1 minute read

5 Scraper knives

5.1 Calibrating scraper knives

17 mm 19 mm 5-6 mm 2 mm 4 mm

Calibrating scraper knives

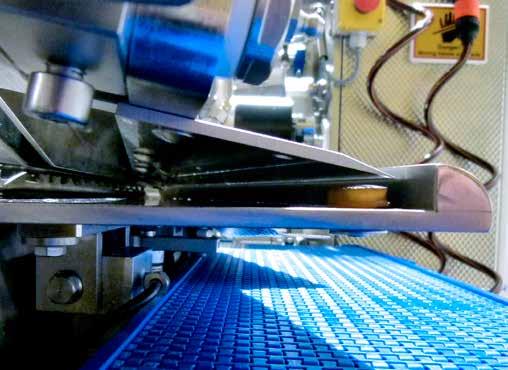

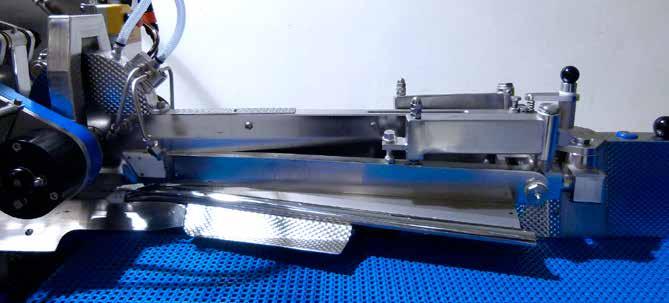

Run the machine so that it is in its primary position (Figure 2.1). When the scraper knives are calibrated, start by checking whether the knife holder (42) follows the slope of the directing plate (35). Bolt calibrated with 19 mm wrench (31). Calibrate scraper knife so that it is 1 mm above the last cog of the saddle. The height of the scraper knife is calibrated with a 17 mm wrench. ( 31 ). Now the scraper plate (37) is configured to be 4 mm above the edge of the scraper knife (34) and fixed with bolt (33) (Figure 5.3). The scraper plate must be adjusted in/ out so that there is 4 mm at the front and 3 mm at the back (Figure 5.1). Now you can calibrate the spring pressure on the bolts (32) so that from 0 (the nut on the lower edge of the holder (39) is turned in 4-8 clockwise circles; depending on the size and condition of the fish.

Then the spring pressure on the scraper plate is calibrated with nut (40) so that it is pre-stressed and is approx. 18 mm in length, depending on the condition of the fish (Figure 5.2). Pressure of the scraper plate is calibrated with nut (41) spring length approx. 45 mm (depending on the state of fish) (Figure 5.2).

5–6 mm

35

42

4 mm 37

Adjust space to Note, make sure there is tension on the spring

32 36

31

39

2 mm 34

5.2 Calibrating scraper plate

13 mm 19 mm 24 mm 3 mm

40 3 mm 33

approx. 45 mm

approx. 18 mm Figure 5.2

34