2 minute read

7 Guide plates

7.1 Calibration of upper guide plates

13 mm 17 mm 5-6 mm 3 mm

Calibration of guide plates

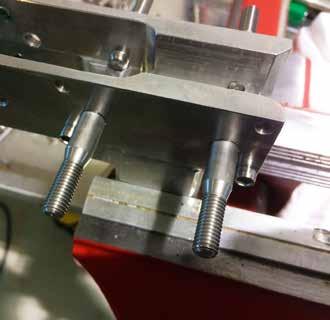

Saddle is driven under the front part of the upper guide plates. (Figure 7.2) Upper guide plate height calibrated with the 13 mm wrench on bolt (45) (Figure 7.0) until it is 3 mm above the upper cog of the saddle (Figure 7.2). Saddle is driven under the rear upper guide plate (Figure 7.3) and a gap calibrated on bolt (46) with the 17 mm wrench at 5 mm above the saddle cog (Figure 7.3)

45

Figure 7.0 46

Figure 7.1

Adjust space to 3 mm

Lower guide plate 2 mm below the saddle piece

Figure 7.2

Adjust space to 5 mm

7.2 Calibration of upper guide plates

13 mm 1.5 mm 3 mm 5 mm 6 mm

Calibration of upper guide plates

Adjust the gap between the knife and the upper guide plate to 1.5 mm (plate turned to or from the knife). Make sure that the gap does not exceed 2 mm otherwise the fish tails will be flawed (Figure 7.4). Gap between the upper guide plate shall be set 5-6 mm in front of the copper sheath of the separating knife and 10-14 mm behind the separating knife (Figure 7.5)

1.5 mm

Figure 7.4 Knife and plate are always parallel!

10–14 mm

Figure 7.5 5–6 mm

PLEASE NOTE! It is important that the sheath always covers the separating knives.

7.3 Adjustement on suspention type upper bone guide.

Figure 7.6 Do not remove bolts when replacing plates only remove 8mm. nuts (see fig

Figure 7.8 Spring force is set at 2-5 kg 5-6 mm

Figure 7.7 Spring force is set at 2-5 kg

Clearance between plate and back knifes is set to 0,2-0,5mm.

Spring nuts

Figure 7.9

7.4 In-feed

17mm