FOOD PACKAGING MARKET CONTINUES TO BROADEN WAYS

Packaging ensures easy identification of a product. The most important function of packaging is to ensure protection of a product from spoilage, leakage, breakage etc It also ensures effective protection during storage and transportation of a product. Packaging acts as an important promotional tool The attractive color scheme or photograph used in packing helps in attracting the attention of the people and inducing them to purchase the product. Therefore, it plays the role of silent salesman

Simply stated, packaging maintains the benefits of food processing after the process is complete, enabling foods to travel safely for long distances from their point of origin and still be wholesome at the time of consumption However, packaging technology must balance food protection with other issues, including energy and material costs, heightened social and environmental consciousness, and strict regulations on pollutants and disposal of municipal solid waste.

A package is the face of a product and often is the only product exposure consumers experience prior to purchase Consequently, distinctive or innovative packaging can boost sales in a competitive environment Next, the most used materials in the food industry are detailed: plastics, glass, metals and wood and its derivatives

Due to a lower cost and lower energy consumption during manufacturing, plastics have replaced traditional packaging materials In addition, they are able to preserve and protect the food for longer, minimizing the use of preservatives. Tin cans are made of steel sheet coated with tin as a measure of protection against corrosion of steel, especially when they contain products with low pH. Aluminum is increasingly used for canning due to its lightness, low cost and capacity to be recycled Glass uses one of the most abundant raw materials on the planet, silica, but it is not renewable. Despite this, it is a recyclable product, since it can be used as a container repeatedly More than 75 billion glass containers are used per year in the food industry, being its main use for wines, juices, baby food and soft drinks

Products derived from wood are widely used in the packaging of food in the form of paper and cardboard Paper is a very cheap, lightweight product with excellent printing capacity. Although it is very sensitive to moisture, it can be corrected with a combination of paper and other materials such as plastic or paraffin

Cardboard is a material made up of several superimposed layers of paper, making it thicker, harder and more resistant than paper Its main use is for packaging and containers in the form of boxes

The evolution of packaging techniques, together with those of food preservation, transform the processes of manufacturing, distribution, purchase and preparation of food, for both businesses and consumers. Technological advances, such as the incorporation of antioxidants in food packaging, increase the shelf life of food This system is based on the addition of particles to the packaging materials to prevent the oxidation of nutrients. In this case, the antioxidants can be incorporated during the manufacturing process or impregnate the walls of the container before coming into direct contact with the food.

In short, it is important to choose the appropriate packing and container material for each food to be conserved, taking into account the transport circumstances and storage conditions to which it is going to be subjected.

Based on type, the market has been segmented as flexible packaging, paper & paperboard packaging, rigid plastic packaging, glass packaging, metal packaging and others. Currently, flexible packaging dominates the market holding the largest share

The global food packaging market size is expected to reach USD 411 3 billion by 2025, according to a new report by Grand View Research, Inc., registering a CAGR of 5.1% during the forecast period Rising demand for convenience foodstuff owing to lifestyle changes and altering eating habits is anticipated propel the growth of the global market.

Flexible packaging is expected to register the highest CAGR of 5 9% in terms of revenue from 2023 to 2025, owing to its cost-effectiveness, high performance, and constant innovations undertaken by major manufacturers

The market in Asia Pacific is expected to reach a value of USD 166 7 billion by 2025 on account of growing population, increasing urbanization, and rising disposable income of consumers

The publisher does not necessarily agree with the views expressed by contributors nor do they accept any responsibility for any errors The publisher reserves the right to accept or reject any advertising or editorial material Acceptance of any ad does not imply endorsement from the publisher All rights reserved The publisher assumes no responsibility for materials submitted Letters to the editor are welcome and will be considered for publishing in whole or in part

Esko launches software and hardware products

Esko showcases innovations that help label converters and brands produce more at a faster pace while maintaining optimal quality These advancements include cloud technology, estimating software and inline inspection hardware

‘Representing a significant advancement in software architecture, the new Esko S2 platform is a multi-tenant cloud-native platform that delivers on a new technological reality based on cloud computing, data sharing and artificial intelligence,’ said Jan De Roeck, Esko director of marketing, industry relations & strategy.

‘All strategic Esko applications from ArtPro+, ArtiosCAD and the award-winning Phoenix through to Cape Pack and Automation Engine connect to the new platform, giving all stakeholders in the value chain 24/7 real-time access to live data and identical resources, wherever in the world they reside Moreover, Esko S2 is an open platform supporting connectivity with partners.’

As well as introducing Labelexpo visitors to its newest software platform, Esko demonstrates its latest hardware innovations, with its AVT varnish inspection equipment featuring at the heart of booth 335.

Heidelberg and Gallus announce new matte finishing technology

Gallus, a subsidiary of Heidelberg, has worked on a new matte finishing technology for digital inkjet, Gallus MatteJet

t e c h n o l o g y .

According to the company, this advancement in inkjet printing opens the possibilities of inkjet technology to the wine label market for the very first time.

MatteJet was developed in-house at Gallus’ innovation hub in St Gallen, the Gallus Experience Center

At Labelexpo Americas 2024, Gallus is exhibiting alongside Heidelberg, where it explains how this technology addresses one of the key challenges that has historically restricted the growth of digital inkjet technology Importantly, visitors at the show also learn how MatteJet can transform the market segment for wine and spirit labels and provide converters with a new area of business growth. The glossy finish inherent to digital inkjet technology has been one of the foremost barriers to its widespread adoption across labels and packaging – specifically in premium segments such as wine and spirit labels where brands traditionally expect a sophisticated matte finish Until today, this was only achievable through conventional printing, or the addition of post-processing equipment to utilize matt varnishes, adding time, complexity and cost.

Mark Andy unveils Digital Series HD HighSpeed 1200 press

Mark Andy unveils the Digital Series HD HighSpeed 1200 press at Labelexpo 2024, doubling the speed of its predecessors at 1,200 DPI resolution

Running at an unprecedented 480 ft/min, the Digital Series HD HighSpeed 1200 boosts productivity by maintaining resolution above 1,200 DPI, delivering full-color variable data printing and holding tight olerances in print-toprint and print-todie registration

The press is owered by Mark

Andy s new ProWORX Digital Front End (DFE), which delivers additional productivity by streamlines pre-press workflow and color management

‘We’re incredibly excited about this technological breakthrough,’ said Mark Andy CEO Duane Pekar ‘The market is asking for greater digital press speeds and efficiencies We listened, and we delivered. The HighSpeed 1200 is not just two times faster, it does so without compromising quality and capability Available in hybrid or roll-to-roll formats, the new opportunities this technological advancement creates for converters are substantial Our customers’ growth is our growth, and we’re looking forward to showing the market this new digital technology at Labelexpo ’

Ukrpol invests in Flexcel NX 4260 system

One of the leading Ukrainian printers Ukrpol Printing Company has taken the flexographic platemaking in-house by installing a Flexcel NX 4260 system from Miraclon. The platemaking system supplied by Uniprint, the Miraclon representative in Ukraine, is part of a significant investment in flexo production at Ukrpol.

The company recently

installed a 670mm-wide press, and an even wider 1300mm press is due to be installed soon. The Flexcel NX system and presses are located in a new dedicated flexo facility at Ukrpol’s plant in Stryi, in the Lviv region of Western Ukraine. Ukrpol offers packaging customers all four production options with gravure and offset collectively making up 70 percent of production, flexo 25 percent and digital 5 percent.

However, technical director Andriy Boichuk says the company has identified an opportunity to increase flexo’s proportion: ‘There are applications suited to each process, but the conditions are right for flexo to take a bigger share. Shorter run-lengths and tighter delivery deadlines play to its strengths and give it an edge over a process like gravure. It’s also a more sustainable process.

Shanghai Bozhi installs second Xsys ThermoFlexX imager

S h a n g h a i B o z h i G r a p h i c R e p r o d u c t i o n , a C h i n a - b a s e d

flexographic plates manufacturer, has installed a second ThermoFlexX 60 (TFxX 60D) digital imaging system from Xsys to enhance output quality, speed and capacity As per the company, the dual-head TFxX 60D model, with added

installed for the first time in the country and has set a n e w b e n c h m a r k f o r platemaking in China.

The company’s customers serve a multitude of global brand owners, such as Procter & Gamble, Johnson & Johnson, Unilever, Disney, Adidas and Yinlu Foods, as well as fast food restaurant chains KFC and McDonald’s Its applications include wine labels, aseptic packaging, selfadhesive labels, film and soft tubes and various paper cups As a member of the Flexographic Printing Branch of China P r i n t i n g T e c h n o l o g y A s

installed ThermoFlexX thermal imaging technology in 2020. It started with a ThermoFlexX 60S imager

CCL ASEAN adopts Asahi AWP-DEW and CleanFlat water-washable plates

CCL ASEAN, headquartered in Thailand and a subsidiary of C C L L a

flexographic printing enabled by Asahi’s Carbon Neutral plates To date, CCL has implemented

equipment in plants located in Thailand and Vietnam with plans to expand to other plants in the region

‘We chose to work with Asahi in implementing these Carbon Neutral water-washable flexographic plates to deliver more sustainability, durability, and quality, especially in highlights, to our many customers across the region,’ said Kittipong Kulratanasinsuk, vice president and managing director at CCL

L a b e l A S E A N . ‘ W

differentiator for us as we continue to grow our business across region with support from our partner, Asahi Kasei ’ Water-based and UV inks flexo printing has lower VOC emissions compared to printing technologies with a large amount of solvent-based inks such as gravure Furthermore, w a t e r - w a s h a b l e p l a t e s u s e a w a t e r - b a s e d d e v e l o p i n g solution, avoiding the use of organic solvents containing VOCs, thereby reducing associated CO2 emissions even more

Itoen adopts Asahi’s AWP water-washable flexo plate

I

specializing in tea production, distribution and sales, has

printing the packaging of its barley tea bags.

In collaboration with Sagawa

Fujieda City, Shizuoka, Asahi’s product has contributed to approximately 14 percent reduction in CO2 emissions c

printing and dry lamination methods, claims Itoen

The company reports that water-based flexo printing has lower VOC emissions compared to gravure printing, which uses a large amount of solvent-based inks Additionally, water-based inks dry at lower temperatures, reducing energy consumption during the drying process, thus cutting CO2 emissions

Furthermore, water-washable plates use a water-based d

solvents containing VOCs, thereby reducing associated CO2 emissions even more

DuPont focuses on innovation, sustainability, performance and quality

At the show, Cyrel Flexographic Solutions displays its brandnew equipment, the DuPont Cyrel Fast 1000 TD solvent-free flexographic plate processor designed to offer productivity, quality and lower environmental footprint It features a compact footprint, high productivity and improved user interface

Cyrel Flexographic Solutions also features the Esko XPS Crystal exposure unit, which utilizes the latest UV LED technology to maximize the consistent, high-quality performance of the Cyrel flexographic plates The awardwinning Cyrel Lightning plate family provides quick access times and print quality, designed from the ground up for UV LED exposure units

Additionally, attendees can experience Cyrel University, an online, on-demand training platform designed to reduce errors in the plate-room The courses are entirely digital and allow users to get up to speed, accelerating their learning process. ‘I am thrilled to join Cyrel Flexographic Solutions as we participate in Labelexpo Americas 2024, one of the biggest events in the label and package printing industry,’ said Nolan Dzielak, North America commercial leader at Cyrel Flexographic Solutions

LAVIGNE to accelerate growth with new RICOH Pro™ Z75 B2+ sheetfed inkjet press

LAVIGNE, part of France’s CLAIREFONTAINE Group, has chosen RICOH Pro Z75 B2+ sheetfed inkjet technology to accelerate growth and elevate productivity

LAVIGNE produces a wide range of illustrated calendars, bank card calendars, diaries, desk pads, greetings cards,

production

and business gifts

technology very early on and invested in a fleet of

Heidelberg, Solenis to Cooperate on Paper Packaging

Heidelberger Druckmaschinen AG (Heidelberg) and Solenis, a leading manufacturer of specialty chemicals, announce a collaboration in the field of paper packaging at Fachpack 2024 in Nuremberg, Germany

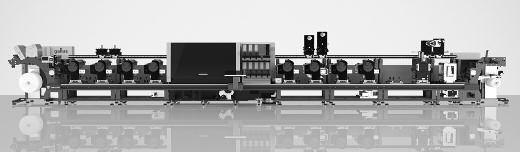

The aim of the agreement is to develop a cost-effective process to integrate barrier coatings for fiber-based packaging directly into the existing roll-fed flexo printing process with the

prevent water or water vapor, hot and cold liquids, oils and fats

packaging

Today, Ricoh’s revolutionary B2+ duplex sheetfed inkjet press with aqueous ink, the RICOH Pro Z75, is the latest addition to the operation’s portfolio of production presses

The RICOH Pro Z75 provides all the benefits of a sheetfed p r e s s , b u t w i t h t h e l o w p

h productivity of inkjet It delivers exceptional print quality, quick turnaround times and minimal staff intervention, enabling LAVIGNE to double its production capacity.

INNI Group recognizes the value of longlasting rotec®

Offset Sleeve technology

As a dedicated eco-conscious company, INNI Group prides itself on using sustainable production methods that also improve the working conditions of its press operators while maximizing productivity and print quality Among the preferred technologies are rotec® Offset

Sleeves from XSYS, which have kept its Drent Goebel VSOP (Variable Sleeve Offset Printing) 520 press running smoothly since May 2009.

After years of efficient production, INNI Group is now confidently selecting rotec® again to replace the original set, along with additional repeats

With over 130 years of experience and a rich history, INNI Group is located in Kortrijk in West Flanders (Belgium) since the 2013 merger of Drukkerij Strobbe and Continuga In 2023, high-end printer Drukta joined the Belgian company, further expanding the product range and strengthening the presence in the region.

INNI Group defines itself as more than just a multi-specialist printing company In a world dominated by fast-paced digital interactions, print can create moments of real connection INNI Group believes that print can bring stories to life, bring people closer together, and support sustainable choices Every day, they create these moments for their customers

"The growing global demand for sustainably produced, costeffective, recyclable and compostable packaging makes the flexible paper sector an attractive growth market for us," says Dr. David Schmedding, chief technology and sales officer at H

machine, with its production speed of up to 600 meters per minute and an availability of up to 90 percent, offers the ideal conditions for this In our collaboration with Solenis, we are

solutions for the food industry that are geared towards efficiency and sustainability "

Cosmo Films to launch seven new films at Labelexpo Americas

Cosmo Films has confirmed its plans to launch seven new products for the US market at Labelexpo Americas 2024.

The new films include Graphic films PVC fee (used for signages), high shrink label films – PETG and Crystalline Pet (used in label industry), CPP extrusion lamination films (used in packaging), Teplo R- heat resistant films for printing layer of the laminate (used in packaging), 92 microns white and clear films (used in label industry), Flexi premere films –elongation films for non-tear (used in label industry) and primer coating for printability in label films

Sandeep Dutta, president- overseas operations Cosmo Films said: ‘Labelexpo Americas brings likeminded individuals from our industry under one roof, making it an ideal platform for showcasing our new launches and creating large-scale visibility. Our product offerings have been widely accepted by the American market, and we have established ourselves as trusted packaging partners With these new launches, we look forward to serving our existing clientele with more offerings from the world of Cosmo Films and tapping into a new set of customers to expand our market share.’ Advancing toward a sustainable and green future, Cosmo Films now focuses on developing films from mono-material structures that are easily recyclable, helping customers reduce their carbon footprint.

Srichakra

Polyplast triples

bottle-grade

rPET production capacities

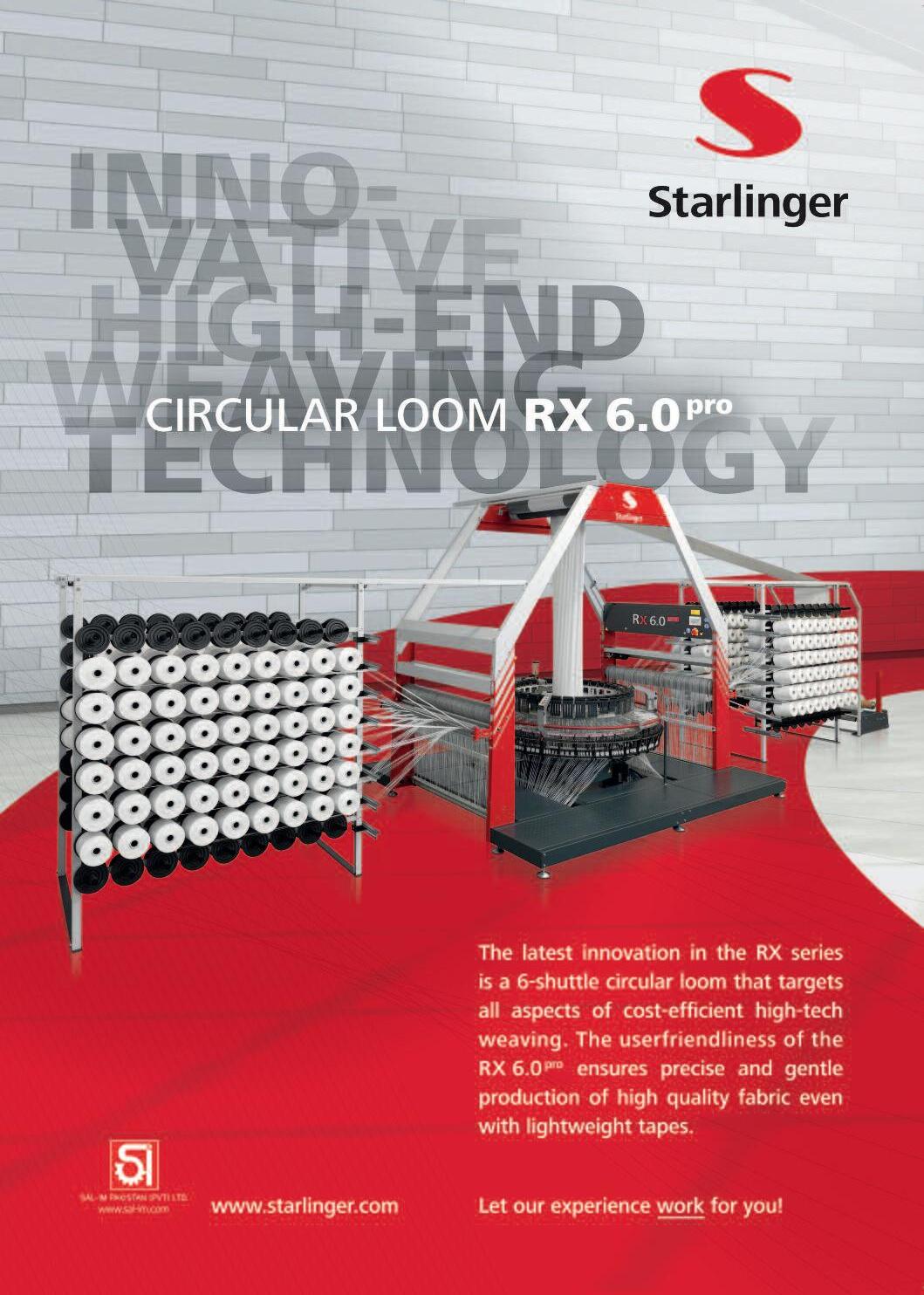

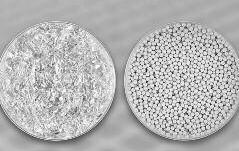

Indian plastics recycler Srichakra Polyplast commissioned two new Starlinger PET bottle-to-bottle recycling lines in the first half of 2024 The company already recycles post-consumer PET bottles and polyolefin packaging on two Starlinger plastics recycling lines installed in 2021 The two new recoSTAR PET 165 HC iV+ PET bottle-to-bottle recycling lines have been installed at Srichakra’s recycling facility at the outskirts of Hyderabad, Telangana state, where the existing Starlinger lines – one with odor reduction technology for processing post-consumer polyolefins, the other one a PET bottle-to-bottle recycling line – are already in operation With the addition of the two new lines Srichakra Polyplast has tripled rPET production capacities and now reaches a combined output of 42,000 tons of bottle-grade rPET per year

“Due to the implementation of Extended Producer Responsibility by the Indian government and the requirement for brand owners and producers to include a share of 30 % of post-consumer recycled PET in their beverage bottles by 2025, the demand for rPET in India is on the rise”, said P V Ravindra, Managing Director at Srichakra Polyplast “As an end-to-end recycling and plastic waste management company, we are committed to make meaningful contributions for more sustainability in the plastic packaging industry

Esko to showcase how innovation and sustainability can drive label & packaging profitability at Dubai event

Esko and Dubai-based iTM (Industrial Tools & Media) will be joined by partners from Comexi, Asahi and MacDermid for the special “Esko on Tour – Dubai” event held at the city’s Novotel World Trade Centre

including learnings from this year’s drupa event, attendees will discover how the latest advances in automation, flexo plate technology and prepress

objectives whilst also boosting profitability

“In today’s world, where the landscape is changing on a daily or even hourly basis, it’s crucial that businesses have the capability to adapt and be flexible to meet their customers’

Business “With this event, we’re working with some of the industry’s biggest names to shed light on the key packaging sector trends affecting businesses right now We’ll not only be demonstrating some of the very latest innovations new to the market or at an advanced stage of development, but we’ll also spotlight how focusing on sustainability can help

profitability ”

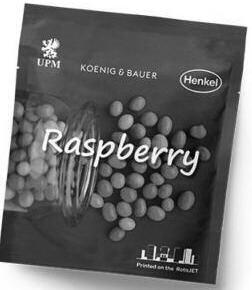

XSYS joins industry partners to futureproof flexo with sustainable solutions

XSYS has announced the successful result of a new collaboration aimed at creating more eco-friendly flexo solutions The trailblazing project brings together the expertise of leading industry suppliers across pre-press, plates, ink, substrates, sleeves, plate mounting and

production

Visitors at drupa 2024 in

were able to inspect a

zipper bag, produced with

established in response to the accelerating demand fro m

sustainable manufacturing processes and high-quality products.

The zipper bag project utilizes seven-color extended gamut (ECG) process backed with white. Both the print and lamination substrates are made from polyethylene (PE), creating a complete mono-material construction.

Label World doubles its sales with Mark Andy presses

Irish converter Label World, which recently installed a highspec Performance Series P3, has registered an increase in its business by 100 percent over the past four years with the aid of its new Mark Andy flexo technology

Founded in 1998 and owned and managed by Declan O’Rourke, Label World has plotted a path of continual growth and success over the past 26 years, winning both flexo and digital print awards along the way and building a business that is both diverse and environmentally friendly

The company was founded with two 10in 5-color Comco Cadet UV/flexo presses and moved onto the popular Mark Andy 2200 8-color UV flexo press series in 2004

‘The presses are almost over-engineered, which makes them reliable and consistent performers long-term and just what you need when you are building a business,’ said O’Rourke. The company headquarters has grown from 5,000sqft to 15,000sqft over the years and now employs 30 staff ISO 9001 and BRC/IoP Global Standard were achieved in 2007 and 2008 respectively and by 2015 business had grown to a point where additional flexo capacity was required Following extensive print tests at Mark Andy’s UK showroom in Macclesfield a Performance Series P3 was ordered and was one of the first to be installed in Ireland.

Northern Label redefines production with Bobst Digital Master 340

Northern Label Group, one of the leading label printers in Canada serving the health, beauty and personal care markets, has taken a leap forward in its digital printing capabilities by investing in a Bobst Digital Master 340

Founded in 2004 by Sean Murray and Don Rees, Northern Label initially made its mark with an 8-color, 10inch UV flexo press. The decision to integrate the Bobst Digital Master 340 into the company’s production line marks a new era by enhancing speed, automation and overall quality with an all-in-one platform.

Designed for high productivity, the Digital Master 340, prints at speeds up to 328 ft/min with a resolution of 1,200x1,200 DPI, utilizing Bobst’s proprietary digital inkjet technology. With the acquisition of the new press, Northern Label has elevated its production efficiency and quality, allowing it to better serve clients ranging from global brands to smaller, local businesses. The automation capabilities minimize downtime and maintenance, while its print speed and quality enable Northern Label to meet demanding customer requirements. Another significant advantage is the ability to incorporate new modules to the Digital Master 340, allowing Northern Label to evolve and adapt the machine as their customers’ requirements change.

Japanese Printing Company

NABEPROCESS Adds Asahi AWPLOOP™ Water Recycling System to Reduce Water Usage, Hazardous Waste

A s a h i P

photopolymer plate development, a subsidiary of Asahi Kasei, reported that NABEPROCESS Co , Ltd , a major Japanese printing company and one of the first companies in the world to install CrystalCleanConnect, has advanced its sustainability initiatives even further by adding an Asahi AWP-LOOP™

CrystalCleanConnect is an offering jointly developed by A

automates the flexographic platemaking process, reducing steps from 12 to 1 and dramatically reducing potential for error The system produces flexographic plates ready for mounting on press

In this configuration, NABEPROCESS is using Asahi’s A W P ™ w

CrystalCleanConnect which automates platemaking and reduces overall time to market Mr Naka adds, “We are using the AWP-LOOP™ system once a day on average, working in harmony with CrystalCleanConnect

NextGen expands capabilities with Gallus One hybrid press

NextGen Label Group has invested in the Gallus One hybrid press with extended capabilities to expand its capabilities with both flexographic and digital printing.

NextGen Label Group serves some of the world’s most

recognizable brands in the spirits, beverage, beer, food, health and beauty markets

‘The Heidelberg Gallus One met all the criteria we consider when investing in new technology,’ emphasized Tom Sargent, president and CEO of NextGen Label Group ‘Built on the Gallus

provides reliability, redundancy, and full modularity. It will allow us to continually deliver on our promise of Brand Custodianship ’

Nick Noyes, chief operations officer at NextGen worked closely with the team at Gallus Heidelberg to custom configure this latest addition to NextGen’s equipment offering

The 17-inch wide, 15-color hybrid press is the first of its kind in North America. It is perfectly suited to print a variety of labels using flexographic and digital print technologies.

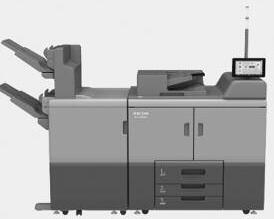

New print production standards in reliability and sustainability set by the RICOH Pro™ 8400 series

t i v i t y

e n h a n c e m e n t s d e s i g n e d t o

e l e v a t e t h e p r o d u c t i o n o f a

w i d e r a n g e o f f a s t

t u r n a r o u n d , o n d e m a n d

a p p l i c a t i o n s , f o r i n h o u s e ,

c o r p o r a t e , t r a n s a c t i o n a l ,

a n d c o m m e r c i a l p r i n t i n g

e n v i r o n m e n t s

T h e s e r i e s ’ h i g h s p e e d o u t p u t a n d s u p e r i o r i m a g e q u a l i t y i s

d e l i v e r e d b y V e r t i c a l C a v i t y S u r f a c e E m i t t i n g L a s e r

( V C S E L ) i m a g i n g t e c h n o l o g y w h i l e c r i s p t e x t , f i n e l i n e s ,

a n d s m o o t h h a l f t o n e s a t 2 4 0 0 x 4 8 0 0 d p i r e s o l u t i o n a r e

e n a b l e d b y e n h a n c e d t o n e r P r e c i s e h a n d l i n g , e v e n w i t h

p r e - p r i n t e d a n d d a r k c o l o u r e d p a p e r s , i s m a n a g e d b y t h e

M e c h a n i c a l R e g i s t r a t i o n S y s t e m , w i t h a C o n t a c t I m a g e

S e n s o r ( C I S )

s

c h a n g e d , t h e p r i c e i s

c a l c u l a t e d i n r e a l

t i m e , w i t h o u t

f i r s t h a v i n g t o g o

t h r o u g h t h e

p r o c e s s o f l o g g i n g i n o r r e g i s t e r i n g T h i s n e w o n l i n e

l a b e l c o n f i g u r a t o r w i l l b e p r e s e n t e d f o r t h e f i r s t t i m e a t

t h i s y e a r ' s F a c h p a c k i n N u r e m b e r g , G e r m a n y .

‘ T h e c u s t o m i z e d c o n f i g u r a t i o n a n d o r d e r i n g o f

r e c t a n g u l a r o r r o u n d l a b e l s i s c o m p l e t e l y i n t u i t i v e , ’

e x p l a i n e d M a r c T r a p p , t e a m l e a d e r f o r i n d u s t r i a l l a b e l s

s a l e s a t H e r m a ‘ T h a n k s t o t h e c o n f i g u r a t o r ' s c o m p a c t

d e s i g n , t h e u s e r i s i m m e d i a t e l y a b l e t o s e e

a l l p a r a m e t e r s a t a g l a n c e w i t h o u t b e i n g c o n f r o n t e d w i t h

u n p l e a s a n t s u r p r i s e s i n t h e f o r m

t h e e n d , e . g . s h i p p i n g f e e s . T h e u s e r c o m p l e t e s t h

e

i

T h e l a b e l c o n f i g u r a t o

Mactac launches Ask Sam technical support

Mactac, a Lintec Company, introduces Ask Sam, a technical service program at Labelexpo Americas 2024 in Chicago Labelexpo attendees can learn more about Ask Sam and engage directly with application experts at booth 143

Ask Sam short for Ask Spinnaker and Mactac embodies a major advancement in customer support, drawing on the combined strengths and technical acumen of both portfolios and synergy achieved through recent mergers, the company said ‘Ask Sam perfectly illustrates the stronger, more unified Mactac of today,’ said Dalia Naamani-Goldman, vice president, sales and marketing, Mactac North America ‘With the backing of our parent company, Lintec, and the integration of recent acquisitions like Duramark, Spinnaker and Label Supply, we have built a powerhouse of industry expertise This allows us to present our customers an even wider array of solutions, marking a new chapter in service and technical excellence.’

Ultimate Tech launches Ultimate Impostrip for Canon’s new press

Canada-based imposition, ganging, nesting and finishing automation software specialist, Ultimate Tech, has launched a fully automated and optimized label production product for Canon’s upcoming LabelStream LS2000 inkjet label press Ultimate Impostrip drives the full set of functionalities of the

product is designed to allow users to fully leverage the yet to b

C

’ s LabelStream LS2000 press and help to get the maximum ROI from this product combination

The new product is designed to centralize and automate imposition, step and repeat, lane imposition, ganging and true s h a p e n

barcodes to automate the workflow.

It has been developed to empower the ability to manage a high number of SKUs dynamically with very short turnaround times As a fully automated technology, users can submit, for example, a full days’ worth of work and get optimized and batched output ready to print.

‘Canon USA and Ultimate believe in open collaborations, and we are happy to come together for Labelexpo to showcase the power of using the combined solutions,’ said Julie Watson, Ultimate Tech CEO

Herma launches online label configurator

MPS expands portfolio with EF Packaging press

MPS has expanded its portfolio with the introduction of the EF Packaging press targeted at flexible packaging and shrink sleeve applications operating at an extended web width of 26in

The MPS EF Packaging press builds on the foundation of the MPS EF narrow web press series and can open new markets and opportunities for label converters that are looking to venture into different market segments or flexible packaging converters that are looking for a press for short runs, MPS reported

The EF Packaging press is specifically engineered for broad spectrum of applications, including wraparound labels, shrink sleeves, flexible packaging, laminated products and filmic labels or products

The new EF Packaging press offers a wider print format that not only boosts production capacity but also offers quick changeover times between jobs and is designed with operators in mind, according to the company

The press offers Crisp Dot Technology for high-quality print and repeatability on a wide range of substrates. Its E-Sleeve Technology offers quick changeovers MPS patented lightweight aluminum E-Sleeves offer an even distribution of print pressure and durability

Miraclon joins Consortium for Waste Circularity

Miraclon has joined the Consortium for Waste Circularity (CWC) as part of its ongoing environmental, social and governance (ESG) agenda John Anderson, director of advanced application development for Miraclon, will serve

w i t h i n t h e C W C , w h i c h aims to expand industry

c o l l a b o r a t i o n a n d g r o w recycling technology.

‘ W h e n l o o k i n g a

sustainability, we take a

extends beyond a lifecycle analysis of our products and related manufacturing processes to the impact that our technology and services can have on the complete packaging printing value chain,’ said Emma Weston, chief marketing officer at Miraclon ‘We are focused on understanding the big, material impacts and challenging how we can make a difference As a member of CWC, we can push this even further ’ C

, working to ensure that all municipal solid waste that winds up in landfills is dealt with and returned to virgin materials or fuel that can be used again They also make contributions to R&D, outreach and education to advance recycling efforts

Carminati in world first with second Catena-WDLS automated flexo plate processing system from XSYS

Operating mainly in the corrugated sector, Carminati is a leader in its field. Located in Antegnate, east of Milan in northern Italy, the progressive company makes flexographic printing plates for customers across Italy, into France and

on two state-of-the-

modern plant, where 35 staff work tirelessly to maintain the company’s well-established reputation for high quality and excellent customer support.

ThermoFlexX Catena-WDLS integrates washing, drying, light-finishing, and stacking into one smooth process The operator simply loads the imaged plate at the start using a pinbar system and then collects the print-ready version at the other end This high level of automation brings n

processing, and exceptional quality. In addition, the system is very energy efficient, helping Carminati to reach its sustainability targets. For instance, the company reports a reduction in drying time per plate of 30 minutes compared to the old system

drupa 2028 Dates are Set for May 9-17, 2028

drupa will continue its four-year cycle and will be held again in May 2028 in Düsseldorf, Germany, for the first time as a nine-day event. As the world’s leading platform for printing technology, the trade fair is adjusting to the changing needs and expectations of exhibitors and visitors and reflecting the continuous transformation of the industry.

The printing and packaging industry is undergoing a dynamic transformation that requires industry events to evolve as well. This also applies to drupa, which once again demonstrated its importance and relevance as a leading global trade fair in 2024 and provided pioneering inspiration.

The industry can already look forward to the next edition of the No. 1 event for printing technology to be held from May 9-17, 2028 at the fairgrounds in Düsseldorf, Germany.

“drupa 2024 was more international than ever and the positive atmosphere throughout the halls reflected our industry’s determination to drive profound change in order to make the printing and packaging industry more sustainable through automation, artificial intelligence and strategic partnerships,” said Wolfram N. Diener, chairman and CEO of Messe Düsseldorf. “And these are exactly the kind of important goals that will continue to require a reliable platform such as drupa in future.

Avery Dennison launches INGEDE12certified paper label materials

Avery Dennison has launched the first range of INGEDE12certified paper label materials advancing its mission to develop technologies that enable recycling for a more circular economy

The range of paper label materials uses a newly developed

out from pulp during the recycling screening

higher quality output for new cardboard and paper production

The range offers good print and conversion for a wide variety of use cases and industries

Products within the range include rVellum, Coated Paper, Thermal Eco and Thermal Top facestock combinations for both decorative labeling and variable information/barcode labeling options

In addition, rVellum facestock is made from 100 percent recycled materials, offering sustainable advantages such as reducing CO2.

Domino launches next-generation DxSeries CO2 laser coders

Domino has launched Dx-Series, the latest generation CO2 l a s e r c o d e r s o p t i m

n , advanced variable data printing for a wide variety of packaging types.

According to Domino, Dx-Series lasers deliver up to 30 percent faster coding than previous generation CO2 coders, with no reduction in code quality, making them suitable for complex advanced variable

r e

2 D codes such as QR codes powered by GS1

‘Interest in laser technologies in the coding and marking industry is booming, with global market growth predicted at rates of almost 10 percent CAGR until 2029,’ says Frauke Schroeder, senior product manager for laser at Domino ‘This growth has been driven in part by global government policies a n d r e g u l a t o r y f r a m e w o r k s d r i v i n g t h

o r h i g hresolution, on product 2D codes

‘Manufacturers are increasingly looking for advanced laser solutions to satisfy these requirements – for this reason, we have launched our Dx-Series CO2 laser coders, for reliable, fast-paced, advanced variable data printing across a broad range of product and packaging types, and manufacturing environments ’

Heidelberg and Gallus celebrate successful Labelexpo Americas

Heidelberg North America and its subsidiary Gallus Group have returned to this year’s edition of Labelexpo Americas in Chicago to reconnect with industry peers, customers and future clients

The companies celebrated the debut and installation of their latest technologies and a major industry award for Gallus legend Ferdinand Rüesch IV.

H

showcased the recently

latest version of the Gallus

One and the new MatteJet technology, which delivers premium matte finishing capabilities for digital inkjet printing

With MatteJet technology, converters can achieve a high-end matte finish with digital inkjet printing without changing inks or adding overprint varnish. This eliminates the need for external finishing processes or separate conventional machines

The new MatteJet technology also enables more converters and brands to benefit from digital printing capabilities, including cost-effective short runs, personalization and on-demand production

Henkel and Panverta CPP develop film for improved barrier performance

Together with Panverta CPP, manufacturers of cast polypropylene (CPP) and linear low density polyethylene (LLDPE) film, Henkel Adhesive Technologies has developed films with an improved oxygen barrier layer that makes it possible to reduce the number of packaging layers to protect dry foods from the environment

Dry food items such as flour, rice or pasta can quickly spoil or lose flavor when exposed to air, light or moisture Packaging for dry foods must therefore be airtight, light-proof and moistureproof High-quality packaging that meet all these requirements usually consist of several layers of different materials These composite materials are often difficult to recycle because they cannot be easily separated, the company said Henkel’s cooperation with PT. Panverta Cakrakencana, one of the leading film manufacturers in Indonesia, has successfully provided a packaging to improve the oxygen barrier performance of metallized cast polypropylene (CPP) to less than 0.5 cc/m2.day and CPP with aluminum oxide coating (AIOx) films to less than 8 cc/m2 day The jointly developed innovations ensure that these vital oxygen barrier properties for dry food packaging can be achieved when switching from multi-material designs to mono-material polypropylene (PP)

UPM Specialty Papers and Unipaco create salad pot wrapper

UPM Specialty Papers partnered with Unipaco S A , a Polish c o n v e r t e r i n f l e x i b l e p a

recyclable, heat-sealable salad and herb pot wrapper that guarantees product safety The structure also meets German

accounting for 95 percent of the packaging mass Brands worldwide are setting

Husky Labels installs Epson SurePress L6534VW UV

Indiana-based Husky Labels has installed the SurePress L6534VW UV digital label press to meet the incoming customer needs, expand media compatibility, increase output versatility and workflow productivity.

After decades of experience in the label printing industry, coowner Glenn DeRossett, decided to start his own printing business While still in the initial start-up phase, he quickly inherited customers from a closing business and needed to expand output capabilities

time, global regulations are

stringent As a result, the industry has seen an exponential growth in the demand for alternatives to flexible plastic packaging. The partnership between UPM Specialty Papers and Unipaco has resulted in two versions of packaging that combine UPM papers and Unipaco coatings

The first is based on innovative barrier base paper UPM Solide Lucent 78 g/m2 with a 4 g/m2 PE coating. This barrier base paper offers a natural look and feel Proven to be particularly well suited to coating and lamination, UPM SolideLucent provides a surface for further converting and printing, including rotogravure

Networkpak invests in Screen L350UV SAI S

Networkpak, an Australian folding carton printer, has taken a significant step towards expanding its services to digitally printed labels with the installation of a Screen L350UV SAI S press in collaboration with Jet technologies, Screen’s local distributor This strategic investment transitions Networkpak from its traditional focus on folding cartons to include high-quality digital label printing The new Screen L350UV SAI S press is expected to play a crucial role in this expansion, allowing the company to fulfil the increasing demand for premium labels and packaging

Paul O'Sullivan, director of Networkpak, said: ‘As a company with deep roots in printed folded cartons, we have earned the trust of leading Australian brands by consistently delivering top-tier products The addition of the Screen L350UV SAI S to our lineup is a natural progression for us, enabling us to offer an even wider array of solutions to our clients We can now meet their label and packaging needs with the same level of quality and reliability they've come to expect from our carton work ’

‘I really wanted a UV press,’ said DeRossett. ‘I have a UV flexographic printer, and I wanted to leverage that technology with a streamlined, efficient workflow for our label printers as well ’

The company purchased the SurePress L-6534VW with Orange Ink and has been thrilled with the immediate results.

‘We replaced an older model with the SurePress L-6534VW and now handle most incoming orders with it The high speed and output quality are exactly what we wanted,’ commented DeRossett.

Husky Labels currently prints nearly three million labels per month on the SurePress L-6534VW for customers spanning a variety of industries including alcohol, food and beverage, cosmetics, health and more.

Mitigating the effects of climate change

The Indian PET recycling specialist ramps up its PET bottleto-bottle recycling capacities with two Starlinger recycling lines to a total of 42,000 tons per year It aims to recycle 25 % of India’s PET bottle waste by 2026

recoSTAR PET 165 HC iV+ recycling lines are set up at

Ganesha Ecopet Private Ltd in Warangal, Telangana State

The company, a subsidiary of Indian PET recycling pioneer Ganesha Ecosphere Ltd , already produces recycled PET flakes and pellets for food-grade packaging as well as for filament yarns and fibres on two Starlinger lines installed in 2022 The new recycling lines are in operation since mid2024 and triple Ganesha Ecopet’s annual production of bottle-grade rPET, raising it from 14,000 tons to a total of 42,000 tons

The increasing demand for food-safe recycled PET in India has two main reasons On the one hand, the Indian g o v

Responsibility (EPR) for importers, brand owners and plastic waste processors as part of its Plastic Waste M

systematic collection of plastic waste

Label Link continues digital journey with second Screen press

Zhenguan enhances paper production capacity with PM4 investment

Chinese manufacturer expands its product

South African converter Label Link has taken another step on its digital transformation and invested in a second Screen Truepress Label 350UV SAI-S press through its partnership with Rotocon, the regional Screen distributor

Established in 2003, Label Link has been one of the key players in Cape Town's wholesale label printing market, serving resellers primarily in the fast-moving consumer goods sector

In 2018, Label Link took a significant step towards modernizing its operations by partnering with Rotocon to acquire a Screen Truepress JET L350UV+ inkjet press and a Rotocon Ecoline RDF 340 finishing machine This investment marked the company's initial foray into digital production, laying the foundation for Label Link's digital future

‘We focus primarily on short-run label production,’ said Wiaan Stemmet, owner of Label Link ‘While flexo still remains a big part of our business, we've found that for limited, efficient and accurate label printing, digital makes a lot more financial sense '

Domino Launches Compact Monochrome Inkjet Printer at Labelexpo

Domino Printing Sciences announces the launch of a new, compact monochrome inkjet printer, the K300, at Labelexpo Americas Building on the success of Domino’s K600i print bar, the K300 has been developed as a compact, flexible solution for

capabilities to analog printing lines.

The K300 monochrome inkjet printer will be on display at the Domino stand, booth 5821, at Labelexpo Americas from Sept. 10-12, 2024 The printer will form part of a code printing and verification solution, including automated machine vision from Domino Group Company Lake Image Systems

“The industry move to 2D codes at the point of sale has led to an increase in demand for variable data printing, with many brands looking to incorporate complex 2D codes, such as QR codes powered by GS1, into their packaging and label designs,”

s a i d A l e x M o u n t i s , s e n i o r p r o d u c t m a n a g e r a t D o m i n o

“Packaging and label converters need a versatile, reliable, and compact digital printing solution to respond to these evolving market demands We have developed the K300 with these variable data and 2D code printing opportunities in mind ”

Zhenguan, a subsidiary of YG Group, has invested in a PM4 paper machine to significantly enhance paper production capacity and support its further expansion into the glassine and thermal paper markets.

Zhenguan successfully completed its test run and held a grand commissioning ceremony From planning and construction to installation and testing, the entire project team meticulously addressed key milestones and overcame various challenges, ensuring the project’s smooth progress. The project achieved its goals while maintaining strict control over safety, quality, and schedule

Zhenguan offers a diverse range of products, including coated paper, wood-free paper, thermal transfer paper, direct thermal paper, PP film, PE film, PET film, lamination film, glassine and thermal paper).

The launch of the PM4 paper machine is expected to significantly enhance paper production capacity and support Zhenguan’s expansion into markets such as glassine paper and thermal paper This will also help clients access a wider range of highquality paper products and further meet the growing market demand

Xsys appoints Colombian distributor

appointed Polyprint as the distributor for nyloprint printing plates in Colombia. This strategic partnership will enhance the availability and support of Xsys’s

Colombia.

Founded in 1983, Polyprint

presence in the Colombian market, Polyprint offers s o l u t

packaging equipment, making them a valuable partner for Xsys

Matias Katila, sales director LATAM at Xsys, said: ‘

market presence make them an ideal partner for us Their commitment to quality and customer service aligns perfectly with our values We are excited to work together to bring our nyloprint solutions to a broader audience in Colombia.’

Xsys acquires MacDermid Graphics Solutions

xsys has signed an agreement with Element Solutions to acquire certain shares and assets held by subsidiaries of the latter, comprising the MacDermid Graphics Solutions business for

approved by the board

subject to regulatory approvals and customary closing conditions

Xsys has also announced a change in leadership at Xsys Departing group CEO Oliver Dohn has driven profitable growth and set a new strategic growth and innovation agenda for Xsys Dohn has now decided to pursue other endeavors

Dr Alexander Unterschütz has taken the position of the new group CEO in order to spearhead Xsys’s next growth chapter Prior to joining Xsys, Dr Unterschütz led the components business at Linde Engineering, where he worked for 14 years Before that, he worked a

& Company

James Thomas returns to Focus Label Machinery

Focus Label Machinery has announced that James Thomas will be rejoining the company as head of sales and business development

Thomas worked for Focus as business development and marketing manager from 2016 and helped drive the growth

o f t h e c o m p a n y a n d t h e b r a n d bringing in new business, partners and products during his four years there

David Lee, director of Focus Label Machinery, said: ‘James has a wealth of industry knowledge, especially in digital print production, with a good business understanding he will be a great asset to the business, as he was previously We are all absolutely delighted James is rejoining Focus and see his appointment as a fresh approach for the company

‘Sadly, we say goodbye to Antony Cotton who is moving to pastures new We thank Antony for his long service and dedication to the business and wish him well in the future.’

T h o m a s c o m m e n t e d : ‘ F o r m e t h i s i s a w o n d e r f u l opportunity to bring Focus and its brand back to pre-Covid levels

Mark Andy names VP of advanced customer support

Mark Andy has appointed Steve Luedke as vice president of advanced customer support. Luedke joins Mark Andy with a deep well of experience in the label and packaging industry, bringing more than 26 years of expertise from his tenure at WS Packaging, now part of Multi-Color Corporation

In his new role, Luedke will lead Mark Andy’s newly launched end-toe n

Support, providing customer support from pre-press to finishing operations His focus will be on helping customers increase the utilization and ROI of Mark Andy’s flexo and digital hybrid presses, and finishing machines, by bringing a team of cross-functional experts to the table. Luedke’s first-hand experience in converting c

optimization, software tools, application development and workflow will ensure customers get the most from their converting processes

Luedke’s career in the industry has included a wide range

sales, with extensive hands-on involvement in product development, particularly in the realm of flexo systems and digital hybrid presses

Korozo group welcomes new CPO

International sustainable flexible packaging manufacturer Korozo group has appointed Banu Celik as its new chief planning officer (CPO).

Celik is an experienced supply chain and business development professional who has worked in various senior planning and management roles This includes businesses such as Yildiz Holding, one of Turkey’s oldest food production companies; Şişecam, one of the largest manufacturers of flat glass in Europe; and global CPG businesses Unilever and Henkel

Commenting about her appointment, Celik said: ‘I look forward to using my knowledge of supply chains and business development to help Korozo Group fulfil its ambitions As well as my understanding of business processes and their end-to-end integration, I am passionate about sustainability. This must be evident through all of a company’s activities and I strive to make sure this is true throughout procurement and supply chains.’

Adam Barnett, CEO, Korozo group, commented: ‘By bringing in team members with the skills and aptitude to fuel our strategic aims, Korozo Group is on a clear growth trajectory

With smartGRAVURE, gravure printing enters the digital age

With smartGRAVURE, BOBST has achieved a great, game-changing leap forward for gravure printing. smartGRAVURE totally revolutionizes the gravure printing process from being a highly manual operation to a fully digitalized workflow The traditional advantages and disadvantages of gravure are well known. While it enables high-quality printing and highspeed production with excellent consistency, the setup is timely and expensive, resulting in longer production lead times and making small print runs non-viable. In addition, gravure printing traditionally has had some challenges around manual and time consuming color adjustment compared to other printing methods like offset or digital printing, and there are also some sustainability challenges around the use of solvent-based inks smartGRAVURE changes all that.

BOBST has developed smartGRAVURE for its gravure machine platform MASTER RS 6003 smartGRAVURE offers an endto-end digitalized process, which enables printers to meet and exceed the highest industry standards with ease It overcomes the set-up time and tuning required with gravure printing, which requires high level operator skills. With offline setup and automatic selection of the optimal process data for each new job, the machine frees up press time and disengages from the operator skills level

Therefore, the optimal settings for each print job are automatically determined by smartGRAVURE at the push of a button, while the system continuously ensures that the gravure machines operate with the optimal production parameters during the printing process Compared to the previous manual setup process, the time required is minimized, input errors are reduced, and waste during setup is significantly lowered

With ECG printing, digitalized set up and controls, and connectivity with BOBST Connect, smartGRAVURE increases productivity and output consistency, reduces downtime and complexity, and offers considerable sustainability benefits Easy as 1-2-3: oneSET, onePRINT, oneECG

smartGRAVURE is modular The complete system includes three components oneSET, onePRINT, and oneECG (Extended Color Gamut) each offering various benefits and collectively revolutionizing the gravure printing process.

oneSET is part of the BOBST Connect recipe management function It is 100% automated, meaning a fast and accurate machine set-up. After taking over the customer's order data in the form of PDF files, the system suggests the most suitable and efficient machine settings on its own Importantly, this step no longer needs to be performed on the printing machines but can be moved to the prepress stage One click is enough to transfer the offline-created recipes to the print queue of the machines.

onePRINT is an innovative new inking system with in-line and fully automated process color measurement and adjustment, significantly relieving machine operators Continuous monitoring and adjustment of the process colors are based on measurements with an inline spectrophotometer This provides input for the onePRINT color control, that when combined with oneECG ensures reliable color stability from the first to the last print. The new system limits the amount of ink in the color circuit to the necessary minimum, reducing ink in the machine by over 50% compared to conventional gravure solutions and reducing ink waste simultaneously oneECG is BOBST’s technology for fixed palette printing, now available for gravure printing and an essential element of digitizing this printing process oneECG works with a fixed set of up to seven printing inks, so gravure printers only need to change the printing cylinders for job changes, while the inks remain in the printing machines This reduces ink waste A digitalized version of “color matching” can therefore be performed in the prepress stage before the print jobs are transferred to the machine controls to be Continue

Mark Andy appoints new CEO to lead company to growth

Mark Andy appointed Duane Pekar as its new CEO earlier this year In this exclusive interview, he sits down with Chelsea McDougall for a look at what’s in store for the flexo and digital press manufacturer

Mark Andy’s new CEO, Duane Pekar, has joined the company at an interesting time

The label industry still reeling after several years of supply chain disruptions, rising costs of raw materials, excess inventory and a labor shortage that is looking more systemic every day.

Pekar, however, is no stranger to leading organizations through periods of transformation.

As he gets to know Mark Andy, its customers and the industry as a whole, he is committed to leading the company with a customer-centric approach that extends beyond just selling capital equipment

Since he started at Mark Andy earlier this year, Pekar has been on a whirlwind tour visiting Mark Andy’s facilities in the US and abroad, as well as touring converter customers’ facilities to help him understand the label industry

‘It’s just so exciting to visit with our customers, to learn how they make a living, how our customers support their customers, and what Mark Andy can do to help them all,’ Pekar says

Jordan Liebman joins Konica Minolta

konica Minolta Business Solutions U S A , Inc (Konica Minolta) has appointed Jordan Liebman as senior vice president of marketing and communications

With more than two decades of leadership, Liebman brings a wealth of experience in building world-class brands, leveraging his expertise in global brand strategy, performance marketing, product development, demand generation and corporate communications

In his new role, Liebman will oversee Konica Minolta’s marketing and communications team. He will spearhead efforts to accelerate revenue growth, enhance brand visibility, strengthen the company’s industry reputation and lead digital transformation initiatives that position the company for sustained success and growth

‘We are thrilled to welcome Jordan to our leadership team and are confident that he will deliver exceptional value and unparalleled experiences to our customers,’ said Sam Errigo, president and CEO of Konica Minolta. ‘His extensive marketing expertise across key disciplines will set us apart in the market, highlighting our products and solutions and propelling Konica Minolta into a bold new chapter of success ’

Durst Group appoints new global sales director software D u r s t G r o u p h a s a p p

a m

H e w i l l a l s o p l a y a k e y r

l e i n s t r e n g t h e n i n g c u s t o m e r

r e l a t i o n s h i p s , i d e n t i f y i n g c u s t o m e r n e e d s , a n d d r i v i n g

e f f i c i e n c i e s t h r o u g h o u t t h e p r o c e s s f o l l o w i n g t h e “ P i x e l t o

O u t p u t ” s t r a t e g y

M i c h a e l D e f l o r i a n , b u s i n e s s u n i t m a n a g e r , D u r s t s o f t w a r e

a n d s o l u t i o n s , s a i d : ‘ W e a r e t h r i l l e d t o w e l c o m e C h r i s

S c h o w a l t e r t o t h e D u r s t t e a m H i s e x p e r t i s e a n d v i s i o n w i l l

b e i n v a l u a b l e a s w e c o n t i n u e t o i n n o v a t e a n d e x p a n d o u r

s o f t w a r e s o l u t i o n s w o r l d w i d e ’

W i t h o v e r 2 0 y e a r s o f e x p e r i e n c e i n p r i n t , p r i m a r i l y i n

i n k j e t , S c h o w a l t e r p o s s e s s e s a p r o f o u n d u n d e r s t a n d i n g

t h e e v o l v i n g s o f t w a r e t e c h n o l o g y l a n d s c a p e a n d i t s

i n t e r s e c t i o n s w i t

Directors and Foundation of FTA Board of Trustees

president, effective September 23, 2024

FTA’s day-to-day

association to evolve to meet its membership’s needs

‘We are thrilled that Nathan has accepted this presidential r o l e H i s s u c c e s s f u l

associations, his customer focus, and his team-oriented management style will enable him to determine and implement an informed direction for the association,’ said Laura Wright, FFTA chair ‘We look forward to Nathan supporting the staff and our members as he takes on the challenge of managing FTA and FFTA ’ Ridnouer most recently held the position of senior vice p r e s i d e n t o f t h e C o m p u t i n g Te c h n o

Association where he led operational departments for member training delivery and certification and technical support

Nathan Ridnouer named FTA president

Haleon Pakistan awarded for exporting Rs1.1bn pharma products

Haleon Pakistan Limited has been was awarded with export award at the Pakistan Pharma Summit and Awards for exporting Rs1.1 billion pharma products to international markets, including Vietnam and Philippines

The award was presented to Chief Executive Officer Haleon Pakistan Farhan Muhammad Haroon by Senate Chairman Yousaf Raza Gillani hosted by the Pakistan Pharmaceutical Manufacturer ’s Association (PPMA) the other day.

CEO Haleon, while talking to Business Recorder, here on Thursday, said his company is incredibly proud to receive this prestigious export award and the company is aiming to achieve economies of scale by expanding its production lines.

He said that this will not only control the cost but will also ensure smooth availability in the local market besides fostering growth in exports Deregulation of the prices of non-essential medicines is also a good omen for the industry and will allow the companies to share the cost shocks with their consumers

He said that in the next few years, the company is committed to increase exports as well as locally increase market share He said that at present, Pakistan’s pharma industry’s total exports were roughly around $700 million dollars and the entire pharma industry is committed to take it to $3 billion within the next few years

Nishat Mills looks to sell hospitality business, will establish subsidiary in Türkiye

The board of Nishat Mills Limited (NML), the flagship company of Nishat Group, has approved to dispose off 100% equity held in Nishat Hospitality while also giving its green-light to establish a wholly-owned subsidiary in Turkiye and a liaison office in Bangladesh

The company made these announcements in its notice to the Pakistan Stock Exchange (PSX) on Friday It also announced financial results for

Rs10 5 billion

“The Board of Directors has accorded its approval for the

owned subsidiary company in Republic of Türkiye subject to applicable regulatory approvals, and in compliance with laws of Republic of Türkiye,” read the notice Similarly, NML’s board accorded its approval for setting up a liaison office in Bangladesh, “subject to applicable regulatory approvals, and in compliance with laws of People’s Republic of Bangladesh”.

Systems Ltd wins ‘Top IT Services Exporter Award’

Systems Limited has once again marked its success at the P@SHA ICT Awards 2024 by securing the esteemed Top I T S e r v i c e s E x p

Rasheed, Senior Vice President Telco Growth Leader, and Javeria Fahad, Head of Marketing, from Systems Limited. Over the years, Systems Limited has been a consistent recipient of P@SHA’s accolades, showcasing its relentless commitment to digital excellence

R e c o g n i s e d f o r i t s o u t s t a n d i n g p e r f o r m a n c e a n d contributions to the IT sector, Systems Limited continues to expand its presence in diverse international markets, delivering world-class technology solutions The Top IT Services Exporter Award reflects the company’s significant growth and role as a key player in Pakistan’s thriving tech ecosystem.

SPL posts Rs1.49bn profit after tax

l a s t y e a r

S P L h e l d i t s 5 9 t h A n n u a l G e n e r a l M e e t i n g ( A G M ) a t i t s h e a d

o f f i c e , w h e r e s h a r e h o l d e r s a p p r o v e d t h e a n n u a l a u d i t e d

f i n a n c i a l s t a t e m e n t s f o r t h e y e a r e n d e d J u n e 3 0 , 2 0 2 4

M o h a m m a d A f t a b M a n z o o r ,

C h a i r m a n o f t h e B o a r d ,

c h a i r e d t h e m e e t i n g a n d

a t t e n d e d b y o t h e r m e m b e r s o f

t h e B o a r d o f D i r e c t o r s a n d

S e n i o r M a n a g e m e n t

D u r i n g t h e A G M , s h a r e h o l d e r s

r e v i e w e d a n d a p p r o v e d t h e

C o m p a n y ' s i m p r e s s i v e

f i n a n c i a l p e r f o r m a n c e , m a r k e d b y a 5 5 p e r c e n t i n c r e a s e i n

p r o f i t b e f o r e t a x t o R s 2 . 3 9 2 b i l l i o n a n d r e c o r d s a l e s

r e v e n u e o f R s 7 3 1 2 b i l l i o n

N o t a b l y , t h e p r o f i t a f t e r t a x s t o o d a t R s 1 4 8 9 b i l l i o n i n

2 0 2 4 , r e p r e s e n t i n g 5 4 p e r c e n t i n c r e a s e f r o m l a s t y e a r

T h e s h a r e h o l d e r s a l s o a p p r o v e d t h e h i g h e s t - e v e r d i v i d e n d

o f R s 1 2 . 5 0 p e r s h a r e , r e p r e s e n t i n g 1 2 5 % . T h i s i n c l u d e s a n i n t e r i m c a s h d i v i d e n d a l r e a d y p a i d a t t h e r a t e o f R s 2 5 0 p e r

s h a r e , a n d a f i n a l c a s h d i v i d e n d o f R s 1 0 0 0 p e r s h a r e

T h e s h a r e h o l d e r s e x p r e s s e d s a t i s f a c t i o n w i t h t h e

C o m p a n y ' s p e r f o r m a n c e a n d a p p r e c i a t e d t h e m a n a g e m e n t ' s

e f f o r t s i n a c h i e v i n g r e m a r k a b l e g r o w t h d e s p i t e c h a l l e n g i n g e c o n o m i c c o n d i t i o n s

Siemens Pakistan announces ‘Rs556mn strategic transformation’

Siemens (Pakistan) Engineering (SIEM) announced that it is transforming one of its operational segments within the Smart Infrastructure -

Wednesday

Automation Business

shared the development

IT minister claims Dr Umar sabotaged deal with Paypal

Minister of State for IT and Telecom Shaza Fatima Khawaja accused former caretaker federal minister Dr Umar Saif of sabotaging a private deal of bringing

Pakistan by leaking it before time.

“Bringing PayPal to Pakistan was a private deal, which Dr Saif leaked before time This action annoyed PayPal and he (Dr Umar) sabotaged it”, said Khawaja

“This change aims to better align the business to serve the l o c a l m a r k

shareholders’ value by embedding the required flexibility in its operations,” Siemens Pakistan said

The company said that due to the latest decision, “certain employees have voluntarily chosen to part ways with Siemens Pakistan and avail themselves of severance benefits” In its notice, Siemens Pakistan did not specify the reduction in its number of employees

“The estimated one-time cost of this transformation is approximately Rs556 million, which will be borne by the company,” it said, adding that the transformation will not affect any business lines of the company, “which will continue to operate as usual”

Replying to a question, the minister said that insufficient spectrum, increasing number of users; load management practices of telecom operators due to expensive electricity, low investment due to issues in opening of letters of credit (LCs) as well as faults in two submarine cables were the major reasons behind the slow internet in the country

When asked about the slow internet connectivity, she explained that Pakistan currently operated with 274 MHz of spectrum, while 550 MHz had recently been freed from litigation over the past six months. The minister also said that the 5G auction had been delayed due to ongoing legal matters.

She said restrictions on opening LCs had a bad impact since they delayed the import of necessary telecom equipment The minister further revealed no new telecom infrastructure has been established in the past two years due to a lack of investment, while energy and fuel price hikes have burdened the sector

2024

Visom Italia 2024

16-18 October, Milano, Italy https://www.viscomitalia.it/en-gb.html

Asia Ink Expo 2024

16-18 Oct, Guangzhou, China www ink-expo com

Remax World Expo 2024

17-19 October, Zuhai, China www rtmworld com/remaxworld

Tokyo Pack 2024

23-25 Oct, Tokyo, Japan https://www tokyo-pack jp/en/

Eurasia Packaging 2024

23-26 October, Istanbul, Turkey https://www packagingfair com/en/

Plastic, Packaging & Print Asia 2024 29-31 October, Karachi, Pakistan https://plastpackasia.com.pk

Sign Istanbul 2024

31 Oct-3 Nov, Istanbul, Turkey https://en.signistanbul.com/

Pack Expo 2024

3-6 November, Chicago, USA https://www packexpointernational com

ALL4Pack 2024

4-7 Nov, Paris, France https://www all4pack com/

ICE China 2024

6-8 November, Shenzhen, China https://www.film-expo.com/engb/icechina html

Paperworld Middle East 2024 12-14 Nov, Dubai, UAe www.paperworld-middleeast ae messefrankfurt com/dubai/en html

Label Expo India 2024 14-17 November, Delhi, India https://www.labelexpo-india.com/

Paperworld China 2024

15-17 November, Shanghai, China https://paperworldchina.hk.messefrankf urt com/shanghai/en html

SWOP 2024

18-20 November, Shanghai, China https://www swop-online com/en/

Paper ME 2024

18-20 Nov, Jeddah, Saudia Arabia https://www.papermideast.com/ksa/ Plaspak Indonesia 2024

20-23 November, Jakarta, Indonesia www plasticsandrubberindonesia com/

China Coat 2024

3-5 December, Shanghai, China

https://www chinacoat net/

LabelExpo South China 2024 4-6 December, Shenzhen, China https://www.labelexpo-southchina.com/

Plast Eurasia Istanbul 2024

4-7 December, Istanbul, Turkey https://plasteurasia com/en/

Iran Print & Pack 2024

12-15 December, Iran www icffair com/en/2024/iranpack html

2025

Arabplast 2025

7-9 January, Dubai, UAE https://www arabplast info/

Fespa Middle East 2025

20-22 January, Dubai, UAE https://www.fespamiddleeast.com/

Paperworld India 2025

23-25 January, Mumbai, India https://paperworldindia in messefrankf urt com/mumbai/en html

Printpack India 2025

1-5 February, Delhi, India https://www.printpackipama.com/

IPF Bangladesh 2025

12-15 February, Dhaka, Bangladesh https://www chanchao com tw/IPF/

Printpack Alger 2025 24-26 February, Algiers https://www printpackalger com/

Printing South China 2025 4-6 March, Guangzhou, China www printingsouthchina com

Sino label 2025 4-6 March, Guangzhou, China www sinolabelexpo com

Sino Pack 2025

4-6 March, Guangzhou, China https://www.chinasinopack.com/

Packinno 2025

4-6 March, Guangzhou, China https://www.packinno.com/

Appp Expo 2025

4-7 March, Shanghai, China https://www.apppexpo.com

Inprint 2025

11-13 March, Munich, Germany https://www cce-international com/

ICE Europe 2025

11-13 March, Munich, Germany https://www ice-x com/en-gb html

Prod & Pack 2025

18-20 Nov, Lyon, France https://www prodandpack com/en/

Plastic & Rubber Vietnam 2025 18-20 March,Ho Chi Minh, Vietnam www plasticsvietnam com

Graphics Canada 2025

9-11 April, Toronto,Canada https://graphicscanada com/

Label Expo Mexico 2025

1-3 April, Guadalajara https://www labelexpo-mexico com/

Tissue World 2025

1-3 April, Dusseldorf, Germany https://www tissueworld com/

Sino Corrugated 2025

8-10 April, Shanghai, China https://www sino-corrugated com/

Sino Folding 2025

8-10 April, Shanghai, China https://www.sino-foldingcarton.com/

Label Expo South East Asia 2025

8-10 May, Bangkok, Thailand https://www labelexpo-seasia com/

China Print 2025

15-19 May, Beijing, China http://www.chinaprint.com.cn/

IPACK-IMA 2025

27-30 May, Milano, Italy https://www ipackima com/

Print4all 2025

27-30 May, Milano, Italy

https://www.print4all.it/en

Print4All 2025

27-30 May, Milano, Italy

https://www.print4all.it/en

Plasti&Pack 2025

29-31 May, Lahore, Pakistan https://plastipackpakistan.com/

HanoiPlas 2025

4-7 June, Hanoi, Vietnam https://hanoiplas.chanchao.com.tw/en

Coat Expo 2025

17-19 June, Guangzhou, China http://www.coatexpo.cn/en/index.php

Propak China 2025

24-26 June, Shanghai, China https://www propakchina com/en

Hanoi Print Pak 2025

2-5 July, Hanoi, Vietnam www.chanchao.com.tw/HanoiPrintPack

Print Expo 2025

10-12 July, Chennai, India https://www printexpo co in/

PackPlus 2025

31 July-2 August, New Delhi, India https://www.packplus.in/

KIPES 2025

20-23 August, Seoul, Korea https://kprint kr/eng/

K Label 2025

20-23 August, Seoul, Korea https://kprint kr/eng/

K Pack 2025

20-23 August, Seoul, Korea https://kprint.kr/eng/

K Digital Print 2025

20-23 August, Seoul, Korea https://kprint kr/eng/

K Textile 2025

20-23 August, Seoul, Korea https://kprint.kr/eng/

K Sign & Ad 2025

20-23 August, Seoul, Korea https://kprint kr/eng/

Paper ME 2025

9-11 September, Cairo, Egypt https://www.papermideast.com/eg/

3P Pakistan 2025

10-12 September, Karachi, Pakistan https://www plasprintpack com/

Label Expo Europe 2025

16-19 September, Barcelona, Spain https://www labelexpo-europe com/

Sign China 2025

17-19 September, Shanghai, China https://www.signchinashow.com/en/

Vietnam Plas2025

17-20 Sept, Hochi Min CIty, Vietnam www vietnamplas chanchao com tw/en

Pack Print International 2025

17-20 September, Bangkok, Thailand https://www.pack-print.de/

CorruTec Asia 2025

17-20 September, Bangkok, Thailand www corrutec-asia com

Fachpack 2025

23-25 Sept, Nuremberg, Germany https://www.fachpack.de/en

The Print Show 2025

23-25 September, Birmingham, UK https://www theprintshow co uk/

Gulf Coating Show 2025

24-26 September, Sharjah, UAE https://www.gulf-coatings-show.com/

Fespa Eurasia 2025

24-27 September, Istanbul, Turkey https://fespaeurasia com tr/en/

Fespa Mexico 2025

25-27 September, Mexico https://mexico.fespa.com/

India Paper Expo 2025

25-27 September, Mumbai, India https://www indiapaperexpo com/

Pack Expo 2025

29 Sept-1 October, Las Vegas, USA https://www packexpolasvegas com/

All Print Indonesia 2025

8-11 Kemayoran, Indonesia https://allprint co id/

K 2025

8-15 October, Dusseldorf, Germany https://www k-online de/

ProPaper Dubai 2025

13-15 Oct, Dubai, UAE https://propaperdubai com/

Printing United 2025

22-24 October, Orlando, USA https://www printingunited com/

Paperex 2025

3-6 December, New Delhi, India https://india paperex-expo com/Home 2026

Pamex 2026

27-30 January, Mumbai, India https://www.pamex.in/

Metpack 2026

5-8 May, Essen, Germany https://www metpack de

Interpack 2026

7-13 May, Dusseldorf, Germany https://www.interpack.com/

All in Print China 2026

12-16 October, Shanghai, China https://www allinprint com/en/