PRELIMINARY SUMMARY FOR HIGH PRESSURE PROCESSING (HPP) IN HAWAIʻI

Prepared by: University of Hawaiʻi Community Design Center

Submitted to: The Agribusiness Development Corporation

May 2022

DRAFT

Proof of Concept Design Cont.

53

Proof of Concept Design

Draft Conceptual Master Plan

Draft 3D Conceptual Master Plan

Phase 1 Draft Conceptual Master Plan

-Civil Drawing

Phase 2 Draft Conceptual Master Plan

-P3 Lease Area Boundary

Proof of Concept New Construction for HPP Facility

HPP Facility Program Matrix

HPP Facility Program Description

HPP Facility Program Inventory

New Construction Proposed Floor Plans

New Construction Proposed Elevation Drawings

New Construction Section Drawings

HPP Facility Warehouse Expansion

Matrix

HPP Facility Warehouse Expansion Description

HPP Facility Warehouse Expansion Program Inventory

HPP Facility Warehouse Expansion

Proposed P3 Development Warehouse Configurations

128 Recommended Next Steps

Hawaiʻi Department of Agriculture, Agribusiness Development with support and collaboration from the Office of Senator Donovan Dela Cruz

Department of Business, Economic Development and Tourism

UHCDC Team

Cathi Ho Schar, Principal Investigator

Kimi Makaiau, Project Supervisor

Darlyn Chau, Project Designer

Jonathan Malu Stanich, Project Designer

Maleah Reynolds, Project Designer

Rebecca Ogi Denzer, Research Associate

Jolie Wanger, Graduate Research Assistant

Daniel Luna, Student Assistant

Kaylen Daquioag, Student Assistant

Kiana Dai, Student Assistant

Moises Lio Can, Student Assistant

Renz Carlo Laforteza, Student Assistant

Consultants

Fehr & Peers Transportation

HiCal Partners LLC

Insynergy Engineering Inc.

J. Uno & Associates

PBR Hawaiʻi

Sam H. Hirota Engineering

Advisor

Honua Consulting

2 3 Table of Contents 06 Introduction Project Site Related Site What is High Pressure Processing (HPP)? Manufacturers Machine Comparison Benefits Product Types Food Safety 08 10 12 14 15 16 18 Consultation Interviews Site Visits Public Seminar Additional Community Engagement HPP Research & Outreach 22 23 24 26 27 28 21 Process 133 193 206 221 241 245 251 285 289 313 Appendix A - Manufacturer Comparison Appendix B - Testing Facilities Appendix C - Hawaiʻi Working Group Report and Findings Appendix D - Survey Results Appendix E - Foreign Trade Zone Fact Sheet Appendix F - Civil Basis of Design Appendix G - Mechanical/Electrical/ Plumbing Study Appendix H - Public Use and Structures Appendix I - Renovation of Building R & T Appendix J - HPP Machine & Market Preliminary Analysis 130 Appendix Staff Maintenance Efficiency Auxiliary Equipment Testing Packaging Requirements and Food Safety Considerations Regulatory/Insurance Considerations Toller Pricing Marketing Facilities Plans 32 34 35 36 37 38 39 40 41 42 31 Information Synthesis 55 56 58 59 60 62 72 74 76 78 80 82 84 86 88 90 91 92 94 96 98 100 101 102 104 106 88 110 112 114 116 118 120 122 124 126 Proof of Concept Renovation Alternatives for HPP Facility Building R Building R Existing Site Plan Building R Existing Floor Plan Building R Existing Elevation & Section Drawings Building R Proposed Floor Plans Building R Proposed Elevation Drawings Building R Proposed Section Drawings Building R and Warehouse Expansion Drawings Proposed P3 Development Building R Warehouse Configurations

85

Proof of Concept

Existing

Plan Master Plan

Community Engagement

Master Plan

Design Considerations Draft Conceptual

Components Phase

Master Plan

Site

Engagement Approach

Synthesis

Engagement Feedback

Master Plan

1 Phase 2 Phase 3 - 4

This project was made possible by

Acknowledgments 46 48 50 HPP Food Services HPP LA Dora’s Naturals 51 Precedent Studies 04 Executive Summary

DRAFT DRAFT

Executive Summary

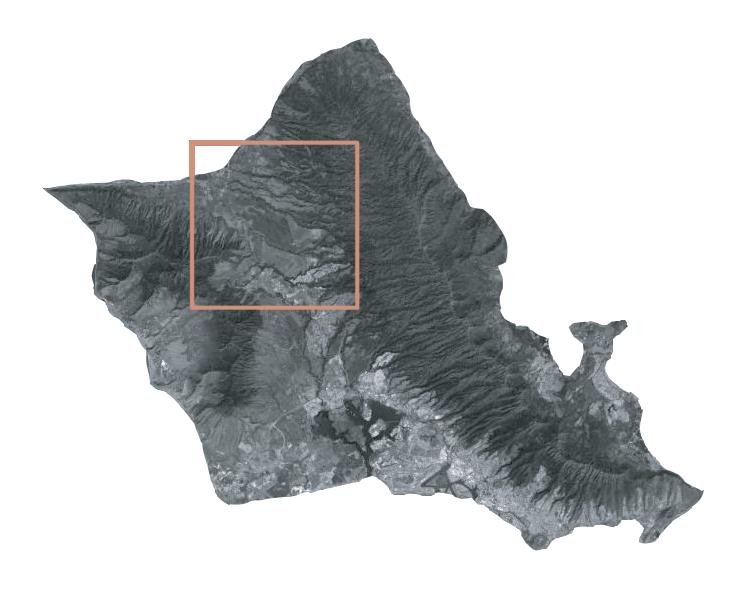

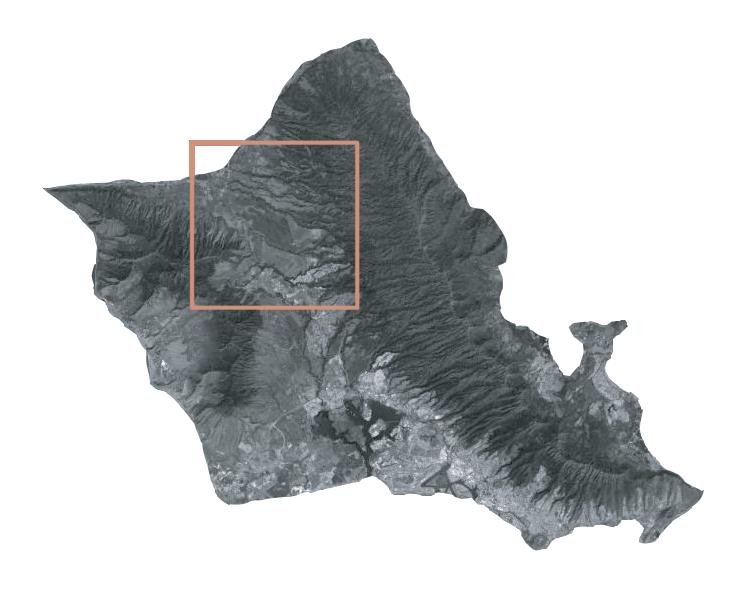

The Whitmore Community Food Hub Complex (WCFH) is proposed on the parcel currently occupied by the Whitmore Agricultural Tech Park, formerly the Dole Company Operation Facility, south of Whitmore Village. The Agribusiness Development Corporation (ADC) owns and manages the property that will support the proposed WCFH.

The project aims to create a post-harvest facility that meets the requirements of the Food Safety Modernization Act (FSMA), while integrating logistical spaces for agricultural tenants and related businesses. The complex is designed to pool services for the aggregation, processing, storage, marketing and distribution of locally produced foods by small growers throughout Oʻahu’s central, northern, and leeward regions. Agricultural tenant spaces, commercial kitchen facilities, warehouse and office spaces, greenhouses, and workforce housing are also envisioned on the parcel.

The ADC has identified High Pressure Processing technology (HPP) as an important investment to support Hawaiʻi’s agricultural industry. HPP is a food preservation technique that uses pressure rather than heat or chemicals to inactivate harmful pathogens and vegetative spoilage microorganisms to extend product shelf life. This new food preservation technology would be among the first in the state, and the intent is to make its use accessible to value-added producers from across the islands. The ADC plans to acquire, house, and operate an HPP machine(s) at the WCFH to help grow Hawai‘i’s local value-added products market.

Additionally, the Hawai‘i State Department of Education (DOE) is proposing to build a centralized kitchen facility and accompanying warehouse that would allow for more efficient production of school lunches as well as increase the procurement of locally sourced ingredients.

The proposed project consists of retaining and renovating some current assets from the previous operation facility, constructing new warehouse and office spaces, as well as the addition of a state operated centralized kitchen facility, and workforce housing. The project is envisioned in four phases: 1) infrastructure improvements to support the project’s long-term development goals; 2) renovation and/or construction of agricultural processing warehouse(s) and DOE centralized kitchen facilities; 3) renovation and/or construction of warehouses and office spaces; and 4) the construction of workforce housing. The project will encompass approximately 34 acres and include TMK parcels (1) 7-1-002 :009, 004 {POR.), 022, 023.

This report introduces and documents the feasibility of applying HPP technology at the WCFH. It also documents the public engagement process UHCDC employed as part of this initial study. Since HPP is a new technology to the state, UHCDC conducted extensive research including consultation with HPP manufacturers and existing HPP operators and users in North America, potential users of the technology in Hawaiʻi, and other interested parties to inform the planning and design process.

This report synthesizes the information gathered through the engagement process in three ways: 1) Data collected is categorized and listed in the Information Synthesis section; 2) Information is incorporated into proof of concept designs for an HPP facility and design considerations which guided the development of a conceptual master plan; and 3)Recommended next steps for the ADC and/ or the future HPP operator to consider as the project progresses.

Key findings:

• HPP technology has strong interest and momentum among the valueadded product industry in Hawai‘i and has great potential to help local producers grow this market.

• Industry and community outreach and consultation in the planning process is key to the success of this project.

• Viable options exist for both construction of new facilities or renovation of existing buildings to house the HPP machine(s) and expand to build additional food hub warehouse facilities.

• Due to food safety requirements, some important considerations for HPP facility configuration include a one-way flow of product to prevent cross-contamination, facility for an onsite USDA inspector, sufficient cold storage for anticipated product volume and consideration of adjacent support amenities (such as co-packing).

• Marketing needs to be considered and initiated at an early stage to help prepare the market for the technology.

Recommended Next Steps:

• The future HPP operator should outreach to existing HPP manufacturers, tollers, and testing facilities to better understand HPP operational designs and needs.

• It is important to conduct outreach to the Whitmore/Wahiawā community early and often to gather their input and feedback.

• Additional outreach should include potential statewide users of the HPP technology, farmers and producers as prospective tenants of and contributors to the food hub, as well as educational institutions to support agricultural pathways to employment.

• The operator will also need to work with ADC to coordinate infrastructure improvements.

• A traffic consultant should be engaged to develop a traffic mitigation strategy.

• Create a strategy for securing the site and a visitation plan for any public visits to the facility.

• Collaborate with the Leeward Community College’s Value-Added Product Development Center in Wahiawā to improve coordination among product development and commercial industry needs.

4 5

DRAFT DRAFT

Introduction

Background

The Whitmore Community Food Hub (WCFH) is proposed on the parcel currently occupied by the Whitmore Agricultural Tech Park, formerly the Dole Company Operation Facility, south of Whitmore Village. The Agribusiness Development Corporation (ADC) owns and manages the properties which will support the proposed WCFH. While the ADC is the managing agency, they are collaborating with other federal, state, county, and community organizations/agencies for the successful implementation of this project. The goals for the project, established by ADC are:

1. To demonstrate that farming is an attractive profession that can be revenue generating and can allow farmers the ability to live and work in Hawai‘i;

2. To create synergy and scale by providing a food processing facility that results in reducing the overall costs of farming and ensures supportive systems and activities become efficient;

3. To develop a comprehensive, economically sustainable facility for farmers that supports several stages of agricultural production including farms, packing and processing facilities, distribution systems, infrastructure and water, public-private partnerships and long-term investments.

In 2019, an Environmental Assessment (EA) for the project’s master plan was completed, and received a “Finding of No Significant Impact” determination. In 2021, The University of Hawaiʻi Community Design Center (UHCDC) was contracted by ADC to update the existing master plan to reflect any changes related to evolving discussions across agencies, to seek additional input from agricultural and community stakeholders, and to develop more detailed information needed to guide future funding requests for capital improvements and site development.

Agribusiness Development Corporation

High Pressure Processing

The state has identified High Pressure Processing (HPP) technology as an important investment to support Hawaiʻi’s agricultural industry. HPP is a food preservation technique that uses pressure rather than heat or chemicals to inactivate harmful pathogens and vegetative spoilage microorganisms. The WCFH will house this technology to help grow Hawaiʽi local value-added products market. As part of the overall master plan update, UHCDC is assisting ADC with research, engagement and conceptual plans for the proposed HPP facility. This report synthesizes UHCDC’s preliminary findings and recommended next steps, which can be used to inform procurement and successful implementation of the project.

ADC, established in 1994, facilitates and provides direction for diversification of Hawai‘i’s agricultural industry. ADC’s mission is “to acquire and manage, in partnership with farmers, ranchers and aquaculture groups, selected high-value lands, water systems and infrastructure for commercial agricultural use and to direct research into areas that will lead to the development of new crops, markets and lower production costs.” ADC’s stated responsibilities include: “transitioning former plantation lands and water systems to diversified long-term agricultural use, initiating and developing diversified agriculture facilities, and finding innovative solutions for issues facing the agricultural industry today.”

UHCDC

DRAFT DRAFT

UHCDC is a collective of University of Hawai‘i faculty, staff, and allied professionals across university departments and disciplines, assisted by student interns and recent graduates. UHCDC provides a platform for collaboration on public interest built environment work.

UHCDC provides alignment, engagement, communication, research, planning, and design services that provide stakeholders with data, analysis, prototypes, insights, resources, and visualizations that help to collectively guide and inform next steps.

WHITMOREAVE SAIPAN DR *57 Acres ~ 34 Acres UAKANIKO’O ST KULIA ST ‘IHI’IHI AVE LALAWAI ST KAMEHAMEHA HWY *POTENTIAL FUTURE FOOD HUB EXPANSION PENDING INTER-AGENCY TRANSFER & NEW EA FOOD HUB SITE 0’ SCALE FEET 500’1000’ DRAFT DRAFT

Related Site

ADC currently owns and manages roughly 2,000 acres of agricultural land in Wahiawā, O‘ahu. ADC also owns a 1.5 acre parcel in the Wahiawā community business district. The subject property was acquired by ADC in 2013 with the goal to advance agriculture in Hawai‘i. The Leeward Community College (LCC) Value-Added Product Development Center (VAPDC) is currently under construction on this site and is anticipated to open in Spring 2023. The VAPDC will support post-secondary education in the incubation and marketing of value-added food products through the recycling of nearby agricultural waste streams. Besides delivery of post-secondary education services in food science, the goal of the VAPDC is to convey scalable (capable of commercialization) food production processes. Essentially, entrepreneurs can graduate from the LCC VAPDC and move on to a larger scale production at WCFH.

As an integral part of the WCFH initiative, the VAPDC will have facilities that support the development and marketing of products and platforms that promote the promulgation of locally grown food resources through the upcycling of agricultural by-products. This facility will house a HPP machine and ancillary equipment. Current plans are to acquire a small higher pressure processing machine and offer workshops on its application, benefits, and uses.

10 11

H-2

KAMEHAMEHAHWY

TOWAIALUA FARRINGTONHWY TONORTHSHORE

WHITMORE COMMUNITY FOOD HUB

LEEWARD COMMUNITY COLLEGE VALUE ADDED PRODUCT DEVELOPMENT CENTER

NOTE: ADC FARMLAND HIGHLIGHTED IN ORANGE

DRAFT

DRAFT

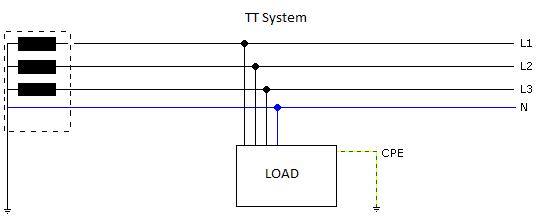

What is High Pressure Processing (HPP)?

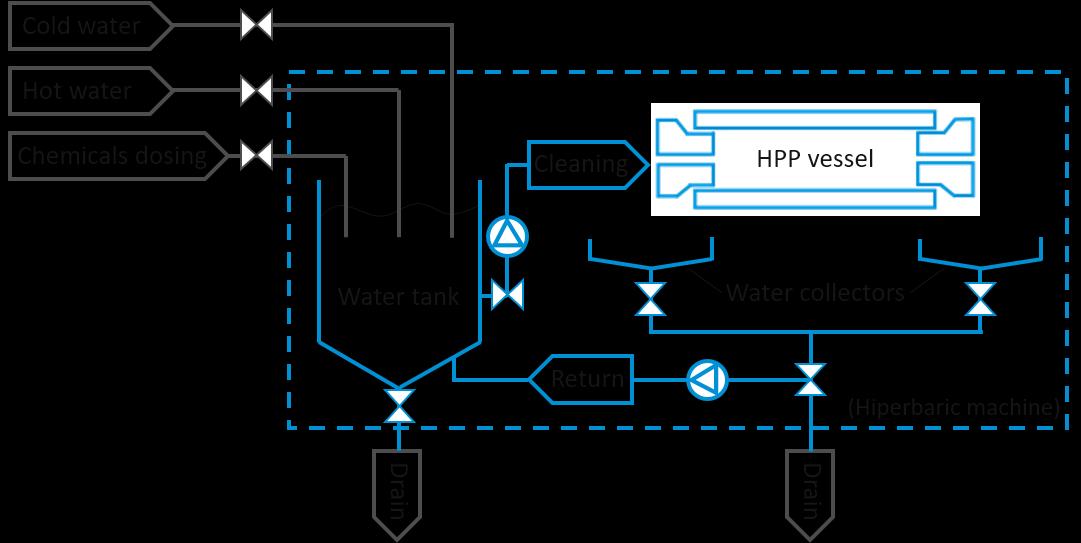

High Pressure Processing (HPP) is a food preservation technique that uses pressure rather than heat or chemicals to inactivate harmful pathogens and vegetative spoilage microorganisms.

HPP provides a means for retaining food quality while avoiding the need for excessive thermal treatments or chemical preservatives. HPP technology will provide new benefits and opportunities for Hawai‘i’s agricultural products through food safety improvements, shelf-life extension, and expansion of operational efficiencies to name a few.

12 13

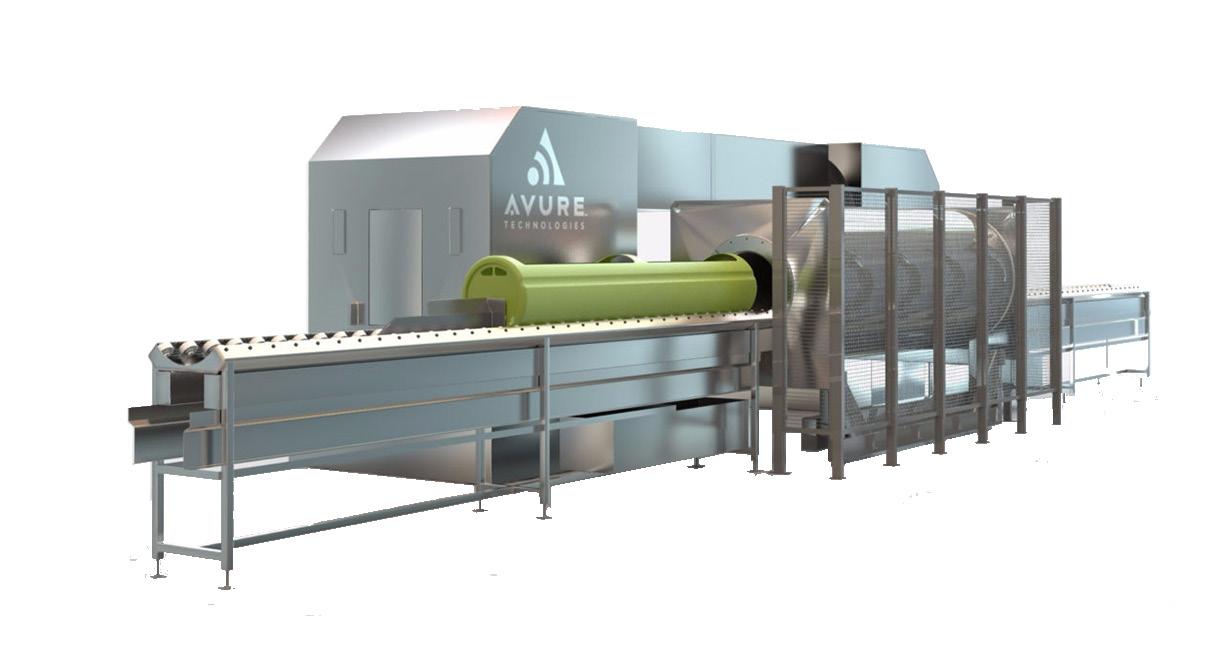

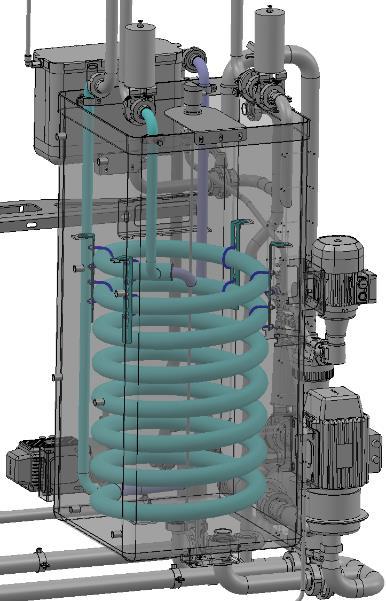

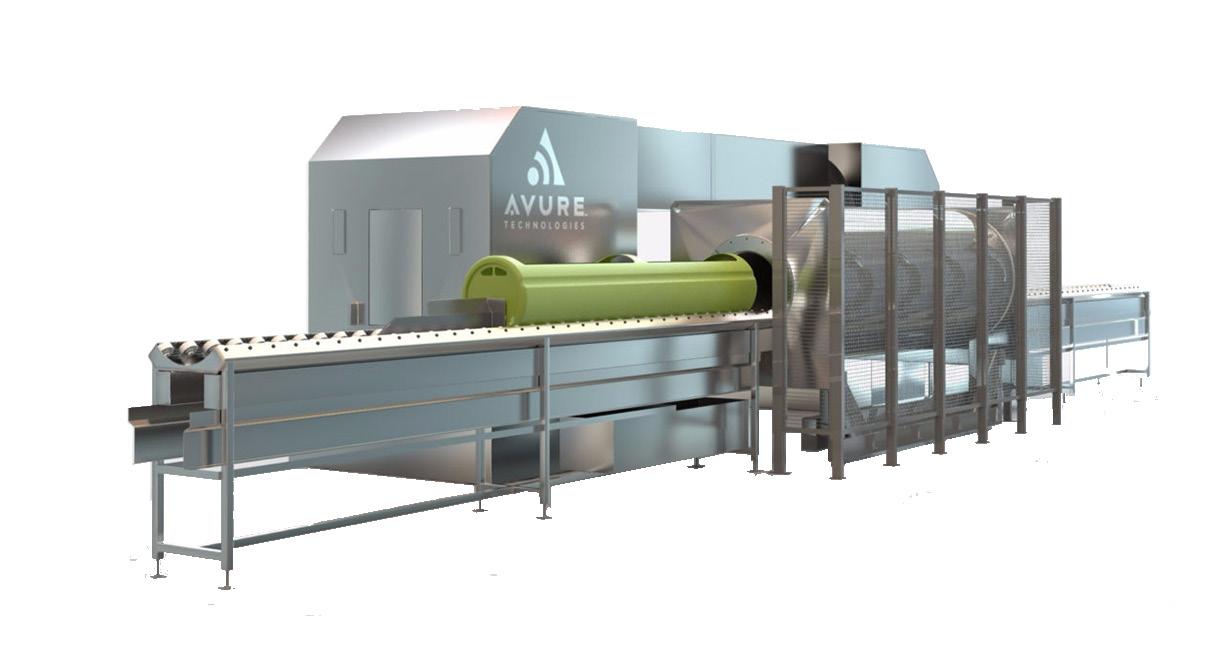

JBT Avure Technologies HPP Machine

Hiperbaric HPP Machine

DRAFT DRAFT

Images

from https://universalpure.com/high-pressure-processing/

Manufacturers

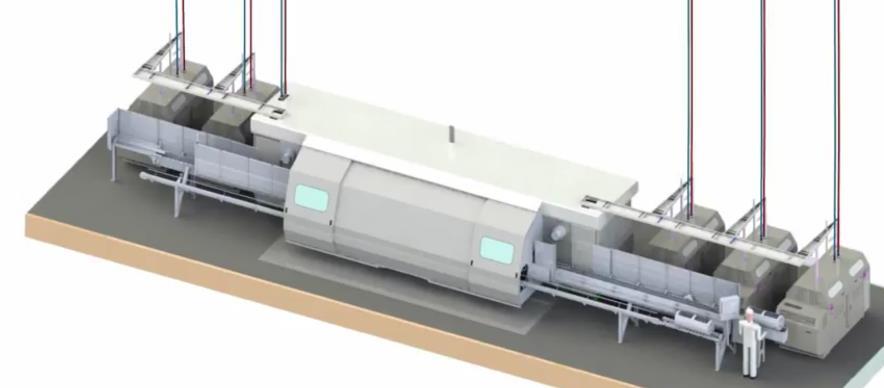

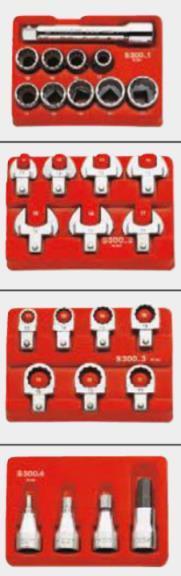

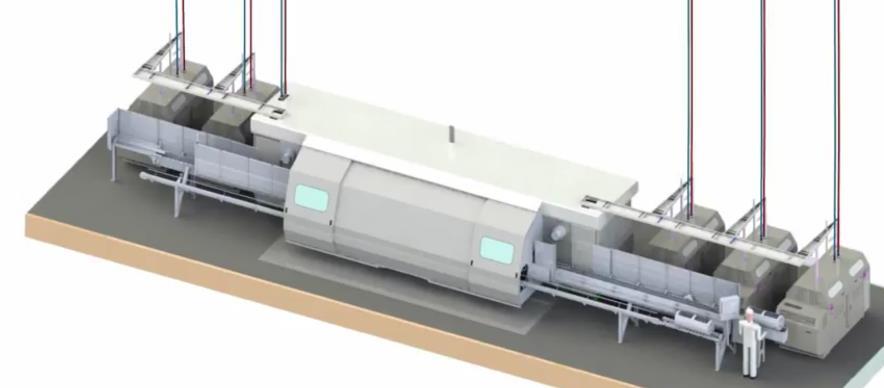

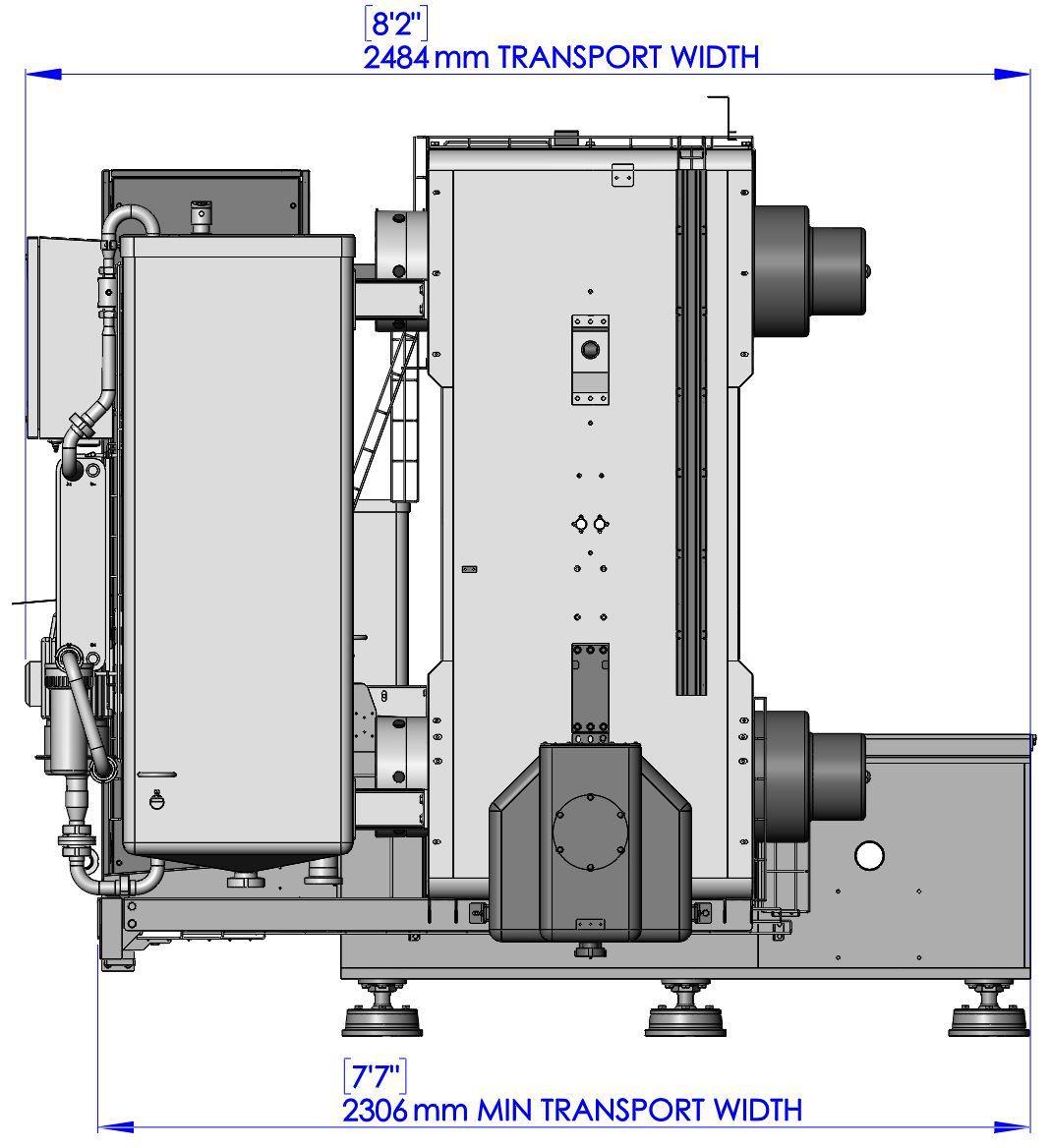

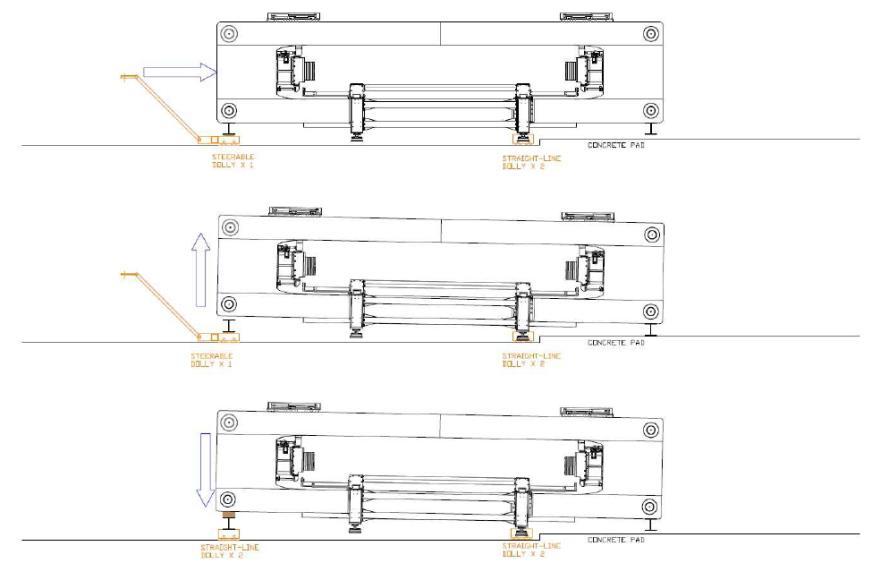

The two leading HPP manufacturers that supply the US domestic market are Hiperbaric and JBT Avure Technologies. UHCDC has engaged both companies to better understand the equipment and services provided, projected operating and maintenance costs, facility and personnel recommendations, etc. in order to provide ADC and the HPP operator with the best information. The HPP operator will select a supplier with the funding support from ADC.

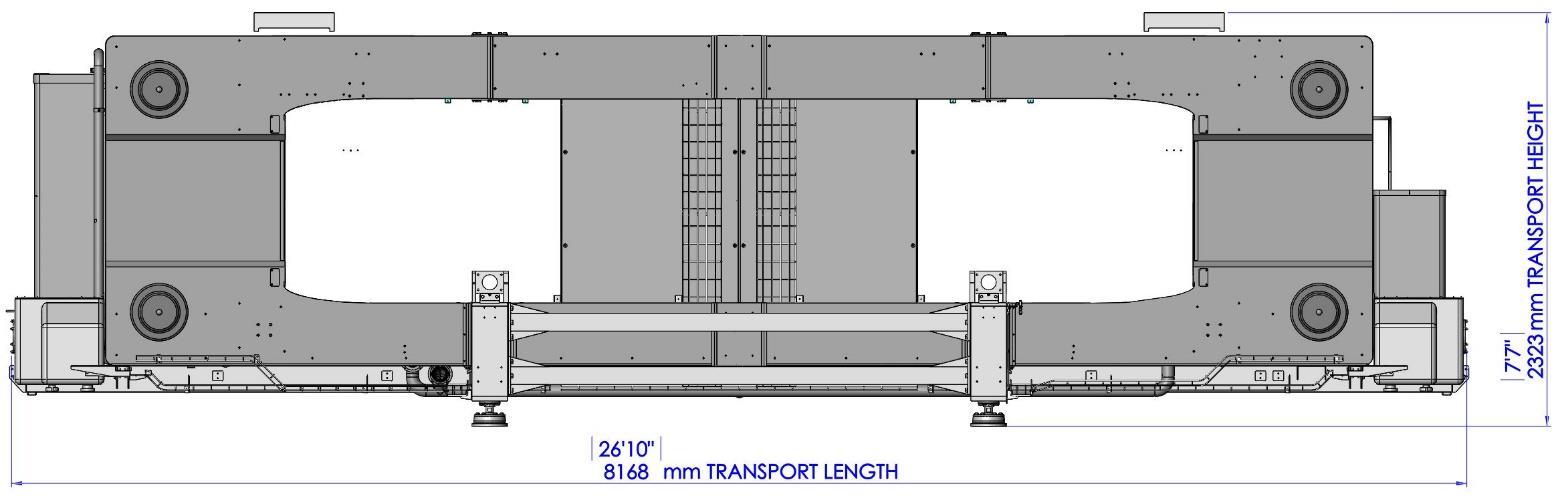

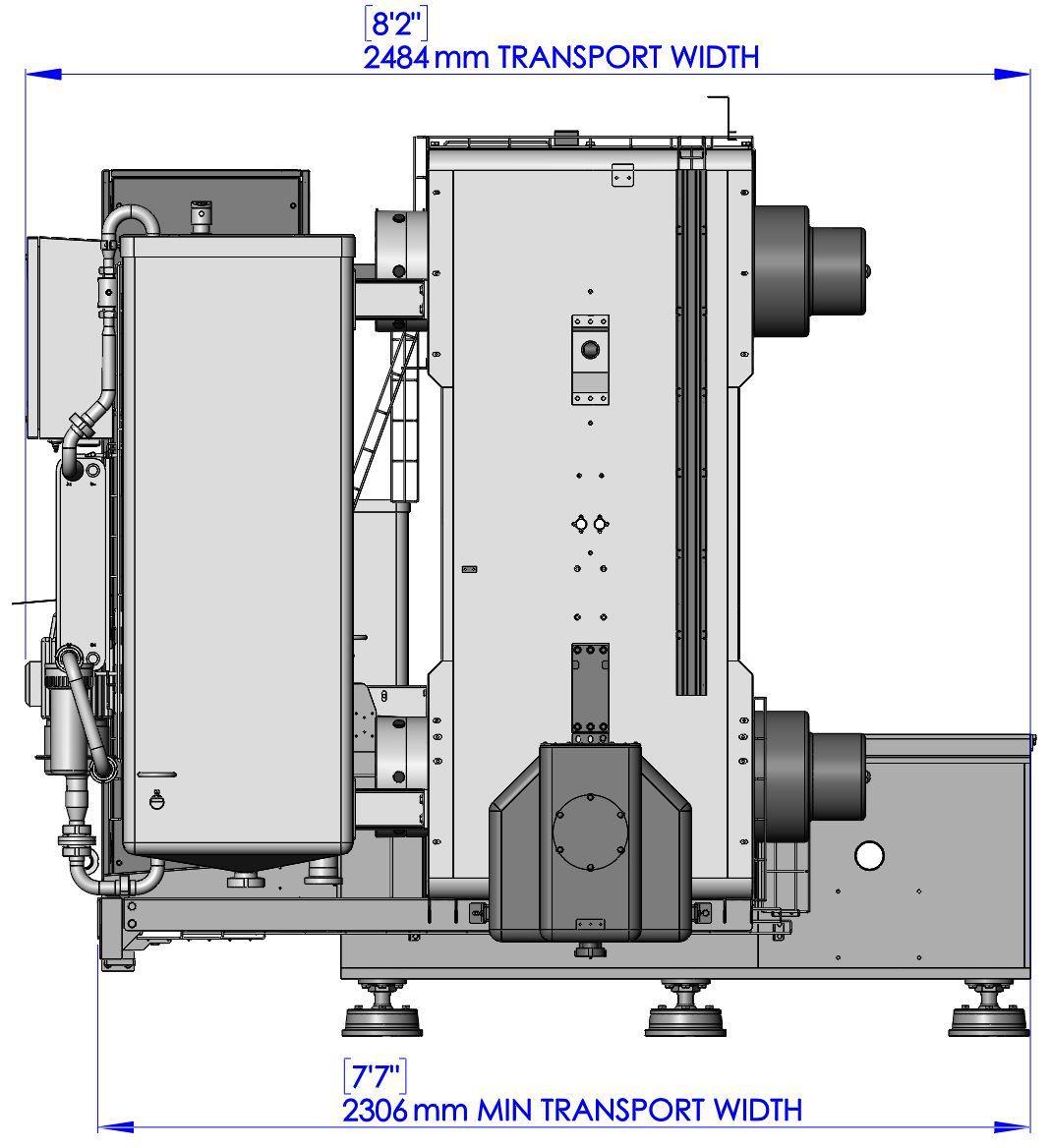

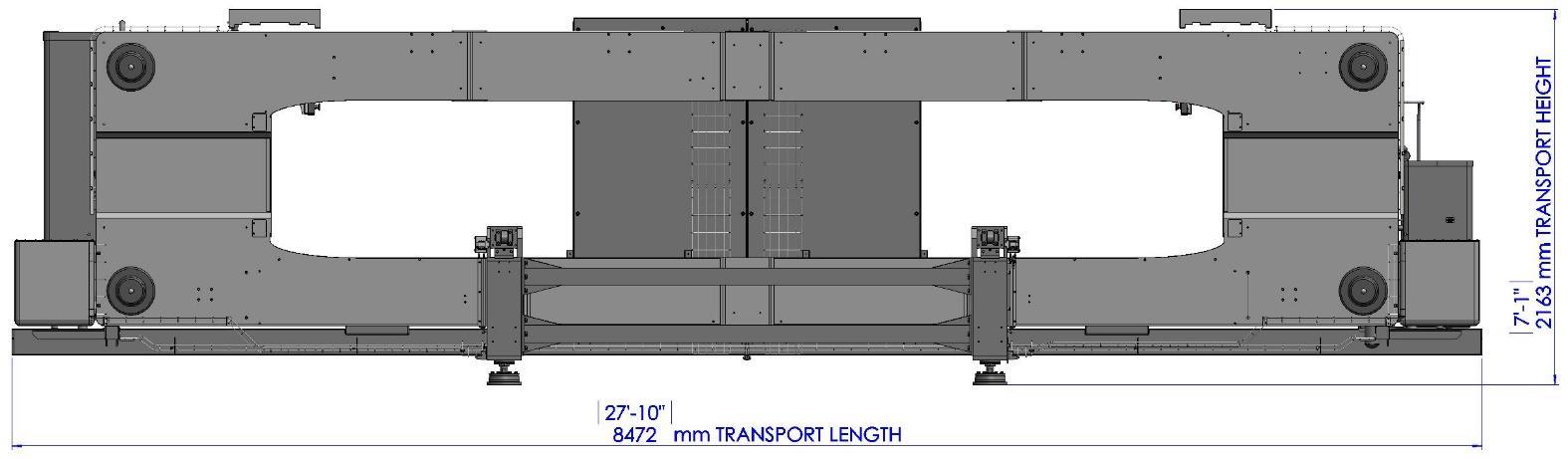

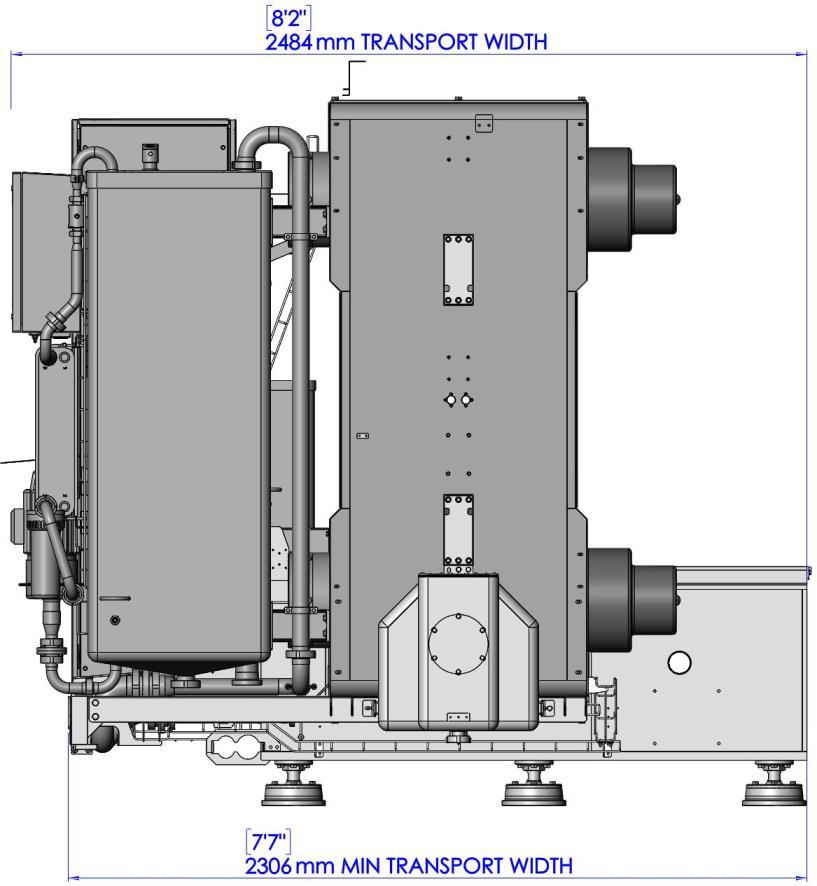

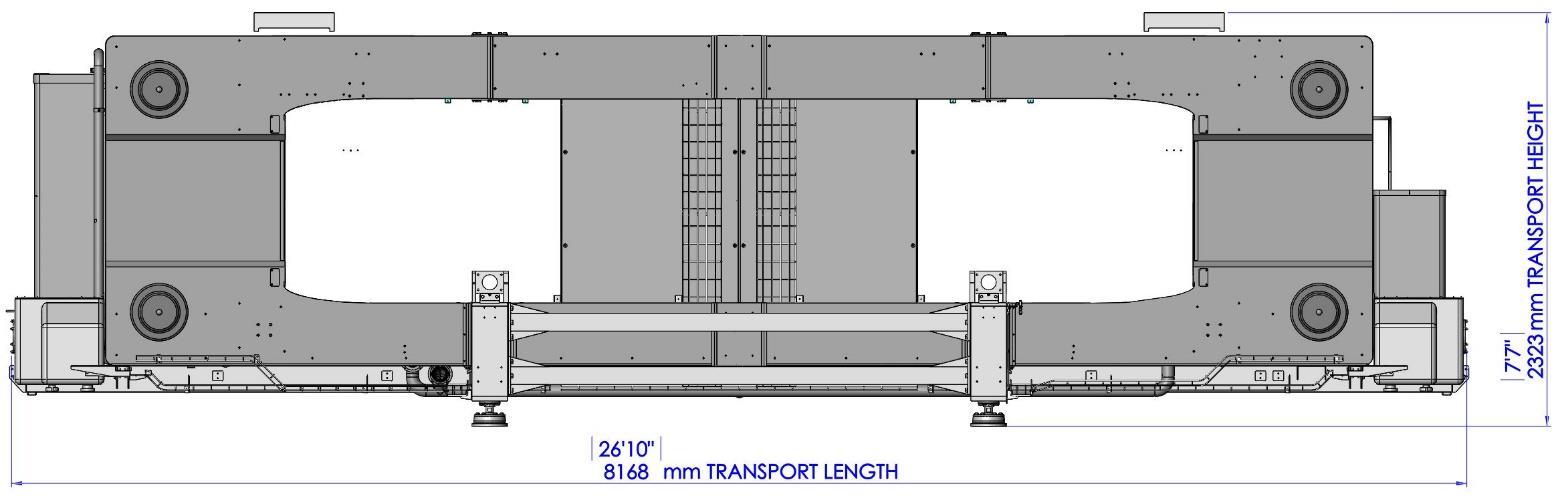

Machine Comparison

There are many factors to consider when selecting the appropriate machine(s) to support Hawai‘i’s growing value-added product industry. Each manufacturer offers a range of machines at different sizes and throughputs. Physical considerations include machine size (footprint, height, auxiliary space needed, etc.). Production considerations include vessel capacity, throughput, operating costs, uptime, etc..

For more information, please review the manufacturer documents included in the Appendix A.

Hiperbaric High Pressure Technologies

Headquarters: Burgos, Spain

US Headquarters: Miami, Florida

Models available: H55; H135; H300; H420; H525

JBT Avure Technologies

Headquarters: Middletown, Ohio

Models available: AV-10; AV-20m; AV-30M; AV-40X; AV-50X; AV-60X; AV-70X

14 15

Hiperbaric HPP Machine

DRAFT DRAFT

JBT Avure Machine

Food Safety

Shelf Life Extension & Food Waste Reduction

Fresh Taste & Nutrient Retention

HPP destroys pathogens (Salmonella, E. Coli, Listeria, Vibrio, Norovirus, etc.) and spoilage microorganisms (lactic acid bacteria, coliforms, etc.), meeting the requirements of food authorities.

HPP can extend a product’s shelf life by three times to thirty times, while still ensuring a high-quality product. It also prevents food waste on the retail shelf and in the consumers’ refrigerator since it has an extended shelf life.

HPP is a non-thermal processing method that maintains the freshness of the original product. This allows the nutritional characteristics, fresh taste, and texture of food products to be retained.

Clean Label

Brand Protection

HPP allows to drastically reduce or eliminate the use of preservatives or additives in food while maintaining freshness and taste.

HPP is applied in final packaging which will eliminate the risk of re-contamination and prevent costly product recalls.

Operational Efficiency & Business

Opportunities

HPP allows producers to develop innovative products and open new market niches, including exporting to new overseas markets. With an extended shelf life, supply chain operations can optimize production and scale operations.

Text adapted from https://universalpure.com/high-pressure-processing/

16 17

Benefits

01

02

03

04

05

06

DRAFT DRAFT

Food Safety

Food safety in the United States relates to the processing, packaging, and storage of food in a way that prevents food-borne illnesses. The U.S. Food & Drug Administration (FDA) is responsible for protecting public health by ensuring the safety of our nation’s food supply. In addition to federal and state food safety standards, the processing of products through HPP requires their own validation and shelf life studies if the products will be sold commercially.

FDA Food Safety Modernization Act (FSMA)

The FSMA is a preemptive set of regulations that are designed to ensure that safety measures are implemented throughout the food system. It enables the FDA to focus more on preventing food safety problems rather than relying primarily on reacting to problems after they occur. The law also provides FDA with new enforcement authorities designed to achieve higher rates of compliance with prevention and risk-based food safety standards and to better respond to and contain problems when they do occur.1

Hazard Analysis Critical Control Point (HACCP)

HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.

Validation Studies

An HPP Validation Study is required under HACCP regulations1. Validation Studies establish and document the scientific processes to control potential hazards and assess how well and how consistently

a particular processing procedure or combination of procedures can deliver products that meet food safety specifications. A validation study is required for every product (Sku) going through HPP processing and the HPP facility is required to maintain the study results on file to meet FDA regulations. An HPP validation (pathogen challenge) study does not determine the overall shelf life of the product. For more information on testing facilities, please see Appendix B.

The critical parameters for determining differences in product and if they can be grouped to minimize validation studies are the pH, water activity and ingredients (See Synthesis for more detail). These parameters will determine the HPP conditions for pathogen inactivation, generally Listeria monocytogenes, Salmonella and E. coli. Inactivation levels required by regulations/ customers will vary depending on food product. In addition, for certain products the FDA Guidelines for Refrigerated Food need to be followed to control issues with nonproteolytic strains of Clostridium botulinum Types B, F and the marine strain Type E.

Shelf-life Studies

An HPP shelf life (spoilage) study is required for labeling (“Best By” dates) and evaluates the effect of HPP process on spoilage microorganisms to determine the time a product can be expected to keep without appreciable change in quality (color, texture, odor, flavor, nutrients and spoilage microbial growth). An HPP shelf Life study should be done prior to or simultaneously with an HPP validation study.2

1FDA Food Safety Modernization Act

2Per Cornell HPP Validation Center / Micro lab

Product Types

Examples of products that are suitable for HPP:

• Fresh juice, kombucha, cold brew coffee

• Dips, hummus, salsa, guacamole

• Poi, ‘ulu hummus

• Baby food

• Soups and sauces

• Ready-to-Eat meals

• Wet salads

• Deli meats, raw meat, raw poultry, cooked poultry, dairy products, shellfish, oysters,

• Cosmetic products

Products not suitable for HPP:

• Spices, powders, and extracts

• Dry nutes, fruits and cereals

• Whole fruits

• Vegetable leaves and leafy salads

• Bread and pastries

18 19

Image adapted from https://www.hiperbaric.com/en/

DRAFT DRAFT

Process

UHCDC conducted community, stakeholder and industry engagement in order to drive an informed planning and design process for the facility which will house the HPP machine(s). As HPP is a new technology for the state of Hawaiʻi, significant research and outreach was required for this report. This process informed our understanding of facility requirements to house and operate the HPP machine(s) as well as the existing and potential business environment for the state’s investment. Outreach included interviews with HPP manufacturers, operators, and users across the continental U.S. and Canada. Additional outreach was conducted to identify potential operators and users in Hawaiʻi. The insights gathered from this outreach was used to directly guide the technical considerations and provide useful contextual resources to aid UHCDC in developing the programming, scope, and direction for this project.

DRAFT DRAFT

Consultation

Hawaiʽi Working Group

Prior to UHCDC’s involvement in the WCFH project and subsequent HPP research and outreach, a small working group comprised of the University of Hawai‘i’s College of Tropical Agriculture and Human Resources, Department of Agriculture, Agribusiness Development Corporation, Department of Business Economic Development and Tourism, Department of Education, Kamehameha Schools, Mana Up, Hawaiʻi Agricultural Foundation and Hawaiʻi Farm Bureau, convened by Senator Donovan Dela Cruz had been advocating to bring HPP technology to Hawai‘i. In 2019, an ad-hoc agricultural hui led by Meli James, Cofounder of Mana Up Hawai‘i and Denise Yamaguchi, Executive Director of the Hawai‘i Agricultural Foundation, started to examine Hawai‘i’s potential HPP market. In 2020, they produced a report summarizing the prospects of bringing HPP technology to Hawai‘i. Their report, Business Case for a High Pressure Processing Facility in Hawai‘i, Economic Recovery & Value-Added Products, provided an overview of High Pressure Processing and was presented to Senator Donovan Dela Cruz. They additionally partnered with HPP manufacturer Hiperbaric to host a web presentation in March 2021. EAT THINK

DRINK 14: High Pressure ProcessingInnovation & Value-Add can be viewed on YouTube (https://www.youtube.com/ watch?v=jFC8li7H-K0). UHCDC consulted with this group to learn from their earlier research and they have continued to provide feedback and recommendations throughout this process. Their report and findings can be found in Appendix C.

Interviews

HPP Manufacturers

UHCDC met with representatives from the two primary manufacturers of HPP machines, Hiperbaric and JBT Avure Technologies. Both manufacturers provided detailed information on their machine specifications as well as maintenance requirements, basic facility requirements, and services they provide to customers.

HPP Toller

UHCDC conducted interviews with HPP facility operators known as tollers to gain technical understanding of the operational and facilities requirements. UHCDC interviewed a total of six different tollers as part of this process. Interviews were informal and the format evolved to fill in information gaps. Early interviews focused on understanding the basic infrastructure and spatial requirements for HPP machines and operations as well as auxiliary services and equipment. Later interviews explored details of operations and facility design.

HPP User

UHCDC interviewed producers who currently utilize HPP technology to better understand the process of HPP. These interviews were helpful in providing context and revealing differences in experience and between product types.

Potential User Research

In order to better understand the potential demand for HPP technology, UHCDC reached out to individuals and businesses who were identified as potential users through a working group of Hawai‘i producers and an inventory of related businesses in Hawaiʻi. A list of potential users were put together based on their prior expressed interest in HPP technology These individuals and businesses were contacted through existing networks, public meetings, and through email to participate in facilitated focus groups and to fill out two surveys in an attempt to refine user input into the design process.

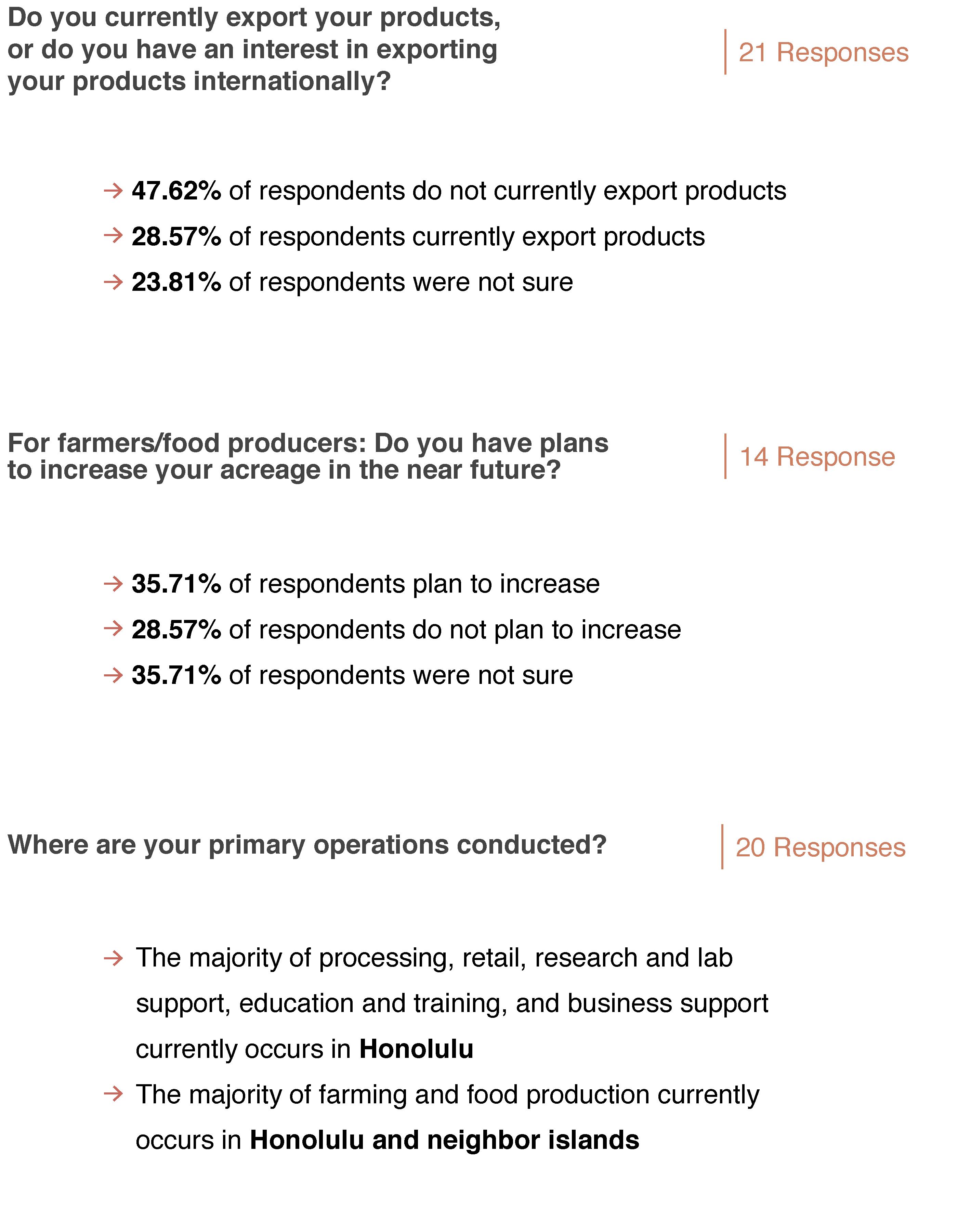

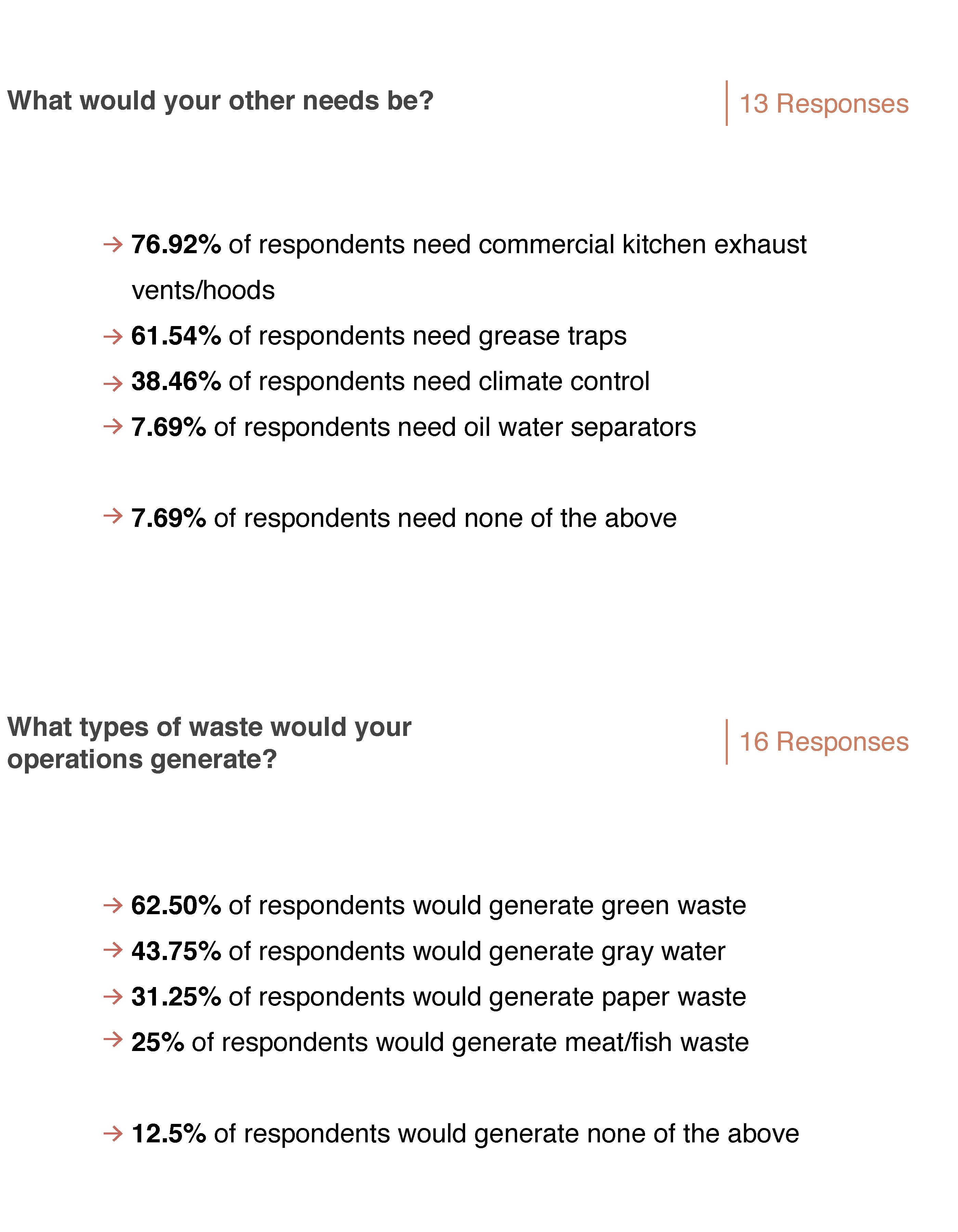

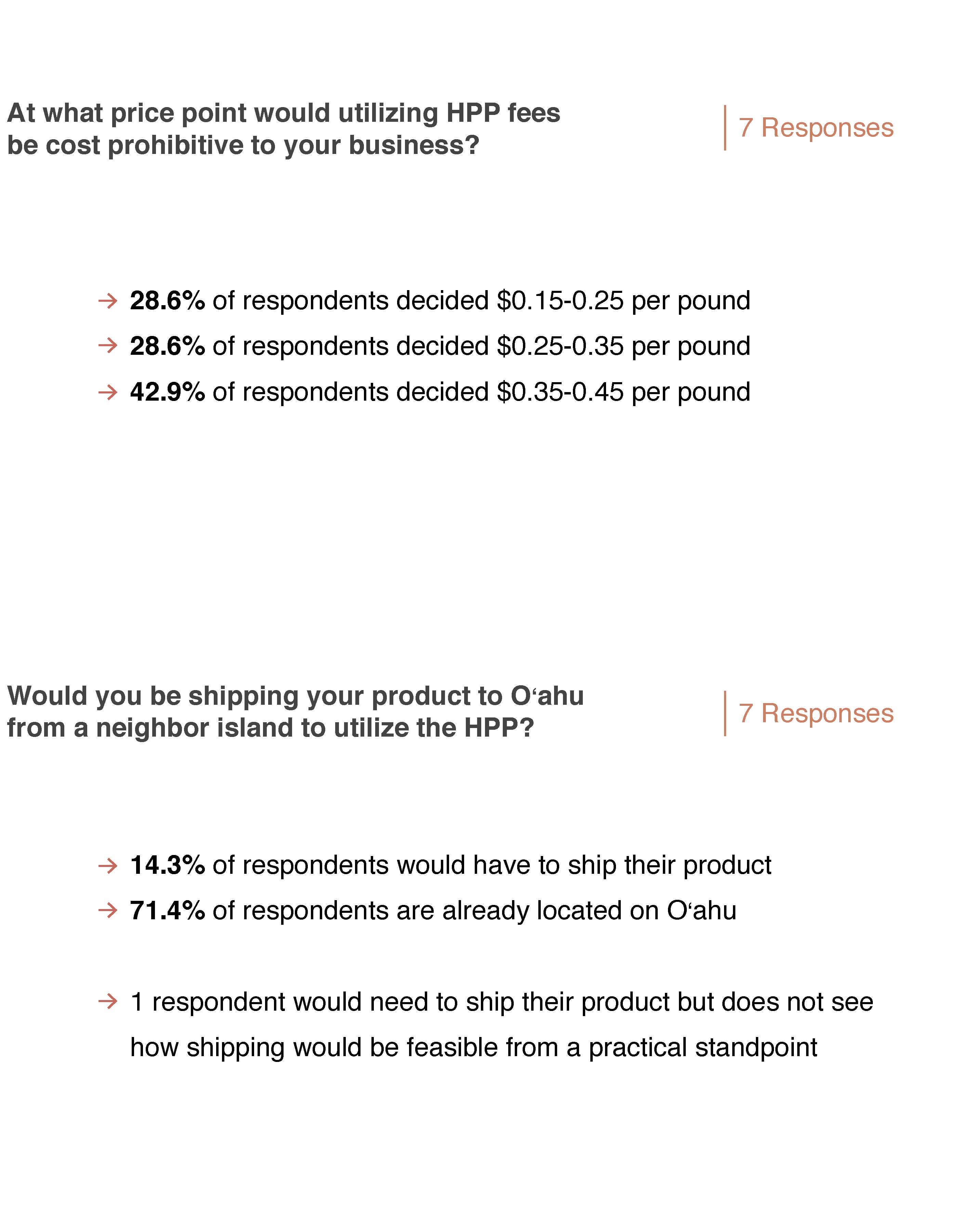

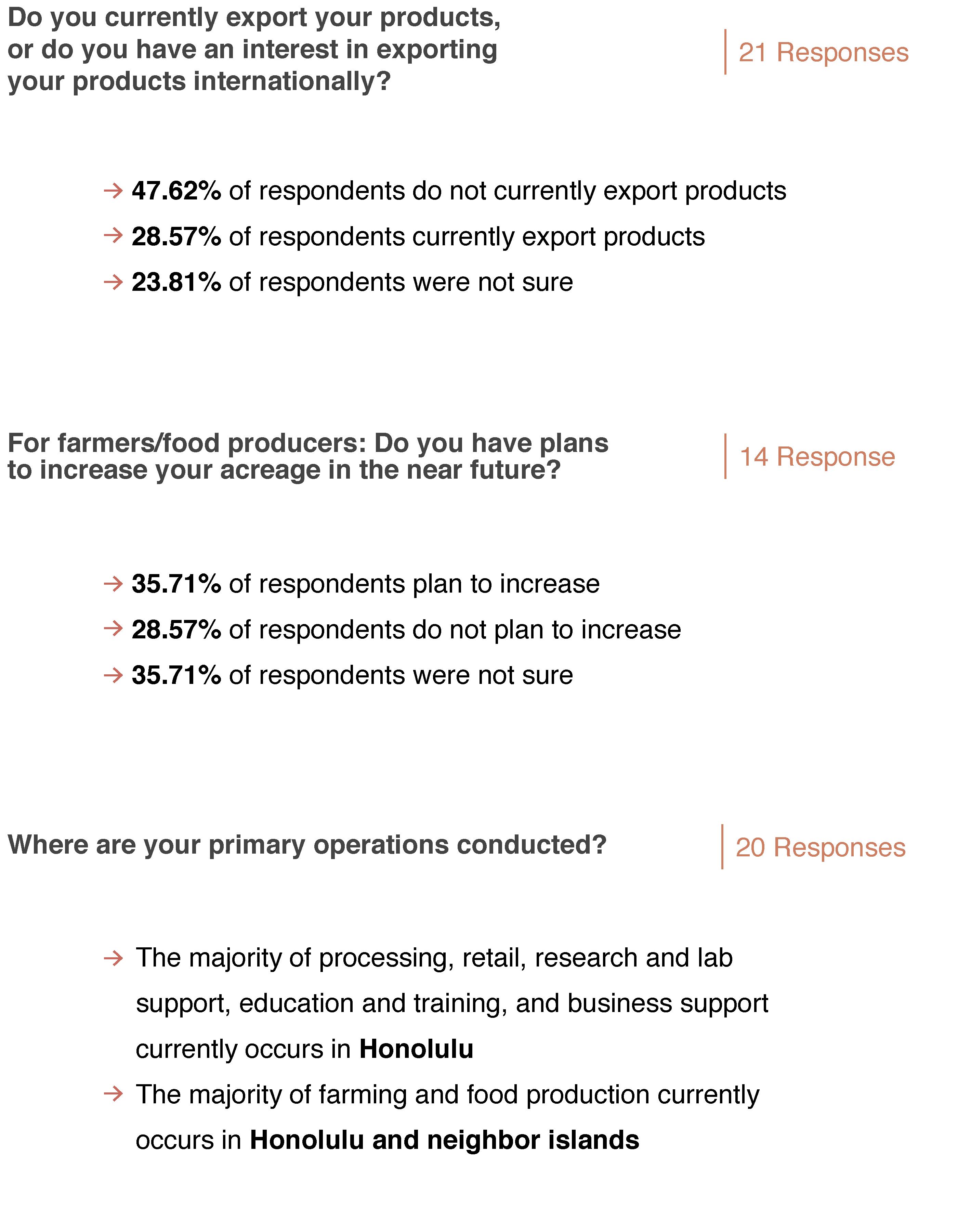

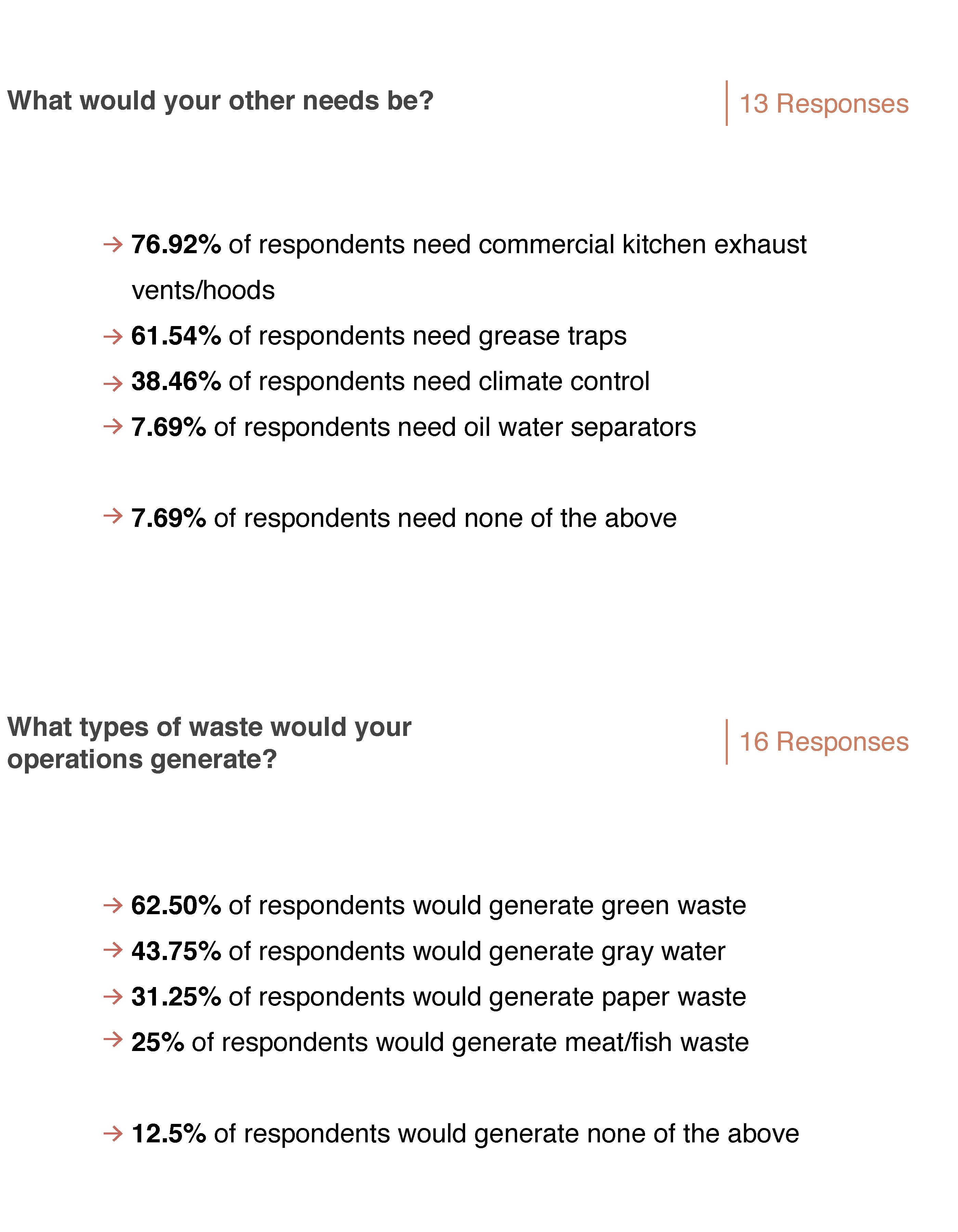

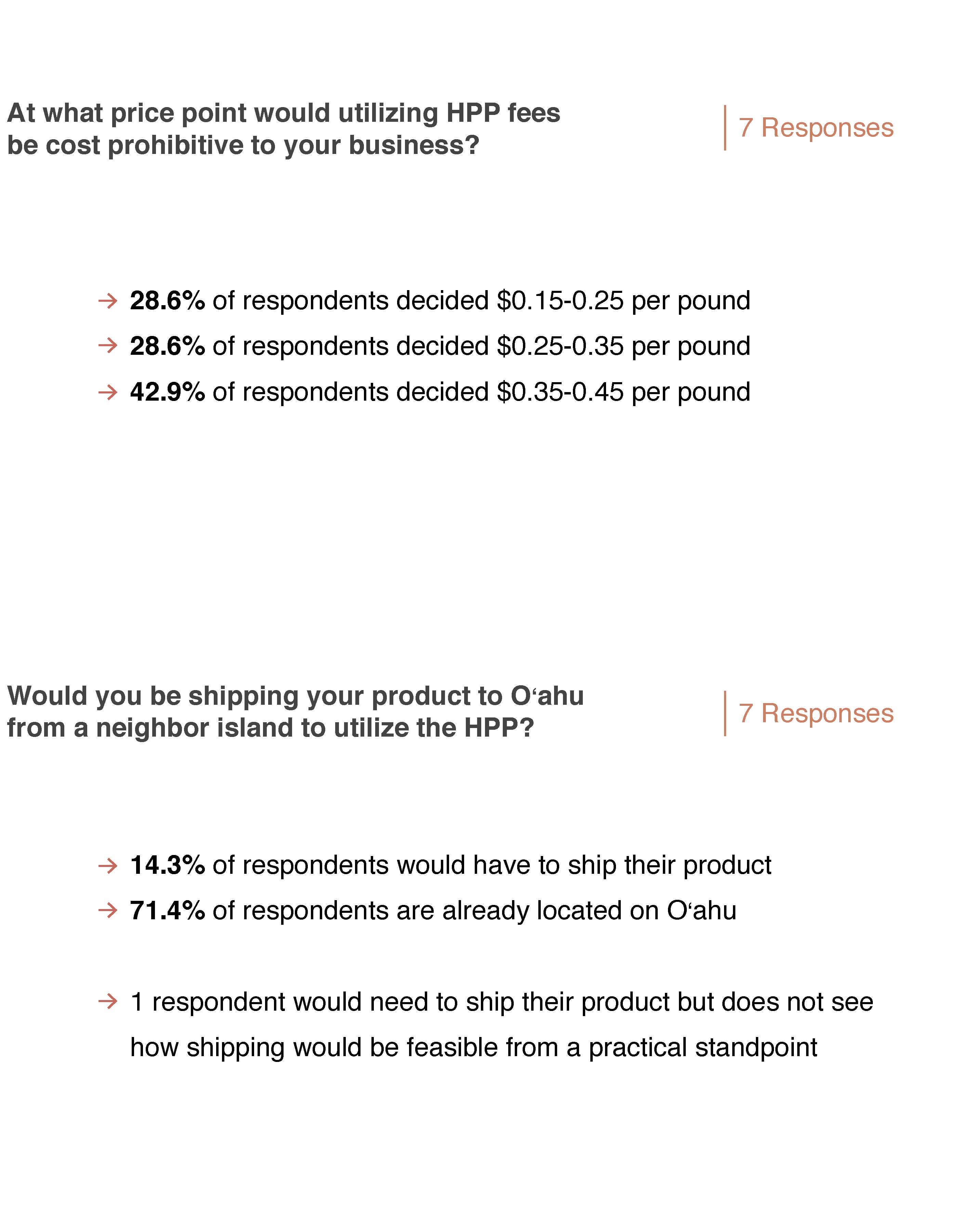

An initial survey was designed to solicit input on potential use of the broader food hub amenities including HPP. A second survey was developed to gather more information from businesses identified as potential HPP users. Due to limited responses, we focused our efforts on other types of engagement. However, survey response information was incorporated into the information synthesis. A summary of survey responses, full results, and survey instruments are included in Appendix D.

22 23

DRAFT DRAFT

Site Visits

UHCDC traveled as part of a delegation from Hawaiʻi to visit various food innovation and HPP manufacturers and tolling sites in California, Oregon, and Nebraska from Dec. 14-18, 2021. These visits provided an opportunity to visualize the operations and machines as well as ask more detailed questions. In addition to UHCDC, interested parties from local industry, higher education, and government also attended.

List of site visits:

HPP LA (Tolling Facility)

Los Angeles, CA

Evolution Fresh (Food Producer)

Los Angeles, CA

HPP Food Services (Tolling Facility)

Los Angeles, CA

Oregon State University, Food Innovation Center

Portland, OR

University of Nebraska, The Food Processing Center

Lincoln, NE

Oregon State University, Food Innovation Center

University of Nebraska, The Food Processing Center

24 25

HPP Food Services

DRAFT DRAFT

Public Seminar Additional Community Engagement

Community Meetings

UHCDC both hosted and attended a variety of virtual and in-person meetings including talk stories, one-on-one meetings, and group presentations with elected officials, community organizations and individuals, as well as educational institutions.

In-person Walk-through Open House

UHCDC hosted an in-person walk-though event in Whitmore Village outside the community park gym. There was an estimated attendance of over 100 individuals (55 signed in), most of which were community residents. Engagement posters, feedback boards, comment cards and 12 UHCDC staff and student assistants were on site to share information and capture feedback from attendees.

Website

A project website was provided to communicate updates to the community throughout the project at engagehawaii.org.

Neighborhood Board Meetings

UHCDC hosted an informational web presentation led by a JBT Avure Technologies’ food scientist. This seminar provided information on HPP technology, its benefits for the valueadded product industry, and the food science behind the technology. The web presentation can be viewed on Youtube ( https://www.youtube.com/watch?v=VV075o_eyFc&t=3s ).

UHCDC connected regularly with the Wahiawā-Whitmore Neighborhood Board to provide project information, updates and solicit feedback. UHCDC also presented to Neighborhood Boards in the wider geographic region whose constituency might utilize and/or benefit from the WCFH including the Mililani Mauka-Launani Valley and the Mililani-Waipiʽo Neighborhood Boards.

26 27

DRAFT DRAFT

HPP Research & Outreach

Manufactures

Hiberbaric USA

Miami, FL

JBT Avure Technologies, Inc.

Middletown, OH

Tollers

CalPack Food/HPP Food Service

Torrance, CA

Dora’s Naturals

New York, NY

HPP Food Services

Wilmington, CA

Buena Park, CA

HPP LA

Los Angeles, CA

HPP Services Canada

Burlington, Ontario, Canada

Intermountain HPP

Ogden, UT

Youngstown Grape Distributors

Reedley, CA

HPP Users

Live Organic Food

Ontario, Canada

Love Grace Juice

Astoria, NY

Slurp Mix

Ontario, Canada

Food Safety

JL Consulting Service LLC

Ontario, Canada

Elected Officials

Senator Donovan Dela Cruz

Representative Amy Perruso

Councilmember Heidi Tsuneyoshi

State Agencies

Department of Business, Economic Development and Tourism

Hawaiʽi Technology Development Corporation

Neighborhood Boards

Mililani Mauka-Launani Valley Neighborhood Board

Mililani-Waipiʽo Neighborhood Board

Wahiawā-Whitmore Village Neighborhood Board

Food Hubs/Culinary Business Incubators

Kahumana Farm Hub

Kōkua Kalihi Valley

Oʽahu Fresh Pacific Gateway Center

University of Hawaiʽi Community Colleges

Kapiʽolani Community College

Leeward Community College

Value- Added Producers and Other Interested Parties/Individuals

AgTech Pacific

Alice Malama Solomon

Banán

Beer Lab HI

Costco

First Commercial Kitchen

Forage Hawaiʽi

Friends of Waimānalo

Hawaiʽi Business Group Incorporated

Hawaiʽi Foodservice Alliance

Hawaiʽi ‘Ulu Cooperative

Ho Farms

Honolulu Poi Company

Lanakila Meals on Wheels

Lanakila Pacific

Kalona Brand Company

KAS Technology

Kings Hawaiian

Mana Up

Mānoa Honey

Mari’s Garden

Ohana Hui Ventures

Opala Foods

Organic Innovation

Performance Landscape

Piko Provisions

Sun Noodle

Uncle’s Ice Cream

‘Ulu Island Nation

‘Ulu Mana, Inc.

Villa Rose

Y.Hata

28 29

DRAFT DRAFT

Information Synthesis

Information gathered from interviews with HPP industry contacts including tollers, manufacturers, and users was compiled and synthesized for future reference. The information is organized into the following categories:

01. Staff - How much staffing, qualifications and training that is required for operation.

02. Maintenance - Information related to the anticipated maintenance costs, required spare parts, and other insights.

03. Efficiency - Suggestions for maximizing operational efficiencies.

04. Auxiliary Equipment - Information related to the types of additional equipment associated with the HPP operation such as those required for labeling, drying, and moving product around.

05. Testing - Information related to the tests and studies required to certify products for processing.

06. Packaging Requirements and Food Safety ConsiderationsInformation regarding the specific types of packaging that can be used with HPP and other chemical requirements.

07. Regulatory/Insurance Considerations - Information related to the complicated regulatory environment surrounding HPP and the food industry.

08. Toller Pricing - HPP Operators known as tollers configure their pricing in different ways depending on volume and other factors. Most tollers consider this information proprietary, however we have included some general information in this report.

09. Marketing - Information to help with launching HPP and building the HPP industry base. Marketing will be important for potential customers of HPP to learn about the technology and system.

10. Facilities Plans - A lot of information was gathered in order to better understand facility design. This information is listed here and also captured in the Proof of Concept designs.

DRAFT DRAFT

01.Staff

Start-up Logistics

• Some operators contracted manufacturer employees to work on site for 3-6 months to set up the operation and train employees or hired a previous manufacturer employee to operate the facility.

• The manufacturer may offer assistance with installation, training, and set up.

• One toller hired airplane mechanics because skill set was similar and easily transferred.

• It may be a steep learning curve to learn how the machine works.

Staffing Needs

• An operator will need a minimum of three people per shift to operate a machine plus co-packing operations.

• Total staffing needs for machine operation: 12 people (four staff per shift)

• Responsibilities of the three people during each shift include:

• Operator: Loading/unloading the baskets and starting the machine

• Mechanic: Can float between tasks:

• Other responsibilities: Boxing, packing, transporting, maintenance, sanitation, shipping/receiving, admin, quality assurance, plant manager

• Total staffing for co-packing: 8 people

• Generally tollers schedule (3) eight hour shifts per day. If running 7 days a week, 21 shifts are possible.

• Also include 1 shift for cleaning the machine(s) (recommend Sunday midnight - 4 am).

• USDA inspectors are needed on site when meat is being processed. Available for 8 hr shifts. USDA charges for overtime only.

• Scheduling all meat operations during certain time windows is a good model

Staff Training/Qualifications

• Manufacturer may provide training for operations and maintenance, no specific qualifications necessary

• Mechanic with experience with large equipment (e.g. aerospace).

32 33

DRAFT DRAFT

02.Maintenance

• Having a parts inventory and maintenance crew are critical to shorten down time.

• The typical investment in spare parts is $120,000.

• The typical cost of parts inventory once up and running is approximately $510,000/mo.

• The cost for an inventory of plugs, wedges and chamber seals is approximately $12,000

• It is recommended to maintain a stock of extra filters.

• About 60% of the parts are common to different size machines and can be pooled. Specifically, pumps and tubing sizes are the same. Seals around the plugs and baskets differ.

• Larger components will last their specified lifetime.

• Both manufacturers promise immediate 24-hr help (customers confirmed).

• Operator will need to work with the Manufacturer to ship parts to Hawai’i. Manufacturers may coordinate with other customers to expedite access to parts.

• Machines are cleaned weekly (Sunday, midnight - 4 am)

• There are a range of efficiencies reported by users and manufacturers (6090%). Estimate for 60% efficiency (HPP supplier will state 90% efficiency). One operator reported 80% efficiency.

• Consider the need for washing the machine between different food products when switching between products containing allergens, meat or in the case of spillage (e.g. tollers often designate a shift for processing meat products).

• To minimize washing, it is recommended to schedule batches based on food sensitivities and food type.

• Consider odors and allergens related to seafood when scheduling product processing (Requires 1 hr for cleaning, may be best to batch all seafood during specific time shift).

• One shift (Sunday at midnight - 4 am) is used to clean the machine.

• Machine is in production (maximum production) 20 out of 21 shifts.

34 35

DRAFT DRAFT

03.Efficiency

04.Auxiliary Equipment

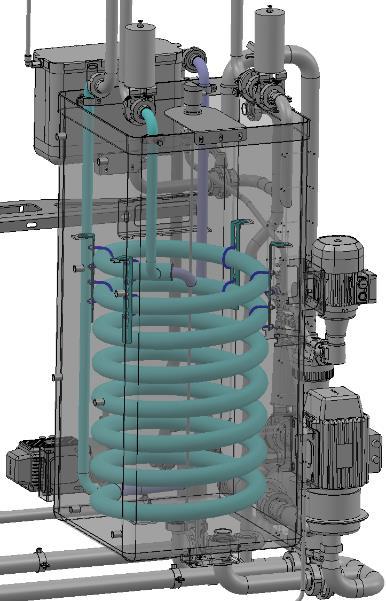

• A general recommendation is to determine what will be processed first, then buy any auxiliary equipment.

• Blower/dryer - useful for drying product instead of wiping.

• Inkjet printer - necessary for each machine to print labels (coding). Also, customers prefer to have the expiration date printed by the HPP toller.

• Additional conveyors can be added to each machine.

• Shrink wrap - useful for palletizing finished product.

• Pallets and forklifts are necessary along with space for storage and to move product around the space.

• Consider space requirements for a packaging line and placing product into boxes.

• An overhead crane may be useful if heavy machinery needs to be lifted.

05.Testing

• An HPP Validation Study is required under HACCP regulations1. An HPP validation (pathogen challenge) study does not determine the overall shelf life of the product. A validation study is a scientific examination to determine whether the HPP process will achieve, and maintain, at least a 5-log reduction in pathogen growth for at least as long as the estimated storage time. A validation study must be obtained for every product (Sku) going through HPP processing2

• Validation study cost: $4,600 per product2 - may not need validation study if only looking for shelf-life extension.

• An HPP shelf life (spoilage) study is required for labeling (“Best By” dates) and evaluates the effect of HPP process on spoilage microorganisms to determine the time a product can be expected to keep without appreciable change in quality (color, texture, odor, flavor, nutrients and spoilage microbial growth). An HPP shelf life study should be done prior to or simultaneously with an HPP validation study2 .

• Shelf life study cost: $1500.00 + $75.00 per testing point (per product)2

• Testing takes the amount of time of the shelf life test - no add-on waiting time.

• Testing should be in a separate facility to avoid any pathogens near the processing center.

• Recommended testing sites for Hiperbaric include The Cornell High Pressure Processing (HPP) Validation Center and The Food Processing Center at the University of Nebraska. JBT Avure’s microbiological laboratory conducts pathogen challenge studies to validate HPP parameters and incorporate into HACCP’s.

• A list of recommended testing facilities can be found in Appendix B.

1HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.

2Per Cornell HPP Validation Center / Micro lab

36 37

DRAFT DRAFT

06.Packaging Requirements and Food Safety Considerations

• Chemistry and Food Safety:

• To maximize protections from lethal pathogens, a food water activity (aW) above 0.96 is required. In other words, HPP is more effective in high aW products because the product will have a higher content of free water available to transmit the pressure, leading to a higher microbial inactivation and extended shelf-life.

• aW of 0.96-0.97 is required to maximize protections from lethal pathogens.

• Commercial HPP products with aW 0.80-0.95 use HPP to extend shelf life and minimize recontamination risk with Listeria as in the case of cooked products or sliced deli meats.

• HPP can also be combined with other processing steps to tally or exceed 5-log pathogen reductions, as in the case of cured/fermented meats, where curing/fermentation combined with HPP meet the food safety objectives.

• HPP is capable of processing acid (below pH 4.6) and low-acid foods (pH 4.6 or higher).

• HPP does not eliminate bacterial spores and it is always recommended that the formulation includes components that prevent the germination and toxin production of spores, particularly of Clostridium botulinum (see FSA Guide in Appendix). Food safety consultation is highly recommended.

• Product must be at least 28°F before entering the machine.

• Packing Material : PET plastic is required (no glass/aluminum); PET, PE, LDPE, PP, EVOH, PA

• Consider allergen cross-contamination possibilities

• Consider how to maintain “Organic” requirements

• Small bottles (shots) require extra labor for larger numbers of units.

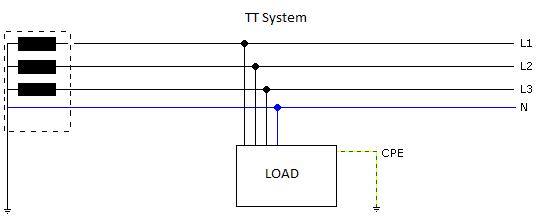

07.Regulatory/Insurance Considerations

• All relevant local, state, and federal codes and standards must be followed.

• Hawaiʻi State Department of Health (DOH) and Federal Department of Agriculture (FDA) both need to approve the warehouse.

• Ensure Food Safety Modernization Act (FSMA) compliance.

• Foreign Trade Zone designation - based on research and consultations, this may not be a good fit for an agricultural processing facility. U.S. Foreign-Trade Zones Fact Sheet can be found in Appendix.

• Insurance requirements: General Liability insurance, Product insurance

38 39

DRAFT DRAFT

08.Toller Pricing

• Across the United States, most tolling facilities charge by volume (fee per pound).

• There are some instances in the beverage industry where tollers charge by the unit (bottles); for larger volume clients, tollers may also charge by the cycle.

• On the U.S. West Coast where there are more tolling facilities, it is common to find tolling fees around 40-45 cents/lbs. Larger volumes may decrease in price, smaller volumes may be higher.

• In Canada, one toller offered self-service to clients. Users paid on a per cycle basis, and were extended discounts for more cycles per month.

• Best practice is to have a price structure dependent on volume; the higher the volume, the lower the rate. This provides an incentive for local manufacturers to increase production and/or utilize the HPP process more efficiently to keep lower their costs.

• Tollers keep their pricing sheets confidential and do not share them publicly.

09.Marketing

• Marketing will be important, especially if there are not anchor customers to begin with.

• Most tollers start with an anchor customer or toll their own product.

• A website is most often used as the primary outreach/marketing tool.

• Hiperbaric can help with marketing outreach/seminars.

• It is recommended to start with the low hanging fruit (juices/bottles).

• Marketing will be important to educate potential HPP users about the benefits of HPP, which products would benefit from HPP, and how the system works.

• It is recommended to utilize the existing producer networks to support the marketing and launch.

40 41

DRAFT DRAFT

10. Facilities Plans

Facility Program Needs

• Required space: Approximately 3,000-4,000 sf for a large HPP machine; 1200 sf -1500 sf for a small HPP machine.

• Required Height: A large machine is approximately 14 ft high and a small machine is approximately 8.5 ft high.

• Building needs to include an outdoor area to house chillers that accompany each machine. See Program Matrix and Inventory for more detail.

• Plan ample space for loading and unloading and around the machines.

• Physical separation between pre-processed and finished product is critical.

• It is useful to plan space to include an office, restroom(s), staff dressing area/ break room. The HPP facility is refrigerated throughout so climate controlled space for breaks is recommended.

• Cold storage is required on the inbound and outbound sides of the facility (separate). Inbound estimate sufficient space for 3-day’s worth of product. Outbound, estimate sufficient space for 1-day’s worth of product. The outbound area is fully cooled and includes the HPP machine, storage space and copacking as desired.

Facility Design Considerations

• FSMA compliance

• Potential Foreign Trade Zone requirements.

• It is helpful to provide ways to see into the operation without walking through such as a mezzanine or windows from the office space.

• Provide high bay space for high bay storage (30 ft.).

• Provide at least 10 ft between machines and 3-6 ft between machine and wall. (Recommend widths that accommodate forklifts throughout.

• Dry storage needs to be separate from the product because it creates dust.

• It is important to use insulated panels for the building since the entire facility will be chilled.

• A depressed loading zone is useful to allow direct forklift access to larger trucks.

• A drive-in loading dock area is useful to allow smaller vans to drive into the facility for loading and unloading - especially when accessing a self-serve machine.

• It is important to maintain a one way flow of product. Gates and turnstiles are helpful to restrict any backways movement of product.

• Avoid conditions where vehicles can drive into the HPP machinery.

• Noisy activities are best kept towards the back of the site to allow the building to act as a noise buffer.

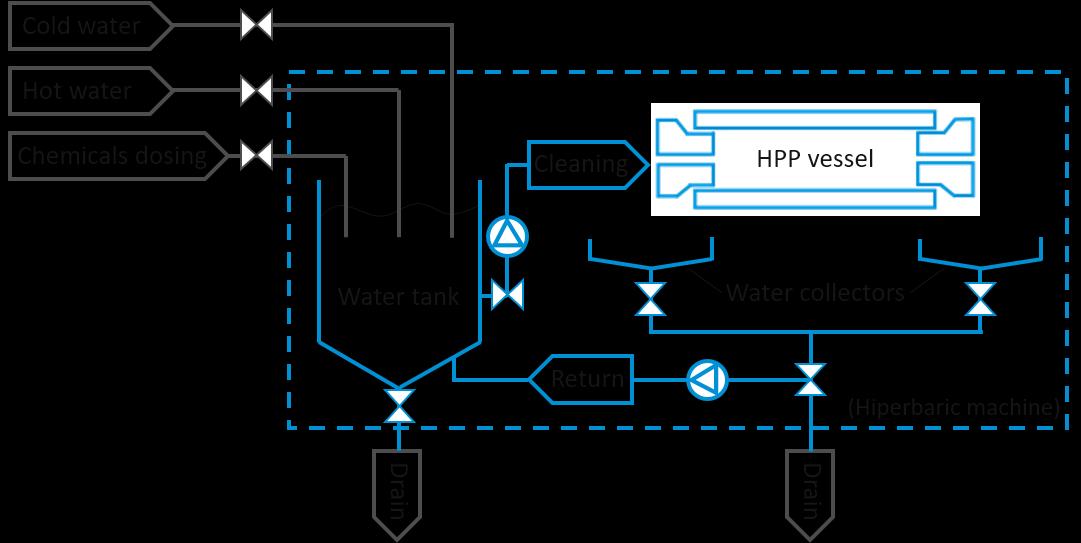

Facility Utility Considerations

• The entire space where the HPP machine is housed and product is stored is completely refrigerated.

• The fire sprinkler system should be appropriate for refrigerated space.

• Ensure drains are installed in the floor

Sustainability Considerations

• Consider adding photovoltaic panels for power

• Consider water reuse options to conserve water

• Consider programs to reuse food waste

Delivery/Traffic

• Expected traffic for HPP business is approximately five trucks per machine per day, or 10 total trips per machine

• One consolidated delivery system would reduce the trips

• A traffic management plan with use times should be developed by the operator

42 43

DRAFT DRAFT

Precedent Studies

Precedent studies are a form of research used to aid design processes by modeling existing theories, concepts, and strategies. Analysis of previous occurrences, offer inspiration that can be referenced and reinterpreted in one’s own work.

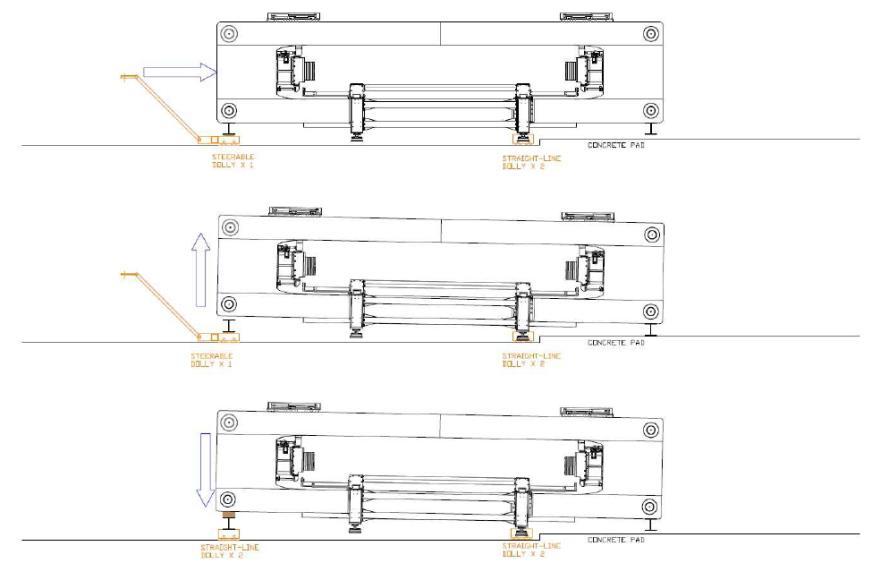

Three U.S. tollers participated in one-onone consultations and virtual sketching activities, which provided insight into programmatic areas, adjacencies, and floor plans for different HPP facilities.

There was consensus among tollers that it was ideal to have products flow one-way from receiving (loading or preprocessing cold storage) into HPP then to a post-processing cold storage area before exiting the facility. This mitigated cross contamination of pre and post HPP products, equipment, waste, and people.

The following precedents have been used to visualize the program areas and spatial relationships found in three HPP facilities. They also helped to inform the new construction and renovation alternatives proof of concepts designs found later in this report.

DRAFT DRAFT

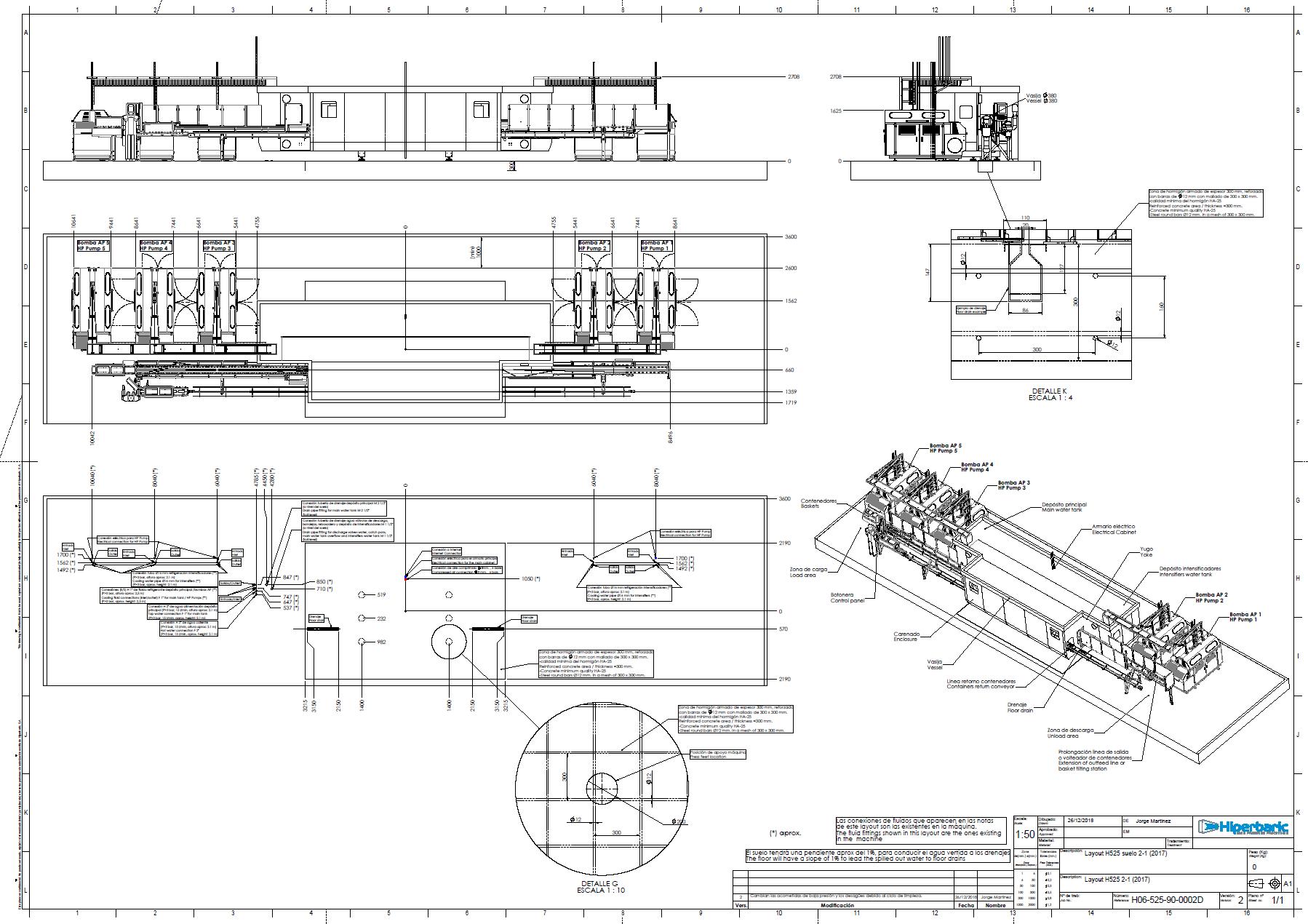

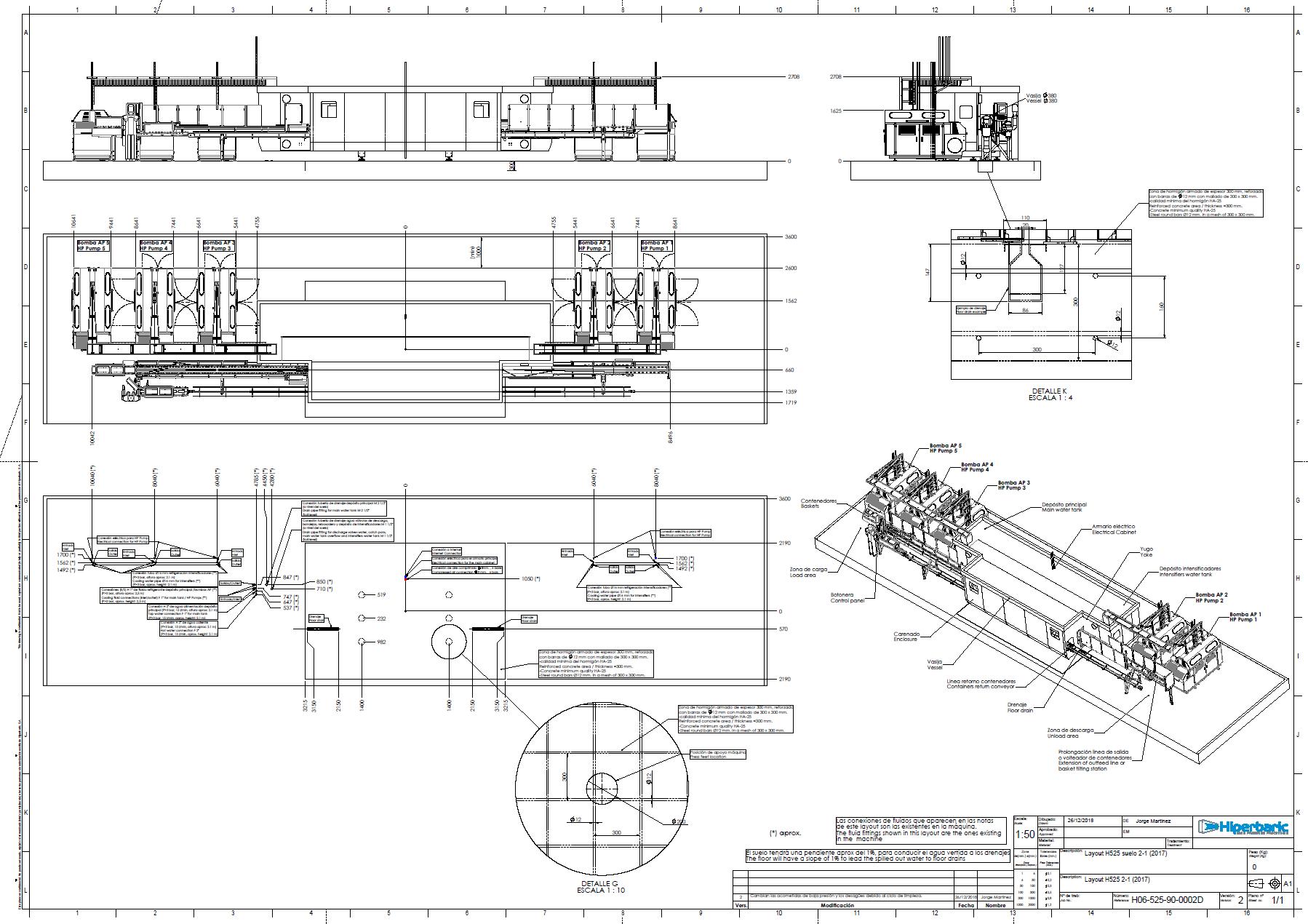

Precedent Studies - HPP Food Services

Name: HPP Food Services

Website: https://www.hppfs.com/ Location: Wilmington, CA

HPP Machine(s):

Manufacturer: Hiperbraric Model: H525

No. of each machine: 4

Services: Tolling only

Processed Foods: Juices, smoothies, coconut water, salad dressing, and baby food.

Process Volume: 12-14 millions pounds per year per machine

Size of facility: HPP Room: Storage (dry/cold/freezer): Co-packing:

Comments: N/A

46 47

DRAFT DRAFT

Precedent Studies - HPP LA

Name: HPP LA

Website: https://www.hpplosangeles.com/

Location: Los Angeles, California

HPP Machine(s):

Manufacturer: Hiperbaric Model: 135

No. of each machine: 1

Services: Tolling only

Processed Foods: Juices, deli meats, dips, salas, dairy, products, and seafood.

Process Volume: 200,000 units/week

Size of facility: Multiple warehouses with a 55,000 sf HPP facility.

HPP Room: 3,000 sf

Storage (dry/cold/freezer): 4,000 sf (dry storage)

Co-packing: 5,000 sf

Comments: N/A

48 49

DRAFT DRAFT

Precedent Studies - Dora’s Naturals

Name: Dora’s Naturals

Website: http://www.dorasnaturals.com

Location: South Hackensack, NJ

HPP Machine(s):

Manufacturer: Hiperbaric Model: 525L

No. of each machine: 1

Services: Co-packing, tolling, packing, storage, distribution and direct-to-customer.

Processed Foods: Juice, smoothies, sliced meat and whole log product, sauces, dips and pet food.

Process Volume: 15-20MM lbs/yr and are rapidly expanding

Size of facility: Multiple warehouses with a 55,000 sf HPP facility.

Comments: N/A

50 51

DRAFT DRAFT

Proof of Concept Design

In addition to research and engagement, UHCDC provides proof of concept design services to better define and fund projects ahead of contracting professional planning and design teams. These proof of concept designs synthesize engagement feedback and visualize design options as a form of discourse and to inform future work. The designs are not final or intended for permitting or construction. UHCDC developed a Proof of Concept Master Plan and Proof of Concept HPP Facility (New Construction and Renovation Alternatives), included in this section.

Civil Drawings for Phases 1 and 2 conclude this section. Additionally, a Civil Basis of Design and Mechanical/ Electrical/Plumbing study are included with this report to provide guidance on the infrastructure needs for near term and long term build out.

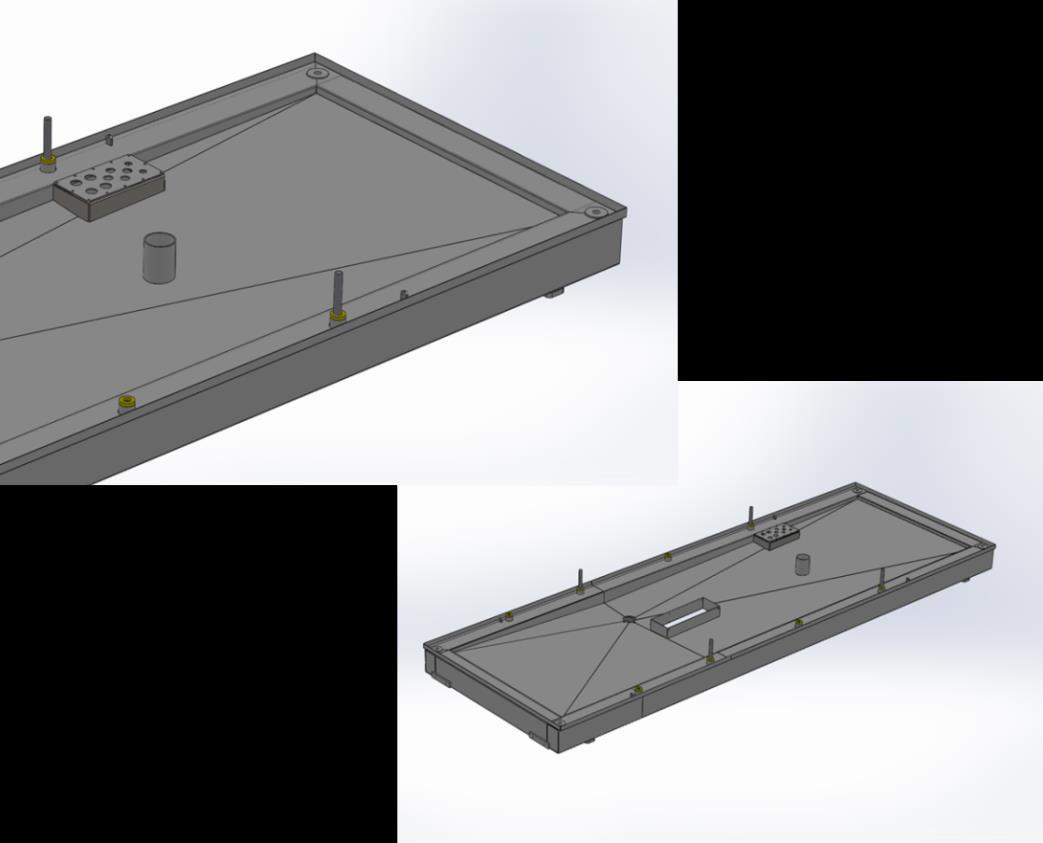

Proof of Concept New Construction for HPP Facility

Proof of Concept Master Plan

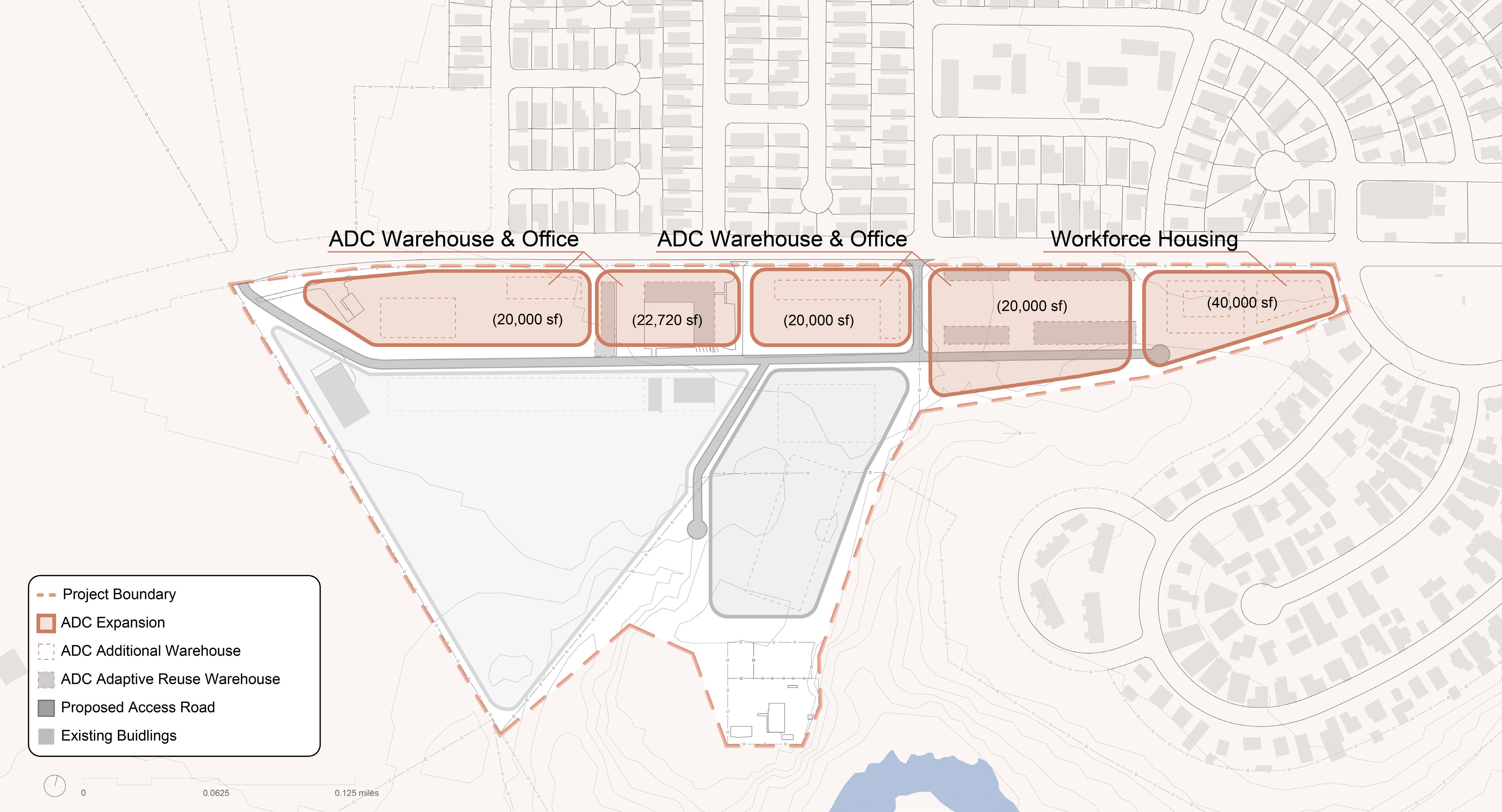

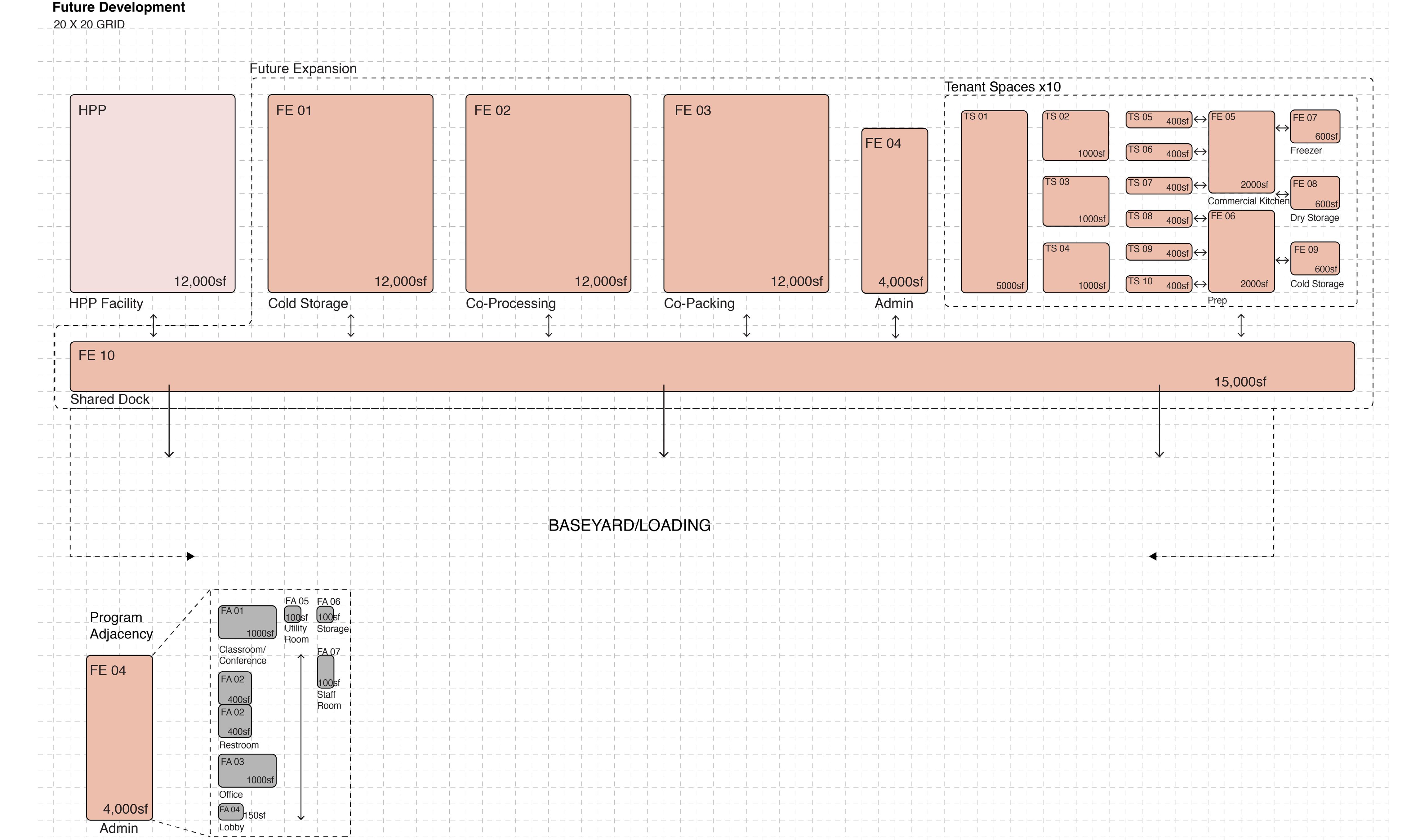

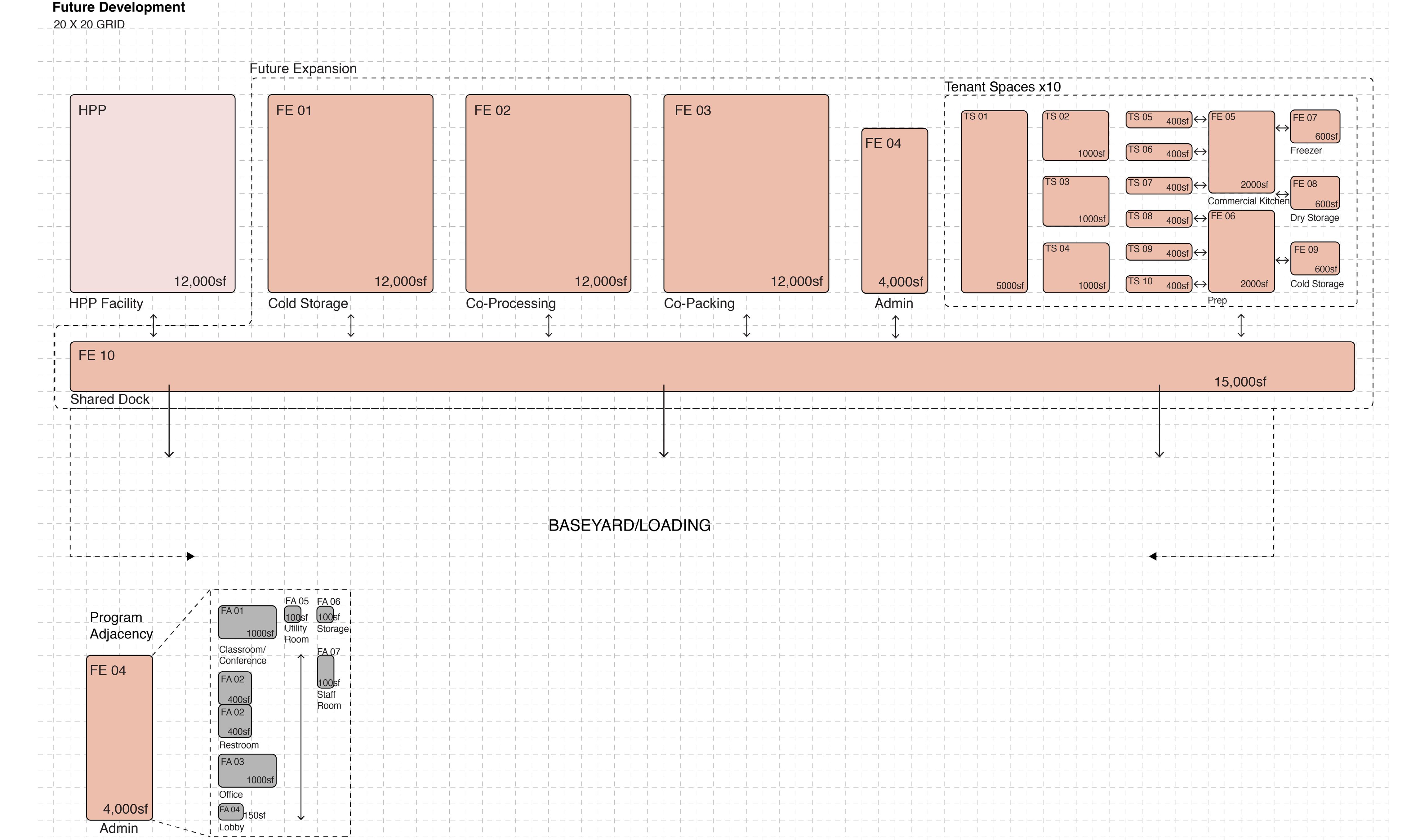

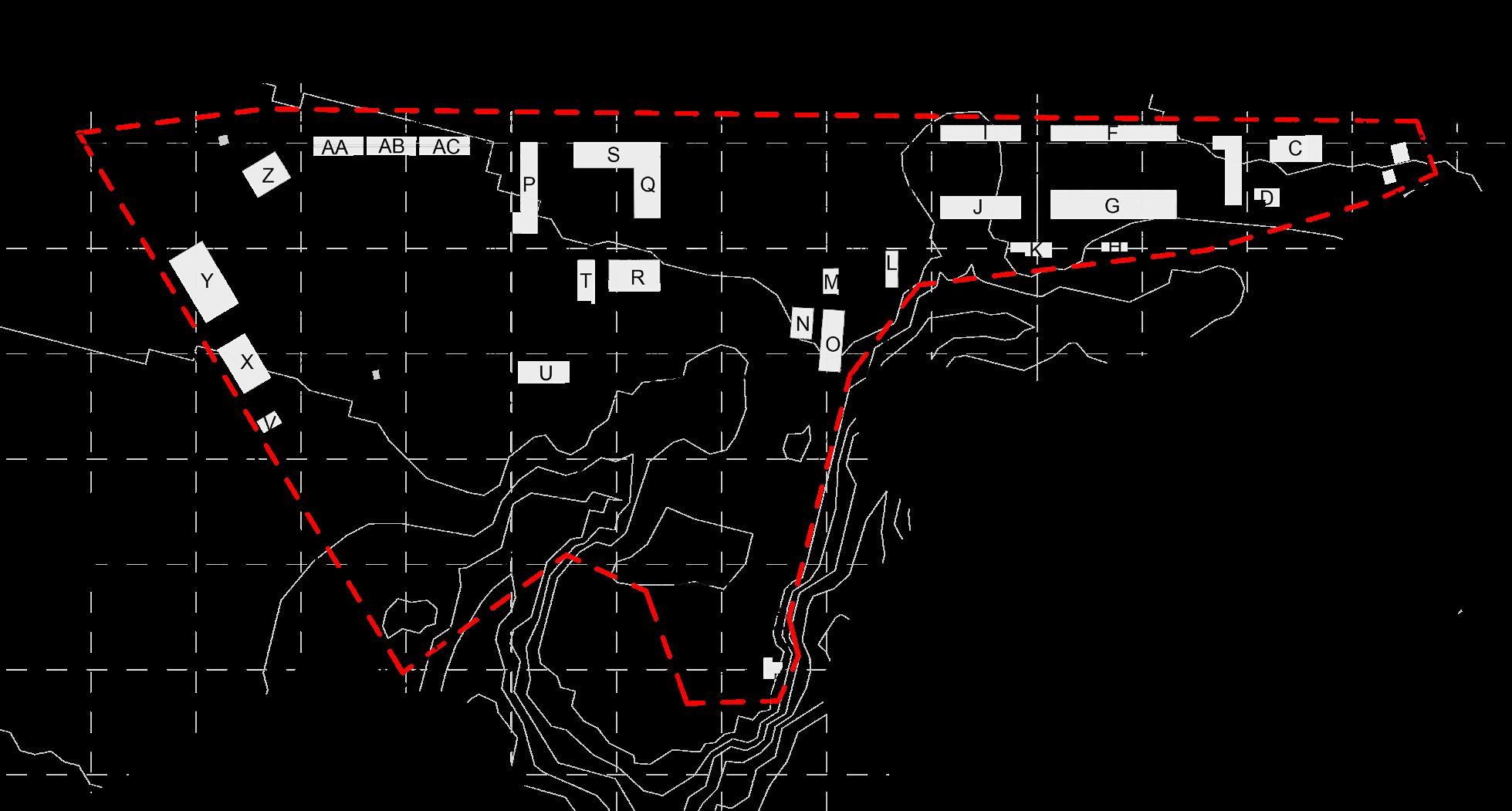

UHCDC integrated feedback from the community engagement events to compile a set of design considerations which guided the development of a master plan that includes spaces for an HPP facility, P3 development, DOE centralized kitchen, warehouse office space, and workforce housing. These components are discussed further in the Proof of Concept Master Plan section. A Draft Conceptual Master Plan is envisioned in four phases:

1)infrastructure improvements to support the project’s long-term development goals; 2) renovation and/or construction of agricultural processing warehouse(s) and Hawai‘i State Department of Education centralized kitchen facility; 3) renovation and/or construction of warehouses and office spaces; and 4) the construction of workforce housing.

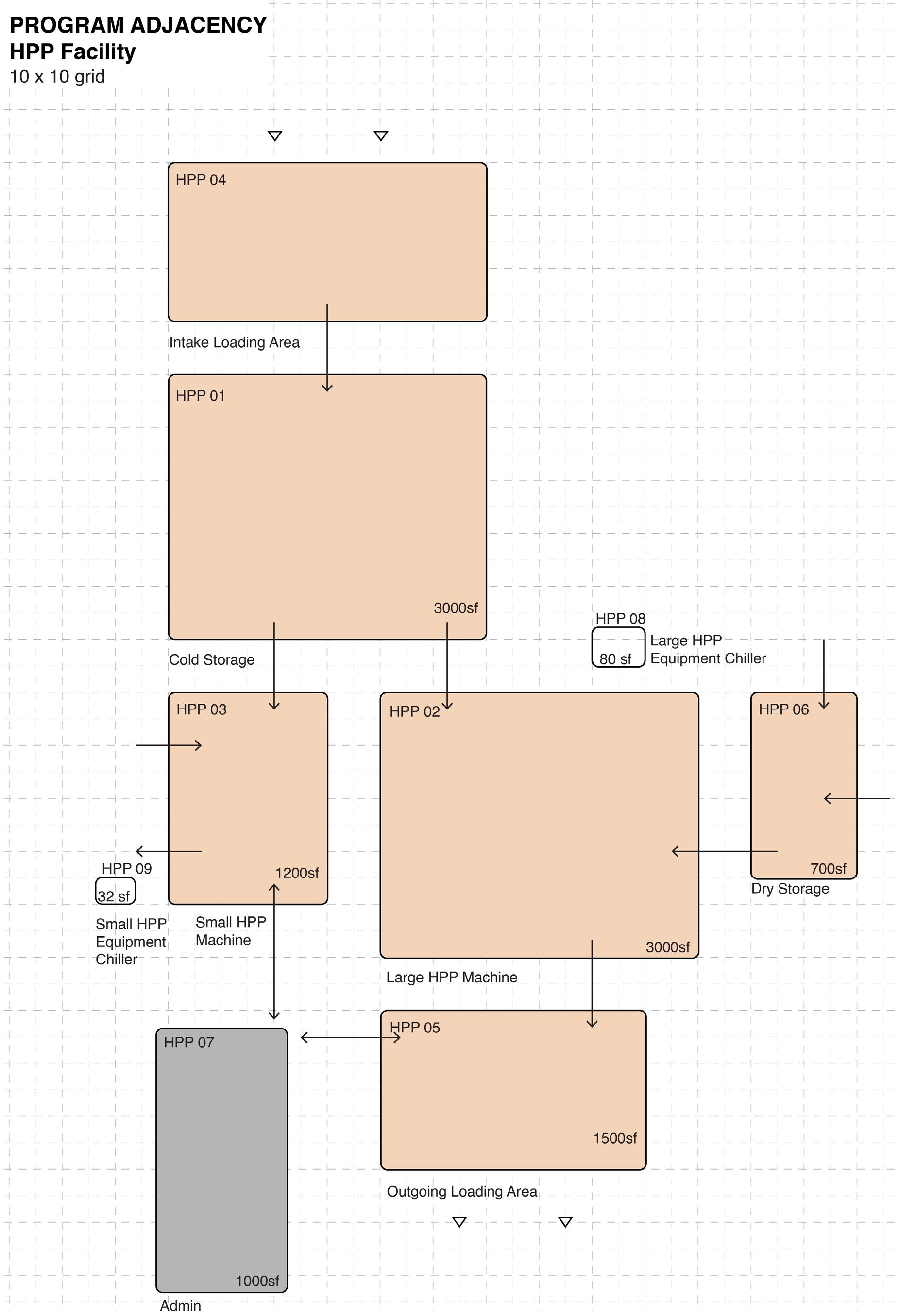

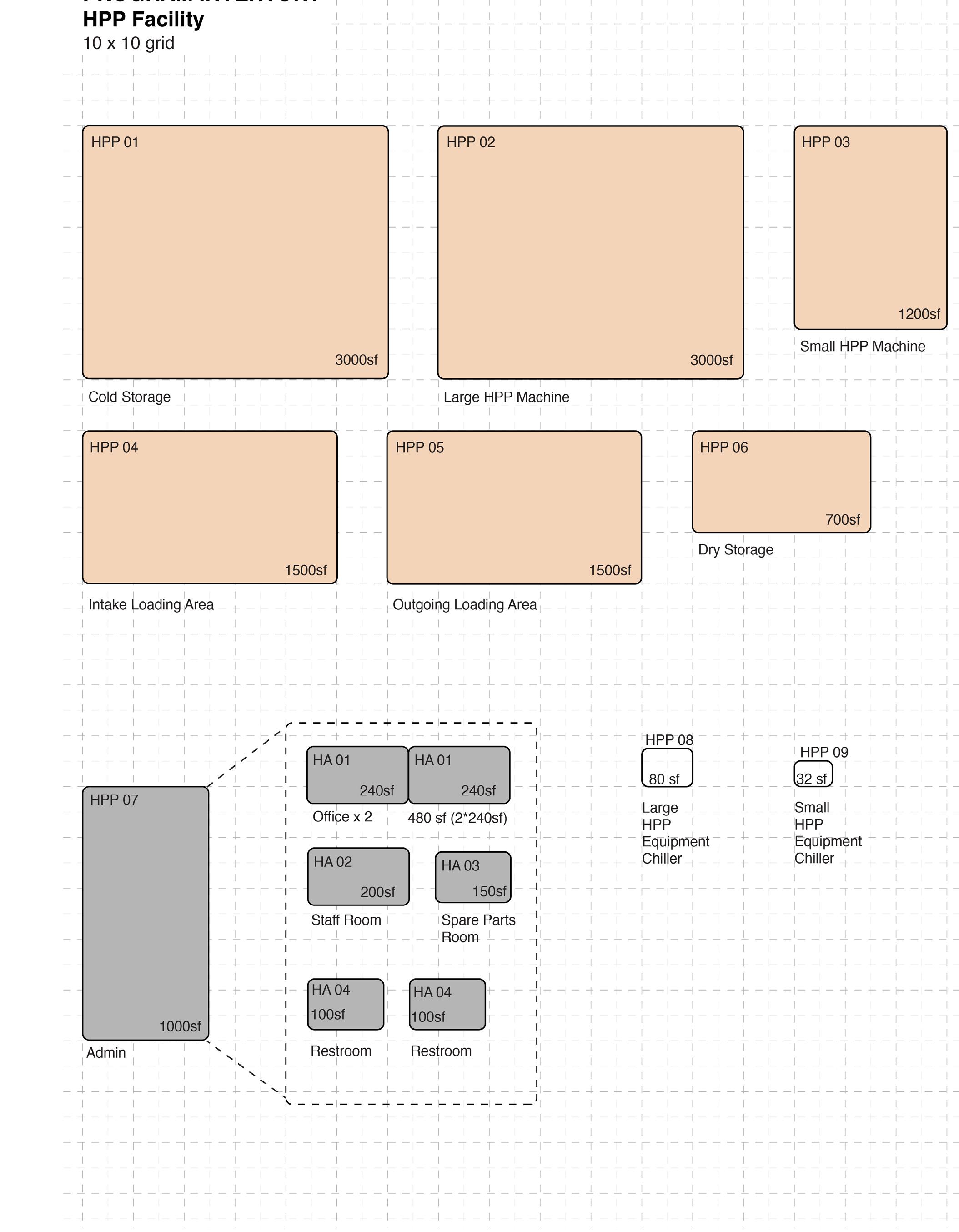

Based on site visits and feedback from HPP tollers, users, and potential users, UHCDC developed a baseline program inventory, adjacency diagrams, and program matrix for a new HPP facility. UHCDC explored two approaches to the facility: new construction and renovation.

DRAFT DRAFT

UHCDC developed new construction proof of concept design options between 14,400 sf - 15,200 sf for a warehouse to house two HPP machines, cold storage, dry storage, loading bays, offices, meeting and other support spaces. These designs reflect different floor plan configurations that represent deliberately diverse approaches to the circulation of people and products through the facility. Also included are designs for future warehouse expansion up to 67,800 sf as well as four potential campus configurations.

Proof of Concept Renovation

Alternatives for HPP Facility

UHCDC also developed proof of concept designs utilizing existing buildings R and R & T. The renovation of Building R alone is presented as the most efficient path to housing and running at least one small HPP machine in the near term.

Proof of Concept Master Plan

UHCDC integrated feedback from the community engagement events to compile a set of design considerations which guided the development of a master plan that includes spaces for an HPP facility, P3 development, DOE centralized kitchen, warehouse office space, and workforce housing.

Design Considerations

Through feedback gathered from all engagement activities and events, UHCDC developed a set of design considerations to be further explored by the ADC and/or future development partners for the WCFH. There are five primary objectives included in the Design Considerations:

• Consider ways to mitigate traffic;

• Consider relationship with nearby residential area;

• Consider relationship to Wahiawa town and surrounding context;

• Utilize productive landscape strategies;

• Plan for a safe and securable campus.

It is recommended that these considerations be taken into account starting from and throughout the planning and design phase.

Draft Conceptual Master Plan

A Draft Conceptual Master Plan is envisioned in four phases: 1) infrastructure improvements to support the project’s long-term development goals; 2) renovation and/or construction of agricultural processing warehouse(s) and Hawai‘i State Department of Education centralized kitchen facility; 3)renovation and/or construction of warehouses and office spaces; and 4) the construction of workforce housing.

Civil Drawings for Phases 1 and 2 conclude this section. Additionally, a Civil Basis of Design and Mechanical/ Electrical/Plumbing study are included with this report to provide guidance on the infrastructure needs for near term and long term build out. Please see Appendix F and Appendix G, respectively for these aforementioned studies.

Existing Project Site

56 57

DRAFT

DRAFT

Master Plan Engagement Approach Community Engagement Synthesis

UHCDC conducted community, stakeholder and industry engagement in order to drive an informed planning and design process for a proof of concept study for the WCFH. The insights gathered from the community engagement provides useful contextual resources to aid ADC and the professional design team in developing the programming, scope, and direction for this project. This engagement afforded the opportunity to provide project updates to the community and various stakeholder groups, in addition to collecting their input on the project’s genealogy and progress.

UHCDC’s engagement process consisted of informal talk stories, virtual meetings, farm visits, food hub visits, educational seminars, community presentations, an in-person walk-through event and a postcard mailed to Wahiawā/ Whitmore residents in advance of the event, a request for information and survey targeted to potential users, and a project website.

Summary of key community engagement input that influenced the design considerations for the Master Plan.

Concern: Increase in noise from the industrial activities on the nearby residential neighborhood.

Solution: Located HPP and other proposed future warehouses away from the residential areas/ Whitmore Avenue.

Concern: Increase in traffic to the already congested local traffic flow.

Solution: Ingress/egress for the site is located at the farthest point from Whitmore Village. In addition, new access road alternatives and improvements are being explored. The HPP operator is also required to develop a traffic demand management plan.

Concern: Potentially unsightly industrial look from the main roadway

Solution: Included an additional landscaping buffer along Whitmore Avenue.

58 59

DRAFT DRAFT

Design Considerations

Objective 1.0 Consider ways to mitigate traffic.

1a. Explore alternative access roads.

Continue to explore an alternative road connecting Saipan Drive to Kamehameha Hwy. for Navy and Food Hub use.

Explore improvements at Whitmore Ave. and Kamehameha Hwy. intersection per EA recommendations.

Explore improvements at Food Hub entry per EA recommendations.

1b. Create traffic management strategy.

Create a traffic management strategy to minimize Food Hub deliveries to off peak hours.

1c. Consolidate distribution.

Integrate consolidated distribution to Food Hub business and operation plan to minimize vehicular access.

1d. Develop a visitation plan for educational purposes.

1e. Develop a communication and outreach strategy.

Develop a communication and outreach strategy to engage community stakeholders.

62 63

SaipanDr. KamehamehaHwy. Whitmore Ave.

DRAFT DRAFT

Design Considerations

Objective 2.0

Consider relationship with nearby residential area.

2a. Provide landscape buffer.

Utilize landscape as a visual and noise buffer.

Select native trees and plants suitable to the area.

2d. Locate residential next to residential.

Locate future workforce housing on the corner of the parcel designated as urban, adjacent to the Whitmore residential neighborhood.

2e. Identify one access point for industrial uses.

Keep primary entry of the site away from the neighborhood intersections.

2b. Maintain neighborhood scale.

Locate smaller buildings closer to Whitmore Avenue and taller buildings near the back of the site to manage the transition in height from residential to industrial buildings.

2f. Consider surrounding agricultural land for neighborhood/community farming.

2c. Locate industrial activities at the back of the site.

Locate baseyard, industrial uses, and deliveries toward the back of the site to minimize disruption and to reduce impacts to neighborhood.

64 65 EXISTING SCALE NEW SCALE WHITMORE AVE ACCESS ROAD HEAVY INDUSTRIAL USE LIGHTER INDUSTRIAL USE WHITMORE AVE ACCESS ROAD

New residential next to existing residential PRIMARY ENTRY RESIDENTIAL

DRAFT DRAFT

Design Considerations

Objective 3.0 Consider relationship to Wahiawā Town and surrounding context.

3a. Respect Wahiawā historical character.

Consider historical building and town design guidelines.

3b. Plan for pedestrian bridge connectivity.

Anticipate a future pedestrian bridge to connect Wahiawā town with Whitmore. Allow for pedestrian easements and consider safety and surveillance issues. Coordinate with the Department of Transportation for any updates.

3c. Locate retail in town.

Retail activities should be located in Wahiawā town to revitalize the urban center.

3d. Recognize connection to Kūkaniloko.

Consider traditional Kuhikau Circle 1000 ft cultural buffer (as explained by the Hawaiian Civic Club of Wahiawā).

3e. Provide space for entrepreneurs from Value-Added Product Development Center to scale up.

66 67 Wahiawā OPTION B OPTIONA

RetailCore

RetailconcentratedinWahiawa

Kūkaniloko Whitmore Food Hub Connecionb weenKūk lko+ h FoodHub

DRAFT DRAFT

Design Considerations

Objective 4.0

Utilize productive landscape strategies.

4a. Cultural productive landscapes.

Incorporate plants and landscape strategies that help with surface water management, education, or food production.

4b. Prioritize low impact design parking and baseyard strategies.

Use porous paving, swales, and other landscape features to capture surface water run-off and minimize need for underground storage tanks.

4c. Maintain valuable trees.

Assess and determine valuable existing trees to keep on site.

4d. Connect green corridors.

Consider connecting planted corridors to surrounding plant communities.

68 69 Bioswales for stormwater filtration Porous paving Native plant species with multiple uses Habitat for endemic species Reduction of impervious surfaces for drainage Bioswales for stormwater filtration

DRAFT DRAFT

Design Considerations

Objective 5.0 Plan for a safe and securable campus.

5a. Bridge security.

Locate 24-hour activities next to the pedestrian bridge to keep the area monitored.

5b. Anticipate Foreign-Trade Zone (FTZ) requirements.

Consider site fencing and building configuration that would allow an FTZ area to be completely secured. Refer to FTZ requirements.

5c. Develop a security strategy to deter illegal activity on site.

70 71 OPTION B OPTIONA Monioed24hou

DRAFT DRAFT

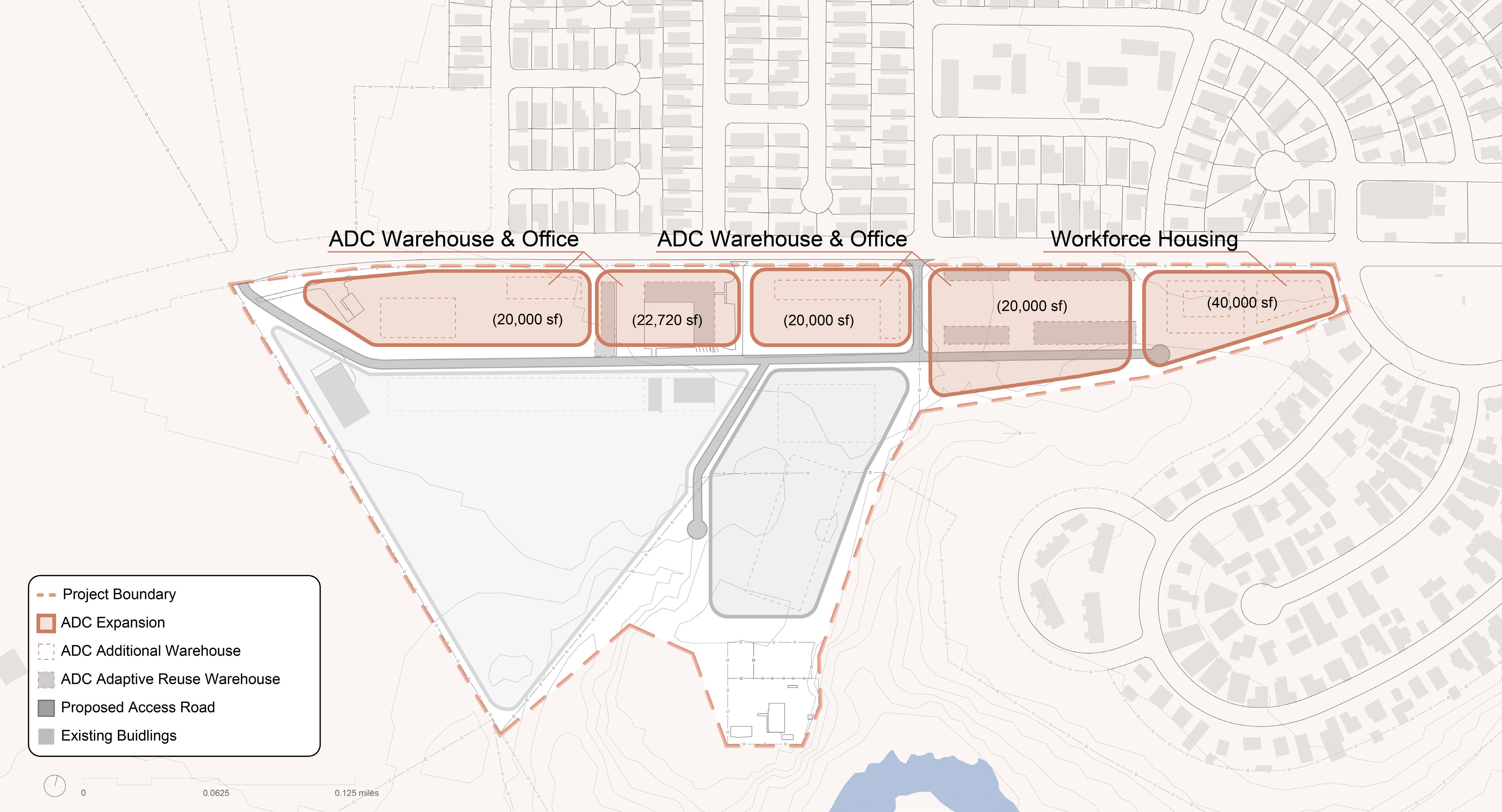

Draft Conceptual Master Plan Components

The Hawai‘i Department of Agriculture, Agribusiness Development Corporation (ADC) is developing the Whitmore Community Food Hub on the parcel currently occupied by the Whitmore Agricultural Tech Park, south of Whitmore Village. The project aims to create a post-harvest facility that meets the requirements of the Food Safety Modernization Act (FSMA), while integrating the logistical spaces of the Food Hub. The project will encompass approximately 34 acres and include TMK parcels (1) 7-1-002 :009, 004 (POR.), 022, 023.

The complex is designed to pool services for the aggregation, processing, storage, marketing and distribution of locally produced foods by small growers throughout Oʻahu’s central, northern, and leeward regions. Agricultural tenant spaces, commercial kitchen facilities, warehouse and office spaces, greenhouses, and workforce housing are also envisioned on the parcel. The ADC is also acquiring and plans to house a highpressure processing machine(s) at this site. This new food preservation technology would be among the first in the state, and the intent is to make its use accessible to value-added producers from across the islands.

Additionally, the Hawai‘i State Department of Education (DOE) is proposing to build a centralized kitchen facility and accompanying warehouse that would allow for more efficient production of school lunches as well as increase the procurement of locally sourced ingredients.

The Conceptual Master Plan is envisioned in four phases:

Phase 1 of the project will provide infrastructure improvements to support the project’s long-term development goals. The State of Hawai‘i Department of Accounting & General Services is managing this first phase of development. Planning for Phase 1 is anticipated to commence in May 2022. The UHCDC provided a Civil Basis of Design and Mechanical/Electrical/Plumbing Study to the ADC in March 2022.

Phase 2 of the project includes a private partner to renovate and/or design and construct a warehouse to house a highpressure processing machine(s) as well as a food hub facility on the southwest portion of the parcel. The DOE is also proposing to construct two new buildings on a portion of land adjacent to the HPP facility.

Public-Private Partnership Warehouses and Offices

Up to 12.3 acres of land is being reserved for lease to a private operator through a publicprivate partnership (P3). The ADC will issue a request for proposals (RFP) soliciting bids to construct and operate a high pressure processing and agricultural facilities at the WCFH. While these facilities will be built and operated by a private partner, they will still serve a public function. A public use and structures determination was provided by the City and County of Honolulu Department of Planning and Permitting to the ADC in April 2020. Please refer to Appendix H. Some of the functions that have been identified include:

• Renovation and/or design and construction of a warehouse to house a high-pressure processing machine(s);

• Operation and maintenance of a highpressure processing machine(s);

• Development of agricultural facilities;

• Commercial lease spaces with multiple square footage options for farmers and value-added producers;

• Cold, freezer and dry storage at various scales to support HPP operations and commercial tenants;

• Processing, packing and co-packing facilities with different configuration possibilities including fee-based services;

• Food incubation services such as shared commercial kitchen space, specialized equipment rental, and other business development training and support;

• Distribution services to improve opportunities for small farmers and food producers.

High Pressure Processing Facility

The ADC will select a public-private partner from the offerers whose proposal best meets ADC’s objectives and the RFP selection criteria. UHCDC identified two alternatives identified by the UHCDC to house the HPP machine(s) in the P3 lease area include:

1) a newly constructed warehouse to accommodate the machine(s) and all ancillary equipment, or 2 ) refurbishment of an existing building.; both in the P3 lease area.

DOE Centralized Kitchen and Warehouse

The DOE envisions a new 30,000 sf centralized kitchen to house food aggregation, preparation, cooking, and distribution to allow for more efficient production of school lunches as well as increase the procurement of locally sourced ingredients. The centralized kitchen will also include dry, cold, and freezer storage, loading, receiving, food preparation, and food packaging. An additional 50,000 sf warehouse may be built to support the centralized

kitchen. This facility will improve quality management, increase local use of farm products, and will reduce costs to renovate aging facilities distributed across school campuses. Additional acreage for warehouses and greenhouse development is available on the parcel. *The ADC and the DOE have not formally entered into lease negotiation at the time of this publication.

Phase 3 may include additional warehouses and offices to be constructed and operated by the ADC. Approximately 83,000 square feet of renovated and newly constructed buildings are accommodated in this phase.

Warehouse and office space will be made available to small to large tenants to support agricultural related businesses and operations. Warehouse buildings will be a refrigerated shell that can be subdivided into various subleased tenant spaces.

Phase 4 may include the design and construction of agricultural workforce housing as first presented in the master plan as defined by the Final Environmental Assessment published in May 2019. ADC will not develop the workforce housing on the site, but may instead lease the property to the Hawai‘i Housing Finance and Development Corporation (HHFDC) or a private partner to develop and operate.

Housing will be located on eastern end of the parcel, nearest the residential community, and will aim at housing employees on site, to reduce traffic, and provide affordable options for employees. The master plan projects 40,000 sf of single level workforce housing.

72 73

DRAFT

DRAFT

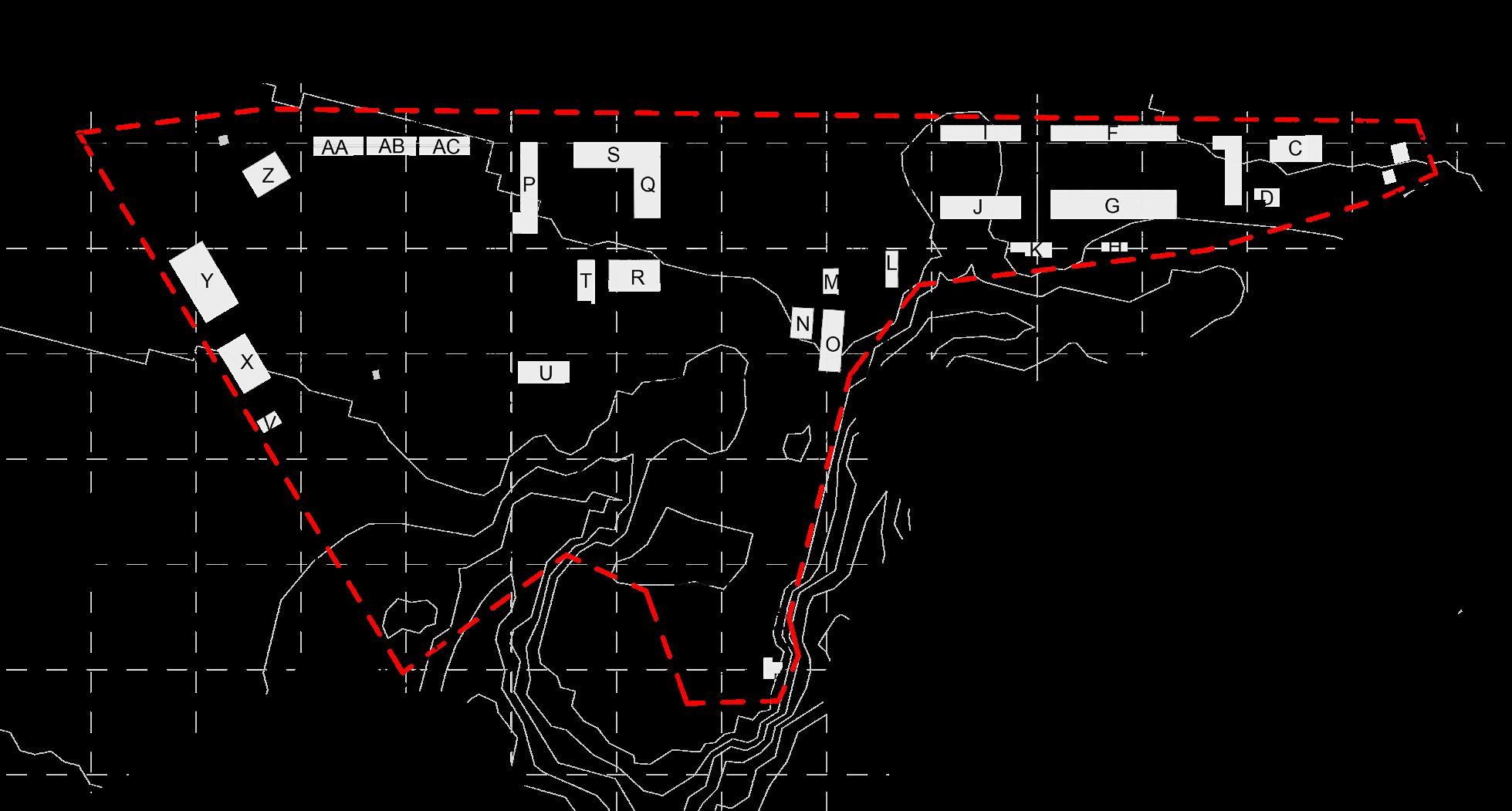

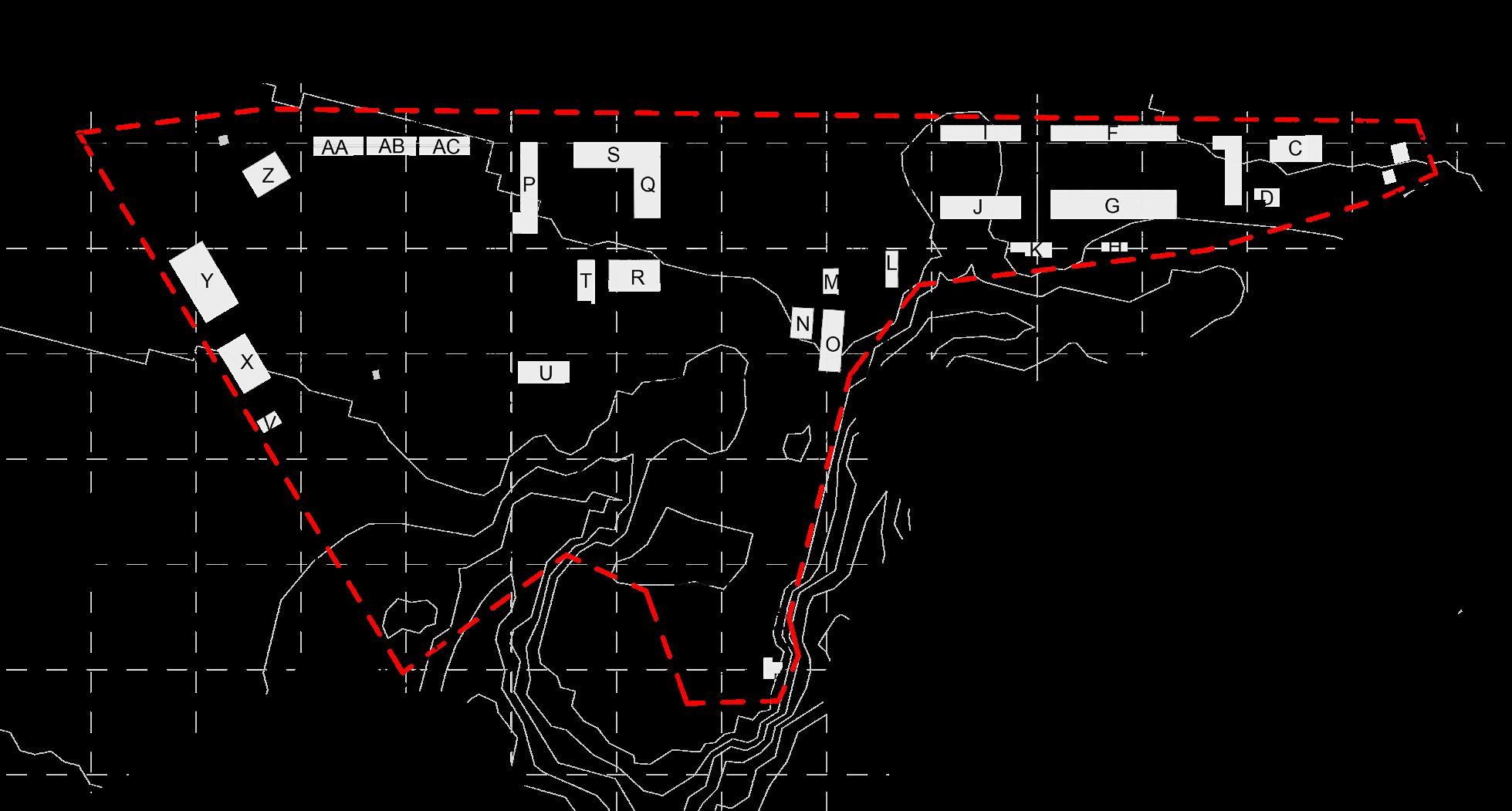

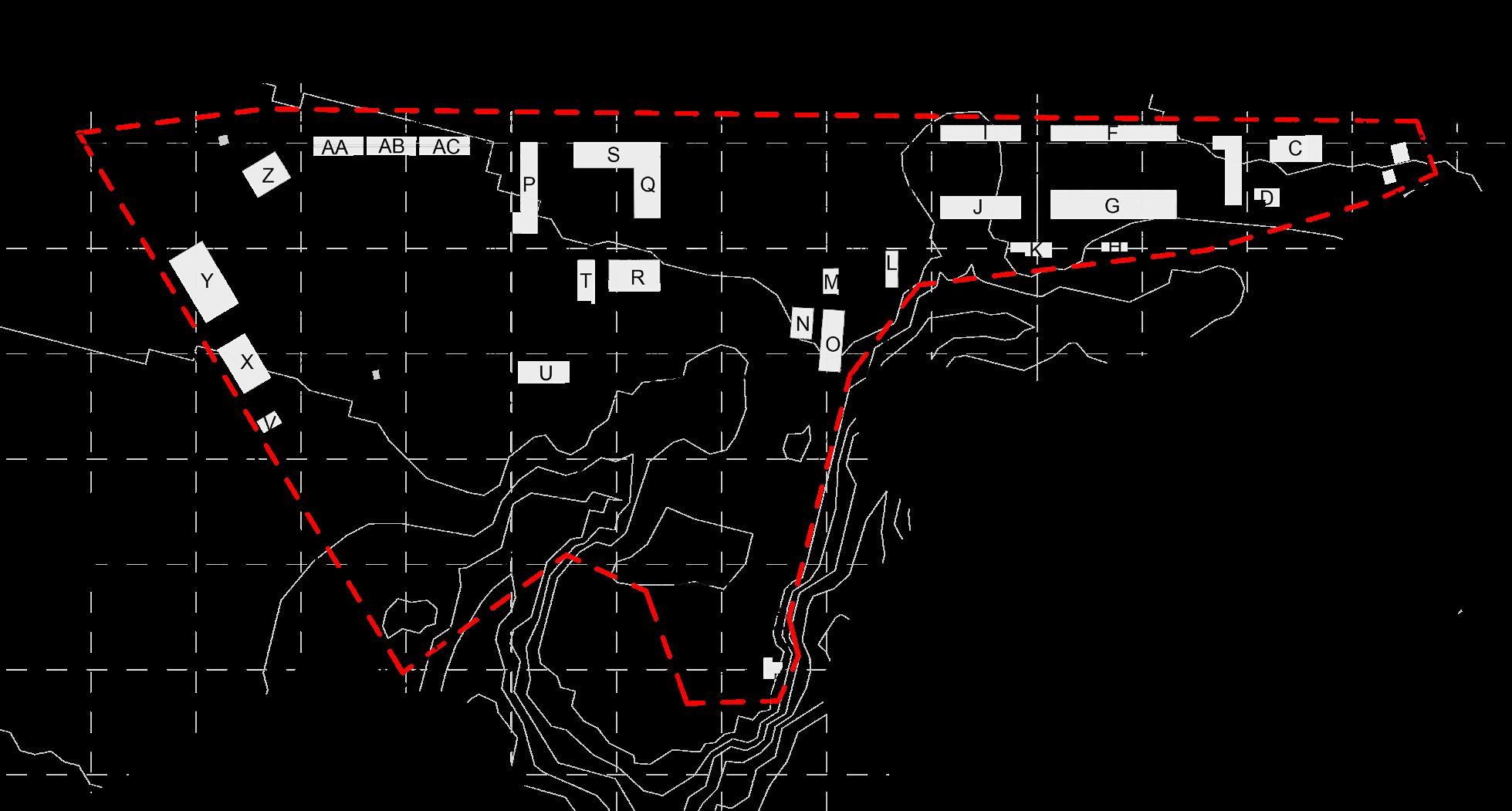

Phase 1 Draft Conceptual Master Plan DRAFT

74 75

DRAFT

Phase 2 Draft Conceptual Master Plan DRAFT

76 77

DRAFT

Phase 3 - 4 Draft Conceptual Master Plan

78 79

DRAFT DRAFT

Draft Conceptual Master Plan DRAFT

80 81

DRAFT

82 83

DRAFT

Draft 3D Conceptual Master Plan DRAFT

Phase 1 Draft Conceptual Master Plan - Civil Drawing

84 85 SMH TOP=982.5 INV=967.5 SMH TOP=991 INV=978 SMH TOP=988 INV=974.9 SMH TOP=986 INV=973.2 W8" W8" W8" W8" W8" W8" SFM4" SFM3" SFM3" S6" W8" W8" W8" W3" W3" W6" SMH TOP=988 INV=975.3 SMH TOP=982 INV=967 W3" W3" W3" SFM4" SFM4" SFM4" W3" W3" W6" W3" W3" W6" S6" S6" S8" SMH TOP=998 INV=991.8 SMH TOP=994.5 INV=986 SMH TOP=1000 INV=992.4 W3"W6" W3" S8" W8" W8" W2.5" S8" S8" S8" S8" PREPARED BY: SAM O. HIROTA, INC. April 28, 2022 PROPERTY LINE, TYP. LEGEND: PROPERTY LINE EXISTING EASEMENT AC PAVEMENT POTABLE/FIRE WATER MAIN POTABLE WATER LATERAL FIRE LATERAL PROCESS WATER MAIN PROCESS WATER LATERAL SEWER MAIN (FORCE MAIN) SEWER MAIN (GRAVITY) 6" SEWER LATERAL EXISTING SEWER MAIN FUTURE DEVELOPMENT PROPOSED FENCING LID INFILTRATION BASIN (UNLESS OTHERWISE SPECIFIED) LANDSCAPED AREA TRUE NORTH SCALE: 1" = 100' GRAPHIC SCALE 0 100 200 100 50 SCALE: 1"=100' EXISTING EASEMENT, TYP. PROPOSED ACCESS ROAD FROM WHITMORE AVE. PROPERTY LINE, TYP. PROPOSED WATER POINT OF CONNECTION PROPOSED SEWER PUMP STATION LOCATION FFE ~ 970 PROPOSED ACCESS ROAD POINT OF CONNECTION TO WHITMORE AVENUE FUTURE PROJECT: P3 FOOD PROCESSING FACILITY WHITMORE AVENUE (STATE) WHITMORE AVENUE (STATE) 4/28/2022 4:40 PM X:\PROJECTS\PBR\WHITMORE\DWG\1-EXHIBIT\SCHEMATIC SITE LAYOUT UPDATED LAYOUT.DWG EXISTING 15" SEWER LINE TO BE UPGRADED (CONSTRUCTION ANTICIPATED FROM 2024 TO 2026) PROPOSED WATER LATERAL, TYP. PROPOSED WATERLINE, TYP. PROPOSED GRAVITY SEWER POINT OF CONNECTION SEWER MANHOLE FORCE MAIN TO GRAVITY FLOW BASIS OF DESIGN NOTES: WATER: · 500-FT MAX. DISTANCE BETWEEN MAIN VALVES · 250-FT HYDRANT SPACING · 3-FT MIN. COVER FOR 12" AND 8" MAINS · 3-FT HORIZONTAL CLEARANCE TO OTHER UTILITIES GRAVITY SEWER: · 4-FT MIN. COVER FOR SEWER MAIN · 15-FT MAX. DEPTH FROM FINISHED GRADE TO PIPE INVERT · 2% MIN. SLOPE FOR 6" LATERAL TO MAIN · 0.5% MIN. SLOPE FOR 8" MAIN · 100-FT MAX. 6" LATERAL LENGTH · 350-FT MANHOLE SPACING IN ROADWAYS · 250-FT MANHOLE SPACING IN NON-ROADWAY AREAS PROPOSED SEWER PUMP STATION LOCATION FFE ~ 983 SEWER MANHOLE FORCE MAIN TO GRAVITY FLOW PROPOSED FIRE LATERAL, TYP. FIRE HYDRANT, TYP. POTENTIAL PROCESS WATER TANK, WELL, PUMP SITE (IF REQUIRED) PROPOSED PROCESS WATER LATERAL, TYP. FUTURE PROJECT: DOE CENTRALIZED KITCHEN RENOVATED BLDG T RENOVATED BLDG R w/ HIGH PRESSURE PROCESSING MACHINE PROPOSED ACCESS ROAD POINT OF CONNECTION TO WHITMORE AVENUE

W8" W8" W8" SFM3" W8" W8" W3" W3" W6" SMH TOP=982 INV=967 W3" W3" W6" S8" PROPERTY LINE, TYP. LEGEND: PROPERTY LINE EXISTING EASEMENT AC PAVEMENT POTABLE/FIRE WATER MAIN POTABLE WATER LATERAL FIRE LATERAL PROCESS WATER MAIN PROCESS WATER LATERAL SEWER MAIN (FORCE MAIN) SEWER MAIN (GRAVITY) 6" SEWER LATERAL EXISTING SEWER MAIN FUTURE DEVELOPMENT PROPOSED FENCING LID INFILTRATION BASIN (UNLESS OTHERWISE SPECIFIED) LANDSCAPED AREA EXISTING EASEMENT, TYP. PROPOSED ACCESS ROAD FROM WHITMORE AVE. PROPERTY LINE, TYP. PROPOSED POINT OF PROPOSED ACCESS ROAD POINT OF CONNECTION TO WHITMORE AVENUE FUTURE PROJECT: P3 FOOD PROCESSING FACILITY WHITMORE AVENUE (STATE) 3/10/2022 8:48 AM X:\PROJECTS\PBR\WHITMORE\DWG\1-EXHIBIT\SCHEMATIC SITE LAYOUT UPDATED LAYOUT.DWG EXISTING 15" SEWER LINE TO BE UPGRADED (CONSTRUCTION ANTICIPATED FROM 2024 TO 2026) BASIS OF DESIGN NOTES WATER: · 500-FT MAX. DISTANCE BETWEEN MAIN VALVES · 250-FT HYDRANT SPACING · 3-FT MIN. COVER FOR 12" AND 8" MAINS · 3-FT HORIZONTAL CLEARANCE TO OTHER UTILITIES GRAVITY SEWER: · 4-FT MIN. COVER FOR SEWER MAIN · 15-FT MAX. DEPTH FROM FINISHED GRADE TO PIPE INVERT · 2% MIN. SLOPE FOR 6" LATERAL TO MAIN · 0.5% MIN. SLOPE FOR 8" MAIN · 100-FT MAX. 6" LATERAL LENGTH · 350-FT MANHOLE SPACING IN ROADWAYS · 250-FT MANHOLE SPACING IN NON-ROADWAY AREAS PROPOSED SEWER PUMP STATION LOCATION FFE ~ 983 SEWER MANHOLE FORCE MAIN TO GRAVITY FLOW PROPOSED FIRE LATERAL, TYP. FIRE HYDRANT, POTENTIAL PROCESS WATER TANK, WELL, PUMP SITE (IF REQUIRED) PROPOSED PROCESS WATER LATERAL, TYP. RENOVATED BLDG T RENOVATED BLDG R w/ HIGH PRESSURE PROCESSING MACHINE DRAFT DRAFT

Phase 2 Draft Conceptual Master Plan - P3 Lease

Area Boundary

10 Foot Setback From Property Line

Run Along Edge of Sidewalk

P3 Lease Area

12.3 acres (535,944 sqft)

Run Along Edge of Access Road

Run Along

Property Line

86 87 SMH TOP=982.5 INV=967.5 SMH TOP=991 INV=978 SMH TOP=988 INV=974.9 SMH TOP=986 INV=973.2 8 W 8 W W8" W8" W8" W8" 4 M F S SFM3" 3 M F S 6 S W8" W8" W8" 3 W 3 W 6 W SMH TOP=988 INV=975.3 SMH TOP=982 INV=967 3 W 3 W 3 W SFM4" 4 M F S 4 M F S 3 W 3 W 6 W 3 W 3 W 6 W S6" S6" S8" SMH TOP=998 INV=991.8 SMH TOP=994.5 INV=986 SMH TOP=1000 INV=992.4 W3"W6" W3" 8 S W8" W8" 5 2 W S8" S8" S8" S8" PREPARED BY: SAM O. HIROTA, INC. April 28, 2022 PROPERTY LINE, TYP. LEGEND: PROPERTY LINE EXISTING EASEMENT AC PAVEMENT POTABLE/FIRE WATER MAIN POTABLE WATER LATERAL FIRE LATERAL PROCESS WATER MAIN PROCESS WATER LATERAL SEWER MAIN (FORCE MAIN) SEWER MAIN (GRAVITY) 6" SEWER LATERAL EXISTING SEWER MAIN FUTURE DEVELOPMENT PROPOSED FENCING LID INFILTRATION BASIN (UNLESS OTHERWISE SPECIFIED) LANDSCAPED AREA TRUE NORTH SCALE: 1" = 100' GRAPHIC SCALE 0 100 200 100 50 SCALE: 1"=100' EXISTING EASEMENT, TYP. PROPOSED ACCESS ROAD FROM WHITMORE AVE. PROPERTY LINE, TYP. PROPOSED WATER POINT OF CONNECTION PROPOSED SEWER PUMP STATION LOCATION FFE ~ 970 PROPOSED ACCESS ROAD POINT OF CONNECTION TO WHITMORE AVENUE FUTURE PROJECT: P3 FOOD PROCESSING FACILITY WHITMORE AVENUE (STATE) WHITMORE AVENUE (STATE) 4/28/2022 4:40 PM X:\PROJECTS\PBR\WHITMORE\DWG\1-EXHIBIT\SCHEMATIC SITE LAYOUT UPDATED LAYOUT.DWG EXISTING 15" SEWER LINE TO BE UPGRADED (CONSTRUCTION ANTICIPATED FROM 2024 TO 2026) PROPOSED WATER LATERAL, TYP. PROPOSED WATERLINE, TYP. PROPOSED GRAVITY SEWER POINT OF CONNECTION SEWER MANHOLE FORCE MAIN TO GRAVITY FLOW BASIS OF DESIGN NOTES: WATER: 500-FT MAX. DISTANCE BETWEEN MAIN VALVES 250-FT HYDRANT SPACING 3-FT MIN. COVER FOR 12" AND 8" MAINS 3-FT HORIZONTAL CLEARANCE TO OTHER UTILITIES GRAVITY SEWER: 4-FT MIN. COVER FOR SEWER MAIN 15-FT MAX. DEPTH FROM FINISHED GRADE TO PIPE INVERT 2% MIN. SLOPE FOR 6" LATERAL TO MAIN 0.5% MIN. SLOPE FOR 8" MAIN 100-FT MAX. 6" LATERAL LENGTH 350-FT MANHOLE SPACING IN ROADWAYS 250-FT MANHOLE SPACING IN NON-ROADWAY AREAS PROPOSED SEWER PUMP STATION LOCATION FFE ~ 983 SEWER MANHOLE FORCE MAIN TO GRAVITY FLOW PROPOSED FIRE LATERAL, TYP. FIRE HYDRANT, TYP. POTENTIAL PROCESS WATER TANK, WELL, PUMP SITE (IF REQUIRED) PROPOSED PROCESS WATER LATERAL, TYP. FUTURE PROJECT: DOE CENTRALIZED KITCHEN RENOVATED BLDG T RENOVATED BLDG R w/ HIGH PRESSURE PROCESSING MACHINE PROPOSED ACCESS ROAD POINT OF CONNECTION TO WHITMORE AVENUE

W8" W8" W8" SFM3" W8" W8" W3" W3" W6" SMH TOP=982 INV=967 W3" W3" W6" S8" PROPERTY LINE, TYP. LEGEND: PROPERTY LINE EXISTING EASEMENT AC PAVEMENT POTABLE/FIRE WATER MAIN POTABLE WATER LATERAL FIRE LATERAL PROCESS WATER MAIN PROCESS WATER LATERAL SEWER MAIN (FORCE MAIN) SEWER MAIN (GRAVITY) 6" SEWER LATERAL EXISTING SEWER MAIN FUTURE DEVELOPMENT PROPOSED FENCING LID INFILTRATION BASIN (UNLESS OTHERWISE SPECIFIED) LANDSCAPED AREA EXISTING EASEMENT, TYP. PROPOSED ACCESS ROAD FROM WHITMORE AVE. PROPERTY LINE, TYP. PROPOSED POINT OF PROPOSED ACCESS ROAD POINT OF CONNECTION TO WHITMORE AVENUE FUTURE PROJECT: P3 FOOD PROCESSING FACILITY WHITMORE AVENUE (STATE) 3/10/2022 8:48 AM X:\PROJECTS\PBR\WHITMORE\DWG\1-EXHIBIT\SCHEMATIC SITE LAYOUT UPDATED LAYOUT.DWG EXISTING 15" SEWER LINE TO BE UPGRADED (CONSTRUCTION ANTICIPATED FROM 2024 TO 2026) BASIS OF DESIGN NOTES WATER: · 500-FT MAX. DISTANCE BETWEEN MAIN VALVES · 250-FT HYDRANT SPACING · 3-FT MIN. COVER FOR 12" AND 8" MAINS · 3-FT HORIZONTAL CLEARANCE TO OTHER UTILITIES GRAVITY SEWER: · 4-FT MIN. COVER FOR SEWER MAIN · 15-FT MAX. DEPTH FROM FINISHED GRADE TO PIPE INVERT · 2% MIN. SLOPE FOR 6" LATERAL TO MAIN · 0.5% MIN. SLOPE FOR 8" MAIN · 100-FT MAX. 6" LATERAL LENGTH · 350-FT MANHOLE SPACING IN ROADWAYS · 250-FT MANHOLE SPACING IN NON-ROADWAY AREAS PROPOSED SEWER PUMP STATION LOCATION FFE ~ 983 SEWER MANHOLE FORCE MAIN TO GRAVITY FLOW PROPOSED FIRE LATERAL, TYP. FIRE HYDRANT, POTENTIAL PROCESS WATER TANK, WELL, PUMP SITE (IF REQUIRED) PROPOSED PROCESS WATER LATERAL, TYP. RENOVATED BLDG T RENOVATED BLDG R w/ HIGH PRESSURE PROCESSING MACHINE

DRAFT DRAFT

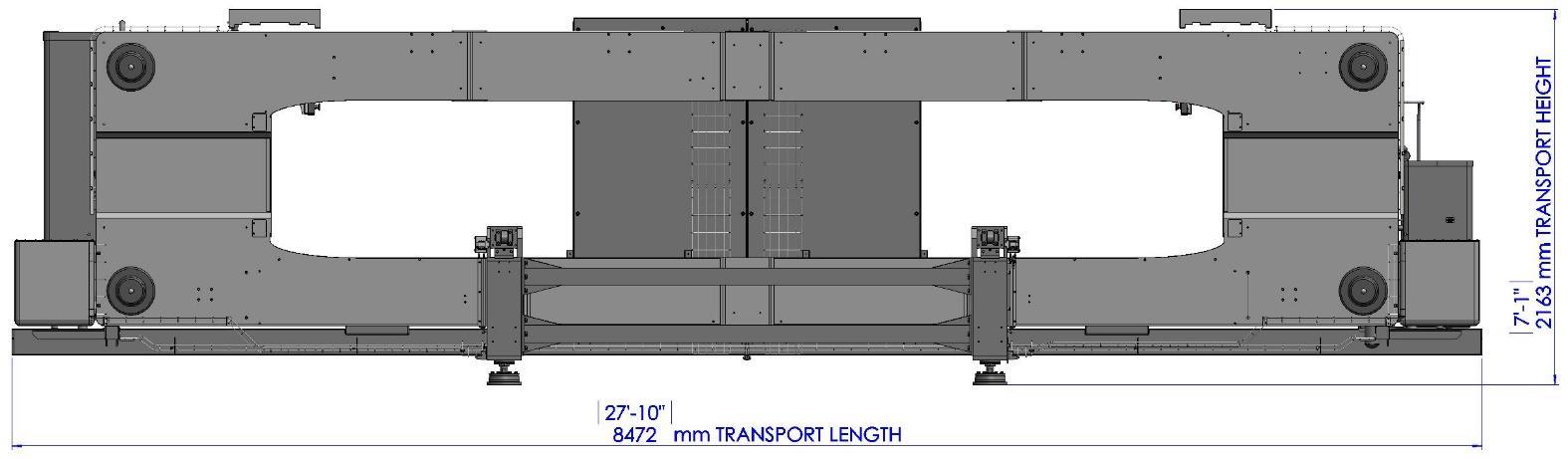

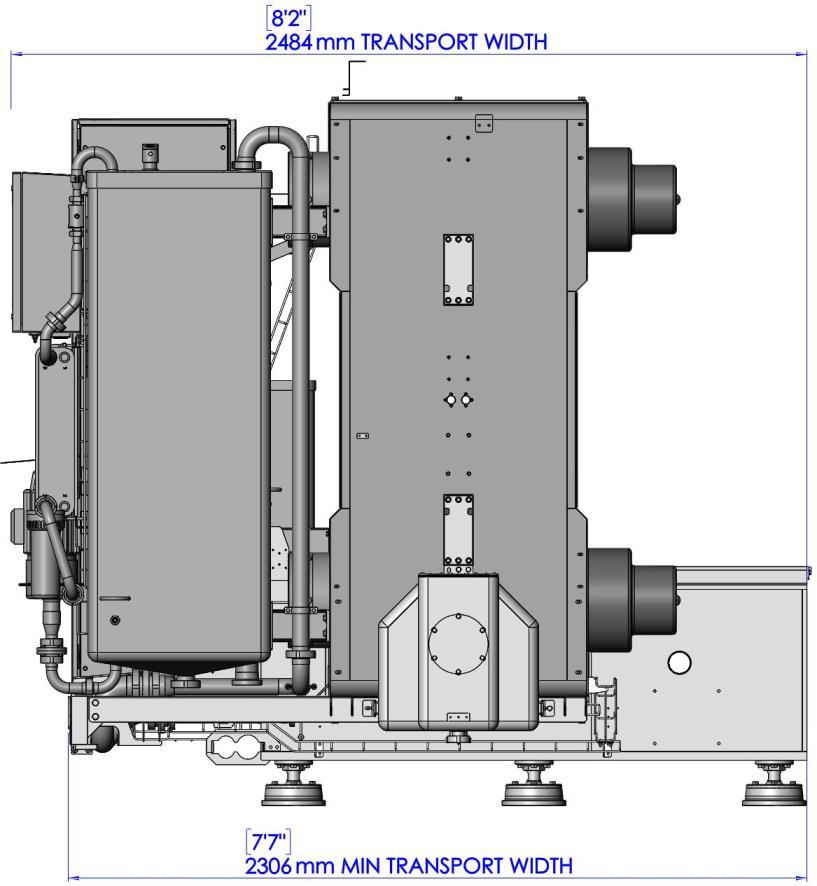

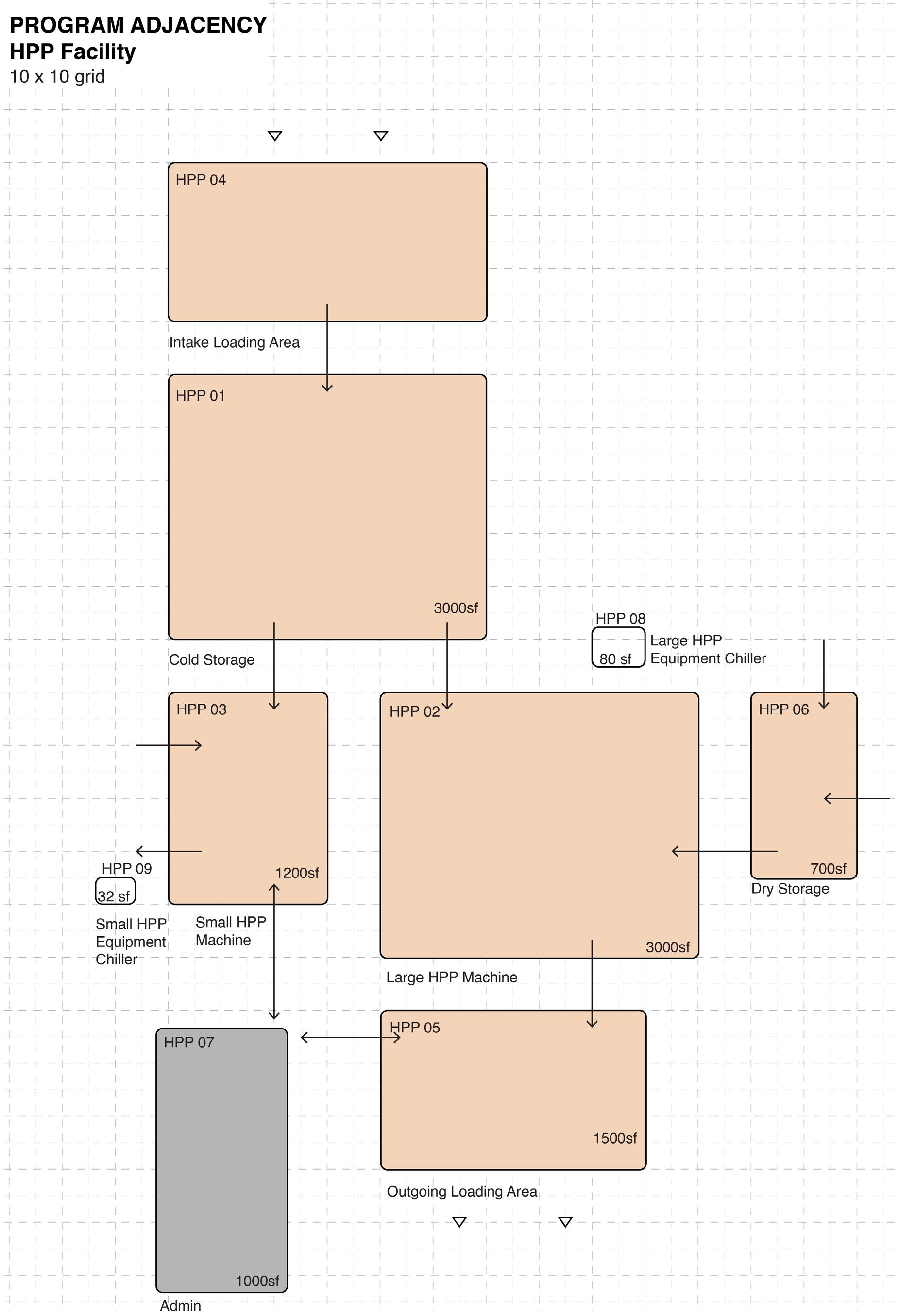

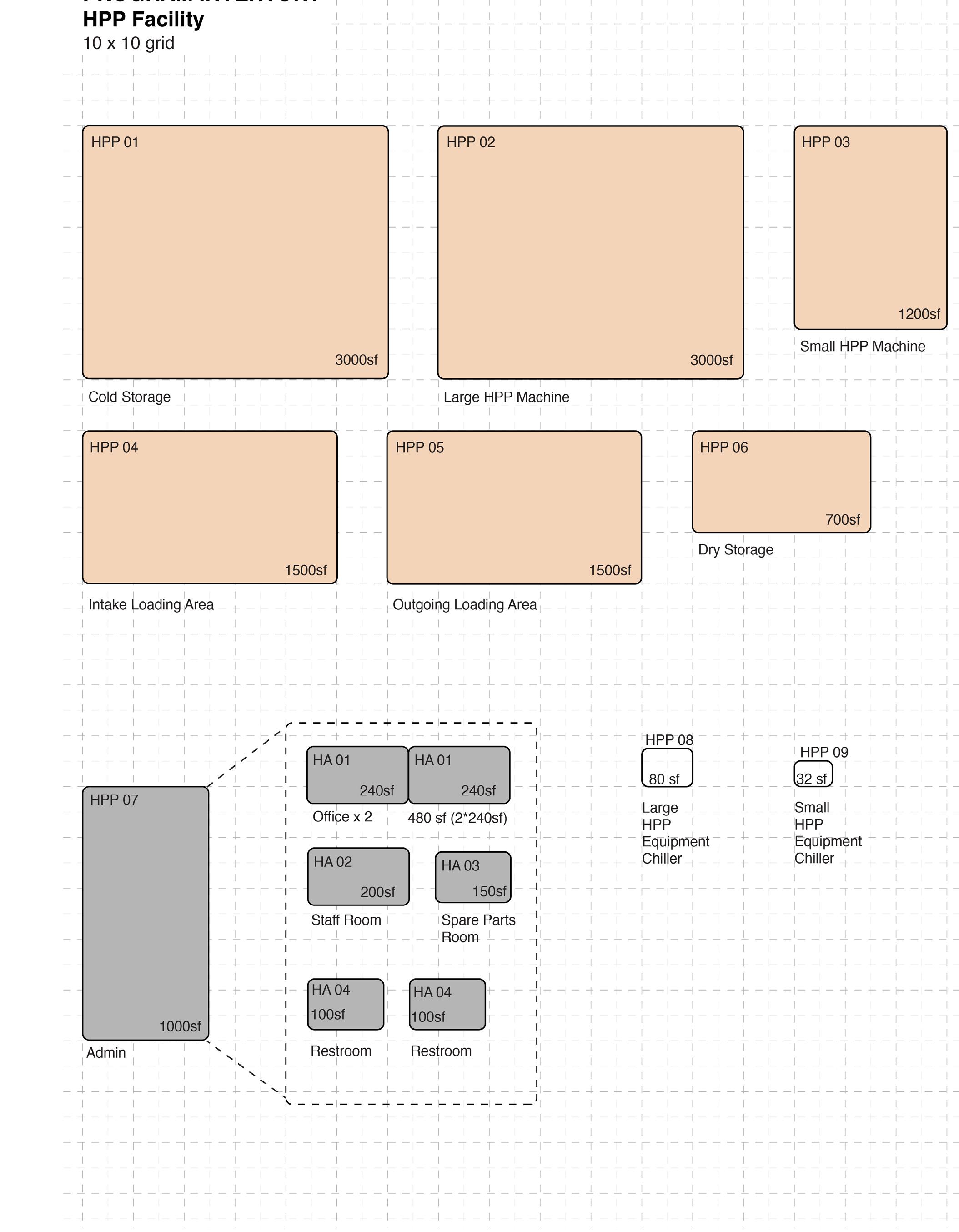

Proof of Concept New Construction for HPP Facility

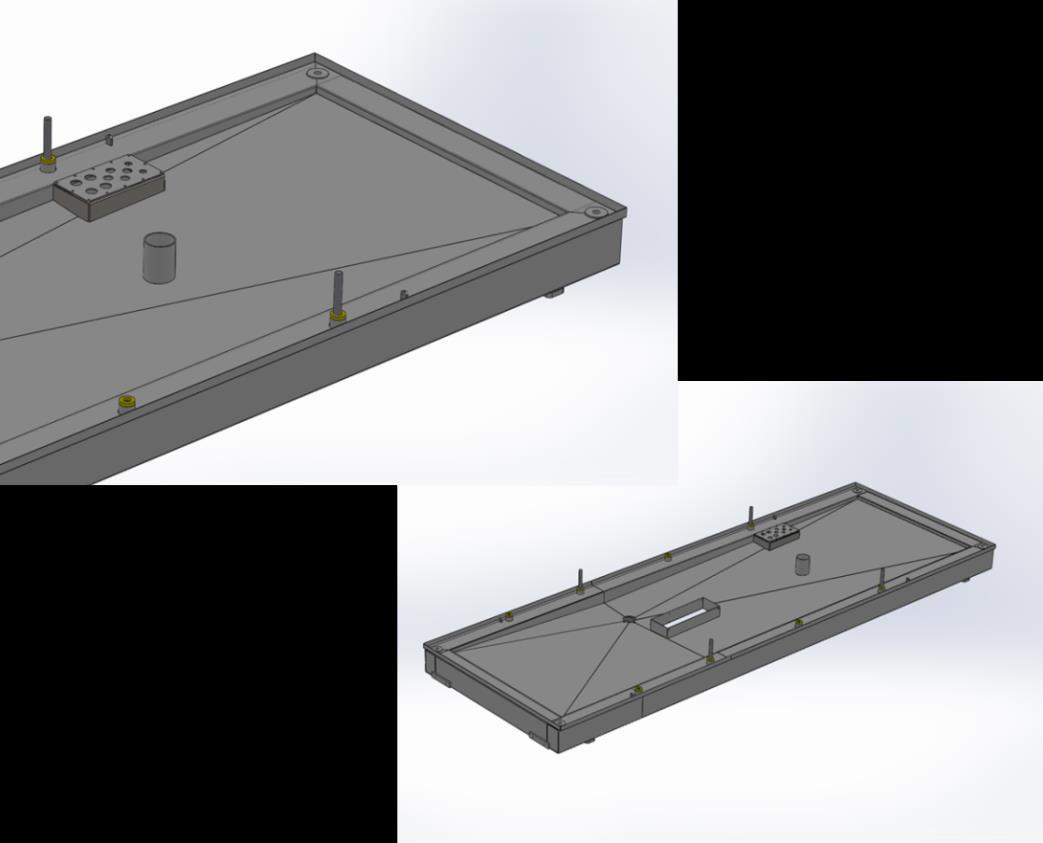

Based on site visits and feedback from HPP tollers, users, and potential users, UHCDC developed a baseline program inventory, adjacency diagrams, and program matrix for a new HPP facility. UHCDC explored two approaches to the facility: new construction and renovation.

UHCDC developed new construction proof of concept design options between 14,400 sf - 15,200 sf for a warehouse to house two HPP machines, cold storage, dry storage, loading bays, offices, meeting and other support spaces. These designs reflect different floor plan configurations that represent deliberately diverse approaches to the circulation of people and products through the facility. Also included are designs for future warehouse expansion up to 67,800 sf as well as four potential campus configurations.

HPP Facility Program Matrix

The HPP facility program matrix lists programs recommended by tollers.The tollers provided key programs with rough dimensions that they believe are necessary for a stand alone HPP facility.

HPP Facility Program Description

HPP Facility

Large HPP Machine

Space to house a large HPP machine.

Small HPP Machine

Space to house a small HPP machine.

Intake Loading Area

A loading dock for farmers and producers to unload products.

Outgoing Loading Area

A loading dock for farmers, producers, and distributors to pick up finished products.

Cold Storage

Refrigerated/cold space to store products. Pre-cold storage is used to store cold products prior to going through the HPP machine.

Post-cold storage is used to store cold products coming out of the HPP machine.

Dry Storage

Space to store dry products.

HPP Facility Admin Office

Office (x2)

Space for administrative work.

Staff Room

Space for employees to store personal items and take breaks.

Storage/Spare Parts Room

Storage space for maintenance items and equipment spare parts.

Restroom (x2)

Public restrooms for admins and tenants to use.

Baseyard

Large HPP Chiller Equipment

The chiller for the large machine.

Small HPP Chillder Equipment

The chiller for the small machine.