From Oil Fields to Metro Lines

How Indian Tube & Pipe Makers Are Riding the Growth Wave

From Oil Fields to Metro Lines

Vol. 03 No. 06 | Aug-Sep 2025

24. Jindal Industries Hissar Coming Up with New 1.5 Million...

28. APL Apollo’s Industry-First Innovations Setting...

29. Carol Petroleum: Innovating Synthetic and...

30. Sambhv Steel Tubes’ Focus on Backward Integration, Product...

31. Goodluck India’s Focus on CustomerCentric Innovation...

34. Surya Electric, Surya MFR. Tube Mill: Way: Future- Read...

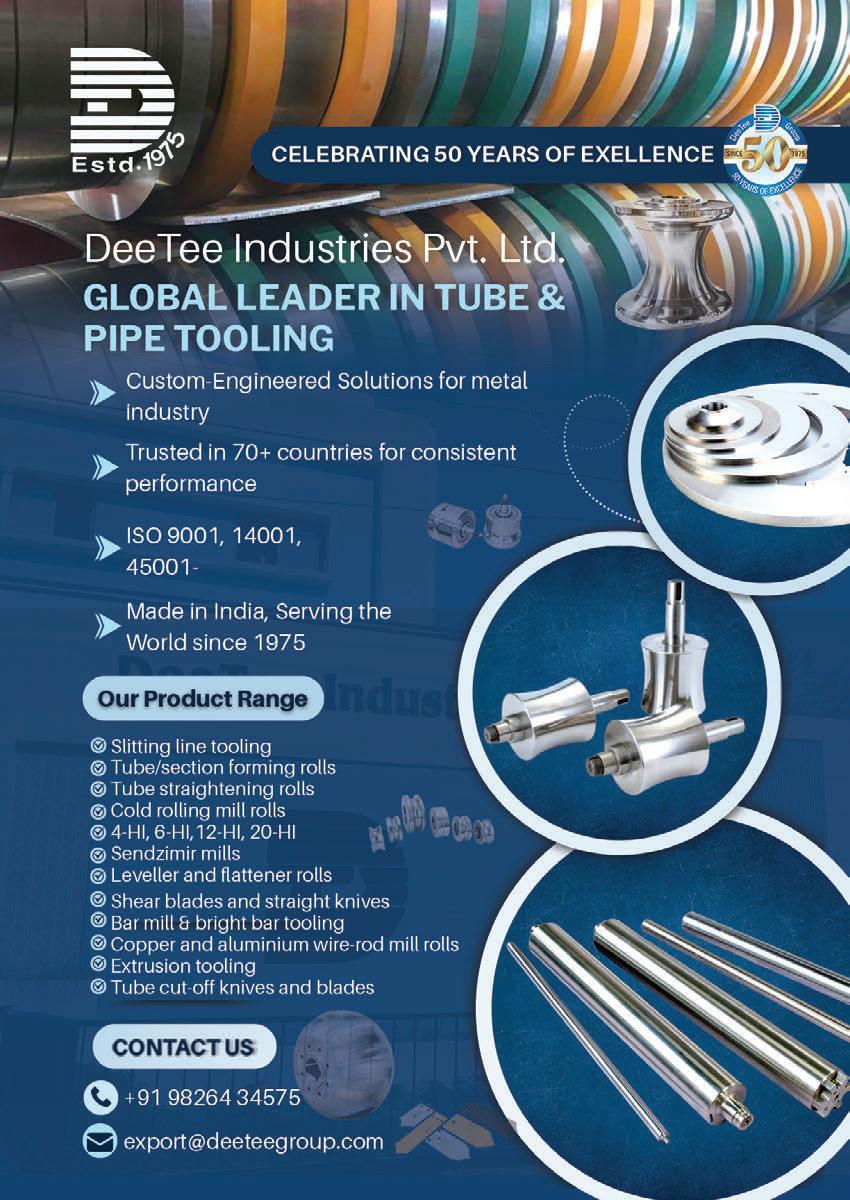

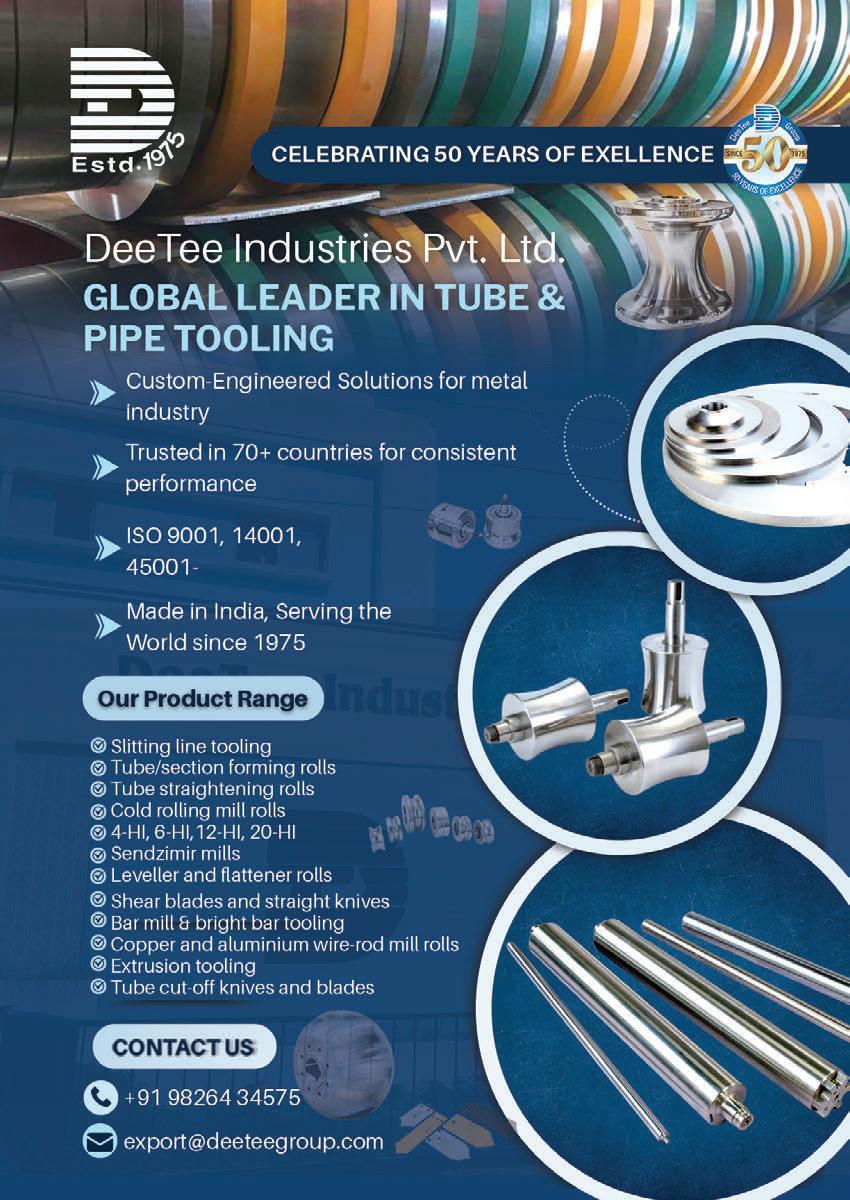

35. DeeTee Industries Bets Big On R&D and Manufacturing...

36. Jindal SAW: Future-Ready with NextGen Seamless Pipe...

37. MKK Metal Sections Expands Focus on High-Performance...

38. JTL Industries – Forging the Future of Steel Structure...

39. PP Rolling Mills Matching Global Standards- Bringing in...

40. Goel Pipes Expands Product Portfolio Targeting...

42. Innovation, Expansion, and Sustainability – Rawalwasia...

43. Chandranchal Group Investing in Advanced Manufacturing...

44. PREET GALLIUM: Powering India’s Tube and Pipe Industry...

45. GMT Industries Gearing Up for the Future with New DFT...

v v46. Avon Steel Industries: Powering Growth with Innovation...

47. Micro Steel Tube Bets on Advanced Mills and Testing...

48. Ravindra Tubes Strengthens Future Readiness with...

49. Nandini Entrepreneur Equipments Investing in R&D...

50. Not Just Supplier But Partners: Industrieofenbau on...

51. Mahler: Advancing Excellence in Tube Heat Treatment...

52. Blue Star Engineering & Electronics Advancing NDT and...

53. BizSol ERP: Driving Digital Transformation With...

54. ERCS Driving Regulatory Preparedness to Strengthen...

55. OM Techcorp: Strategic Partner for Specialty Stainless...

56. Ravik Engineers: Advanced Cutting, Bending, Sawing...

57. Satyam Pipes: Future-Ready with Scale and Integration...

58. Harder India: Staying Ahead Through Innovations in....

59. Swastik Furnaces: Driving Efficiency and Safety...

60. 30% Waste Reduction with Automation: Grow Ever Sheds...

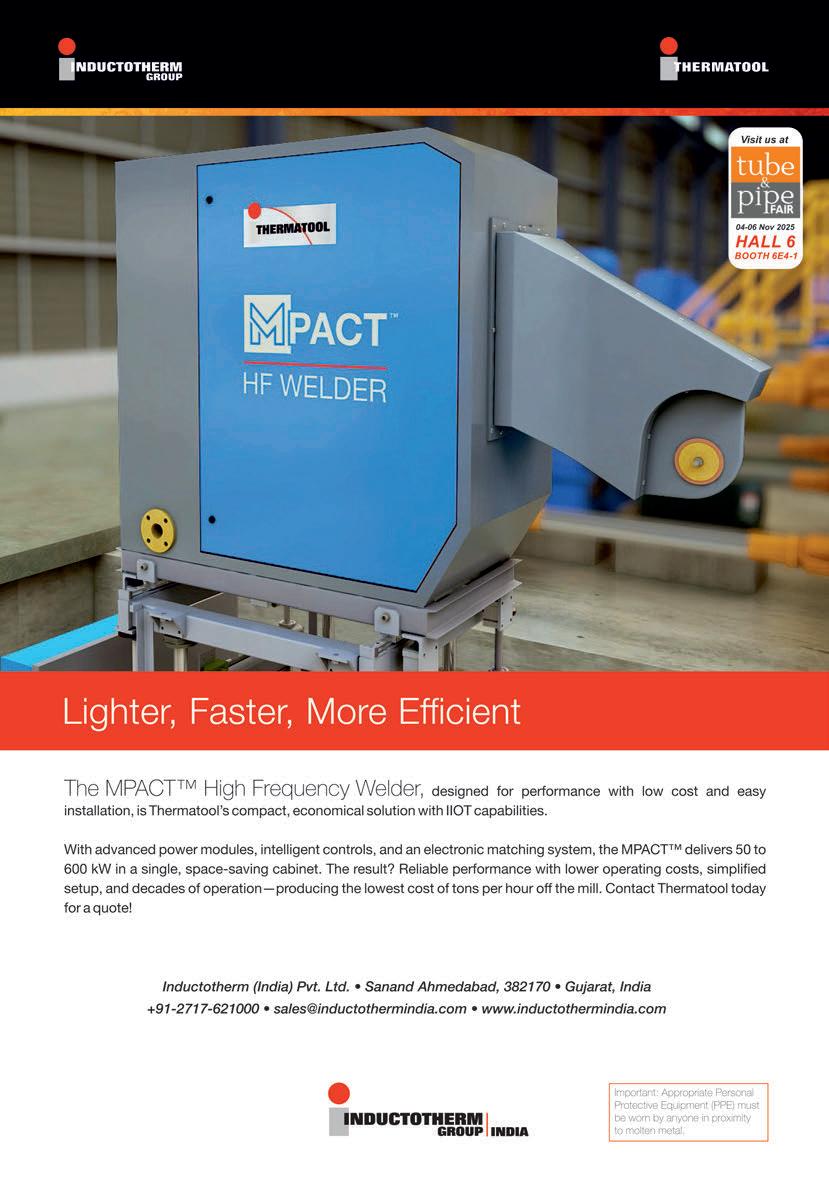

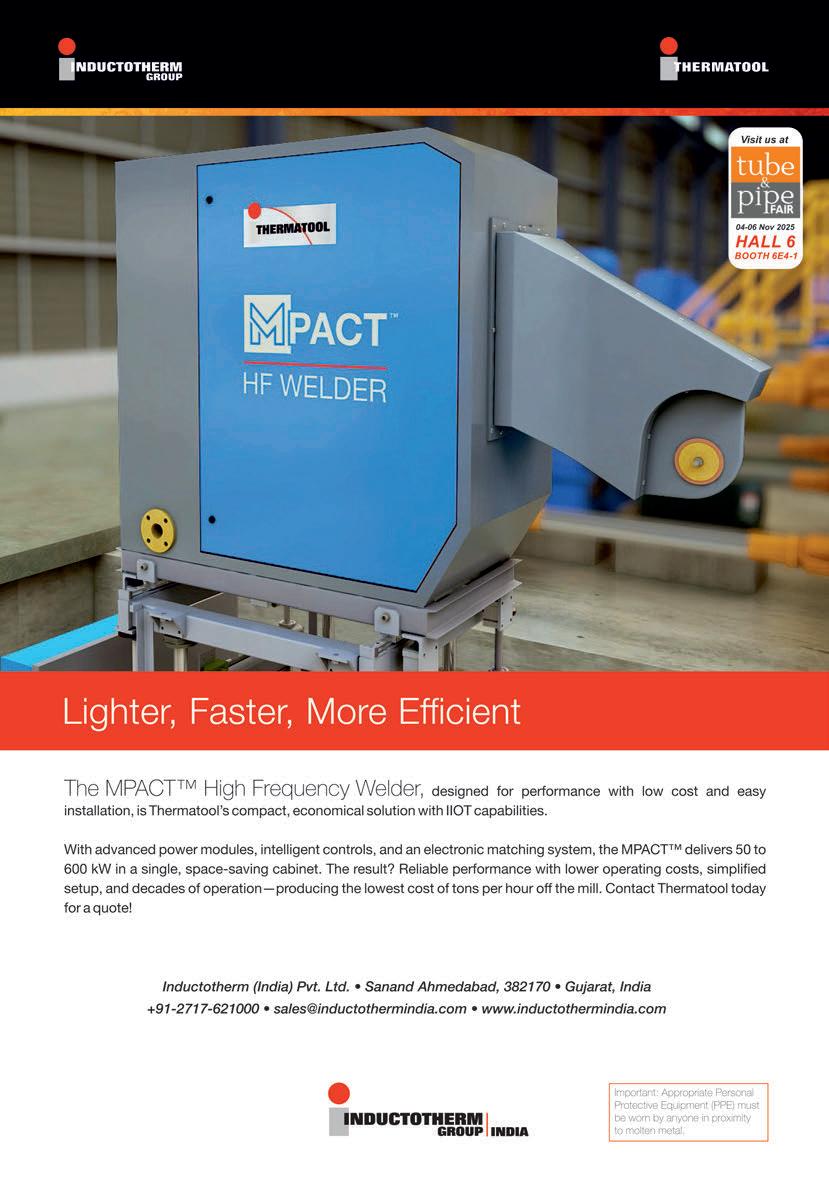

62. Advanced Induction Welding Solutions for the Tube &...

63. Arora Technologies Strengthens Industry Standards...

64. Jindal (India) Limited Expanding Capacities, Investing...

65. Supreme Rolls and Shears: Shaping the Future of Steel...

66. STPL Industrial Laser Enhances Efficiency, Quality, Out...

67. Tacklers Engineering: Customised EOT Cranes for the...

68. Megatherm: Competing for Tomorrow with Innovation and...

69. Technofour Strengthens Future Readiness with Investment...

70. From -40°C Brine to 630mm OD PPR FRP Pipes: Viral V...

71. Bachan Industries: Driving Growth Through Innovation...

72. Eddy Electro Mech to Showcase Advanced Welding and Auto...

73. ARB Bearings: Powering Growth in India’s Tube & Pipe In...

74. ENRX: Driving Technological Excellence in Tube and Pipe...

75. M.C. Tools Future-Ready Through Technology, Materials...

76. Guangzhou Blue Sky Machine Co Ltd: Driving Innovation...

77. Indira Tools & Engineering: Strengthening R&D, Supply...

78. Quality, Customization, and Innovation: Indus Tubes’...

79. Technotherma India’s Three-Pillar Approach to Market...

80. U-tech Engineers Fulfilling Premium Quality Machine...

81. Saffaire Industrial Saws: Advancing Cutting Technology...

82. From Scale to Specialization: Indipower Steel Works’ Vision...

84. Maxwell Slitter Industries Boosts Future Readiness with...

85. KK Engineering Works Anticipates Industry Needs with...

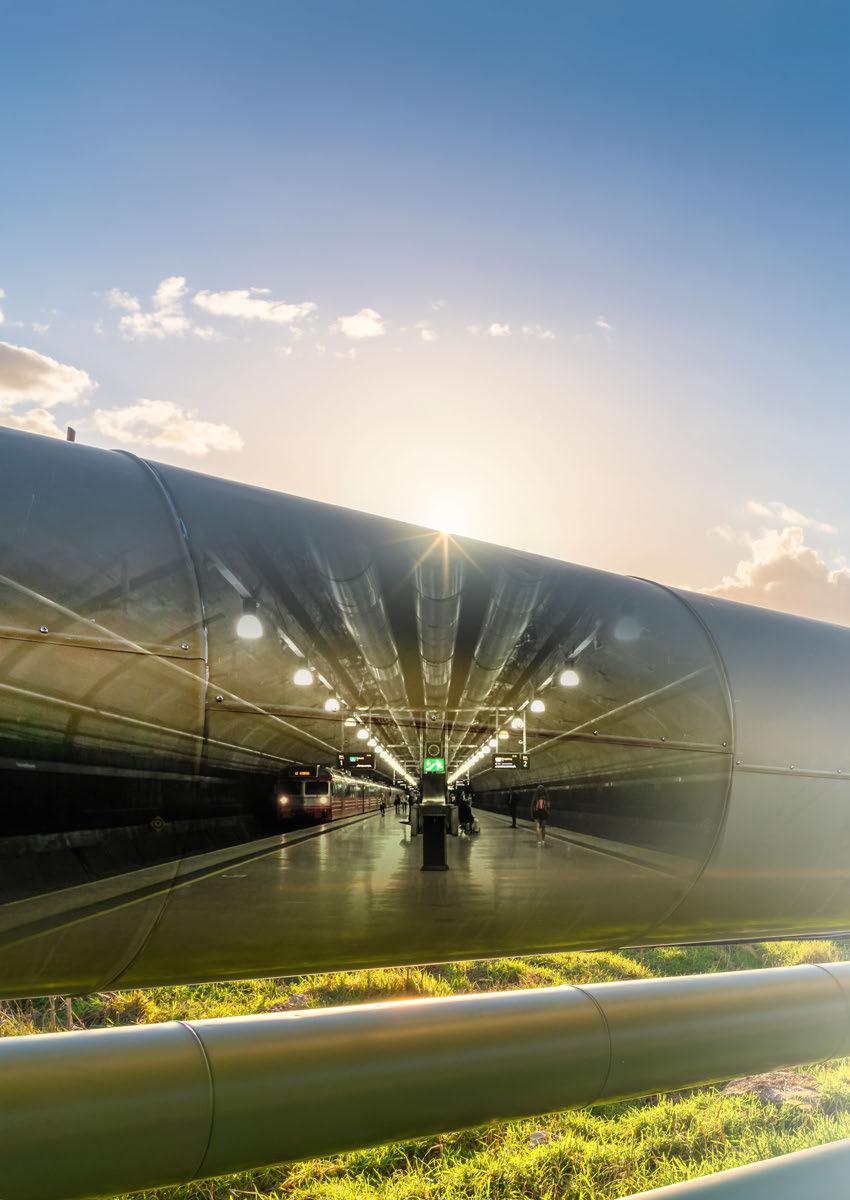

FROM OIL FIELDS TO METRO LINES

Fueled by government infrastructure initiatives, oil and gas exploration, water projects, and increasing global demand, the Indian tube and pipe industry is entering a significant growth period, with stainless steel, carbon steel, and plastic pipes.

The concealed network of tubes and pipes supports all modern economies. Oil pipelines stretching across deserts and water supply systems reaching rural households rely on specialized tubes and pipes that serve industries as diverse as construction, energy, and transportation. The Indian tube and pipe industry is growing structurally, fueled by multi-sectoral demand, infrastructure spending, and government plans.

In 2023, the Indian tube and pipe market was worth USD 32.88 billion and is expected to grow at a CAGR of 6.43% until 2030, reaching almost USD 37.7 billion. Steel pipes command the market through established welded and seamless manufacturing capacity, while plastic alternatives gain traction in water infrastructure and residential construction projects.

The global tube and pipe market was worth USD 171.8 billion in 2023, and is expected to reach USD 297.7 billion by 2032, growing at a CAGR of 6.3%. India’s manufacturing expansion and export capacity development align with this international growth trajectory, positioning domestic producers to capture increased market share while serving infrastructure projects that support broader economic development goals.

The domestic tube and pipe industry caters to a broad spectrum of applications, including construction, oil and gas, water management, agriculture, automotive, and industrial engineering. Construction and building materials consume 68% of tube and pipe production, according to industry data, while energy and engineering applications account for 10% of demand. Infrastructure projects represent 9% of consumption, with agriculture at 8% and automotive manufacturing taking 5%.

Carbon steel pipes capture the largest market share through applications in oil and gas transmission, municipal water systems, and construction frameworks. Stainless steel variants target specialized sectors including chemical processing, pharmaceutical manufacturing, and power generation facilities where corrosion resistance proves essential.

Indian stainless steel seamless pipe production expanded

10.7% annually from 2019 to 2023, with manufacturers projecting 7.2% growth through 2027. This production increase reflects rising demand from domestic infrastructure projects and export opportunities in chemical processing equipment.

On the other hand, India’s plastic pipe market reached INR 55,000 crore in fiscal 2023 projecting growth to INR 1,30,000 crore by 2030, according to EY analysis. This 12% compound annual growth rate reflects infrastructure investment through government initiatives including the Jal Jeevan Mission and Smart Cities program.

PVC and OPVC pipes dominate water supply, sewage treatment, and irrigation applications due to corrosion resistance and reduced maintenance requirements compared to metal alternatives. Custom Market Insights forecasts the Indian PVC pipe segment will expand from USD 374.7 million in 2024 to USD 1.24 billion by 2033, representing 14.2% annual growth.

Urban expansion drives infrastructure upgrades across water distribution and sanitation systems. Manufacturing capacity increases target these requirements while government procurement contracts provide revenue visibility for established producers and new market entrants seeking to capture infrastructure spending.

Demand Drivers: A MultiSectoral Pull

The tube and pipe industry’s expansion rests on a stacked demand structure, where multiple sectors drive growth concurrently.

Construction and Urban Infrastructure

Construction alone accounts for nearly two-thirds of domestic pipe consumption. Rapid urbanization, which will push India’s urban population to 600 million by 2036, is fueling demand for pipes in housing, commercial complexes, and largescale urban projects. Government initiatives such as PMAY (Pradhan

Mantri Awas Yojana), Smart Cities Mission, and AMRUT are generating large-scale orders for structural and plumbing pipes.

The Smart Cities Mission completed 8,000 projects worth INR 98,000 crore by its March 31, 2025 closure, with water supply, sewerage, and urban mobility infrastructure consuming substantial volumes of mild steel, ductile iron, and HDPE pipelines. These municipal contracts provided consistent revenue streams for domestic pipe manufacturers including Welspun Corp, APL Apollo Tubes, and Supreme Industries through multi-year project cycles.

AMRUT 2.0 approvals encompass 3,568 water supply projects valued at INR 1.14 lakh crore and 592 sewerage projects worth INR 67,608 crore. This government spending creates sustained demand for ductile iron pipe producers like Electrosteel Castings and polymer pipe manufacturers such as Finolex Industries and Prince Pipes through 2028.

PMAY-Urban’s extension to December 2025 maintains procurement schedules for last-mile plumbing systems and gas distribution networks in affordable housing developments. Tube manufacturers supplying residential construction expect order visibility through the program’s completion, supporting capacity utilization rates while municipal infrastructure projects transition to state-level funding mechanisms.

Metro projects in major cities like Delhi, Mumbai, Pune, and Bengaluru require significant volumes of steel pipes for structural purposes and plastic pipes for water and sewage systems. India’s operational metro rail network crossed 1,013 km as of May 27, 2025, with another 1,055 km under construction, keeping steel tubes/ pipes demand elevated for viaduct utilities, station MEP, and depot networks.

Oil and Gas Transportation India’s energy ambitions, including expanding its natural gas grid and

enhancing LNG import terminals, are major demand drivers. Steel pipes, especially high-strength welded and seamless varieties, form the backbone of these transmission networks. Projects under the National Gas Grid and pipeline expansions by GAIL, IOCL, and ONGC are creating a sustained order book for manufacturers.

PNGRB has authorized 33,500 km of natural gas pipelines; about 25,000 km are already operational, driving steady demand for LSA-Welded SAW line pipes, bends and coatings. India’s crude oil pipeline network totals about 10,943 km (capacity 153.1 MMTPA) and product pipelines approximately 23,618 km (capacity 140.4 MMTPA), indicating a sizable, replacement-plus-brownfield market for API pipes and station piping.

Policy is reinforcing throughput: the government is targeting 15% natural gas share in the energy mix by 2030 (vs about 6.7% currently), with expansion of the National Gas Grid and CGD as core levers, both intensive in line pipe and city distribution networks (PE, steel).

The Petroleum and Natural Gas Regulatory Board (PNGRB) has so far authorized 307 geographical areas (GAs) under the City Gas Distribution (CGD) network. This expansion translates into the rollout of lakhs of kilometres of MDPE service pipelines alongside substantial steel interconnects, creating a robust urban gas infrastructure. Over the medium term, this buildout is expected to not only strengthen last-mile connectivity but also anchor broader urban utilities integration.

The Jal Jeevan Mission (JJM) aims to provide piped water supply to 100% households, translating into a massive requirement for DI pipes, PVC/OPVC pipes, and steel pipes for trunk and distribution lines. This single program is estimated to boost demand for pipes by over 15% annually during its peak implementation years.

JJM now reports 15+ crore rural

households with tap water (coverage 80%); over 2.63 lakh villages are certified ‘Har Ghar Jal’. The Centre is also considering extension till 2028, implying continued bulk DI/steel/PE pipe procurement for schemes and retrofits.

The Department of Drinking Water & Sanitation’s 2024-25 Annual Report pegs households getting tap water at 15.43 crore (as of Jan 22, 2025), with 12.19 crore connections added in five years, evidence of unprecedented execution scale benefiting DI and MS pipe producers. A six-year JJM review quantifies 12.45 crore connections delivered and overall 81% coverage, another confirmation of sustained DI/ HDPE demand in rural transmission and distribution grids.

Steel tubes are widely used in boilers, heat exchangers, and process industries, while stainless-steel seamless pipes find applications in chemical, petrochemical, and nuclear facilities, where corrosion resistance and high-pressure tolerance are critical. India’s crude steel capacity reached 198.5 MT (prov.) in FY25, with specialty steel output targeted at 42 MT by FY27 under the PLI scheme, supporting domestic availability of pipe grades, tubes for boilers/HRSGs, and process/structural applications.

Finished steel consumption growth remains robust; provisional Joint Plant Committee trends signal 7–10% demand growth in FY25, with DRI output leadership bolstering billet availability for ERW tubes. Trade policy is supportive: a 12% provisional safeguard tariff (April 2025) on select steel imports, largely targeting Chinese inflows, has already contributed to a 29% YoY drop in finished steel imports during Apr–Jun 2025, a challenge for domestic mills and downstream tube makers.

Agriculture

With agriculture consuming over 80% of India’s water resources, efficient irrigation systems are key to sustainability. Plastic pipes, especially uPVC and cPVC, are increasingly

replacing conventional materials in irrigation and rural water supply projects, supported by government subsidies and modernization programs. Under PMKSY–PDMC (Per Drop More Crop), cumulative micro-irrigation coverage has reached 96.83 lakh ha (as of Aug 2025), driving steady demand for PVC/PE laterals, risers and GI/SS tube support systems.

The Cabinet cleared Modernization of Command Area Development & Water Management (M-CADWM) on Apr 9, 2025 to push underground pressurized piped networks from source to farm gate (upto 1 ha), with SCADA/IoT-enabled water accounting, direct upside for DI/ MS/HDPE pipes and control valves. Meanwhile, NABARD’s MicroIrrigation Fund notes 21.69 lakh ha covered by states (to Mar 31, 2025), signaling a continuing pipeline (pun intended) of district-level tenders for buried mains/sub-mains and on-farm distribution.

Automotive applications, though smaller in share, demand precision tubes for fuel lines, shock absorbers, and structural components, a niche but high-value segment that is growing with the push for electric vehicles and lightweighting. In fiscal 2025, with total vehicle production reaching 31.03 million units. Passenger vehicle sales hit 4.30 million units while commercial vehicle output reached 960,000 units, sustaining demand for electric resistance welded and drawn-over-mandrel tubes in chassis construction and body-inwhite applications.

Two-wheeler production of 19.61 million units drove consumption of lightweight tubes for exhaust systems and frame construction as manufacturers including Hero MotoCorp and Bajaj Auto adopted thinner-wall specifications to reduce vehicle weight. Electric vehicle adoption creates additional demand for specialized aluminum and steel tubes rated for battery cooling systems and structural protection.

Vehicle exports rose 19% to 5.36

million units in fiscal 2025, tightening delivery schedules for tube suppliers. This export growth maintains capacity utilization at precision tube manufacturers despite mixed monthly production data in early fiscal 2026.

Tube manufacturers targeting automotive applications command higher margins than commodity producers serving construction markets. Electric vehicle transition requires investment in aluminum processing capabilities and precision welding equipment to meet lightweighting requirements from original equipment manufacturers.

Government policies have acted as powerful enablers for the growth of the tube and pipe sector. The Production Linked Incentive (PLI) Scheme for Specialty Steel encourages the production of high-grade steel, thereby reducing import dependence. Similarly, the Domestically Manufactured Iron & Steel Products (DMI&SP) Policy promotes the use of indigenous steel in government projects, boosting domestic demand.

The National Infrastructure Pipeline, with an allocation of INR 11.21 lakh crore for FY2025-26, including INR 1.16 lakh crore earmarked for roads and bridges, is expected to significantly drive demand for structural and drainage pipes. Complementing this, the PM Gati Shakti National Master Plan is improving logistics and connectivity, thereby facilitating the execution of large-scale pipeline projects. Additionally, the implementation of Quality Control Orders, mandating BIS compliance for both steel and plastic pipes, ensures standardized quality and safety across the sector.

While the domestic market remains the primary growth engine, export opportunities are expanding, particularly in oil & gas, water transmission, and specialty stainlesssteel segments.

The global tube and pipe market, projected to reach USD 297 billion by 2032, presents a huge opportunity for India. Welspun Corp, Surya Roshni, and Jindal Stainless are already significant exporters to GCC nations, North America, and Europe.

Global supply chain diversification under the China+1 strategy is beginning to benefit Indian manufacturers. Although India’s current share is modest compared to China’s dominance, its cost competitiveness, compliance with API/BIS standards, and growing capacity position it as a credible alternative for international buyers in oil & gas and infrastructure segments.

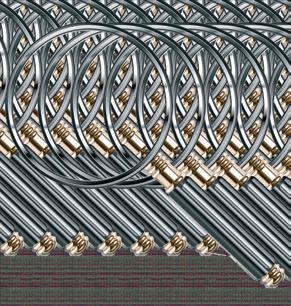

Modern tube and pipe manufacturing has evolved well beyond conventional commodity steel, embracing advanced technologies and sustainable practices. For instance, state-ofthe-art high-end coatings are being routinely applied to steel used in oil and gas pipelines to significantly

enhance corrosion resistance and extend service life, an increasingly critical feature given the aggressive environments these pipelines often traverse. In parallel, innovations in seamless pipe technology are enabling their use in demanding high-pressure applications, where traditional welded pipes may fall short.

On the plastic side, the evolution of OPVC (modified PVC) and related plastic pipe technologies is gaining momentum. The Indian PVC pipes market alone reached 2.9 million tonnes in 2024, and is projected to more than double to 5.5 million tonnes by 2033, growing at a robust CAGR of 6.8%. Broader estimates of the Indian plastic pipe market, including PE, PP, and other types, suggest it will reach around USD 9 billion by 2030, expanding at a steady 5% CAGR from 2024 to 2030.

Beyond volume growth, Indian manufacturers are increasingly adopting advanced extrusion technologies, such as twin-screw extruders, energy-efficient heating

systems, in-line quality control tools, and automation with AI-based monitoring, to ensure precision, reduce downtime, and scale production while maintaining quality standards.

On the sustainability front, there’s a growing shift toward greener steelmaking practices. Although challenges remain, such as the fact that only about 21% of India’s steel production currently comes from scrap-based (electric arc furnace) routes, the potential is significant. Scrap-based processes substantially lower carbon emissions and energy consumption, especially when combined with renewable electricity. While traditional coal-based blast furnaces remain predominant, greener alternatives like electric arc furnaces (EAFs) are gaining ground as lowemission options. Moreover, emerging innovations such as hydrogen-based direct reduced iron (DRI) and the HIsarna process (demonstrated by Tata Steel to reduce CO₂ emissions by more than 50% without carbon capture) are being explored for

their efficiency and environmental advantages.

Energy efficiency is another cornerstone. Many steel producers are transitioning to energy-efficient furnaces and adopting zero-liquiddischarge practices to minimize environmental impact and conserve water, key considerations for sustainable manufacturing. Although precise figures for these practices in the Indian tube and pipe sub-sector are harder to isolate, they align with broader industrial shifts toward greener operations across the steel and plastic value chains

The Indian tube and pipe sector is strongly supported by some of the country’s largest steel producers and specialized pipe manufacturers, whose financial strength and strategic investments continue to drive growth and competitiveness. Leading pipe manufacturers reported fiscal 2025 financial results that illustrate the sector’s revenue scale and growth

trajectory across steel, plastic, and specialty segments. Coverage constraints limit analysis to only a handful of companies, though many other producers and specialty fabricators contribute significantly to India’s tube and pipe manufacturing capacity.

Tata Steel, with revenues of INR 2,18,543 crore and a profit of INR 3,174 crore in FY25 (profit turnaround of 165% YoY), remains the largest player in the domestic steel ecosystem. Its Tubes Division crossed the milestone of 1 million tonnes in both production and sales, consolidating its leadership in structural and conveyance tubes. The company is also investing heavily in green-steel technologies, including electric arc furnaces and pilot projects in hydrogen-based reduction, positioning itself as a global frontrunner in sustainable steelmaking. Tata Steel India, the core operating unit, reported revenues of INR 1,33,444 crore (up 6.6% YoY) and profits of INR 13,803 crore (up 6.1% YoY), and continues to focus on high-value tube products and supply-

chain integration for downstream industries.

Steel Authority of India Limited (SAIL), with a turnover of INR 1,01,716 crore and profits of INR 2,148 crore, plays a pivotal role as a domestic supplier of crude steel, feeding into the pipe manufacturing ecosystem. Its modernization and capacity expansion plans, particularly at Bhilai and Bokaro, strengthen its ability to meet the growing demand for pipes used in infrastructure, energy, and construction projects.

Among stainless-steel producers, Jindal Stainless (JSL) has emerged as a global force. With revenues of about INR 40,182 crore (up 5%) and profits of INR 2,711 crore (up 7% YoY), it is India’s largest stainless-steel producer and among the top five globally. The company is expanding stainless steel pipe capacities and targeting a stronger export footprint, building on its already significant presence across more than 40 countries.

APL Apollo Tubes, India’s leading

structural steel-tube manufacturer, reported revenues of INR 20,690 crore (up 13.7% YoY) and profits of INR 757 crore (up 3.4% YoY) in FY25. With an installed capacity of 4.5 MTPA and plans to expand towards 6.8 MTPA by FY28, APL Apollo has positioned itself as a key enabler of India’s infrastructure boom. Its product mix, spanning structural, construction, and agricultural applications, underscores its diversified strategy.

Welspun Corp remains a major player in welded pipes, with revenues of INR 13,978 crore and EBITDA of INR 1,858 crore (up 3% YoY). The company has been aggressive in expanding ductile iron pipe capacities and continues to strengthen its global footprint, supported by a healthy order book and ongoing capex exceeding INR 900 crore. Welspun’s international arm, Welspun Pipes Inc. (USA), together with its holdings in Welspun Tubular LLC and Welspun Global Trade LLC, reported consolidated revenues of INR 2,442 crore and a profit of INR 101 crore in FY25, reflecting its continued role as a material foreign subsidiary. On the domestic front, Welspun DI Pipes Ltd. delivered robust growth with revenues of INR 2,062 crore (up 36% YoY) and profits of INR 292 crore (up 186% YoY), attaining the status of a material subsidiary under SEBI regulations. Additionally, Welspun Corp holds a 26.5% stake in East Pipes Integrated Company for Industry (EPIC), a Saudi Arabian associate that reported revenues of INR 4,141 crore (up 22% YoY) and profits of INR 863 crore (up 46% YoY). EPIC supplies advanced HSAW pipes, certified up to API 5L X-80 grades, to major clients such as SWCC and Saudi Aramco, further reinforcing Welspun’s global leadership in the pipes industry.

In the mid-sized category, Surya Roshni reported revenues of INR 5,749 crore and EBITDA of INR 446 crore (up 2.3% YoY). With state-ofthe-art facilities across Haryana, Gujarat, Madhya Pradesh, and Andhra Pradesh, the company is executing a INR 500 crore capex plan over two years to increase pipe capacity from 1.2 MTPA to 1.9 MTPA. This includes

raising investment at its Hindupur facility from INR 75 crore to INR 125 crore, adding 2,00,000 TPA capacity, and a INR 75 crore investment at Bhuj (Anjar) for large diameter pipes. It has also commissioned a new spiral plant in Gwalior in February 2025 and is expanding cold rolling capacity at Bahadurgarh by H1FY26. Products marketed under the ‘Prakash Surya’ brand are exported to over 50 countries, including a strong presence in GCC markets, while domestically, Surya maintains a wide B2C presence, particularly in Tier II cities and rural regions through its dealer-distributor network.

In this category, Maharashtra Seamless Limited (MSL), with revenues of INR 5,266 crore and profits of INR 793 crore, continues to dominate the seamless pipe market, catering to oil & gas and engineering sectors while pursuing export opportunities despite margin pressures. Ratnamani Metals & Tubes, with revenues of INR 4,959 crore and profits of INR 579 crore, is distinguished by its high export orientation and technical leadership, including the supply of hydrogenservice-compliant pipes for global energy projects.

Goodluck India, with revenues of INR 3,936 crore (up 11.7% YoY) and profits of INR 162 crore (up 23.9% YoY), has diversified into value-added tubes, including a new hydraulic tube facility with 50,000 tonnes annual capacity, aimed at sectors such as railways, defence, and automotive. Hi-Tech Pipes posted revenues of INR 3,068 crore (up 13.6% YoY) and profits of INR 73 crore (up 66% YoY), supported by double-digit volume growth and a strategy focused on infrastructure and agriculture demand. JTL Industries, with revenues of INR 1,916 crore and profits of INR 99 crore, is scaling up its structural tube capacity while concentrating on margin expansion through value-added product lines.

Among the emerging players, Sambhv Steel Tubes reported revenues of INR 1,511 crore (up 17.5% YoY) and profits of about INR 57 crore. Having recently

launched an IPO to raise capital for expansion, the company reflects the dynamism of smaller, fast-growing firms consolidating their position in India’s highly competitive pipe and tube sector.

Collectively, these companies demonstrate a robust blend of financial resilience, capacity expansion, technological innovation, and sustainability focus. Their strategies, from Tata Steel’s net-zero roadmaps to Ratnamani’s hydrogenready pipelines and Surya Roshni’s export-led growth, highlight how India’s tube and pipe industry is aligning with both national infrastructure priorities and global energy transitions.

Despite its rapid expansion, the Indian tube and pipe industry continues to contend with multiple challenges that affect margins and long-term sustainability.

Steel and PVC are the primary raw materials for the tube and pipe industry, and their prices remain highly volatile due to fluctuations in global commodity markets, energy prices, and trade policies. For instance, Surya Roshni noted that sharp swings in hot-rolled coil (HRC) steel prices directly impact margins in its ERW and structural pipe business. Similarly, volatility in crude oil derivatives drives cost fluctuations in PVC resins, putting pressure on profitability in the polymer pipe segment. This uncertainty compels companies to either absorb higher costs, reducing margins, or pass them on to customers, which risks demand slowdown.

Indian pipe manufacturers face stiff competition from imports, particularly from countries like China, Vietnam, and Middle Eastern producers, where production costs are lower. Reports highlight that Indian companies, despite investing in capacity and advanced technologies

such as Direct Forming Technology (DFT) and 3LPE coating facilities, are often undercut by cheaper imports. This pressure intensifies in segments like API-grade pipes and structural tubes used in infrastructure projects, eroding domestic players’ pricing power.

Transportation delays, high freight costs, and port congestion remain bottlenecks for both domestic and export markets. For exportfocused players such as Surya Roshni, one of the largest Indian exporters of ERW pipes, timely shipments to over 50 countries are often challenged by shipping line shortages, rising container costs, and infrastructure gaps in last-mile connectivity. Domestically, rail and road bottlenecks lead to higher lead times and costs, which affect order execution schedules for large-scale infrastructure and oil & gas projects.

Pipe and tube manufacturers in India must adhere to stringent BIS specifications as well as API and ISO certifications for international sales. While these standards enhance product credibility, the associated compliance and testing requirements raise operational costs. Companies frequently invest in advanced testing, coating, and R&D facilities to remain compliant, but the burden is heavier for mid-sized players who operate on thinner margins. Surya Roshni, for example, invested in state-ofthe-art coating and quality-testing facilities to meet international project consultancy accreditations (like EIL and Mecon). However, continuous upgrades and audits add to recurring compliance expenditure.

The Indian tube and pipe industry is poised to evolve from being a volume-driven sector to one that increasingly competes on technology, sustainability, and value-added solutions. Beyond the expected 6–7% annual growth, the next phase

will be marked by greater product specialization, including precisionengineered hollow sections for infrastructure, higher-grade stainless steel for process industries, and advanced coatings for longer service life in demanding environments.

Digitalization and automation are set to reshape manufacturing processes, with leading companies deploying smart quality-control systems, AI-based demand forecasting, and end-to-end supply chain integration. These capabilities will not only reduce costs but also improve reliability and responsiveness, which are critical in global markets.

Sustainability will emerge as both a challenge and an opportunity. As customers across oil & gas, water utilities, and infrastructure increasingly mandate lower carbon footprints, Indian manufacturers are expected to invest in green steel, energy-efficient production lines, and circular material usage. Firms that embed ESG compliance early will gain a distinct advantage in global tenders and long-term contracts.

The industry is also likely to witness consolidation, with larger players expanding capacity, acquiring regional competitors, and diversifying into adjacent product categories such as structural tubes, PVC fittings, and composites. Access to capital, both domestic and international, will play a critical role, as companies with stronger balance sheets can accelerate expansion and R&D investments.

On the global front, India is well positioned to capture a larger share of the tube and pipe supply chain as Western economies diversify sourcing beyond China. Securing certifications such as API, ASTM, and PED will remain essential, but equally important will be building long-term partnerships with EPC contractors, utilities, and energy companies.

In essence, the industry’s trajectory will be defined by rising demand and how effectively it aligns with global megatrends: sustainability, digital manufacturing, supply chain

resilience, and strategic consolidation. Companies that adapt to these shifts will shape India’s transition from a cost-competitive supplier to a global hub for high-quality, future-ready tube and pipe solutions.

Against the backdrop of sustained demand and rising export ambitions, B2B exhibitions occupy a distinctive position in the industry’s growth ecosystem. They condense the extended timelines of market outreach and trust-building into a concentrated, face-toface exchange. For tube and pipe manufacturers, this setting allows for direct demonstration of product performance, on-the-spot validation of quality, and detailed technical discussions with institutional buyers, all within a compressed timeframe that accelerates decision-making.

Launched by Tulip 3P Media in 2023, the Tube & Pipe Fair (TPF) has quickly emerged as South Asia’s largest dedicated platform for the sector. The inaugural edition at Delhi’s Pragati Maidan (October 2023), co-located with Cable & Wire Fair (CWF), attracted over 3,000 visitors and more than 70 leading brands, offering a glimpse into the latest technologies and product innovations. Encouraged by its success, the organizers expanded the footprint to Hyderabad’s HITEX Centre in August 2024. With participation crossing 100 brands and footfall rising to 5,000, supported by greater involvement of both domestic and international technology providers, the southern sojourn proved to be a success.

Building on this momentum, the third edition of TPF is scheduled to return to New Delhi’s Pragati Maidan from 4th to 6th November 2025. Its co-location with the Cable & Wire Fair and the inaugural Bharat Metal Expo (BME) reflects the increasing interdependence of the industries it serves, with cables, tubes, and metals forming the material backbone of energy, transport, and manufacturing systems. This convergence creates

opportunities for buyers and suppliers to address interconnected procurement needs in a single venue, while also enabling cross-sector technology transfer.

Evidence from previous editions points to tangible commercial outcomes. Exhibitor surveys indicate that over 40 percent of participants secured confirmed orders during the event, while more than 30 percent of leads generated translated into business within the following year. For smaller and mid-tier companies, the fair offers cost-effective access to national and export markets; for larger players, it has become a strategic point for launching new products, reinforcing brand leadership, and, in

some cases, pre-booking production slots for high-demand items months in advance. International buyers often use the event to assess Indian suppliers first-hand, a step that can lead to long-term contracts or joint ventures, particularly in markets such as Europe, the Middle East, and North America.

Beyond the transactional dimension, TPF along with BME serves as a setting for sector-wide dialogue on technology, regulation, and market direction for tube and metal industries. Its conferences and technical sessions have addressed issues ranging from evolving BIS norms and export compliance requirements to innovations in

conductor and insulation technology. The introduction of new machinery, materials, and testing protocols at the fair has often accelerated the industry’s adoption of best practices, whether in extrusion line upgrades or enhanced fire safety measures.

As the sector enters a phase of consolidation and deeper integration with global supply chains, forums like the Tube & Pipe Fair provide more than visibility; they function as mechanisms for aligning domestic capabilities with international benchmarks. In doing so, they help ensure that the industry’s projected growth is matched by parallel advances in quality, innovation, and competitiveness.

Ratnamani Metals and Tubes Limited (RMTL) has executed a share purchase agreement with Technoenergy AG, Switzerland to purchase the entire shareholding held by it in Ratnamani Trade EU AG, Switzerland.

Ratnamani Metals and Tubes Limited (RMTL) has announced that the company has executed a share purchase agreement with Technoenergy AG, Switzerland to purchase the entire shareholding held by it in Ratnamani Trade EU AG, Switzerland.

Ratnamani Trade EU AG was incorporated to become the exclusive trading house to import and distribute various categories of stainless-steel products in Europe, which are manufactured by RMTL under its brand, to help RMTL to develop its local presence, branding, superior servicing to European customers and also to meet the faster delivery commitments by maintaining the stock of its key products

The company shall purchase 40,000 shares of EUR 10 each, at a purchase price of EUR 4,00,000 in Ratnamani Trade EU AG, Switzerland, the subsidiary company, thereby Ratnamani Trade EU AG shall become a wholly

owned subsidiary company of the company.

The Board of Directors gave authority to the executives of the company to finalise the terms and conditions and execute the agreement at its meeting held on August 1, 2025.

Technoenergy AG is not related to the promoter / promoter group in any manner. However, RMTL has incorporated a subsidiary company namely Ratnamani Finow Spooling Solutions Private Limited (RFSS) in India wherein Technoenergy AG is a joint venture partner holding 49% in the share capital of RFSS.

Mr. Sunil Jain, Director and CEO, Jindal Industries Hissar Pvt. Ltd.

The growth of the tube industry slowed down in the first half of 2025-26, largely due to record-breaking rains across the country that disrupted operations and demand. In addition, government spending on infrastructure projects, including the Jal Jeevan Mission, has reduced significantly—and in some cases come to a standstill— compared to previous years. This decline in public investment has further added to the weak demand for pipes across the country.

Despite these short-term challenges, we believe the longterm growth outlook for the industry remains strong. India’s aspiration to become a developed nation by 2047 will continue to drive large-scale infrastructure development, ensuring sustained demand for tubes and pipes in the years ahead.

The Indian tube and pipe market is growing steadily, with a projected compound annual growth rate (CAGR) of over 7.6% from 2025 to 2033. This growth is driven by several key factors:

Infrastructure Development: The government’s focus on building and upgrading infrastructure, including railways, highways, smart cities, and public utilities, is the primary driver of demand. Projects like the Jal Jeevan Mission, which aims to provide tap water to all rural households, are creating a huge need for pipes.

Real Estate and Construction: Rapid urbanization and a robust housing cycle are fueling demand for steel and plastic pipes in residential and commercial construction.

Industrial and Energy Sectors: The oil and gas, power, and renewable energy sectors, particularly green hydrogen initiatives, require specialized pipes for transportation and processing.

Untapped Market Potential: Despite the growth, India’s per-capita pipe consumption is significantly lower than the global average, indicating a large, untapped market with substantial room for future expansion. This suggests that the current growth trajectory can be sustained for the foreseeable future.

The industry is undergoing major transformations driven by technology and market dynamics. Key trends include:

Technological Advancements: Manufacturers are adopting Industry 4.0 technologies like AI, IoT, and automation to enhance efficiency, precision, and safety. This includes using robotics for welding and cutting, and AI algorithms for predictive maintenance. Using quick change over mills and high speed mills, robotic packing, and reducing cost of production will be key going forward.

Product Mix Evolution: There’s a growing demand for highperformance and specialized products. This includes highstrength, low-alloy (HSLA) steel pipes, corrosion-resistant pipes, and custom-fabricated hollow sections for specific applications, including sections of special dimensions as per the application with use of DFT mill. The industry is also seeing an increased focus on developing environment friendly and sustainable products.

Supply Chain Optimization: The rise of digital platforms and ERP systems is creating more transparent and efficient supply chains. Manufacturers are also exploring modular fabrication, where pipe components are prefabricated offsite, leading to faster and more controlled on-site assembly.

Focus on Sustainability: The industry is increasingly focused on sustainable practices, including using energyefficient furnaces, water recycling systems, and promoting the use of recyclable materials.

The entry of new players is making the market more competitive, pushing established companies to innovate. This increased competition is leading to:

Product Innovation: New entrants and existing firms are investing in to develop innovative products, such as specialized pipes for hydrogen transport, to gain a competitive edge. Special size hollow sections completely customized as per customer need.

Price Competition: A more crowded market can lead to price wars, which ultimately benefits consumers but

requires companies to focus on cost-efficiency and valueadded products to maintain margins.

Improved Quality and Service: JINDAL-HISSAR is synonymous with high quality ERW pipes, and we stand out not only on price but also most importantly on product quality, service delivery, and technological superiority. This pressure to excel drives the entire industry forward.

JINDAL – HISSAR, is already in process of setting up a 1.5 Million TPA capacity plant at Hansi, near Hissar for round as well as hollow sections. The plant will have a DFT mill of the latest technology and is expected to be in production in the first quarter of 2026. With this plant we will have more product size availability and will be catering to the markets in the north region, which has been a long demand from our existing customers.

B2B exhibitions like the Tube & Pipe Fair are essential catalysts for industrial growth. They serve as a crucial platform for:

Networking and Partnerships: These fairs bring together the entire value chain—from raw material suppliers and machinery manufacturers to end-product buyers and industry experts. This convergence facilitates new business partnerships, collaborations, and joint ventures.

Showcasing Innovation: Exhibitions provide a physical space for companies to display their latest products, machinery, and technologies, allowing visitors to see and

Stand: 6E1-1

experience the innovations firsthand. This accelerates the adoption of new technologies and best practices.

Market Insight: Attending and exhibiting provides invaluable market intelligence. Companies can gauge customer needs, assess the competitive landscape, and identify emerging trends, which helps in strategic planning.

Brand exposure: For established firms like JINDALHISSAR, these events offer a powerful platform to build brand awareness and demonstrate their capabilities to a large, targeted audience.

It helps customers to understand the organization better and also their clarity on brands. Many new customers have been added, especially B2C from this fair. We are very happy with the results and have been associated with this fair from inception.

As a participant in Tube & Pipe Fair 2025, we are looking forward to several key outcomes. Our past participation has been highly beneficial, generating quality leads, strengthening existing partnerships, and helping us discover new market opportunities. We’ve seen firsthand how the fair provides a unique environment for fruitful discussions with potential clients and collaborators.

This year, we are confident that Tube & Pipe Fair 2025 will be even more impactful with our team of experts on hand to provide one-on-one consultations, helping visitors find the right solutions for their specific needs. We will be expanding in infrastructure fabrication and that will be something to look for in our booth this year.

Beekay Steel Industries Limited has expanded its manufacturing footprint with the launch of commercial production at its newly acquired Cuttack Unit in Odisha, marking a key milestone in the company’s growth strategy.

Sep 9, 2025

Beekay Steel Industries Limited, a leading steel manufacturer, has commenced commercial production at its newly acquired Cuttack Unit in Odisha. The facility, located at Rampei, Khuntuni in Athagarh, was earlier part of Maheshwari Ispat Ltd. and has now been integrated into Beekay Steel’s operations. It will produce billets, silico manganese, TMT bars, and power through its AFBC plant. With installed capacities of 1,30,000 MTPA of billets, 15,000 MTPA of silico manganese,

1,80,000 MTPA of TMT bars, and 14 MW of power, the new facility will cater exclusively to the domestic market.

Mr. Rahul Gupta, Director, APL Apollo Tubes Ltd.

The Indian tube and pipe industry is experiencing robust growth, fueled by large-scale infrastructure development, rapid urbanization, and the government’s continued focus on ‘Make in India’ and housing for all. Additionally, the shift toward modern construction practices and the demand for sustainable, lightweight, and cost-effective solutions are driving adoption. This growth is not just short-term; it is structural. With rising investments in real estate, renewable energy, and logistics, the demand is expected to remain strong for the foreseeable future.

We are seeing three major shifts. First is the technology adoption, which includes automation, AI-driven quality checks, and advanced forming technologies are transforming efficiency and consistency. Secondly, product mix, wherein customers are increasingly seeking pre-fabricated solutions, customized sizes, and products with value-added coatings that ensure durability and sustainability. And third is supply chain evolution, where the industry is moving toward integrated supply chains with just-in-time delivery models, closer vendor partnerships, and digital platforms to ensure speed and reliability.

The entry of new players has intensified competition, encouraging the entire sector to innovate and enhance value for customers. Today’s buyers demand higher quality, faster deliveries, and sustainable practices, making continuous improvement essential. At APL Apollo, we see it as an opportunity to reinforce our leadership by investing in R&D, expanding our product mix, and elevating service standards. A prime example of this commitment is the launch of India’s first 1000 mm x 1000 mm hollow section with a thickness of up to 40 mm at our advanced Simga, Raipur facility. This industry-first innovation sets a new benchmark in structural steel solutions and showcases our ability to anticipate and meet evolving infrastructure needs.

At APL Apollo, leadership in a dynamic market means agility, innovation, and foresight. We are strengthening our portfolio by introducing new product categories, expanding capacity, and investing in cutting-edge technologies. At the same time, we are deeply focused on sustainability, developing solutions that not only meet current needs but also align with future environmental goals. Most importantly, we continue to build strong partnerships with distributors, architects, and engineers, ensuring that we remain the preferred choice across India and beyond.

B2B exhibitions like Tube & Pipe Fair serve as true catalysts for the tube and pipe industry. They unite manufacturers, buyers, and innovators on a shared platform, creating opportunities for new technologies, collaborations, and partnerships that foster industry growth. For an industry built on trust and long-term relationships, such events are invaluable for creating visibility and strengthening networks. At APL Apollo, we actively participate not only in national platforms but also in global exhibitions, which allow us to benchmark ourselves against international standards and stay ahead of emerging trends. These platforms reaffirm our leadership, showcase our innovations, and help us align with the evolving needs of customers both in India and worldwide.

Our past participation in Tube & Pipe Fair has been immensely rewarding. It has given us the chance to engage directly with key decision-makers, understand emerging customer needs, and present our innovations to a highly relevant audience. We have built new partnerships, strengthened existing ones, and explored untapped markets through the exposure provided by the event. For us, it has always been more than a showcase; it has been a growth accelerator.

For Tube & Pipe Fair 2025, we look forward to engaging in meaningful conversations, gaining industry insights, and

building collaborations that can drive the sector forward. At the APL Apollo booth, visitors will experience our latest product innovations, advanced solutions for modern infrastructure, and live demonstrations that highlight how our technologies are shaping the future of construction and design. A key highlight will be our DFT technology, now

implemented across all 11 APL Apollo plants nationwide, which ensures faster production, seamless customization, and timely deliveries PAN India. This capability strengthens trust, simplifies order placement, and reinforces our commitment to combining innovation, scale, and sustainability to lead the industry with confidence.

Visit Stand: 6F1 at Tube & Pipe Fair 2025, New Delhi

Mr. Paresh R Parekh, Managing Director & Founder, Carol Petroleum Pvt. Ltd.

The Indian tube and pipe industry is witnessing robust growth driven by infrastructure development, urbanization, and expansion in oil & gas, power, and automotive sectors. Demand is being fueled by government initiatives such as ‘Make in India’ and investments in manufacturing and construction. We believe this momentum can be sustained as long as the industry continues to adopt advanced materials, energy-efficient practices, and environmentally responsible technologies.

We see a clear shift toward automation, digitalization, and higher-quality products designed for longer life cycles. At the same time, global supply chain disruptions have prompted companies to focus on local sourcing and stronger vendor partnerships. As a lubricant and grease manufacturer, we are aligning with these trends by introducing next-generation formulations that ensure equipment reliability, reduce downtime, and enhance energy efficiency.

The entry of new players has increased competition, which in turn is accelerating innovation. Customers now demand higher performance at optimized costs. For us, this has meant doubling down on R&D—developing tailor-made lubrication solutions for tube and pipe manufacturers to reduce operational costs, extend machinery life, and support sustainability goals.

Visit Stand: 6F6-1 at Tube & Pipe Fair 2025, New Delhi

We are investing significantly in R&D to develop synthetic and semi-synthetic lubricants, eco-friendly greases, and high-performance fluids designed for heavy-duty applications in the tube and pipe sector. Our laboratories and field-engineering teams work closely with clients to deliver customized solutions, ensuring we stay ahead in technology, quality, and service.

B2B exhibitions like Tube & Pipe Fair provide an essential platform for knowledge exchange, networking, and exploring innovations. They allow us to showcase our latest developments, engage with decision-makers, and understand evolving customer needs, which fuels collaboration and industry-wide growth.

Our past participation has been instrumental in expanding our customer base, strengthening partnerships, and generating new opportunities. The fair has helped us demonstrate the critical role of advanced lubrication solutions in improving efficiency and reliability across the tube and pipe sector. It also positioned us as a trusted partner in enabling sustainable growth.

At Tube & Pipe Fair 2025, we look forward to engaging with industry leaders and showcasing our latest innovations in high-performance lubricants and greases. Visitors to our booth can expect live demonstrations, technical consultations, and insights into how our R&D-driven solutions are helping the tube and pipe industry achieve greater productivity, sustainability, and cost efficiency.

Mr. Vikas Goyal, CEO & Managing Director, Sambhv Steel Tubes

The Indian tube and pipe industry is experiencing robust, sustained growth, largely fueled by rapid infrastructure development, government focus on ‘Make in India’, urbanization, renewable energy projects, and strong demand from construction, automotive, solar and preengineered building segments. This growth is not just cyclical — it reflects structural changes in India’s economy. With rising investments in logistics, housing, solar, and industrial expansion, demand for reliable steel tubes will remain strong in the medium to long term.

Several significant trends stand out in the industry. In terms of technology, increasing automation, precision manufacturing, and quality certifications are becoming standard expectations. In product mix, there is a visible shift from commodity-grade products to value-added, coated, galvanized, and specialty tubes tailored for solar, HVAC, and automotive applications. And in supply chains, buyers now demand reliability, shorter lead times, and digital integration in order tracking — moving from transactional to relationship-based supply chains.

The entry of new players has intensified competition, but it has also pushed the entire industry to raise its game. Customers are now more informed and expect stronger service, innovation, and transparency. For established players like us, this is an opportunity to differentiate through trust, scale, and consistency — qualities that cannot be built overnight. It encourages innovation not just in products, but also in branding, dealer engagement, and sustainability practices.

At Sambhv Steel Tubes, we are advancing on multiple strategic fronts to drive sustainable growth and market leadership. Through a backward integrated process, we ensure superior quality, cost competitiveness, and timely delivery by maintaining control over the entire value chain

— from raw materials to finished products. Our product diversification strategy includes expanding into galvanized coils and pipes, stainless steel coils, and specialized tubes catering to high-growth sectors. We are also strengthening our market reach by building a robust distribution network across India while actively exploring international markets. To support this expansion, a state-of-the-art greenfield manufacturing facility is being established at village Kesda, which will add 1.2 Million Metric TPA of finished product capacity. Additionally, we are leveraging digital tools and CRM integration to enhance dealer engagement, supply chain visibility, and customer service.

In parallel, our brand-building initiatives aim to reposition Sambhv Steel Tubes from a regional commodity supplier to a trusted national brand through consistent campaigns and communication. Finally, achieving our IPO milestone with NSE/BSE listing has bolstered our governance, credibility, and access to growth capital — strategically positioning us to lead in an evolving and competitive steel market.

Exhibitions like Tube & Pipe Fair are vital because they create a common platform where manufacturers, suppliers, OEMs, and end-users come together. These events facilitate knowledge sharing, technology exchange, and relationship building. For Sambhv, it’s an opportunity to showcase our wide range of products-from ERW and GP pipes to HR/ CR coils, slabs, and blooms-demonstrating our quality and innovation. Such participation builds customer confidence, strengthens relationships, and reinforces our credibility with domestic and international buyers.

Our past participation has given Sambhv strong visibility among decision-makers and influencers in the industry. It has opened doors to new OEM relationships, strengthened dealer confidence, and provided us with insights into evolving customer needs.

Equally important, it allowed us to showcase Sambhv as more than a manufacturer — as a brand with a philosophy: “Sab Sambhv Hai.” That emotional connection has translated into real business opportunities and lasting partnerships.

This year, we view Tube & Pipe Fair 2025 as a key platform to showcase Sambhv Steel Tubes’ progress, capabilities, and vision for the future. We will present our expanded product portfolio across ERW, GP, and stainless steel tubes, reflecting our commitment to innovation and diversification. As a newly listed company, the event also provides an opportunity to highlight our journey of growth and reinforce our core values of transparency and trust. Through

case studies, we will demonstrate our growing contribution to critical sectors such as infrastructure, solar energy, and pre-engineered buildings. The fair will also serve as a venue to engage directly with partners and customers through live demonstrations, product showcases, and meaningful discussions on how Sambhv can enable their business growth. Visitors to our booth will experience Sambhv’s philosophy in action — the conviction that “everything is possible” when innovation, quality, and trust come together.

Visit Stand: 6D1 at Tube & Pipe Fair 2025, New Delhi

Mr. Mahesh Garg, Chairman, Goodluck India Ltd.

The Indian tube and pipe industry is experiencing robust and sustained growth, fueled by the country’s expanding infrastructure, automotive, oil & gas, and renewable energy sectors. Government initiatives such as ‘Make in India’, PM Gati Shakti, and increased investment in housing, railways, and urban development have significantly boosted steel consumption, directly benefiting the tube and pipe segment. Additionally, India is emerging as a reliable global sourcing base for precision and structural tubes, supported by continuous capacity expansion and modernization across manufacturing units. These factors indicate that the industry’s growth momentum is likely to continue over the next decade.

However, certain challenges remain—particularly the inconsistent supply and quality of raw materials. Erratic availability and the influx of substandard raw materials can adversely affect product quality and tarnish India’s reputation in export markets. It is therefore essential for the industry and governing bodies to establish stricter quality checks, enforce material traceability, and promote responsible sourcing to ensure sustainable and credible growth for the Indian tube and pipe sector.

There is a clear shift toward higher-value and precision-engineered products—such as cold-drawn seamless tubes, precision ERW tubes, and customized alloy solutions. The adoption of automation, digital process control, and online

testing technologies is enhancing quality consistency, improving productivity, and minimizing wastage. On the supply chain side, the industry is moving toward localization of critical inputs and diversification of raw material sources to reduce dependency on imports. Sustainability is also emerging as a key focus area, with many companies adopting cleaner galvanizing processes, energy-efficient furnaces, and recyclable packaging materials.

However, the sector still faces certain challenges. There is a need to upgrade the skill level of the workforce to match evolving technologies and global standards. Many galvanizing and processing plants must modernize their equipment to overcome inefficiencies and production limitations. Furthermore, increased investment in R&D is essential to drive product innovation, improve process efficiency, and strengthen India’s global competitiveness in the tube and pipe industry

The entry of new players—both domestic and international—has intensified competition, but it’s also accelerated innovation. Established companies are investing more in R&D, process automation, and quality systems to stay ahead. This healthy competition is leading to better product differentiation, improved customer service, and greater efficiency across the value chain.

Our focus is on continuous improvement and customercentric innovation. We’re expanding our product range

to serve both standard and niche applications, investing in advanced machinery, and upgrading quality systems to meet global standards. At the same time, we’re strengthening our supply network and digital engagement with clients to ensure faster response times and technical support.

Our goal is not just to meet demand but to shape it—by providing solutions that improve performance, efficiency, and sustainability for our customers.

B2B exhibitions like Tube & Pipe Fair play a crucial role in connecting manufacturers, suppliers, buyers, and technology providers. They create a live platform for collaboration, learning, and networking. Exhibitions accelerate the adoption of new technologies and help the industry align with global best practices. For many companies, such events are the starting point for long-term business relationships.

This year marks our first participation in Tube & Pipe Fair, and we are truly excited to be part of such a renowned

platform that brings together key stakeholders from across the tube and pipe ecosystem. We see this as a valuable opportunity to showcase our capabilities, connect with industry leaders, and explore new avenues for collaboration—both in domestic and international markets.

Our aim is to leverage this event to build strong partnerships, exchange technical knowledge, and strengthen our presence within India’s fast-evolving steel and tube industry. We believe our debut at the fair will open new doors for business growth, innovation, and long-term industry relationships.

We look forward to an even more engaging edition in 2025, with greater international participation and technology showcases. Visitors to our booth can expect to see our latest range of high-performance tubes designed for automotive, hydraulic, and industrial applications. We’ll also be sharing insights into our new quality assurance systems and sustainable manufacturing initiatives. Our team is eager to connect with industry partners, explore collaborations, and contribute to the collective growth of the tube and pipe ecosystem

Visit Stand: 6B1 at Tube & Pipe Fair 2025, New Delhi

Jindal Industries Private Limited recently held a foundation stone laying ceremony for its upcoming manufacturing plant in Hisar. The plant will specialize in the production of section pipes with an annual capacity of 1.5 lakh tonnes.The facility is expected to become operational by 2026.

Aug 25, 2025

Jindal Industries Private Limited recently held a foundation stone laying ceremony for its upcoming manufacturing plant in Hisar. The event was graced by Ms. Savitri Devi Jindal, Chairperson Emeritus of the O.P. Jindal Group, along with Mr. Sunil Jain, Director and CEO of Jindal Industries Pvt. Ltd.

Mr. Jain highlighted that the new facility marks a significant step in the company’s strategic growth. Spread across 32 acres, the plant will specialize in the production of section pipes with an annual capacity of 1.5 lakh tonnes.

Ms. Savitri Jindal emphasized that the project will not

only generate employment opportunities for the youth but also foster the growth of ancillary industries, contributing to the overall development of the region. The facility is expected to become operational by 2026.

Mr. Suraj Bhan Sharma, CMD, Surya Electric , Surya MFR. Tube Mill

The steel pipes market is booming, with a solid CAGR of around 7.65% expected from 2025 to 2033, reaching 27.76 million tons. Driving factors include massive infrastructure projects, oil & gas expansion, urbanization, government schemes like Jal Shakti Mission, and rising demand from construction, automotive, and power sectors. Demand is further fueled by investment in seamless and welded pipes, technological advancements, and growing exports. This growth looks sustainable thanks to ongoing infrastructure development and government support, but quality, raw material costs, and environmental challenges need managing.

Tech and automation are shaping the industry with the fast adoption of automation, AI, and Industry 4.0 to improve quality, efficiency, and defect detection, while robotics and laser inspection systems are becoming increasingly important. On the product mix side, the market is shifting toward customized pipes, advanced alloys, cold-formed steel tubes, composite pipes, and specialized polymer pipes such as antimicrobial and PPRC, with composite pipes gaining traction in sectors like solar energy and EV plants. On the supply chain front, challenges persist with raw material pricing, import competition, and logistics, but the industry is responding with more strategic partnerships and the development of local manufacturing hubs in Gujarat, Maharashtra, and Tamil Nadu.

New players entering the Indian tube and pipe industry are shaking things up by boosting competition and innovation. They’re pushing existing firms to improve product quality, adopt newer tech like automation and AI, and diversify into advanced materials like composites and specialty pipes. This fresh blood is also expanding capacity, improving supply chains, and accelerating localization helping make the market more dynamic and tech-driven.

To lead in a fast-changing and competitive market, the firm is focusing on several key areas. It is investing heavily in automation and AI to boost quality and efficiency, while also

expanding its product range with advanced alloys and composite pipes. At the same time, the company is strengthening local manufacturing hubs and building strong supply chain partnerships to remain agile. A major emphasis is being placed on sustainability and eco-friendly production, ensuring longterm viability. Alongside these efforts, the firm is setting new benchmarks in customer support by prioritizing after-sales service, with service points successfully established across multiple locations in India. In essence, staying sharp with technology, innovation, sustainability, and service excellence forms the core of its game plan.

B2B exhibitions such as Tube & Pipe Fair play a crucial role in driving industry growth by creating a focused networking platform where manufacturers, technology providers, suppliers, and buyers can connect directly. They serve as a stage to showcase the latest technologies and innovations, accelerating product development and market adoption. These events also help companies generate qualified leads, shorten sales cycles, and enhance brand visibility in a highly competitive market. In addition, real-time product demonstrations and industry insights provide valuable feedback that speeds up improvements, while the collaborative environment fosters partnerships that ultimately drive overall market expansion and innovation.

Our past participation in Tube & Pipe Fair has been highly beneficial, providing great exposure to key industry players and potential clients while opening doors to strong partnerships and networking opportunities with suppliers and manufacturers. The event has also given us access to new business leads, enabling expansion into untapped markets. It has served as a valuable platform to showcase our innovations and stay updated on the latest industry trends, helping us align our offerings with evolving customer needs.

For Tube & Pipe Fair 2025, expectations are high for strong industry engagement, new partnerships, and showcasing cutting-edge technology. Visitors can look forward to seeing the latest in advanced pipe materials, automation tech, and eco-friendly solutions at the booth, plus live demos and expert chats. It’s going to be a tech-packed, interactive experience.

Visit Stand: 6G1 & 6G2-1 at Tube & Pipe Fair 2025, New Delhi

Mr. Aaradhya Baheti, Managing Director, DeeTee Industries Pvt. Ltd.

The Indian tube and pipe industry is witnessing robust growth, fueled by infrastructure development, construction, automotive, renewable energy, and oil & gas projects. Government initiatives like ‘Make in India’ and the push for self-reliance in steel and allied sectors have further accelerated demand. With growing urbanization and industrialization, this demand is not short-term but a long-term growth cycle that will sustain over the coming decades.

We are seeing rapid adoption of automation, AI-driven quality control, and high-precision tooling to ensure greater efficiency and consistency. In terms of product mix, there is a rising demand for high-strength, corrosion-resistant, and customized tubes catering to diverse industries. Supply chains are becoming more digitized and localized, with companies focusing on reducing dependence on imports and ensuring sustainable sourcing.

The entry of new players is pushing the entire ecosystem to raise its standards. Competition has fueled innovation in tooling, faster delivery, and customer-focused solutions. At DeeTee Industries, we view this positively, as it keeps us motivated to continuously innovate and strengthen our position as a technology-driven, quality-first company.

At DeeTee Industries, we are investing heavily in

R&D, advanced manufacturing technology, and skill development. We focus on providing custom-made solutions, precision tooling, and world-class quality. We are also expanding our global footprint and adopting digital platforms for customer engagement, ensuring that we remain ahead of industry changes and customer needs.

Exhibitions like Tube & Pipe Fair provide a knowledgesharing and networking platform where industry leaders, manufacturers, and technology providers come together. They help in creating awareness about new technologies, building partnerships, and opening new markets, ultimately fueling overall industry growth.

Our past participation has been extremely fruitful. We have gained exposure to new customer segments, forged partnerships with global and domestic players, and showcased our innovative solutions to a wider audience. These events have not only enhanced our visibility but also helped us better understand evolving customer expectations.

We look forward to meeting industry leaders, strengthen existing partnerships, and exploring new collaborations. At our booth, visitors can expect to see a wide range of services and tools we offer for metal industry- cold rolling mill rolls, tube/ section mill rolls, slitting line tooling, leveller/flattener rolls, bar mill tooling, shear blade, straight knives etc from DeeTee Industries. We aim to present how our customized, high-performance tooling solutions can add value to their operations and help them stay competitive in a rapidly evolving market.

The Indian tube and pipe industry is experiencing robust growth, driven primarily by infrastructure development, energy transition projects, water transportation, and oil & gas exploration. Government initiatives such as Atmanirbhar Bharat, rapid urbanization, and the expansion of renewable energy and hydrogen infrastructure are fueling consistent demand. With India’s focus on becoming a global manufacturing hub, we strongly believe this momentum is sustainable over the long term.

The industry is steadily moving towards high-performance materials, advanced metallurgies, and digitally integrated manufacturing. Automation, robotics, and AI-driven quality monitoring are becoming more widespread. There is also a visible trend toward green steel and sustainable production processes, in line with global ESG mandates. On the supply chain side, localization and resilience are gaining priority, with domestic players reducing reliance on imports and ensuring timely deliveries for mega projects.

New entrants are expanding the competitive landscape, but this is also accelerating innovation. Established players like Jindal SAW are continuously investing in R&D, product diversification, and process optimization to stay ahead. The competition pushes the entire industry toward higher efficiency, cost competitiveness, and adoption of global best practices—ultimately benefiting end-users and India’s industrial growth story.

At Jindal SAW, we are positioning ourselves as technology leaders and solution providers rather than just product suppliers. We are enhancing our capabilities in seamless, welded, and specialty pipe segments, investing in

digitalization, sustainability, and skill development. In line with growing demand, we also have a clear plan to enhance our product capability from 16” to 18” and 20” seamless pipes, ensuring we can serve a broader spectrum of critical applications. Moreover, we are expanding our global footprint, ensuring that our expertise in delivering world-class projects translates into leadership in a dynamic, competitive environment.

B2B exhibitions create an invaluable platform for knowledge exchange, networking, and showcasing innovations. They bring together manufacturers, technology providers, EPCs, and end-users under one roof, catalyzing partnerships and new opportunities. For the tube and pipe sector, which plays a pivotal role in critical infrastructure, such exhibitions accelerate adoption of new technologies and highlight India’s growing capabilities on the global stage.

Our participation in past editions of similar kinds of exhibitions and fairs has significantly boosted our industry’s visibility and credibility. We have engaged with key stakeholders from across the value chain—government bodies, EPC contractors, and international buyers— leading to new partnerships and project opportunities. The platform has also enabled us to showcase our innovations, reinforcing our leadership in the Indian tube and pipe industry.

At Tube & Pipe Fair 2025, we look forward to engaging with global and domestic stakeholders, exchanging insights on the future of the industry, and strengthening collaborations. Visitors at the Jindal SAW booth can expect to see cutting-edge solutions, advanced product offerings, and our latest initiatives in sustainability and technology. We are excited to showcase how Jindal SAW is shaping the future of tubes and pipes in India and beyond.

The Indian steel tube and pipe industry is growing at a strong pace, and at MKK Metal Sections Private Limited, we are witnessing this momentum firsthand. Large-scale infrastructure development, affordable housing, oil & gas projects, and renewable energy are all fuelling demand. Government initiatives like ‘Make in India’ and the focus on self-reliance have also given the sector a major boost. We believe this growth is not a short-term trend — with rising domestic consumption and export opportunities, the industry is well-positioned for long-term expansion.

We are seeing rapid adoption of automation and precision manufacturing, which enhances product quality and consistency. At MKK Metal Sections, with the commissioning of our DFT, we have moved towards automation, and we are expanding our offerings toward value added products like galvanised and special grade, sizes and thicknesses, which are increasingly demanded by automotive, infrastructure, and energy sectors. On the supply chain front, the industry is focusing more on local sourcing and digitisation, and we too are strengthening our procurement and logistics systems to ensure efficiency and reliability. In terms of product mix, MKK Metal Sections has one of the largest SKUs in circular, square and rectangular sizes - making it a one-stop solution.

The entry of new players has made the market more dynamic, and we welcome this healthy competition. It pushes established companies like ours to innovate, adopt global best practices, and stay ahead through superior quality

and service. This environment ultimately benefits customers by raising overall industry standards and encouraging continuous improvement.

At MKK Metal Sections, we are investing in advanced technologies, expanding production capacity, and diversifying our product portfolio to address emerging customer needs. We have an unmatched size range and offer customisation in terms of length, bevelled end or fin cut, along with hydro testing is provided on request. MKK Metal Sections has been the trusted partner for providing tubes of grades matching from YST-170, YST-210, YST-240, YST-310, YST-355, YST-400, YST-450 and YST-530- which are used for heavy machinery and industrial purposes.

We are strengthening our dealer networks, scaling up exports, and embedding sustainability across our operations. More importantly, we focus on reliability, speed of delivery, and building long-term partnerships — qualities that we believe will keep us ahead in a highly competitive market.

B2B exhibitions like Tube & Pipe Fair are extremely valuable for the industry. They provide a platform to showcase new products and technologies, engage with buyers and suppliers, and exchange knowledge. For us at MKK Metal Sections, these events are an opportunity to strengthen visibility, benchmark ourselves against peers, and stay updated on global trends.

Our past participation has been very rewarding. The fair has allowed MKK Metal Sections to showcase our production capabilities and experience to a wide audience, both in India and internationally. We have built strong trade relationships, explored new export avenues, and connected directly with decision-makers across sectors. The exposure has translated into valuable partnerships and fresh business opportunities.

We expect Tube & Pipe Fair 2025 to attract even greater participation, with more domestic and international buyers and a sharper focus on innovation. At the MKK Metal Sections Private Limited booth, visitors can look forward to our latest product range - a testimony of our advanced manufacturing processes, and conversations around sustainable solutions for industries such as infrastructure, energy, and automotive. We are excited to share how we are aligning with global quality benchmarks while continuing to serve the evolving needs of the Indian market.

Mr. Dhruv Singla, Executive Director, JTL Industries Limited

The company is pursuing a phased capacity expansion with major projects at Raipur and Mangaon. At Raipur, capacity is being doubled to 2,00,000 MTPA, adding 200 new SKUs with a focus on value-added products. The Mangaon facility is set to reach 5,00,000 MTPA in March 2025 with Direct Forming Technology (DFT), enabling faster, more flexible, and customized production. Together, these sites will boost output, enhance product diversity, and support global expansion into markets like the US, Canada, and Mexico.