Hire Catalogue

Viking Hire plays a major role in this area, giving our customers the opportunity to access high quality equipment and incorporate automation into workflows to increase production capacity.

With Viking Hire, you will have the equipment you need to expand your product range and progress to the next stages in new product development. Through our simple hire process, we can have you up and running with your equipment in a matter of days, with equipment in stock at Viking locations.

Browse our range of equipment available for hire, and book in a visit for a trial at one of our locations to see the equipment for yourself.

1300 88 99 51

vikingfoodsolutions.com.au

Scan

Scan

Viking Hire

Hire is a simple and cost-effective option to buying and owning your food processing equipment, removing the initial outlay barrier of entry for capital improvements, and giving your business the flexibility of terms to suit you at an affordable rental rate.

With equipment in stock and ready to go, hire is a smart alternative to equipment purchasing.

Features & Benefits of Viking Hire

Access to a large range

Our large hire fleet includes the latest in automation and packing efficiencies

Low upfront costs

Minimise the barrier to entry for trialling new products and markets

Buy at any time

Purchase selected hire machinery at any time during or after the hire period

Simple & Fast Approval

No credit check required! Simple approval process

High quality equipment

Choose from our large fleet of new & well-maintained machinery

Book in a Trial & Visit our Showrooms

Victoria - 35 Shirley Way, Epping 3076 VIC

A team to support you

From service to spare parts, we’ll keep your production running

New South Wales - 9 Mcilwraith Street, Wetherill Park 2164 NSW

Thermoforming

ULMA Thermoformer

Model Cycles / Min

ULMA TFS 200 6 - 9

With its advanced technology, the ULMA TFS 200 offers high-speed and efficient packaging, reducing production time and costs. Its versatility allows for various packaging formats, ensuring flexibility for different product types and its precision guarantees consistent, high-quality packaging results, enhancing customer satisfaction.

The TFS 200 uses two rolls of film - top and bottom ‘webbing’ to form the pack, only one operator is required to utilise this packing machine, simply loading the pack in-line in an ergonomical setup and operating with a conveyor at outfeed.

Both top & bottom webbing films are available from Viking in plain and custom brand print, in a range of thicknesses to suit your product needs.

Thermoforming

The ultimate advantage of these machines are the cost savings you experience when incorporating them into your production line, as the packs are formed during the process, minimises pack wastage & double-handling.

Other exciting benefits include:

• Maximises packing efficiencies

• Improved product appearance as the pack is formed around the product

• Faster product loading in an ergonomical setup

Tray Sealers

Tray Sealers

Models Capacity

Viking AMAPs up to 4 cycles / min

ULMA TSB 300 Skin on Board up to 12 cycles / min

ULMA TSB 300 MAP & Skin on Tray up to 12 cycles / min

Packing fresh meat, fish, produce, ready meals and more with tray sealers, allows you to maximise production efficiencies while extending the shelf-life of the product and providing an attractive appearance.

Ensuring safe transport from production to shelf, tray sealing offers a confident alternative to traditional vacuum and shrink packaging, guaranteeing less wastage and uniform displays.

Tray Sealers

MAP

• Extended shelf life

• Gas flush to help retain nutrients

• Recyclable trays available

• Retains optimal freshness

• Convenient for retail market

Skin on Tray

• Minimises visible plastic

• Pack forms around shape of product

• For boneless & bone-in products

• Prevents movement in transport

• Minimises leaks & purge

• Most effective in retail market

• Does not require gas flush

Skin on Board

• Extended shelf life

• Product retains shape

• Recyclable board trays

• Retain optimal freshness

• Provides a second skin

• Increases total recyclability of pack

• Minimises leaks & purge

• Custom print board for visual aids

• For boneless & bone-in products

Vacuum Packers

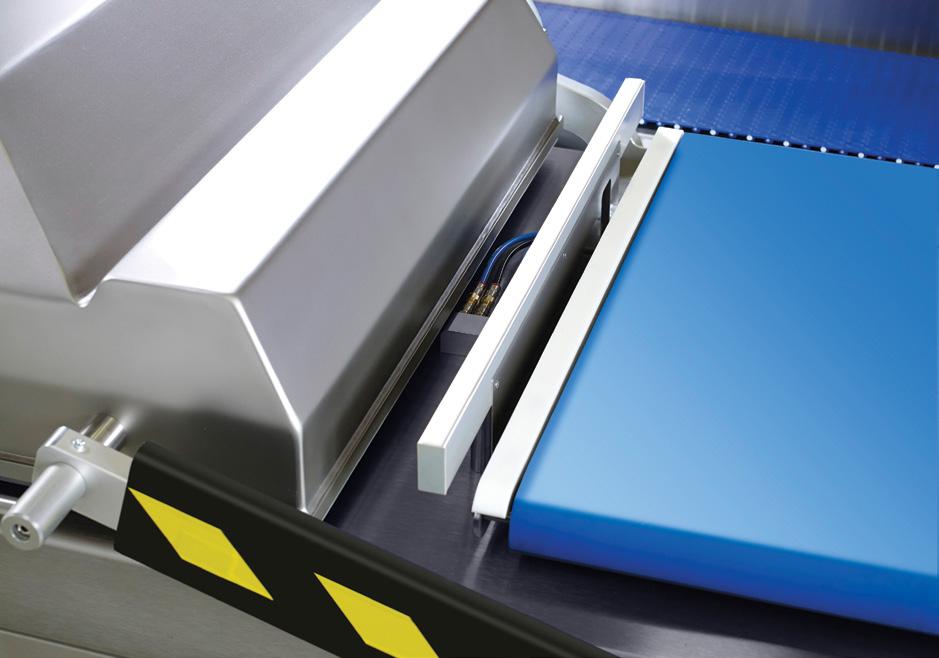

Viking Conveyor-Belted Vacuum Packer

Heavy-duty fully stainless steel automatic packaging machine with conveyor belt for high volume, industrial applications.

Viking V1020 840 x 890 x 220mm

Its smart design allows for easy cleaning and optimum hygiene at all times.

Features

• Extensive command parameters

• Intelligent full colour control interface

• User-friendly and low maintenance

• Well-designed solid construction

• High capacity unit

Vacuum Packers

Viking Swing Lid Vacuum Packers

Viking

Viking

Viking

Viking

Viking

Viking

Viking Freestanding Vacuum Packers

Viking 423

Viking 323A

Viking 323

Viking

Viking V101

Viking

Dip Tanks

Viking Dip Tanks

Models

Viking DT 66

Viking DT 99

Viking Auto In-Line

Chamber Dimensions

500 x 600 x 240mm

600 x 800 x 240mm

800 x 600 x 418mm

Shrink safeguards product freshness and quality, reduces purge, minimises wrinkles, folds and tears which are caused during the packaging process.

In-line Dip Tanks are designed to operate with both belt and swing lid model vacuum packers for high volume output.

This concept allows for greater efficiency and through-put of product, while also guaranteeing a consistent result with the shrink packaging.

The wide product tunnels allow for greater versatility of product.

Viking Burger & Portion Formers

The Viking Planus Burger & Portion Formers allows operators to automate the burger forming process, providing consistency in output - not achieved by manual process.

Custom shaped drums for nuggets, sliders, fish fingers, koftas, and more also available.

Brine Injectors

Suhner Brine Injectors

Suhner Brine Injectors have proven to be robust, high performance machines, ideal for small to medium size brine injecting applications.

They can be used for a range of meat, poultry and seafood processing with bone-in or boneless products.

Models Needles

Suhner WS10 10 Needles

Suhner WS20 20 Needles

For use with:

String Tying

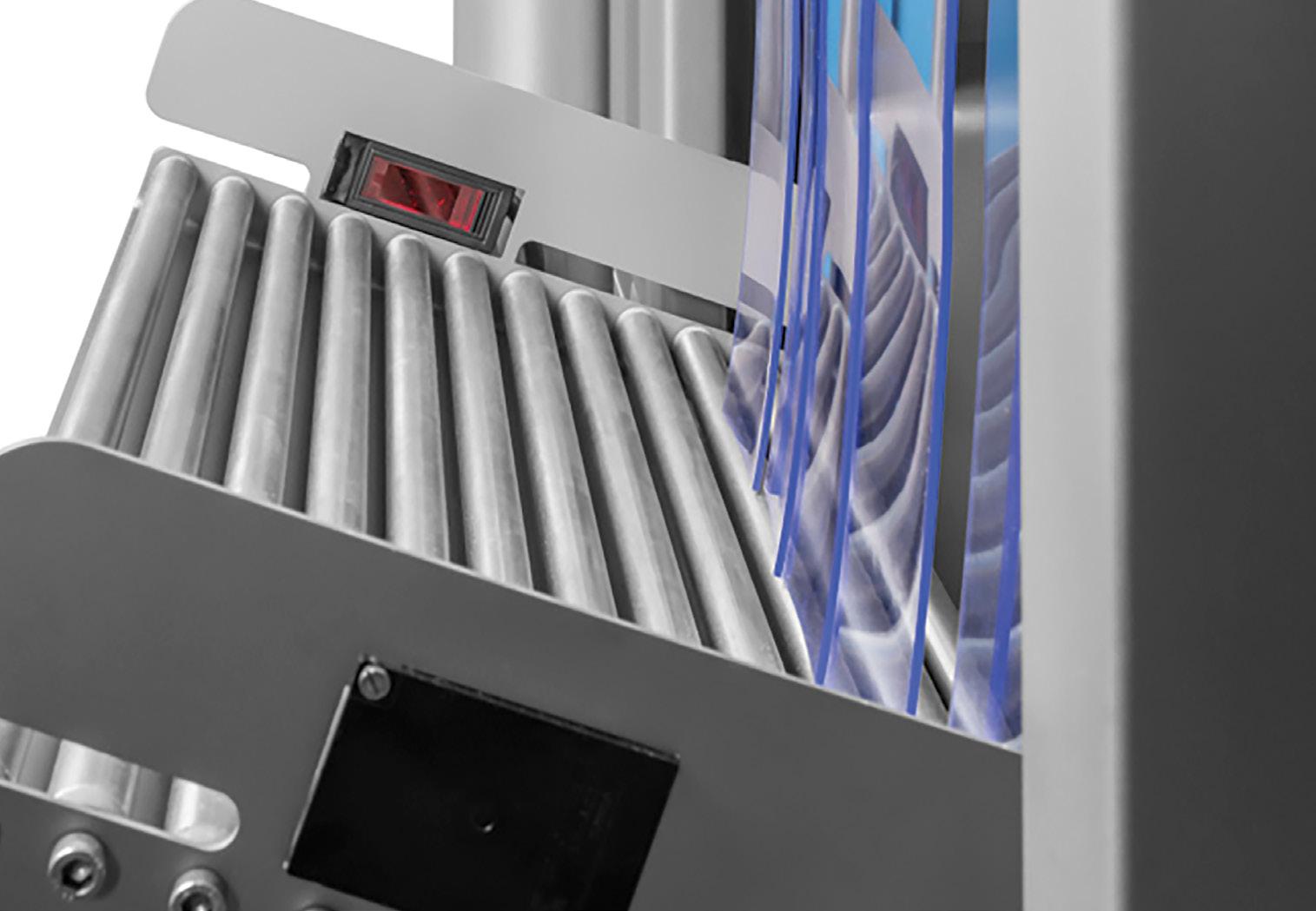

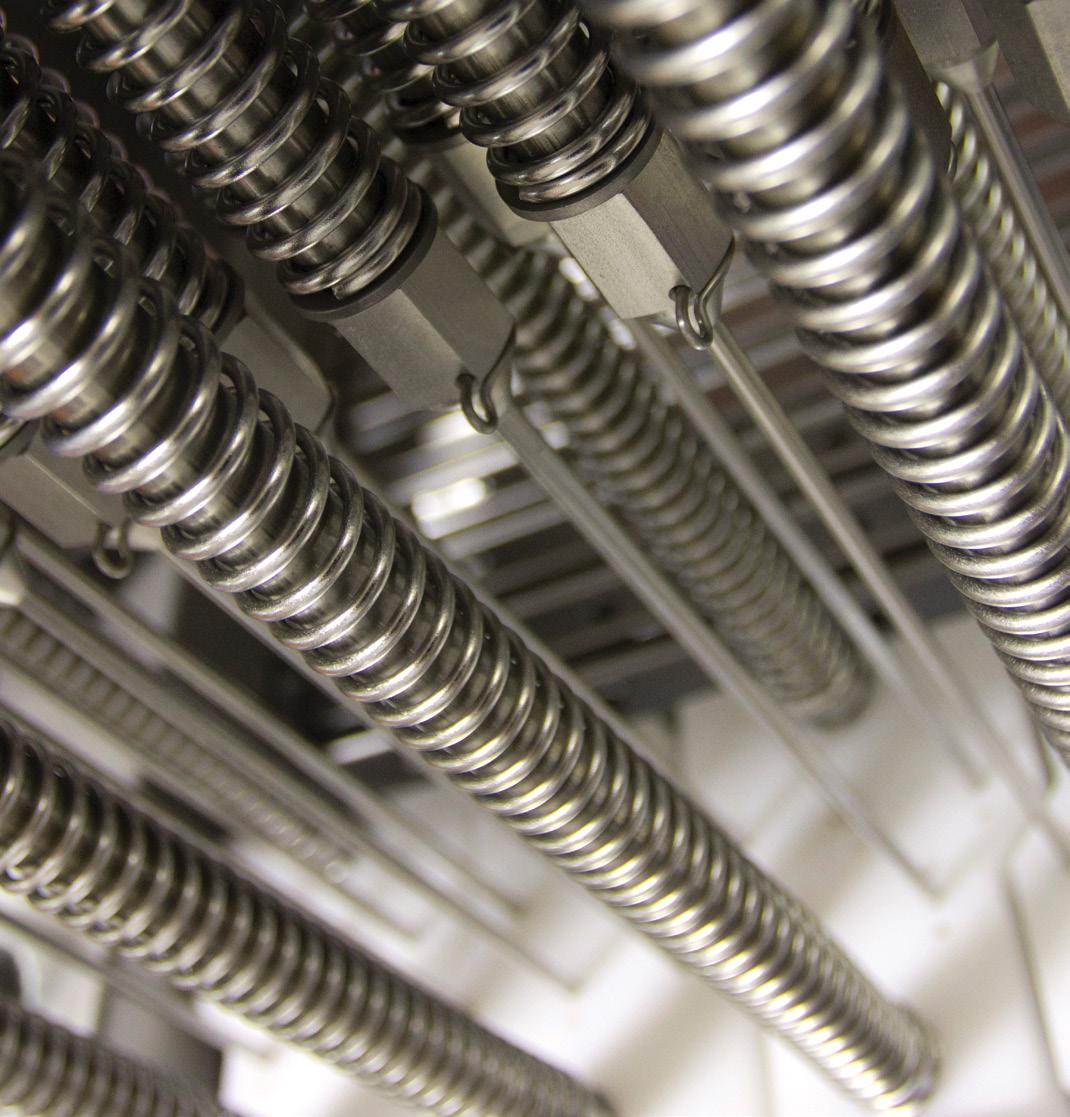

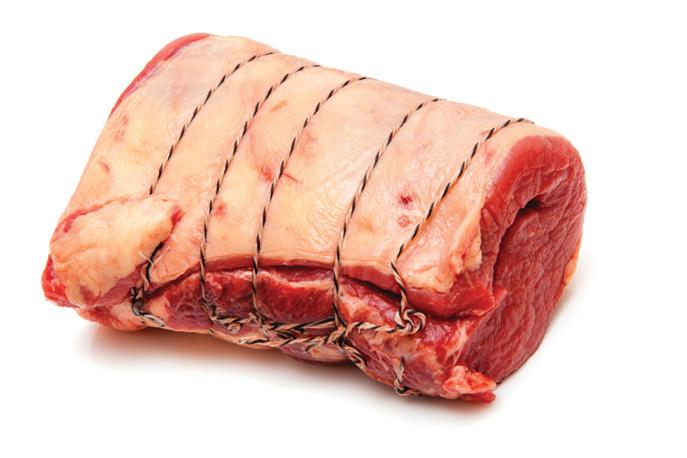

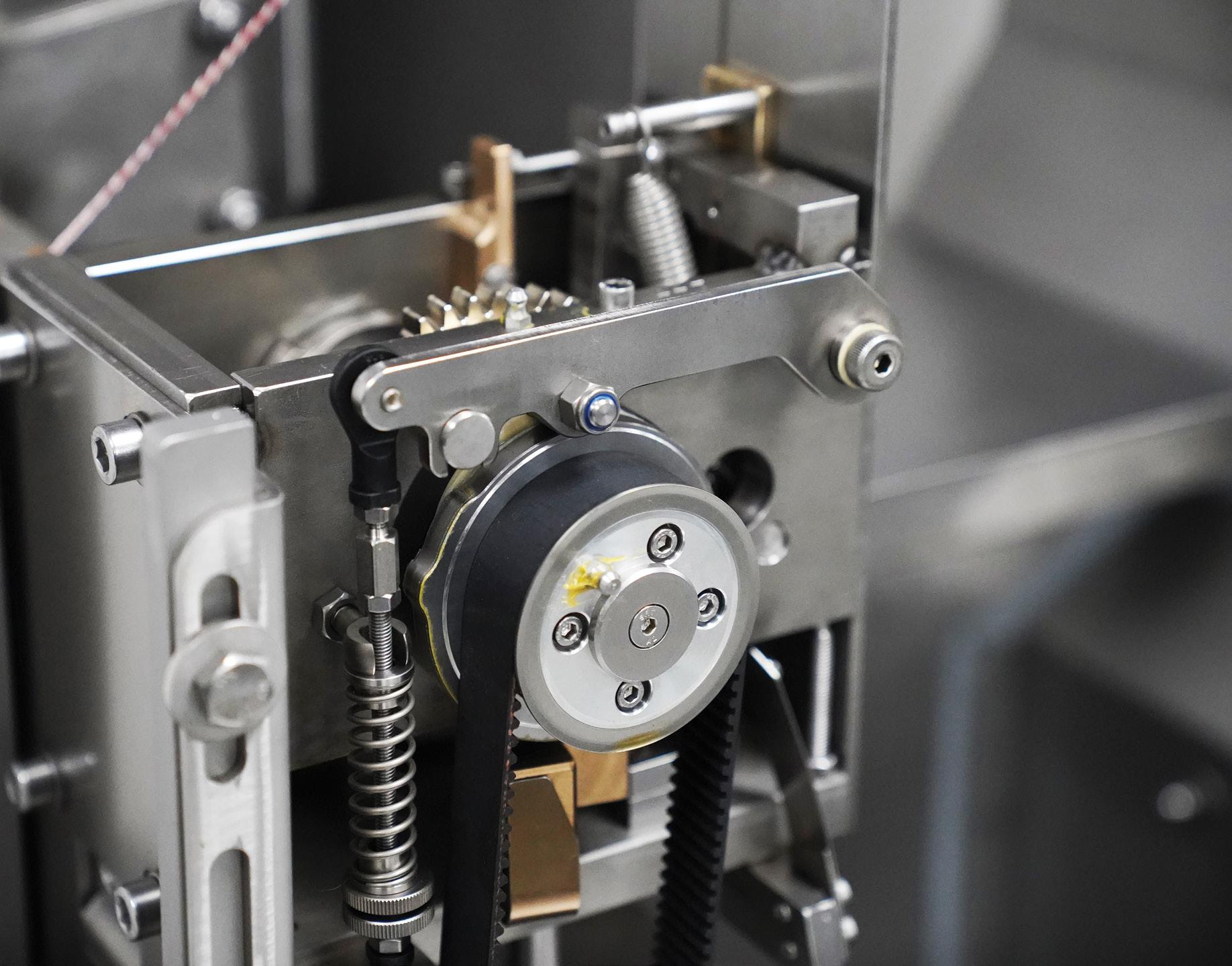

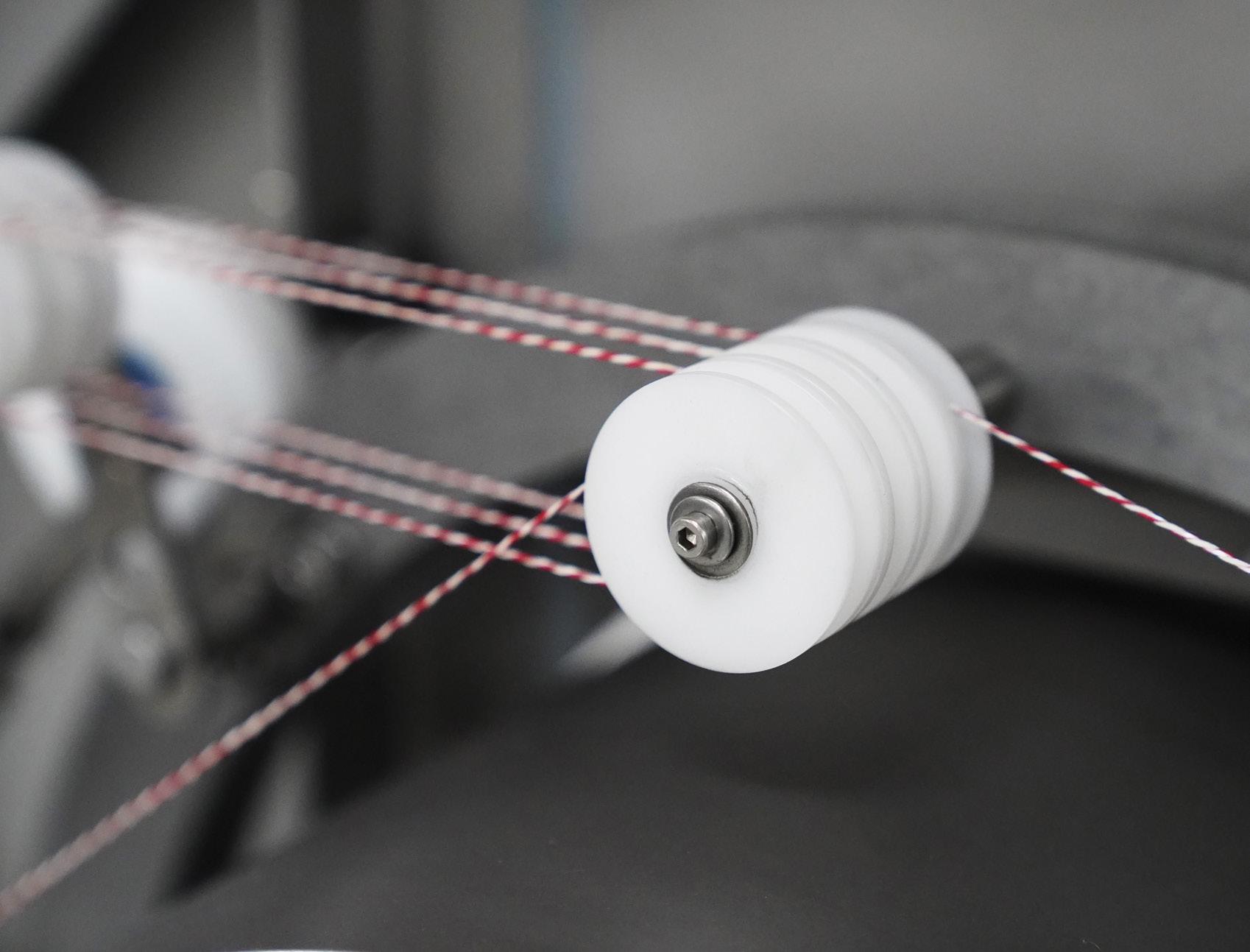

Viking TGM 350

This tunnel string tyer does away with the tiresome manual binding with meat twine.

The Viking TGM 350 guarantees optimal binding results and an attractive appearance of your product even for irregular cuts of meat.

The tunnel concept ensures a continuous flow of material.

Its ergonomic design allows for a user-friendly experience, with minimal manual intervention required.

After a short examination of the Viking TGM 350, you will realise that this string tyer is built to do the job.

The single operator system utilises a foot pedal to engage the string tyer, allowing the operator to use both hands to handle the product during use.

TGM 350 60 bindings / min

Vacuum Tumblers

Thompson Vacuum Tumblers

Models Tumbler Capacity

Thompson TM300 120kg

Thompson TM500 200kg

Thompson TM1000 400kg

Thompson Vacuum Tumblers are constructed with heavy duty stainless steel, BUSCH vacuum pumps with liquid trap, variable speed, continuous vacuum and reverse discharge function.

Great for marinating product, improved quality, increased productivity and higher profit margins.

Dry aging just got a whole lot smarter

Smoke Ovens

Smoke Rite Smoke Ovens

Smoke

Smoke

1055

1060

Smoke Rite 1080

Smoke Rite 1200

Smoke Rite 1400

-

- 15 Hams

- 35 Hams

Smoke Rite Ovens offers users with an outstanding value and optimum conditions for smoking a range of products such as hams, cheese, smallgoods and more.

The Smoke Rite Oven range offers a perfect size for your needs, designed to maximise cooking space while minimising the footprint in your workspace.

Combi Ovens

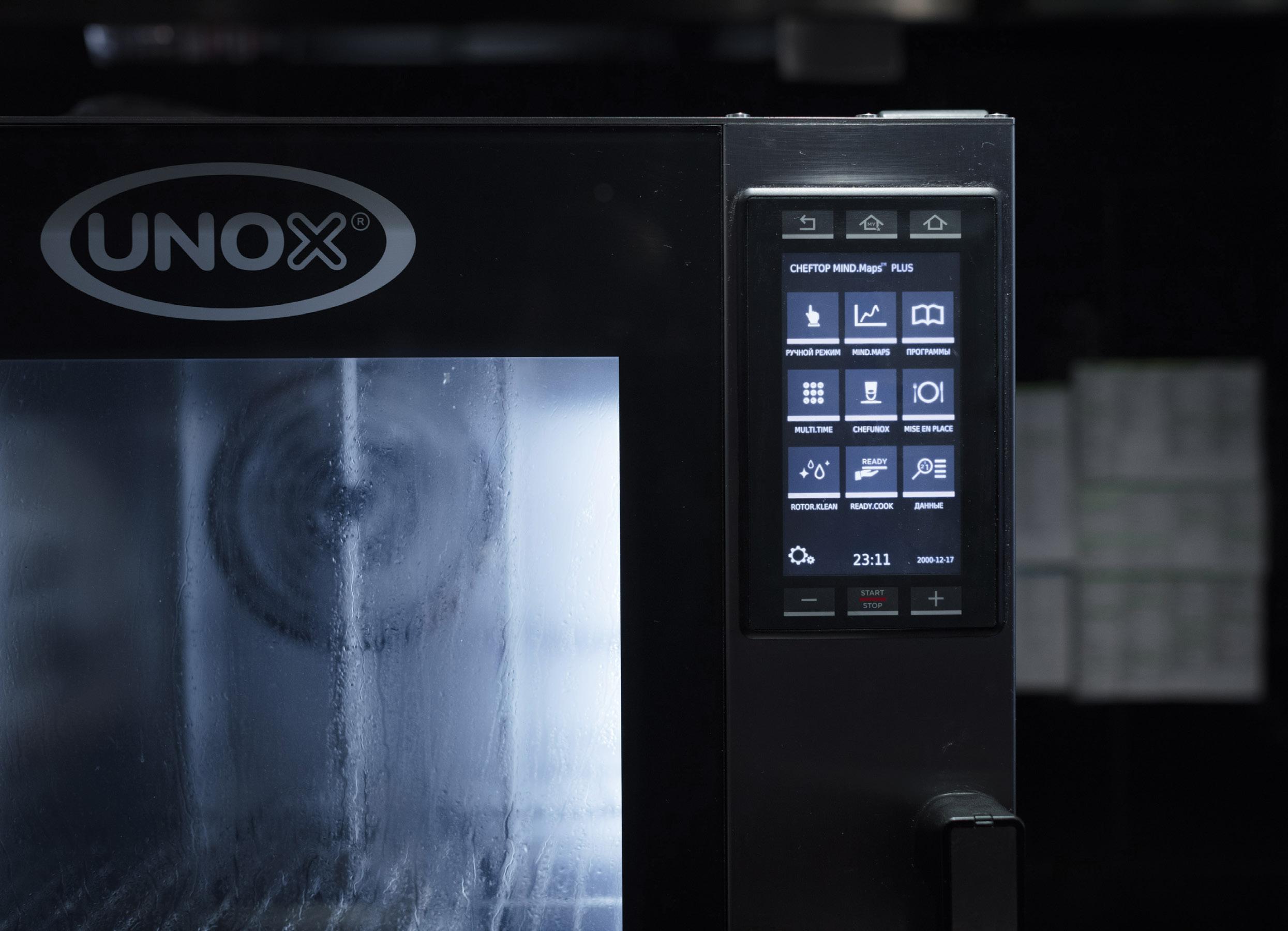

UNOX Combi Ovens

Technologically advanced combi oven for gastronomy cooking processes including dehydrating, steaming, low temperature cooking, sous vide cooking, roasting, grilling, pan frying, regeneration and plate regeneration for any load size.

Automatic management of cooking processes for perfect results, even without trained staff.

Talsa Water Cookers

Talsa Water Cookers are designed for boiling meat products such as smallgoods and other applications in the food industry.

All model sizes include an oil chamber, allowing for uniform heat distribution for optimal cooking results and eliminates the possibility of burning food at the bottom of the chamber.

The User Interface for setting temperature, duration and delayed program start is externally mounted to the water cooker on a separate switchboard to allow for precise setting of the unit and programs.

Bowl Cutters

Talsa 30lt 5 - 22kg 5 - 15kg

Talsa 55lt - New 7 - 40kg 7 - 30kg

Talsa 95lt - New 20 - 70kg 20 - 50kg

Talsa 135lt - New 25 - 100kg 25 - 70kg

Talsa 200lt 20 - 160kg

20 - 100kg

Used extensively in Food Production and Meat Processing, Bowl Cutters are designed to emulsify all types of food products, from thick to very fine textures.

Bowl Cutters are manufactured with a horizontally revolving bowl and a set of knives rotating vertically, with results right before your eyes, allowing you to adjust the program during the cycle to guarantee perfect results.

Mixer Mincers

Viking PM Mixer Mincers

Models Capacity

Viking PM 32 1,050kg / hr

Viking PM 42 2,800kg / hr

High performance mixer mincer, ideal for use in supermarkets and retail butcher stores, combining excellent mixing and grinding properties.

Thompson 900 Series

Models

Thompson 900 Premium

Thompson 900E 2,000kg

Thompson 900 Omega

- 10mm

The Thompson 900 Mixer Mincer Series has the capacity to mince very efficiently giving a high definition of cut. The labour savings achieved along with the high quality of cut and product consistency will impress the most conscientious operators.

Industrial Mixer Mincers

Thompson 3000 Series

The Thompson 3000 Series is constructed from heavy gauge stainless steel, including stainless steel feedscrew and paddle.

It is fully seam welded inside and outside, finished with smooth hygienic surfaces in an appealing satin finish to achieve a clean bowl on product discharge.

Thompson 3000 3,000kg / hr - 13mm

Thompson 4000 Series

The Thompson 4000 Series is renowned for its outstanding performance and reliability, used extensively in high production facilities throughout the world.

The Cross-Feed Channel with large infeed chute works symmetrically with the polished stainless steel feedscrew provides balanced pressurised flow through the spiral mincing barrel and cutting system to produce efficient mince, improved production output rates and finished product quality with high definition meat particle.

This greatly improves meat product flow on whole muscle, trim, 2nd cut mince and sausage emulsions.

Feed rates through 12.7mm hole plate are in excess of 4,000 kg per hour i.e. approximately 70 to 80kg / min (depending on product and product temperature).

Models

Thompson 4000 150kg - Fresh Trim

Thompson 4200 1 x 200lt Bin

Thompson 4300C 1.5 x 200lt Bin

Industrial Mixer Mincers

Thompson 5000 Series

Model Capacity

Thompson 5000 8,000kg / hr

The Thompson 5000 Mixer Mincer has the option of a unique product discharge chute that enables the mixing bowl to be emptied without passing through the feedscrew and cutting system.

Reverse Feedscrew during end discharge process (non-mince) ensures the product is dispensed from feedscrew channel into to mixing bowl and discharged out of the end discharge chute.

High efficiency cutting system is available as an option which increases production output rate by up to 100%.

• Primary cut through 13 mm hole plate, 8,000 kg/hr, 130 kg/min

• Secondary cut through 4 mm hole plate, 7000 kg/hr, 120 kg/min

The labour savings achieved from this remarkable machine, along with the high quality of cut and product will deliver outstanding production savings.

Viking 200lt Bin Hoist

Frozen Flaker

Thompson Frozen Block Pre-Breaker

The Thompson Frozen Block Pre-Breaker is designed to break up hard and frozen food blocks including meat and dairy products without destroying the texture of the product, eliminating the inconsistently sized particles and product emulsification.

The Thompson Frozen Block Pre-Breaker can take any frozen product without thawing from -18°C to -3°C saving operator’s valuable time and energy. The blocks can be processed within a remarkable 4 seconds to produce an extraordinary throughput of up to 8T /hr.

Maximum output of the Thompson Frozen Block Pre-Breaker is ensured by the high cutting speed of the rotor-type blade mechanisms. The frozen blocks are drawn to the slow speed rotor blades with high torque cutting forces, achieving exceptional production output rate.

The frozen meat blocks are easy to load into the cutting area, where they are transformed by sharp blades into slices or with cross blades into smaller cube pieces. It is simple and safe to operate.

The Thompson Frozen Block Pre-Breaker discharges product into 200L euro bins (available from Viking), various size tubs or onto conveyor for continuous feeding. 20T per hour production output can be achieved if continually conveyor fed.

The robust and reliably built quality means low maintenance and operating costs, providing years of trouble-free operation.

Bandsaws

Viking Bandsaws

Viking V500 Freestanding 280

350mm

Viking V700 Freestanding 370 x 420mm

Viking V800 Freestanding 420 x 480mm

Bandsaw blades available from Viking

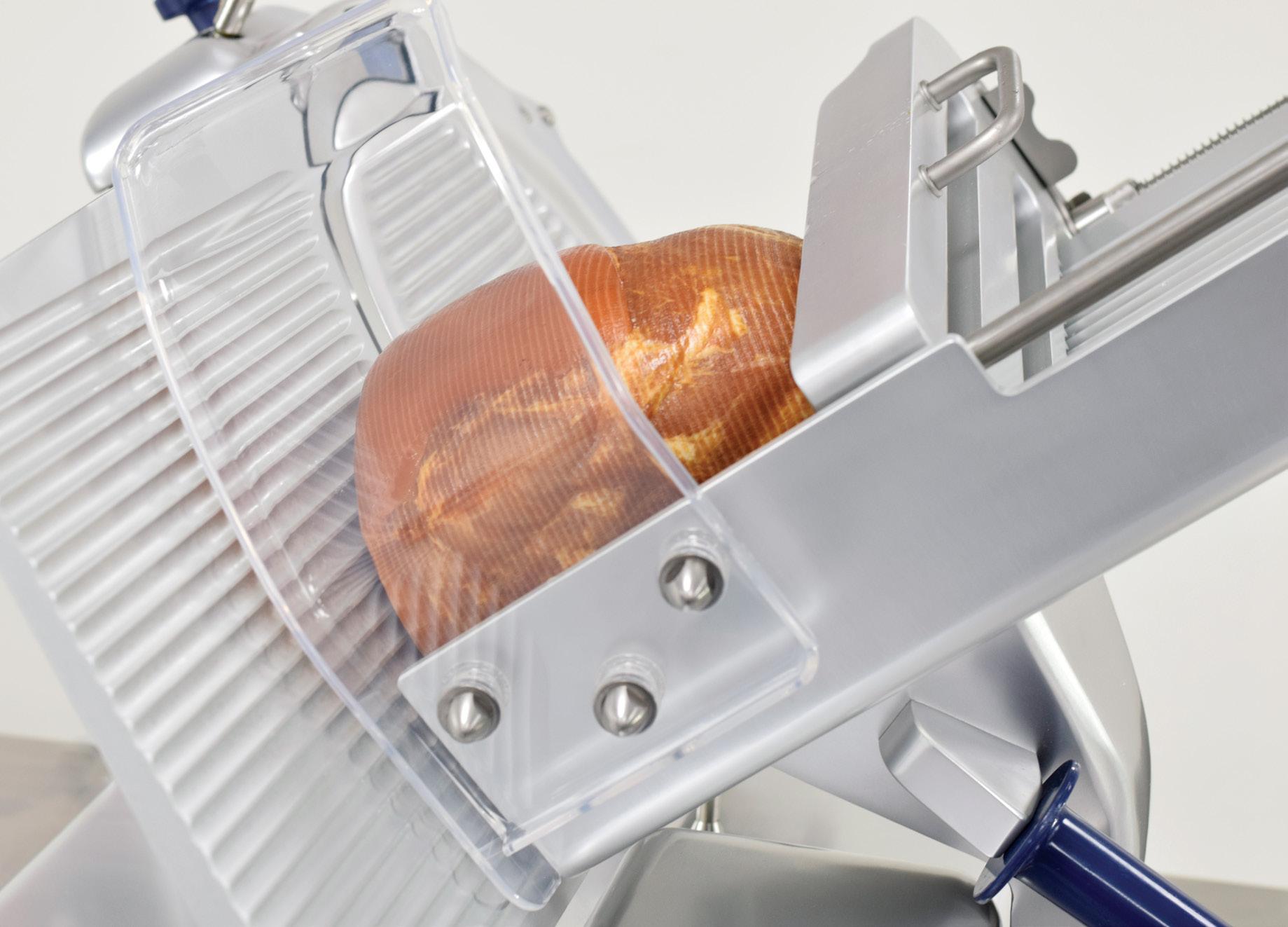

Viking Bench Deli Slicers

Models Blade Size

Viking 300 Belt Driven 300mm

Viking 330 Belt Driven 330mm

Viking 350 Belt Driven 350mm

Viking 350 Gear Driven 350mm

Viking 330A Auto Belt Driven 330mm

Viking 385A Auto Belt Driven 385mm

Viking 350 Vertical 350mm

Thanks to the unusual geometry of the blade, the cutting action is both powerful and very precise, with no bone fragments produced and halving wastage.

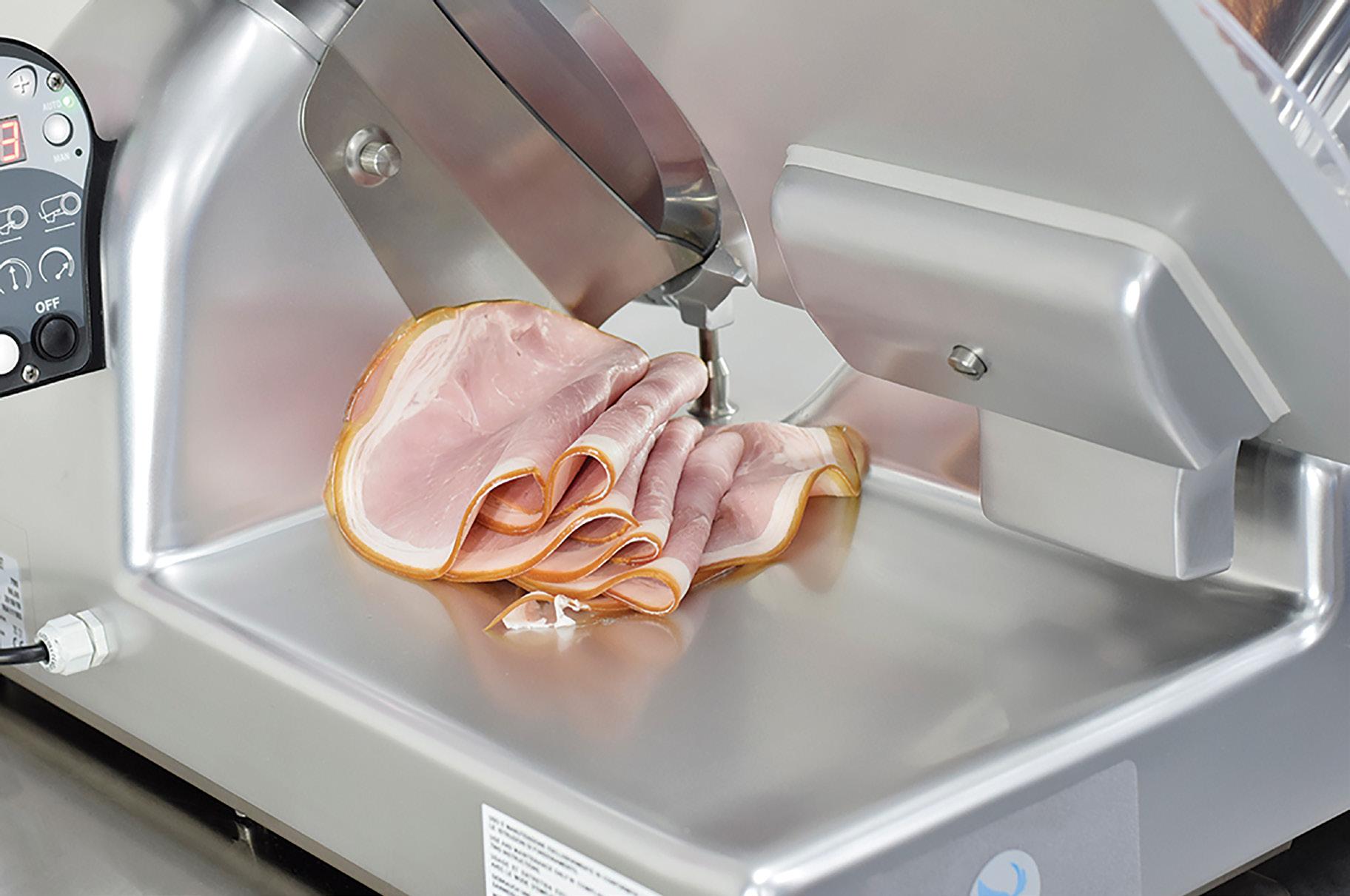

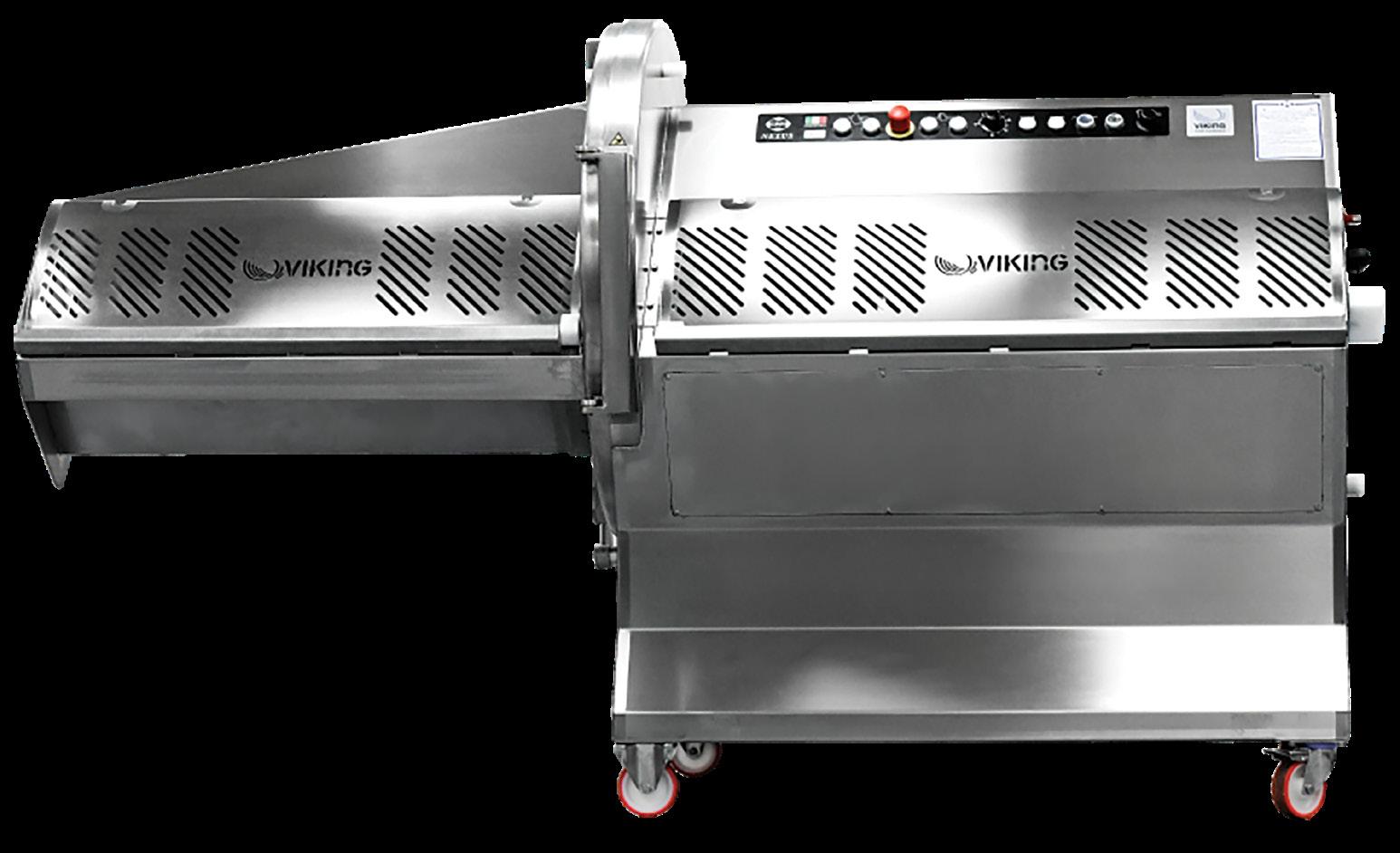

Boneless Slicers

Viking Boneless Slicers

The Viking Sector Simplex multi-blade slicers can cut a whole pieces of meat into slices of identical thickness, in a single action in less than 4 seconds, and thus, eliminating discard entirely.

In one minute, these slicers can cut up to 200 slices of beef, boneless loin, rump steak and turkey breast, resulting in substantial savings in time and product loss.

Models

Cutting Thickness

Viking Sector Simplex 6 - 50mm

Viking Sectormatic 300 7 - 100mm

Viking Sector Simplex

Viking Sector Simplex

Boneless Slicers & Dicing

Boneless Slicers

Models Capacity

Gaser Bench Chicken Slicer 300kg / hr

Ebaki Mini 400kg / hr

TREIF Dicer

Model

The TREIF range of dicing equipment allow users to safely perform the task with minimal manual intervention.

Tenderising & Stuffing

Dare In-line Tenderiser

Model Capacity

Dare 225mm 400kg / hr

With a substantial belt width, the all-new Dare In-line Tenderiser provides you with high efficiency and capacity, in a sturdy, mobile unit.

Stir fry attachments also available in 6, 8, 10, or 12mm.

Scotnet Single Stuffer

Model Output

Single Stuffer

800 units / hr

The Scotnet Single Stuffer is designed for medium processors looking to incorporate automation into netting workflows and require a high output with a unit that is designed to be compact and mobile.

It is simple to operate, entirely constructed from stainless steel and only requires compressed air to function.

The user simply loads the product into the chamber, then the pneumatics engage as the lid is shut, pushing the product from the chamber into the pre-loaded netting, and the operator then cuts the netting.

Hydraulic Sausage Fillers

Viking Hydraulic Sausage Fillers

Models - All pictured Barrel Capacity

Viking 14kg 14.2lt

Viking 25kg 25.2lt

Viking 35kg 35.1lt

Viking 50kg 51lt

High performance hydraulic sausage fillers, ideal for use in supermarkets and retail butcher stores.

Popular for use with artifical and natural casings.

Vacuum Filling

REX Vacuum Filler

Model Filling Capacity

REX RVF 327 2.7t / hr

The REX RVF 327 is a perfect and cost-effective solution for newcomers to vacuum filling technology, yet also suitable as a replacement purchase for your existing filling machine.

It comes with all the technical features necessary for the trade and is ideal for frequent product changes.

The machine housing is manufactured completely from stainless steel in hygienic design, is compact and space saving.

Maximum infeed with minimal residual amounts of meat emulsion are typical here.

Benefits:

• Perfect for frequently changing product

• For use with artificial & natural casings

• Reliable, quick and easy cleaning

• Efficient energy running costs

• Guaranteed gentle transport of all filling substances

Features:

• 35 Bar filling pressure

• Easy to use touch screen

• Manufactured in Germany