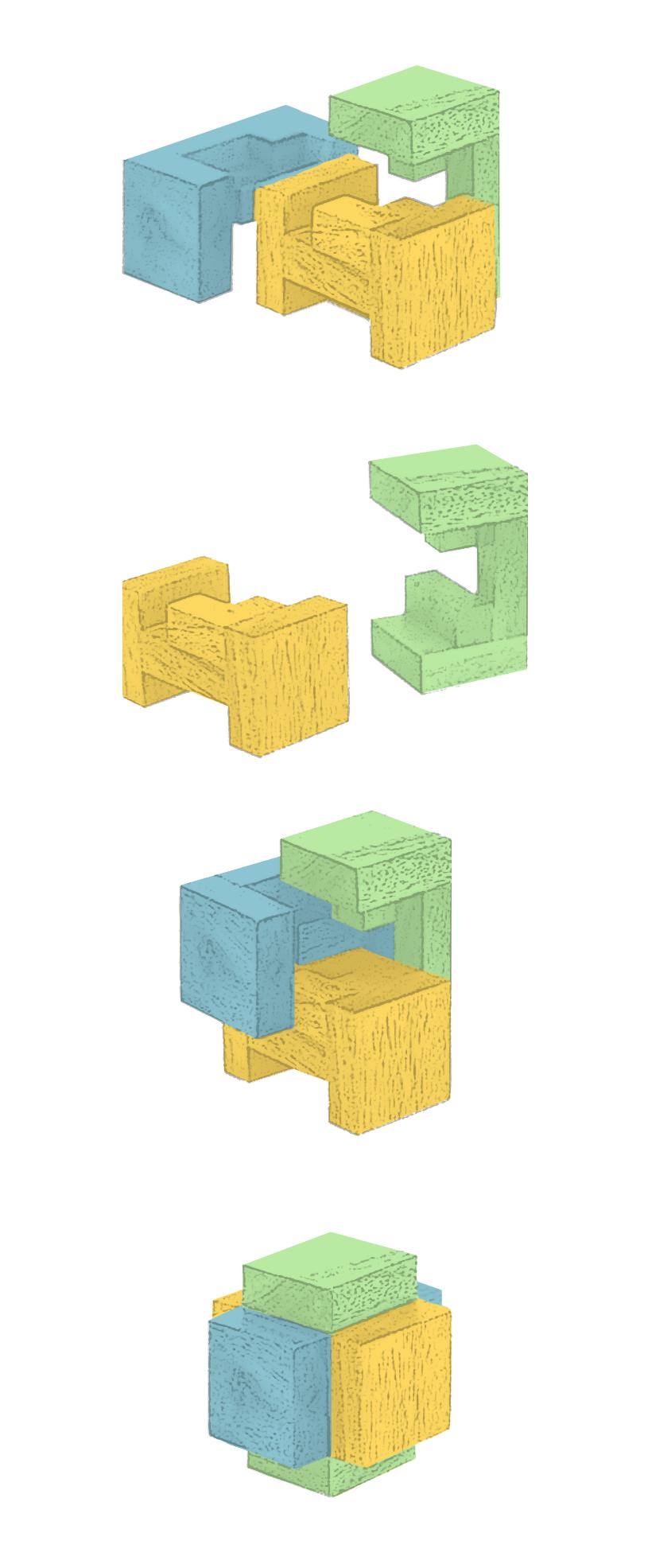

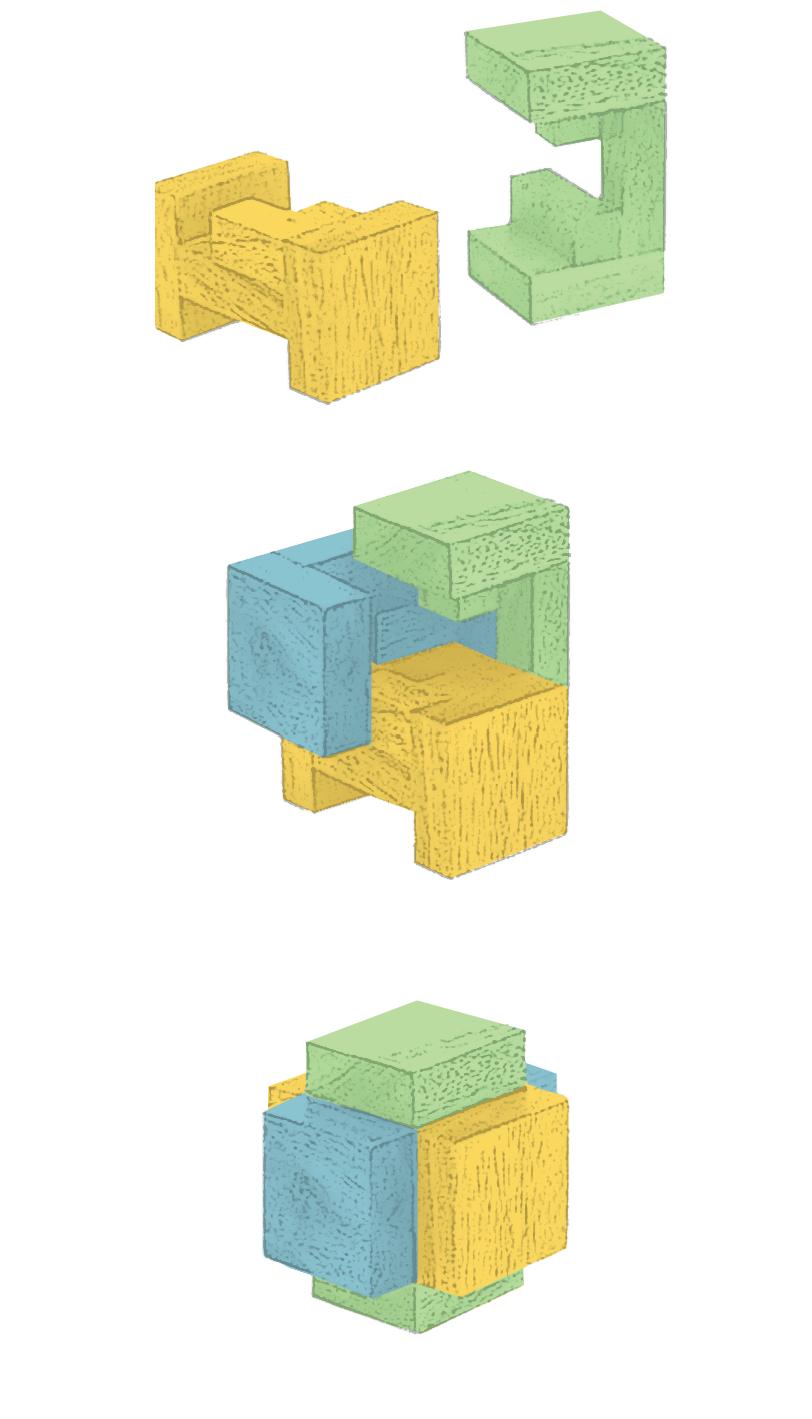

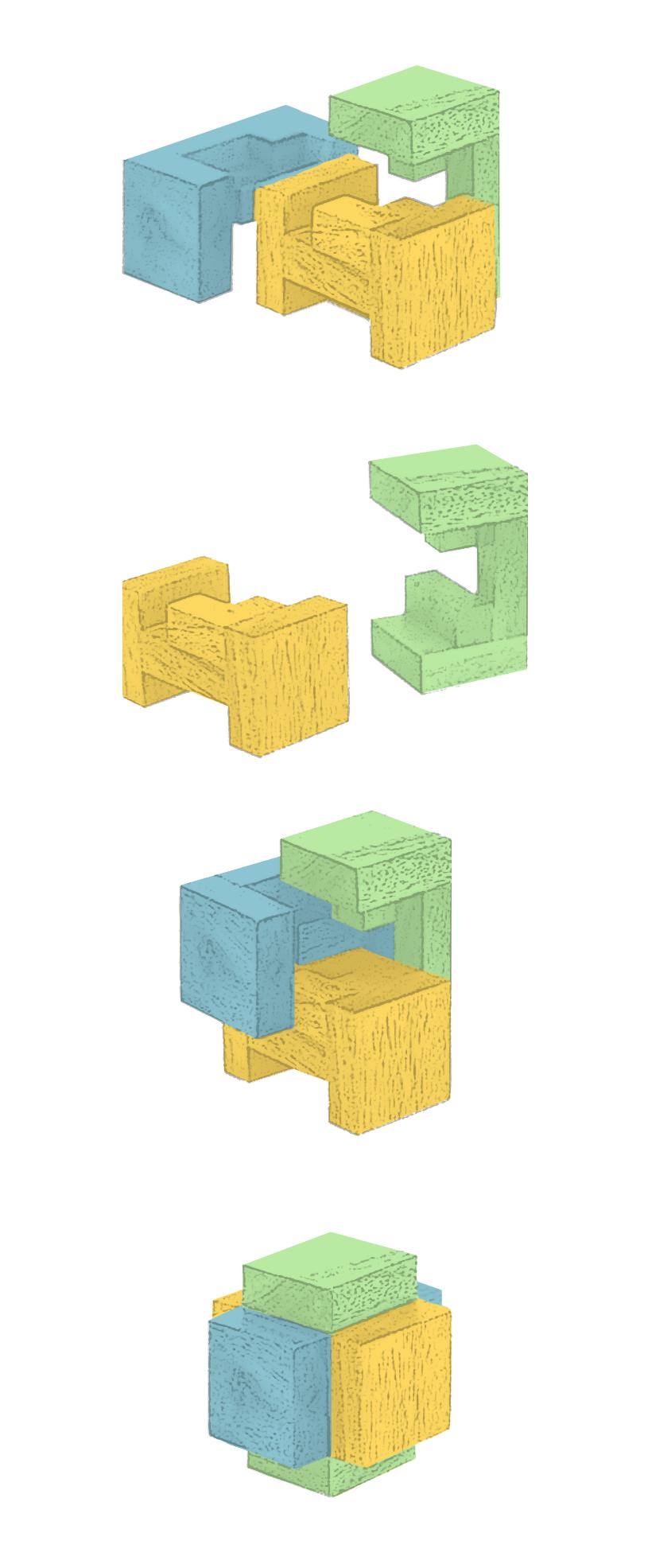

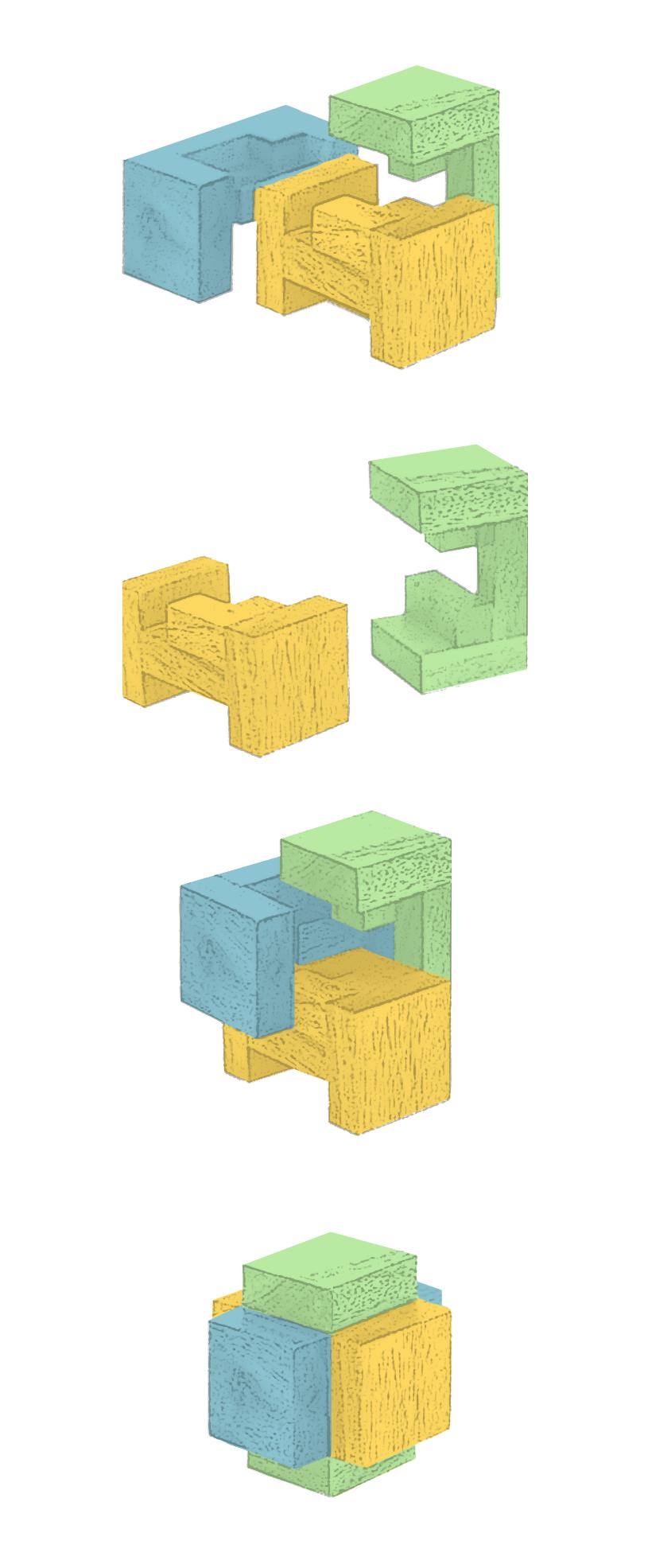

2.2.4 A note on cost plans

Designing for manufacture and assembly requires decisions to be made throughout the design phase which, once agreed, can have far reaching implications if changed later in the design process, like a puzzle where all the pieces are reliant on each other to make a cohesive whole. If one piece changes it will not fit together, as shown in Figure 15.

A thorough cost analysis of the scheme is required by the client at every workstage to ensure the budget is adhered to. If possible, tendering to suppliers early in the design process is preferable as a fully coordinated supply chain is essential for the smooth operation of the manufacturing process.

2.2.5 Changes to the design

Change control must be carefully monitored throughout the process. Design development is not always linear and a clear record of the decision path is vital. Three types of change management strategies can be implemented, depending on the circumstances:

Each design decision is reliant on one another to create a cohesive whole

– Lessons Learned is a method of understanding what could have made the project more efficient by tracking and recording changes that have not been implemented to ensure they are considered for future projects. The knowledge and experience gained from each project will be used to update the NU build Modular Design Guide and the NU build Modular System Guide and improve and refine NU build’s modular product, as shown in Figure 16.

and assembly process

Design

– The Change Order process is used to analyse the advantages and disadvantages of a proposed change, and how it will affect the manufacturing process. The production line continues while this is evaluated. Once the analysis has taken place, the factory is consulted to decide if the change is sufficiently beneficial to warrant resetting the production line in order to implement it.

– A Concession Note is used if there are fundamental errors in the design that mean it simply does not work and the production line may require resetting to rectify it. The process of procuring a Concession Note is intentionally difficult – it can only be signed by Managing Directors – as the cost and time implications of resetting the production line when it is fully staffed and working at capacity are critical.

2.2.6 Early engagement of consultants

The early engagement of all consultants is required when designing for modular so that all disciplines can input during design development. For example, the size and location of servicing holes have fundamental impact on the structural design and vice versa.

In a conventional design development, the services and structural engineers would wait until the plans are fixed before beginning to develop their design. In designing for modular there are servicing and structural parameters that impact on the development of the plans and so must be understood early in the design development. This is particularly important when considering vertical elements such as the stacking of risers and servicing penetrations, therefore the design should always be considered in three dimensions.

31 Design and assembly process

P r oject L e ss o n s L e s s o n s L e s so n s

Proj e c t

Proje ct

Project

Figure 16 Evolution of the modular system, where the lessons from the previous project help refine and improve the current project

2.2.7 Appointments

Each consultant will agree their own appointment. Both client and consultant should be aware of how the design services required by the modular process differ from a conventional contract. Swan have a suite of documents that refer to the design process for DfMA.

In traditional construction the temporary works design is usually undertaken by the contractor, whereas in modular design the site assembly works need to be considered during the design process by the entire design team, particularly the structural engineer. This ensures any site assembly works are integrated into the design to minimise on site intervention prior, during and after module assembly.

Key considerations in making appointments include:

– Early appointment of all consultants.

– Close collaboration between consultants is required.

– Consultants appraise themselves of the services required when designing for modular. Additional considerations such as input into logistics will be part of each consultant’s scope.

– Complete design and costing to be signed off prior to manufacture. The scope for change once the modules are in production is limited.

– BIM level 2 is fundamental to the delivery of the project. A BIM coordinator should be identified.

– Information provided by Swan’s DfMA suite of documents and appointment information.

32 Design and assembly process

Figure 17 The consultants in the design team need to be appointed early in the design process

2.2.8 Training and people

Everyone involved in the project must have a thorough understanding of the modular method of manufacture and how all processes integrate.

Teams require skills in industry standard software, such as Revit, and an understanding of standard operating procedures in the factory. This is essential to achieve a fully coordinated design and collaborative team.

2.2.9 Warranties

The NU build modular system is accredited by the Build Offsite Property Assurance Scheme (BOPAS). BLP provided the technical assessment for BOPAS. Separate accreditations are provided for multistorey buildings and single family houses.

Building warranty insurance is required for each project. This may be offered by BLP, or

a different provider such as Premier or NHBC. The client should confirm the building‘s warranty provider at an early stage of the design process to ensure the building is developed to the necessary technical requirements as these are specific to each warranty provider.

2.2.10

The NU build Modular System Guide

The NU build Modular System Guide will set out a toolbox to use when designing with the NU build Modular System. It will show examples of modular buildings, material specification, typical details and standard layouts.

The NU build Modular System Guide will include a range of products that have been selected by NU build and Swan for their compatibility with the factory’s manufacturing process and on site assembly. This should be used to inform the project specification and schedule of fixtures and fittings.

33 Design and assembly process I n f o r m s .

Figure 18 Everyone involved with the project needs to understand the modular process

Figure 19 The NU build Modular System Guide will feed into the NU build Modular Design Guide, and vice versa

3

MODULAR PRINCIPLES

3.1 TRANSPORTATION

Transporting modules from the factory to site is the first consideration when determining the dimensions of modules for the scheme and will impact on nearly every design decision going forward. Therefore, designers should fully understand the size considerations outlined in this chapter.

3.1.1 Transport size considerations

The optimal dimensions of a module are determined by the size of the lorry and the restrictions associated with the route to the site, such as road widths and obstructions.

The usual width of a single road lane in the UK is 3.65m, and a two lane carriage way is approximately 7.3m. A load width of +/2.89m is optimum for ease of transportation. As a rule of thumb, the wider the load the shorter the length needs to be to allow for the geometry of the turning circle. Although the maximum load width on a flat bed lorry

is 5m, this will require special interventions in most regions, including delivery time restrictions, police escorts, road closures, temporary removal of kerbs, street furniture etc.

The dimensions and weights of vehicles used on British roads are regulated by the Road Vehicles (Construction & Use) Regulations 1986 (C&U) Regs and the Road Vehicles (Authorised Weight) Regulations 1998 (AW) Regs.

Special types vehicles (STGO) do not meet the C&U and AW Regulations but can be used outside these rules under the authority of the Road Vehicles (Authorisation of Special Types) (General) Order 2003 (STGO).

36

Road type A A B B C C D D E Varies Berm Berm Slope Slope Verge Verge Hard strip Hard strip Carriageway (A) (A) (B) (B) (C) (C) (D) Lane 1 (L1) Lane 1 (L2) (D) (E) Varies Varies Varies Varies Varies Varies Varies 2.50 2.50 1.0 3.65 3.65 L2 L1 2.50 1.0 1.0 2.50 1.0 7.30 5.00 5.00 10.00 Single (S2) Wide single (WS2)

Figure 20 Carriageway width restrictions in the UK

Easy site access

No requirement for vehicle escort Slim load

STGO type vehicles

No time restriction (0700-1900 monday to friday)

No time restriction (0700-1000 and 1630-1900)

Vehicles that do not comply with an STGO order can be used on the road if Special Orders have been issued by:

– Highways England regarding abnormal loads not covered by C&U and STGO

– The Vehicle Certification Agency (VCA) regarding special vehicles and divisible loads such as crane ballast outside the scope of C&U and STGO

3.1.2 Route to site

A track analysis by a transport consultant should be undertaken in the Logistic Stage to understand the constraints of transporting modules to site. This should not simply be a desktop study, but requires a test run using the necessary vehicle, taking physical measurements and photographs which will Wide load

form an in depth report that highlights the nuances of the route.

The track analysis should be a ‘live’ document that is updated throughout the design and manufacturing stages to ensure it captures any changes and alterations that might arise.

WOOLWICH ROMFORD

DARTFORD ILFORD THURROCK

37 Transportation

GRAYS BRENTWOOD

Figure 21 Transportation constraints are determined by the width of the module and restrictions on the route from the factory to the site

Figure 22 Constraints are specific to the route to site

The tracking analysis report will investigate:

– Turning circle restrictions.

– Low bridges and obstacles e.g. trees, telegraph wires etc.

– Restricted delivery times.

– Signage, lighting or street furniture limitations.

– Road closures that might be required.

– Bridge and power line height considerations.

This report should enable the designer to understand the following:

– The proposed route from the factory.

– Highway authorities responsible for the route.

– Time and size constraints imposed by the relevant highways authority.

A standard UK motorway bridge allows a clear height of 5m. Other bridges and overhead power lines at level crossings may have lower maximum heights and should be avoided.

Height restrictions are required to be clearly signposted and should therefore be picked up during the test run.

All vehicles with an overall travelling height of over 3m must have the height displayed in the cab. The highways authority must be notified if loads are over 5m high and affect street furniture such as lights and gantries. Telecommunications companies that operate along the route must be notified if transporting loads over 5.25m.

3.1.3 Calculating the module width

When calculating widths of modules all projecting elements, such as windows or cills, must be included, as well as any finishes applied in the factory, such as insulation.

38 Transportation

T O T A L W I D T H T O T A L L E N G T H (includes protrusions) (includes

Figure 23 Understand the constraints specific to the route to site

protrusions)

Figure 24 The total module dimensions should include any protrusions and finishes such as window reveals or insulation

39 Transportation

Figure 25 The overall module size will impact on cost and time

3.1.4 Oversized modules

Modules larger than the optimal dimensions can result in increased transportation costs and should be kept to a minimum or avoided. If the design requires oversized modules, the following additional considerations need to be taken into account:

– Police escort

– Restricted delivery times

– Road closures

3.1.5 Time constraints

Depending on the size of the module, constraints that dictate permitted delivery times can be placed on transportation by local and national highways authorities and the police. Restrictions on time of delivery, such as during the night, can conflict with planning conditions that limit hours of working. For example, large loads may not be permitted between 7am and 7pm Monday to Friday. This can conflict with planning conditions that stipulate hours of working.

3.1.6 Abnormal loads

An abnormal load is a vehicle that has any of the following:

– A weight of more than 44,000kg.

– An axle load of more than 10,000kg for

a single non-driving axle and 11,500kg for a single driving axle.

– A width of more than 2.9 m.

– A rigid length of more than 18.65 m.

Abnormal loads are not permitted anywhere in London during the following times:

– Monday to Friday: 07:00 - 10:00 and 16:30 - 19:00

– Saturday: 10:00 - 19:00

In addition, abnormal loads are not permitted within a three mile radius of Charing Cross station during these times:

– Monday to Friday: 07:00 - 19:00

– Saturday: 10:00 - 19:00

Further guidance and information on abnormal vehicle loads can be obtained from the Metropolitan Police, Transport for London (TfL) and the Electronic Service Delivery for Abnormal Loads (ESDAL).

3.1.7 Protection of modules during transport

Modules must be protected from damage during transportation, particularly if there is a risk of the module getting wet. Protection against rain and splash from the road when in transit is vital. Further information can be found in Chapter 3.6 : Waterproofing.

40 Transportation

KEY CONSIDERATIONS: T RANSPORTATION

– What are the size restrictions associated with the lorry?

– Are there time restrictions for transporting the module to site?

– Has a track analysis report to check the route for obstructions and access considerations been instructed? NB this should be a test run with a vehicle rather than a desktop study.

– How do obstructions and access considerations along the route effect the maximum module dimensions?

– If the module is oversized, how will this impact on transportation and site access? Will there be time and cost implications? What arrangements should be made with the relevant authorities?

– Are protrusions and finishes that are applied in the factory accounted for within the module width dimensions?

– How will the module be protected during transportation?

– Should cladding and insulation be applied in the factory or on site?

41

3.2 SITE CONSIDERATIONS

The designer will need to understand the constraints of each site and the impact this has on the type of crane that can be used. This chapter highlights the key considerations for crane selection and outlines typical strategies for lifting the modules into position.

3.2.1 Access and site considerations

Firstly, the design team should investigate the best location to access the site to deliver the modules.

The location of the access points will have an impact on the assembly sequence of the modules. If one corner of the site is landlocked, the installation is likely to begin there. The construction sequence will always start from the least accessible part of the site.

One of the first considerations is to establish what type of crane the site and size of development will allow. A thorough survey of access and neighbouring properties should be carried out - will over-sailing of adjacent properties be an issue?

42

Figure 26 Will over-sailing of adjacent properties be an issue?

SITE ACCESS 2 3 4 5 6 7 8 9 10 11 1 14 13 12 15

Figure 27 The sequence of assembling the modules on site should start from the least accessible location

If modules are to be assembled adjacent to existing party walls, the designer should consider how the junction between the existing and modular walls are detailed, and if there will be room to install cladding on site. If not, the modules may need to be clad in the factory. Access to install connection details and fire stopping also needs to be considered. Refer to Chapter 3.10 : Fire design principles.

3.2.2 On site storage capacity

Storing modules on site can be advantageous as it frees up space in the factory and makes delivery and installation times more flexible. The possibility of on site storage should be investigated.

3.2.3 Surveys

Ground conditions and site surveys will be required, identifying the location of obstructions, underground and overground services etc.

3.2.4 Crane considerations

The crane position and size needs to be assessed. The maximum loads the crane can carry as well as the maximum reach needs to be calculated.

The size of the crane is dependent on the crane reach required, the angle of boom and the weight of module. The designer should consider the cost implications of the proposed crane size - the cost of a larger crane is considerably higher than a smaller crane so should be avoided where possible.

43 Site Considerations

Figure 28 Crane weight capacity is determined by weight and reach

25 t 50 t 75 t 100 t C o s t

A decision on whether the crane will be static or mobile needs to be made during the Logistic Stage as the choice has implications on phasing and foundation design.

The location of power and communications cables in the vicinity of the site should be established to ensure that the path of the crane does not clash with any overhead services.

3.2.5 Impact on foundation design

If a mobile crane is used to install the modules, the engineer will need to consider a number of additional factors when designing the foundations. The following

questions need to be answered before finalising the foundation design:

– Does the route of the crane or delivery vehicle cross underground services? Can this be avoided?

– Can the foundations for the whole site be constructed in one go prior to the modules being delivered to site? If not phasing may need to be considered.

– Is the crane or delivery vehicle required to drive over the foundations, if so can the foundations bear the load of a crane and a module together?

– Can the route of the crane avoid the foundations? The loads of the crane can impose lateral loads to the piles so the route must allow a sufficient distance to avoid this.

44 Site Considerations

Static crane Cost Loads Foundations Size Availability Mobile crane

Figure 29 Each project should understand the benefits and disadvantages of each crane type

Figure 30 Impact of crane loadings on foundations

– What is the combined weight of the crane plus the load of the heaviest module?

How will this affect the requirements of the hard standing surface needed beneath the crane?

– Can the outriggers of the crane align with the building foundations? If not, will a crane mat be required?

– If a pile mat is needed, can it be designed so that it can act as the crane mat too?

3.2.6 Lifting considerations

The centre of gravity of the modules must be calculated and coordinated with the factory prior to lifting. If possible, it is preferable for modules to be lifted from underneath. Otherwise, the connection detail between modules can be designed to double as a

lifting eye. This allows for the modules to be lifted from the top corners.

Multistorey developments are likely to experience higher stability forces during assembly, therefore temporary bracing may be required. This will require more work on site and can prove costly. To avoid the need for temporary bracing, the central core can be used to give additional stability during assembly. Further information can be found in Chapter 3.4 : Structural principles and Chapter 3.9 : Communal stair cores.

3.2.7 Phasing

If the space around the foundations is tight and access is restricted it may be necessary to phase the project. A construction phasing strategy and programme needs to be provided so that the factory can manufacture the modules in the correct order. The phasing strategy should also describe how the modules are accessed and uncoupled from the crane.

45 Site Considerations

Figure 31 Stacking principles - a ‘ziggurat’ form might be most appropriate for structural stability in the temporary condition

3.2.8 On site CDM, water and fire strategy

Written phasing, crane requirements and lifting strategies will be required and signed off by the principal designer, designers and principal contractors for pre-construction, factory and on site CDM reports.

An on site fire strategy will need to be established, as will a water management strategy to ensure there is no standing water on the modules during assembly worksfurther information can be found in Chapter 3.6 : Waterproofing

3.2.9 Module assembly strategy

A module assembly strategy needs to be agreed by the design team in collaboration with NU build during the Logistic Stage and updated with each stage report.

This should include, as a minimum:

– Site access strategy.

– Module delivery/storage strategy.

– Foundation strategy.

– Foundation sequencing/phasing strategy.

– Size and type of crane.

– Module lifting strategy.

– Module installation phasing strategy.

– On site water management strategy.

46 Site Considerations

Figure 32

Example of craning a module

KEY CONSIDERATIONS: S ITE C ONSIDERATIONS

– Has site access for delivery been planned?

– What type of crane is required and how will it impact on the foundation design?

– Has the foundation design sequencing and phasing been considered?

– Are services coordinated with crane locations and lifting strategy?

– Has an on site fire safety and water management strategy been completed during the Strategy Stage, for review and implementation into DfMA information at the Performance Stage and Detail Stage?

– Has a draft module assembly strategy been agreed at the Logistic Stage? Has this been updated at each subsequent stage?

– Has a risk assessment method statement been produced?

47

3.3 CLT PANELS

In order to make the most efficient use of the material, the designer should find out the proposed panel size at the earliest opportunity, as the size of standard CLT panels can influence the design of modules in a number of different ways. This information will be provided by the factory.

3.3.1 Panel size

There are a number of CLT manufacturers, each producing a slightly different range of panel sizes. The designer should establish if NU living have a preferred supplier for the project and work with the specified dimensions. Otherwise it is preferable to design the modules to accommodate a range of panel sizes.

3.3.2 Economic use of panels

Setting out the way the panel is cut to minimise wastage is essential. To do this the designer must understand the format of the standard panel size to maximise efficient use of the material and minimise offcuts. To aid with this, the CNC machine is programmed using specialist software that can simulate the machining to maximise efficient use of the CLT panels, reducing errors and waste.

48

50 - 350 mm 13,500 mm 2,950 mm

Figure 33 Standard panel dimensions

Designing openings by joining smaller panels together can be a more efficient than cutting openings out of a single panel which can cause large amounts of wastage. Guidance from the factory will help to establish the most efficient process. Large offcuts should be reused where possible. Small offcuts will be recycled and used in the factory’s biomass boiler.

around the factory simpler and will increase the overall floor to ceiling height of the module. However in certain circumstances it may be beneficial to span the floors between the walls (balloon construction) which would reduce the overall floor to ceiling height of the module.

The ceiling panel may need to sit below the top of the walls to allow a zone for services to be installed, covered in Chapter 4.2 : Servicing principles.

3.3.3 Impacts on module heights

The height and length of standard panels should be considered in determining the floor to ceiling height and length of the modules. It can be easier for the factory to build the modules with the walls sitting on top of the floors (platform construction). This makes the transportation of them

49 CLT Panels

Figure 35 Platform construct allows a greater floor to ceiling height than balloon construction

Figure 34 Panel cut efficiency

2.95 2.95 2.95 Less wastage as off cuts reused 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1 Floor to ceiling height reduced 2.95 Floor to ceiling height maximised 2.95 Platform construction Balloon construction

Figure 37 If possible, module walls should be made from one span of CLT

3.3.4 Vertical or horizontal panels

Using one CLT panel, rather than multiple panels stitched together, is preferable to avoid transferring shear and moment forces over CLT joints. However if the height of the module exceeds the standard panel width, it may be decided to join vertical panels of CLT. In this case the strength of the wall panels will be dependent on the connections between the panels, which may need to be reinforced. This will result in additional material and labour cost.

3.3.5 € and £ exchange rate

As CLT is procured from Europe, fluctuating exchange rates may impact on the profitability of the project and should be considered in the cost plan.

3.3.6 Visual quality

CLT is manufactured in three different visual qualities:

50 CLT Panels

I ndustrial For visible Th e outer spruce lamellas. side by side surface lamellas surface quality. S elected For visible Th e outer spruce lamellas, All lamellas By using selected surface has

X AM P L E: S URFACE –I N D USTRIAL VISIBLE QUALITY

AM P L E: S URFACE –S ELECTE D N OR D IC

E

E X

I ndustrial For cladding on site All lamellas are exclusively appearance. Knots, discolouration, I ndustrial visible For visible surfaces Th e outer surface layer spruce lamellas. Th e surface side by side without gluing surface lamellas to occur. surface quality. E X AM P L E: S URFACE –I N D USTRIAL QUALITY

X AM P L E: S URFACE –I N D USTRIAL VISIBLE QUALITY 20 METSÄ WOOD — LENO® CROSS LA M INATED T I M BER (CL T ) S elected For Th spruce All By surface E X AM P L E: S URFACE –S ELECTE D N OR D IC 1 2 3

E

KEY CONSIDERATIONS: CLT P ANELS

–– What are the standard panel sizes from NU build’s chosen supplier?

– Can the standard panel sizes achieve the required floor to ceiling heights?

– Has the CLT been used in the most efficient way to avoid wasted material?

– Will platform or balloon construction be used?

– Can the standard panel sizes achieve the required module length?

– Can the panels be used horizontally or do they need to be joined vertically? If so, how will the connection design work?

– What visual quality is required?

– Are £ and € exchange rates considered in the cost plan?

51

3.4 STRUCTURAL PRINCIPLES

Before starting to design the layout, the whole design team should have an understanding of the key structural considerations. Early engagement of all consultants is therefore essential.

3.4.1 Typical weights

Although timber is considered to be a lightweight material, modules can become heavy: larger modules can weigh up to 20 tonnes.

When undertaking the structural design, calculations of the typical weight of a module must reflect the varying assumed densities of timber, as shown in Figure 38:

– For connection design, a low density value should be used.

– For lifting, a high density value should be used.

– The mean density should be used when considering the requirements of the modules in their final built form.

This will have an impact on the requirements of the crane, both in terms of load and reach.

3.4.2 Lifting considerations

Consultants should consider how the modules will be lifted, how the main structural CLT panels perform and how any connecting elements will perform. Depending on the final configuration of the building, the process of lifting the module may be the most onerous structural case to design for. Because of this, to standardise the connection design all connections may be designed for the heaviest case even though module weights may vary.

Mean density (Permanent self weight of structure)

Fifth percentile density (Connection design)

Density for lifting calculations as per CLT manufacturer’s European Technical Approval

DENSITY

38 Graph showing normal density distribution

52

Figure

In some circumstances it may be necessary to introduce bracing for the module lift and transportation. This is not desirable and should be avoided if possible. For example, the opening positions could be adjusted to facilitate lifting without needing further bracing.

If bracing is required during the assembly of the modules, interference with the doors and windows should be avoided where possible.

3.4.3 Dynamic amplification

During the lifting of the modules there is a dynamic amplification factor to consider. This is because as the module is lifted it is accelerated and using the formula:

Force = Mass x Acceleration (F = ma),

This means the weight of the module increases. This additional weight should be factored into the connection design.

3.4.4 Stacking

A construction sequence for the assembly of the modules should be produced. Each module will need a unique identification number, which should be agreed and coordinated with the design team and the factory.

In multistorey buildings the modules should ideally be stacked floor by floor. For example, the ground floor is assembled, followed by the first floor and so on. If site access is restricted and this is not possible, the structural requirements of the modules while they are being assembled will need to be assessed to determine the most appropriate assembly sequence.

It should be noted that proportions of the building during assembly will have an effect on the connection design: if it is tall and thin, the connection forces will be higher than if it is low and wide.

Alternative sequences must consider the stability of the modules during assembly

53 Structural principles

1 2 3 4 3 4 1 2 8 7 3 2 1 15 10 9 5 4 17 16 12 11 6 20 19 18 14 13 Modules

should preferably be stacked floor by floor

5 4 3 2 1 10 9 8 7 6 15 14 13 12 11 20 19 18 17 16 1 2 3 17 10 9 2 1 18 12 11 4 3 19 14 13 6 5 20 16 15 8 7

Figure 39 Dynamic amplification affects the module in lifting

Figure 40 The assembly sequence should consider the structural stability of the modules

3.4.5 Layout considerations

‘Land locked’ modules, as shown in Figure 41 should be avoided. This is because the connections are not easily accessible during assembly as it is only possible to access the modules from inside the building.

3.4.6 Structural differences between houses and multistorey buildings

For the NU build Modular System, housing is considered to be an arrangement of three by three modules, and multistorey greater than this.

Figure 42 shows the relationship between the height of the building and the depth of each floor/number of modules required to ensure structural stability.

When designing multistorey buildings above five storeys, it is advised the CLT core walls provide additional stability. Beyond eight storeys further stability may be needed, which could be provided by a concrete core. Further information is provided in Chapter 3.9 : Communal stair cores.

54

principles

Structural

deep Min no. of modules deep Additional stability walls or

required above 5 storeys No. of modules high 0 0 4 6 8 2 10 12 14 16 1 2 3 4 5 6 7

Figure 42 Typical limit for number of modules high versus number of modules

core

Figure 41 ‘Landlocked’ modules

‘Land locked’ module to module connections that are only accessible from inside the building

3.4.7 Connection strategy

The connection design is critical to the success of the module design. This can be broken down into two main types: connections for joining CLT to CLT, and connections between the modules.

The DfMA process also applies to the connection design. Since the connections will be repeated multiple times they should be optimised to make savings where possible.

The designer should agree the screw and standard bracket supplier with the client and the factory.

3.4.8 Typical connections

Typical connections are used to connect pieces of CLT to one another. These are usually the standard connections that can be found in more traditional CLT superstructure buildings, such as brackets and screws. Housing Multistorey

3.4.9 Module connections

The steel connections that join the modules are a critical component of the modular system, and require comprehension of a number of factors when designing them, such as:

– How will the dynamic amplification of the module impact the weight of the module, and therefore the requirements of the connections as the modules are lifted?

BRACKET

(Copyright Simpson Strong Tie)

Fully threaded

Partially threaded

SCREWS

(Copyright Rothoblaas)

55 Structural principles

Figure 44 Typical connections

Figure 43 Elevation of housing and multistorey assembly

– Can the connections double as lifting eyes?

– What are the timber settlement requirements and how will these affect the design of the connection? This is particularly important for multistorey buildings.

– Can the connections be fabricated at scale? Has the designer investigated the steel fabrication process to ensure this is possible?

– Can the weight of the connections be reduced so that manual handling requirements are met?

– What tolerances are needed for fitting the connection in the factory? The CLT is cut within certain tolerances that can affect the connection design.

– The connection design can be complex and potentially costly. How can this be reduced? Has the cost been considered early in the design process?

In addition to these, the requirements of the module connections on site should be considered, such as:

– What tolerances are needed? Note that these should include any concrete tolerances at ground or podium levels.

– How will the connection be accessed during assembly? Are there any restrictions to access and can they be avoided?

– Will the connection pond or fill with water on site? How can this be prevented?

3.4.10 Jointing

In order to achieve the module lift, the long side panels need to be continuous with the floor and ceiling panels spanning between.

The position of the half-laps need to consider the diaphragm action of the floor and should avoid unsupported edges across door thresholds.

56 Structural principles

Floor and ceiling panels half-lapped together

Long edge to be one continuous panel to allow for module lift

Half-lap joints to avoid door openings

Half-lap joints

Figure 45 The location of joints should be considered in parallel with the lifting strategy

KEY CONSIDERATIONS: S TRUCTURAL PRINCIPLES

– Landlocked modules should be avoided.

– If designing buildings taller than five storeys, it may be necessary to use the core for structural stability.

– Connection design should be considered at the earliest opportunity.

– How will the dynamic amplification of the modules during lifting impact on the lifting strategy and the crane specification?

– Each module should have a unique identification number.

– Has an assembly sequence for the modules been produced?

– Has the position of the half-laps in the CLT been considered, and are they avoiding door thresholds?

57

3.5 GROUND FLOOR CONSTRUCTION

The ground floor construction detail is of paramount importance, particularly if CLT modules are located on the ground floor of the proposed building. Design solutions that protect the CLT from moisture should be proposed at the earliest opportunity.

3.5.1 Site ground conditions

An early ground conditions survey will be required as water table, ground gas and site stability could all effect the choice of ground floor detail.

3.5.2 Ground floor use

This will vary depending on whether the design is for single family dwelling or a multistorey development.

Normally the ground and upper floors of single family dwellings line through. It therefore makes sense to retain the same structural material at ground, first and second floors in low rise developments.

Often, in multistorey, the ground floor plan does not line through with the flat layouts on the floors above. This can be for a number of reasons such as:

– When commercial uses are at ground floor, they are typically set out on a different grid to upper residential floors.

– When fully accessible dwellings are required they can be larger than standard units. Their layout may not stack with units above.

– Communal spaces, stores, service cupboards and substations require different structural and spatial requirements.

The use will determine the construction method of the ground floor. If possible, it is preferable to install modules at ground floor to simplify construction. However, depending on the requirements, it may be appropriate to install a steel or concrete framed podium.

58

Figure 46 Various uses of modules at ground floor level

Commercial Plant Residential

3.5.3 Modular ground floor

It is preferable for the whole building to be made from modules. This ensures the quality of finish is maintained throughout the project, on site labour is minimised and the efficiency of the modular system is maximised. Care needs to be taken to ensure the CLT module is kept dry.

The relationship between the base of the timber and the external drainage level and the provision of adequate drainage to the perimeter are key considerations which may have implications on level thresholds and external landscaping.

The design of the ground floor also depends on the strategy for transferring the loads from the upper floors to the foundations. Two ground floor details should be investigated: a concrete slab or ventilated void foundation under the module. Both have their advantages and disadvantages, which should be analysed and understood when determining the appropriate strategy.

It is important that all four walls of the module are evenly supported to avoid differential movement. The strategy to achieve this is dependent on whether the module to slab connection is via point loads, line loads or a combination of the two.

59 Ground floor construction

Figure 47 Module at ground floor

3.5.4 Modular foundation options

There are two types of ground floor modular foundation details:

– Sit the modules on a concrete slab with no ventilation.

– Sit the modules on concrete perimeter upstands and crossbeams with a ventilated void below.

Sitting the module on a concrete slab reduces the risk of ground water rising up to underside of module, but increases the risk of moisture building up at the perimeter.

Alternatively, the module can sit on a ventilated concrete upstand, with breathable insulation fixed to the underside of the CLT. This requires sufficient space around the building to allow cross ventilation under the modules, which might not be possible on constrained sites. Drainage to prevent rising ground water reaching the underside CLT must also be included and maintained once the building is in use.

In both cases, the underside of the CLT should be a minimum of 75 mm above external drainage level. With drainage provided to the perimeter and the corners of the modules supported on concrete upstands. The tolerance of slab and perimeter upstands needs to be + 0 mm to - 10 mm, meaning that the concrete can be raised, but not reduced.

3.5.5 Underground drainage

Adequate drainage needs to be installed across the site to ensure that ground water is drained away from the modules.

3.5.6 Waterproofing around perimeter

It is good practice in all projects to install perimeter drainage. Ensuring the integrity of DPCs and DPMs in the factory and during assembly is critical.

3.5.7 Disabled units/level threshold

If modules are raised above ground, level access to disabled units is still required. This needs to be incorporated in the landscape design.

60 Ground floor construction

Figure 49 Ventilated slab ground floor

Figure 48 Concrete slab ground floor

3.5.8 Concrete or steel frame ground floor (podium)

The CLT modules are raised above the ground and there is no timber at ground floor level thereby reducing the risk from ground water ingress.

A metal deck or concrete slab supports the module at first floor level. Installing a frame at ground floor level allows flexibility in the design of the ground floor spaces. It is easy to achieve a level threshold for disabled accessible units.

However the ground floor cannot be volumetric and fitted out in the factory so NU living have to coordinate trades on site for the fit out. This is not as efficient as building entirely out of modules.

Another draw back is access - installation of a concrete or steel frame could restrict access to the rest of the site and needs to be considered in the context of the module assembly strategy.

61 Ground floor construction

Figure 50 Overview of concrete or steel frame ground floor

3.5.9 Modules on basement foundation

Installing a basement can be costly, so will not be appropriate for all projects. If feasible, it can protect the CLT from moisture, as well as providing space for plant, storage or parking, freeing up more area on ground floor.

The CLT modules sit on top of a concrete slab above the basement, where they are protected from moisture collecting on the underside of the timber. There is still a risk of moisture build up at the perimeter, so this needs to be considered in the design of the ground detail.

The introduction of basements can impact on accessibility to the site for craning in modules. This would need to be assessed in the module assembly strategy.

62 Ground floor construction

Figure 51 Modules above a basement

KEY CONSIDERATIONS: G ROUND FLOOR CONSTRUCTION

– Has a ground conditions survey been undertaken and the results considered?

– What will the use of the ground floor be, and how will this impact on the construction method and ground floor detail?

– Is a basement required? If so, consider site access for module assembly.

– Is a ground floor podium required? If so, consider site access for module assembly.

– If modules are at ground floor, is the underside and end grain of the CLT protected from moisture at external ground level, with drainage around the perimeter and the corners of the modules supported on upstands?

– Agree a foundation strategy at the earliest opportunity, and ensure that it is coordinated with the assembly process.

– Agree a site wide drainage strategy.

– Has level access to ground floor units been provided?

– Are wet rooms required?

63

3.6 WATERPROOFING

Although it is essential that the waterproofing is managed in all buildings, modular construction varies slightly from traditional construction. Waterproofing must be considered inside the modules, during transportation and assembly as well as when the building is in use.

3.6.1 Waterproofing design

CLT needs to breathe, therefore where possible the construction of the walls, floors and roofs need to be fully breathable and moisture must be prevented from entering the fabric of the building. The use of breathable wall build ups is encouraged.

Dew point analysis is required with all U-value calculations to ensure moisture does not condense within the fabric of the building. Further information can be found in Chapter 3.11 : Thermal principles.

3.6.2 Tanking and wet room design

Kitchens and bathrooms should be lined with a wet room tanking membrane. This should be applied to all low level areas to prevent possible damage from dripping taps or leaks and full height to areas of heavy exposure such as showers. Additional protection can be added to high risk areas such as bathrooms by designing them as wet rooms, where the tanking membrane is linked to a gully that connects with the main waterproofing line e.g. tiles and grout. Sanitary ware and bathroom furniture are then fitted above. This mitigates the risk of water damage and resulting costs should a tap or pipe leak or an item of sanitary ware overflows.

64