Fruit Logistica 2026 for more details, turn to page 10...

Fruit Logistica 2026 for more details, turn to page 10...

The Schmersal Group has designed a new safety light barrier especially for hygiene-sensitive uses in the food processing industry, such as milk and meat processing.

This version has evolved with the demands of standard cleaning operations in the industry as the sophisticated design helps to ensure IP69 degree of protection (protection against the ingress of water from high-pressure of steam cleaning).

The protective enclosure with external gaskets satisfies stringent standards and is designed to cope with frequent cleaning with water, foam, lyes, high-pressure or hot steam.

SCHMERSAL | Enigma Business Park Malvern, Worcestershire, WR14 1GL

www.schmersal.co.uk

uksupport@schmersal.com

EDITORIAL:

Aberfield Communications

Appleyard Lees

Ashfords LLP

Clarion Events

Golden Brain

Harford Control

Koelnmesse

Krombacher

M1 Marketing

Marbles PR

Messe Berlin

Montgomery Group

The ice cream alliance

The Right Agency Think B2B

ADVERTISEMENT SALES:

KIMBERLEY READ (Advertisement Sales Manager) JOANNE MURPHY

AMANDA WALMSLEY EVELYN WOOLSTON

RACHEL RILEY - Manager

WALTONS PUBLICATIONS LTD

46 HENEAGE ROAD, GRIMSBY N.E. LINCOLNSHIRE DN32 9ES

Kimberley Read at: kimberley@foodanddrinknetwork-uk.co.uk or Joanne Murphy at: joanne@foodanddrinknetwork-uk.co.uk foodanddrinknetwork.co.uk

Martello Transport is strengthening its container haulage capability with 18 new Krone Box Liner sliding skeletal trailers, adding capacity and flexibility to meet what the company describes as strong demand across the UK’s export and import markets.

Based in Felixstowe, Martello Transport operates nationwide container haulage services, linking all major UK ports and freight hubs. The new trailers will handle a wide range of standard containers, including import and export cargo, as well as ADR-compliant loads where required.

Explaining the decision to buy Krone, Director Danny Huwen says: “We’ve bought from Krone before and found their product to be standing the test of time. Great quality, combined with their ability to meet our exact requirements, made the decision straightforward.”

Durability was a deciding factor. “Each trailer comes with a 10-year paint warranty against rust and combined with the robust construction, we know they will stand up to heavy, daily use over the long term,” adds Danny.

Martello’s fleet now exceeds 150 vehicles, and the company continues to expand. “Demand for container carriers is strong,” says Danny. “The UK’s container

Shoryu Ramen Brings

Japan’s Most Infamous Ramen Bowl to the UK for the First Time.

Shoryu Ramen is about to make history.

On 7th October 2025, Shoryu Ramen are bringing its interpretation of the cult phenomenon Jiro Ramen to the UK.

Exclusively available at Shoryu Carnaby St, Covent Garden, Regent Street, Soho, Shoreditch, Westfield Stratford City World Food Court, Oxford and Manchester.

Forget everything you think you know about ramen. This is ramen like you’ve never seen before: rich, intense aromas, mountains of garlic, and a bowl so epic that by the time you’ve recovered, you’ll already be craving your next one.

First created in Tokyo in the 1960s, Jiro Ramen is more than a dish; it’s a cultlike movement. In Japan, it’s said to have divided households (some even joke that it’s caused divorces). It’s loud, indulgent, and designed to overwhelm in the best possible way. Superfans call themselves Jirorians , proudly claiming it’s “the ultimate ramen bowl” and “the best thing you’ll ever eat.” Critics say it’s “too much of everything” and “like a punch in the face.”

Each bowl of Shoryu’s Jiro Ramen (£23) features braised kakuni pork belly, thick futomen noodles, a mountain of bean sprouts, extra seabura (pork back fat), and heaps of minced garlic. Diners can upgrade their bowl with nitamago (soft-boiled egg) (£2.70).

While Ramen is celebrated for its heritage, refined technique and precision, Jiro Ramen is gloriously messy and unapologetically chaotic - and that’s precisely why people are obsessed with it. It’s ramen served in outrageous proportions; a ramen with a reputation.

To celebrate the launch, diners can take on the Jiro to Hero speed eating challenge. When the bowl hits the table, the clock starts, and it must be finished in under five minutes to qualify. Winners earn exclusive Jiro merch and a spot on the UK leaderboard, with the top challenger each month taking home a year’s supply of Shoryu Ramen.

Jiro Ramen will be available for a limited time until November 9, 2025, when it will be moved to the festive menus.

movement is resilient, and customers are increasingly looking for reliable, flexible haulage solutions. Investing in new, high-quality equipment will ensure we stay ahead of demand.”

The Box Liners feature robust steel construction with welded cross members and double longitudinal beams, reinforced parking brakes, and extractable rear bumpers compliant with EC regulations. “Also,” adds Danny Huwen, “the telematics and tyre-monitoring systems give us real-time diagnostics, which helps maximise uptime and plan maintenance more efficiently.”

Founded in 2017, Martello Transport has grown into a nationwide operator from its Felixstowe base, combining container haulage with specialist transport and rail interface services.

FS Pack Solutions: a new French company continuing Karlville France’s legacy, dedicated to pouch filling and shrink-sleeving technologies

As the global packaging industry strives to balance performance, flexibility, and sustainability, FS Pack Solutions officially announces its launch. This new French company, the direct continuation of Karlville France following its liquidation, positions itself as a key player in the design and manufacturing of pouch filling and shrink-sleeving equipment for flexible packaging applications.

Based in Saint-Didier-de-Formans (Ain), near Lyon and Villefranche-enBeaujolais, FS Pack Solutions (Fill & Sleeve Pack Solutions) builds on over 20 years of experience in the development, assembly, and commercialization of advanced packaging machinery.

The company benefits from a strong industrial partnership with CMF Automation and Technibag for equipment manufacturing and integration, and from the collaboration of former Karlville USA and Karlville France engineers, ensuring technical continuity, service reliability, and consistent quality standards.

The trust of Karlville’s long-standing customers has been instrumental in this transition: several have already transferred their ongoing projects and orders to FS Pack Solutions, demonstrating confidence in the team’s technical expertise and operational stability.

Operating in an increasingly demanding regulatory environment, FS Pack Solutions is now developing two next-generation equipment lines: the NeoFill range for pouch filling, and the SteamBox range for shrinksleeving applications. Both are designed to be more compact, modular, and recyclable-material compatible, meeting the evolving needs of food, cosmetics, detergent, pharmaceutical, and converting industries.

With its creation, FS Pack Solutions aims to strengthen French industrial expertise in flexible packaging machinery, while expanding its European partnerships and reinforcing its local roots in the Auvergne-Rhône-Alpes region.

Visit www.fspacksolutions.com

The global oat drink sector is entering a new phase of accelerated growth, powered by the increasing demand for plant-based and lactose-free alternatives, sustainability awareness, and rapid innovation across the beverage industry. Leading food and beverage consultants, FnB predict the market’s value will surge from USD 3.67 billion in 2025 to USD 10.68 billion by 2034 - highlighting the category’s powerful global momentum.

As oat milk cements its place as a mainstream dairy alternative, consumer expectations for texture, creaminess and stability are rising. Yet, replicating the sensory qualities of traditional milk remains a technical challenge for producers.

Responding to this demand, KRÖNER-STÄRKE, a leading international producer of high-quality food ingredients, has launched an innovative pregelatinized oat (wholemeal) flour - a functional solution that helps manufacturers deliver smooth and stable oat-based products without artificial additives.

This development comes at a critical time for the global beverage industry, where innovation and differentiation are key to staying competitive. KRÖNERSTÄRKE’s new solution offers manufacturers the flexibility to fine tune texture,

DataLase, a global leader in photonic printing solutions, has announced that Bergman & Beving AB has acquired a 90% shareholding in the business. Based in Widnes, Cheshire, DataLase provides patented, sustainable, inkless (at point of packing) and customised printing solutions for product and packaging applications worldwide.

The company’s unique photonic printing technology enables high-quality, high-speed, and sustainable printing directly onto a wide range of materials without the need for traditional inks. The result is a cleaner, more efficient and environmentally friendly process that meets the growing market demand for sustainable printing and packaging.

Bergman & Beving, founded in 1906, is listed on Nasdaq Stockholm. The group comprises around 40 companies, represented in more than 25 countries, employing approximately 1,400 people worldwide. Its business model focuses on long-term ownership and supporting autonomous, entrepreneurial companies with strong growth potential.

As part of the acquisition, DataLase will join Bergman & Beving’s Safety Technology division, becoming part of a group that has been acquiring and developing leading niche industrial companies for over a century.

Clare Lewis, CEO of DataLase, said: “We are delighted to become part of the Bergman & Beving Group. Their long-term approach, proven ability to develop specialist technical companies, and commitment to sustainability align perfectly with our own values and ambitions. This partnership will allow us to accelerate our global growth, continue advancing our photonic printing technology, and deliver even greater value to our customers.”

Following the transaction, Clare Lewis will continue in her role as CEO and retain a 10% shareholding in the business.

fat content and nutritional profiles - opening up opportunities for expanded product lines ranging from premium oat drinks and fortified smoothies to ready-to-drink meal replacements.

By combining instant hydration, superior mouthfeel and natural stability, KRÖNER-STÄRKE’s pregelatinized oat flour marks an important advancement in the formulation of plant-based beverages. The company continues to work closely with global partners to develop clean-label, functional ingredients that support the growing market demand for sustainable, high-quality alternatives.

For further information visit www.kroener-staerke.de.

Culina Group, the UK’s largest privately owned logistics supply chain partner, is proud to announce that its subsidiary, iForce, has been recognised with an International Green Apple Environment Award for its outstanding environmental achievements.

The award recognises the work done by iForce, alongside its partner Allwood Recycling Services, to reduce waste, including food waste, and increase the rebate revenue on cardboard, polythene, pallets, and metals.

The win reflects the wider groups’ outstanding contribution to sustainable logistics and our ambitious goal of reaching net zero emissions by 2050.

By introducing new sorting practices and baling technology, alongside improved employee education and training, at its headquarters in Corby, iForce has reduced costs, improved recycling rates and increased revenue. This includes the recovery of around 200 pallets per week which now go back into network and would previously have gone to waste.

Now, selected from over 700 entries worldwide, they are being honoured at a prestigious ceremony in the House of Lords, London, on November 17, 2025. The award not only recognises their accomplishments but also positions iForce as a leader in sustainability.

Following this achievement iForce has also been invited to accept Green World Ambassador status, which includes the opportunity to have its awardwinning project published in The Green Book, the leading international reference on environmental best practice. They are also invited to represent their country at the Green World Environment Awards, the premier international showcase of environmental leadership.

Liam McElroy, CEO of Culina Group said: “To see the recognition being gained by iForce for this significant transformation is extremely satisfying for the whole group. It reflects our commitment to being at the forefront of sustainable practices in the logistics sector and is further evidence of the steps we are taking to drive change in our industry.”

The iForce sustainability strategy is aligned with the Science Based Targets initiative (SBTi) and supported by a cross-functional project team within Culina Group. The company actively engages with customers, suppliers, and industry experts to share best practices and foster a culture of environmental stewardship.

The International Green Apple Awards are run by The Green Organisation, an independent, non-profit group founded in 1994 to recognise, reward, and promote environmental excellence worldwide.

An article By Roy Green, Harford Control Ltd.

November 2025

Between January 2020 and July 2025, UK food and non-alcoholic drink prices rose by 37%, outpacing the 28% increase in overall UK prices. This marks one of the sharpest periods of inflation in decades, with the five-year average running at more than double the rate seen between 1990 and 2010.

Such sustained inflation has reshaped the economic landscape for both consumers and manufacturers, forcing the food and drink sector to adapt under unprecedented cost pressures.

Over recent years, food manufacturers have shouldered much of the burden of rising costs to protect shoppers from steeper price hikes at the tills. However, with average production costs up 6.3% last year—well above the rate of inflation—many have reached the limits of what they can absorb.

The result is now evident on supermarket shelves. Households are spending £70.50 a week on food and drink, nearly double the £38.50 spent on energy, highlighting how essential yet increasingly expensive this area of spending has become (Food and Drink Federation).

For UK food and drink manufacturers, one of the largest cost drivers remains the price of ingredients and commodities. And these costs don’t exist in isolation—they’re closely tied to wider global events and supply chain disruptions.

A major contributor to these increases has been the volatility in raw material prices. The combined effects of the Covid-19 pandemic and the war in Ukraine disrupted global supply chains, reducing the availability of key ingredients and driving up costs.

Compounding the issue, Brexit introduced new trade barriers and administrative costs, particularly affecting imports and exports. With 42% of the food consumed in the UK imported, even minor disruptions have had significant ripple effects.

Some of the steepest price increases between January 2020 and July 2025 include:

Jan 2020 Price

£1.15 per 4 pints

£0.72 per kg

£6.90 per kg

£0.68 per 1.5kg

(Source: Food and Drink Federation)

These escalating costs underscore a key challenge for manufacturers: while external pressures such as global conflict, pandemics, and trade barriers may be beyond their control, how efficiently they operate within the factory is not.

With the rising costs of materials, increased efficiency and precision have become essential for maintaining profitability and competitiveness. Harford Control’s solutions help manufacturers minimise waste, enhance traceability, and ensure consistent quality— directly addressing the root causes of cost escalation that remain under manufacturing control

• Weight and Volume Control: Avoid overfill and giveaway in materials, improving yield and reducing waste.

• Material Tracking and Traceability: Maintain full visibility of materials through every stage of production, ensuring compliance and accountability whilst avoiding the dreaded LIFO (Last In First Out).

Jul 2025 Price

£1.68 per 4 pints

£1.12 per kg

£9.01 per kg

£0.81 per 1.5kg

• Laboratory Information Management System (LIMS): Digitally manage testing, results, and quality data to improve responsiveness and reliability.

• Paperless Quality: Streamline quality checks and documentation, reducing administrative overhead and error, identifying and fixing problems earlier.

By integrating these systems, manufacturers can reduce material waste, ensure consistent quality, and gain real-time visibility across every stage of production. This connected approach not only improves efficiency and compliance but also supports datadriven decision-making that leads to lasting operational and financial gains.

Despite the challenges, the Food and Drink Federation identifies a £14 billion growth opportunity for the UK’s food and drink manufacturing sector. To realise this potential, the industry must continue to invest in automation and digital transformation—key enablers of efficiency, quality, and long-term resilience.

This opportunity was clearly reflected at this year’s PPMA Show, where we were thrilled by the level of interest in digital manufacturing

solutions. It’s encouraging to see more manufacturers recognising that success will come to those who view technology not as a cost, but as a strategic investment in stability and growth.

With over 55 years experience, Harford Control is the market-leading provider of Manufacturing Execution Systems (MES)— helping manufacturers achieve higher efficiency, improved quality, and complete compliance.

Contact Harford today to start your digital transformation journey. Contact Harford today to start your digital transformation journey. Email us at sales@harfordcontrol.com or call us on +44 (0)1225 764461.

The UK’s biggest packaging event returns to NEC Birmingham, 11 & 12 February 2026

Registration is now open for Packaging Innovations & Empack 2026, the UK’s largest and most comprehensive packaging event, taking place at NEC Birmingham on 11 & 12 February 2026. Over two days, more than 7,400 visitors, 450 world-class suppliers, and 80 expert speakers will come together to explore the full packaging supply chain under one roof. From concept to fulfilment, every stage of the journey is represented, and real-world challenges are addressed by experts across design, materials, automation, machinery, logistics, and sustainability.

The 2026 edition highlights how packaging can meet today’s demands while preparing for tomorrow. Visitors will explore cutting-edge solutions in automation, robotics, AI, and smart manufacturing, gain practical insights in CPD-accredited seminars, and hear from regulators, brand owners, suppliers, and disruptors tackling the industry’s biggest challenges. Dedicated show zones, including the Smart Packaging Zone, Start-Up Zone, and Foodservice Zone, provide tailored insights, while live demonstrations at Empack showcase automation and machinery

innovations in action. Contract Pack & Fulfilment, hosted by the BCMPA, connects brands with over 200 trusted outsourcing partners to streamline production, improve efficiency, and scale e-commerce fulfilment, while offering startups and emerging disruptors opportunities to pitch to co-packers.

The event also champions inclusivity and talent development. Partnerships with charities and industry programmes celebrate diversity and accessibility, while the Future Trailblazers Awards, supported by The Institute of Materials, Minerals & Mining (IOM3), will once again shine a spotlight on the next generation of leaders shaping the future of packaging. Leading FMCG brands and retailers such as Unilever, Boots, Tesco, Mondelez, Coca-Cola, PepsiCo, P&G, Diageo, Red Bull, Nestlé, Nando’s, ghd, and LUSH attend year after year, alongside top suppliers including Zeus, Saica Flex, Wepack, Constantia, and Pont Packaging.

“Packaging Innovations & Empack 2026 will once again bring the full packaging ecosystem together under one roof,” said Josh Brooks, Divisional Director, Packaging – Easyfairs. “From brand owners to suppliers, start-ups to scale-ups, visitors will have the chance to explore innovations across design, materials, machinery, and sustainability, all in a single, accessible location.

“The show is about more than just products and solutions - it’s about collaboration, learning, and preparing for the challenges of tomorrow.”

Visitors can benchmark innovations across sectors, gain actionable

strategies to cut costs, reduce waste, and future-proof operations, and connect with a multi-sector audience spanning FMCG, beauty, food and drink, pharmaceuticals, retail, automotive, and e-commerce. Networking opportunities in the VIP Lounge, cocktail bar, and beer bar complement the learning experience, enabling attendees to build meaningful connections while exploring the full breadth of packaging solutions.

Rob Thompson, Senior Packaging Manager at Co-op, commented: “I have been attending Packaging Innovations at the NEC for over 20 years. It’s the UK’s premier event for anyone looking to network with other packaging professionals.”

William Guest, Sustainable Packaging Manager at Tesco, said: “It’s a really well-organised event in a fantastic location. There is a good mix of suppliers and speakers, allowing you to see the latest innovations while listening to the thoughts of industry leaders and specialists.”

Lionel Barnett, Operations Manager at Oh Polly, added: “We find the show very interesting and always make a lot of contacts, some of whom we ended up doing business with.”

Secure your complimentary visitor pass today and join thousands of packaging professionals at Packaging Innovations & Empack 2026. Discover the latest innovations, connect with leading suppliers, and gain practical insights to future-proof your business - all under one roof.

Every February, the international fresh produce industry converges in Berlin. From 4 to 6 February 2026, FRUIT LOGISTICA once again sets the global standard for innovation, networking, and market momentum. The leading trade show for the global fresh produce business is more than a meeting place – it is where markets move, ideas inspire, and business grows.

Exhibitors from over 90 countries present their latest products, technologies, and solutions that shape the industry year-round. The entire value chain – from production to retail – comes together to explore the trends and technologies defining the future of fresh trade.

The Fresh Produce segment showcases everything that defines freshness: fruits, vegetables, mushrooms, herbs, flowers, organic and fair trade goods, and frozen products. Here, diversity, quality, and sustainability take center stage.

In Machinery & Technology halls, innovation drives efficiency. From advanced processing lines and intelligent cultivation systems to automation and AI-powered precision farming, cutting-edge solutions reveal how technology is transforming the sector.

The Logistics area focuses on the seamless, sustainable movement of goods across the globe. Cooling systems, smart packaging, robotics, freight drones, and digital telematics highlight how efficiency and sustainability go hand in hand.

Innovation takes the spotlight from day one. During the first two days, trade visitors can cast their votes for the FRUIT LOGISTICA Innovation Award (FLIA), recognizing the idea that will shape the industry’s future. The New Product Showcases offer a glimpse of tomorrow’s trends – fresh concepts, smart solutions, and pioneering approaches to competitiveness and sustainability.

A highlight beyond the exhibition halls, the Welcome Party brings the global community together in an atmosphere of exchange and inspiration, setting the tone for three dynamic days of business and innovation.

With more than 91,000 professionals on-site, FRUIT LOGISTICA is the beating heart of the international fresh produce business – a place where ideas turn into action and the future of the industry takes shape.

fruitlogistica.com

The Ice Cream & Artisan Food Show 2026, the UK’s only dedicated trade event for the ice cream industry, is back for another round of showcasing the sweetest desserts the country has to offer!

Hosted by the Ice Cream Alliance, the trade show is an unmissable platform for ice cream professionals and enthusiasts to connect with the people and trends shaping the future of the industry.

After the success of the 2025 show, which welcomed over 6,500 trade visitors, the show will return on the 3rd-4th February at NEC Birmingham.

Last year’s event delivered impressive results:

• £28,000 – the average order value placed at the show

• More than 80% of visitors placed future orders post-show

• 85% of attendees had direct purchasing authority

The 2026 show will have a newly-introduced Demonstration Area, which will showcase:

• Inspiring ice cream

• Innovative gelato

• New flavours and trends for 2026/2027

• Coffee and latte art demos

• Hot offerings - quick and cost effective

A star-studded lineup of speakers will also be at the show, including:

Sara Davis MBE of Dragons Den & Business Woman Entrepreneur James Sinclair on business expansion. And more experts on franchising your ice cream business, marketing & social media.

The Ice Cream Alliance has an historic connection with the ice cream businesses of the UK. The annual trade show is a highlight of the calendar, offering invaluable networking opportunities and industry insights.

With the top buyers, suppliers, wholesalers, parlours, restaurants and businesses in the ice cream industry in attendance, the 2026 Ice Cream & Artisan Food Show is sure to impress!

Reflecting on this year’s show, Catherine McNeil, The Ice Cream Alliance’s Director of Operations, says, “Last year, the trade show moved to the NEC Birmingham – a larger and more connected venue that reflects the growth of the event. This year, we hope to be even bigger and better, offering more to our members and helping to grow the UK’s ice cream industry.”

Find out more about exhibiting or attending the Ice Cream & Artisan Food Show visit https://ice-cream.org/ice-cream-and-artisan-food-show/#!form/ExhibitorEnquiry

From 1 to 4 February 2026, exhibitors will present future-oriented AI technologies that are transforming production and packaging processes in the sweets and snacks sector. Intelligent 2D and 3D vision sensors, smart data applications, and generative assistants will show how digitalisation is driving automation and quality assurance.

Efficiency under pressure

Manufacturers face increasing challenges: packaging lines must be ready quickly, production stable, and system efficiency assured. Market dynamics demand ever-new product variants — from family packs to limited editions — requiring flexible, quickly convertible machinery.

“Highly flexible systems that enable fast format changes and rapid restarts are key to remaining competitive,” says Guido Hentschke, Director of ISM Ingredients and ProSweets Cologne.

Smart sensors as the foundation of AI integration

The industry’s machines already feature extensive automation, yet much of their data remains untapped. Now, smart sensors with integrated microprocessors are enabling predictive maintenance and process optimisation by communicating with the cloud. These sensors don’t just measure — they interpret. Their ability to predict system performance helps improve overall equipment effectiveness (OEE).

Sensors can even be installed in mobile components, such as chocolate moulds equipped with measurement technology. These monitor hard-to-reach areas like cooling tunnels or vibrating tables in real time, detecting irregularities before failures occur.

AI-driven assistants now allow operators to query production and packaging systems directly. Connected to ever-growing databases, these generative copilots answer operational questions instantly, automate routine tasks, and guide users through format changes — eliminating downtime due to incorrect settings.

Vision systems take quality control to the next level

“AI and machine learning are transforming sweets and snacks production,” says Hentschke. “Systems increasingly act proactively, improving quality and using resources more efficiently.”

2D and 3D vision sensors are now widespread across the food industry. They handle diverse product types and packaging formats without extra setup. Using AI-based image recognition, robots identify and grasp products even in disordered arrangements — a “grasp into disorder” enabled by advanced vision technology and multi-axis robotics. The result: precisely positioned cookies and crackers, perfectly presented at the point of sale.

Trade visitors at ProSweets Cologne can experience these systems live at exhibitors’ stands. Detecting foreign bodies in real time

Vision sensors are now essential for AI-supported quality assurance. They classify products such as gummi bears, bonbons or chocolates by appearance, check quantities and fill levels, and detect foreign materials. Modern systems rely on multispectral imaging, identifying the chemical composition of glass, metal, or plastic fragments in real time — something previously impossible. Defective products, such as broken cookies or miscoated wafers, are automatically rejected with accuracy exceeding that of human inspectors.

Deep learning in raw material inspection

AI is also improving raw material quality control. Deep-learning algorithms evaluate images of cacao beans to detect mould, insect damage, or poor fermentation based on colour patterns. This enables targeted adjustments to preserve flavour and product consistency.

From 1 to 4 February 2026, ProSweets Cologne will demonstrate how AI already optimises production and how it addresses broader industry challenges — from the skilled labour shortage to rising costs.

Parallel to ISM and ISM Ingredients, the trade fair offers a comprehensive event programme focusing on:

• Technological innovations: Sustainable, AI-supported solutions that make production more efficient and future-ready.

• Ingredients and processing technologies: Healthier, more attractive, and marketable sweets through innovation.

• Global challenges: Strategies for resilience amid supply chain disruptions and geopolitical uncertainties.

• Sustainable packaging: Eco-friendly materials and functional concepts that combine sustainability with performance.

• Retail experience: How packaging shapes brand perception and drives purchasing decisions.

• Shelf marketing: Packaging as a bridge between brand, marketing, and people.

With this focus, ProSweets Cologne 2026 positions itself as an international hub for innovation and as a source of inspiration for tackling the most pressing questions of the future in the sweets and snacks industry.

In a landmark strategic move set to fundamentally reshape the UK logistics exhibition landscape, between 30 June to 2 July 2026, the UK logistics supply chain will converge like never before across two leading Midland venues – the NEC Birmingham and NAEC Stoneleigh to create UK Logistics Week — the UK’s annual destination for logistics innovation, collaboration and opportunity.

At the NEC, Multimodal, Warehouse., Yard. and eDX will co-locate in adjoining halls, linked by walkthroughs for effortless visitor movement. Meanwhile, shuttle buses will connect The Road Transport Expo at NAEC Stoneleigh with the NEC, creating a seamless visitor experience across both venues. Together, these events will attract a shared audience of more than 25,000 logistics professionals.

More than a collaboration of exhibitions, UK Logistics Week will be the undisputed epicentre of UK logistics innovation and commerce.

Nairn Foster, Managing Director of Warehouse. & Yard., comments:

“The food industry lives and dies by the efficiency of its logistics.

UK Logistics Week brings together the innovators keeping Britain’s food supply moving safely and efficiently.

Our spotlight on warehouse and yard operations can drive critical improvements that directly impact efficiencies, profits, and customer satisfaction.”

Robert Jervis, Event Director of Multimodal, described the strategic decision as a natural and necessary evolution, focused entirely on delivering maximum value to the industry.

“Multimodal has built a trusted, nearly two-decade-long legacy as the premier event for the movement of goods, connecting ports, shipping lines, air freight, rail freight, and the entire freight forwarding community. Our 2026 event was already on track to be a record-breaker, welcoming over 13,500 highly-engaged visitors and hundreds of exhibitors. This collaboration reflects that same drive to excel - it’s about enhancing the attendee experience and increasing tangible outcomes for our partners and exhibitors.

Vic Bunby, Event Director of Road Transport Expo added: “We are delighted to be a core partner in UK Logistics Week. We know that being part of this initiative will not only give our exhibitors an enhanced experience - but all visitors to all of the shows will benefit - which can only be good. More content, more exhibitors, more networking and more time efficient for everyone. It’s a win-win.”

Multimodal: The established core for freight, transport, supply chain management, and logistics services.

Warehouse 2026: Focused on warehouse innovation, automation, intralogistics, and operational excellence.

Yard 2026: The world’s only event dedicated exclusively to yard operations, safety, site flow, and infrastructure.

E-Delivery Expo (eDX): The vital new addition under the Multimodal umbrella, targeting last-mile fulfilment, digital delivery innovation, and e-commerce logistics.

RTX: The UK’s leading road transport event - held at NAEC Stoneleigh - is firmly established as the premier tradeshow for the road haulage industry. The show features over 300 exhibitors and attracts over 14,000 visitors.

The combined platform is projected to offer unmatched access to over 30,000 logistics professionals, including an estimated 6,000+ cross-sector buyers actively looking to invest across every single link in the supply chain.

Further information can be found at www.Logisticsweek.uk

Entries are now open for the third annual IFE Manufacturing Ingredients Awards, in association with the Institute of Food Science & Technology (IFST). The awards return to Excel London on 30 March 2026, recognising excellence and achievement across the food and drink ingredients industry.

The ceremony will take place on the Trends & Innovation Platform stage at IFE Manufacturing, part of Food, Drink & Hospitality Week. Entries close on Friday 9 January 2026.

The awards celebrate organisations and individuals driving progress across the ingredients supply chain, from sustainable sourcing and product development to enabling technologies that enhance nutrition, functionality and performance.

The 2026 categories are:

• Sustainable Ingredient Innovation

• Responsible Sourcing & Ethical Partnerships

• Public Health Impact – Ingredients

• Start-Up Ingredient Launch

• Enabling Technologies for Ingredients

An Innovation of the Year Award will also be selected from all entries.

Each category highlights a specific area of advancement within the food and drink ingredients sector, with judges seeking verifiable impact, sound evidence and measurable results. The judging panel for 2026 brings together leading figures from across retail, food & drink, ingredients, manufacturing and food science.

• Claire Costello, Head of Technical Packaged Foods, Tesco

• Iain Beck, Senior Director Innovation Programme, Dsm-firmenich

• James Brace, Managing Director, Daymer Ingredients Ltd.

• Sarah Munday, Head of R&D, Innocent Drinks

• Prosper Nyabanga, Technical Manager, Isle of Man Creamery Ltd.

• Henrietta Sameke, Regulatory Affairs Manager, Holland and Barrett

• Jas Scott de Martinville, Global R&D Head of Technical & Regulatory, Scientific Affairs, Nestlé

• Mark Spurdens, Director; Honorary Fellow, Rice Consulting; University of Lincoln

• Richard Werran, Global Director Food & Retail, BSI

Federico Dellafiore, Event Director for IFE Manufacturing, comments: “The Ingredients Awards have quickly become a highlight of the IFE Manufacturing calendar. It is a genuine opportunity to recognise the expertise and hard work happening across the supply chain, from start-ups to global businesses. In association with IFST, we aim to showcase the most impactful developments shaping the future of food and drink.”

Richard Werran adds: “It was both a pleasure and privilege to serving as a judge for the IFE Manufacturing Ingredients Awards at Excel London in 2025. The standard of entries was outstanding, providing a remarkable glimpse into the ingenuity and passion that drive our industry forward. I was particularly inspired by the creativity, technical excellence, and commitment to quality demonstrated by every entrant.

“For those considering submitting an entry for 2026, I encourage you to share your story and your achievements that may inspire and set new benchmarks across the sector. This is a unique platform to celebrate innovation and gain well-deserved recognition among your peers. I look forward to seeing more exceptional work as the IFE Manufacturing Ingredients Awards continue to champion the very best in our field.”

Entries for the IFE Manufacturing Ingredients Awards are open now.

More information and entry details are available at https://www.ifemanufacturing.co.uk/ife-manufacturingingredients-awards-association-ifst-2026.

Global innovation in traditional meat alternatives – namely plantbased and cultivated meat – has faced a downward correction after years of consistent growth, according to the latest patent data* reported by Appleyard Lees.

These are among the findings in the fifth annual edition of the now-published Inside Green Innovation: Progress Report** from the leading intellectual property firm.

Annual patent filings for cultivated meat inventions fell by almost 10% (from 125 in 2022 to 113 in 2023) compared to a circa nine per cent increase the previous year and a more than trebling of filings from 2019 to 2021.

The annual drop in patent applications for plant-based meat has continued for a second year, falling 20% from 280 to 223. This followed the sector’s all-time peak innovation activity in 2021, reaching 296 patent filings.

Appleyard Lees’ Emily Bevan-Smith, patent attorney, said: “In the cultivated meat sector, funding, regulation and consumer uptake remain key challenges for innovators, alongside upscaling and production efficiency.”

James Myatt, partner at Appleyard Lees, said: “In plant-based meats, sales fell by 12% and some manufacturers have either reduced operations or gone into administration.”

Increasing the appeal of meat alternatives – and cutting costs

Despite the relative drop in innovation activity, new patent filings for cultivated meat technologies include ways to reduce production costs and increase efficiency, add nutritional components and ingredients to culture media, improve texture, flavour and smell via improved fibre structures and use fats and genetically modified cells/cell lines.

In plant-based meat, companies are filing patents relating to advances in lentil flour, pea protein and corn protein alternatives, techniques to improve the texture and structure of plant-based meat alternatives, as well as novel soybean and soy protein-based meat compositions and plant-based fish meat alternatives.

Myatt added: “Global patent activity in the cultivated meat sector shows a strong push to appeal to consumers by creating products that closely resemble conventional meat in flavour, texture, nutritional value and cooking behaviour. For plantbased meats, innovations relating to plant-based fish appeared prevalent among many of the top filers.”

Lack of regulatory consensus for cultivated meat products in the US has likely contributed to the more than 40% fall in patent applications in the country (2022 to 2023) – now making it only the marginal leader in the sector ahead of Europe and the Republic of Korea.

Despite US federal agencies approving various cultivated meats for consumption, some state authorities have begun banning or enforcing strict product labelling – therefore affecting consumer perception and investor confidence. An anti-cultivated meat stance in Europe – such as moves in Italy and France to ban its production and sale – may have led to the almost 25% drop in the continent’s patent activity.

However, Japan’s published roadmap for the cultivated meats industry and Prime Minister’s endorsement has helped fuel a more than 100% increase in patent applications.

The US experience for plant-based meat-related innovation mirrors its cultivated meat counterpart, with a 37% drop in patent filings, while Europe has taken the lead with a total of 85 in 2023.

Among companies active in cultivated meat technology, Dutch company Meatable BV was the top filer, with applications focused on culturing and maturing cells while improving flavour with increased fat.

South Korean business, Hanwha Solutions Corporation, is investing in cell culture media and improving product texture and taste.

In the UK, Ivy Farm Technologies, a leader in cultivated meat manufacturing, has filed patent applications relating to genetically modified and manipulated cells, bioreactors for culturing the cells, cell culture methods, substrate assemblies for culturing cells and artificial meat products.

Cargill and Unilever dominate plant-based meat-related patent filings, with – for example –innovation in wheat gluten alternatives to minced meat.

*Inside Green Innovation: Progress Report – Fifth Edition, examines patent filing data through 31 Dec 2023, the latest date complete filing data is available from public sources.

**Appleyard Lees’ Inside Green Innovation: Progress Report – Fifth Edition is available to read here https://www.appleyardlees.com/inside-green-innovation-progress-report/

Milestone marks world’s largest business ecosystem for the consumer packaged goods supply chain

TraceGains, the leading provider of compliance, quality, and innovation solutions for the food and beverage (F&B) industry, today announced TraceGains Gather® has grown to 100,000 supplier locations worldwide. This milestone underscores the scale and power of the TraceGains Network, which connects brands, co-packers, and ingredient suppliers to accelerate time to market, strengthen compliance, and drive supply chain resilience.

Working with half of the top 100 global F&B manufacturers, TraceGains has built the industry’s most comprehensive source-to-shelf ecosystem. Today, 100,000 supplier facilities rely on the TraceGains platform to collaborate more effectively, share critical compliance documentation, and bring safer, more innovative products to consumers faster.

“This achievement demonstrates the strength of the TraceGains community, and validates our vision of a connected, collaborative supply chain,” said Gary Iles, Senior Vice President, Marketing and Business Development, TraceGains. “Every new supplier location means one less data silo, and one more opportunity for faster onboarding, cleaner documentation, and real-time insights. By centralizing and streamlining supplier management, we’re helping brands and their partners unlock agility, efficiency, and trust at scale.”

TraceGains Gather® now hosts more than 10 million live documents, including allergen declarations, certificates of analysis, nutrition fact panels, kosher certifications, and third-party audits. This unprecedented volume of real-time, verified data allow brands to proactively manage regulatory changes, reduce risk, and accelerate product launches.

Lewis Rogers-Duffield, Lead Supplier Quality Manager, Europe, with Baker & Baker - one of Europe’s leading suppliers of bakery products - explained how with 12 manufacturing sites across Europe, the company uses a wide range of raw materials and packaging and maintains a significant database of approved suppliers.

“But a couple of years ago, we got talking about what we could do to streamline things to work smarter, to futureproof our supplier approval processes, and mostly – and thankfully - to

retire the very old Excel database that takes about ten minutes to start because it has just so much historic data on there,” he said.

“We wanted to create a consistent approach to approvals where we could be presented with the good and the bad and be able to make an informed risk based decision. We also wanted to provide our local teams with a self-service solution,” said Lewis. “We wanted to be able to empower our teams to feel confident in demonstrating supplier approval to customers and auditors without relying on too much support from my team who might not always be available.

“We also wanted to find a solution that was a one stop shop for supplier management, a place where we can keep our procedures, our approvals, audits, and horizon scanning all under one roof, rather than going between different systems and databases to access the information. And we wanted to manage supplier audit corrective actions in a way that reduces backwards and forwards emails and deadline chasing.”

Now more than 12 months through its implementation process with TraceGains, Lewis said: “We are really happy to say that we have managed to achieve each and every one of these goals through our integration of TraceGains into our dayto-day ways of working.”

Powered by AI and TraceGains’ patented PostOnce technology, suppliers can upload a document once and instantly share it with multiple customers, eliminating duplicative effort and ensuring consistency across the network. This automation not only saves time and reduces errors, but also strengthens the relationship between buyer and supplier.

Sign up for free to TraceGains Gather® at www.gather.tracegains.com

For more information about TraceGains, please visit www.tracegains.com

Krombacher, Germany’s leading private brewery and the country’s No. 1 beer brand, has published its latest Sustainability Factsheet. The publication provides a transparent overview of the brewery’s progress and priorities for the 2024 financial year and reaffirms its long-standing commitment to responsible business and environmental protection.

For more than two decades, Krombacher has been guided by one principle: To the good of people and nature. This mindset shapes decisions across the entire business. From sourcing and production to community engagement, sustainability is anchored in the way the family-owned company works and plans for the future.

The factsheet shows that Krombacher has reduced its CO₂ emissions by almost 30 percent since 2019 and continues to pursue its goal of achieving climate neutral production. The brewery is expanding renewable energy capacity through photovoltaic and wind projects that gradually reduce dependence on fossil fuels and support long-term decarbonisation.

Krombacher also strengthens circular systems across its operations. The brewery achieves a 99 percent recycling rate and relies on reusable packaging. Raw materials are sourced responsibly from the region, and barley comes from Germany and neighbouring countries to ensure quality and traceability.

Water efficiency remains another key focus. Krombacher currently uses 3.9 litres of water per litre of beer produced, a figure well below the industry average, and continues to invest in modern systems to reduce consumption even further.

Krombacher continues to support long-term environmental and social initiatives. In 2024, the brewery planted 400,000 trees in North Rhine-Westphalia and further advanced its rainforest protection programme in Africa. The company also supported 100 charitable organisations across Germany. In Kenya and Malawi, Krombacher’s drinking water projects give people reliable access to clean water, helping to improve daily living conditions over the long term.

“For us, sustainability is not a goal to be achieved, but a continuous journey,” says Wolfgang Schötz, Chief Sustainability Officer at Krombacher. “We are committed to taking responsibility, seizing opportunities, and actively shaping a better future—for people and nature alike.”

Looking ahead, Krombacher will continue to invest in renewable energy at the brewery and launch one of its most ambitious reforestation projects to date. The plan is to plant one million trees, primarily in the region surrounding the brewery, strengthening local ecosystems and protecting natural water resources.

The full Sustainability Factsheet 2024 is available at www.krombacher.com/sustainability

Leading HVAC specialist Jet Environmental has successfully installed an innovative and sustainable frost protection solution at Prologis Park Hams Hall DC2, a new manufacturing and distribution hub centrally positioned in the West Midlands to serve the UK and international markets.

Prologis required durable and environmentally friendly frost protection to safeguard the internal fire sprinkler system of its newly constructed warehouse. Collaborating closely with fit-out contractor TanRo, Jet implemented an advanced all-electric air-to-water heat pump system, delivering reliable performance even in extreme winter conditions.

After a comprehensive site assessment, Jet Environmental’s engineers designed a solution featuring an external air-to-water heat pump and an indoor air-handling unit connected to a thermal buffer tank. This innovative setup keeps a steady internal temperature of 5°C, even when external temperatures fall to -5°C, effectively safeguarding critical systems and assets.

The large warehouse facility, spanning 22,892 m² with a volume of 366,272 m³, required a sophisticated system capable of delivering 300kW of heating capacity and an air supply of 10 m³/s. Jet Environmental successfully completed the installation within just three months, satisfying the high standards set by Prologis and TanRo.

“Jet Environmental Systems delivered an exceptional frost protection solution for our project at Prologis Park Hams Hall DC2,” said Mike Wall, contract manager at TanRo. “Their technical expertise, attention to detail and ability to provide a sustainable, all-electric system have been invaluable. We are extremely pleased with the results.”

Jason Hibbs, managing director at Jet Environmental, added: “We understand that HVAC systems are critical assets, especially where frost protection is vital for operational continuity. Our aim was not just to meet Prologis’s high standards, but to provide an environmentally sustainable solution that performs reliably, even in the most demanding conditions. We’re pleased to have achieved this and look forward to supporting similar initiatives in the future.”

This project highlights Jet Environmental’s commitment to delivering energy-efficient and sustainable climate control solutions across the logistics and warehousing sectors.

Businesses seeking similar innovative solutions can contact Jet Environmental directly at 0121 770 7466 or via email at sales@jetenvironmental.com

For further information, visit Jet Environmental’s website jetenvironmental.com

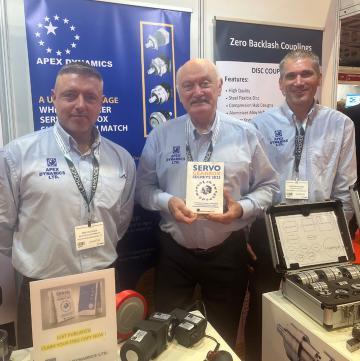

A new book about gearboxes from Apex Dynamics expert Mike Gulliford provides a comprehensive guide to servo gearbox technology; its applications, specifications, gearbox types, the global landscape, and future outlook.

A new book, Servo Gearbox Secrets 2025, has been published by Apex Dynamics. Providing a unique insight into the critical and growing role of servo gearboxes at the heart of modern motion control, it demystifies the whole topic of servo gearboxes and provides valuable guidance about the process of specifying and applying servo gearboxes.

Subtitled The Definitive Guide to Specifying and Applying Precision/ Servo Gearboxes in Motion Control Projects, the book has been written by Mike Gulliford, Managing Director of Apex Dynamics UK. Launched at Machine Building Live in Coventry (15th October), it draws on his more than 30 years of experience in the industrial automation industry and his expertise in precision gearboxes, providing essential reading for anyone involved in motion control projects.

Servo Gearbox Secrets 2025: Insightful, informative and free

The printed version of the book is being offered free of charge, as Mike and Apex Dynamics UK attempt to ensure the market has the best possible understanding of the history, technology and benefits of servo gearboxes. In addition, it provides clarity and structure to selecting gearboxes, helping readers manage the careful balance of design trade-offs, operating conditions, and project objectives. It can be requested by visiting the Apex Dynamics website and filling in the contact form here.

Designed to be a living guide that bridges the engineering and business worlds, Servo Gearbox Secrets 2025 provides the technical depth and strategic clarity needed to help design engineers, project managers, system integrators and end users make informed choices.

Clear, informed servo gearbox expertise at your fingertips

Divided into a series of clear sections, the book provides information about servo gearboxes that’s not generally available, as well as about their history and their usage. Offering an introduction to servo gearboxes for those with no prior knowledge, it’s also packed full of valuable insights for experienced engineers and expert predictions for the future of precision gearboxes.

The wide-ranging guide covers gearbox geometry and manufacturing, types of gearboxes, and their application across industries, operating conditions and environments. The guide also features advice on practical engineering concerns such as sizing and specifying, safety and performance factors, and lifecycle and maintenance, as well as business considerations, including supplier selection, procurement, ROI, and global market. Finally, it concludes with an exploration of the current landscape and a look at how the servo gearbox market could evolve in the age of AI, smart manufacturing, and demand for greater sustainability.

Gain access to decades of real-world experience

Mike is passionate about precision gearboxes and wants to share his extensive knowledge, gathered during a long and successful career within the industrial automation industry.

He explains, “As far as I am aware no one else has done this. I have tried with this book to include all the things I wish I’d known sooner. Precision servo gearboxes are great technology and they’re playing a growing role in the automation industry, in applications ranging from robotics and automation to renewable energy and precision manufacturing. Companies are demanding higher accuracy, higher efficiency, and higher reliability from every component in the system.

“Too often, gearbox selection is treated as an afterthought, or reduced to a catalogue comparison based only on ratios and torque. In reality, the choice is more complex and involves a delicate balance to achieve the optimal result for each application. Whether enabling the precise positioning of a robotic arm, the smooth feed of a CNC tool, or the controlled acceleration of a packaging line, these components often determine the performance and reliability of the entire system.”

Click here https://apexdynauk.com/contact-us/ to secure your copy of Gearbox Secrets 2025

In today’s food and drink factories, automation is surging – and so are the stakes for safety. A recent industry survey found that more than 81% of end users identified automation as their main challenge in 2023. Robots and high-speed lines promise higher throughput, but any fault can be catastrophic. In Great Britain 2024/25, 13 workers were fatally injured by contact with moving machinery, underscoring why modern plants must invest in advanced safeguards.

One key solution is the safety light barrier (often called a light curtain). These devices create a virtual wall of infrared beams across a hazard zone; if any beam is broken, the machinery halts instantly. Unlike a heavy metal gate, a light barrier lets operators and products move freely when safe – boosting productivity. In one automotive line, replacing a slow interlocked door with a light curtain cut each cycle time by around two seconds, a huge gain over thousands of parts, while improving safety for the system operator. Across manufacturing sectors, it is estimated that up to 90–95% of machine workstations include moving components or pinch points – making safety light curtains a must for preventing injury.

Safety light barriers act as virtual guards for machinery. A transmitter and receiver emit dozens of invisible beams in a wall-like array. If an operator’s hand or any object interrupts a beam, the system instantly signals the machine to stop. This allows access during loading or maintenance without the need to open physical doors. Advanced systems can cascade multiple curtains or use timed muting functions to maintain protection even in complex layouts.

Modern light curtains are certified safety components, often rated to the highest (Type 4) category. They must be integrated into safety circuits or relays so that an interruption triggers a controlled stop. In one Bosch production line, replacing a mechanical guard with a light curtain shortened the cycle time to its optimal 12 seconds while maintaining compliance and safety integrity.

Installation, however, is critical. The UK Health and Safety Executive (HSE) requires electro-sensitive devices to be positioned at defined distances from moving parts, ensuring that even fast movements cannot breach the safety zone before the machine stops. Inspectors test each curtain’s stop-time to calculate its correct position, and systems are verified so that they cannot be bypassed or “defeated.”

In the UK, the Provision and Use of Work Equipment Regulations 1998 (PUWER) mandate that machinery hazards must be guarded appropriately – including through the use of active opto-electronic protection devices like light barriers. Meanwhile, the Supply of Machinery (Safety) Regulations 2008 ensure that all safety components meet essential health and safety standards before being placed on the market.

As of 2024, the UK continues to recognise CE marking for machinery under transitional rules, while also requiring UK Conformity Assessed (UKCA) marking for equipment sold in Great Britain. Manufacturers and system integrators must therefore ensure that all light barriers installed meet both sets of requirements and are properly documented.

Regulation does not stop at purchase. PUWER also requires that safety equipment be maintained in a safe condition and subject to periodic inspection. Although light curtains have no moving parts, they must be checked regularly for alignment, cleanliness,

and stopping performance. UK safety experts advise at least annual inspections to confirm that any beam interruption triggers the machine stop within the required time.

The consequences of neglect can be serious. A UK food-packaging firm once switched off an infrared safety sensor because dust particles were causing false stops. The result was a severe accident when an employee was drawn into a laminator, sustaining major burns. The company was prosecuted for breaching PUWER after inspectors found the sensor had been disabled deliberately. The case serves as a stark reminder that tampering with safety systems can have devastating results – legally, financially, and morally.

While regulations provide the framework, innovation continues to redefine machine safety. Modern light curtains are increasingly connected devices, designed for integration with Industry 4.0 and smart manufacturing environments. Rather than functioning in isolation, they now communicate with factory networks, logging data and enabling predictive maintenance.

When a light beam is interrupted, this information can be recorded in real time, helping engineers identify patterns, perform diagnostics, or schedule servicing before a fault causes downtime. In highly automated food and beverage facilities, where robots and conveyors work side-by-side with humans, this connectivity ensures immediate visibility across the production floor.

Hardware design has also evolved. Traditional light barriers were unsuitable for washdown areas, but today’s models are built specifically for hygienic environments. Manufacturers now offer IP69K-rated light curtains with stainless steel housings and food-safe polymer lenses, resistant to high-pressure cleaning and disinfectants. These are ideal for use in dairies, bottling plants, and ready-meal facilities where equipment must withstand frequent sanitation cycles.

In addition, new control features have emerged. Some light barriers use IO-Link or Ethernet communication for instant diagnostics and flexible configuration. Others incorporate Bluetooth or NFC connectivity so that engineers can adjust settings from a mobile device. Intelligent muting modes allow finished products to pass safely through a detection zone without halting the line, while maintaining protection for operators nearby.

Research is now exploring AI-driven machine vision that could enhance or even replace traditional infrared curtains in certain applications. However, the reliability and simplicity of conventional light barriers keep them the preferred choice for high-speed food manufacturing environments where consistent uptime is vital.

Practical examples show how safety light barriers can deliver measurable gains in both performance and protection. At a Bosch assembly line, engineers replaced a mechanical door guard that had been slowing down production. The light curtain solution allowed continuous access without compromising safety, increasing throughput while maintaining compliance. The system also proved durable and operator-friendly, reducing maintenance interruptions.

By contrast, incidents where safety devices are removed or ignored highlight the opposite effect. The previously mentioned UK packaging accident led to prosecution, fines, and reputational damage – outcomes that far outweigh the minor production delays that might have prompted the unsafe decision.

Best practice today combines technology with training. Operators must understand why safety curtains exist and how to work safely around them. Maintenance teams should keep spare components on hand and follow a clear inspection schedule. Management, meanwhile, should reinforce a proactive safety culture by reviewing each process for potential hazards and ensuring that light curtains are installed wherever human access intersects with moving machinery.

Visible, well-maintained light barriers send a powerful message: safety is integral to productivity. They not only protect workers but also build trust and efficiency across the organisation.

The food and drink industry is under constant pressure to produce more, faster – but never at the cost of worker safety. Safety light barriers provide a sophisticated yet straightforward way to achieve both protection and productivity. By forming invisible shields around dangerous zones, they allow seamless operation without physical obstructions.

UK regulations such as PUWER and the Machinery Safety Regulations make these systems a legal necessity, but the benefits go well beyond compliance. Modern, networked safety barriers enable smarter manufacturing, better uptime, and safer workplaces. As the industry continues to evolve toward fully automated smart factories, the fusion of safety and technology will remain at its core.

A factory that maximises efficiency while protecting its people is not only compliant – it’s competitive, responsible, and future-ready.

References

Food Manufacture – “Automation biggest challenge facing firms”: https://www.foodmanufacture.co.uk/Article/2023/09/18/automation-biggest-challenge-facing-firms HSE – Fatal injuries statistics: https://www.hse.gov.uk/statistics/fatals.htm

RS Components – Machine Guarding Guide: https://uk.rs-online.com/web/content/discovery/ideas-and-advice/machine-guarding

HSE – HSG180: Guidance on electro-sensitive protective equipment: https://www.hse.gov.uk/pubns/priced/hsg180.pdf

HSE – PUWER Regulations overview: https://www.hse.gov.uk/work-equipment-machinery/puwer.htm

UK Legislation – Supply of Machinery (Safety) Regulations 2008: https://www.legislation.gov.uk/uksi/2008/1597/contents/made

GOV.UK – Using the UKCA marking guidance: https://www.gov.uk/guidance/using-the-ukca-marking

Process Engineering – “Ensuring the safety of light curtains”: https://www.processengineering.co.uk/article/2034891/ensuring-the-safety-of-light-curtains

Packaging Digest – “UK company fined after worker burned when machine sensor disabled”: https://www.packagingdigest.com/safety/uk-company-fined-after-worker-burned-when-machine-sensordisabled-2202

Molex – Smart factory safety overview: https://www.molex.com/molex/products/part-detail/smart-factory-safety

Banner Engineering – Safety Light Curtains product page: https://www.bannerengineering.com/us/en/products/safety/light-curtains.html

SICK UK – deTec4 Core Safety Light Curtains: https://www.sick.com/gb/en/safety-light-curtains/detect4-core/c/g180309

Keyence – Light Curtain Case Studies (Bosch example): https://www.keyence.co.uk/ss/products/safety/light-curtain/case-studies.jsp

A significant portion of food innovation never truly lands with consumers. What’s going wrong with product development? Why do so many promising food products fail to make a lasting impression on our palettes and in our shopping baskets? Drawing on information from consumer innovation expert Guy White, CEO of Catalyx, this article looks at how brands can unlock hidden tensions to create true category innovations.

Despite billions being spent by brands worldwide each year on product development and innovation, at least 50% of all new products are pulled from the shelves within two years. This failure to stickdespite heavy investment in research, marketing and promotions - is alarming, proving extremely costly for all involved. In food and beverage especially, competition is fierce and shelf space is limited. Consumers are bombarded with choice, but loyalty is hard-won. But why is this the case? And why are brands failing to deliver products with lasting success despite spending such eye watering sums?

There are many variables when it comes to product success or failure. But ultimately a product’s survival comes down to its rate of sale versus expectations. Essentially how many people pick the product from the shelf and how often.

Some of this can be put down to poor execution, bad retailer negotiations and of course communication strategies that don’t work, but a huge driver of a product’s success or failure is driven by… well… the product itself.

So often we are dazzled by the latest communication campaign that goes viral. The lacklustre product that has its moment in the sun because of a brilliant bit of comms. But for over 97% of products on a supermarket shelf, it is the product that has to sell itself. So, this is what I am going to concentrate on.

Product success requires product market fit.

A new product to market (regardless of category) will only survive and thrive if it offers more perceived value to consumers than the existing alternative - assuming they can find it on shelf. And an existing product will only continue to be chosen if the consumer doesn’t see a new alternative that they feel could do the job better.

This is a never ending merry go round. Although consumer core needs don’t generally evolve all that much, the ways people meet those needs do. Competing products are always aiming to serve the consumer better—emotionally, socially, and functionally—keeping the market in perpetual motion.

So, at the heart of this issue is the fact that so many products fail because they don’t crack this code. Or they are asleep at the wheel and don’t upgrade when others do crack the code more effectively.

But even those that do invest in research, that are consumercentric, that buy the trends and share data, engage in focus groups, commission the Usage and Attitude studies and test relentlessly often still don’t make the grade.

In fact, over £13bn is spent every year on innovation focussed research. So how can this possibly be?

The answer, in my experience, lies in their approach. Many are reliant on old fashioned methods which, whilst may appear to dig deep into consumer behaviour, barely even scratch the surface.

Yes, conducting surveys and asking consumers what they want may reveal a level of insight, but it simply doesn’t dig deep enough. It can lead to incremental ideas or ‘me too’ products and uncover trends that consumers think they like, but crucially, it doesn’t tap into the emotional and psychological drivers that could deliver category disrupting products. This is the well documented “say/do” gap.

As David Ogilvy said “Consumers don’t think what they feel, they don’t say what they think and they don’t do what they say.”

So what should brands do instead?

For real breakthrough innovation, brands need to uncover ‘hidden tensions’. These are the unspoken compromises that consumers don’t even realise exist – things they’ve accepted as ‘just the way it is’ AND they need to determine how to best bring this to life in a way consumers can’t wait to buy.

If you think about the popularity of pod/capsule coffee such as Nespresso, this is a prime example of innovation that addressed a deeper need many didn’t even realise they had. It not only gives consumers that indulgent sense of high quality of coffee at home but removed the mess and hassle of grinding beans or cleaning filters — without the consumer ever needing to ask for it.

Similarly, the rise of pre-portioned meal kits is another example. Taking some of the hassle out of deciding what to cook each night, they also reduce food waste from unused ingredients, and relieve the guilt associated with relying on takeaways or ready meals. On the surface, they offer convenience but underneath, they resolve anxiety, stress, and decision overload.

These kinds of innovations could not have been achieved by relying on traditional indicators such as skin-deep customer surveys or reacting to shifting trends. What brands did here was move beyond the superficial. They delved deeper into consumer behaviour, needs and wants. The traditional survey and focus group approach doesn’t get even close to this. Often, what matters most is what consumers don’t say.

To uncover the truths that people may not articulate but that ultimately drive their decisions, it’s about asking “why” repeatedly when confronted with a piece of data and observing real-world behaviour at scale.

Context is key in innovation. Emotions impact heavily on consumer food choices and what they say doesn’t always correlate with what they do. For example, a customer may say they want healthy snacks in a survey but in reality, opt for a mid-afternoon packet of crisps or chocolate bar due to a deeper emotional need such as comfort, reward or stress relief.

In fact, I have done work that shows that consumers can quite easily compartmentalise healthy and non-healthy in one shopping trip. They will buy the healthy breakfast to start their day off right, but they also know they will fall off the wagon by 3pm and so the brownies slip into their basket as well. All of this despite telling you in the survey that they are watching their weight.

So, how should brands avoid being caught in this trap? I’d recommend approaching product innovation with a structured, evidence-led approach.

Ethnographic studies and behavioural economics are essential in this process, helping brands to identify subconscious behavioural signals that can be translated into lucrative opportunities before anyone else. Importantly, this has to be done at scale. Historically, the cost of such work has meant brands have tried to extrapolate the behaviour of the few into the perceived behaviour of the many, which has produced varying rates of success. But modern capabilities now allow us to crowdsource this behavioural insight more reliably and at a fraction of the cost.

Brands should also consider the following five steps when approaching product innovation.

The first is to truly understand the job the consumer wants donethe underlying reason they are buying the product in the first place. Made famous by Clayton Christensen, ‘Jobs To Be Done’ discovery frames the whole rest of the development process and is a critical step. And it is often not what you think. For example, McDonald’s milkshakes sell well during morning commute times as they provide the perfect level of flavour hit and engagement for a 30-minute drive into the office.

Once this is sorted, finding out what is getting in the way of current products delivering this job perfectly is the next step. That might be because existing solutions have a perceived gap or there is simply a better way. Take Pataks Curry paste for example, it felt authentic until Spice Tailor created their ingredients kits which made the cooking process feel even more homemade and customisable, bridging the gap between convenience and authenticity. This kind of insight requires observational research and paying close attention to consumer workarounds or unconscious habits.

Brands should then look to reframe the familiar and view existing products through a fresh lens. Can an existing product be transformed to meet evolving expectations? Yoghurt, for example, was once seen as a basic, healthy food option but brands such as Bonne Maman and Muller have reframed it into an indulgent treat through clever marketing and recipe development.

Alternatively, brands can look at balancing opposing desires. For example, many consumers want both healthy options and indulgence. The most successful innovations will reconcile the two instead of forcing a choice between them, think protein-packed puddings or low sugar ice creams. Consumers, wherever possible will always want to have their cake and eat it and by taking this approach to innovation you will ensure they can.

Brands also need to think about simplifying anything complex and reducing friction in the customer experience. The simpler and more intuitive a product is to use, the more likely it will be adopted. If you consider how sauce bottles have been re-packaged into an ‘upside down’ format you will get a good idea of what I mean. This small packaging tweak removed the frustration of shaking, hitting, or waiting for sauce to pour — solving a low-level annoyance that consumers had accepted for years. Again, this is something you are very unlikely to uncover in a survey or even a focus group.

Functionality aside, brands also need to achieve emotional resonance with their products. Products that connect emotionally always outperform those that only deliver on function. Sometimes even inferior products win if they capture emotion better. Pepsi famously always beats Coke on taste tests but is nowhere close on market share because Coke is all about “Opening Happiness”.

Getting to this job/tension/benefit combo is really just the start because at the end of the day, the only thing the consumer sees is the execution itself. Everything from pack design, materials, ingredients and messaging to claims and price needs to be developed in collaboration with the consumer to ensure the final product lands.

Ongoing product–market fit checks are also crucial. Competitors are always ready to pounce and so holding onto success is a continuous process.

Ultimately, successful innovation is about designing products that feel inevitable not engineered — rooted in real human behaviour and grounded in deep understanding of consumers’ actual needs. And then keeping your finger on the pulse continuously to make sure you keep what works and evolve what doesn’t as your consumer and marketplace evolves year in year out.

The Producer Responsibility Obligations (Packaging and Packaging Waste) Regulations 2024 came into force on 1 January 2025 and introduce new legal obligations for packaging producers under the extended producer responsibility regime for packaging in the UK (referred to as pEPR).

The pEPR is being introduced under powers in the Environment Act 2021, to ensure packaging producers pay the full net cost of managing their products at end of life to incentivise them to design their products with sustainability in mind.

The key obligations under the regulations are that packaging producers must register their organisation, report packaging data, and ensure their products are collected and recycled or recovered properly.

An organisation must comply with the regulations if it meets all of the following criteria:

• It’s an individual business, subsidiary or group (but not a charity)

• Annual UK turnover exceeds £1 million

• It has a physical presence in the UK

• It is responsible for more than 25 tonnes of packaging and/ or packaging materials in the previous calendar year

• It carries out any of the described packaging activities

Businesses need to be aware that even if they fall below the above thresholds or are otherwise exempt, it may still have obligations to collect and report certain data, particularly if the business is part of a larger group of companies or operating as a franchise or online.

A packaging producer includes the performance of any of the following activities in the UK: