4 minute read

2 Instructions for use

2.1 Technical properties

Marin700 whitefish filleting machine - Specifications

Machine use:

The machine is designed for filleting beheaded and gutted whitefish of the following types and sizes:

Cod, haddock, pollock, saife, ling and similar whitefish.

Species of fish:

Cod, haddock, pollock, saife, ling and similar whitefish.

Size range for fillet processing:

Whitefish measuring 25 - 95 cm including the head and tail.

Examples of incorrect operation:

Do not fillet other types of fish or other sizes than specified above.

Do not fillet fish in the machine, which has not been previously beheaded and gutted.

Throughput:

5-45 fish per / min.

Free-flow speed control when the machine is running. The speed is increased by pushing the „Increase speed“ button (7) in the control box. The speed is decreased by pushing the „Decrease speed“ (8). Speed setting locks when the button is released.

Size and weight of machine:

Length: 3610 mm (4000 mm / with filleting machine M800)

Width: 1030 mm.

Width with work platform: 1245 mm

Height: 1350 mm.

Weight: 1152 kg

Power consumption:

Maximum power requirement: 3.37 kW

Voltage: 400V

Current requirement: 16A

Water consumption:

20 L / min

Water pressure: 3 bar.

Water connection 3/4"

Additional equipment:

Channel between filleting machine and skinning machine.

M800 skinning machine.

M500 heading machine.

Site of operation:

The machine is designed for use indoors in fish processing plants and ships that comply with all the requirements of the relevant authorities.

The machine must stand on a flat floor, which can carry the weight of the machine and fastened according to the manufacturer's instructions.

DECLERATION OF CONFORMITY

Vélfag ehf Múlavegi 18 – 625 Ólafsfjörður – ICELAND TEL: +354 466 2635 Mobile: +354 864 2635

We hereby declare that the design of:

Identifier: Filleting machine

Machine type: M700 Filleting Machine

Machine number:

Made in: Iceland

complies with the applicable provisions valid on the issue date stated below:

EC directive 2006 / 42 / EC, in its current version EC directive 2004 / 108 / EC, in its current version

Harmonised standards applied, in particular: ÍST EN ISO 12100-1:2003/A1:2009, ÍST EN ISO 12100-2:2003, ÍST EN 602041:2006/A1:2009, ÍST EN1672-2:2005/A1:2009, ÍST EN 81346-2:2009, ÍST EN 1037:1995 /A1:2008, ÍST EN 953:1997/A1:2009...…

Person empowered to draw up the technical documentation: _______________________________________ ( Name of the person)

____________________________ (Place, date)

2.2 Instructions for use

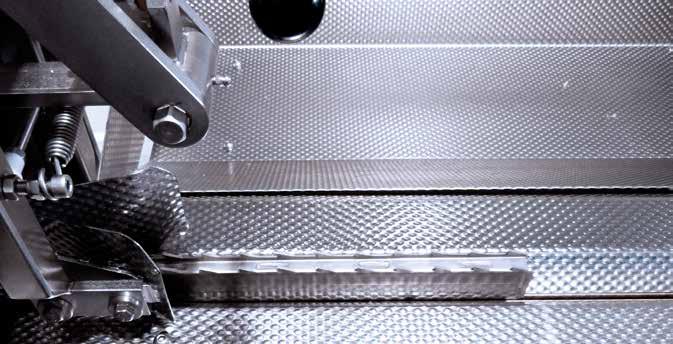

Figure 2.1

ATTENTION! It is best to do the most common adjustments and knife replacements when the saddle is stopped, see figure 2.1

Start up and shut down

1. All machine guards and covers on the machine must be closed. Make sure that starting the machine will not pose any danger.

2. Testing of safety equipment: See the chapter on safety issues.

3. Note that before the machine is started, you must open for the flow of water. The machine is started by pressing the Start button in the control box and stopped by pressing the Stop button in the control box. Emergency stop button / bar should normally only be used to stop the machine in an emergency as such stopping can cause unnecessary stress on the variable speed drive of the machine.

4. If you need to adjust the position of the fish in the saddle or the fish is placed incorrectly in the machine, so that the resistance is sufficient to cause the saddle conveyor to stop you can reverse the saddle back out of the filleting area with the „Back“ (9) button in the control box. Correct the position of the fish and/or remove that, which has caused the saddle conveyor to stop. Press the start button in the control box. Loosen the springs from the infeed, push the infeed apart, lift the measuring device and then reverse.

5. Free-flow speed control: Increase the speed by pushing the „Faster“ button (7) in the control box.

Speed can be decreased by pressing the „Slower“ (8) button. See diagram. The speed control will lock when you release the button.

Processing method

6. Fish, that has been beheaded/ gutted in the M500 beheading machine or equivalent, is taken from the supply belt.

7. The abdominal cavity of the fish must be clean and free of all intestines and shell fragments. Abdomen faces down and the tail faces to wards the infeed plates when the fish is laid into the slide that the saddles follow.

8. When the saddle comes up and runs past the user, the fish needs to be held so that the bottom of the abdomen meets the tip of the saddle and the fish can even be pushed slightly against the flow direction of the saddle so that the fish sits properly and securely in the saddle before it enters into the filleting machine.

The user monitors how much pressure is needed in relation to the quality of fillet from the machine.

See figure 2.3

9. The saddles conveys the fish forward to filleting through the infeed, filleting and separating areas.

CAUTION!

The fish is released when the tail enters the infeed.

Figure 2.2

It is extremely important that the saddle is aligned with the end of the abdomen, otherwise the measurement will be wrong, resulting in filleting flaws. It is also important that the spinal column lies between the cog pieces of the saddle, otherwise there will be flaws in the fillet!

Figure 2.3