OPERATIONS MANUAL

"A NEW JOURNEY BEGINS FROM A LOVE FOR THE SEA”

1 INTRODUCTION

This manual has been compiled to help you to operate your boat with safety and pleasure. Please read it carefully and familiarize yourself with the boat before using it.

This owner's manual is not a course on boating safety or seamanship. If this is your first boat, or if you are changing to a type of boat, you are not familiar with, for your own comfort and safety, please ensure that you obtain handling and operating experience before “operating” the boat. The national sailing federation or yacht club will be pleased to advise you of local sail training schools, or competent instructors.

Ensure that the anticipated wind and sea conditions will correspond to the design category of your boat, and that you and your crew are able to handle the boat in these conditions.

Even when your boat is categorized for them, the sea and wind conditions corresponding to the design categories A, B and C range from severe storm conditions for category A, to strong conditions for the top of category C, open to the hazards of a freak wave or gust. These are therefore dangerous conditions, where only a competent, fit and trained crew using a well-maintained boat can satisfactorily operate.

Do not exceed the maximum recommended load (see section 2.5) as this could subject the boat to excessive loads with possible structural damage. The reduced freeboard will also increase the risk of flooding in sever conditions.

This owner's manual is not a detailed maintenance or trouble-shooting guide. In the case of difficulty, refer to the boat builder or his representative. If maintenance manuals are provided, use it for the boat's maintenance.

Always use trained and competent people for maintenance, repairs or modifications. Modifications that may affect the safety characteristics of the boat should be assessed, executed and documented by competent contractors. The boat builder cannot be held responsible for modifications that he has not approved. In some countries, a license or authorization are required, or specific regulations are in force that must be met before operating the boat.

Always maintain your boat properly and make allowance for the deterioration that will occur over time and because of heavy use or misuse of the boat.

Any boat, no matter how strong it may be, can be severely damaged if not used properly. This is not compatible with safe boating. Always adjust the speed and heading of the boat to suit the sea conditions.

Your boat is fitted with a life rafts, carefully read its operating manual. The boat should have onboard the appropriate safety equipment (lifejackets, harness, etc.) according to the type of boat, weather conditions, etc. This equipment is mandatory in some countries. The crew should be familiar with the use of all safety equipment and emergency maneuvering (man overboard recovery, towing, etc.), sailing schools and clubs regularly organize drill sessions.

All persons should wear a suitable buoyancy aid (life jacket/personal floatation device) when on deck. Note that, in some countries, it is a legal requirement to wear a buoyancy aid that always complies with their national regulations.

Keep this manual in a secure place, and hand it over to the new owner if or when you sell.

DEGREE OF HAZARD AND CORRESPONDING SAFETY LABELS

The following degree of hazard and corresponding safety labels are used in this owner’s manual.

DANGER: Denotes that an extreme intrinsic hazard exists which would result in high probability of death or irreparable injury if proper precautions are not taken.

WARNING: Denotes that a hazard exists which can result in injury or death if proper precautions are not taken.

CAUTION: Denotes a reminder of safety practices or directs attention to unsafe practices which could result in personal injury or damage to the craft or components or to the environment.

See also Chapter 13 “Symbols and safety warnings” for other safety labels used on VANGUARD

2 GENERAL INFORMATION AND CRAFT DATA

2.1 MANUFACTURER

Name of the model (type): VANGUARD Explorer Yacht

Builder/OWNER: VANGUARD XPM LLC

Address: 454 Old Landing Road Bluffton SC 29910, USA

Website: www.exploreryacht.com

Email: chris@exploreryacht.com

Phone: +1 281 630 3513

2.2 MAIN DIMENSIONS

2.4 DRAFTS

Maximum height (air draft), in the light craft condition: 8.15 meter

Maximum draft, in the fully loaded condition: 1.265 meter

2.5 MASS OF THE CRAFT

Light craft condition: 53,502 kg

Maximum load note 1): 15,000 kg +

Maximum load condition mass: 68,000 kg

Note 1) See section loadings

2.6 TANK CAPACITIES

The weight of liquids, when all permanently installed tanks are in DEPARTURE condition, is 15,000 kg.

Tank No Capacity Notes

Fuel Tanks 7 9,885 Ltr Note 20% reserve in ARRIVAL condition.

FW Tanks 4 7,500 Lts Note – water ballast compensation as fuel used.

Grey Water Tanks 2 410 Ltr Note – pump regularly

Black Water Tanks 2 600 Lts

Gluycol Tanks (2) 400 Ltr 2 tanks joined in series, keel cooled

Tank levels are displayed on the Praxis MIMIC displays in the engine room, main helm and flybridge. Levels are measured using BEP Ultrasonic level gauges or Maretron pressure transducers. Locations of the tank gauges are as shown in the attached drawing.

Caution: Not all of the water and fuel tank capacity should be used due to the trim and loading of the vessel. A 20% reserve FUEL should be kept in ARRIVAL condition

2.7 MAXIMUM RECOMMENDED LOAD

DESCRIPTION

DESIRED CREW

PROVISIONS & PERSONAL EFFECTS

MASS COMMENTS

(6 PERSONS)

MARGIN FOR FUTURE ADDITIONS

kg AS SHOWN ON BUILDERS PLATE

Warning: When loading the yacht, never exceed the maximum recommended load. Always load the yacht carefully and distribute loads appropriately to maintain design trim approximately level. Avoid placing heavy weights high up.

2.8 ENGINE DATA

Engine type:

Propulsion system:

Installed engine power:

Maximum recommended engine power:

John Deere 4045 AFM85 (M1 rated)

Diesel Electric Hybrid

Esco Power PHT 1.4: 1 step up hybrid drive

Twin Disc 2.5:1 step down marine gearbox Praxis 30/70kW motor /generator

235 kW [320 HP]

116 kW [160 HP, continuous]

2.9 ELECTRICAL DATA

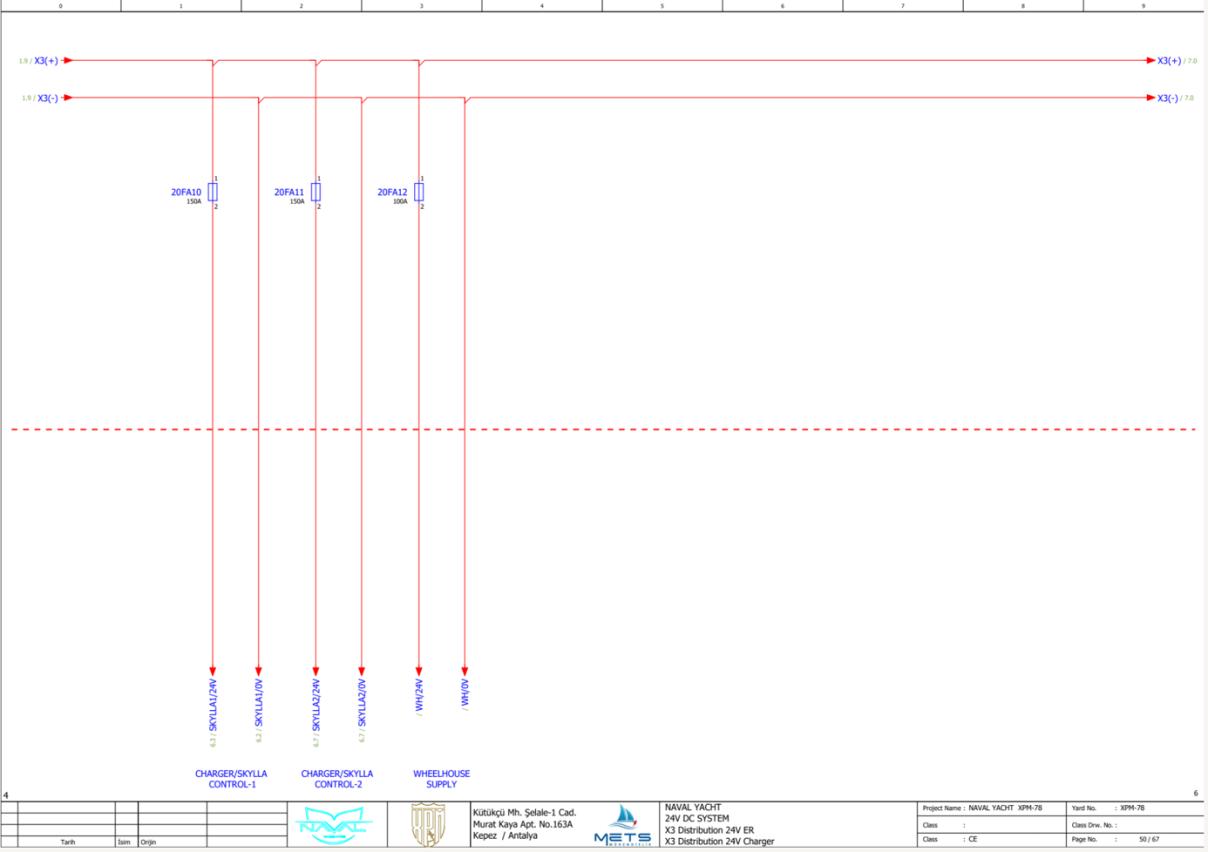

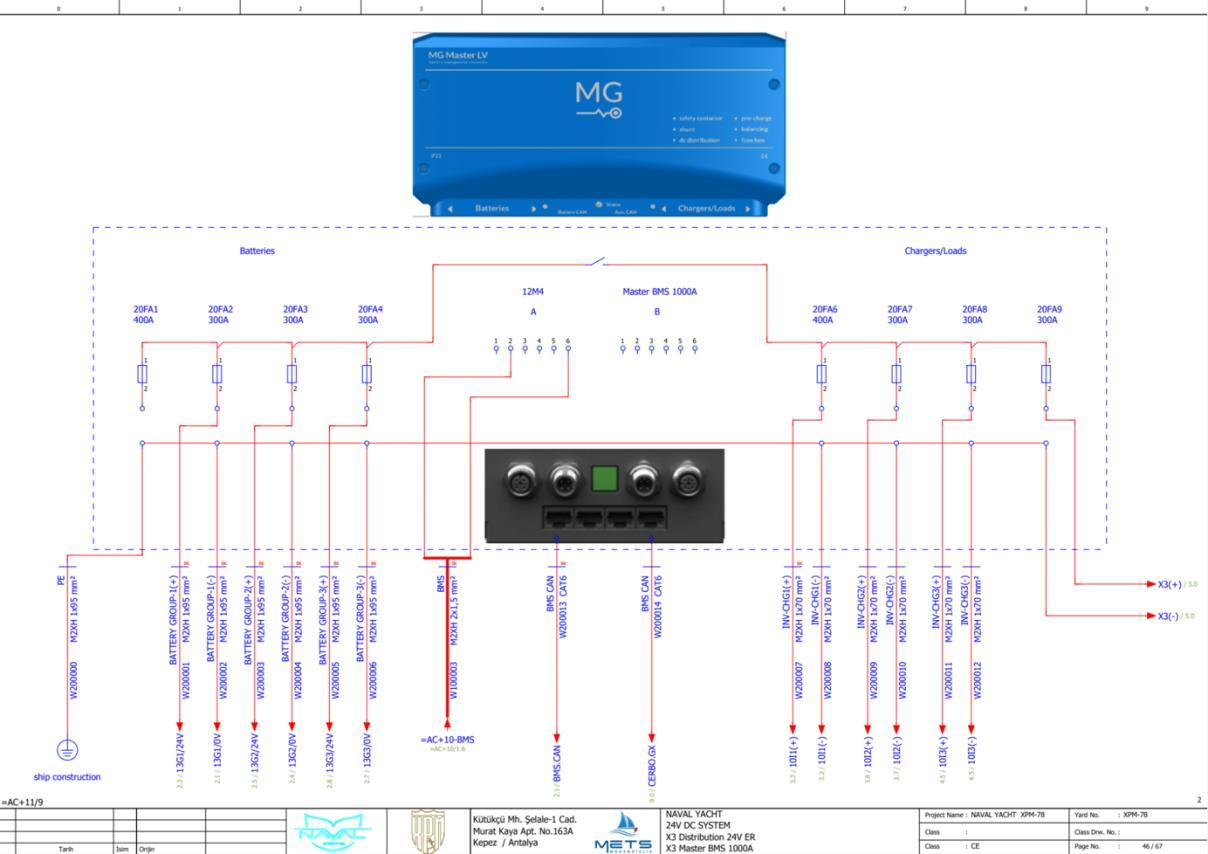

2.9.1 DC SYSTEM (12 V / 24 V)

Capacity House batteries: 3 x7 kWh Ah / 24 V DC (LiPO) plus small navigation battery backup.

Capacity Hybrid Power: 2 x 60 kW.H / 600 V DC (LiPO)

Capacity service battery: 60 Ah / 24 V DC (Lead Acid deep cycle AGM)

2.9.2 AC SYSTEM (230 / 415VAC)

System: 50 Hz @ 230VAC Single phase, 50Hz 415V AC Three phase

Shore Power:

Single Phase 50/60Hz 5kW Three Phase 50/60Hz, 25KVA

4 CERTIFICATION & DESIGN CATEGORY

The VANGUARD is certified according to the essential requirements of:

• EU Recreational Craft Directive 2013/53/EU

• UK MCA Catergory (0) Code as specified in UK MGN 280 (Note 2)

As shown on the builders plate the yacht is designed for operation in conditions as described for DESIGN CATEGORY A

DESIGN CATEGORY A:

DESIGNED FOR EXTENDED VOYAGES WHERE CONDITIONS MAY EXCEED WIND FORCE 8 (BEAUFORT SCALE) AND SIGNIFICANT WAVE HEIGHTS OF 4 M AND ABOVE BUT EXCLUDING ABNORMAL CONDITIONS, AND VESSELS LARGELY SELFSUFFICIENT.

DESIGN CATEGORY B:

DESIGNED FOR OFFSHORE VOYAGES WHERE CONDITIONS UP TO, AND INCLUDING, WIND FORCE 8 AND SIGNIFICANT WAVE HEIGHTS UP TO, AND INCLUDING, 4 M MAY BE EXPERIENCED.

DESIGN CATEGORY C:

DESIGNED FOR VOYAGES IN COASTAL WATERS, LARGE BAYS, ESTUARIES, LAKES AND RIVERS WHERE CONDITIONS UP TO, AND INCLUDING, WIND FORCE 6 AND SIGNIFICANT WAVE HEIGHTS UP TO, AND INCLUDING, 2 M MAY BE EXPERIENCED.

DESIGN CATEGORY D: DESIGNED FOR VOYAGES ON SHELTERED COASTAL WATERS, SMALL BAYS, LAKES, RIVERS AND CANALS WHEN CONDITIONS UP TO, AND INCLUDING, WIND FORCE 4 AND SIGNIFICANT WAVE HEIGHTS UP TO, AND INCLUDING, 0,3 M MAY BE EXPERIENCED, WITH OCCASIONAL WAVES OF 0,5 M MAXIMUM HEIGHT, FOR EXAMPLE FROM PASSING VESSELS.

Note 1 : The significant wave height is the mean height of the highest one-third of the waves, which approximately corresponds to the wave height estimated by an experienced observer. Some waves will be double this height.

Note 2 : VANGUARD was designed and constructed to COMMERCIAL specification under supervision of UK MCA to MCA Catergory (0), Unrestricted navigation to 80 degree N (Summer). A sample of the survey results is available for inspection. Several categories are not in compliance and these represent specific choice of the Owner as the vessel will not be used for commercial purposes. For example a fully compliant medical kit is not carried.

4.1

BUILDERS

PLATE & WATER CRAFT IDENTIFICATION NUMBER

The WIN is fitted on the aft deck above the rear saloon access door O.N.751204, R.T. 34.27 / 100

Warning: Do not exceed the maximum recommended number of persons. Regardless of the number of persons on board, the total weight of persons and equipment must never exceed the maximum recommended load. Always use the seats/seating spaces provided.

Warning: When loading the yacht, never exceed the maximum recommended load. Always load carefully and distribute loads appropriately to maintain design trim approximately level. Avoid placing heavy weights high up.

5 INFORMATION REGARDING RISK OF FLOODING AND STABILITY

5.1 STABILITY DATA FOR SAILING & MOTOR YACHTS

Compliance with the stability criteria does not ensure immunity against capsizing regardless of the circumstances or absolve the owner of the yacht from his responsibilities. The owner should therefore exercise prudence and good seamanship having regard to the season of the year, experience of the crew, weather forecasts and navigational zone, and should take appropriate action as to speed, course and sail setting warranted by the prevailing conditions.

Before a voyage commences care should be taken to ensure that sizeable items of equipment have been properly stowed to minimise the possibility of both longitudinal and transverse shifting under the effect of accelerations caused by pitching and rolling. In adverse weather conditions and when there is the possibility of encountering a severe gust, squall or large breaking wave, all exposed doors, hatches, skylights, vents, etc. should be closed and securely fastened to prevent ingress of water.

Stability recommendations:

- All crew members need to be adequately trained.

- Any change in the disposition of the masses aboard (for example the addition of a fishing tower, radar, a stowing mast, change of engine, etc.) may significantly affect the stability, trim and performance of the boat;

- Stability is reduced by any weight added high up of slack bilges;

- In rough weather, hatches and lockers should be closed to minimize the risk of flooding;

- Stability may be reduced when towing or lifting heavy weights using a davit or boom;

- Breaking waves are a serious stability hazard.

5.2 SIGNIFICANT STABILITY INFORMATION

• Downflooding Angle: 58 degrees (limited by engine room vent openings)

• Maximum Righting Moment: @ 45 degrees

• Angle of Vanishing Stability: >>70 degrees (range of calculation typically >90)

Caution: Before leaving the harbour please make sure that engine room exterior hatch, deck hatches, the salon rear hatch and pantograph doorclosed.

5.3 LOCATION OF THROUGH HULL FITTINGS.

The drawing added to this manual below show all through hull fittings installed in the hull

• All overboard discharge through hull fittings extend above the waterline and can be maintained afloat

• Main sea suction fittings are equipped with shut off butterfly valves and fully redundant for maintenance at sea.

Familiarize yourself with the location of this through hull fittings and inform your crew before leaving the harbor In case of an emmergency these seacocks should be found easily.

Location of through hull overboard discharge fitting

Location of through hull sea suction

5.4 WATERTIGHT CLOSURES

The following openings are marked as “WATERTIGHT CLOSURE – KEEP SHUT WHEN UNDERWAY”:

Location of watertight doors. Note: Pantograph door fitted with a washboard for use at sea.

Location of watertight hatches. Note: FOREPEAK & SWIM PLATFORM MUST BE CLOSED at sea.

Caution: Keep port lights, windows, washboards, doors, hatches or ventilation openings closed when appropriate, e.g. in rough weather.

6 INSTALLATIONS

6.1 ENGINE AND HYBRID DRIVE

VANGUARD is equipped with a fully redundancy diesel electric hybrid drive. This section will concentrate on a single engine, the additional engine is a repeat. Refer also to different sections in this Manual on Fuel system, Batteries, Praxis Power Management …..

VANGUARD can operate on a single or twin engines.

• Trim for good fuel consumption is slightly by the stern. Trim by the bow will cause the bow to dig in, excessive stern trim will result in instability and increased rolling.

• Sweet spot for a single engine is 7.5-8.5 KN in calm weather 80/90% full load. This is the most efficient setting for fuel consumption which should approximate to 3.5 L/NM in calm weather with stabilizers retracted.

• Two engines will be required for greater speed or in more challenging weather. Two engines will also be required when the electrical load is high such as when using HVAC underway or charging the power batteries at higher rates. The sweet spot for this configuration is 8.59.5KN 60/70% load on each engine. Expect fuel consumption to increase to something a round 4.5L/NM.

www.

Engine – this is a John Deer 4 cylinder turbocharged diesel engine. Full power is 112kW or 160BHP. Engine is M<1 rated for continuous operation at 100% load with a 60% fuel factor (meaning average fueling is 60% or maximum taken over time).

Hybrid Drive - The engine is connected via a mechanical clutch to an Esco Power step up of PHT drive. this allows drive to a 30kW Praxis DC motor at a step-up ration of 1.4:1.

The motor spins faster than the engine crankshaft. This motor will also act as a 30-70kW generator either when driving the propeller or when decoupled from the prop shaft. The Escopower drive is rated to 250BHP power transmission.

Gearbox – The hybrid drive also transmits power to the Twin Disc gearbox. The gearbox has a reduction ratio of 2.5:1 and 5 degrees down angle. It provides Forward, Neutral and Reverse. The gearbox is rated to 250HP power transmission.

Starting & stopping the engine

Starting the engine

1. Check oil levels when stationary for engine, PHT drive and gearbox (see above for locations).

2. Check engine coolant level (glycol – see above for location)

3. Check sea water intake is open at the filters between the engines

4. Power the starter battery

5. Switch Clutch controls to “Praxis”

6. Switch on a single engine room extractor fan

7. Select fuel day tank (P or S) and check level is sufficient.

8. Switch on fuel priming pump, when lights stabilize press START.

9. Check engine is operating normally and without system leaks. Note: both engines are noisy when driving the hybrid system at idle. This is normal but there should be no excessive line vibration.

Stopping the engine

1. This is a reverse of the start procedure EXCEPT, engines control should be stopped at the HELM EMS before the engines ae themselves switched off.

2. Before stopping, allow engine a 10 minute cool down period after running under load.

Emergency Stop.

Emergency Stop is at the Muster Station on the Aft Deck. There you will find:

• 2 fuel levelrs to cut of fuel supply from the day tanks.

• 1 button to close Engine Room dampers to allow for release of extinguishers

• 1 button to release the fixed fire extinguishers

• 2 buttons to isolate the Power Batteries

Taking control at the HELM.

1. Ensure throttles are in the ZERO position.

2. Select Wheelhouse or Flybridg control. This is achieved by pressing CONTROL on the EMS for either engine.

3. You now have control of the engines from the pertinent helm station.

4. Use either DIESEL or ELECTRIC when maneuvering but do not use both.

5. When underway, keep the power batteries permanently charged by pressing CHARGE. The system will automatically adjust prop/electric load to keep the batteries fully charged but not overpower the diesels for the load setting.

Charging Power Batteries

1. CHARGE can also be used with the diesel running but the gearbox in neutral. This will charge the power batteries quickly with a maximum (present) setting of 36kW combines house load and battery charge. A typical use would be charging batteries at anchor. House batteries are charged from the 415V 3-phase grid and will be maintained automatically.

2. The EMS Single line MIMIC is convenient for viewing how the charge is progressing.

Please read the accompanying manual of the engine before using the VANGUARD. In these accompanying manual you can also find the procedure to operate the engine and the necessary maintenance.

A separate manual for the engines is provided with the boat. Please read this manual carefully.

Warning: When starting an engine prevent craft movement and/or propeller rotation. Make sure the gearbox control lever is in NEUTRAL position.

Safe operation instructions:

• Ensure the flow of cooling water (feel this at the exhaust muffler exit, it should stay cool.)

• Ensure that ventilation ducts are unobstructed.

Avoid contact of flammable materials with hot engine parts.

Caution! After starting the engine, we recommend to check the following:

• check if there’s water flowing out of the exhaust. By overheating (insufficient or no cooling), a warning light will light up on the engine panel and a loud sound will be heard. In that case, immediately shut off the engine and check if the seacock for the water supply is open (in the engine room, BETWEEN ENGINES). If necessary ask for help.

• all instruments and alarm displays of the engine and drive have to indicate normal values. Regularly review the instruments during navigation.

Warning: When working on or close to the engines it is recommended to disconnect the engine from the starting batteries to prevent accidental starting. This can be done by turning the engine power main switch into the OFF position. The switch is located at the starter battery for each engine.

6.2 SHAFT LINE AND PROPELLER

VANGUARD is fitted with wo independent shafts and propellers. The assembly is as illustrated below. It is sea water lubricated using water from the diesel engine sea water pump. This is not available when using just electric drive with the diesel engine off, because of this use of only electric drive should be restricted to manoeuvering only.

Specific items in the drive line include:

1. Sigmadrive self aligning bearing

2. Autolock shaft break (currently disabled)

3. PSS Pro water lubricated shaft seal

4. S/S shaft line

5. Phenolic cutlass bearing

6. Rope Cutter

7. Varifold self tailing propeller

Note:

• Self-tailing propellers are employed to reduce resistance when operating on a single engine. They will windmill in the flow stream.

• Rope cutters are aligned to move with the shaft. Clearance fore/aft must be allowed when fitting.

A separate manual for the drive line is provided. Please read this manual carefully.

6.3 STEERING & BOW THRUSTER

Steering is achieved by a fully redundant electro-hydraulic steering unit from Wills Ridley. This is integrated with a steering control system from Praxis Automation to provide for the following functions:

FUNCTION

Emergency Hydraulic Steering

NFU Jog Lever

Local Control

FFU Steering

Autopilot

Full Dynamic Positioning

Location Description

Main Helm - WR – manual emergency hydraulic control.

Main Helm Flybridge - WR – on helm stations

Engine Room

WR – on steering control box

Main Helm Flybridge - Praxis – wheel at both helm stations

Main Helm Flybridge - Furuno – both helm stations

Main Helm - Praxis – Main Helm

Two substantial rudders are installed with the lower 1/3 acting as a crush zone. Rudder pintles are 100% oversized and fitted with self-aligning Jeffra Pintle Bearings.

Please read the accompanying manual of the steering before using the VANGUARD. In these accompanying manual you can also find the procedure to operate the steering and the necessary maintenance. Below you will find a check list before operating and details for operating.

A separate manual for the Wills Ridely steering is provided with VANGUARD. Please read this manual carefully.

6.3.1 Starting the Steering and Selecting Steering Mode

• Switch on power at the stering control station in the Engine Room. Two switches ae provided, the cabiner cannot be opened when steering in live.

• Select “REMOTE”

• Select steering function at the Main Helm fo Flybridge. Note: the “steering handover” between the two helm stations is automatic.

• Select PUMP 1 or 2 on the stering pump controller at the Main Helm. Note it is not possible to run two pumps at the same time.

Note Maximum swing for the rudder is 35 degrees each way

Modes are:

MODE Description

NFU SINC (WR Jog Lever)

Praxis (Wheel)

Autopilot (Furuno)

DP (Selected on the DP Unit)

6.3.2 Calibrating the Praxis Steering Controllers

Praxis Controllers provide for day-to-day steering functions plus commercial grade Dynamic Positioning. Fully independent control of each rudder plus twin propellers allows for thrust (Fore and Aft) plus (P & S). Combined with a proportional control, long run Sidepower bow thruster, and VANGUARD can maneuver in very confined spaces.

Set end stop Limits and Zero

• Turn MIMIC to MIMICA/10 – 050 STEERING Settings

• Switch steering to LOCAL

• Adjust to HARD Port (back off 3 clicks). Use trackpad to press SET PS on both rudders

• Adjust to HARD STBD (back off 3 clicks).? Use Trackpad to SET SB on both rudders

• Adjust ZERO. Use trackpad to SET Zero on both rudders.

• Next sea trial to ensure VANGUARD steers in a straight line. If not then, switch to LOCAL and adjust both rudders to reset Zero.

Set Toe in or Toe out for minimum drag.

• Next in LOCAL mode adjust just one rudder to alter tow in.

• Notice if speed increases or decreases or is unaltered.

• Continue to max speed (toe in or out) is optimum.

• Reset ZERO.

www.

6.3.3 Bow Thruster

VANGUARD is fitted with a 15kW, proportional control, long run, bow thruster from Sidepower. The breaker controls are in the forepeak, they are usually left switched on. The thruster tunnel is fitted with grids on either side to limit the possibility of damage from floating debris.

A 15kW unit is powerful and will tax the power supply capability within Vanguard. To ensure power is available it is advisable to switch the Victron Multiplus controllers to “Invert Only” and prevent power being drawn to charge the House Batteries.

This is achieved via the Victron Cerbo controller at the main helm station. Play with these controls to understand their working before needing this setting in anger.

After use, turn this back to RUN or the House Batteries will die at a future and inopportune moment!

The thruster can be operated three ways:

1. From either Helm using the proprietary S-Link Sidepower control system. This is a CAN-bus based system and is stand-alone from other communications.

2. Via the Praxis commercial dynamic positioning system at the Main helm. Communication is hardwired via the I/O unit within the Engine Room VMS Cabinet.

3. Via the portable Dockmate controls allowing positioning from any location on the deck Communication is WIFI between the hand-held controller and the Dockmate control box located at the main helm. This itself is hard wired to the Praxis DP System and exists outside of the normal scope for Dockmate support services (call Praxis).

Vanguard is a full 24m in length with a keel approximately ¾ of that. She responds slowly to bow thruster signals but will continue moving once in motion. Practice in open water to get a feel for the response before attempting operation in confined situations.

6.4 STABILISERS

VANGUARD is equipped with stabilizers from DMS Magnusmaster. These work on the magnus effect where rotating a cylinder in a flow stream produced a force at 90 degrees to the rotation, upwards or downwards depending on the direction of rotation.

These stabilizers use little power in operation. They fold automatically when not in use and are fitted with rope guards Stabilizers are not always necessary depending on trim and sea conditions. Switching them off will gain about 0.5KN of speed between 6/8 knots.

• Stabiliser breaker controls are on the Port side of the steering platform, near to the floors.

• Engage breaker before use.

• Stabilisers controls are at the helm station, Port side. They will be powered when the breaker is engaged.

• To check operation, go to the control screen when they are deployed and press <FORCED ROLL>. Rolling will stop when this button is released, WARN CREW BEFORE DOING THIS.

Deploying and Retrieving Stabilisers

• Stabilisers will only deploy when either (P or S) engine clutch is engaged.

• Press the Green <STABILIZE> button and the image will show the stabilisers deploying.

• Stabilisers can be retrieved by pressing the Red <STOW> button.

• Stabiliser will use energy. They should be docked in calm weather or when induced rolling is comfortable.

• Stabilisers are set to dock automatically when the clutch disengages, this prevents accidental damage when docking near to obstacles.

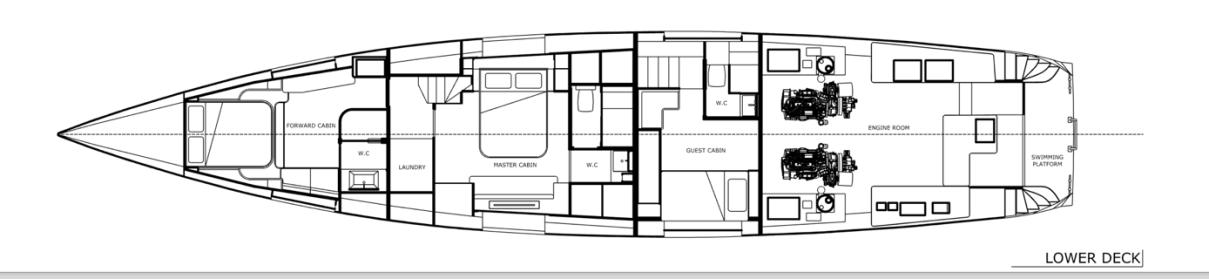

6.5 ENGINE ROOM LAYOUT

Major Engine Room equipment placement is as indicated in the above drawing. The Engine Room is designed for redundancy as demanded by the design mission.

Major elements of the engine room layout include:

• Two independent drive lines are installed each capable of full propulsion at sea.

• Rudders are duplicated and of substantial construction resistant to impact damage.

• Propellers utilize sail drives with feathering blades. They are installed in ice protected partial tunnels.

• Electrical power is provided by two independent 60kW.H Power Batteries and three independent 7kW.H House Batteries

• Engine starter batteries are also independent and fitted with a power cross over in the event of failure.

• Two full flow sea suction filters are fitted and can be maintained with the engines in operation.

• All mission critical systems such as FW/Glycol, heating, fuel oil filters …. are duplex.

• Control and reporting use commercial PLC based infrastructure from Praxis Automation with a fully redundant Ethernet data backbone.

• House electrical is provides via 3 Victron Multiplus inverters charging 3 7kWH house batteries. A n emergency changeover allows powering of the three phase bus bars independent of the Multiplus controllers in the event of a single failure.

• All through hull penetrations can be cleaned at sea and underway.

6.6 BILGE & FIRE PUMPING SYSTEM

The bilge pumping sytem onboard the VANGUARD consists of :

• One large bilge / fire pump in the Engine Room. This is a typical centralised system for a commercial vessel.

• A manual bilge pump accesed via the main deck, aft of the Muster Station.

• A number of electrically operated small condensate pumps providing secondary bile backup.

• Each bilge suction is fitted with a strainer.

• The main bilge pump suction is fitted with an additional strainer to prevent damage to a critical pump and provide operator feedback on what is being pumped.

6.6.1 Electrical Bilge & Fire pumping system

• The electrical fire/bilge pumps are in the Engine Room

• The pump is operated from the switch panel above the Stbd engine control panel.

• The bilge pump can also be operated at the SAFETY MIMIC Panel on either helm station.

• The bilge manifold is located against the forward engine room bulkhead, Starboard side.

• The manifold is left on Engine Room access setting when not in use.

• The bilge/fire pump suction is fitted with a large suction strainer box to catch debris and protect the pump.

6.6.2 Emergency Fire Pump

The Bilge pump can be turned to Fire pump by:

• opening the FIRE MAIN V/V at the manifold

• closing the OVERBOARD V/V at the Stbd Engine Room overboard discharge

• Lay out the hose and open the hydrant.

• Turn the pump on at the pump control panel above the Stbd engine.

6.6.3 Emergency Manual Bilge Pump

The Emergency Bile Pump is operated from the main deck, aft of the Muster Station.

• The handle is stored in the Fire Locker at the Muster Station.

• The system is self-contained and does not need preparation.

• It is used to evacuate only the Engine Room bilge.

Warning: Check function of all bilge pumps at regular intervals. Clear pump inlets of debris.

Warning: The combined capacity of the bilge pumping system is not intended to act as a high capacity Salvage pump.

6.7 FUEL SYSTEM

VANGUARD’s Fuel System is as illustrated in the enclosed drawing. General points to note are:

• Fuel is bunkered directly into the tank from the Port or Sbd bunker station.

o Tanks are fitted with a drain to deck for clearing rain water, this should be sealed when bunkering.

o They are also fitted with a drain to tanks for overflow, this should be opened during bunkering.

• Overflow is passed back down to individual tanks via the air breathers. Tanks are fitted with backflow preventers each with a small hole to allow for overflow drainage in time.

• Fuel transfer manifold is in the Engine Room, Fwd Port bulkhead.

• Fuel transfer pump switch is on the Port pump switch panel, above the port engine controls.

• There is a spare fuel oil transfer pump in the aft locker Fwd of the aft cabin toilet.

• All fuel transfers pass through a high-capacity Cummins Fleetguard SeaPro commercial duplex fuel filter that cleans fuel to John Deere engine fuel system inlet specifications of 3 micron and checks for water contamination.

• Fuel cannot be transferred without passing through this filter. The filter is located at the engine room work bench.

• Fuel flow and return to each of two-day tanks is controlled by a two position 6-way valve by the fuel manifold. A simple 90-degree turn will change both supply and return flow.

• Webasto fuel heater and return are supplied via a fuel manifold at the same location as the Day Tank fuel valve – see also section on HVAC

Do not refuel while the engine is running!

Do not smoke during refuelling! The filling station is only suitable for gravity filling.

Not all of the fuel tank capacity should be used due to the trim and loading of the vessel. A 20% reserve should be kept.

Regularly check for fuel leakage, do not damage the fuel lines. Avoid contact of flammable materials with hot engine parts. Only operate the emergency fuel shut off in case of an emergency as this valve will shut off the engines.

VANGUARD is equipped with a duplex sea water suction filter. Each filter is sufficient to operate two engines and all ancillary systems. Filters are equipped with butterfly valves so they can be cleaned at sea, underway and without shutting down the engines.

• Sea water distribution system is illustrated in the first drawing above.

• Main engine sea water cooling system is illustrated in the second drawing above.

• All sea water is discharged via two overboard manifolds situated on the P & S side of the engine room. These manifolds remain above sea level and can be maintained at sea.

The seawater pump provides the external cooling system of each engine. The pump draws in water through the seawater intake (and water strainer). The water flows through the lines to the intercooler, engine oil cooler and heat exchanger.

Finally, the water is pumped into the exhaust pipe elbow, where it is mixed with the exhaust gases. After passing the water lock and gooseneck, the exhaust gasses and water will leave the ship above the waterline.

Before starting the engine, open the seacock seawater intake for the water supply to the engine (in the engine room, front side of the engine).

Caution!

• The VANGUARD is equipped a water-cooled exhaust. Always open the seacock seawater intake for water supply to the engine for a correct cooling of the exhaust system and the engine to prevent too high temperatures, which could lead to disastrous consequences.

• The water strainer should be inspected frequently and cleaned out when polluted.

• After starting the engine, you must control if there is water flowing out of the engine exhaust opening at the transom.

6.9 VENTILATION SYSTEMS

Cabins are provided with inlet and extraction ventillation according to the following schedule:

Location Level Description

Saloon Main Deck - Two 6” fans drawing air from under the flybridge FWD seating - One circulation fan at the Hel station.

Fwd Cabin Lower Deck

- Various automatic temperature control fans for Praxis Control cabinets.

- Inlet fan drawing air from under main helm station

- Two circulation fans

- One 4” extractor fan in the toilet

Mid Cabin Lower Deck - Inlet fan drawing air from the Stbd aft saloon.

- Two circulation fans - One 4” extractor fan in the toilet

Aft Cabin Lower Deck - Inlet fan drawing air from under the rear saloon access way.

- Two circulation fans - One 4” extractor fan in the toilet

Engine Room Cabin Lower Deck - Two forced draft extractor fans with fire damper. - Inlet through single passive opening with fire damper

Galley Main Deck - one galley extractor hood operated by pulling open.

Note – saloon air inlets are fitted with passive mist eliminators and located high in the structure protected from the weather.

Note – the cabins draw pre -onditioned air from the saloon. This faciltates more effective HVAC performance as the water is humidity is pre controlled by the saloon HVAC when active.

Ventilation fans are controlled via the MIMIC display, <LIGHTING / GEN LIGHTS> THIS MUST BE RESET IN THE EVENT OF A BLACKOUT.

6.9.1 GALLEY HOOD VENTILLATION

You can switch the galley extractor hood ON/OFF at the galley by pulling it OPEN/CLOSED. Kitchen hood exhausts on the Port Side roof of the saloon.

6.9.2 ENGINE ROOM VENTILLATION

• Engine room ventilation is controlled by two Delta T 11” axial forced draft extractor fans located in the aft engine room access.

• Air outlet is at the rear Engine Room access.

• Air inlet is via the Muster Station structure.

• Both inlet and outlet are fitted with 12” fire dampers actuated from the Muster Station Fire & Emergency Stop panel.

• Fans are controlled via the switch panel above the Stbd engine controls.

• One fan can be used to supply air to both engines. Use two fans to limit the local air temperature.

Note - Extractor fans are not effective when the rear engine room access is open.

Note – In the event of emergency, engines can operate without ER extractor fans. In this instance, the rear engine room access and engine room hatch should be open and monitored.

6.10 FRESH WATER SYSTEM

The freshwater system consists of 4 water tanks that act as storage but also ballast compensation to maintain trim and stability as fuel is consumed. Water is provided either from shore or via a Water maker located in the aft engine room, starboard side.

• Water is distributed through a manifold on the Fwd engine room bulkhead, Stbd side.

• A transfer pump is located under the manifold and operated from the pump switch panel in the same location. Transfer pumps can draw and deliver to any of the 4 tanks.

• Two Grundfos Scala pumps provide a constant water pressure. These pumps draw from the Aft Stbd or Port Tanks. Water pressure gauge is by the aft engine room access. These pumps are speed controlled for a constant delivery pressure and should not run dry. In the event they do then the Transfer pump can be used in creating a suction flow to assist in priming. The outlet should be vented via the aft shower or aft cabin bathroom to also assist.

Caution!

• Try not to let the freshwater tank run dry. If this happens you will have to transfer additional water to this tank and then prime the suction pumps.

• Check water filters on inlet and outlet of the water maker and under the galley sink and replace regularly as per the manual.

6.11 WATERMAKER SYSTEM

A 7L/m Delfin water maker is located at the aft engine room access. Water should not be produced within 3 NM of land and never in Marina. The Delfin water maker is situated in the Stbd Aft engine room by the steering gear.

• Replace pump oil after the first 50 thereafter 300 hours of operation 10W/40 oil.

• Chack and replace discharge filters and back flush filter at regular intervals as pe the operating manual.

Preparing the system

• Open the <SEA COCK> located between the engines by the sea water suction manifold.

• Open the water maker inlet valve on the freshwater manifold

• Open the tank that needs filling.

• The sea water overboard valve is permanently open.

Starting the water maker

• Start the <FEED PRESSURE> pump (approx. 4 bar) this will show that water is flowing through the equipment.

• Start the <OPERATING PRESSURE> pump. This will run for about 2 minutes to create the max 55 bar Osmotic Pressure before the unit will start making water.

• The salinity is monitored on the <SALINITY> meter and should remain between 200 to 500 ppm. A high salinity value is an indication of failure of the purification membrane.

• FW output flow should remain around 1.4GPM / 5.5l/min. If falling below, then replace the 5- and 25-micron water filters on the front of the unit.

Stopping the water maker

• Stop the <OPERATING PRESSURE> pump, Stop the <FEED PRESSURE> pump

• Start the <BACKFLUSH> pump. This will cycle automatically and then shut down.

• Close the inlet and FW tank manifold valves.

Caution!

• Do not use the water maker less than 3NM from land or in Marina’s.

• Check filters on inlet and outlet and replace regularly as per the manual.

• Cut operation if salinity rises above 600ppm when in operation.

A separate manual for the watermaker is provided with the boat. Please read this manual carefully.

6.12 GREY WATER SYSTEM

Grey water consists of sink, shower, washing machine and dishwasher water. Within the EU laws it is allowed to drain this water overboard. Although you should always check the local authority regulations against marine pollution and respect these as much as possible.

Grey water should be treated regularly (weekly) by adding biocide agent to each sink and shower drain. This will assist greatly in minimising odour and maintaining a healthy system.

Caution!

Do not discharge grey water in restricted areas of environmental sensitivity.

Check grey water tank levels before operating Washing Machine or Dishwasher.

Overflowing grey water tank will spill via the shower drains and trigger a bilge alarm.

Use mild cleaning detergents as not to damage the rubber parts in toilets and pumps

6.13 BLACK WATER SYSTEM

Toilet units on VANGUARD are macerator types. They will handle human waste and toilet tissue paper only.

DO NOT use toilets for discharge of any other materials such as cotton buds, wet wipes or sanitary towels. In case of blockage, those responsible will be unceremoniously keel hauled in front of their crying heirs and their remaining, possibly live carcass, deposited on the nearest uncharted rock, regardless of provisions or weather.

Additionally, toilets are fitted with a Bidet unit to minimize the use of toilet tissue as its availability is often in short supply. Please use it, even when in arctic waters. In pain you may seek redemption!

Black water should be treated regularly by adding biocide agent to each sink and shower drain. This will assist greatly in minimising odour and maintaining a healthy system.

The black water tanks should be cleaned on a regular basis by flushing water through the “waste” deck pump out suction fitting to prevent waste build up from blocking the lines.

Caution!

• Do not discharge the black water tank close to shore or in any prohibited zone.

• Use marina pump-out facilities to empty the holding tank when in harbor.

• Use mild cleaning detergents as not to damage the rubber parts in toilets and pumps

6.14 GLYCOL COOLING SYSTEM

VANGUARD is a diesel electric hybrid yacht. Her systems are designed to handle large amounts of power for storage or propulsion purposes. This 600VDC electrical power is handled by generators, batteries and inverters and each of these is temperature controlled from a single water/glycol cooling system.

• The storage tank is located between the engines. It is keel cooled against the flow of sea water underneath.

• Glycol flow is provided by one of two Grundfoss Scala pressure-controlled supply pumps located between the engines, Engine Room Aft.

• Flow is distributed through manifolds located at the pumps and on the forward Engine Room bulkhead.

• One pump is required to control operations above a power consumption of approximately 1,500W as displayed on the Victron Cerbo display on the Main Helm Station. It cools the Praxis inverter, HPI 4.

• Large Power Batteries control their own flow, HPI (Praxis Inverters) and Motor/Generator flow is controlled by selection of piping sizes.

6.15 PRAXIS HYBRID PROPULSION AND POWER MANAGEMENT SYSTEM

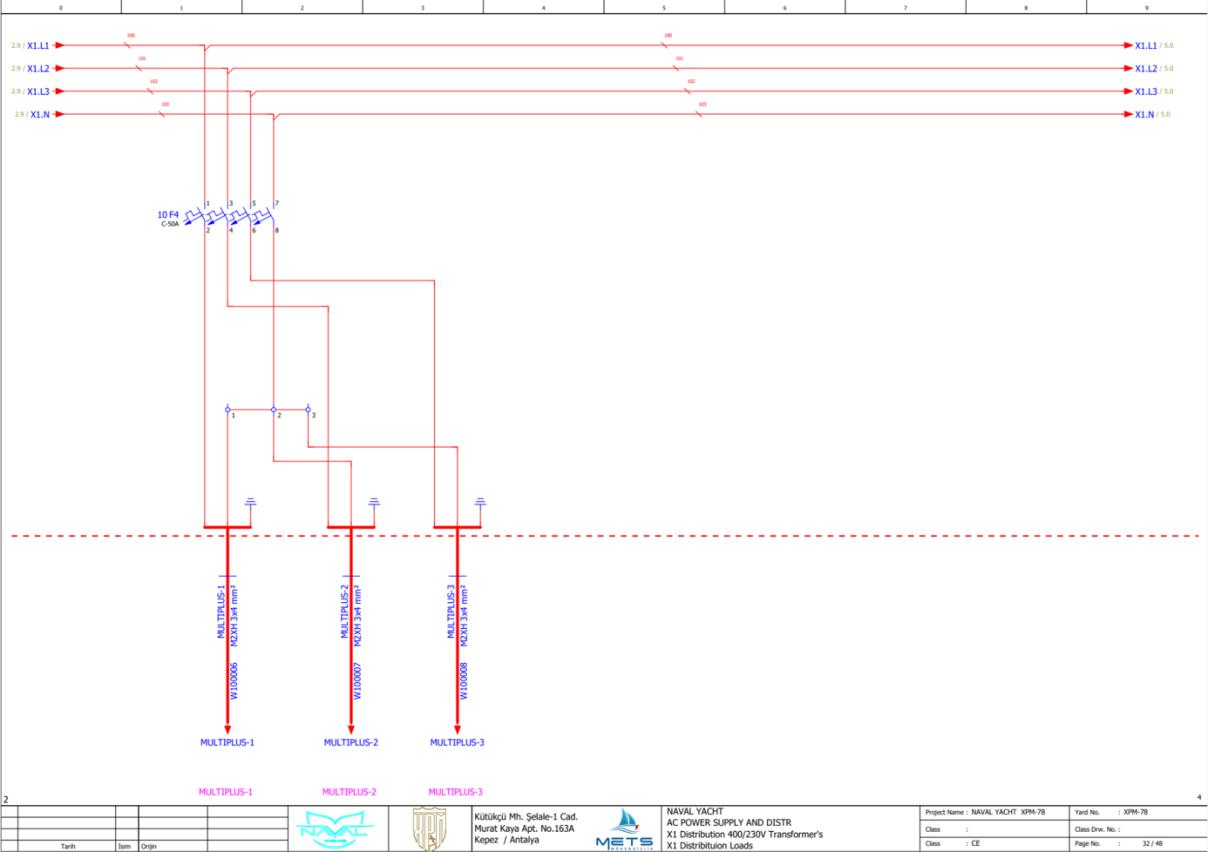

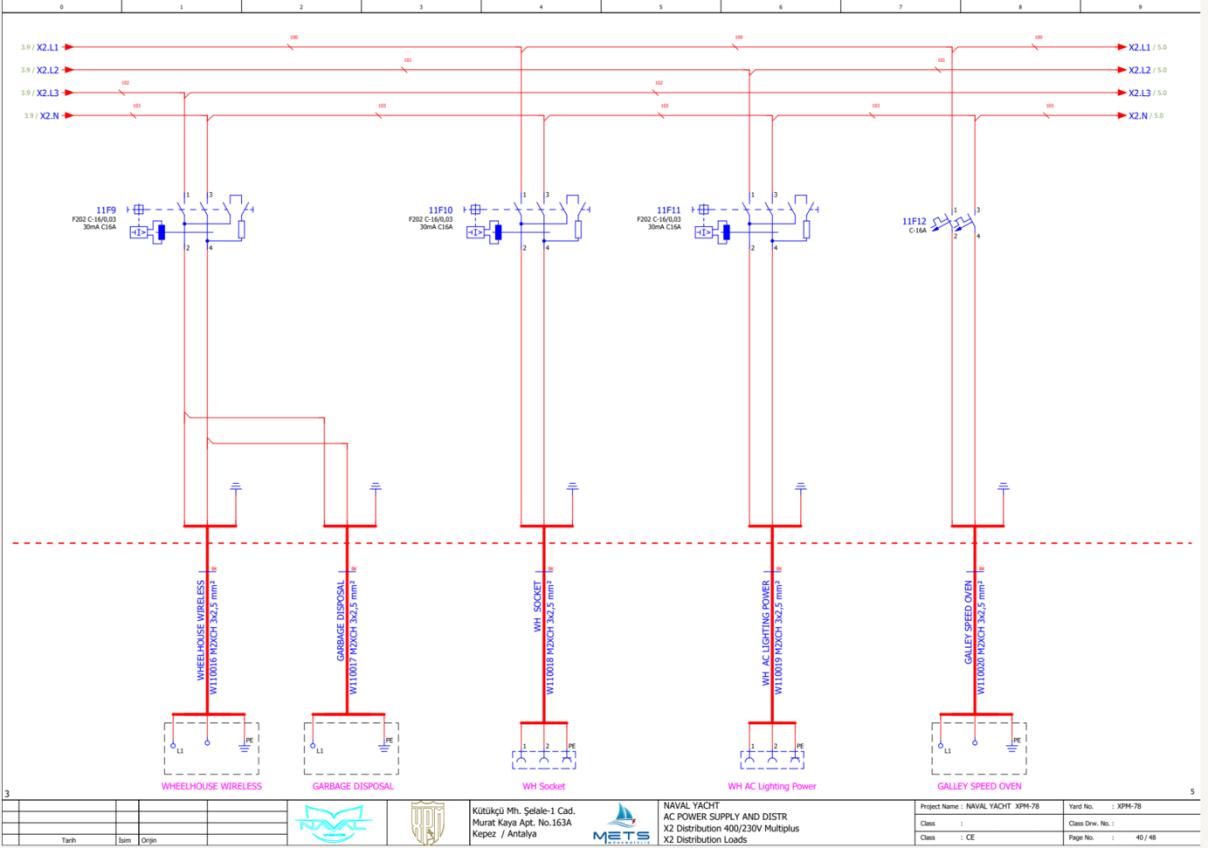

6.15.1 HYBRID ELECTRICAL SYSTEM

An overview of the electrical system is shown above. The system is based on commercial practice for parallel hybrid diesel electric operation. Key features are:

• Propulsion from duplicated parallel hybrid drive lines. 112kW Diesel propulsion, 30kw Electrical Propulsion and 36kW Generating capacity, duplicated.

• Power storage from 2 x 60kW.H 600VDC power batteries and 3 x 7kW.H 24VDC house batteries. All LiPO and monitored, house battery charging is restricted in software to 2kW each max to comply with the stipulations of MGN280.

• Shore power from 50 or 60Hz, three or single-phase giving total worldwide compatibility

• Solar from 6.5kW in stalled array producing 1.5-2.5kW weather and shade dependant

• 100% redundancy of all critical system.

• House electrical system via Victron integration with Cerbo Controller.

Warning:

• Disconnect shore-power connections when the system is not in use and unattendend.

• Use double insulated or grounded (earthed) electrical appliances.

• Do not obstruct PRAXIS POWER BATTERY ventilation ducts.

• Do not allow the shore-power cable end to hang in the water. An electrical field can be caused which can cause injury or death to nearby swimmer.

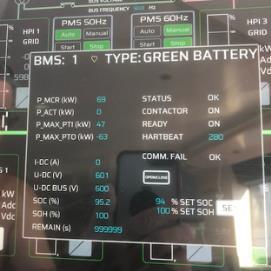

6.15.2 Connecting The Power Batteries

On the attached illustration, the EMS is showing a white line in the red circle indicating Power Batteries are NOT connected.

Power Batteries can be connected when the DC Bus Bar voltage is <50VDC. If DC Bus Bar is >50VDC you first have to drop this voltage to <50VDC before connection.

• Disconnect the three-phase shore power in the SHORE POWER CABINET. The voltage will slowly drop on the DC bus bar as energy dissipates.

• When voltage drops <50 VDC, open the pop-up window for the batteries by tapping on the battery image.

• The contactor will read <OFF> if the battery is not connected.

• Press the framed <OPEN/CLOSE> to connect the batteries.

• Repeat for both batteries. There is some delay in the operation as the batteries slowly come online.

• When connected it becomes green and, (the DC bus bar in the image shows 357 VDC)

• If PMS module of the screen is RED, Press the RESET button.

• Press the “Ready to Start”.

• Make sure the PMS module is in “Auto” mode.

6.15.3 Shore Power Connection

Single Phase - 120/240 VAC 50/60 Hz

• Single-phase shore-power is connected to Victron Skyle isolation transformers

• The Isolation Transformers are located Port side of the steering platform

• Output is delivered to the house batteries at 24VDC.

Shore power will handle 50 or 60Hz 120 – 240VAC even with reverse polarity! The Victron Skyla inverters also act as galvanic isolation transformers to protect the aluminium hull from electrolytic damage. Power is converted to 24VDC and dropped to the house batteries.

• Connect shore-power cable.

• Turn on both Victron Skyla inverter chargers located in the aft Port Engine Room

• Adjust the maximum charge current on the charge controller. VMS panel under the MIMIC screen in the Engine Room.

• charge current.

Shore power is connected to the Praxis 25KVA three-phase isolation transformers, midships on the steering platform. Shore power is controlled by 1 or 2 Praxis Power Management Systems (PMS) at the main helm station and repeated at the MIMIC displays on the helm and engine room. Voltages may dip due to local supply capacity. The system is automated.

240/480 VAC 60Hz

• This is USA & Canada and parts for South America plus Japan.

• Power is supplied to the 600VDC power batteries and isolated from all other ship systems.

• 390/415 VAC 50Hz (approx.)

• This is the ROW shore supply frequency and voltage.

• Power is supplied to the three phase bus bars, L1, L2, L3

Three Phase – 240 – 480VAC 50/60HZ

Connection of three-phase shore supply - Plug and play!

Three-phase is connected via the shore power sockets in the aft locker. One socket for 50Hz and one for 60Hz supplies. 50Hz is fed to VANGUARD’s mail three-phase distribution. 60Hz is converted to DC and used to charge the power batteries. The system uses 2 large 25KVA (20kW) isolation transformer to protect the aluminium hull.

• Connect shore power cable

• The Praxis Power Management system is located at the main helm, upper Port side, one for 50, one for 60Hz supplies. Occasionally the local phase rotation will be opposite to that of VANGUARD. This will set an alarm on the PMS and prevent closure of the breaker. Use the short shore power bobbin piece to reverse the phase and allow full connection.

• Set the maximum shore power current at the EMS on the main helm. Typically, this is 46Amps

• One single line MIMIC, set the shore power to “Automatic”.

• Prime the shore power breaker and press “Connect” shore power will now be connected to the ships systems via the AC Bus Bars in Cabinet X2.

• The single line MIMIC will show “GRID” in blue, this can be changed to “CHARGE” in green if there is need to charge the power batteries from shore and sufficient capacity available.

NOTE:

Shore power consumption is available on the Victron Cerbo display at the main helm station. This will show the draw on each phase L1, L2, L3 and DC 24V system plus the input from Solar and Shore Power (or Power Batteries). It is convinient information allowing adjustment to HVAC, lighting and parasitic loads in order to minimise power consumption on VANGUARD.

• The minimum is typically around 1.4kW with all system usage minimised, lights out in unoccupied rooms, utilities off, natural ventilation.

• A maximum experienced 10kW running HVAC, lighting, charging house batteries and operating utilities. Power availability is large but not infinite!

Low Voltage Dropout

The PMS can be set to <MANUAL> to prevent drop out under fluctuating shore voltages. (Hard stop is 340VAC) On the EMS Single Line Diagram, set the HPI (1 & 2) to <MANUAL>

Switching Shore Power off when set up to resist Low Voltage Dropout

• In the Shore Power Cabinet, trigger the shore power breaker by pressing the <RESET> button

• On the VMS Cabinet in the engine room, EMS, Single Line diagram: Change <MANUAL> to <AUTO> on HPI-1 and HPI-3, Change <CHARGE> to <GRID>

• Press the hard <RESET> button for both PMS(1 & 2)

• This will connect the Power Batteries to the HPI and energise the AC Bus bars in Cabinet X2

• Proceed as normal independent of shore power.

6.15.4 Electrical Earth Detection System

Vanguard vis an aluminium hull yacht. Aluminium is susceptible to galvanic corrosion a result of either a shore power fault or an internal earth leakage. Earth leakage on Shore power on single and three phase connection is protected by Isolation Transformers. To protect from stray current circulation within the systems themselves (Earths), Vanguard is fitted with a detection system designed to monitor earth faults on:

• 24VDC bus bars, both lines

• Port engine and drive, both lines

• Stbd engine and drive, both lines

The earth detection system is situated above the port engine, aft of the pump control panel.

• Each detection circuit is labelled.

• Press <LAMP TEST> on each of the 4 systems to check it is in operation.

• Press <TEST> on each system and observe that the two circuit lamps are lit and of equal intensity. If they are not, then there is an earth present on that particular system.

Analysing an earth leak is a complex task and will require the support of a competent electrical technician. There is no immediate danger, but it will need correction.

6.15.6 Praxis Integrated Power & Energy Management System. This is the heart of VANGUARD. It provides for monitoring, navigation and control functions throughout the vessel. Control is limited to a few discrete items such as steering, engines and navigation lights. For control of pumps and systems, it will be necessary to visit the Engine Room as appropriate.

The basic system is as illustrated below. Workstations or MIMIC diagrams are presented on the Flybridge, main Helm and engine Room. Controllers or PLC are located at the Main Helm and Engine Room. Communication uses a fully redundant Ethernet backbone. System operating computers are located at each of two navigation screens on the main helm and again provide redundancy.

The Navigation uses Time Zero Professional V4 which also displays instrument data and Radar as required. Engineering data is reported on the third helm screen as well as the flybridge and engine room.

See other sections within this manual for specific operating instructions. Information is also available within the maintenance system specific to individual tasks that may be required from time to time. The operator is encouraged to use the screens and better understand just what is available and its function.

6.16 HVAC AIR CONDITIONING SYSTEM

HVAC uses the Webasto Blue Cool system for cooling and heating. The chiller unit is located Stbd side of the Engine room, the system can also be shut down locally from this location.

Cooling water is drawn from the sea suction filters with its own dedicated pump. Chiller coolant is glycol based with its own circulation pump and accumulator. Maintain a circulation pressure above 1 bar. The pressure can be occasionally topped up with fresh water using the hose adapters provided.

Heating is provided by two Webasto diesel heaters located by the aft engine room access. Fuel supply and return comes from the fuel manifold on the Fwd Port engine room bulkhead. These heaters act to heat the circulating glycol fluid when then passes to the various air handlers.

• Air is drawn from under the flybridge seating.

• Air enters the salon at the helm station.

• Two air handlers’ condition for temperature and humidity. These air handlers are located Port side behind the seating, Stbd Side behind the galley storage.

• Air is drawn from the salon into each of three cabins. Each cabin has its own air handler and controls.

Additionally, the system can be controlled remotely using the Webasto Blue Cool App on a smartphone.

NOTE: the HVAC can draw up to 5kW. Close blinds and cabin doors when in use to minimize energy consumption. Shut down system in unused spaces and where possible in the saloon during the day. To preserve batteries, always use natural ventilation in preference to HVAC. Shut the system off when in temperate climates.

6.17 ANCHORING SYSTEM

The main anchor for VANGUARD is a 110kg Rocna anchor. This is oversized for the application with typically recommends 60-70kG for a 24m vessel.

This anchor is fitted with a Mantus anchor swivel and 100m of 14mm Galvanized G40 chain. Chain is color coded as per the table below. The bitter end is tied to a cross beam within the forepeak and provided with a local knife if release is necessary.

COLOR Scope Application

Red 20m - Just about got the anchor wet.

Yellow 30m - Day anchoring most anchorages up to 5m depth

Blue 40m - Day anchoring most anchorages up to 10m dept

White 50m - Day anchoring most anchorages up to 15m dept

Green 60m - Overnight anchoring up to 10m depth

Uncoded 70-100m - Storm anchoring, consider also shorelines and kedge anchor

The anchor is worked by a Maxwell combined anchor windlass and capstan It also has an anchor chain stop and break.

The capstan can be disengaged from the windlass using the rotary clutch on the top. Once disengaged it can be used for warping lines with the windless drum being level with the hull edge for entry at the drum base.

The foredeck is arranged with a forward well that drains through the tow fairlead. This minimizes sludge and mud buildup when anchoring in glacial fields or estuaries.

To prevent difficult in stowing the anchor, it is fitted with a heavy-duty anchor swivel from Mantus.

Opinion is divided about anchor swivels. They represent a point of failure and for most cases are unnecessary. However, the anchor entry on VANGUARD is to the side and the anchor must stow in a single position. Having a swivel greatly eases this process.

The chain is also retained when underway using Mantus anchor hook that can be hooked in at the swivel.

A kedging anchor is also fitted, 35kg Fortress anchor. It is located on the foredeck. 10m of 10mm G40 galvanized chain, suitable shackles and 100 feet of rode for this anchor are stored in the forepeak.

It can be removed by undoing eh 4 retaining bolts and reassembling. It is light enough to be easily carried for deployment in the tender.

There are also two by 100m Dynema shore reels located on the aft deck, Sbd Side. 4000 kg working load. These are provided as Shorefast lines. They should be demounted for use and secured ashore protected from abrasion.

To avoid personal injuries, ensure that limbs, fingers and clothing are kept clear of the anchor rode and windlass during operation. Always ensure that there are no swimmers or divers nearby when dropping your anchor.

A separate manual for the anchor windlass is provided with the yacht. Please read this manual carefully.

6.18 MOORING AND TOWING

At several locations on deck strong points are fitted for anchoring, mooring and towing

Strong point

Hull Lifting cleat

Mooring cleat Fwd

Mooring cleat Aft

Sampson post / Sea Anchor point

Description Size

Description

Strong point through hull location and tow rope anchor

Fitted with bow fairlead for towing/sea anchor

Mooring Lines 6 x 10m x 20mm - Black braided polypropylene -

Storm Lines 6 x 10m x 25mm - Yellow multistrand

Tow / Kedge

Anchor Line 1 x 30m x 25mm - Orange multistrand

Main Anchor 110kg - Rocna, galvanised

Kedge Anchor 31kg - Fortress aluminium

Sea Anchor Custom - Retrievable sea anchor for bow or stern deployment. Needs Dynema retrieval line.

Shorefast 100m - Dynema flat ribbon

Mooring cleats are provided on VANGUARD forward, amidships and aft. Always use the mooring lines provided on board and double up all lines when leaving VANGUARD moored and un-attended. Always check regularly for wear of the mooring lines at the fairleads and mooring ports. Do not use worn, frayed or dirty mooring lines.

VANGUARD can be towed by securing a towline to the Sampson Post sited on the foredeck centerline Fwd of the capstan and/or via a bridle to the two lifting Cleats on the Fwd Quarters When securing to a swinging mooring, a bridle set-up like the towing method allows the anchor to remain in the bow roller.

Warning:

• The owner is responsible for using adequate mooring lines, towing lines and anchor chain and lines.

• The breaking strength of the lines used shall not be more than 80% of the breaking strength of the associated strong point.

• The crew needs to familiarize themselves with attaching the towing line.

• Towing and being towed is done at low speeds e.g. 5 knots.When attaching the towline prevent using knots that can’t be undone under load.

www.Exploreryacht.com for the journey. Page 53 of

6.19 WINDLASS AND WINCHES

Kedging winches

VANGUARD is fitted with two large Maxwell kedging winches on the aft deck. These are used for stern anchoring and mooring, especially in the Mediterranean.

• Breakers for two MAXWELL docking winches are in the engine room, above the workshop bench. They should be engaged before docking.

• Operation of each winch is via the small deck button adjacent to the winch. It provides for <CLOCKWISE ROTATION> only.

• Winches are torque limited and will only turn clockwise.

• Use 4 or more turns of the dock line for optimum grip.

Windlass

• Breaker for the MAXWELL windlass and capstan are in the forepeak. This should be engaged before anchoring or docking.

• The windlass should not be used to break out a stuck anchor. Instead, bring the chain vertical by moving slow ahead and use the momentum of the boat for that purpose.

• Muddy chain should be washed as it comes on board.

• The windlass is fitted with a manual ring break that should be engaged at sea and released for operation.

• Windlass can be controlled locally using the <HAND/AUTO> switch on the breaker box. Then control with the <UP/DOWN> switch.

• Windlass in <AUTO> can be controlled externally with the <HAND CONTROL>, and extension cable kept in the forepeak

• Windlass in <AUTO> can be controlled from Main Helm station (NOT Flybridge) using the UP/DOWN controls

Capstan (Warping Drum)

• The capstan is on top of the windlass.

• First, engage the anchor chain <PAWL> and <BAND BREAK> to secure the anchor chain.

• Disengage the <CLUTCH> using the release bar stored in the forepeak.

• Capstan will operate independently of the Windlass using the same controls.

Caution

• Windlass, Winches and Capstan are powerful devices. Keep fingers and toes well out of the way and use good seamanship practices at all times.

• Do not let children near to these devices if powered up.

6.20 DRYING OUT AND TRAVEL LIFT

VANGUARD has a long flat and substantial keel assisted by two equally robust skegs forward of the propellers. The rudders terminate above the lower edge of the skegs. She is designed to take the ground either to careen alongside a quay wall or pile or in emergency situations. The normal precautions must be observed when grounding:

1. The quay or piles are strong enough to take the weight.

2. The ground under the keel is firm.

3. Substantial fendering placed against the wall or piles.

4. Only take the ground in calm conditions.

VANGUARD can also be lifted by a Travel lift (at least 65-ton capacity) sling type arrangement or by crane and slings.

The flat keel on VANGUARD extends from the Forepeak aft bulkhead to the forward saft end of the propeller skegs. The longitudinal center of gravity is approximately midships.

7 SAFETY, COMMS AND NAVIGATION

7.1 FIREFIGHTING SYSTEM

7.1.1 PORTABLE FIRE EXTINGUISHERS AND EQUIPEMENT

The portable fire extinguishers and additional fire fighting equipment is fitted in accordance with the requirements of UK MGN 280. Additionally, all internal soft furnishings are treated with EMAFLON Fire retardant in accordance with MGN 580(M), Yachts <50m.

For using the portable fire extinguisher, remember The "PASS"-word: Keep your back to an unobstructed exit and stand about 2 metres away from the fire. Follow the four-step PASS procedure:

Pull the pin: This unlocks the operating lever and allows you to discharge the extinguisher. Some extinguishers may have other level-release mechanisms.

Aim low: Point the extinguisher nozzle (or hose) at the base of the fire.

Squeese the lever about the handle: This discharges the extinguishing agent. Releasing the lever will stop the discharge. (Some extinguishers have a button instead of a lever.

Sweep from side to side: Moving carefully toward the fire, keep the extinguisher aimed at the base of the fire and sweep back and forth until the flames appear to be out. Watch the fire area. If the fire reignites, repeat the process.

You should also know that portable fire extinguishers are valuable for immediate use on small fires. They contain a limited amount of extinguishing material and need to be used properly so that this material is not wasted.

7.1.2

FIRE DETECTION, ALARM EQUIPMENT AND SMOKE ALARMS

The addressable Praxis Mega-Guard Fire Alarm System (AFAS) monitors 2 different loops on VANGUARD in compliance with EN54-2. The fire detection sensors of each loop are connected in a loop and the wiring is connected to the Mega-Guard Fire Alarm System at the Main Helm station

The Fire Alarm System is equipped with a 5.7” Touchscreen Operator Panel at the Main Helm Station to display detailed fire alarm messages.

• Smoke detectors are fitted to: Forepeak, Fwd Cabin, Main Cabin, Aft Cabin, Saloon.

• IR detectors are fitted in the Engine Room

• Additionally, a manual fire alarm call point is also fitted in the engine room, forward bulkhead.

The Mega-Guard FAS is connected to the main supply and to the back-up supply for automatic change over in case of failure of supply voltage. The Mega-Guard FAS is built-up from 5.7” Touchscreen AFAS Operator Panel

7.1.3 Fire & Smoke Alarm Test

• Remove roof-mounted fire detector in Saloon (aft by VHF Radio)

• Alarm will sound and then repeaters.

• Replace detector into its holder

• Cancel fire alarm at Fire System Panel Helm. (This may take a few attempts)

Fire detection and smoke alarms

• Fire detection and alarm equipment shall be maintained in accordance with the manufacturer’s instructions or as indicated on the equipment.

• Smoke alarms shall be tested as part of the boarding routine and weekly if aboard for an extended eriod. In the event testing a smoke alarm indicates the alarm is faulty, replace the smoke alarm with one of an equivalent type.

7.1.4 SAFETY WARNINGS

Servicing of fire-fighting equipment

• Have fire-fighting equipment checked at the intervals indicated on the equipment,

• replace portable fire extinguishers, if expired or discharged, by devices of identical firefighting capacity,

• have fixed systems refilled or replaced when expired or discharged, have a maintenance schedule available for fixed systems (if fitted).

Responsibility of boat owners/operators when the craft is occupied

• Ensure that fire-fighting equipment is in serviceable condition and readily accessible;

• unlock any deck hatches, or any other locked escape openings;

• unlock any locked storage containing any folding or deployable device used to aid escape through a fire exit;

• inform craft occupants about:

1) the location and operation of fire-fighting equipment, 2) the location of any fire port discharge openings into the engine compartment, 3) the location of escape routes and fire exits and to plan action in the event of fire.

Cautionary notices to the craft operator

• Keep the bilges clean and check for fuel and gas vapours or fuel leaks at regular intervals and before starting the engine.

• When replacing parts of the fire-fighting installation only matching components shall be used, bearing the same designation or being equivalent in their technical and fire resistant capabilities.

• Do not install free hanging curtains or other fabrics in the vicinity of or above open flame appliances,radiant heat devices or electrical heating and cooking elements.

• Do not stow combustible material in the engine compartment. If non-combustible materials are stowed in the engine compartment they shall be secured against falling into machinery and shall cause no obstruction to access in or from the space.

Cautionary notices to the craft operator - Specific warnings , NEVER:

• obstruct passageways to fire exits and hatches;

• obstruct access to safety controls, e.g. fuel shut-off valves, gas shut-off valves, isolation switches of the electrical system or fire ports;

• deliberately or inadvertently block ventilation for compartments or spaces, particularly those containing fixed petrol engines, fixed petrol tanks and batteries;

• obstruct access to portable fire extinguishers or fire ports;

• leave the craft unattended when cooking and/or heating appliances are in use unless the appliance is designed to operate unattended;

• modify any of the craft’s systems unless competent to do so;

• smoke while handling fuel or gas;

• store petrol containers or equipment containing petrol in any area not designated for the specific storage of petrol.

7.1.5 MEANS OF FIRE ESCAPE

The following hatches, doors and other openings are intended to be a means of escape from the interior in case of a fire:

Location Level

Engine room Aft

Fwd

Mid

Aft Cabin Cabin

Main Cabin Cabin

Fwd Cabin Cabin

Saloon Main Deck

Main Deck

Description

Aft access to swim platform

Fwd access from aft Cabin

Hatch on Stbd deckhead

Hatch to deck

Hatch to saloon

Hatch for fore deck

Rear access

Pantograph door, Port side

7.2 MAN OVERBOARD PREVENTION & MEANS OF REBOARDING

In the event of MOB incident, the following equipment is available to make an effective water recovery of concious or unconcious persons:

• MOB Sling on aft rail, Stbd side and Life Rings behind the Muster Station.

• Swim ladder on swim platform

• Derrick (1500kg) on Aft Deck, Port Side

When people fall over board they can reboard by using the folding down swim ladder fitted at the Swim Platform.

Warning: Stop the engine during use of the swimming ladder. The propeller can cause injury to nearby swimmers.

7.3 TENDER - LAUNCH AND RETRIEVAL

VANGUARD is equipped with a 5.0m Highfield RIB itself fitted with a 100hp Yamaha outboard motor. The tender is stowed on the aft deck. It is launched and retrieved using a 1500 SWL derrick from FEM equipped with a two way Harken winch. The winch can be operated electrically or manually.

Launching the tender is a 2-crew operation. One crew working the winch and the other the securing lines allowing the tender to be swung outboard and back inboard to the deck chocks.

Launching the tender

• Stop VANGUARD in calm weather and allow her to come to rest.

• Remove the Port aft railing bar clipping the lines Fwd and Aft using the attached pelican clips. Remove the aft deck Port rail and stow on deck.

• Release the derrick line and flake for use.

• Ensure the spreader bar is properly attached to four lifting lugs and at the derrick

• Release the four retaining cargo straps that hold the tender to the chocks.

• Install the transom drain plug.

The tender is now ready to lift.

• Move all additional personal to the Stbd side of VANGUARD and forewarn them there will be an approximately 5-degree Port list until; the tender is in the water.

• Raise the tender to the maximum lift. Swing the stern out and over the side allowing eh bow to rotate aft facing the opposite way to the hull of VANGUARD.

• Using line friction, release the tender line until it is floating under her own buoyancy. Vanguard will return to a level trim

• Attach bow and stern lines to VANGUARD.

• One crew member (with Life Jacket) can drop down in to the tender, turn on battery, attach kill cord, lower and start engine, turn on VHF and MFD Nav system.

• After the engine is running, release the spreader retaining cleats.

The tender is now ready for use.

• Replace Port aft railing and re-attach lines.

7.4 NAVIGATION AND WORK LIGHTS

All work and Navigation lights are single bulb LED units with MTBF of > 50,000 hours. For this reason, lights are not duplicated.

You can switch the navigation lights ON/OFF at MIMIC displays on each Helm Station. Additionally, the lights can be switched manually using small contacts on the Praxis Nav Light PLC, Stbd Helm station cabinet.

The following lighting groups can be switched automatically:

• UNDERWAY / STEAMING

• ANCHOR (in conjunction with NUC can signal AGROUND under Rule 30)

• NUC (NOT UNDER CONTROL)

• Additionally, night lights (RED) and Cabin air supply are controlled on the MIMIC. RED lights are for use at night when navigating. They are at the HELM, GALLEY and AFT CABIN HEAD.

• DECK or working lights are controlled individually on the saloon light touch panel.

7.5 NAVIGATION & AUDIO VISUAL EQUIPMENT

Navigation equipment is based upon the Furuno range and includes the following:

Equipment

AIS (A)

Navtex

Fluxgate Compass

Satellite Compass

Multibeam Sonar

Model No

Description

FA170 1 Type A commercial

NX700B 1 Navigation updates

PG-700 1 Position GPS

SCX-21 1 Position GPS, trim, roll, turn

DFF-3B 1 Benthic topography inc. depth

Depth Transducer B54 1 Depth

Weather Station

WX-220 1 Temp, humidity, pressure

Airmar DST810 1 Speed, depth, temp

X Band Radar

DRS6A 2 Doppler

MFD (Praxis) Praxis 3 Running Time Zero Professional

Navpilot 711C 2 Autopilot

All instruments are networked using NMEA0183 and NMEA2000 CAN. All input can be displayed on MFD and repeater instruments at the main helm and flybridge.

7.6 COMMUNICATION EQUIPMENT

Equipment Model No Description

Felcom Sat C 1

YB3i Tracker 19SASS 1

Emergency transponder (helm & master cabin)

Emergency tracker

Max BR1 Router 1 WIFI coms, connected to Starlink

Starlink Marine WIFI 1 Sat Coms

Irridium Satcom 1 Sailor 4300 installed but not used in favor of Starlink.

ICom VHF M510E 2+1 Fixed – 2 aerials on Flybridge roof

ICom VHF M94D 2 Handheld

ICom VHF M37 4 Handheld

• Communications are focused mainly on VHF (both fixed and handheld) and Starlink. Felcom and Yellowbrick remain as emergency response systems.

• Irridium is installed but not presently connected in favor of Starlink

• Starlink has “Mobile Roaming” access providing Worldwide connectivity. The Starlink router is linked via WIFI to the main Pepwave Router. The Pepwave signal is boosted by 6 WIFI hotspots scattered throughout VANGUARD. Control of priority for Comms is achieved via Peplink software. It is possible to connect the WIFI to a SIM card local access via this same system.

• Pepwave Router is also linked by Cat 6 cable (white) to the Praxis System allowing for remote access by Praxis. There is also a local access via another Cat 6 data cable (yellow) used by Praxis when on board. These should not be removed.

Network Account/Pass No Description

Public use WIFI with 6 access points

Direct connection to Starlink Router

Maintenance of Pepwave/Peplink

Sat Coms, linked to Pepwave for general WIFI Vanguard Control 4 chris@exploreryacht.com Vanguard2023 1 Control 4 Automation for audio visual, lighting and blinds

7.7 LIFERAFT STOWAGE

VANGUARD is equipped with two SOLAS approved liferafts.

They can be accessed from the flybridge and will automatically inflate when released. In the event of foundering, they are also fitted with an automativc hydrostatic release.

Servicing of life raft: SOLAS approved life rafts are a survey inspection item and are serviced yearly as indicated on the service record label.

7.8 DECK CRANE OPERATIONS

VANGUARD is fitted with a custom folding derrick for tender and stores operations. (See also 8.3 – Tender Launch and Retrieval)

• The derrick is fitted in a PTFE lined socket on the Port /Aft deck.

• SWL 1,500 kg, tested to 2,500kg

• Electric 24VDC Harken 2-way winch with manual override and winch line break

• Rotational slewing is manual.

• Spreader bar for tender operations and hook swivel

The boom can be folded when not in use by removing the rear S/S pintle and manually lowering. In practice it is generally left attached to the tender ready for lifting.

The maximum Safe Working Load (SWL) of the deck crane is 1,500kg. The crane should not loaded with a higher load.

Make sure that personal DO NOT stand under the payload during operation

7.9 SECURING OF LOOSE EQUIPMENT

To avoid personal injuries always secure loose equipment safely. Make sure that equipment close to machineries shall be secured against falling into machinery. Materials are available in the rigging locker for securing equipment that may move in a seaway.

Loose equipment shall cause no obstruction to escape exits.

7.10 IN HULL PORTS & HELM WINDOWS

Window openings in the hull below the weather deck are triple laminated toughened glass to ISO11336-1 fitted so as not to protrude beyond the hull surface. Windows are symmetrical Port and Stbd and provided with one blank per pair in the event of rupture. Blanks are stored in the cabins; blanking bolts are stored in the muster station.

Make sure that the helmsman has all round visibility at all times. The field of vision from the main helm is 180 degrees FWD from Port to Stbd side. Windows in this location are in Area 2 and untinted triple laminated toughened glass. Window strength is calculated according to ISO11336-1 as >1.5 times the equivalent strength as 5mm 5000 series marine grade alumninium sheet and on that basis no blanks are required in this location for operation at sea.

Note: penetrations below the weatherdeck are provided with window boards in the event of failure. One board is provided for every window pair (P&S). One bolt is fitted every two holes. Bolts are located in the muster station cabinet. Boards are located in the cabins, under the bunks.

Note: the main helm pantograph door is provided with a wash board for use when open at sea. The. Was board is stored under the adjacent seating. Bolts are kept screwed in to their respective threads on the door frame.

The Operator’s vision from the helm can be obstructed by high trim angles of the yacht and other factors caused by one or more of the following variable conditions:

• Speed & Sea conditions.

• Rain and spray – Note: the forward main helm is fitted with a wiper operated from the helm.

• Interior lights – Note: all instruments in this location can be dimmed for operation at night.

• Persons or movable gear in the operator’s field of vision.

The international Regulations for Preventing Collisions at Sea (COLREG) require that a proper lookout be maintained at all times and observance of right of way.

Warning:

• Do not sail at full speed in adverse weather conditions like; limited visibility, high winds or high waves.

• Make sure to have sufficient distance to other vessels to be able to stop or change course in order to prevent collisions.

• Spray and rainwater limit visibility form the helm position, as can dawn, dusk or mist.

• The international rules for prevention collisions at sea (COLREG) and good seamanship require you to maintain a good lookout in all circumstances. Be sure there are no other vessels in your way before you proceed.

7.11 HULL CONSTRUCTION

The construction of VANGUARD consists of a hull of 5000 series marine grade aluminium. She is designed as an explorer yacht to work in remote locations. As such both the scantlings and hull thickness are considerably greater than required by Small Yacht Code <24m requirements.

• Hull thickness below the weather deck is 12mm

• Stem, keel and skegs are 25mm, Deck at the weather deck is 8mm, Hull Stringers are 100mm depth.

• The hull is designed to sit upright when dry by means of two substantial skegs fitted at the stern and supporting the propeller shafts.

• Rudders will remain clear of the floor when in this position.

• Rudders are also provided with a lower 1/3 that can crush and a pintle being 100% increase on Code requirements.

• The lower hull is a double bottom structure meaning that rupture in this location will result in loss of a tank but will not result in flooding to any compartment. The two exceptions ae the forepeak and engine room outside of the Glycol storage tanks.

• The hull is fitted with a crash zone in the forward 1m and 3 further watertight compartments up to the weather deck

It is the responsibility of the owner for ensuring that the normal mode of operation is maintained. This will mean that the speed of the yacht will need to be matched to the prevailing sea state.

8 ENVIRONMENTAL CONSIDERATIONS

Be aware of local environment laws and respect codes of good practice.

8.1 FUEL AND OIL SPILLAGE

In all cases avoid spilling fuel and oil in the open water.

When refuelling, watch the level meter, slow down when reaching the end and make sure you have absorbing materials, like cloth, nearby.